SUBARU LEGACY 1999 Service Repair Manual

Manufacturer: SUBARU, Model Year: 1999, Model line: LEGACY, Model: SUBARU LEGACY 1999Pages: 1456, PDF Size: 59.93 MB

Page 1191 of 1456

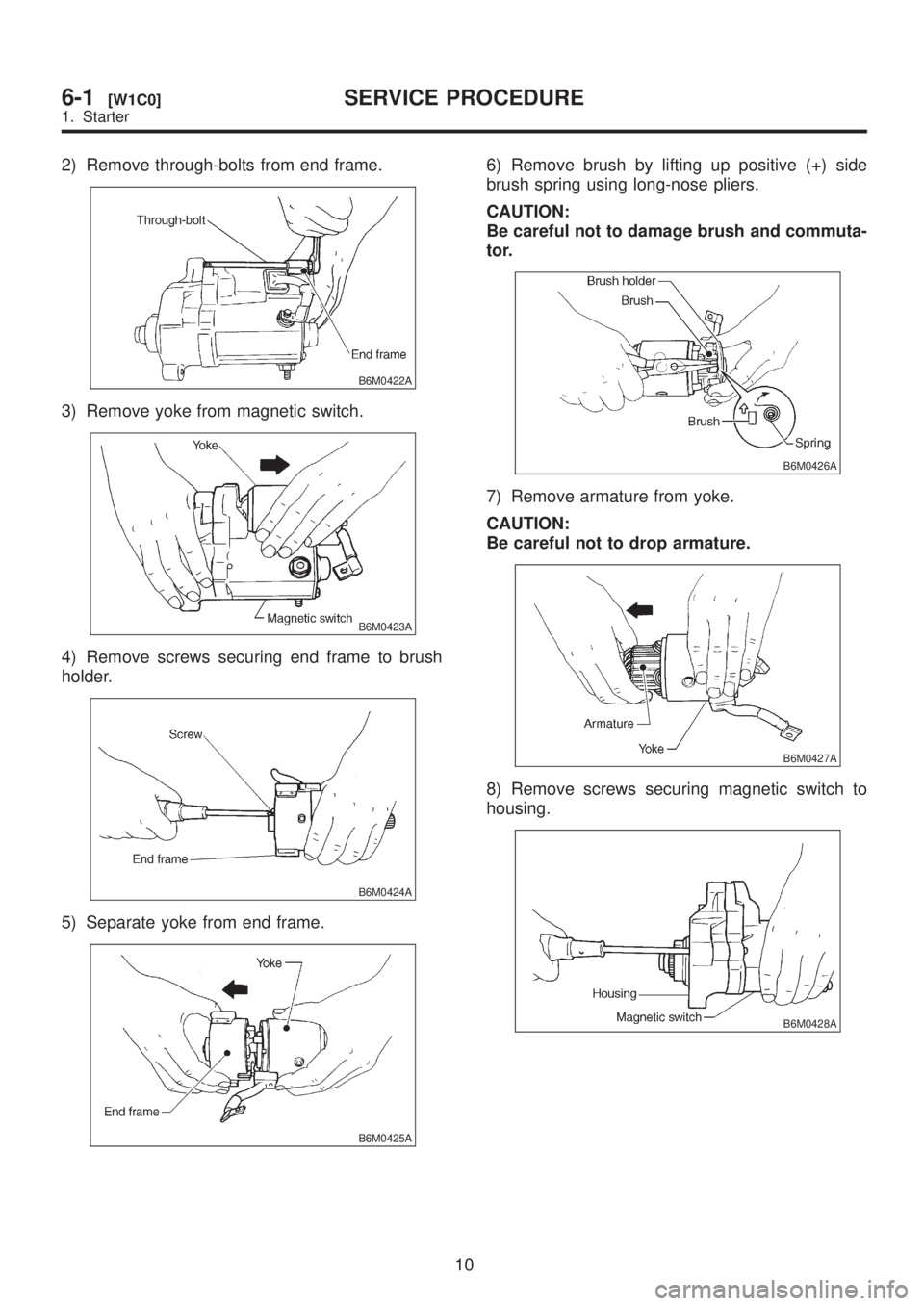

2) Remove through-bolts from end frame.

B6M0422A

3) Remove yoke from magnetic switch.

B6M0423A

4) Remove screws securing end frame to brush

holder.

B6M0424A

5) Separate yoke from end frame.

B6M0425A

6) Remove brush by lifting up positive (+) side

brush spring using long-nose pliers.

CAUTION:

Be careful not to damage brush and commuta-

tor.

B6M0426A

7) Remove armature from yoke.

CAUTION:

Be careful not to drop armature.

B6M0427A

8) Remove screws securing magnetic switch to

housing.

