SUBARU FORESTER 2004 Service Repair Manual

Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 1051 of 2870

LU(H4SO)-23

LUBRICATION

Engine Oil Filter

8. Engine Oil Filter

A: REMOVAL

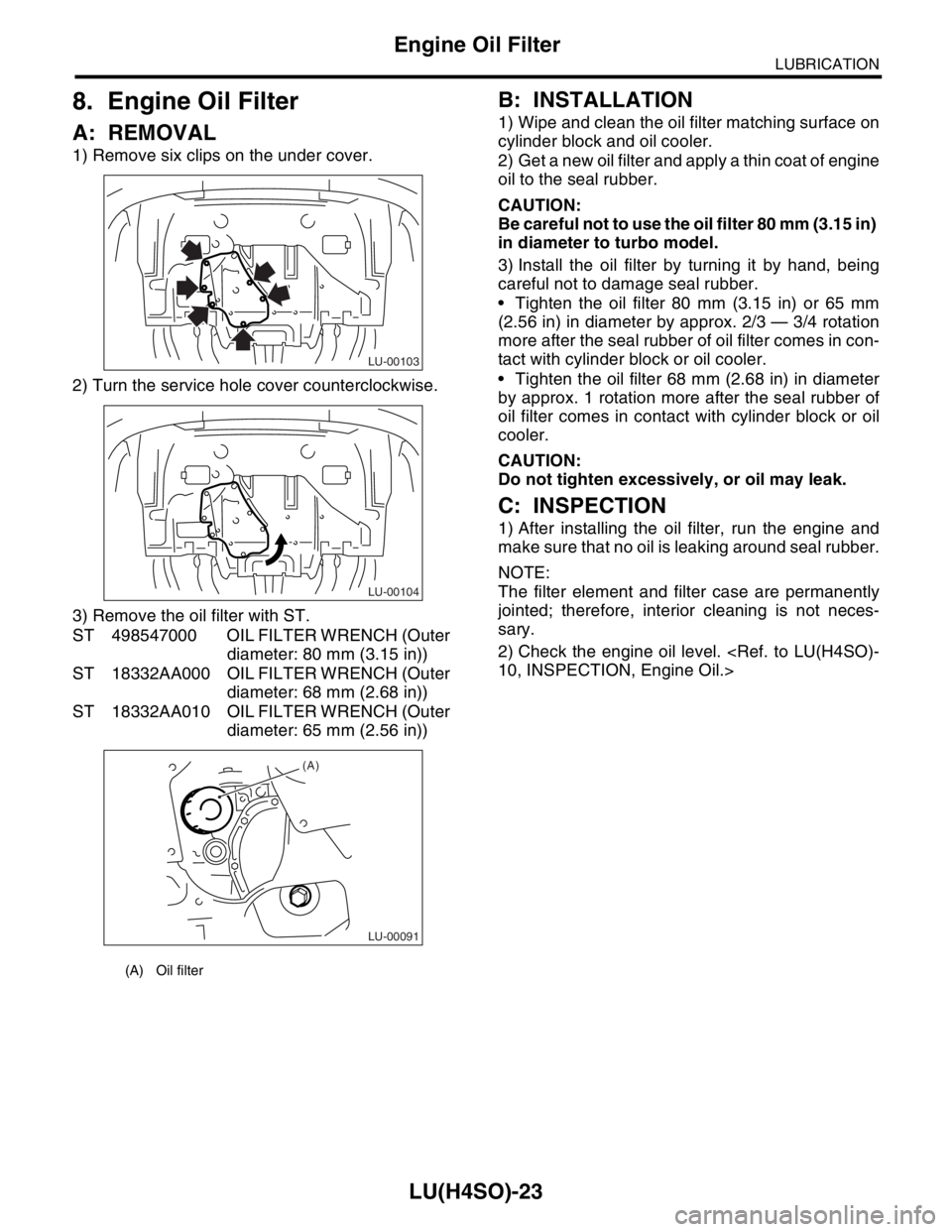

1) Remove six clips on the under cover.

2) Turn the service hole cover counterclockwise.

