SUBARU FORESTER 2004 Service Repair Manual

Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 1021 of 2870

CO(H4SO)-38

COOLING

Radiator Main Fan and Fan Motor

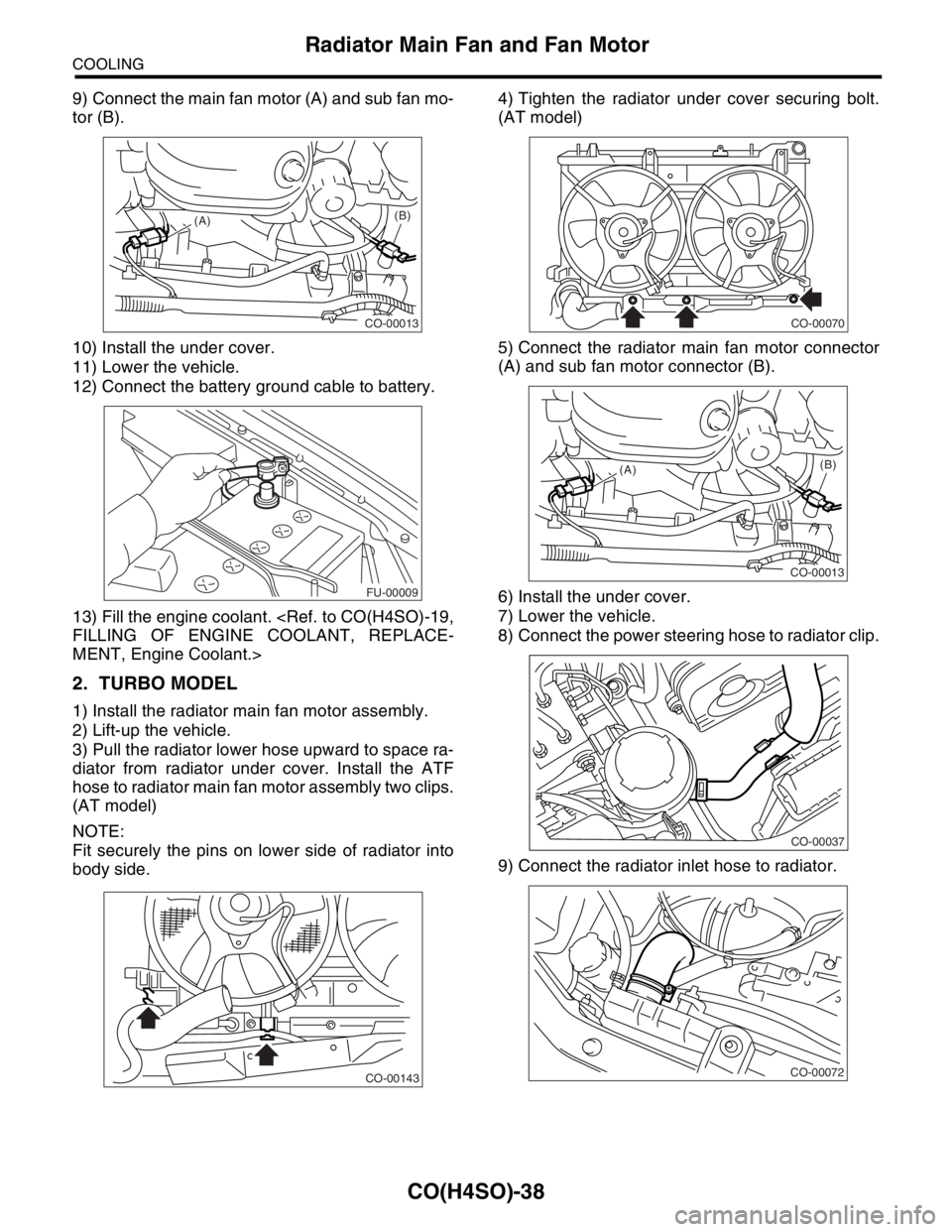

9) Connect the main fan motor (A) and sub fan mo-

tor (B).

10) Install the under cover.

11) Lower the vehicle.

12) Connect the battery ground cable to battery.

13) Fill the engine coolant.

MENT, Engine Coolant.>

2. TURBO MODEL

1) Install the radiator main fan motor assembly.

2) Lift-up the vehicle.

3) Pull the radiator lower hose upward to space ra-

diator from radiator under cover. Install the ATF

hose to radiator main fan motor assembly two clips.

(AT model)

NOTE:

Fit securely the pins on lower side of radiator into

body side.4) Tighten the radiator under cover securing bolt.

(AT model)

5) Connect the radiator main fan motor connector

(A) and sub fan motor connector (B).

6) Install the under cover.

7) Lower the vehicle.

8) Connect the power steering hose to radiator clip.

9) Connect the radiator inlet hose to radiator.

