PONTIAC FIERO 1988 Service Repair Manual

Manufacturer: PONTIAC, Model Year: 1988, Model line: FIERO, Model: PONTIAC FIERO 1988Pages: 1825, PDF Size: 99.44 MB

Page 911 of 1825

6E3-C3-2 5.OL (VIN F) & 5.7L (WIN 8) DRIVEABILITY AND EMISSIONS

The ECM turns "ON" the solenoid valve and allows

purge when:

@ Above a specified road speed.

r Engine is warm

@ After the engine has been running a specified

time.

@ Above a specified throttle opening.

This

is an ECM feedback system that increases

purge until the ECM senses a rich condition from the

O2 sensor. The purge is then regulated until the ECM

no longer receives

a rich signal from the O2 sensor.

This system uses an in-tank pressure control valve to

control the flow of vapors from the fuel tank to the

canister.

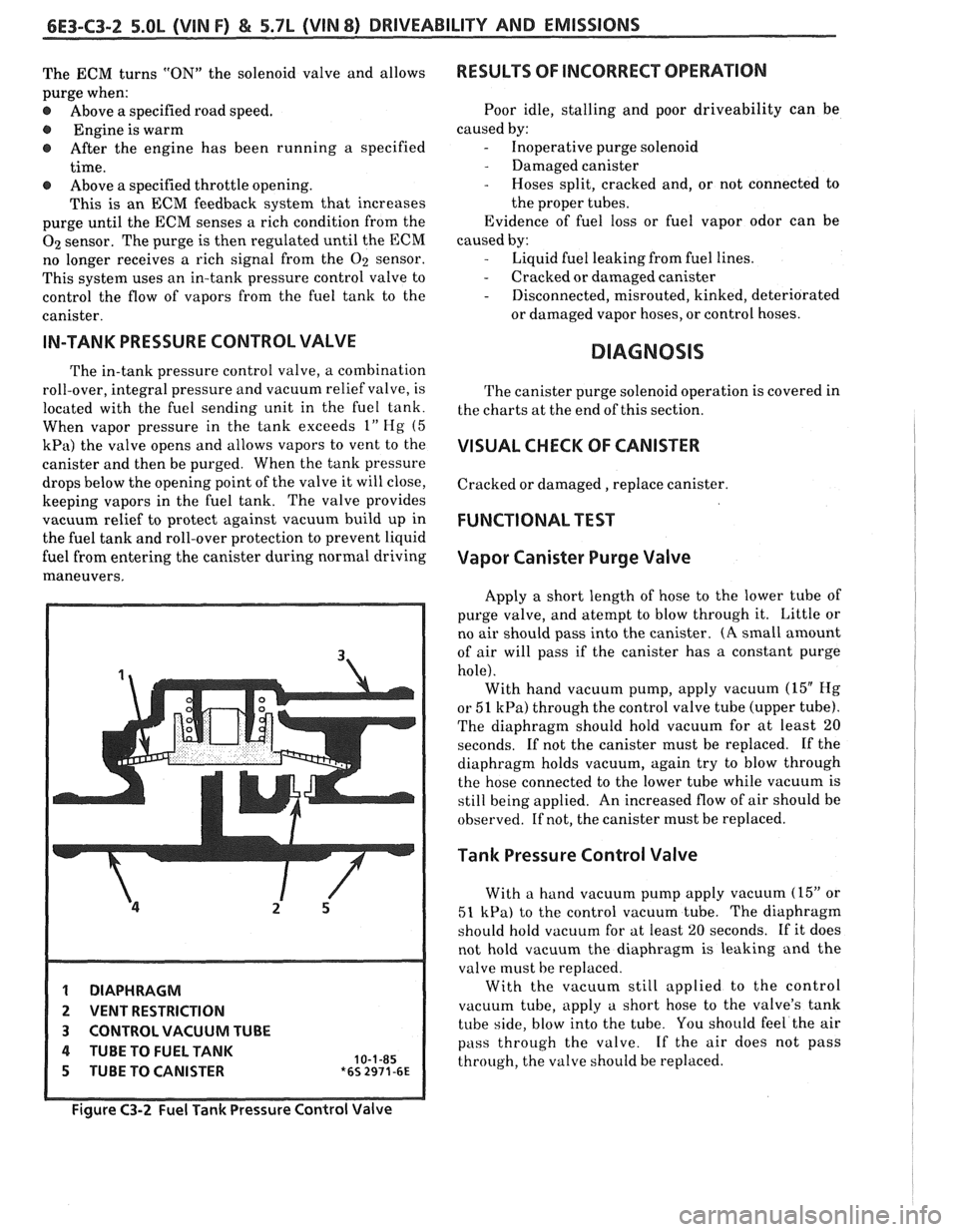

IN-TANK PRESSURE CONTROL VALVE

The in-tank pressure control valve, a combination

roll-over, integral pressure and vacuum relief valve, is

located with the fuel sending unit in the fuel tank.

