SUBARU FORESTER 2004 Service Repair Manual

Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 961 of 2870

ME(H4SO)-90

MECHANICAL

Cylinder Block

O.D.: Outer Diameter

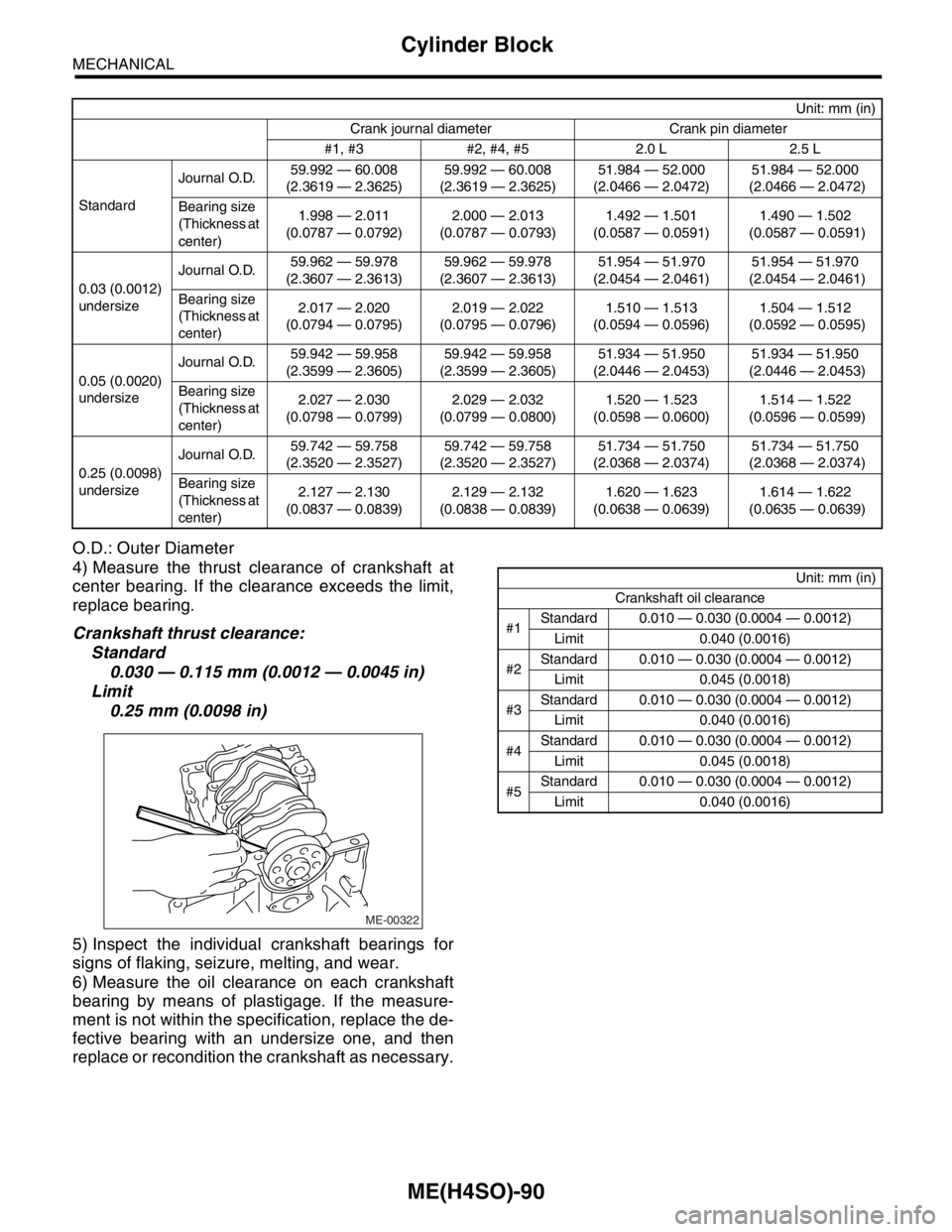

4) Measure the thrust clearance of crankshaft at

center bearing. If the clearance exceeds the limit,

replace bearing.

Crankshaft thrust clearance:

Standard

0.030 — 0.115 mm (0.0012 — 0.0045 in)

Limit

0.25 mm (0.0098 in)

5) Inspect the individual crankshaft bearings for

signs of flaking, seizure, melting, and wear.

6) Measure the oil clearance on each crankshaft

bearing by means of plastigage. If the measure-

ment is not within the specification, replace the de-

fective bearing with an undersize one, and then

replace or recondition the crankshaft as necessary.

Unit: mm (in)

Crank journal diameter Crank pin diameter

#1, #3 #2, #4, #5 2.0 L 2.5 L

StandardJournal O.D.59.992 — 60.008

(2.3619 — 2.3625)59.992 — 60.008

(2.3619 — 2.3625)51.984 — 52.000

(2.0466 — 2.0472)51.984 — 52.000

(2.0466 — 2.0472)

Bearing size

(Thickness at

center)1.998 — 2.011

(0.0787 — 0.0792)2.000 — 2.013

(0.0787 — 0.0793)1.492 — 1.501

(0.0587 — 0.0591)1.490 — 1.502

(0.0587 — 0.0591)

0.03 (0.0012)

undersizeJournal O.D.59.962 — 59.978

(2.3607 — 2.3613)59.962 — 59.978

(2.3607 — 2.3613)51.954 — 51.970

(2.0454 — 2.0461)51.954 — 51.970

(2.0454 — 2.0461)

Bearing size

(Thickness at

center)2.017 — 2.020

(0.0794 — 0.0795)2.019 — 2.022

(0.0795 — 0.0796)1.510 — 1.513

(0.0594 — 0.0596)1.504 — 1.512

(0.0592 — 0.0595)