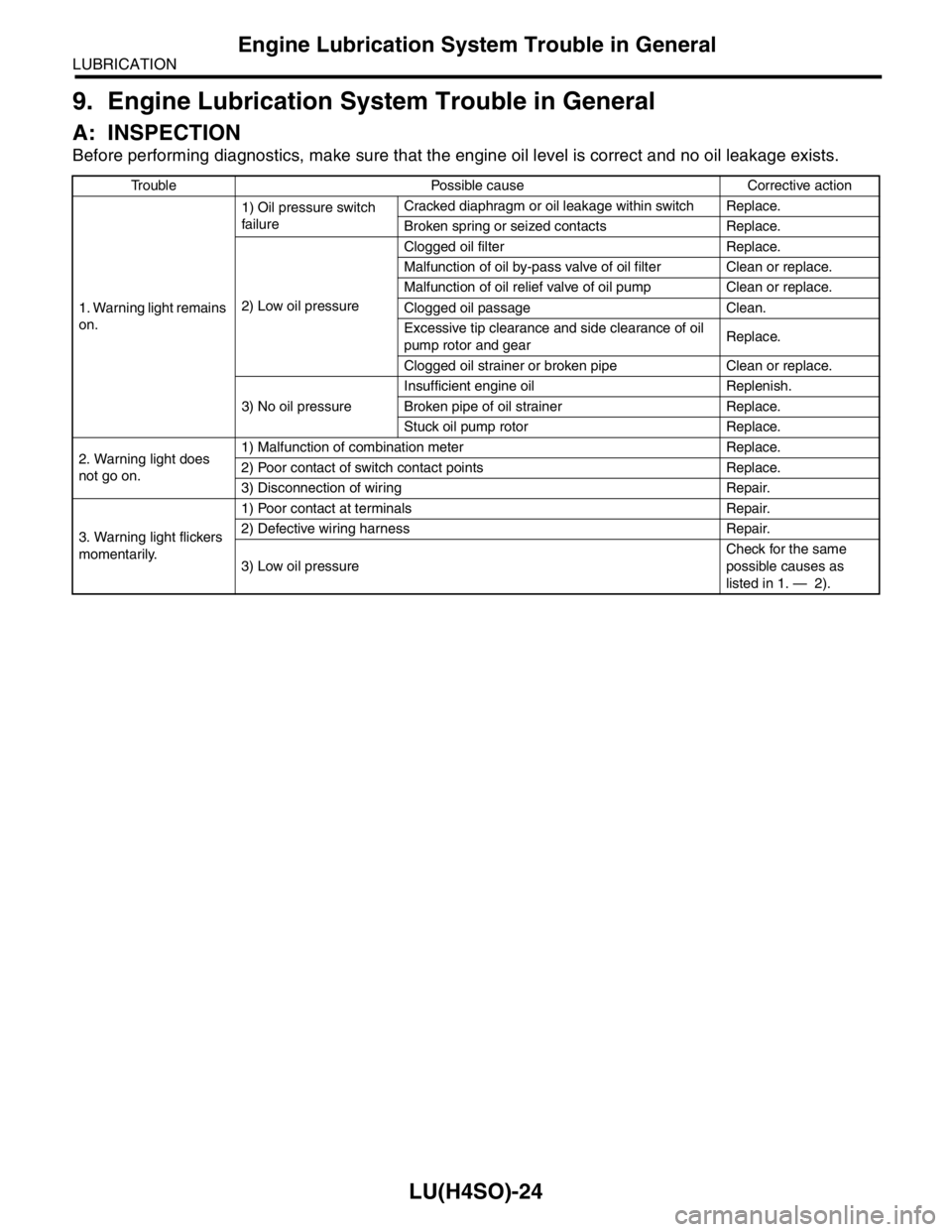

3) Remove the oil filter with ST.

ST 498547000 OIL FILTER WRENCH (Outer

diameter: 80 mm (3.15 in))

ST 18332AA000 OIL FILTER WRENCH (Outer

diameter: 68 mm (2.68 in))

ST 18332AA010 OIL FILTER WRENCH (Outer

diameter: 65 mm (2.56 in))

B: INSTALLATION

1) Wipe and clean the oil filter matching surface on

cylinder block and oil cooler.

2) Get a new oil filter and apply a thin coat of engine

oil to the seal rubber.

CAUTION:

Be careful not to use the oil filter 80 mm (3.15 in)

in diameter to turbo model.

3) Install the oil filter by turning it by hand, being

careful not to damage seal rubber.

Tighten the oil filter 80 mm (3.15 in) or 65 mm

(2.56 in) in diameter by approx. 2/3 — 3/4 rotation

more after the seal rubber of oil filter comes in con-

tact with cylinder block or oil cooler.

Tighten the oil filter 68 mm (2.68 in) in diameter

by approx. 1 rotation more after the seal rubber of

oil filter comes in contact with cylinder block or oil

cooler.

CAUTION:

Do not tighten excessively, or oil may leak.

C: INSPECTION

1) After installing the oil filter, run the engine and

make sure that no oil is leaking around seal rubber.

NOTE:

The filter element and filter case are permanently

jointed; therefore, interior cleaning is not neces-

sary.

2) Check the engine oil level.

(A) Oil filter

LU-00103

LU-00104

LU-00091

(A)

Page 1052 of 2870

LU(H4SO)-24

LUBRICATION

Engine Lubrication System Trouble in General

9. Engine Lubrication System Trouble in General

A: INSPECTION

Before performing diagnostics, make sure that the engine oil level is correct and no oil leakage exists.