B6M0428A

10

6-1[W1C0]SERVICE PROCEDURE

1. Starter

Page 1192 of 1456

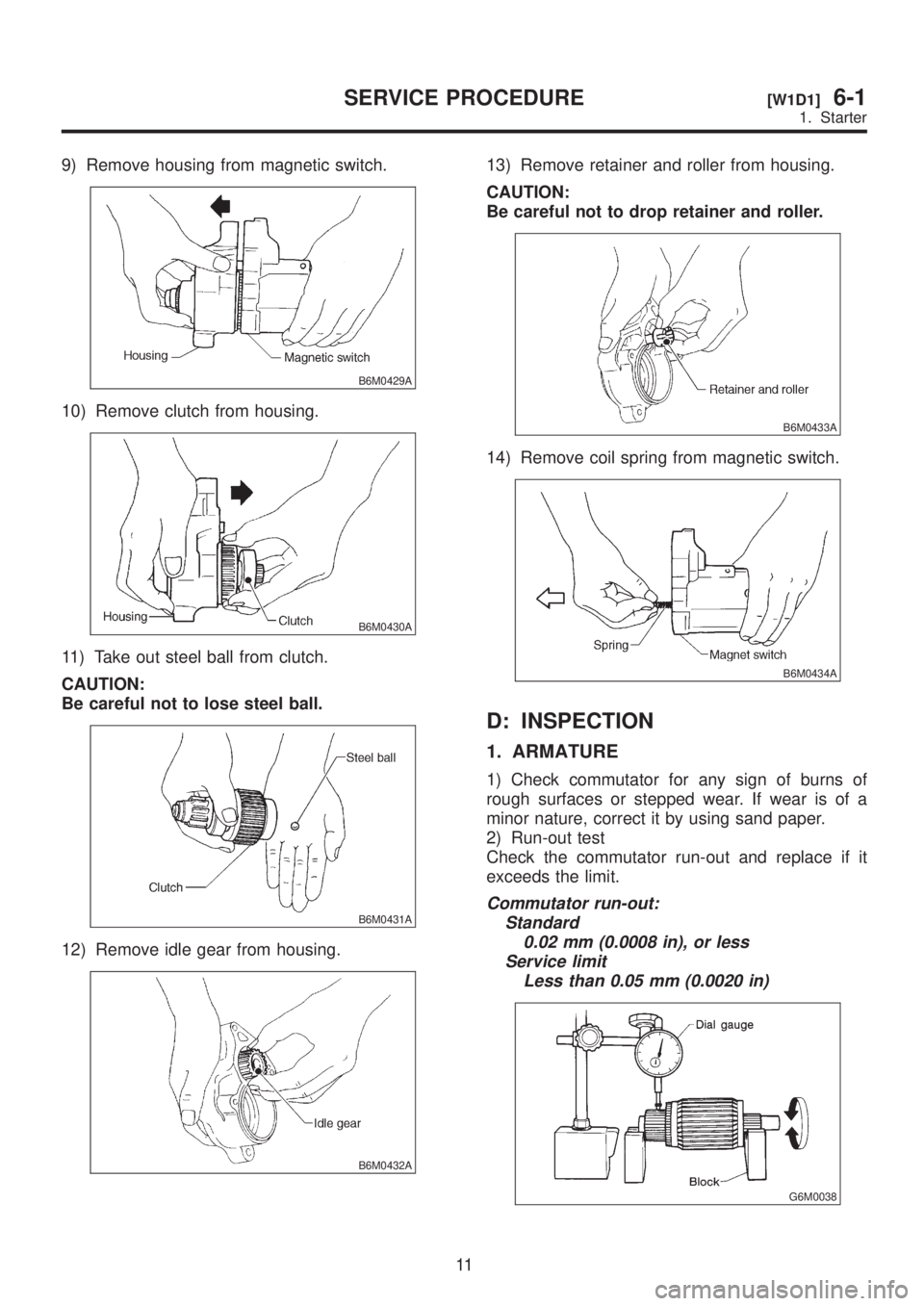

9) Remove housing from magnetic switch.

B6M0429A

10) Remove clutch from housing.

B6M0430A

11) Take out steel ball from clutch.

CAUTION:

Be careful not to lose steel ball.

B6M0431A

12) Remove idle gear from housing.

B6M0432A

13) Remove retainer and roller from housing.

CAUTION:

Be careful not to drop retainer and roller.

B6M0433A

14) Remove coil spring from magnetic switch.

B6M0434A

D: INSPECTION

1. ARMATURE

1) Check commutator for any sign of burns of

rough surfaces or stepped wear. If wear is of a

minor nature, correct it by using sand paper.

2) Run-out test

Check the commutator run-out and replace if it

exceeds the limit.

Commutator run-out:

Standard

0.02 mm (0.0008 in), or less

Service limit

Less than 0.05 mm (0.0020 in)