0.05 (0.0020)

undersizeJournal O.D.59.942 — 59.958

(2.3599 — 2.3605)59.942 — 59.958

(2.3599 — 2.3605)51.934 — 51.950

(2.0446 — 2.0453)51.934 — 51.950

(2.0446 — 2.0453)

Bearing size

(Thickness at

center)2.027 — 2.030

(0.0798 — 0.0799)2.029 — 2.032

(0.0799 — 0.0800)1.520 — 1.523

(0.0598 — 0.0600)1.514 — 1.522

(0.0596 — 0.0599)

0.25 (0.0098)

undersizeJournal O.D.59.742 — 59.758

(2.3520 — 2.3527)59.742 — 59.758

(2.3520 — 2.3527)51.734 — 51.750

(2.0368 — 2.0374)51.734 — 51.750

(2.0368 — 2.0374)

Bearing size

(Thickness at

center)2.127 — 2.130

(0.0837 — 0.0839)2.129 — 2.132

(0.0838 — 0.0839)1.620 — 1.623

(0.0638 — 0.0639)1.614 — 1.622

(0.0635 — 0.0639)

ME-00322

Unit: mm (in)

Crankshaft oil clearance

#1Standard 0.010 — 0.030 (0.0004 — 0.0012)

Limit 0.040 (0.0016)

#2Standard 0.010 — 0.030 (0.0004 — 0.0012)

Limit 0.045 (0.0018)

#3Standard 0.010 — 0.030 (0.0004 — 0.0012)

Limit 0.040 (0.0016)

#4Standard 0.010 — 0.030 (0.0004 — 0.0012)

Limit 0.045 (0.0018)

#5Standard 0.010 — 0.030 (0.0004 — 0.0012)

Limit 0.040 (0.0016)

Page 962 of 2870

ME(H4SO)-91

MECHANICAL

Engine Trouble in General

22.Engine Trouble in General

A: INSPECTION

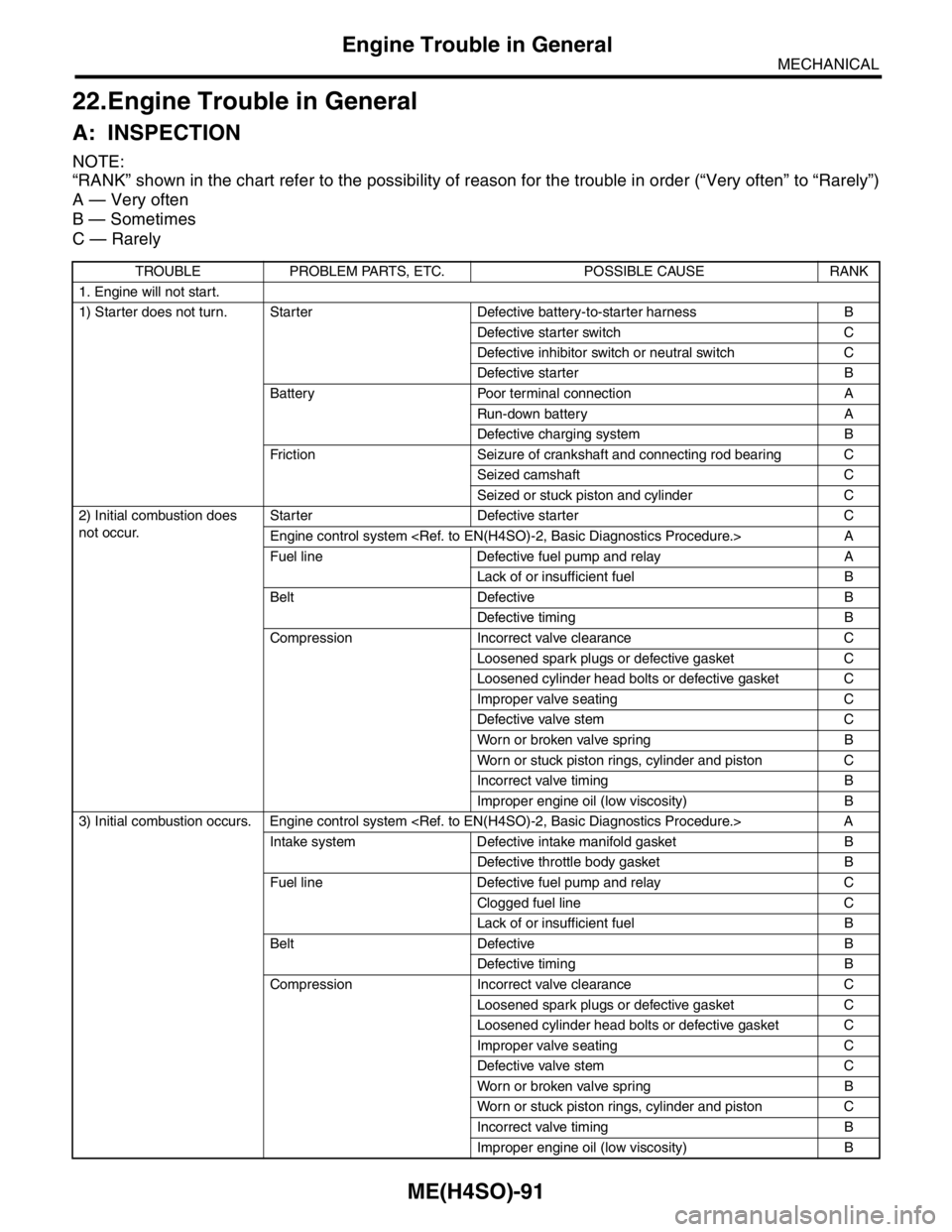

NOTE:

“RANK” shown in the chart refer to the possibility of reason for the trouble in order (“Very often” to “Rarely”)

