SUBARU LEGACY 1999 Service Repair Manual

Manufacturer: SUBARU, Model Year: 1999, Model line: LEGACY, Model: SUBARU LEGACY 1999Pages: 1456, PDF Size: 59.93 MB

Page 1161 of 1456

1. Instrument Panel

A: REMOVAL

Airbag system wiring harness is routed near com-

bination meter.

CAUTION:

IAll Airbag system wiring harness and con-

nectors are colored yellow. Do not use electri-

cal test equipment on these circuits.

IBe careful not to damage Airbag system wir-

ing harness when servicing the combination

meter.

1) Disconnect GND cable from battery.

2) Remove shift knob (MT model).

3) Remove console cover (A) and front cover (B).

B5M0022C

4) Remove console box.

B5M0023

5) Remove lower cover and then disconnect con-

nector.

B5M0024A

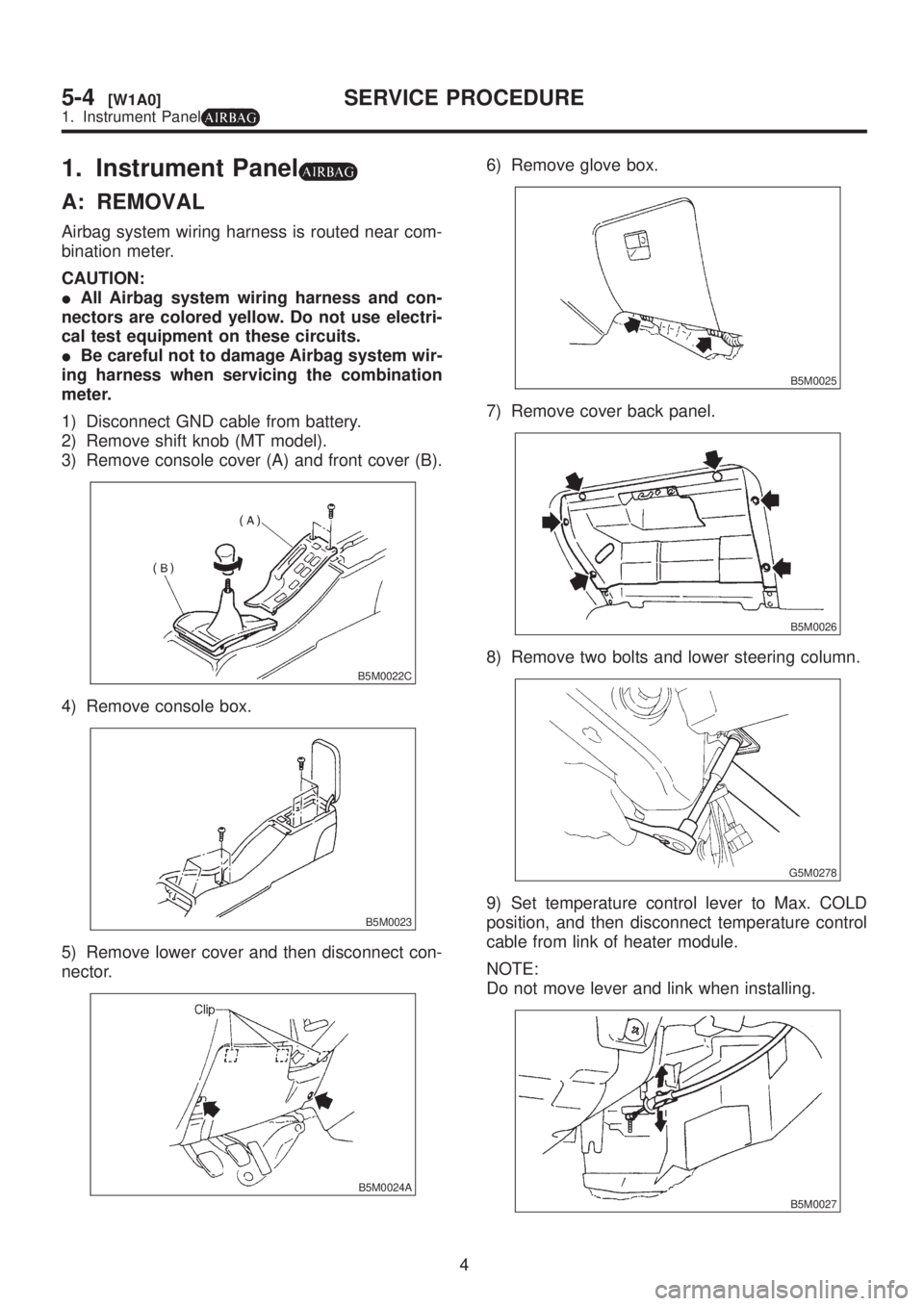

6) Remove glove box.

B5M0025

7) Remove cover back panel.

B5M0026

8) Remove two bolts and lower steering column.

G5M0278

9) Set temperature control lever to Max. COLD

position, and then disconnect temperature control

cable from link of heater module.

NOTE:

Do not move lever and link when installing.