CO-00013

(A)(B)

FU-00009

CO-00143

CO-00070

CO-00013

(A)(B)

CO-00037

CO-00072

Page 1022 of 2870

CO(H4SO)-39

COOLING

Radiator Main Fan and Fan Motor

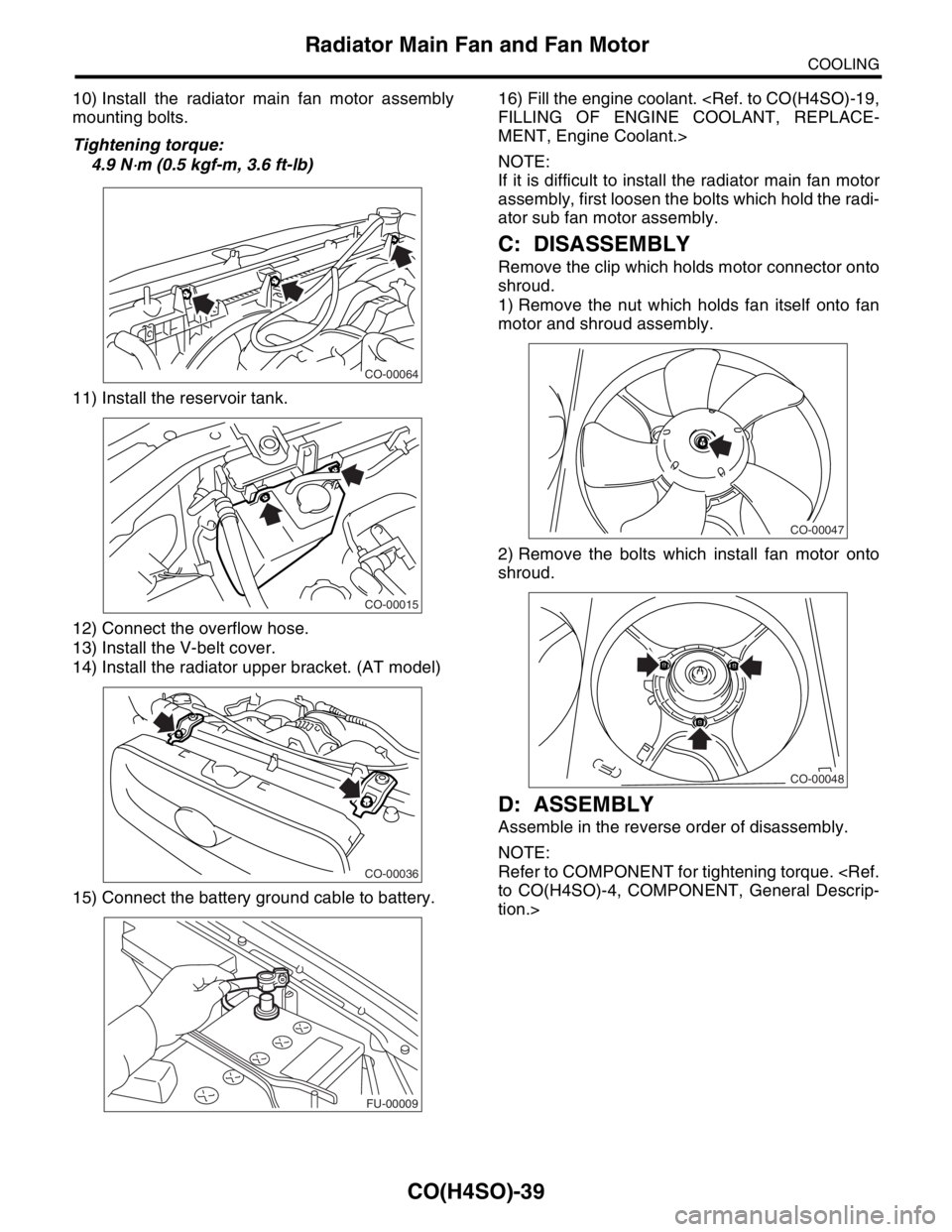

10) Install the radiator main fan motor assembly

mounting bolts.

Tightening torque:

4.9 N

⋅m (0.5 kgf-m, 3.6 ft-lb)

11) Install the reservoir tank.

12) Connect the overflow hose.

13) Install the V-belt cover.

14) Install the radiator upper bracket. (AT model)

15) Connect the battery ground cable to battery.16) Fill the engine coolant.

MENT, Engine Coolant.>

NOTE:

If it is difficult to install the radiator main fan motor

assembly, first loosen the bolts which hold the radi-

ator sub fan motor assembly.

C: DISASSEMBLY

Remove the clip which holds motor connector onto

shroud.

1) Remove the nut which holds fan itself onto fan

motor and shroud assembly.

2) Remove the bolts which install fan motor onto

shroud.

D: ASSEMBLY

Assemble in the reverse order of disassembly.

NOTE:

Refer to COMPONENT for tightening torque.

tion.>

CO-00064

CO-00015

CO-00036

FU-00009

CO-00047

CO-00048

Page 1023 of 2870

CO(H4SO)-40

COOLING

Radiator Sub Fan and Fan Motor

9. Radiator Sub Fan and Fan

Motor

A: REMOVAL

Refer to Radiator Main Fan and Fan Motor.

Fan Motor.>

B: INSTALLATION

Refer to Radiator Main Fan and Fan Motor.