A — Very often

B — Sometimes

C — Rarely

TROUBLE PROBLEM PARTS, ETC. POSSIBLE CAUSE RANK

1. Engine will not start.

1) Starter does not turn. Starter Defective battery-to-starter harness B

Defective starter switch C

Defective inhibitor switch or neutral switch C

Defective starter B

Battery Poor terminal connection A

Run-down battery A

Defective charging system B

Friction Seizure of crankshaft and connecting rod bearing C

Seized camshaft C

Seized or stuck piston and cylinder C

2) Initial combustion does

not occur. Starter Defective starter C

Engine control system

Fuel line Defective fuel pump and relay A

Lack of or insufficient fuel B

Belt Defective B

Defective timing B

Compression Incorrect valve clearance C

Loosened spark plugs or defective gasket C

Loosened cylinder head bolts or defective gasket C

Improper valve seating C

Defective valve stem C

Worn or broken valve spring B

Worn or stuck piston rings, cylinder and piston C

Incorrect valve timing B

Improper engine oil (low viscosity) B

3) Initial combustion occurs. Engine control system

Intake system Defective intake manifold gasket B

Defective throttle body gasket B

Fuel line Defective fuel pump and relay C

Clogged fuel line C

Lack of or insufficient fuel B

Belt Defective B

Defective timing B

Compression Incorrect valve clearance C

Loosened spark plugs or defective gasket C

Loosened cylinder head bolts or defective gasket C

Improper valve seating C

Defective valve stem C

Worn or broken valve spring B

Worn or stuck piston rings, cylinder and piston C

Incorrect valve timing B

Improper engine oil (low viscosity) B

Page 963 of 2870

ME(H4SO)-92

MECHANICAL

Engine Trouble in General

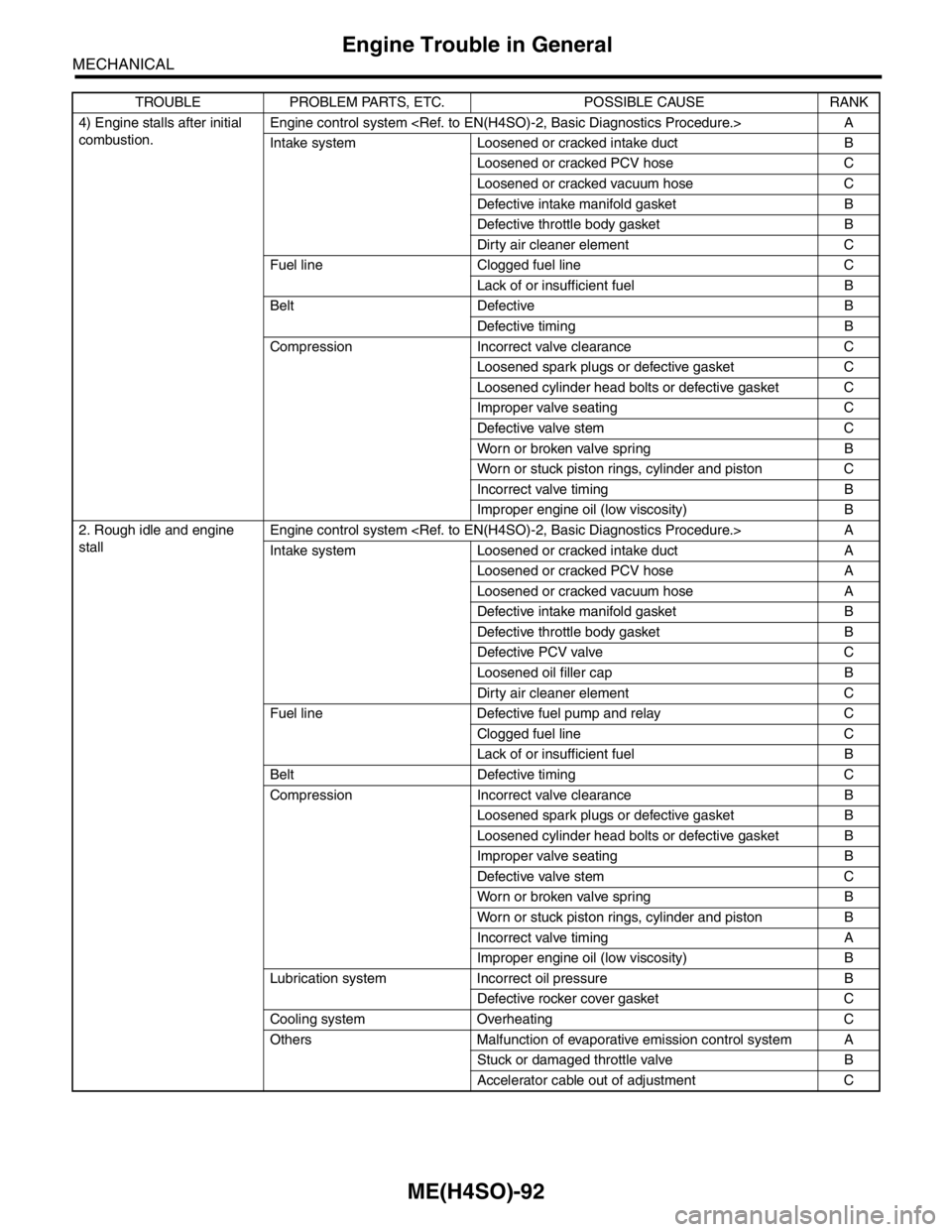

4) Engine stalls after initial

combustion. Engine control system

Intake system Loosened or cracked intake duct B

Loosened or cracked PCV hose C

Loosened or cracked vacuum hose C

Defective intake manifold gasket B

Defective throttle body gasket B

Dirty air cleaner element C

Fuel line Clogged fuel line C

Lack of or insufficient fuel B

Belt Defective B

Defective timing B

Compression Incorrect valve clearance C

Loosened spark plugs or defective gasket C

Loosened cylinder head bolts or defective gasket C

Improper valve seating C

Defective valve stem C

Worn or broken valve spring B

Worn or stuck piston rings, cylinder and piston C

Incorrect valve timing B

Improper engine oil (low viscosity) B

2. Rough idle and engine

stallEngine control system

Intake system Loosened or cracked intake duct A

Loosened or cracked PCV hose A

Loosened or cracked vacuum hose A

Defective intake manifold gasket B

Defective throttle body gasket B

Defective PCV valve C

Loosened oil filler cap B

Dirty air cleaner element C

Fuel line Defective fuel pump and relay C

Clogged fuel line C

Lack of or insufficient fuel B

Belt Defective timing C

Compression Incorrect valve clearance B

Loosened spark plugs or defective gasket B

Loosened cylinder head bolts or defective gasket B

Improper valve seating B

Defective valve stem C

Worn or broken valve spring B

Worn or stuck piston rings, cylinder and piston B

Incorrect valve timing A

Improper engine oil (low viscosity) B

Lubrication system Incorrect oil pressure B

Defective rocker cover gasket C

Cooling system Overheating C

Others Malfunction of evaporative emission control system A

Stuck or damaged throttle valve B

Accelerator cable out of adjustment C TROUBLE PROBLEM PARTS, ETC. POSSIBLE CAUSE RANK