When vapor pressure in the tank exceeds

1" Hg (5

kPa) the valve opens and allows vapors to vent to the

canister and then be purged. When the tank pressure

drops below the opening point of the valve it will close,

keeping vapors in the fuel tank. The valve provides

vacuum relief to protect against vacuum build up in

the fuel tank and roll-over protection to prevent liquid

fuel from entering the canister during normal driving

maneuvers.

1 DIAPHRAGM

2 VENT RESTRICTION

3 CONTROL VACUUM TUBE

4 TUBE TO FUEL TANK 10-1-85 5 TUBE TO CANISTER *6s 2971-6~

RESULTS OF INCORRECT OPERATION

Poor idle, stalling and poor driveability can be

caused by:

- Inoperative purge solenoid

- Damaged canister

- Hoses split, cracked and, or not connected to

the proper tubes.

Evidence of fuel loss or fuel vapor odor can be

caused by:

- Liquid fuel leaking from fuel lines.

- Cracked or damaged canister

- Disconnected, misrouted, kinked, deteriorated

or damaged vapor hoses, or control hoses.

DIAGNOSIS

The canister purge solenoid operation is covered in

the charts at the end of this section.

VISUAL CHECK OF CANISTER

Cracked or damaged, replace canister.

FUNCTIONAL TEST

Vapor Canister Purge Valve

Apply a short length of hose to the lower tube of

purge valve, and atempt to blow through it. Little or

no air should pass into the canister.

(A small amount

of air will pass if the canister has a constant purge

hole). With hand vacuum pump, apply vacuum

(15" Hg

or 51 kPa) through the control valve tube (upper tube).

The diaphragm should hold vacuum for at least

20

seconds. If not the canister must be replaced. If the

diaphragm holds vacuum, again try to blow through

the hose connected to the lower tube while vacuum is

still being applied. An increased flow of air should be

observed. If not, the canister must be replaced.

Tank Pressure Control Valve

With a hand vacuum pump apply vacuum (15" or

51 kPa) to the control vacuum tube. The diaphragm

should hold vacuum for at least

20 seconds. If it does

not hold vacuum the diaphragm is leaking and the

valve must be replaced.

With the vacuum still applied to the control

vacuum tube, apply a short hose to the valve's tank

tube side, blow into the tube. You should feel the air

pass through the valve. If the air does not pass

through, the valve should be replaced.