G6M0038

11

[W1D1]6-1SERVICE PROCEDURE

1. Starter

Page 1193 of 1456

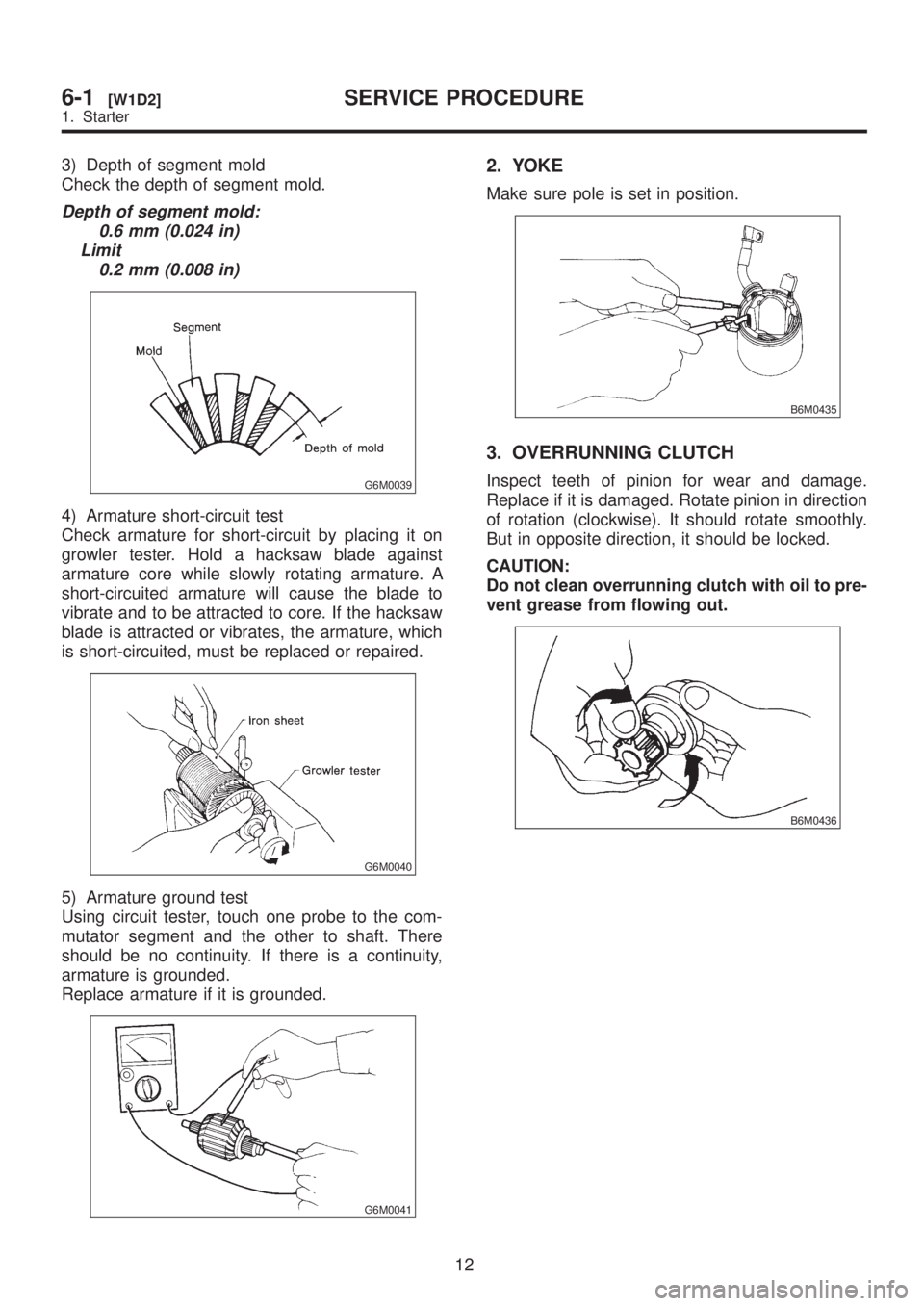

3) Depth of segment mold

Check the depth of segment mold.

Depth of segment mold:

0.6 mm (0.024 in)

Limit

0.2 mm (0.008 in)

G6M0039

4) Armature short-circuit test

Check armature for short-circuit by placing it on

growler tester. Hold a hacksaw blade against

armature core while slowly rotating armature. A

short-circuited armature will cause the blade to

vibrate and to be attracted to core. If the hacksaw

blade is attracted or vibrates, the armature, which

is short-circuited, must be replaced or repaired.

G6M0040

5) Armature ground test

Using circuit tester, touch one probe to the com-

mutator segment and the other to shaft. There

should be no continuity. If there is a continuity,

armature is grounded.

Replace armature if it is grounded.

G6M0041

2. YOKE

Make sure pole is set in position.

B6M0435

3. OVERRUNNING CLUTCH

Inspect teeth of pinion for wear and damage.

Replace if it is damaged. Rotate pinion in direction

of rotation (clockwise). It should rotate smoothly.

But in opposite direction, it should be locked.

CAUTION:

Do not clean overrunning clutch with oil to pre-

vent grease from flowing out.