B5M0027

4

5-4[W1A0]SERVICE PROCEDURE

1. Instrument Panel

Page 1162 of 1456

![SUBARU LEGACY 1999 Service Repair Manual 10) Remove bolt cover and bolt of both side.

B5M0028

11) Remove front side sill cover RH and then dis-

connect airbag connector (AB9) and (AB10) (Air-

bag model). <Ref. to 5-5 [M200].>

B5M0029A

12) Di SUBARU LEGACY 1999 Service Repair Manual 10) Remove bolt cover and bolt of both side.

B5M0028

11) Remove front side sill cover RH and then dis-

connect airbag connector (AB9) and (AB10) (Air-

bag model). <Ref. to 5-5 [M200].>

B5M0029A

12) Di](/img/17/57435/w960_57435-1161.png)

10) Remove bolt cover and bolt of both side.

B5M0028

11) Remove front side sill cover RH and then dis-

connect airbag connector (AB9) and (AB10) (Air-

bag model).

B5M0029A

12) Disconnect harness connectors and then remove the installing bolt.

CAUTION:

Be sure to hold socket section and not harness when disconnecting.

NOTE:

Put matching mark, if necessary, for easy re-assembly.

B5M0030B

(1) 15P/Gray

(2) 22P/Brown

(3) 22P/White(4) 20P/Blue

(5) 22P/Black

(6) 4P/Sky blue(7) 1P/Black

(8) 1P/Black

5

[W1A0]5-4SERVICE PROCEDURE

1. Instrument Panel

Page 1163 of 1456

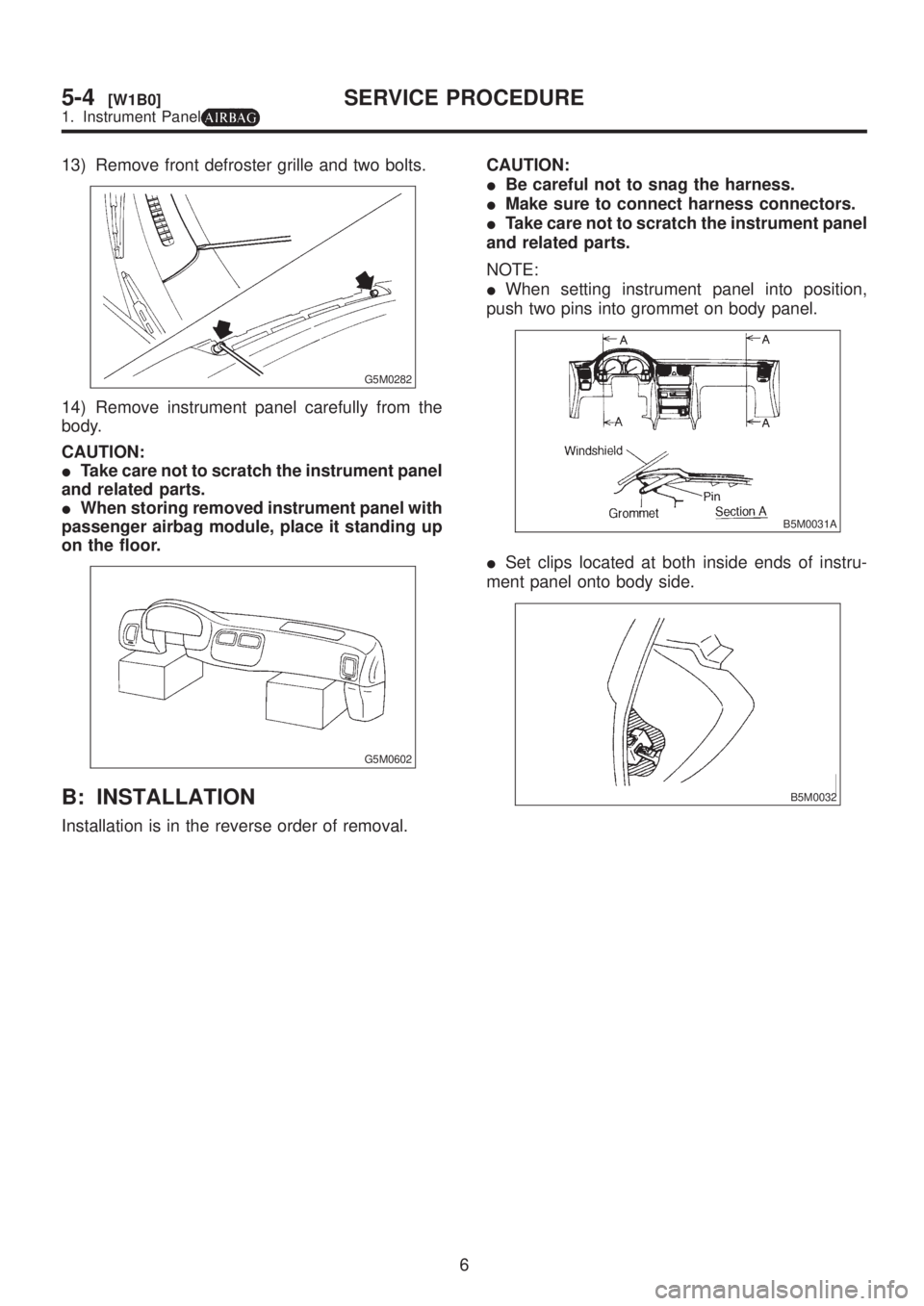

13) Remove front defroster grille and two bolts.