Figure C3-2 Fuel Tank Pressure Control Valve

Page 912 of 1825

DRIVEABILITY AND EMISSIONS 5.OL (WIN F) & 5.7L (WIN 8) 6E3-C3-3

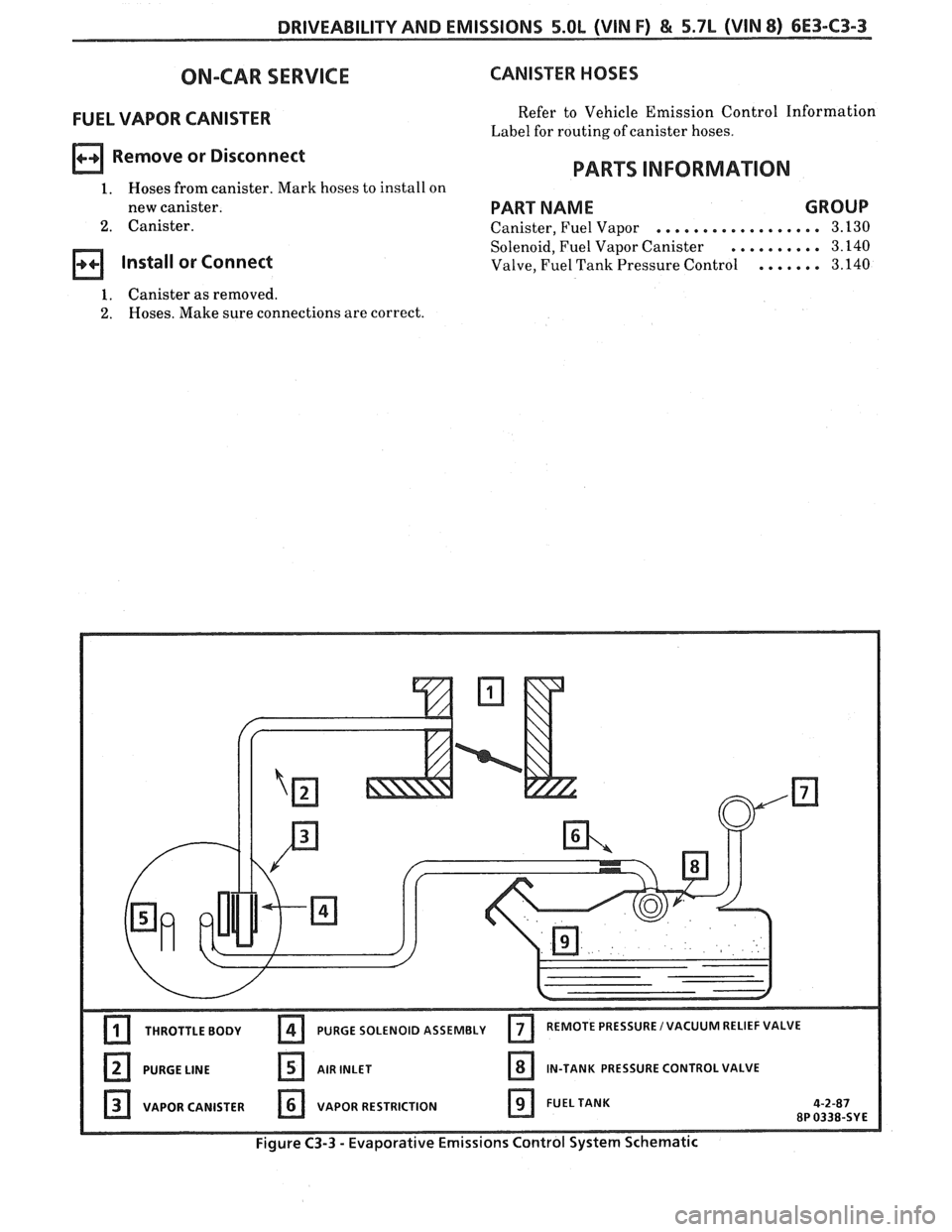

ON-CAR SERVICE

FUEL VAPOR CANISTER

Remove or Disconnect

1. Hoses from canister. Mark hoses to install on

new canister.

2. Canister.

Install or Connect

1. Canister as removed.

2. Hoses. Make sure connections are correct.

CANISTER HOSES

Refer to Vehicle Emission Control Information

Label for routing of canister hoses.