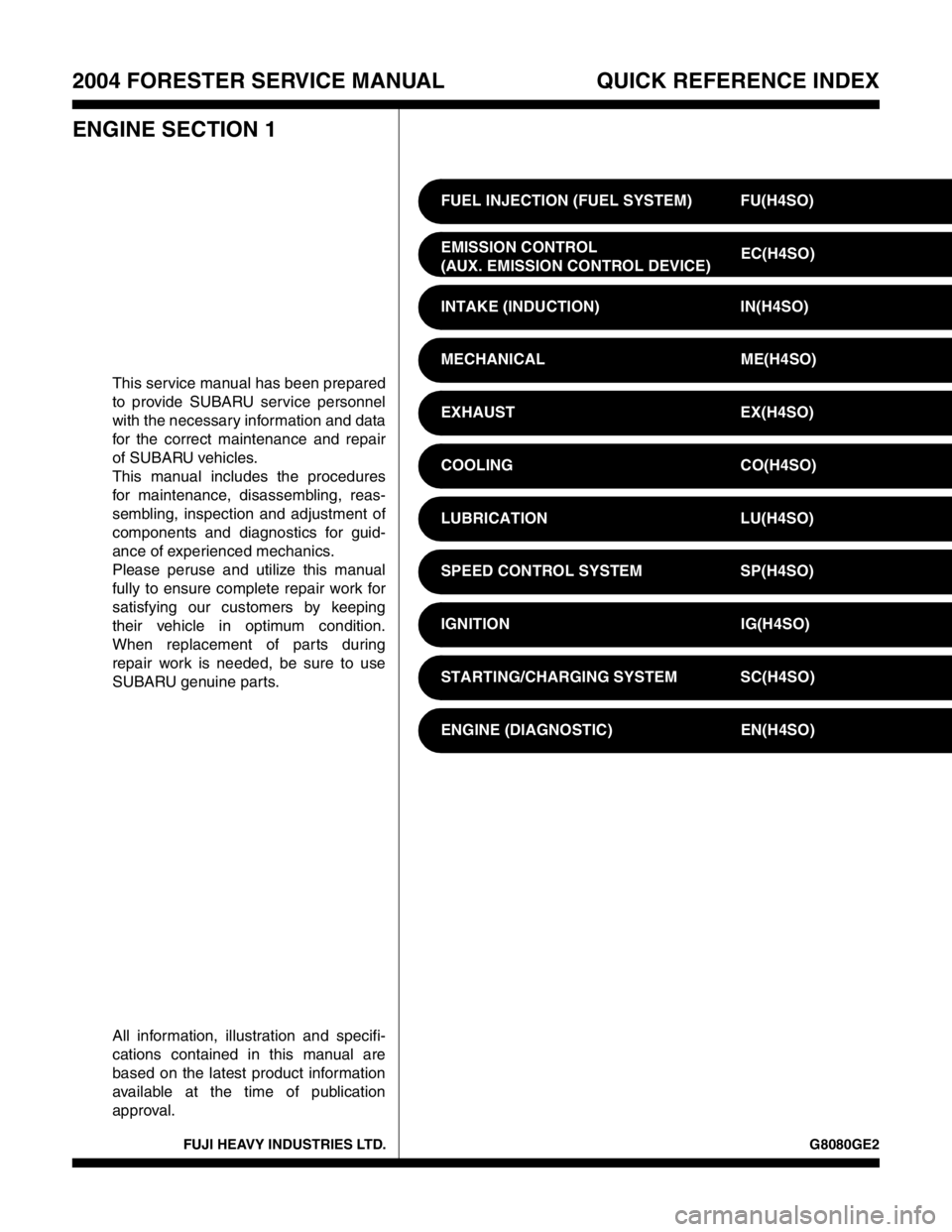

Trouble Possible cause Corrective action

1. Warning light remains

on.1) Oil pressure switch

failureCracked diaphragm or oil leakage within switch Replace.

Broken spring or seized contacts Replace.

2) Low oil pressureClogged oil filter Replace.

Malfunction of oil by-pass valve of oil filter Clean or replace.

Malfunction of oil relief valve of oil pump Clean or replace.

Clogged oil passage Clean.

Excessive tip clearance and side clearance of oil

pump rotor and gearReplace.

Clogged oil strainer or broken pipe Clean or replace.

3) No oil pressureInsufficient engine oil Replenish.

Broken pipe of oil strainer Replace.

Stuck oil pump rotor Replace.

2. Warning light does

not go on.1) Malfunction of combination meter Replace.

2) Poor contact of switch contact points Replace.

3) Disconnection of wiring Repair.

3. Warning light flickers

momentarily.1) Poor contact at terminals Repair.

2) Defective wiring harness Repair.

3) Low oil pressureCheck for the same

possible causes as

listed in 1. — 2).

Page 1053 of 2870

FUJI HEAVY INDUSTRIES LTD. G8080GE2

2004 FORESTER SERVICE MANUAL QUICK REFERENCE INDEX

ENGINE SECTION 1

This service manual has been prepared

to provide SUBARU service personnel

with the necessary information and data

for the correct maintenance and repair

of SUBARU vehicles.

This manual includes the procedures

for maintenance, disassembling, reas-

sembling, inspection and adjustment of

components and diagnostics for guid-

ance of experienced mechanics.

Please peruse and utilize this manual

fully to ensure complete repair work for

satisfying our customers by keeping

their vehicle in optimum condition.

When replacement of parts during

repair work is needed, be sure to use

SUBARU genuine parts.

All information, illustration and specifi-

cations contained in this manual are

based on the latest product information

available at the time of publication

approval.FUEL INJECTION (FUEL SYSTEM) FU(H4SO)

EMISSION CONTROL

(AUX. EMISSION CONTROL DEVICE)EC(H4SO)

INTAKE (INDUCTION) IN(H4SO)

MECHANICAL ME(H4SO)

EXHAUST EX(H4SO)

COOLING CO(H4SO)

LUBRICATION LU(H4SO)

SPEED CONTROL SYSTEM SP(H4SO)

IGNITION IG(H4SO)

STARTING/CHARGING SYSTEM SC(H4SO)

ENGINE (DIAGNOSTIC) EN(H4SO)

Page 1054 of 2870

SPEED CONTROL SYSTEM

SP(H4SO)