B6M0436

12

6-1[W1D2]SERVICE PROCEDURE

1. Starter

Page 1194 of 1456

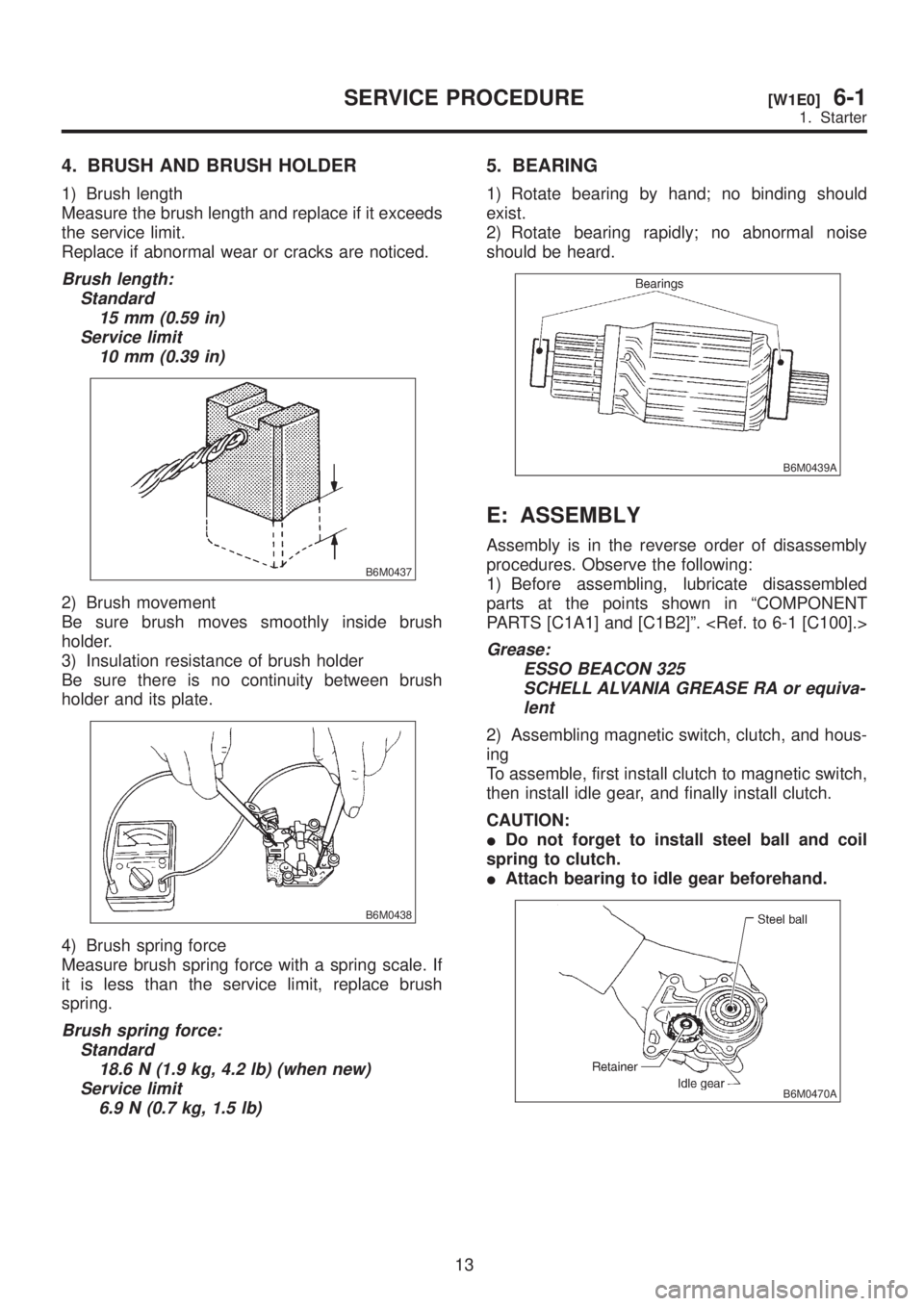

4. BRUSH AND BRUSH HOLDER

1) Brush length

Measure the brush length and replace if it exceeds

the service limit.

Replace if abnormal wear or cracks are noticed.

Brush length:

Standard

15 mm (0.59 in)

Service limit

10 mm (0.39 in)

B6M0437

2) Brush movement

Be sure brush moves smoothly inside brush

holder.

3) Insulation resistance of brush holder

Be sure there is no continuity between brush

holder and its plate.

B6M0438

4) Brush spring force

Measure brush spring force with a spring scale. If

it is less than the service limit, replace brush

spring.

Brush spring force:

Standard

18.6 N (1.9 kg, 4.2 lb) (when new)

Service limit

6.9 N (0.7 kg, 1.5 lb)

5. BEARING

1) Rotate bearing by hand; no binding should

exist.

2) Rotate bearing rapidly; no abnormal noise

should be heard.

B6M0439A

E: ASSEMBLY

Assembly is in the reverse order of disassembly

procedures. Observe the following:

1) Before assembling, lubricate disassembled

parts at the points shown in ªCOMPONENT

PARTS [C1A1] and [C1B2]º.

Grease:

ESSO BEACON 325

SCHELL ALVANIA GREASE RA or equiva-

lent

2) Assembling magnetic switch, clutch, and hous-

ing

To assemble, first install clutch to magnetic switch,

then install idle gear, and finally install clutch.

CAUTION:

IDo not forget to install steel ball and coil

spring to clutch.

IAttach bearing to idle gear beforehand.