G5M0282

14) Remove instrument panel carefully from the

body.

CAUTION:

ITake care not to scratch the instrument panel

and related parts.

IWhen storing removed instrument panel with

passenger airbag module, place it standing up

on the floor.

G5M0602

B: INSTALLATION

Installation is in the reverse order of removal.CAUTION:

IBe careful not to snag the harness.

IMake sure to connect harness connectors.

ITake care not to scratch the instrument panel

and related parts.

NOTE:

IWhen setting instrument panel into position,

push two pins into grommet on body panel.

B5M0031A

ISet clips located at both inside ends of instru-

ment panel onto body side.

B5M0032

6

5-4[W1B0]SERVICE PROCEDURE

1. Instrument Panel

Page 1164 of 1456

![SUBARU LEGACY 1999 Service Repair Manual 1. SRS Airbag

B5M0513A

2

5-5[C100]COMPONENT PARTS

1. SRS Airbag SUBARU LEGACY 1999 Service Repair Manual 1. SRS Airbag

B5M0513A

2

5-5[C100]COMPONENT PARTS

1. SRS Airbag](/img/17/57435/w960_57435-1163.png)

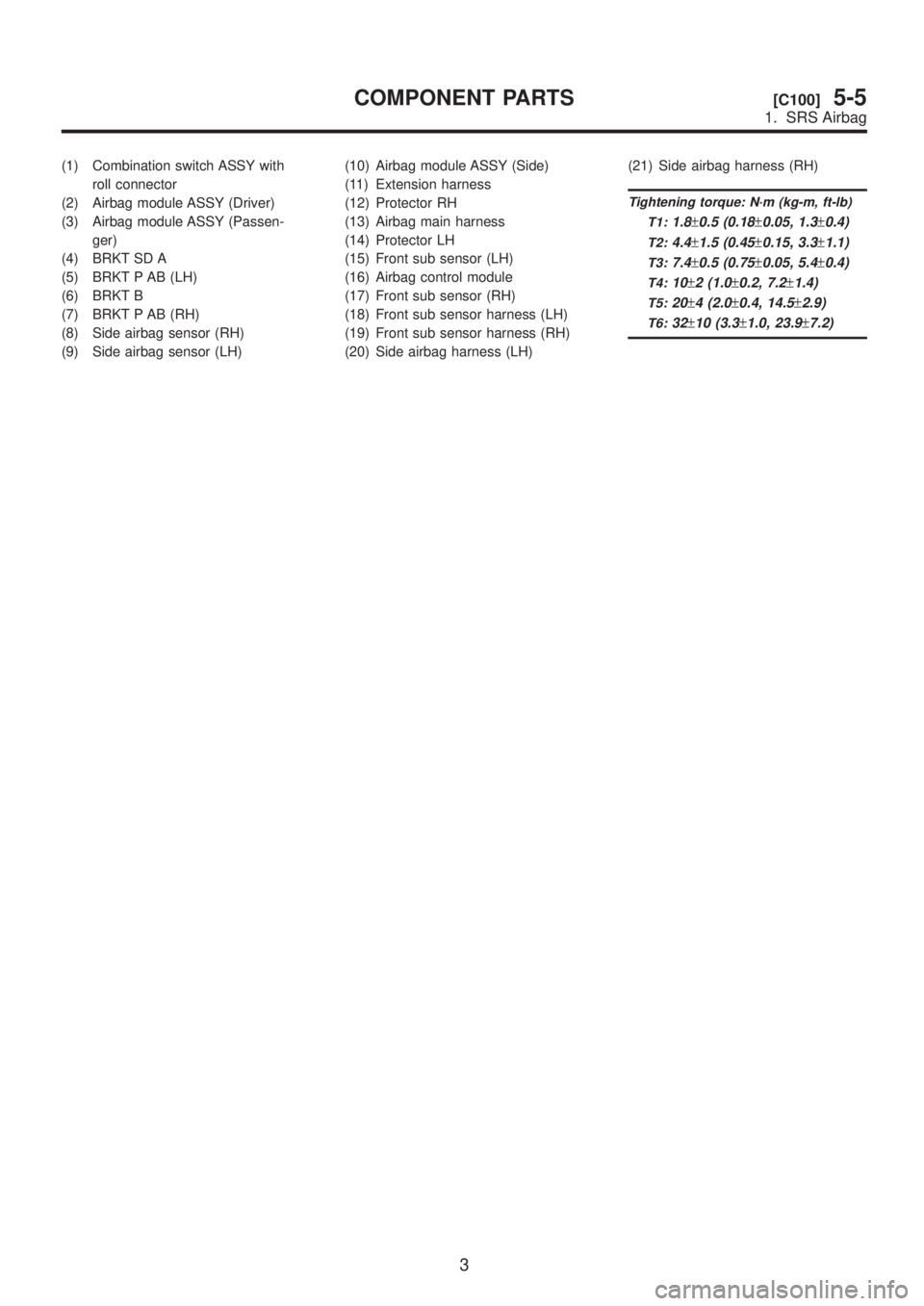

1. SRS Airbag

B5M0513A

2

5-5[C100]COMPONENT PARTS

1. SRS Airbag

Page 1165 of 1456

(1) Combination switch ASSY with

roll connector

(2) Airbag module ASSY (Driver)