Fan and Fan Motor.>

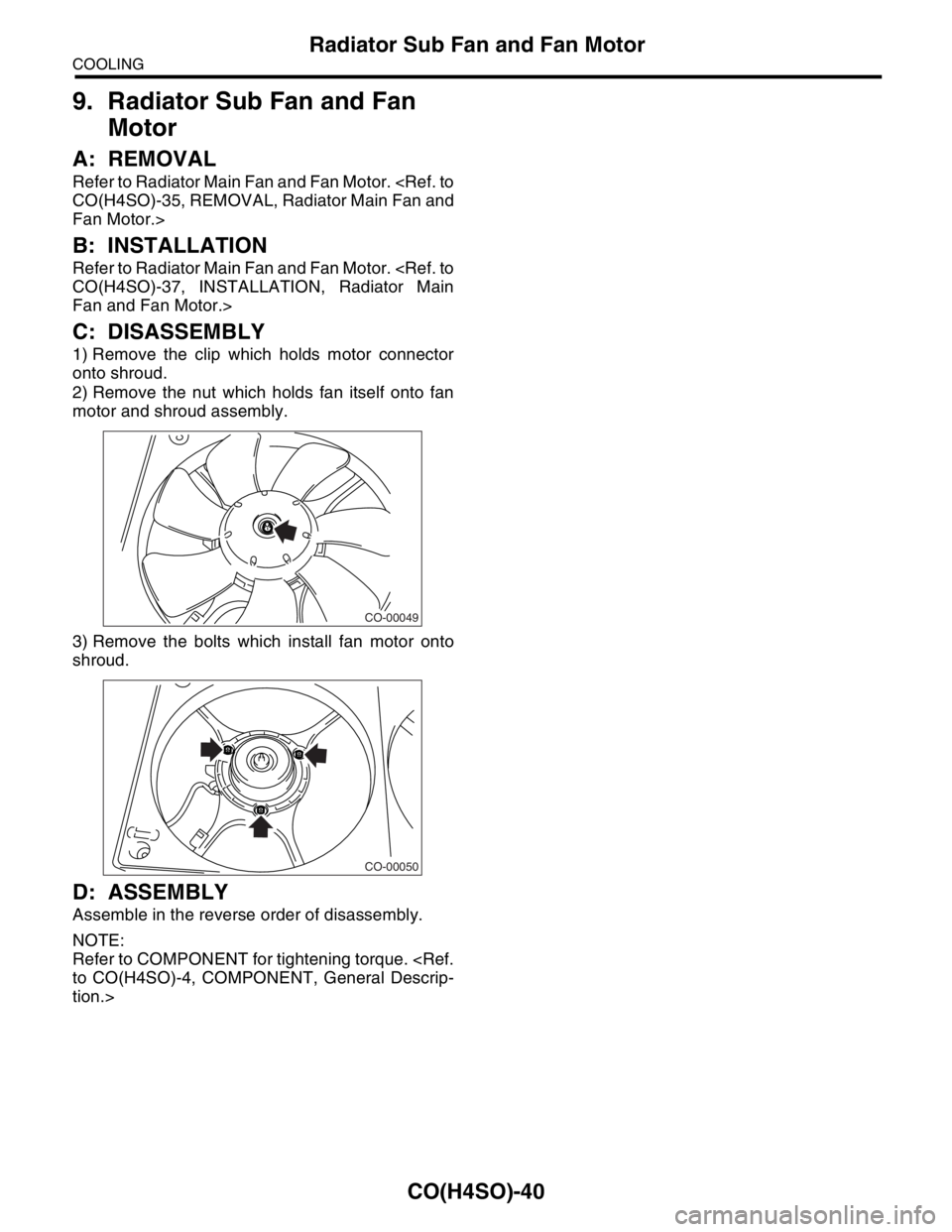

C: DISASSEMBLY

1) Remove the clip which holds motor connector

onto shroud.

2) Remove the nut which holds fan itself onto fan

motor and shroud assembly.

3) Remove the bolts which install fan motor onto

shroud.

D: ASSEMBLY

Assemble in the reverse order of disassembly.

NOTE:

Refer to COMPONENT for tightening torque.