B6M0470A

13

[W1E0]6-1SERVICE PROCEDURE

1. Starter

Page 1195 of 1456

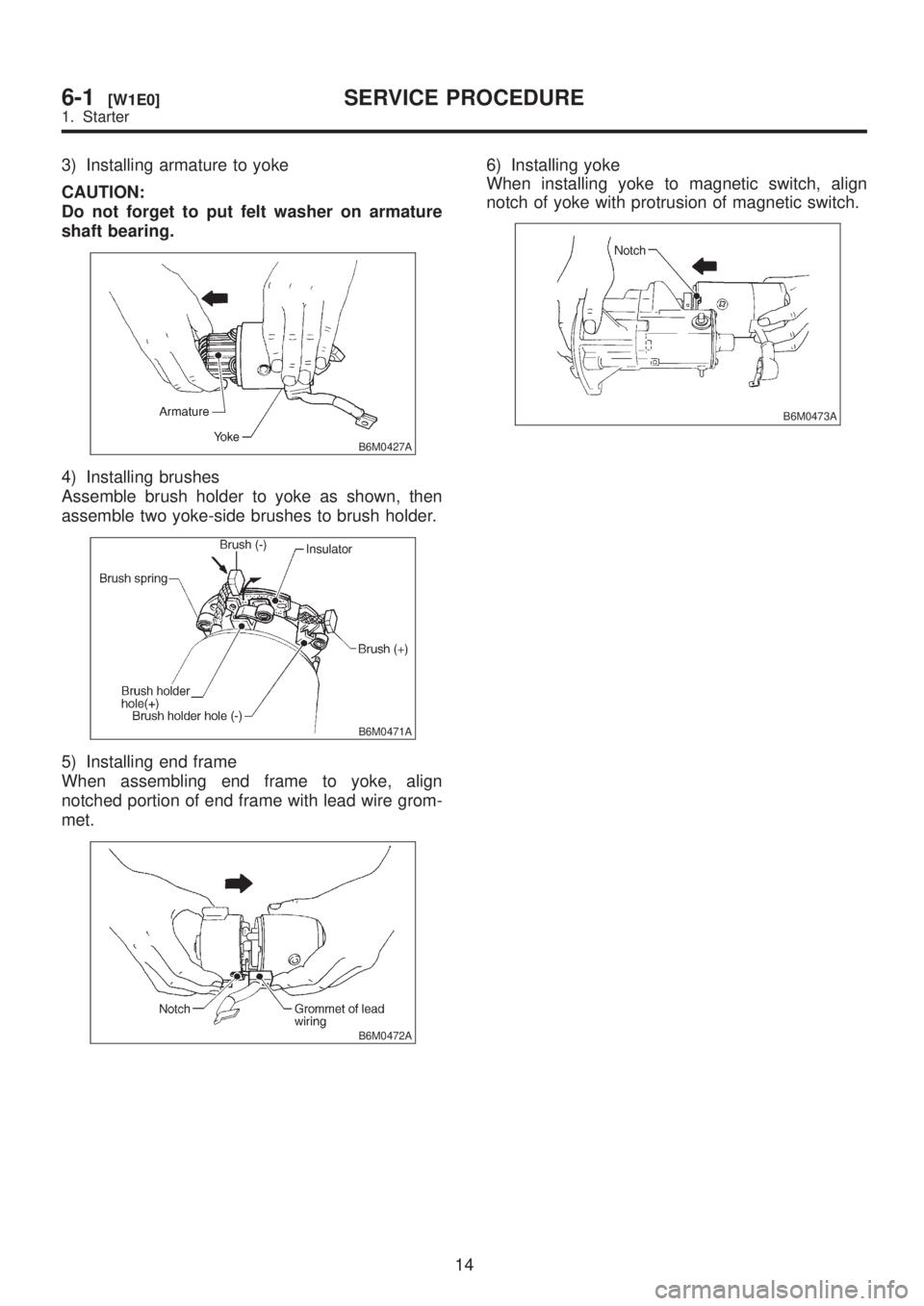

3) Installing armature to yoke

CAUTION:

Do not forget to put felt washer on armature

shaft bearing.

B6M0427A

4) Installing brushes

Assemble brush holder to yoke as shown, then

assemble two yoke-side brushes to brush holder.

B6M0471A

5) Installing end frame

When assembling end frame to yoke, align

notched portion of end frame with lead wire grom-

met.

B6M0472A

6) Installing yoke

When installing yoke to magnetic switch, align

notch of yoke with protrusion of magnetic switch.