Page

1. General Description ....................................................................................2

2. Accelerator Pedal ........................................................................................4

3. Accelerator Control Cable ...........................................................................9

Page 1055 of 2870

SP(H4SO)-2

SPEED CONTROL SYSTEM

General Description

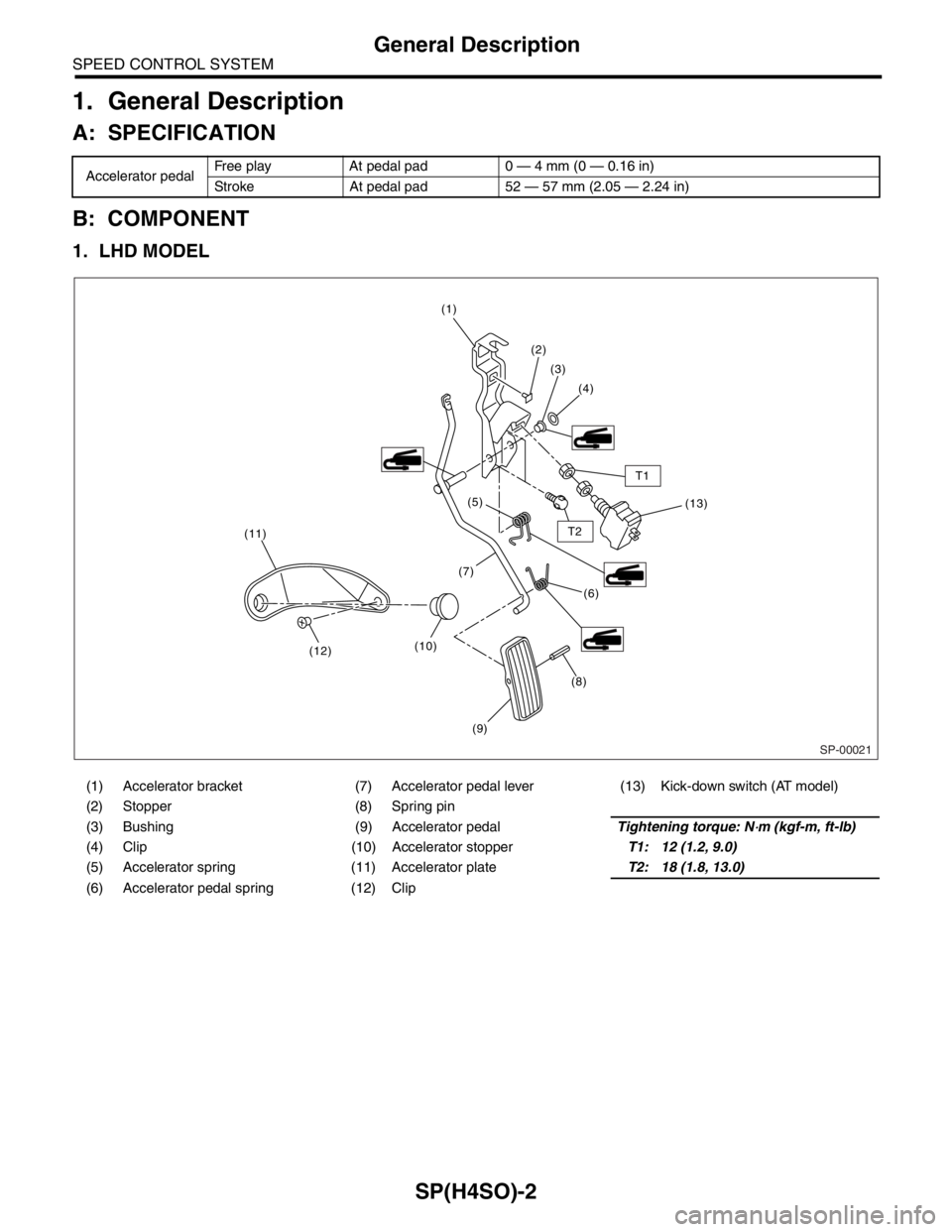

1. General Description

A: SPECIFICATION

B: COMPONENT

1. LHD MODEL

Accelerator pedalFree play At pedal pad 0 — 4 mm (0 — 0.16 in)

Stroke At pedal pad 52 — 57 mm (2.05 — 2.24 in)

(1) Accelerator bracket (7) Accelerator pedal lever (13) Kick-down switch (AT model)

(2) Stopper (8) Spring pin

(3) Bushing (9) Accelerator pedalTightening torque: N

⋅m (kgf-m, ft-lb)

(4) Clip (10) Accelerator stopperT1: 12 (1.2, 9.0)

(5) Accelerator spring (11) Accelerator plateT2: 18 (1.8, 13.0)

(6) Accelerator pedal spring (12) Clip

(8) (1)

(2)

(3)

(4)

(6)(13) (5)

(9) (10)(7)

(12) (11)