PARTS INFORMATION

PART NAME GROUP

.................. Canister, Fuel Vapor 3.130

.......... Solenoid, Fuel Vapor Canister 3.140

....... Valve, Fuel Tank Pressure Control 3.140

VAPOR CANISTER

VAPOR RESTRICTION

Figure C3-3 - Evaporative Emissions Control System Schematic

Page 913 of 1825

6E3-C3-4 5.OL (VIN F) & 5.7L (VIN 8) DRIVEABILITY AND EMISSIONS

428 DK GUNNEL

BULKHEAD

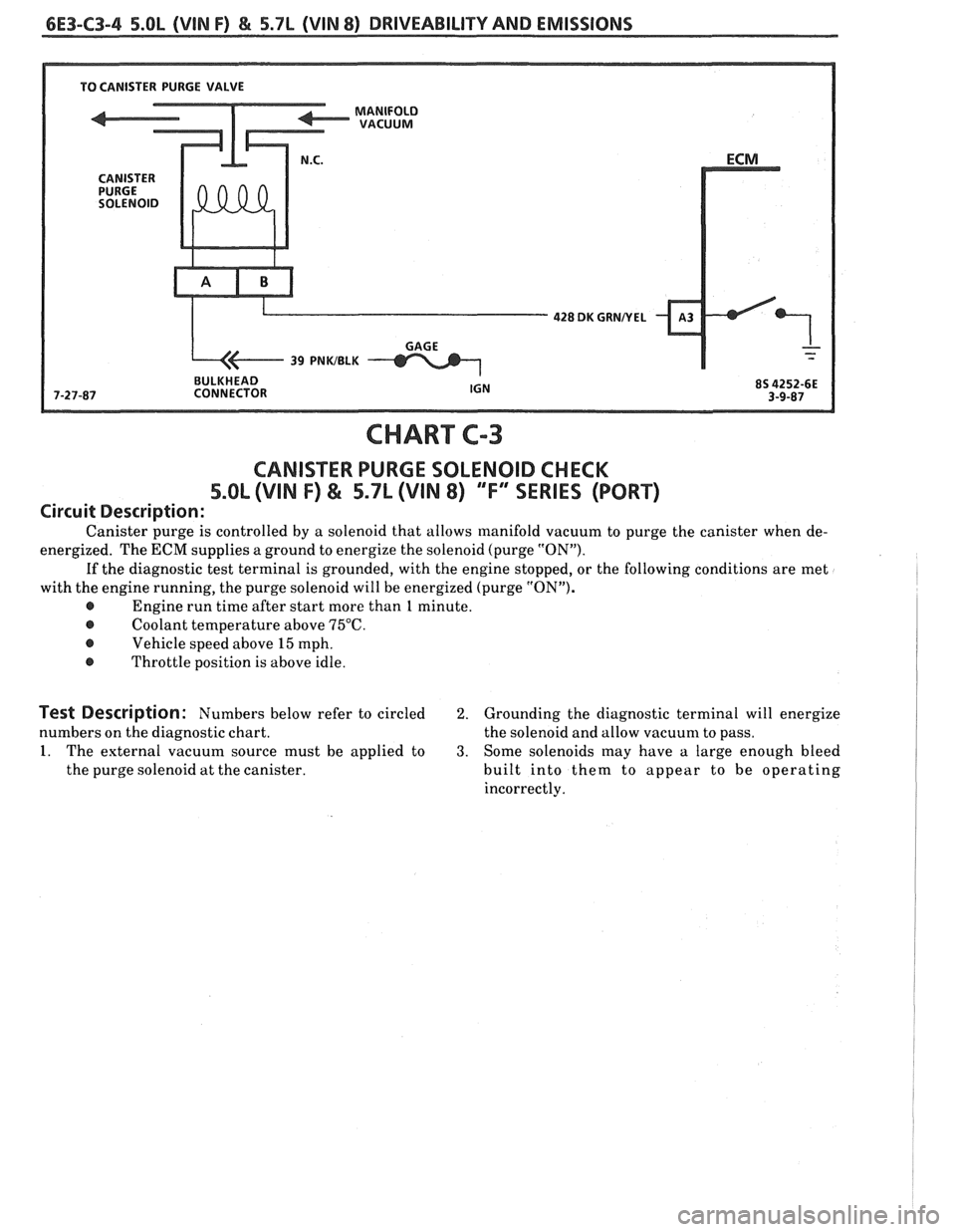

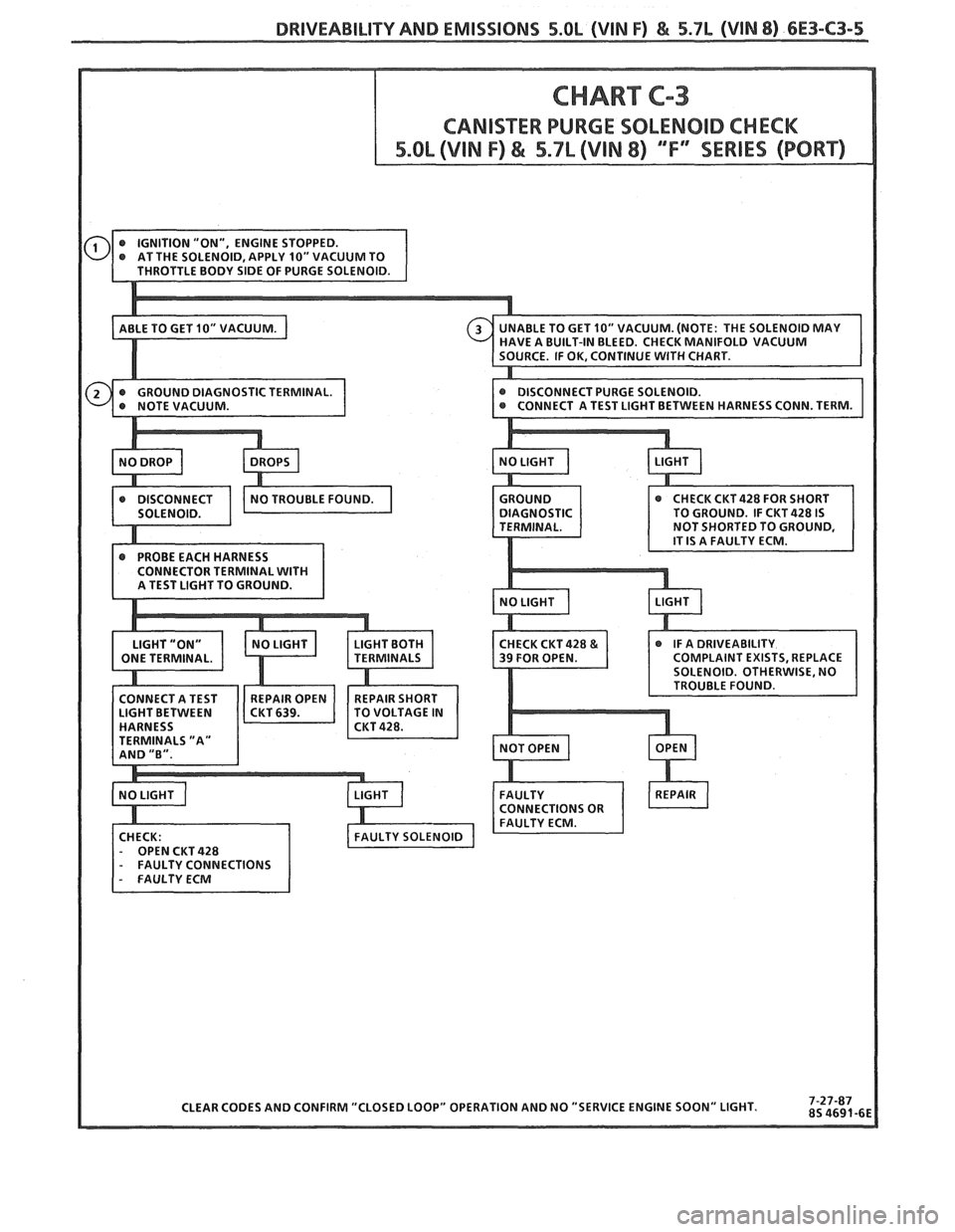

CHART

CANISTER PURGE SOLENOID CHECK

5.OL (VIN F) & 5.7L (VIN 8) ""FYSERIES (PORT)

Circuit Description:

Canister purge is controlled by a solenoid that allows manifold vacuum to purge the canister when de-

energized. The

ECM supplies a ground to energize the solenoid (purge "ON").

If the diagnostic test terminal is grounded, with the engine stopped, or the following conditions are met

with the engine running, the purge solenoid will be energized (purge "ON").

@ Engine run time after start more than 1 minute.

@ Coolant temperature above 75°C.

@ Vehicle speed above 15 mph.

@ Throttle position is above idle.

Test Description: Numbers below refer to circled 2. Grounding the diagnostic terminal will energize

numbers on the diagnostic chart. the solenoid and allow vacuum to pass.

1. The external vacuum source must be applied to 3. Some solenoids may have a large enough bleed

the purge solenoid at the canister. built into them to appear to be operating

incorrectly.

Page 914 of 1825

DRlVEABlLlTY AND EMISSIONS 5.OL (VIN F) & 5.7L (VlN 8) 6E3-C3-5

Page 915 of 1825

6E3-C3-6 5.OL (VIN F) €4 5.7L (VIN 8) DRIVEABILITY AND EMISSIONS

BLANK

Page 916 of 1825