tion.>

CO-00049

CO-00050

Page 1024 of 2870

CO(H4SO)-41

COOLING

Reservoir Tank

10.Reservoir Tank

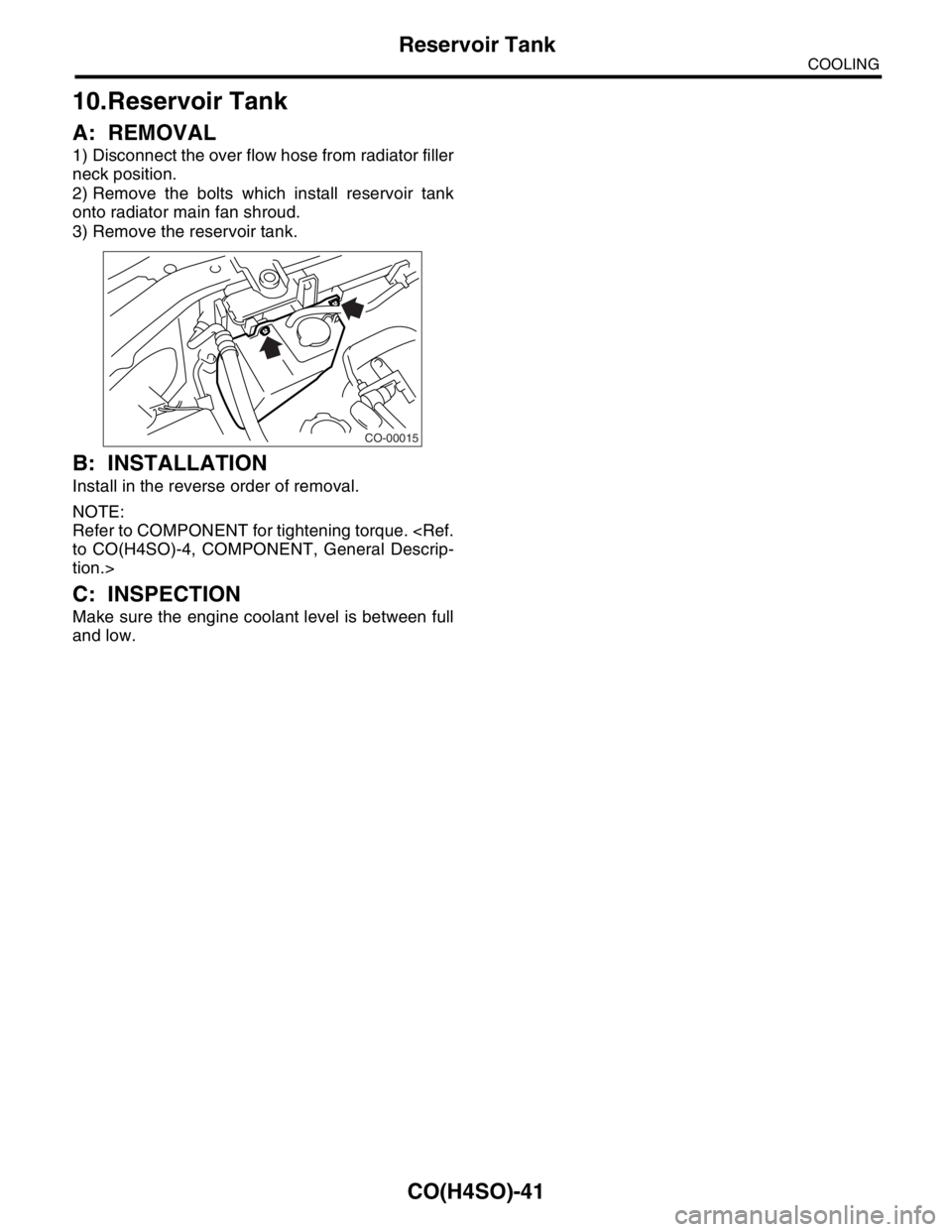

A: REMOVAL

1) Disconnect the over flow hose from radiator filler

neck position.

2) Remove the bolts which install reservoir tank

onto radiator main fan shroud.

3) Remove the reservoir tank.

B: INSTALLATION

Install in the reverse order of removal.

NOTE:

Refer to COMPONENT for tightening torque.

tion.>

C: INSPECTION

Make sure the engine coolant level is between full

and low.