Page 964 of 2870

ME(H4SO)-93

MECHANICAL

Engine Trouble in General

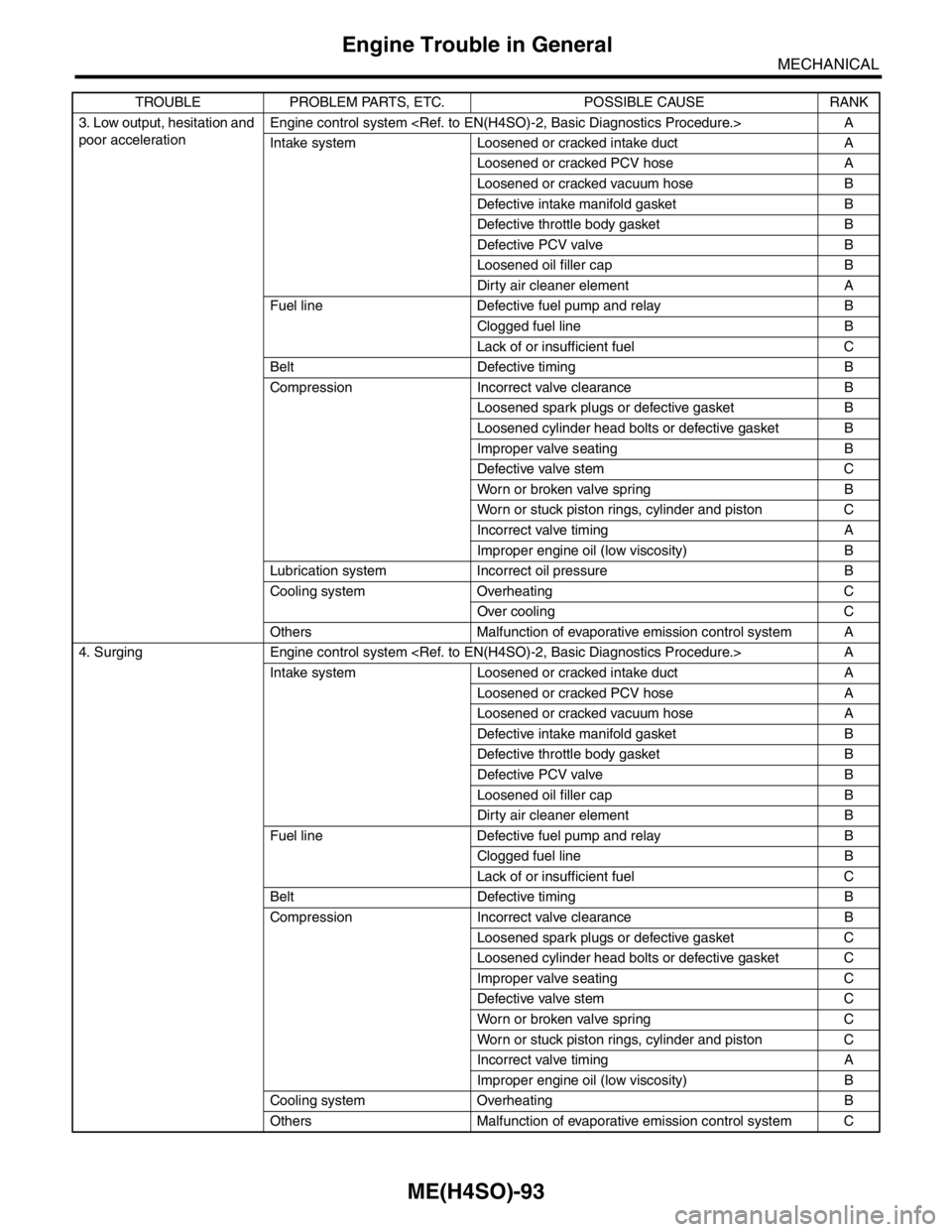

3. Low output, hesitation and

poor accelerationEngine control system

Intake system Loosened or cracked intake duct A

Loosened or cracked PCV hose A

Loosened or cracked vacuum hose B

Defective intake manifold gasket B

Defective throttle body gasket B

Defective PCV valve B

Loosened oil filler cap B

Dirty air cleaner element A

Fuel line Defective fuel pump and relay B

Clogged fuel line B

Lack of or insufficient fuel C

Belt Defective timing B

Compression Incorrect valve clearance B

Loosened spark plugs or defective gasket B

Loosened cylinder head bolts or defective gasket B

Improper valve seating B

Defective valve stem C

Worn or broken valve spring B

Worn or stuck piston rings, cylinder and piston C

Incorrect valve timing A

Improper engine oil (low viscosity) B

Lubrication system Incorrect oil pressure B

Cooling system Overheating C

Over cooling C

Others Malfunction of evaporative emission control system A

4. Surging Engine control system

Intake system Loosened or cracked intake duct A

Loosened or cracked PCV hose A

Loosened or cracked vacuum hose A

Defective intake manifold gasket B

Defective throttle body gasket B

Defective PCV valve B

Loosened oil filler cap B

Dirty air cleaner element B

Fuel line Defective fuel pump and relay B

Clogged fuel line B

Lack of or insufficient fuel C

Belt Defective timing B

Compression Incorrect valve clearance B

Loosened spark plugs or defective gasket C

Loosened cylinder head bolts or defective gasket C

Improper valve seating C

Defective valve stem C

Worn or broken valve spring C

Worn or stuck piston rings, cylinder and piston C

Incorrect valve timing A

Improper engine oil (low viscosity) B

Cooling system Overheating B

Others Malfunction of evaporative emission control system C TROUBLE PROBLEM PARTS, ETC. POSSIBLE CAUSE RANK