DRIVEABILITY AND EMISSIONS 5.OL (VIN F) & 5.7L (VIN 8) 6E3-C4-1

SECTION C4

IGNIION SYSTEM 1 EST

..................... GENERAL DESCRIPTION ................ C4-1 ON-CAR SERVICE C4-2

.................. PURPOSE ......................... C4-1 SETTING TIMING.. C4-2

OPERATION ....................... C4-1 HOW CODE 42 IS DETERMINED.. ....... C4-2

................. RESULTS OF INCORRECT OPERATION .... C4-1 PARTS INFORMATION C4-2

DIAGNOSIS ......................... C4-1

CODE12.......................... C4-1

GENERAL DESCRIPTION

PURPOSE

The high energy ignition (HEI) system controls

fuel combustion by providing a spark to ignite the

compressed

airlfuel mixture at the correct time. To

provide improved engine performance, fuel economy,

and control of exhaust emissions, the

ECM controls

distributor spark advance (timing) with the electronic

spark timing (EST) system.

Only the electronic spark timing (EST) system

will be described here. Additional information on the

FIE1 system is found in Section "6D".

To properly control ignitionlcombustion timing

the ECM needs to know:

e Crankshaft position

e Engine speed (rpm)

@ Mass Air Flow

@ Engine temperature

OPERATION

The EST system consists of the distributor

module, ECM, and connecting wires. The connector

terminals are lettered as shown in CHART C-4.

These circuits perform the following functions:

@ Distributor reference (CKT 430).

This provides the ECM with rpm and crankshaft

position information.

If the wire becomes open or

grounded the engine will not run, because the ECM

will not operate the injectors.

If the engine cranks hut

won't run, see CHART

A-3.

e Reference ground (CKT 453).