CO-00015

Page 1025 of 2870

CO(H4SO)-42

COOLING

Coolant Filler Tank

11.Coolant Filler Tank

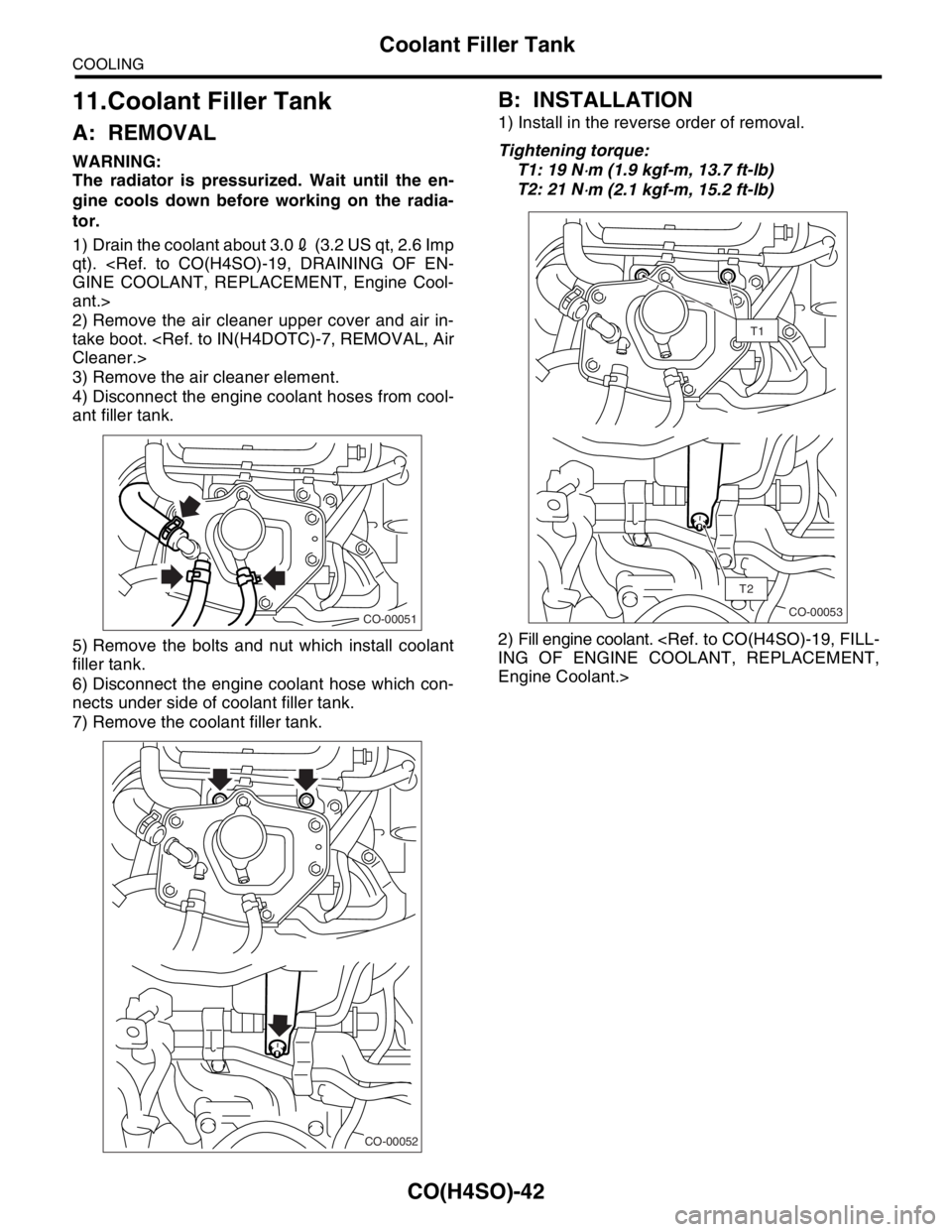

A: REMOVAL

WARNING:

The radiator is pressurized. Wait until the en-

gine cools down before working on the radia-

tor.

1) Drain the coolant about 3.02 (3.2 US qt, 2.6 Imp

qt).

ant.>

2) Remove the air cleaner upper cover and air in-

take boot.

3) Remove the air cleaner element.

4) Disconnect the engine coolant hoses from cool-

ant filler tank.

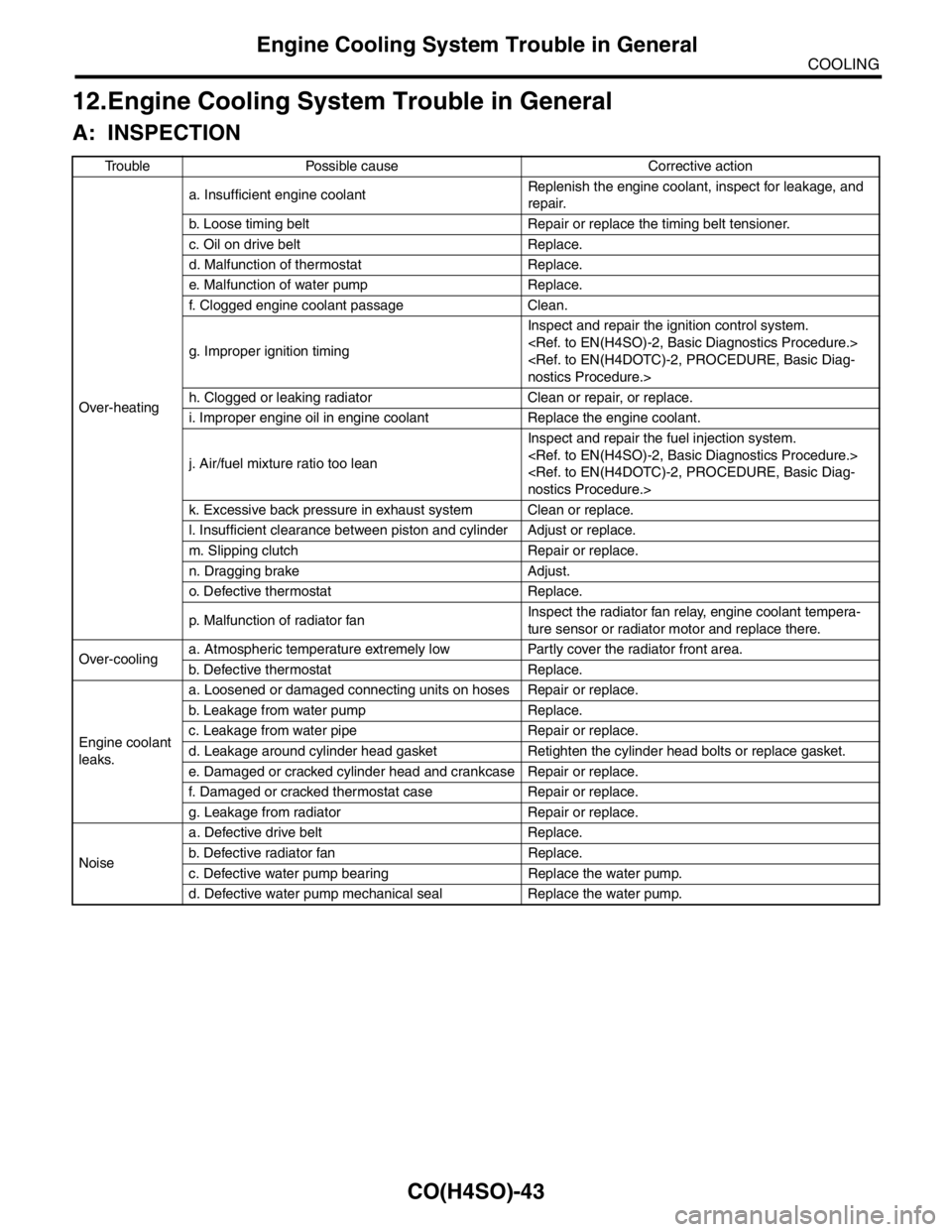

5) Remove the bolts and nut which install coolant

filler tank.