B6M0473A

14

6-1[W1E0]SERVICE PROCEDURE

1. Starter

Page 1196 of 1456

2. Generator

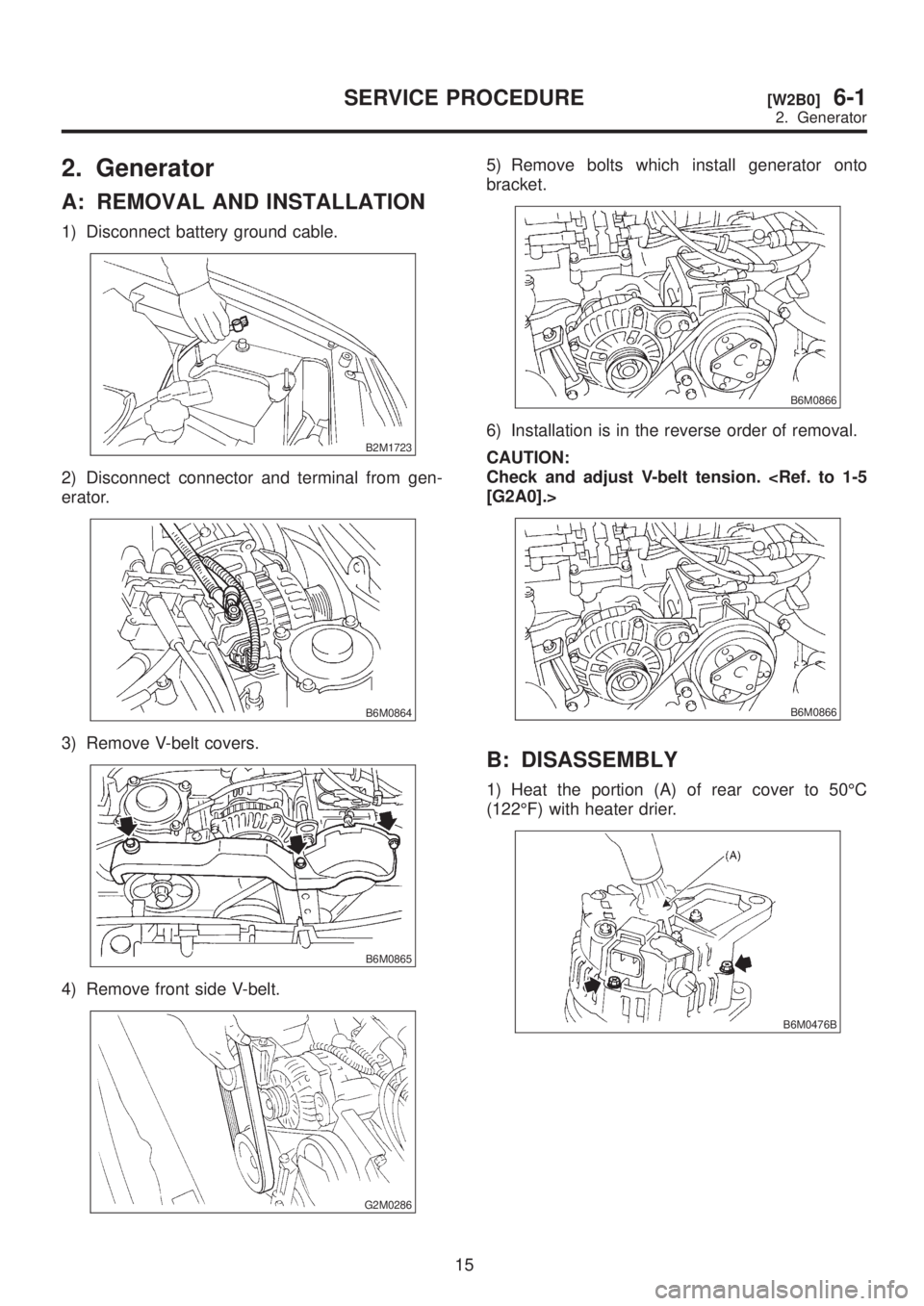

A: REMOVAL AND INSTALLATION

1) Disconnect battery ground cable.

B2M1723

2) Disconnect connector and terminal from gen-

erator.

B6M0864

3) Remove V-belt covers.

B6M0865

4) Remove front side V-belt.

G2M0286

5) Remove bolts which install generator onto

bracket.

B6M0866

6) Installation is in the reverse order of removal.

CAUTION:

Check and adjust V-belt tension.

B6M0866

B: DISASSEMBLY

1) Heat the portion (A) of rear cover to 50ÉC

(122ÉF) with heater drier.

B6M0476B

15

[W2B0]6-1SERVICE PROCEDURE

2. Generator

Page 1197 of 1456

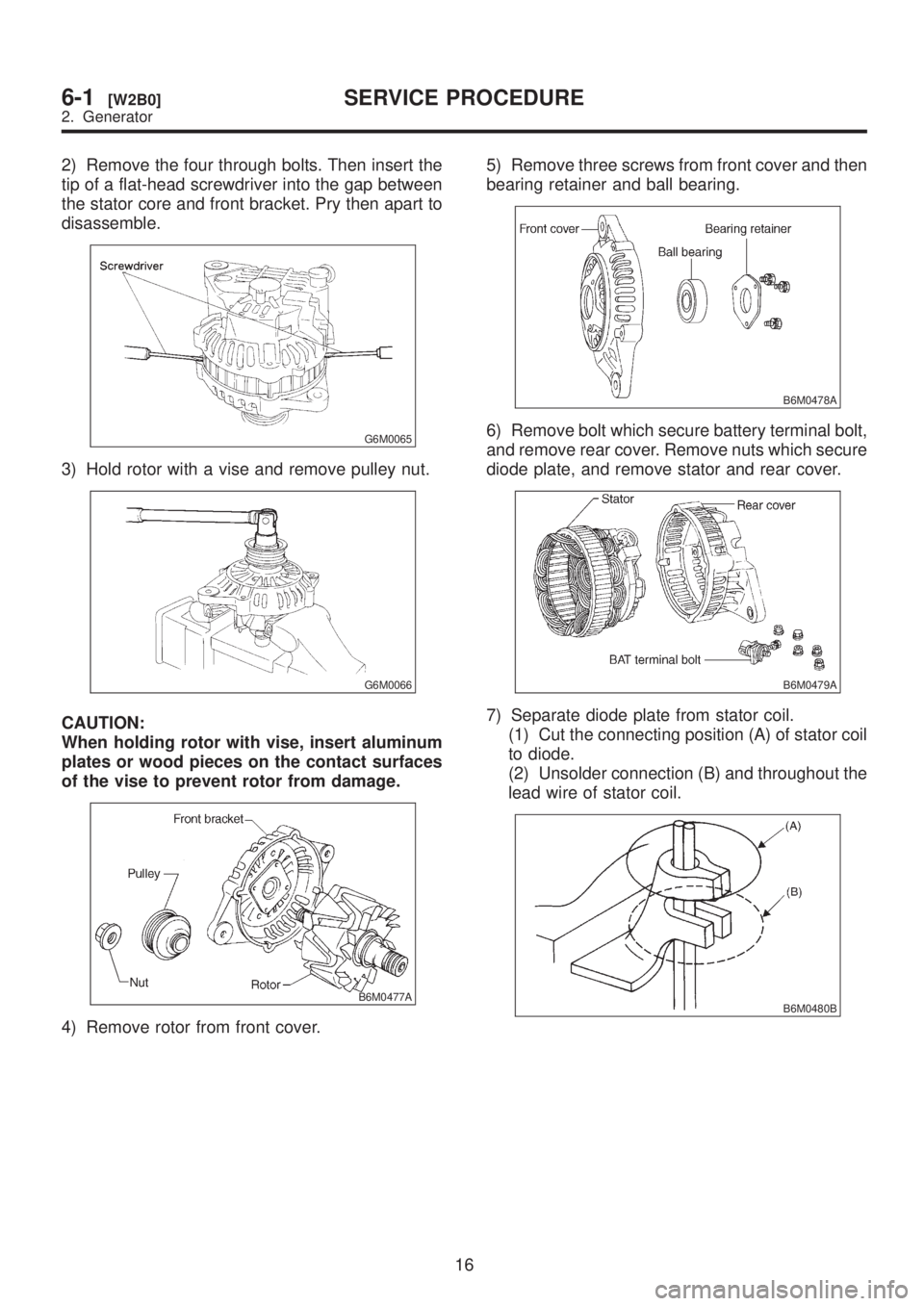

2) Remove the four through bolts. Then insert the

tip of a flat-head screwdriver into the gap between

the stator core and front bracket. Pry then apart to

disassemble.

G6M0065

3) Hold rotor with a vise and remove pulley nut.