Page 965 of 2870

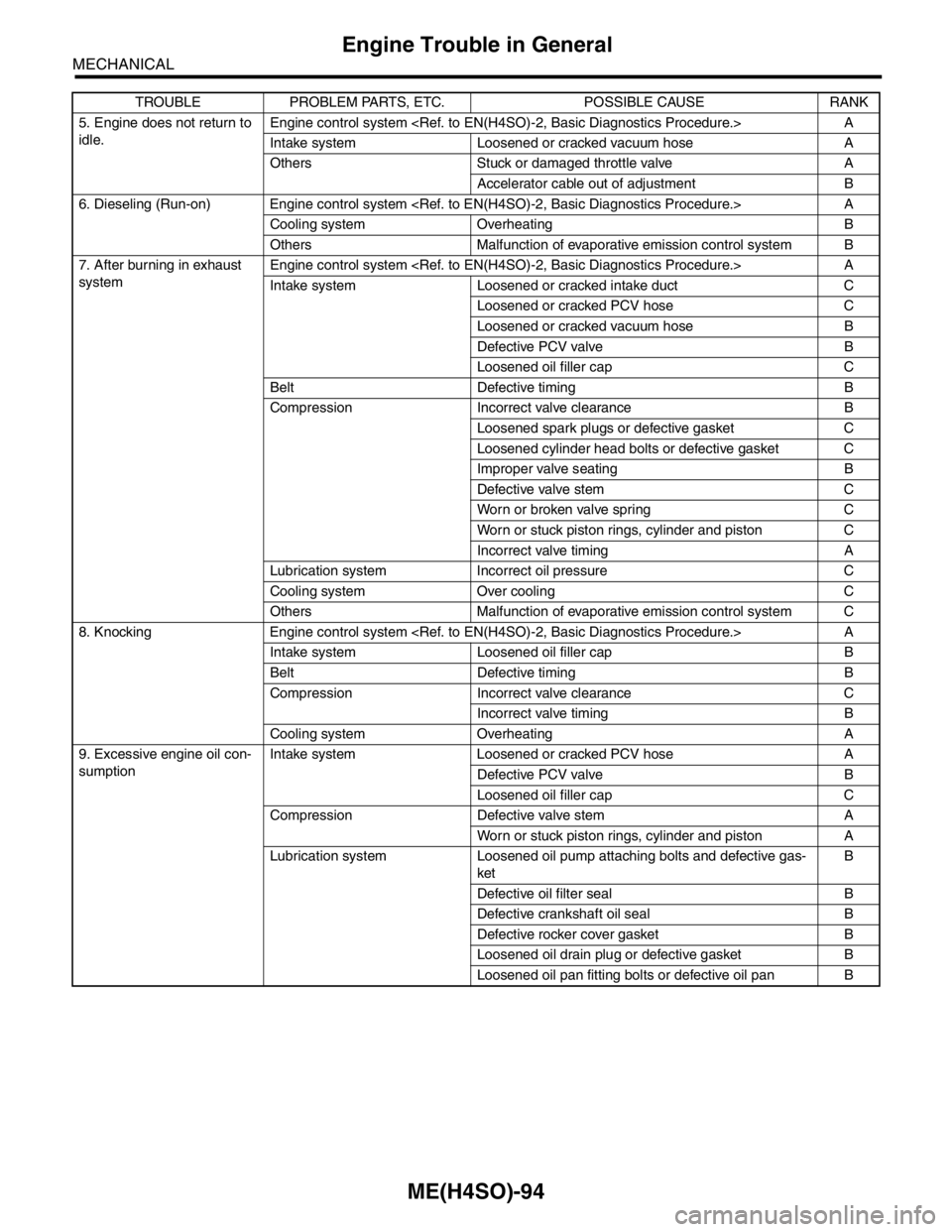

ME(H4SO)-94

MECHANICAL

Engine Trouble in General

5. Engine does not return to

idle.Engine control system

Intake system Loosened or cracked vacuum hose A

Others Stuck or damaged throttle valve A

Accelerator cable out of adjustment B

6. Dieseling (Run-on) Engine control system

Cooling system Overheating B

Others Malfunction of evaporative emission control system B

7. After burning in exhaust

systemEngine control system

Intake system Loosened or cracked intake duct C

Loosened or cracked PCV hose C

Loosened or cracked vacuum hose B

Defective PCV valve B

Loosened oil filler cap C

Belt Defective timing B

Compression Incorrect valve clearance B

Loosened spark plugs or defective gasket C

Loosened cylinder head bolts or defective gasket C

Improper valve seating B

Defective valve stem C

Worn or broken valve spring C

Worn or stuck piston rings, cylinder and piston C

Incorrect valve timing A

Lubrication system Incorrect oil pressure C

Cooling system Over cooling C

Others Malfunction of evaporative emission control system C

8. Knocking Engine control system

Intake system Loosened oil filler cap B

Belt Defective timing B

Compression Incorrect valve clearance C

Incorrect valve timing B