(3) Airbag module ASSY (Passen-

ger)

(4) BRKT SD A

(5) BRKT P AB (LH)

(6) BRKT B

(7) BRKT P AB (RH)

(8) Side airbag sensor (RH)

(9) Side airbag sensor (LH)(10) Airbag module ASSY (Side)

(11) Extension harness

(12) Protector RH

(13) Airbag main harness

(14) Protector LH

(15) Front sub sensor (LH)

(16) Airbag control module

(17) Front sub sensor (RH)

(18) Front sub sensor harness (LH)

(19) Front sub sensor harness (RH)

(20) Side airbag harness (LH)(21) Side airbag harness (RH)

Tightening torque: N´m (kg-m, ft-lb)

T1:

1.8±0.5 (0.18±0.05, 1.3±0.4)

T2:4.4±1.5 (0.45±0.15, 3.3±1.1)

T3:7.4±0.5 (0.75±0.05, 5.4±0.4)

T4:10±2 (1.0±0.2, 7.2±1.4)

T5:20±4 (2.0±0.4, 14.5±2.9)

T6:32±10 (3.3±1.0, 23.9±7.2)

3

[C100]5-5COMPONENT PARTS

1. SRS Airbag

Page 1166 of 1456

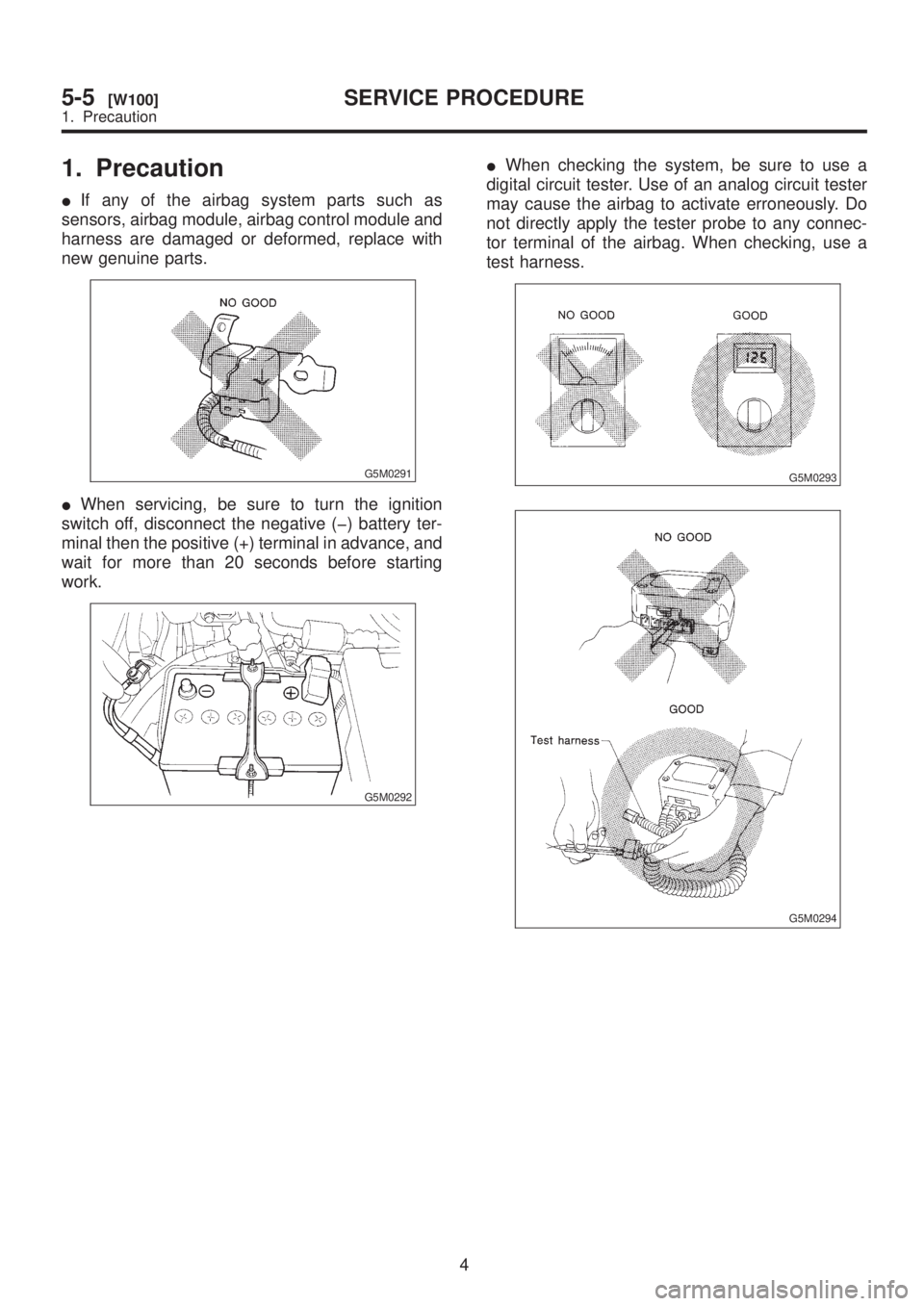

1. Precaution

IIf any of the airbag system parts such as

sensors, airbag module, airbag control module and