T2

T1

SP-00021

Page 1056 of 2870

SP(H4SO)-3

SPEED CONTROL SYSTEM

General Description

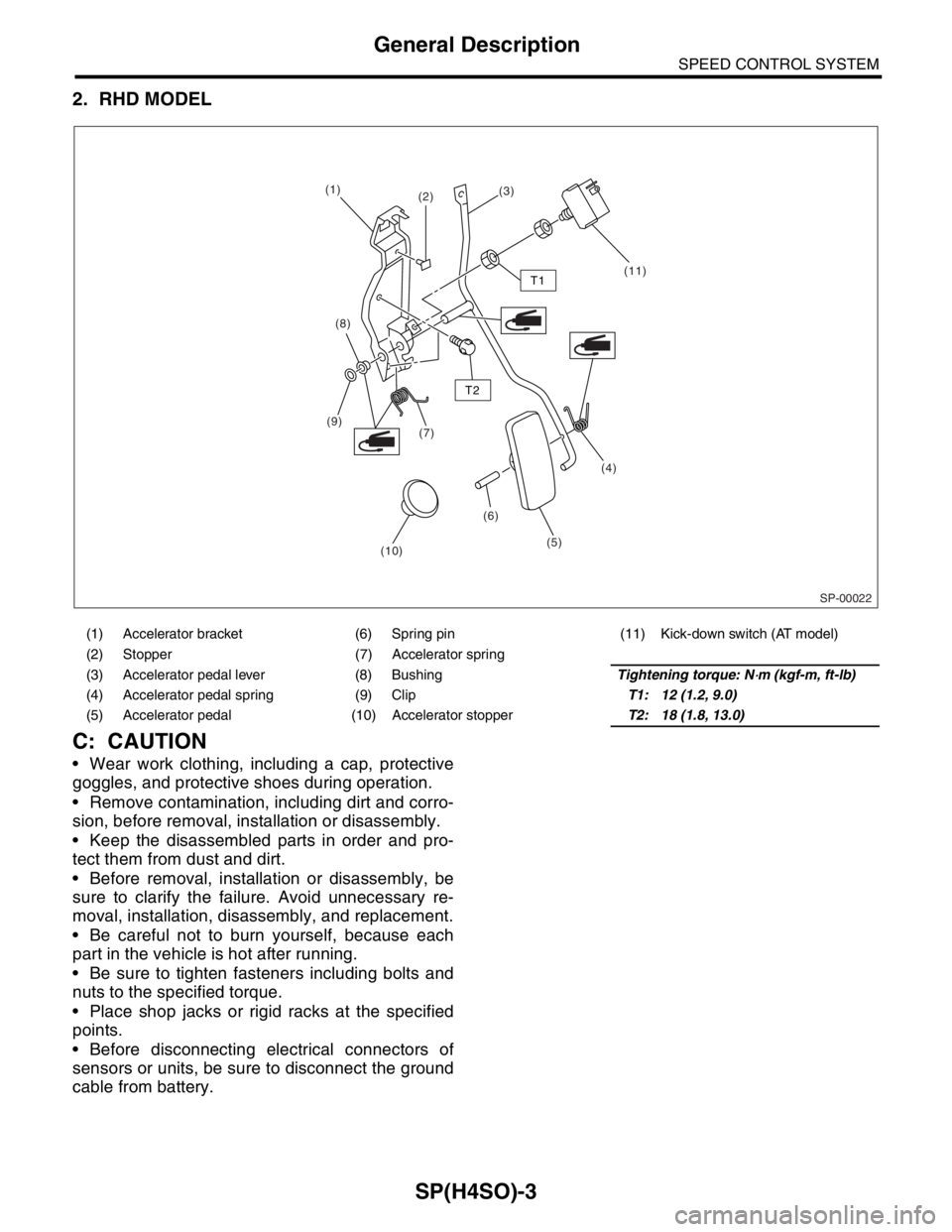

2. RHD MODEL

C: CAUTION

Wear work clothing, including a cap, protective

goggles, and protective shoes during operation.

Remove contamination, including dirt and corro-

sion, before removal, installation or disassembly.

Keep the disassembled parts in order and pro-

tect them from dust and dirt.

Before removal, installation or disassembly, be

sure to clarify the failure. Avoid unnecessary re-

moval, installation, disassembly, and replacement.

Be careful not to burn yourself, because each

part in the vehicle is hot after running.

Be sure to tighten fasteners including bolts and

nuts to the specified torque.

Place shop jacks or rigid racks at the specified

points.

Before disconnecting electrical connectors of

sensors or units, be sure to disconnect the ground

cable from battery.

(1) Accelerator bracket (6) Spring pin (11) Kick-down switch (AT model)

(2) Stopper (7) Accelerator spring

(3) Accelerator pedal lever (8) BushingTightening torque: N

⋅m (kgf-m, ft-lb)

(4) Accelerator pedal spring (9) ClipT1: 12 (1.2, 9.0)

(5) Accelerator pedal (10) Accelerator stopperT2: 18 (1.8, 13.0)

SP-00022

(1)

(2)(3)

(11)

(8)

(7) (9)

(6)(4)

(5)

(10)