Cooling system Overheating A

9. Excessive engine oil con-

sumptionIntake system Loosened or cracked PCV hose A

Defective PCV valve B

Loosened oil filler cap C

Compression Defective valve stem A

Worn or stuck piston rings, cylinder and piston A

Lubrication system Loosened oil pump attaching bolts and defective gas-

ketB

Defective oil filter seal B

Defective crankshaft oil seal B

Defective rocker cover gasket B

Loosened oil drain plug or defective gasket B

Loosened oil pan fitting bolts or defective oil pan B TROUBLE PROBLEM PARTS, ETC. POSSIBLE CAUSE RANK

Page 966 of 2870

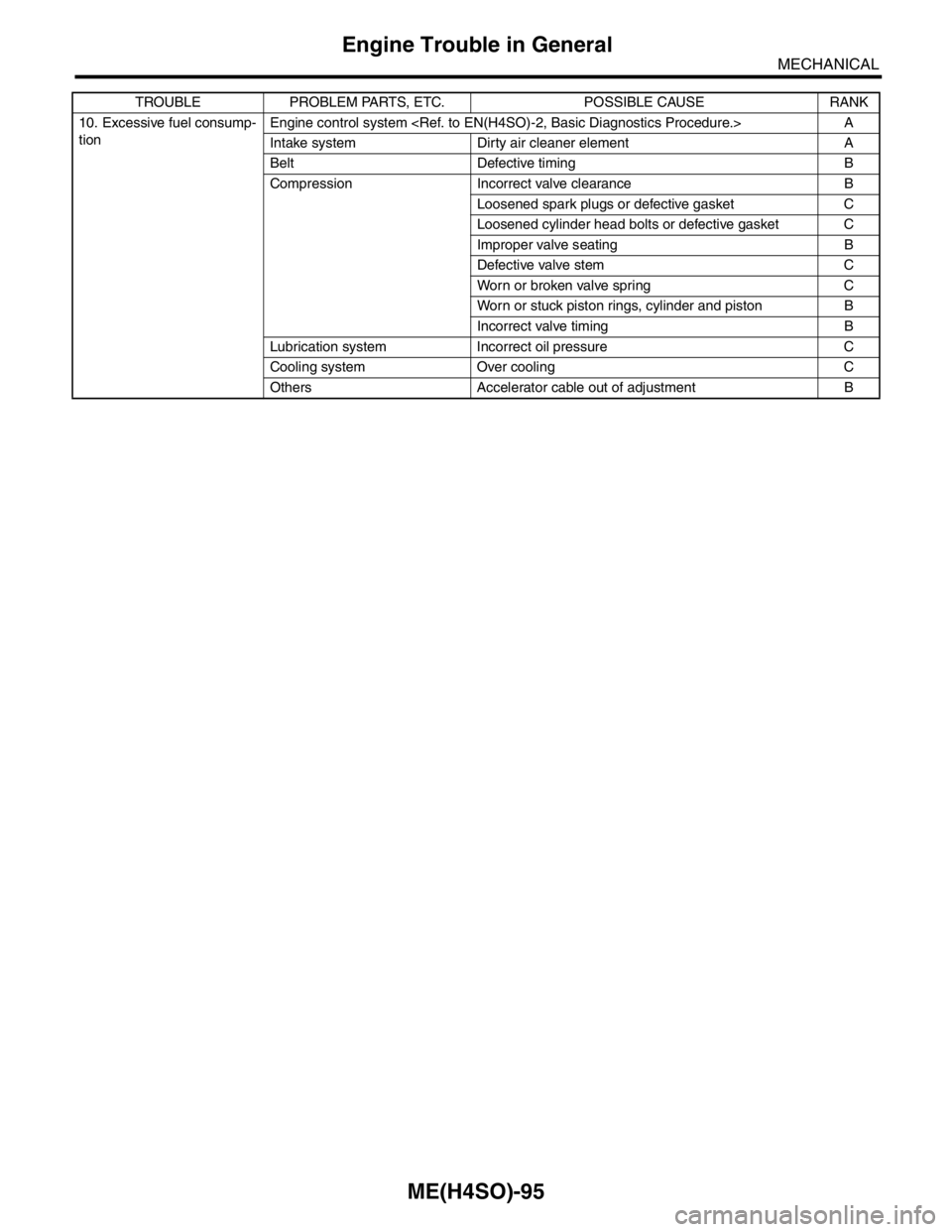

ME(H4SO)-95

MECHANICAL

Engine Trouble in General

10. Excessive fuel consump-

tionEngine control system

Intake system Dirty air cleaner element A

Belt Defective timing B

Compression Incorrect valve clearance B

Loosened spark plugs or defective gasket C

Loosened cylinder head bolts or defective gasket C

Improper valve seating B

Defective valve stem C

Worn or broken valve spring C

Worn or stuck piston rings, cylinder and piston B

Incorrect valve timing B

Lubrication system Incorrect oil pressure C

Cooling system Over cooling C

Others Accelerator cable out of adjustment B TROUBLE PROBLEM PARTS, ETC. POSSIBLE CAUSE RANK