harness are damaged or deformed, replace with

new genuine parts.

G5M0291

IWhen servicing, be sure to turn the ignition

switch off, disconnect the negative (þ) battery ter-

minal then the positive (+) terminal in advance, and

wait for more than 20 seconds before starting

work.

G5M0292

IWhen checking the system, be sure to use a

digital circuit tester. Use of an analog circuit tester

may cause the airbag to activate erroneously. Do

not directly apply the tester probe to any connec-

tor terminal of the airbag. When checking, use a

test harness.

G5M0293

G5M0294

4

5-5[W100]SERVICE PROCEDURE

1. Precaution

Page 1167 of 1456

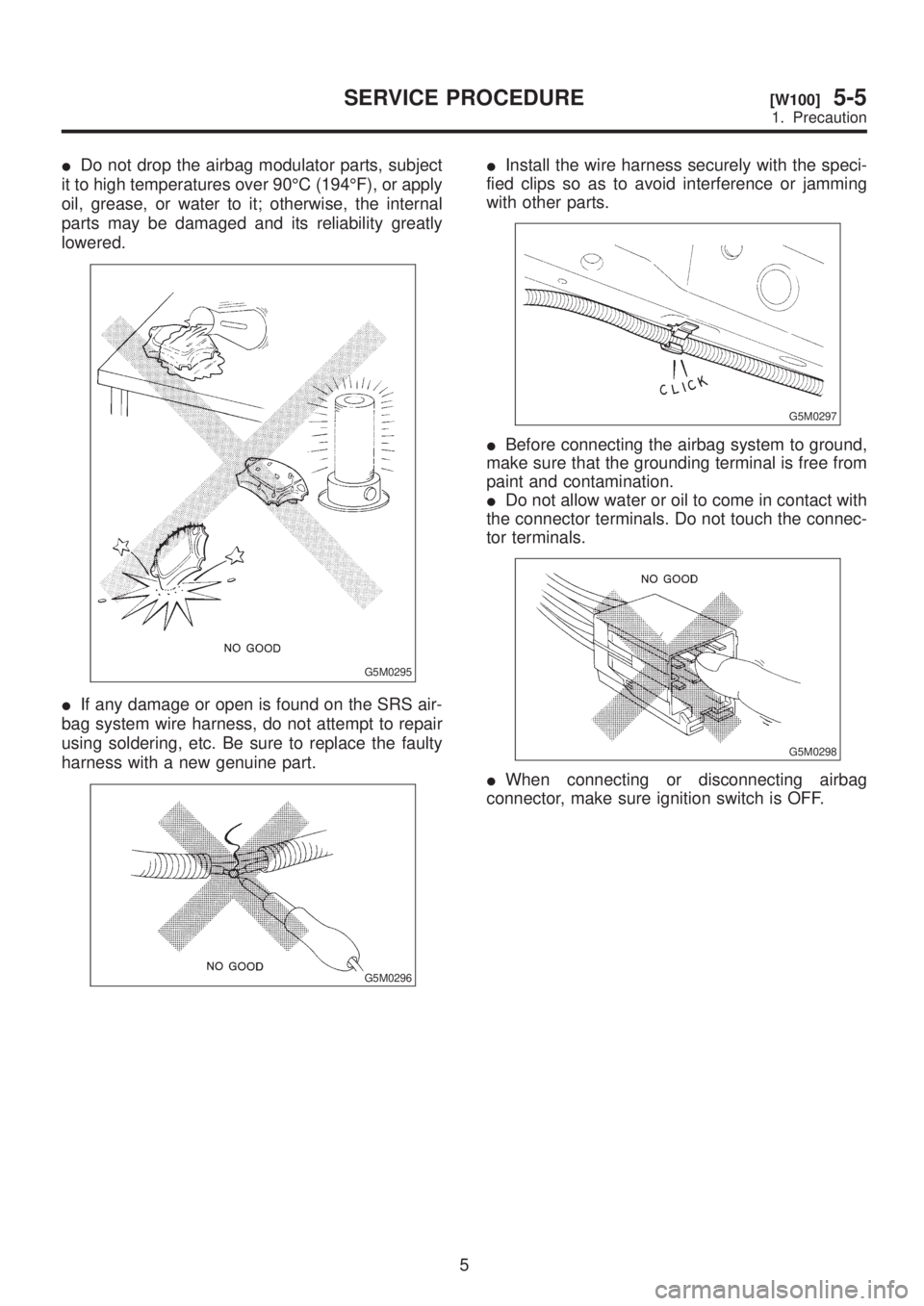

IDo not drop the airbag modulator parts, subject

it to high temperatures over 90ÉC (194ÉF), or apply

oil, grease, or water to it; otherwise, the internal

parts may be damaged and its reliability greatly

lowered.