This wire is grounded in the distributor and

makes sure the ground circuit has no voltage drop

which could affect performance. If it is open, it may

cause poor performance.

@ Bvpass (CKT 424).

At about 400 rpm, the ECM applies

5 volts to this

circuit to switch spark timing control from the

I-IEI

module to the ECM. The wire goes through a

connector between the 4 wire connector and the ECM.

This is disconnected to the set hase timing. An

open or grounded bypass circuit will set a Code

42 and the engine will run at base timing, plus a small

amount of advance built into the

HE1 module.

@ EST (CKT 423). - This circuit triggers the HE1 module after the

engine is started and no Code 42 detected. The ECM

does not know what the actual timing is, but it does

know when it gets the reference signal. It then

advances or retards the spark from that point.

Therefore, if the base timing is set incorrectly, the

entire spark curve will be incorrect.

RESULTS OF INCORRECT OPERATION

An open or ground in the EST circuit will set u

Code 42 and cause the engine to run on the HE1

module timing. This will cause reduced performance

and poor fuel economy.

The ECM uses information from the

MAE' and

coolant sensors in addition to rpm to calculate spark

advance as follows:

e Cold engine = more spark advance.

r Engine under minimum load based on rpm

and low amount of air flow- more spark

advance. Hot engine

= less spark advance.

@ Engine under heavy load based on rpm and

high amount

of air flow- less spark advance.

DIAGNOSIS

The description, operation, and repair procedures

of the

HE1 system are found in Section "6D" of this

manual. For an ignition system check, refer to

CHART C-4 at the end of this section.

CODE 12

Code 12 is used during the diagnostic circuit check

procedure to test the code display ability of the

ECM

This code indicates that the ECM is not receiving the

engine rpm (REFERENCE) signal.

'Phis occurs with

the ignition key

"ON", and the engine not running.

Page 917 of 1825

6E3-C4-2 5.OL (VIN F) & 5.7L (VIN 8) DRIVEABILITY AND EMISSIONS

The "Reference" signal also triggers the fuel

injection system. Without the "Reference" signal the

engine cannot run. This signal can be checked by

using

a "Scan" tool which will help determine the

cause of an engine that cranks but won't start.

OM-CAR SERVICE

SETTING TIMING

The initial base timing is set by disconnecting the

timing connector. Then set the timing to the

specification shown on emmision control information

label. This will cause Code 42 to be stored in the

memory of the ECM. The memory must be cleared

after setting timing.

How Code 42 Is Determined

When the system is running on the HE1 module,

that is, no voltage on the bypass line, the

HE1 module

grounds the EST signal. The ECM expects to see no

voltage on the EST line during this condition.

If it

sees a voltage, it sets code 42 and will not go into the

EST mode.

When the rpm for EST is reached, (about

400

rpm), the ECM applies 5 volts to the bypass line and

the EST should no longer be grounded in the

HE1

module, so the EST voltage should be varying.

If the bypass line is open or grounded, the

HE1

module will not switch to EST mode, so the EST

voltage will be low and Code 42 will be set.

PARTS INFORMATION

PART NAME GROUP

Coil, Distr ........................... 2.170

Controller, ECM

(Remanufactured)