Page 967 of 2870

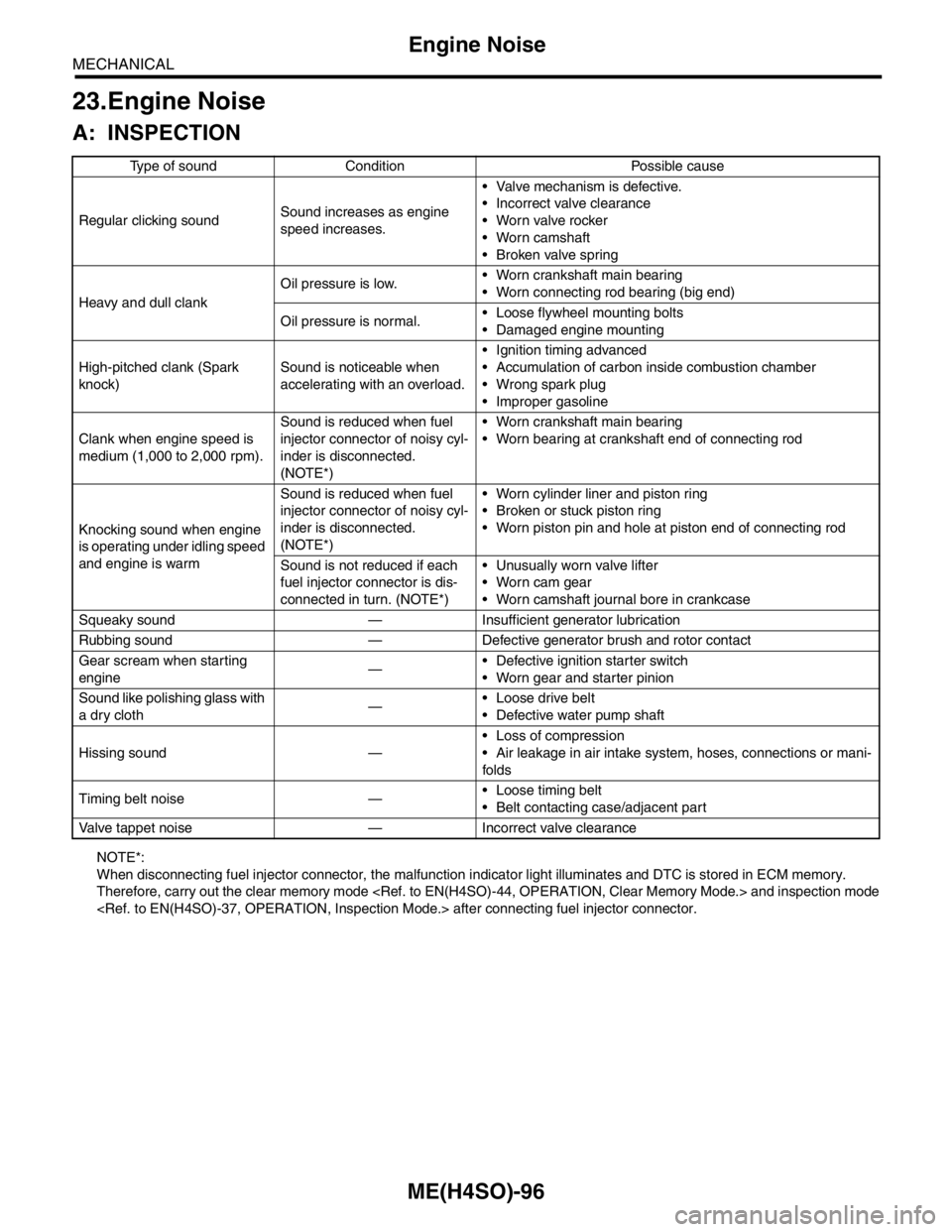

ME(H4SO)-96

MECHANICAL

Engine Noise

23.Engine Noise

A: INSPECTION

NOTE*:

When disconnecting fuel injector connector, the malfunction indicator light illuminates and DTC is stored in ECM memory.

Therefore, carry out the clear memory mode

Regular clicking soundSound increases as engine

speed increases. Valve mechanism is defective.

Incorrect valve clearance

Worn valve rocker

Worn camshaft

Broken valve spring

Heavy and dull clankOil pressure is low. Worn crankshaft main bearing

Worn connecting rod bearing (big end)

Oil pressure is normal. Loose flywheel mounting bolts

Damaged engine mounting

High-pitched clank (Spark

knock)Sound is noticeable when

accelerating with an overload. Ignition timing advanced

Accumulation of carbon inside combustion chamber

Wrong spark plug

Improper gasoline

Clank when engine speed is

medium (1,000 to 2,000 rpm).Sound is reduced when fuel

injector connector of noisy cyl-

inder is disconnected.

(NOTE*) Worn crankshaft main bearing

Worn bearing at crankshaft end of connecting rod

Knocking sound when engine

is operating under idling speed

and engine is warmSound is reduced when fuel

injector connector of noisy cyl-

inder is disconnected.

(NOTE*) Worn cylinder liner and piston ring

Broken or stuck piston ring

Worn piston pin and hole at piston end of connecting rod

Sound is not reduced if each

fuel injector connector is dis-

connected in turn. (NOTE*) Unusually worn valve lifter

Worn cam gear

Worn camshaft journal bore in crankcase

Squeaky sound — Insufficient generator lubrication

Rubbing sound — Defective generator brush and rotor contact

Gear scream when starting

engine— Defective ignition starter switch

Worn gear and starter pinion

Sound like polishing glass with

a dry cloth— Loose drive belt

Defective water pump shaft

Hissing sound — Loss of compression

Air leakage in air intake system, hoses, connections or mani-

folds

Timing belt noise — Loose timing belt

Belt contacting case/adjacent part

Valve tappet noise — Incorrect valve clearance

Page 968 of 2870

FUJI HEAVY INDUSTRIES LTD. G8080GE2

2004 FORESTER SERVICE MANUAL QUICK REFERENCE INDEX

ENGINE SECTION 1

This service manual has been prepared

to provide SUBARU service personnel

with the necessary information and data

for the correct maintenance and repair

of SUBARU vehicles.