G5M0295

IIf any damage or open is found on the SRS air-

bag system wire harness, do not attempt to repair

using soldering, etc. Be sure to replace the faulty

harness with a new genuine part.

G5M0296

IInstall the wire harness securely with the speci-

fied clips so as to avoid interference or jamming

with other parts.

G5M0297

IBefore connecting the airbag system to ground,

make sure that the grounding terminal is free from

paint and contamination.

IDo not allow water or oil to come in contact with

the connector terminals. Do not touch the connec-

tor terminals.

G5M0298

IWhen connecting or disconnecting airbag

connector, make sure ignition switch is OFF.

5

[W100]5-5SERVICE PROCEDURE

1. Precaution

Page 1168 of 1456

2. Inspection and Replacement

Standards

A: VEHICLES WHICH BECOME

INVOLVED IN A COLLISION

If the vehicle equipped with an SRS airbag sys-

tem is damaged in a collision, the airbag sys-

tem parts must be checked and replaced in

accordance with the following standards:

IAfter faulty parts are replaced, the warning light

operation must be checked.

IWhen the ignition switch is turned ON, it lights

up for about 7 seconds and then it goes out for at

least 30 seconds.

IThe trouble code stored in memory must be

erased after the check.

B: AIRBAG MODULE (DRIVER AND

PASSENGER)

1. INSPECTION STANDARD

IThe vehicle damaged in a frontal collision

(regardless of whether or not airbag is deployed).

IThe designated trouble code is output during

self-diagnosis.

2. REPLACEMENT STANDARD

IAirbag is deployed.

IThe pad surface is scratched or cracked.

IHarness and/or connector is deformed or

cracked, their circuits are broken, lead wire is

exposed, etc.

IMounting bracket is cracked or deformed.

IThe module surface is fouled with foreign mat-

ter. (grease, oil, water, cleaning solvent, etc.)

IAirbag module dropped to the floor/ground.

IAirbag module determined as faulty during self-

diagnosis.

C: AIRBAG MODULE (SIDE)

1. INSPECTION STANDARD

IThe vehicle damaged in a side collision (regard-

less of whether or not airbag is deployed).

IThe designated trouble code is output during

self-diagnosis.

2. REPLACEMENT STANDARD

IAirbag is deployed.

IThe front seat assembly is dameged or

deformed.

IHarness and/or connector is deformed or

cracked, their circuits are broken, lead wire is

exposed, etc.

IMounting bracket is cracked or deformed.IAirbag module determined as faulty during self-

diagnosis.

D: MAIN HARNESS

1. INSPECTION STANDARD

IA vehicle damaged in a collision (regardless of

whether or not airbag is deployed).

IThe designated trouble code is output during

self-diagnosis.

2. REPLACEMENT STANDARD

IHarness circuit is broken, lead wire is exposed,

corrugated tube is cracked, etc.

IConnector is scratched or cracked.

IThe designated trouble code is output during

self-diagnosis.

E: AIRBAG CONTROL MODULE

1. INSPECTION STANDARD

IA vehicle damaged in a collision (regardless of

whether or not airbag is deployed).

IThe designated trouble code is output during

self-diagnosis.

2. REPLACEMENT STANDARD

IControl module is cracked or deformed.

IMounting bracket is cracked or deformed.

IConnector is scratched or cracked.

IControl module dropped to the floor/ground.

IControl module determined as faulty during

diagnostics.

IAirbag is deployed.

F: COMBINATION SWITCH

1. INSPECTION STANDARD

IA vehicle damaged in a collision (regardless of

whether or not airbag is deployed).

IThe designated trouble code is output during

self-diagnosis.

2. REPLACEMENT STANDARD

Combination switch or steering roll connector is

deformed or cracked.