T1

T2

Page 1057 of 2870

SP(H4SO)-4

SPEED CONTROL SYSTEM

Accelerator Pedal

2. Accelerator Pedal

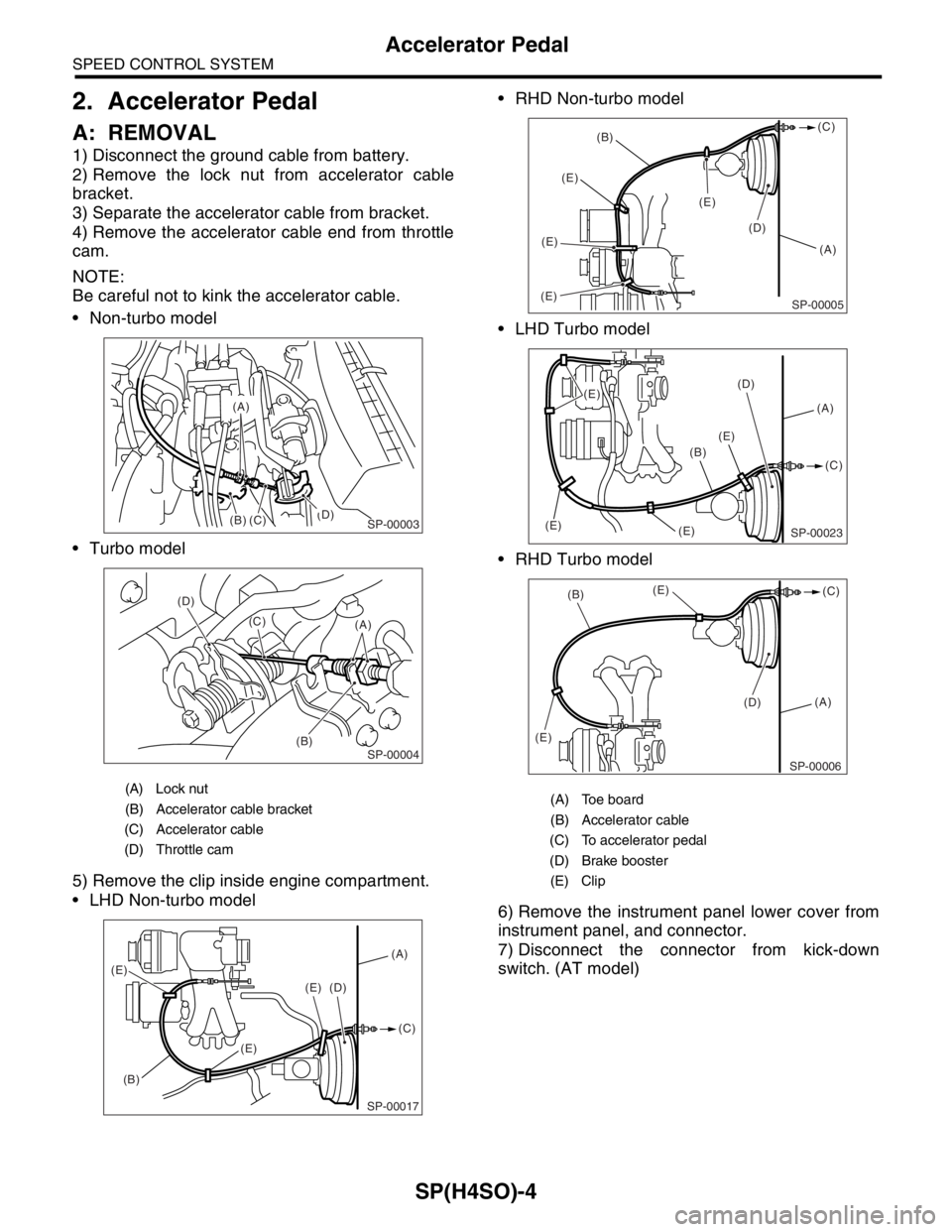

A: REMOVAL

1) Disconnect the ground cable from battery.

2) Remove the lock nut from accelerator cable

bracket.

3) Separate the accelerator cable from bracket.

4) Remove the accelerator cable end from throttle

cam.

NOTE:

Be careful not to kink the accelerator cable.

Non-turbo model

Turbo model

5) Remove the clip inside engine compartment.

LHD Non-turbo model RHD Non-turbo model

LHD Turbo model

RHD Turbo model

6) Remove the instrument panel lower cover from

instrument panel, and connector.

7) Disconnect the connector from kick-down

switch. (AT model)

(A) Lock nut

(B) Accelerator cable bracket

(C) Accelerator cable

(D) Throttle cam

(B)(D)

(C)

(A)

SP-00003

(B) (D)

(C)

(A)SP-00004

SP-00017

(A)

(B)(C) (D)

(E)

(E)

(E)

(A) Toe board

(B) Accelerator cable

(C) To accelerator pedal

(D) Brake booster

(E) Clip

(A) (B)(C)

(E)(E)(E)

(E)

(D)

SP-00005

(A) (D)

(E)

(E) (E)(C)

(B)

(E)

SP-00023

(A)

(D) (E)

(E)(B)(C)

SP-00006

Page 1058 of 2870

SP(H4SO)-5

SPEED CONTROL SYSTEM

Accelerator Pedal

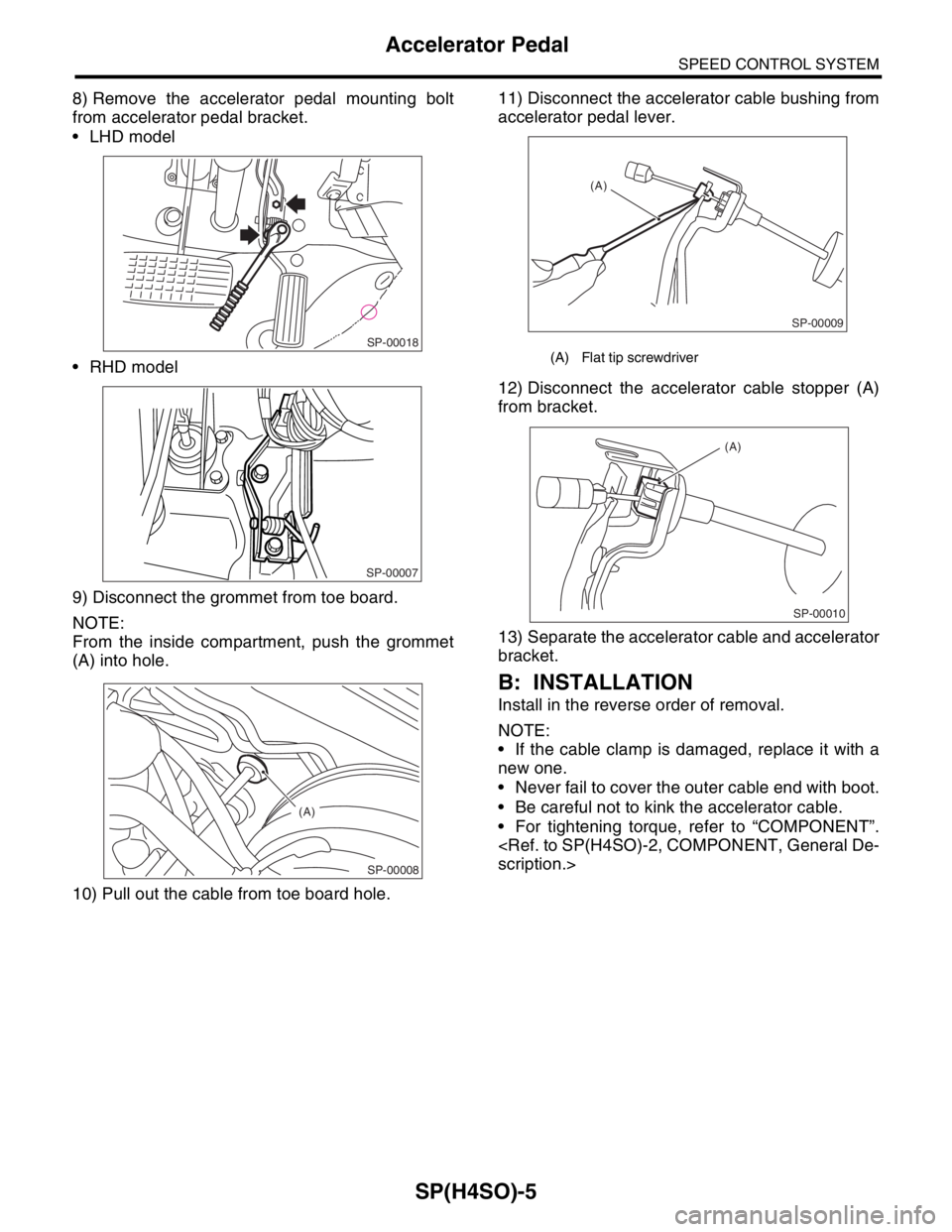

8) Remove the accelerator pedal mounting bolt

from accelerator pedal bracket.