6) Disconnect the engine coolant hose which con-

nects under side of coolant filler tank.

7) Remove the coolant filler tank.

B: INSTALLATION

1) Install in the reverse order of removal.

Tightening torque:

T1: 19 N

⋅m (1.9 kgf-m, 13.7 ft-lb)

T2: 21 N

⋅m (2.1 kgf-m, 15.2 ft-lb)

2) Fill engine coolant.

Engine Coolant.>

CO-00051

CO-00052

T2

T1

CO-00053

Page 1026 of 2870

CO(H4SO)-43

COOLING

Engine Cooling System Trouble in General

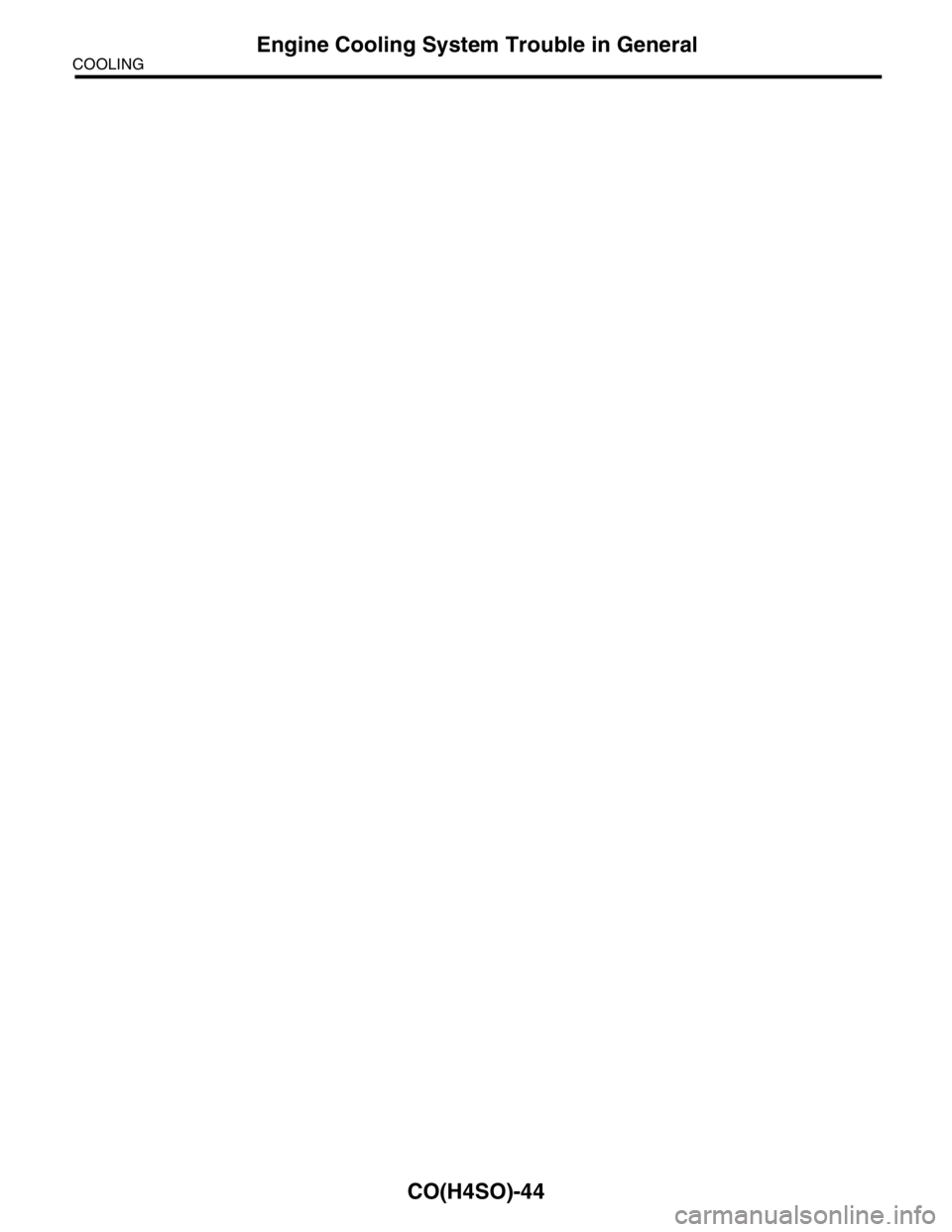

12.Engine Cooling System Trouble in General

A: INSPECTION

Trouble Possible cause Corrective action

Over-heatinga. Insufficient engine coolantReplenish the engine coolant, inspect for leakage, and

repair.