6

5-5[W2A0]SERVICE PROCEDURE

2. Inspection and Replacement Standards

Page 1169 of 1456

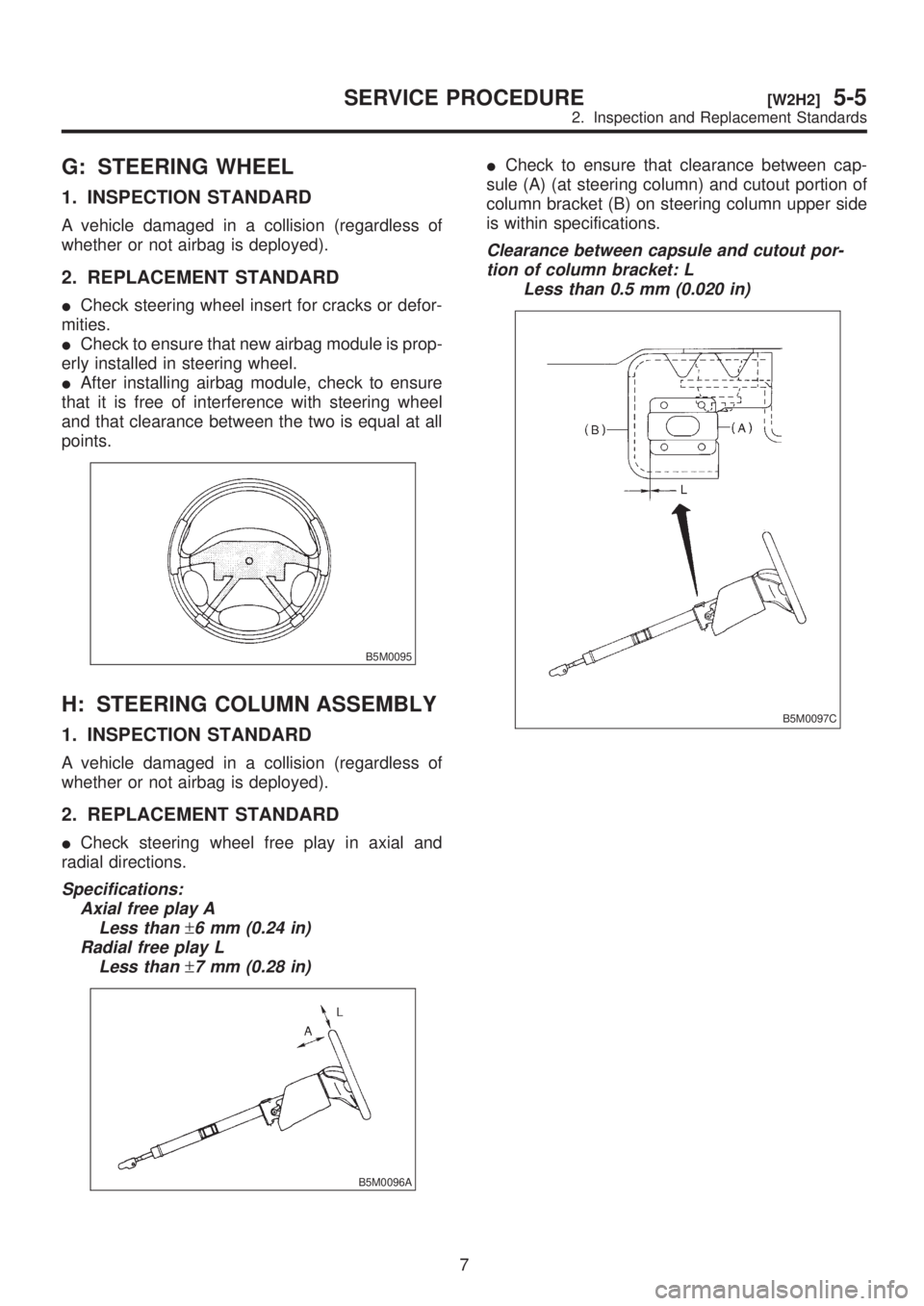

G: STEERING WHEEL

1. INSPECTION STANDARD

A vehicle damaged in a collision (regardless of

whether or not airbag is deployed).

2. REPLACEMENT STANDARD

ICheck steering wheel insert for cracks or defor-

mities.

ICheck to ensure that new airbag module is prop-

erly installed in steering wheel.

IAfter installing airbag module, check to ensure

that it is free of interference with steering wheel

and that clearance between the two is equal at all

points.

B5M0095

H: STEERING COLUMN ASSEMBLY

1. INSPECTION STANDARD

A vehicle damaged in a collision (regardless of

whether or not airbag is deployed).

2. REPLACEMENT STANDARD

ICheck steering wheel free play in axial and

radial directions.

Specifications:

Axial free play A

Less than

±6 mm (0.24 in)

Radial free play L

Less than

±7 mm (0.28 in)

B5M0096A

ICheck to ensure that clearance between cap-

sule (A) (at steering column) and cutout portion of

column bracket (B) on steering column upper side

is within specifications.