G6M0066

CAUTION:

When holding rotor with vise, insert aluminum

plates or wood pieces on the contact surfaces

of the vise to prevent rotor from damage.

B6M0477A

4) Remove rotor from front cover.5) Remove three screws from front cover and then

bearing retainer and ball bearing.

B6M0478A

6) Remove bolt which secure battery terminal bolt,

and remove rear cover. Remove nuts which secure

diode plate, and remove stator and rear cover.

B6M0479A

7) Separate diode plate from stator coil.

(1) Cut the connecting position (A) of stator coil

to diode.

(2) Unsolder connection (B) and throughout the

lead wire of stator coil.

B6M0480B

16

6-1[W2B0]SERVICE PROCEDURE

2. Generator

Page 1198 of 1456

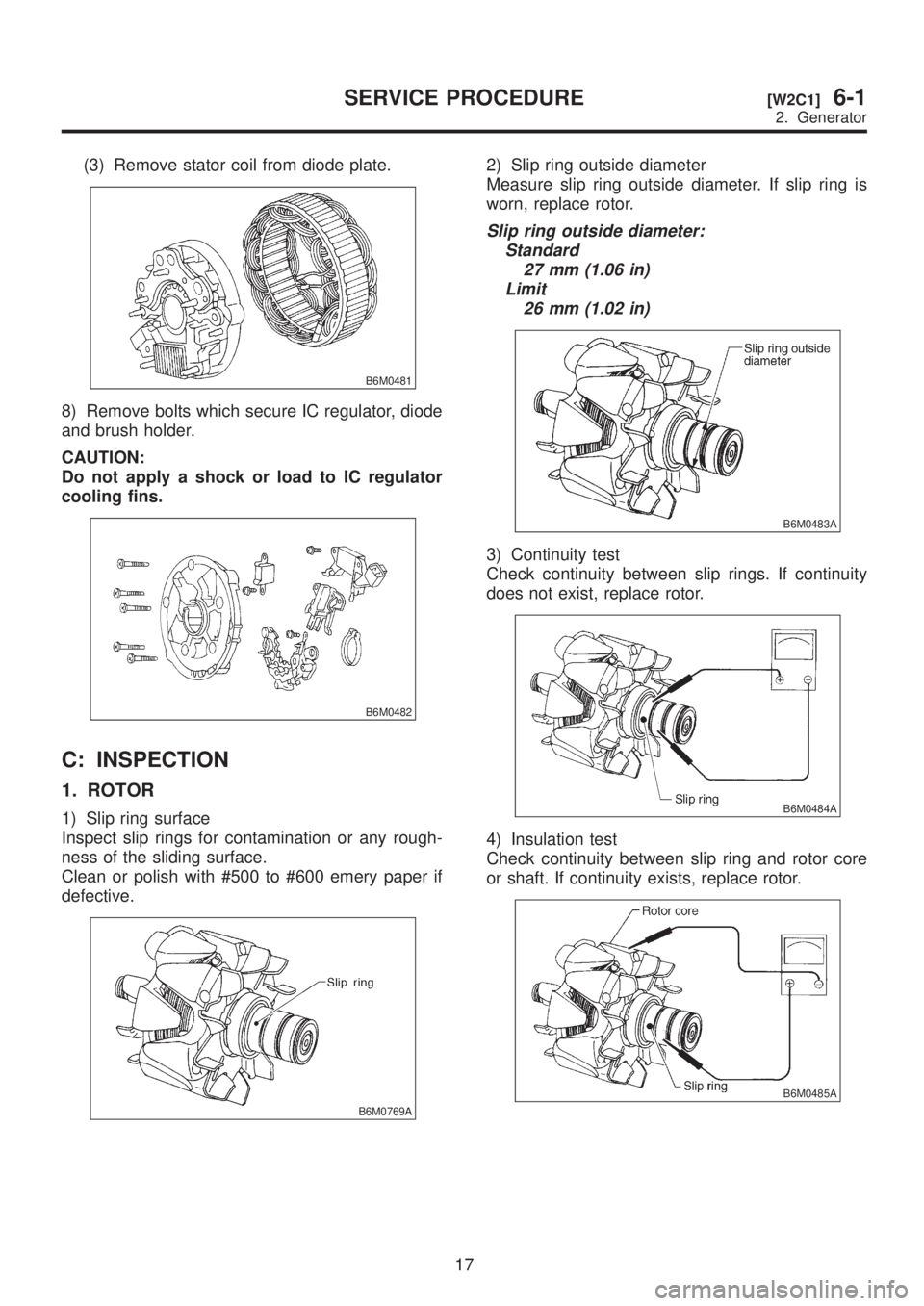

(3) Remove stator coil from diode plate.

B6M0481

8) Remove bolts which secure IC regulator, diode

and brush holder.

CAUTION:

Do not apply a shock or load to IC regulator

cooling fins.

B6M0482

C: INSPECTION

1. ROTOR

1) Slip ring surface

Inspect slip rings for contamination or any rough-

ness of the sliding surface.

Clean or polish with #500 to #600 emery paper if

defective.

B6M0769A

2) Slip ring outside diameter

Measure slip ring outside diameter. If slip ring is

worn, replace rotor.

Slip ring outside diameter:

Standard

27 mm (1.06 in)

Limit

26 mm (1.02 in)

B6M0483A

3) Continuity test

Check continuity between slip rings. If continuity

does not exist, replace rotor.

B6M0484A

4) Insulation test

Check continuity between slip ring and rotor core

or shaft. If continuity exists, replace rotor.