................ 3.670

Distributor

.......................... 2.361

Module, Distr

........................ 2.383

Page 918 of 1825

BLANK

Page 919 of 1825

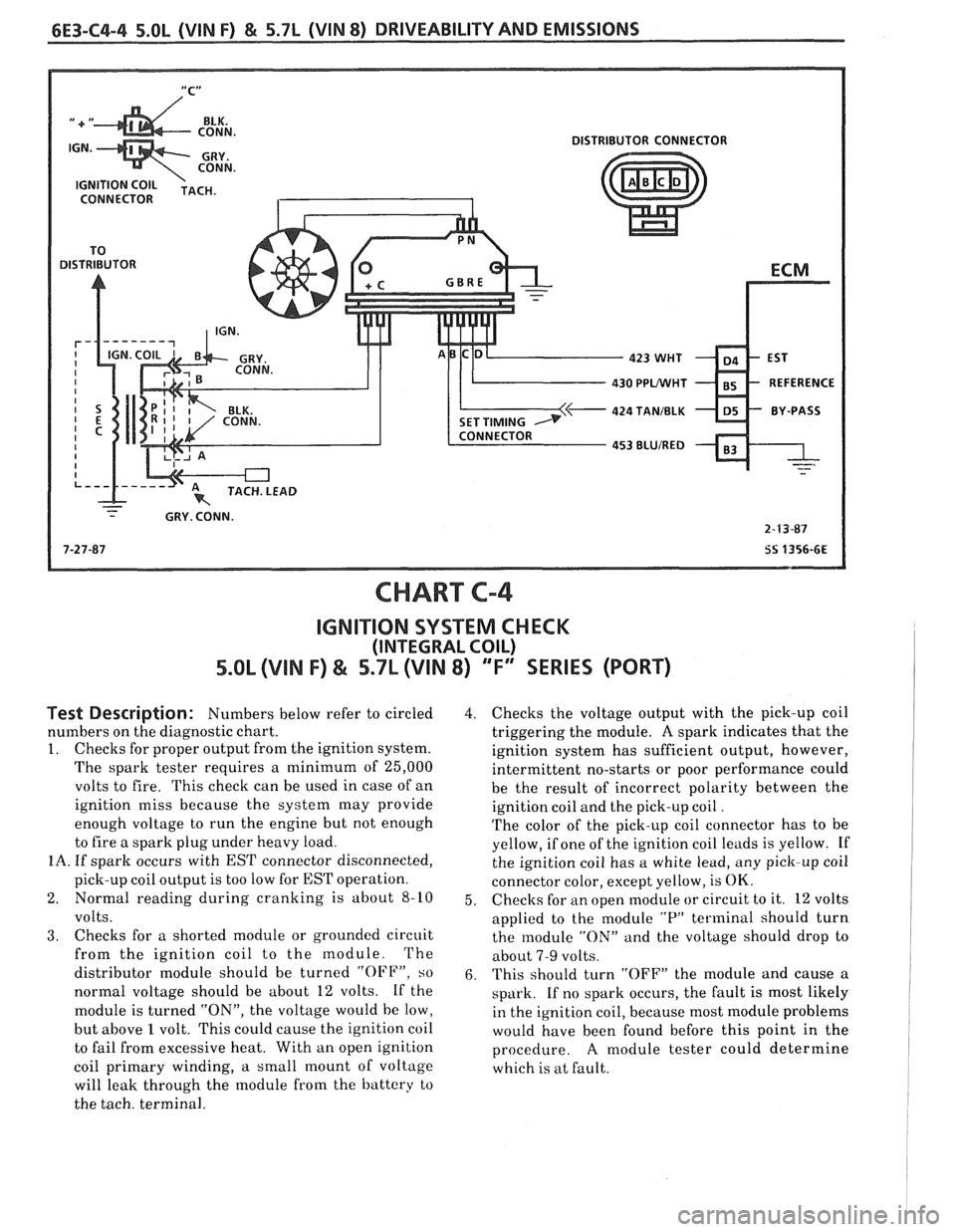

6E3-C4-4 5.OL (VIN F) & 5.7L (VIN 8) DRIVEABILITY AND EMISSIONS

"C" /

DISTRIBUTOR CONNECTOR

CONNECTOR

430 PPLNVHT

424 TANIBLK

- - - GRY. CONN.

2-F3-87

7-27-87

SS 1356-6E

CHART C-4

IGNITION SYSTEM CHECK

(INTEGRAL COIL)

5.0b (VIN F) & 5.7L (VIN 8) "F" SERIES (PORT)

Test Description: Numbers below refer to circled

numbers on the diagnostic chart.

1. Checks for proper output from the ignition system.

The spark tester requires a minimum of 25,000

volts to fire. This check can be used in case of an

ignition miss because the system may provide

enough voltage to run the engine but not enough

to fire a spark plug under heavy load.

IA. If spark occurs with EST connector disconnected,

pick-up coil output is too low for

EST operation.

2. Normal reading during cranking is about

8-10

volts.

3. Checks for a shorted module or grounded circuit

from the ignition coil to the module. The

distributor module should be turned

"OFF", so

normal voltage should be about 12 volts. If the

module is turned

"ON", the voltage would be low,

but above

1 volt. This could cause the ignition coil

to fail from excessive heat. With an open ignition

coil primary winding,

a small mount of voltage

will leak through the module from the battery to

the tach. terminal.

4. Checks the voltage output with the pick-up coil

triggering the module.

A spark indicates that the

ignition system has sufficient output, however,

intermittent no-starts or poor performance could

be the result of incorrect polarity between the

ignition coil and the pick-up coil

.

The color of the pick-up coil connector has to be

yellow, if one of the ignition coil leads is yellow. If

the ignition coil has a white lead, any pick-up coil

connector color, except yellow, is

OK.

5. Checks

for an open module or circuit to it. 12 volts

applied to the module

"P" terminal should turn

the module

"ON" and the voltage should drop to

about

7-9 volts.