LHD model

RHD model

9) Disconnect the grommet from toe board.

NOTE:

From the inside compartment, push the grommet

(A) into hole.

10) Pull out the cable from toe board hole.11) Disconnect the accelerator cable bushing from

accelerator pedal lever.

12) Disconnect the accelerator cable stopper (A)

from bracket.

13) Separate the accelerator cable and accelerator

bracket.

B: INSTALLATION

Install in the reverse order of removal.

NOTE:

If the cable clamp is damaged, replace it with a

new one.

Never fail to cover the outer cable end with boot.

Be careful not to kink the accelerator cable.

For tightening torque, refer to “COMPONENT”.

SP-00018

SP-00007

SP-00008

(A)

(A) Flat tip screwdriver

SP-00009

(A)

SP-00010

(A)

Page 1059 of 2870

SP(H4SO)-6

SPEED CONTROL SYSTEM

Accelerator Pedal

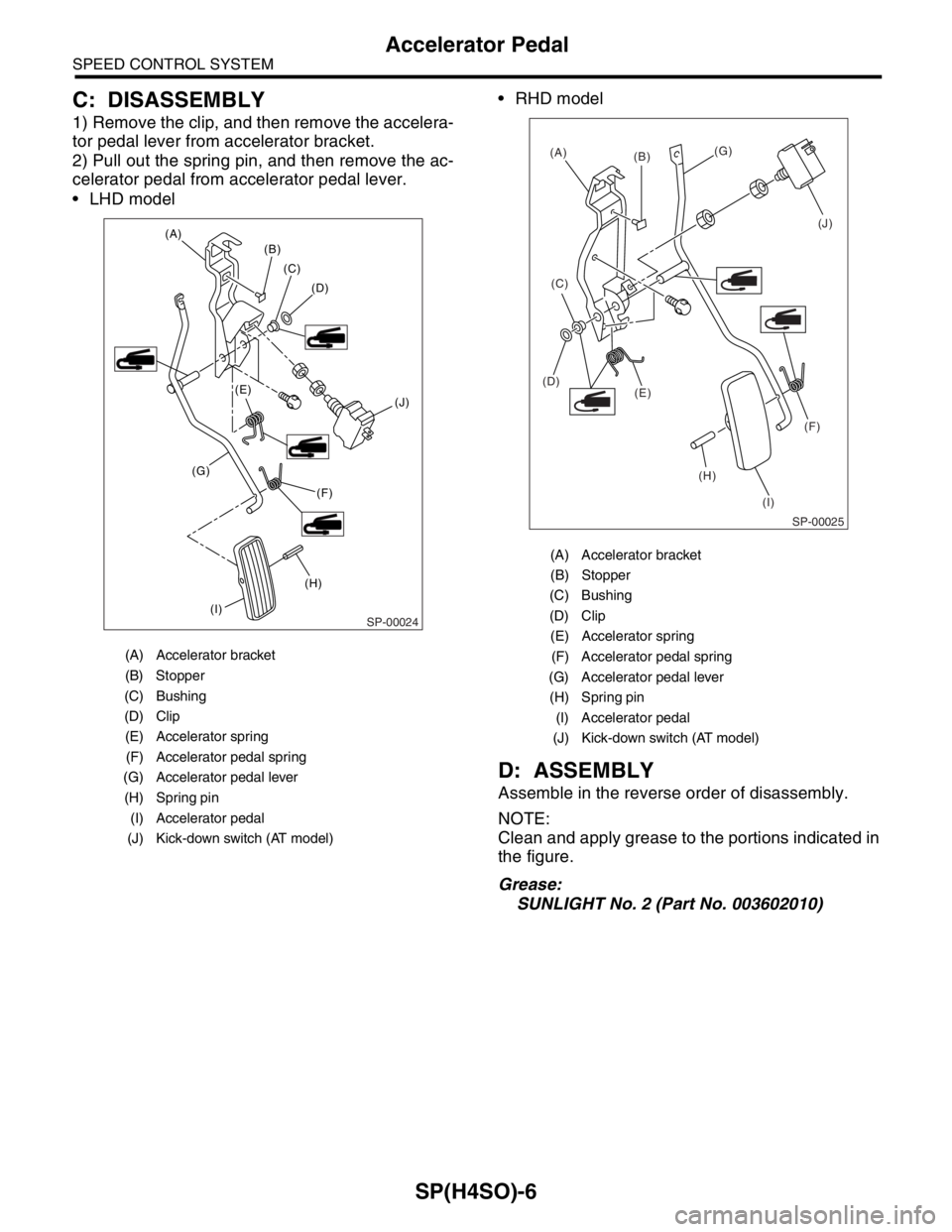

C: DISASSEMBLY

1) Remove the clip, and then remove the accelera-

tor pedal lever from accelerator bracket.

2) Pull out the spring pin, and then remove the ac-

celerator pedal from accelerator pedal lever.

LHD model RHD model

D: ASSEMBLY

Assemble in the reverse order of disassembly.

NOTE:

Clean and apply grease to the portions indicated in

the figure.