b. Loose timing belt Repair or replace the timing belt tensioner.

c. Oil on drive belt Replace.

d. Malfunction of thermostat Replace.

e. Malfunction of water pump Replace.

f. Clogged engine coolant passage Clean.

g. Improper ignition timingInspect and repair the ignition control system.

h. Clogged or leaking radiator Clean or repair, or replace.

i. Improper engine oil in engine coolant Replace the engine coolant.

j. Air/fuel mixture ratio too leanInspect and repair the fuel injection system.

k. Excessive back pressure in exhaust system Clean or replace.

l. Insufficient clearance between piston and cylinder Adjust or replace.

m. Slipping clutch Repair or replace.

n. Dragging brake Adjust.

o. Defective thermostat Replace.

p. Malfunction of radiator fanInspect the radiator fan relay, engine coolant tempera-

ture sensor or radiator motor and replace there.

Over-coolinga. Atmospheric temperature extremely low Partly cover the radiator front area.

b. Defective thermostat Replace.

Engine coolant

leaks.a. Loosened or damaged connecting units on hoses Repair or replace.

b. Leakage from water pump Replace.

c. Leakage from water pipe Repair or replace.

d. Leakage around cylinder head gasket Retighten the cylinder head bolts or replace gasket.

e. Damaged or cracked cylinder head and crankcase Repair or replace.

f. Damaged or cracked thermostat case Repair or replace.

g. Leakage from radiator Repair or replace.

Noisea. Defective drive belt Replace.

b. Defective radiator fan Replace.

c. Defective water pump bearing Replace the water pump.

d. Defective water pump mechanical seal Replace the water pump.

Page 1027 of 2870

CO(H4SO)-44

COOLING

Engine Cooling System Trouble in General

Page 1028 of 2870

FUJI HEAVY INDUSTRIES LTD. G8080GE2

2004 FORESTER SERVICE MANUAL QUICK REFERENCE INDEX

ENGINE SECTION 1

This service manual has been prepared

to provide SUBARU service personnel

with the necessary information and data

for the correct maintenance and repair

of SUBARU vehicles.

This manual includes the procedures

for maintenance, disassembling, reas-

sembling, inspection and adjustment of

components and diagnostics for guid-

ance of experienced mechanics.

Please peruse and utilize this manual

fully to ensure complete repair work for

satisfying our customers by keeping

their vehicle in optimum condition.

When replacement of parts during

repair work is needed, be sure to use

SUBARU genuine parts.

All information, illustration and specifi-

cations contained in this manual are

based on the latest product information

available at the time of publication

approval.FUEL INJECTION (FUEL SYSTEM) FU(H4SO)

EMISSION CONTROL

(AUX. EMISSION CONTROL DEVICE)EC(H4SO)

INTAKE (INDUCTION) IN(H4SO)

MECHANICAL ME(H4SO)

EXHAUST EX(H4SO)

COOLING CO(H4SO)

LUBRICATION LU(H4SO)

SPEED CONTROL SYSTEM SP(H4SO)

IGNITION IG(H4SO)

STARTING/CHARGING SYSTEM SC(H4SO)

ENGINE (DIAGNOSTIC) EN(H4SO)

Page 1029 of 2870

LUBRICATION

LU(H4SO)