6. This should turn "OFF" the module and cause a

spark. If no spark occurs, the fault is most likely

in the ignition coil, because most module problems

would have been found before this point in the

procedure.

A module tester could determine

which is at fault.

Page 920 of 1825

DRIVEABILITY AND EMISSIONS 5.OL (VIN F) & 5.7L (VIN 8) 6E3-C4-5

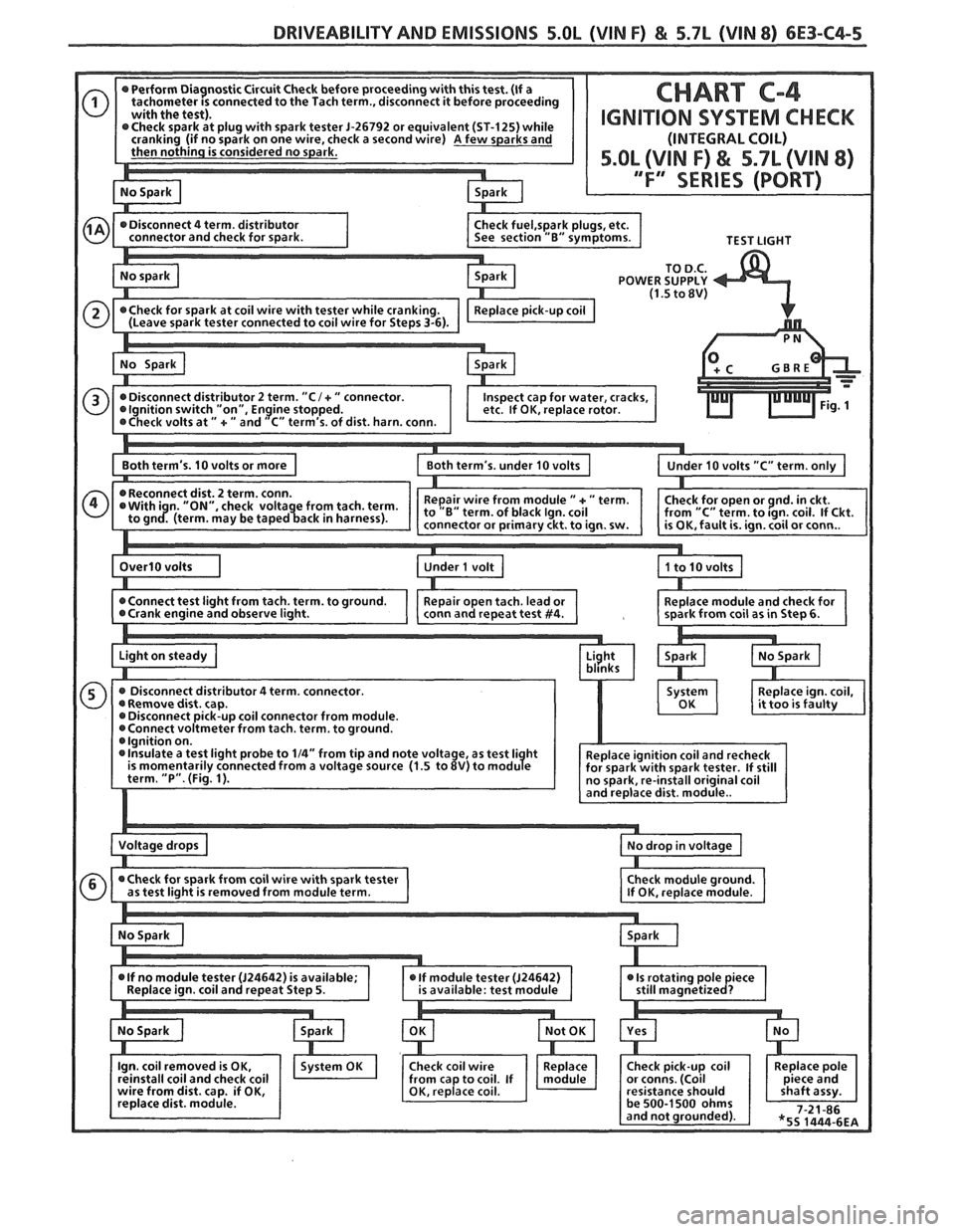

26792 or equivalent (ST-125) while k a second wire) A few sparks and

CHART C-4

IGNIVION SYSTEM CHECK

(INTEGRAL COIL)

5.OL (VIN F) & 5.7L (VIN 8)

/ .F" SERIES (PORT)

TEST LIGHT

POWER SUPPLY

I

dist. harn. conn.

0

ter from tach, term. to ground.