Grease:

SUNLIGHT No. 2 (Part No. 003602010)

(A) Accelerator bracket

(B) Stopper

(C) Bushing

(D) Clip

(E) Accelerator spring

(F) Accelerator pedal spring

(G) Accelerator pedal lever

(H) Spring pin

(I) Accelerator pedal

(J) Kick-down switch (AT model)

SP-00024

(H) (A)

(B)

(C)

(D)

(F)(J) (E)

(I) (G)

(A) Accelerator bracket

(B) Stopper

(C) Bushing

(D) Clip

(E) Accelerator spring

(F) Accelerator pedal spring

(G) Accelerator pedal lever

(H) Spring pin

(I) Accelerator pedal

(J) Kick-down switch (AT model)

SP-00025

(A)

(B)(G)

(J)

(C)

(E) (D)

(H)(F)

(I)

Page 1060 of 2870

SP(H4SO)-7

SPEED CONTROL SYSTEM

Accelerator Pedal

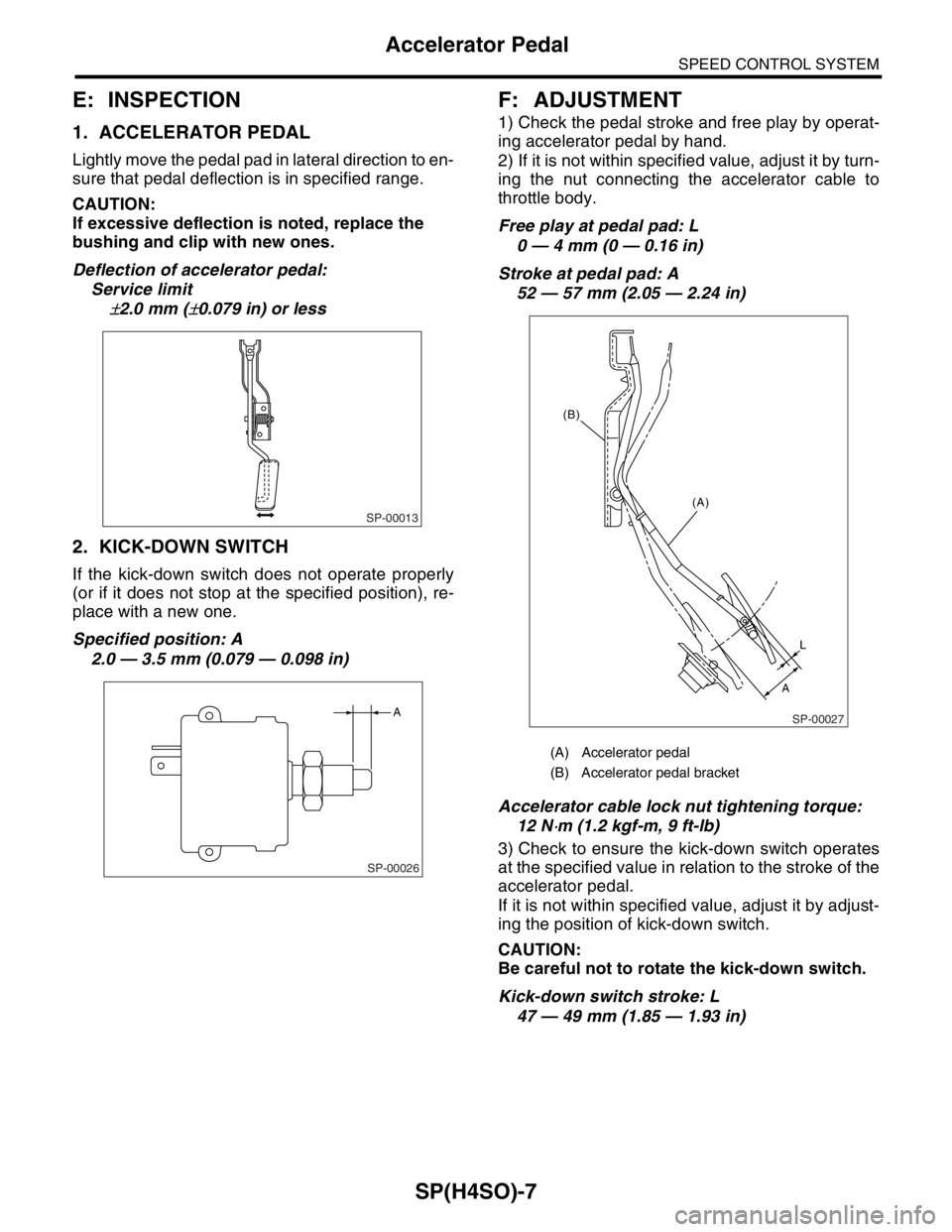

E: INSPECTION

1. ACCELERATOR PEDAL

Lightly move the pedal pad in lateral direction to en-

sure that pedal deflection is in specified range.

CAUTION:

If excessive deflection is noted, replace the

bushing and clip with new ones.

Deflection of accelerator pedal:

Service limit

±2.0 mm (±0.079 in) or less

2. KICK-DOWN SWITCH

If the kick-down switch does not operate properly

(or if it does not stop at the specified position), re-

place with a new one.

Specified position: A

2.0 — 3.5 mm (0.079 — 0.098 in)

F: ADJUSTMENT

1) Check the pedal stroke and free play by operat-

ing accelerator pedal by hand.

2) If it is not within specified value, adjust it by turn-

ing the nut connecting the accelerator cable to

throttle body.

Free play at pedal pad: L

0 — 4 mm (0 — 0.16 in)

Stroke at pedal pad: A

52 — 57 mm (2.05 — 2.24 in)

Accelerator cable lock nut tightening torque:

12 N

⋅m (1.2 kgf-m, 9 ft-lb)

3) Check to ensure the kick-down switch operates

at the specified value in relation to the stroke of the

accelerator pedal.

If it is not within specified value, adjust it by adjust-

ing the position of kick-down switch.

CAUTION:

Be careful not to rotate the kick-down switch.

Kick-down switch stroke: L

47 — 49 mm (1.85 — 1.93 in)

SP-00013

SP-00026

A

(A) Accelerator pedal

(B) Accelerator pedal bracket

SP-00027

(A)

L

A (B)