Page

1. General Description ....................................................................................2

2. Oil Pressure System ...................................................................................8

3. Engine Oil..................................................................................................10

4. Oil Pump ...................................................................................................12

5. Oil Pan and Strainer ..................................................................................16

6. Oil Pressure Switch ...................................................................................20

7. Engine Oil Cooler ......................................................................................21

8. Engine Oil Filter.........................................................................................23

9. Engine Lubrication System Trouble in General.........................................24

Page 1030 of 2870

LU(H4SO)-2

LUBRICATION

General Description

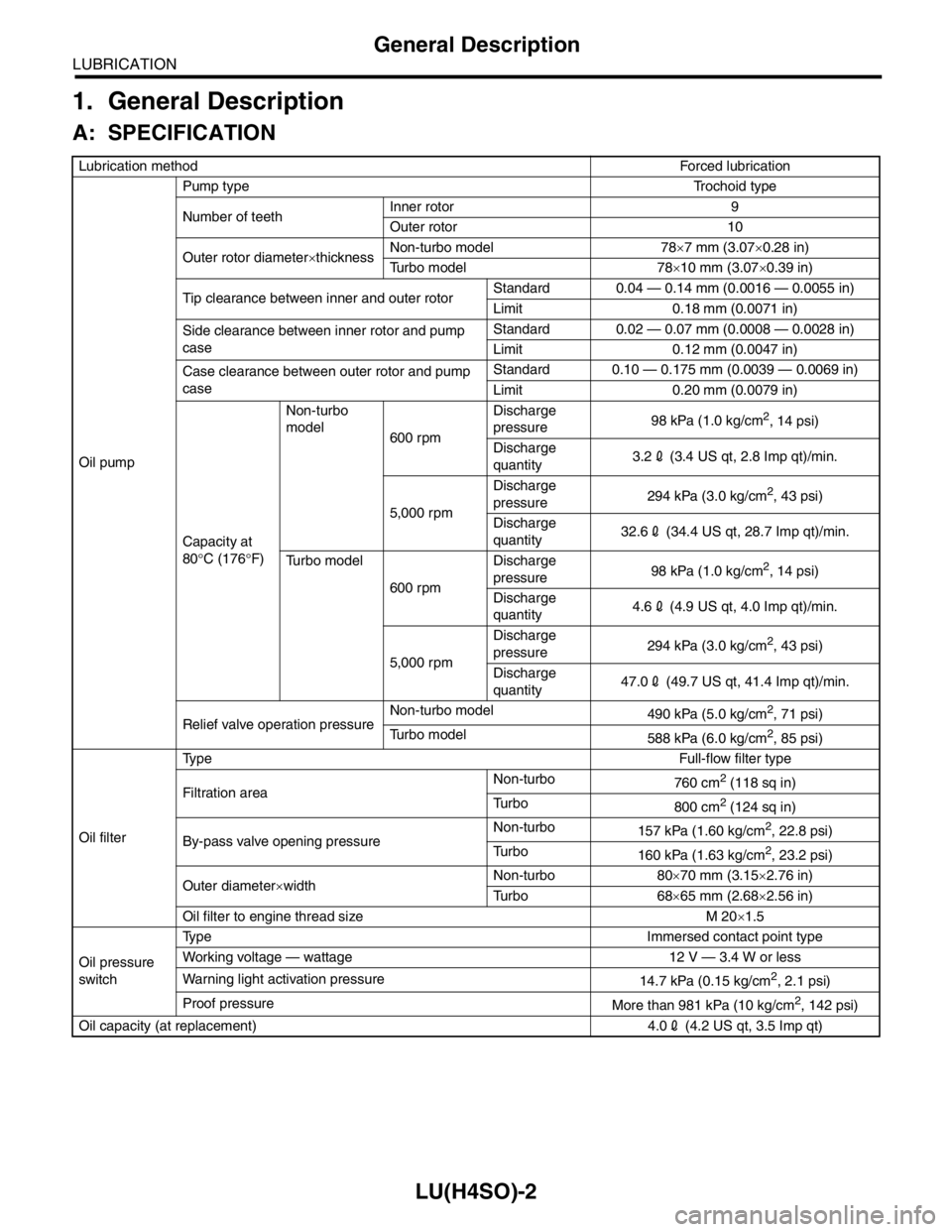

1. General Description

A: SPECIFICATION

Lubrication methodForced lubrication

Oil pumpPump type Trochoid type

Number of teethInner rotor 9

Outer rotor 10

Outer rotor diameter×thicknessNon-turbo model 78×7 mm (3.07×0.28 in)

Turbo model 78×10 mm (3.07×0.39 in)

Tip clearance between inner and outer rotorStandard 0.04 — 0.14 mm (0.0016 — 0.0055 in)

Limit 0.18 mm (0.0071 in)

Side clearance between inner rotor and pump

caseStandard 0.02 — 0.07 mm (0.0008 — 0.0028 in)

Limit 0.12 mm (0.0047 in)

Case clearance between outer rotor and pump

caseStandard 0.10 — 0.175 mm (0.0039 — 0.0069 in)

Limit 0.20 mm (0.0079 in)

Capacity at

80°C (176°F)Non-turbo

model

600 rpmDischarge

pressure98 kPa (1.0 kg/cm

2, 14 psi)

Discharge

quantity3.22 (3.4 US qt, 2.8 Imp qt)/min.

5,000 rpmDischarge

pressure294 kPa (3.0 kg/cm

2, 43 psi)

Discharge

quantity32.62 (34.4 US qt, 28.7 Imp qt)/min.

Turbo model

600 rpmDischarge

pressure98 kPa (1.0 kg/cm

2, 14 psi)

Discharge

quantity4.62 (4.9 US qt, 4.0 Imp qt)/min.

5,000 rpmDischarge

pressure294 kPa (3.0 kg/cm

2, 43 psi)

Discharge

quantity47.02 (49.7 US qt, 41.4 Imp qt)/min.

Relief valve operation pressureNon-turbo model

490 kPa (5.0 kg/cm

2, 71 psi)

Turbo model

588 kPa (6.0 kg/cm

2, 85 psi)

Oil filterTy p eFull-flow filter type

Filtration areaNon-turbo

760 cm

2 (118 sq in)

Tu r b o

800 cm

2 (124 sq in)

By-pass valve opening pressureNon-turbo

157 kPa (1.60 kg/cm

2, 22.8 psi)

Tu r b o

160 kPa (1.63 kg/cm

2, 23.2 psi)

Outer diameter×widthNon-turbo 80×70 mm (3.15×2.76 in)

Tu r b o 6 8×65 mm (2.68×2.56 in)

Oil filter to engine thread size M 20×1.5

Oil pressure

switchType Immersed contact point type

Working voltage — wattage 12 V — 3.4 W or less

Warning light activation pressure

14.7 kPa (0.15 kg/cm

2, 2.1 psi)

Proof pressure

More than 981 kPa (10 kg/cm

2, 142 psi)

Oil capacity (at replacement) 4.02 (4.2 US qt, 3.5 Imp qt)