This manual includes the procedures

for maintenance, disassembling, reas-

sembling, inspection and adjustment of

components and diagnostics for guid-

ance of experienced mechanics.

Please peruse and utilize this manual

fully to ensure complete repair work for

satisfying our customers by keeping

their vehicle in optimum condition.

When replacement of parts during

repair work is needed, be sure to use

SUBARU genuine parts.

All information, illustration and specifi-

cations contained in this manual are

based on the latest product information

available at the time of publication

approval.FUEL INJECTION (FUEL SYSTEM) FU(H4SO)

EMISSION CONTROL

(AUX. EMISSION CONTROL DEVICE)EC(H4SO)

INTAKE (INDUCTION) IN(H4SO)

MECHANICAL ME(H4SO)

EXHAUST EX(H4SO)

COOLING CO(H4SO)

LUBRICATION LU(H4SO)

SPEED CONTROL SYSTEM SP(H4SO)

IGNITION IG(H4SO)

STARTING/CHARGING SYSTEM SC(H4SO)

ENGINE (DIAGNOSTIC) EN(H4SO)

Page 969 of 2870

EXHAUST

EX(H4SO)

Page

1. General Description ....................................................................................2

2. Front Exhaust Pipe......................................................................................7

3. Center Exhaust Pipe .................................................................................10

4. Rear Exhaust Pipe ....................................................................................11

5. Muffler .......................................................................................................13

Page 970 of 2870

EX(H4SO)-2

EXHAUST

General Description

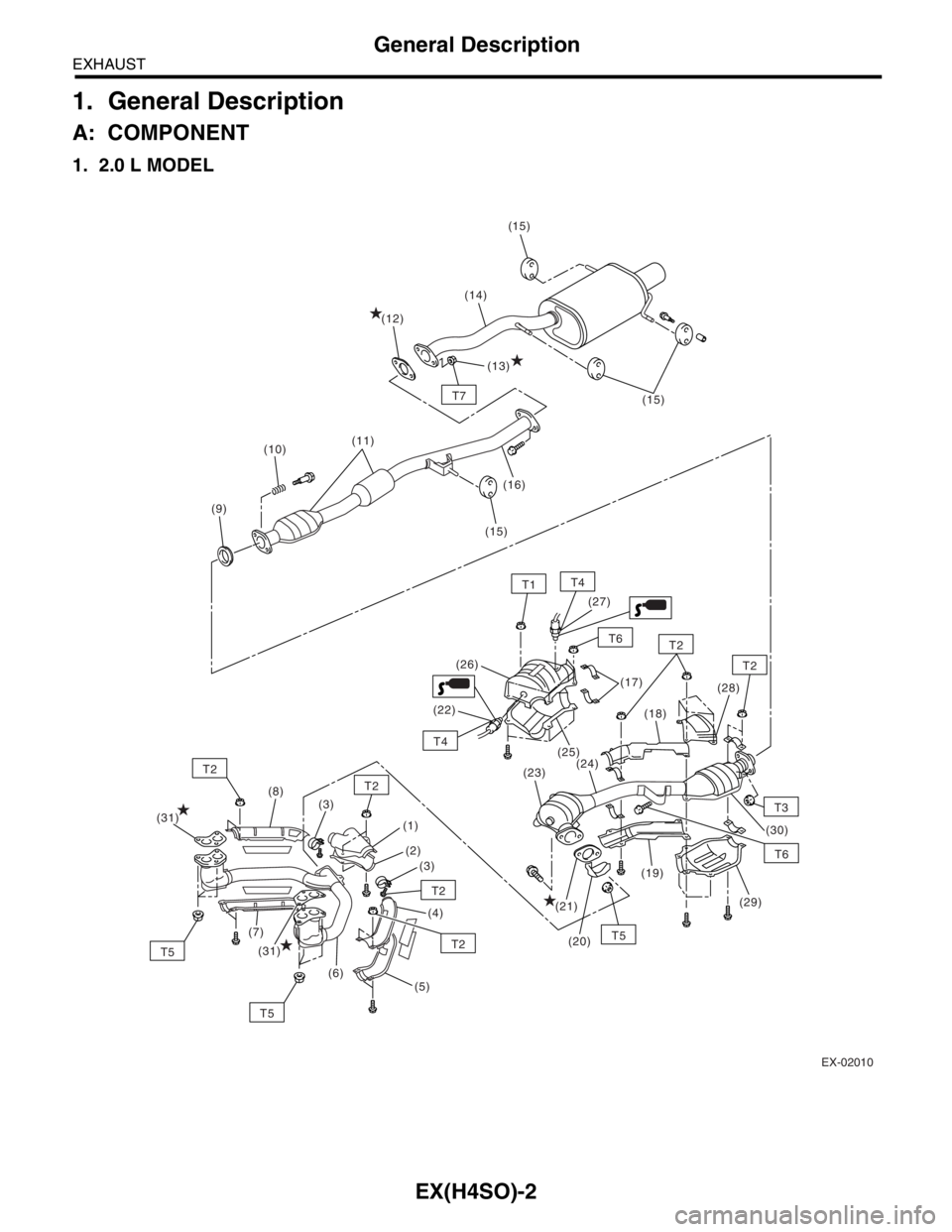

1. General Description

A: COMPONENT

1. 2.0 L MODEL

EX-02010

T7

T2

T2

T3

T6

T5

T5

T2

T2

T2(15)

(15)

(15)

(18)(28)

(29)(30)

(20) (21)(19) (23)

(1)

(2)

(3) (3)

(4)

(5) (6) (7)(8)(24) (11)

(16) (10)

(9)(14)

(12)

(13)

T5T2

(31)

(31)

T1

T6

T4

T4

(27)

(17) (26)

(22)

(25)