Clearance between capsule and cutout por-

tion of column bracket: L

Less than 0.5 mm (0.020 in)

B5M0097C

7

[W2H2]5-5SERVICE PROCEDURE

2. Inspection and Replacement Standards

Page 1170 of 1456

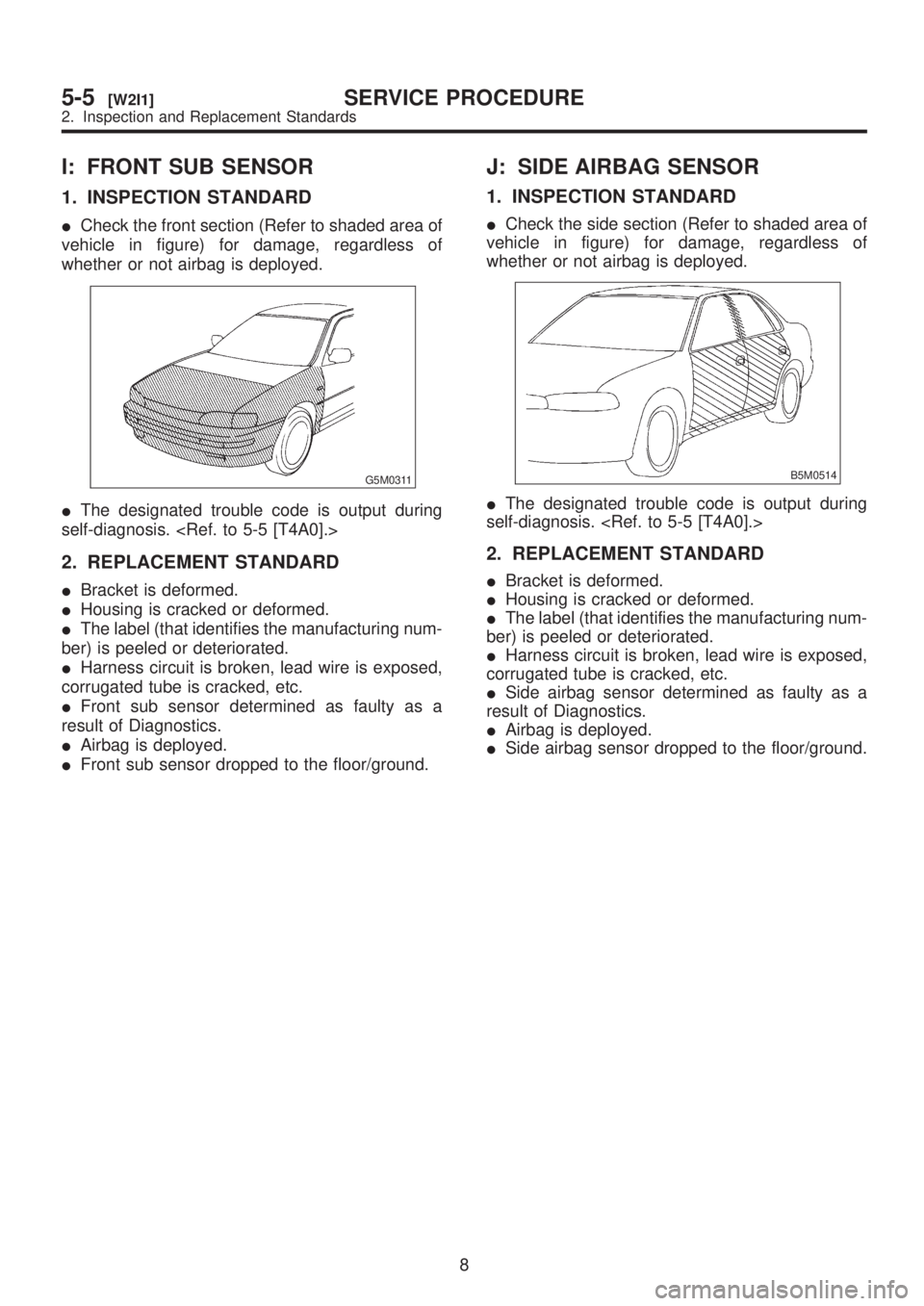

I: FRONT SUB SENSOR

1. INSPECTION STANDARD

ICheck the front section (Refer to shaded area of

vehicle in figure) for damage, regardless of

whether or not airbag is deployed.

G5M0311

IThe designated trouble code is output during

self-diagnosis.

2. REPLACEMENT STANDARD

IBracket is deformed.

IHousing is cracked or deformed.

IThe label (that identifies the manufacturing num-

ber) is peeled or deteriorated.

IHarness circuit is broken, lead wire is exposed,

corrugated tube is cracked, etc.

IFront sub sensor determined as faulty as a

result of Diagnostics.

IAirbag is deployed.

IFront sub sensor dropped to the floor/ground.

J: SIDE AIRBAG SENSOR

1. INSPECTION STANDARD

ICheck the side section (Refer to shaded area of

vehicle in figure) for damage, regardless of

whether or not airbag is deployed.

B5M0514

IThe designated trouble code is output during

self-diagnosis.

2. REPLACEMENT STANDARD

IBracket is deformed.

IHousing is cracked or deformed.

IThe label (that identifies the manufacturing num-

ber) is peeled or deteriorated.

IHarness circuit is broken, lead wire is exposed,

corrugated tube is cracked, etc.

ISide airbag sensor determined as faulty as a

result of Diagnostics.

IAirbag is deployed.

ISide airbag sensor dropped to the floor/ground.

8

5-5[W2I1]SERVICE PROCEDURE

2. Inspection and Replacement Standards