B6M0485A

17

[W2C1]6-1SERVICE PROCEDURE

2. Generator

Page 1199 of 1456

5) Ball bearing

Check rear ball bearing. Replace it if it is noisy or

if rotor does not turn smoothly.

B6M0486

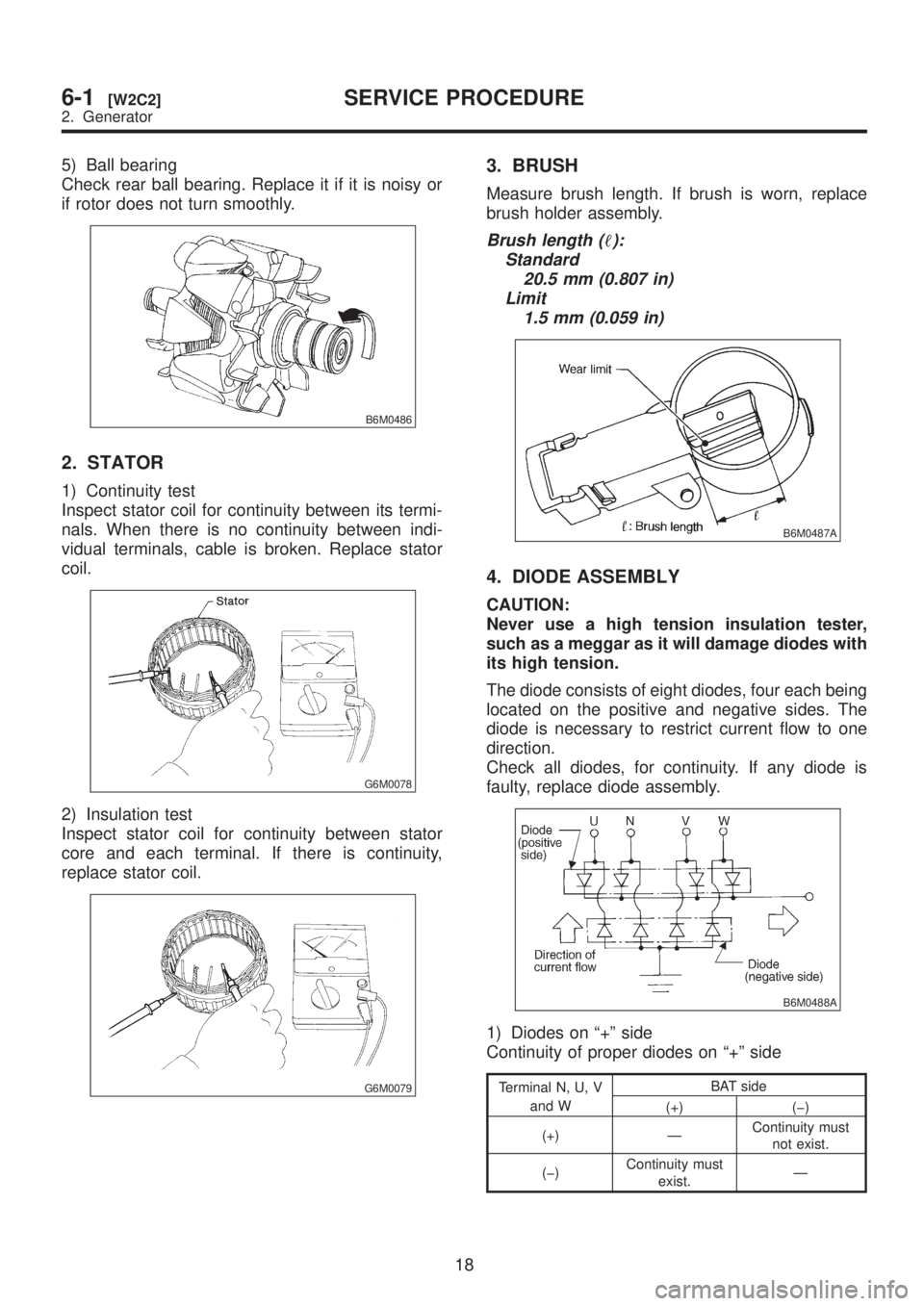

2. STATOR

1) Continuity test

Inspect stator coil for continuity between its termi-

nals. When there is no continuity between indi-

vidual terminals, cable is broken. Replace stator

coil.

G6M0078

2) Insulation test

Inspect stator coil for continuity between stator

core and each terminal. If there is continuity,

replace stator coil.

G6M0079

3. BRUSH

Measure brush length. If brush is worn, replace

brush holder assembly.

Brush length ():

Standard

20.5 mm (0.807 in)

Limit

1.5 mm (0.059 in)

B6M0487A

4. DIODE ASSEMBLY

CAUTION:

Never use a high tension insulation tester,

such as a meggar as it will damage diodes with

its high tension.

The diode consists of eight diodes, four each being

located on the positive and negative sides. The

diode is necessary to restrict current flow to one

direction.

Check all diodes, for continuity. If any diode is

faulty, replace diode assembly.

B6M0488A

1) Diodes on ª+º side

Continuity of proper diodes on ª+º side

Terminal N, U, V

and WBAT side

(+) (þ)

(+) ÐContinuity must

not exist.

(þ)Continuity must

exist.Ð

18

6-1[W2C2]SERVICE PROCEDURE

2. Generator

Page 1200 of 1456

B6M0489A

2) Diodes on ªþº side

Continuity of proper diodes on ªþº side

Terminal N, U, V

and WªEº side

(+) (þ)

(+) ÐContinuity must

exist.

(þ)Continuity must

not exist.Ð

B6M0490A

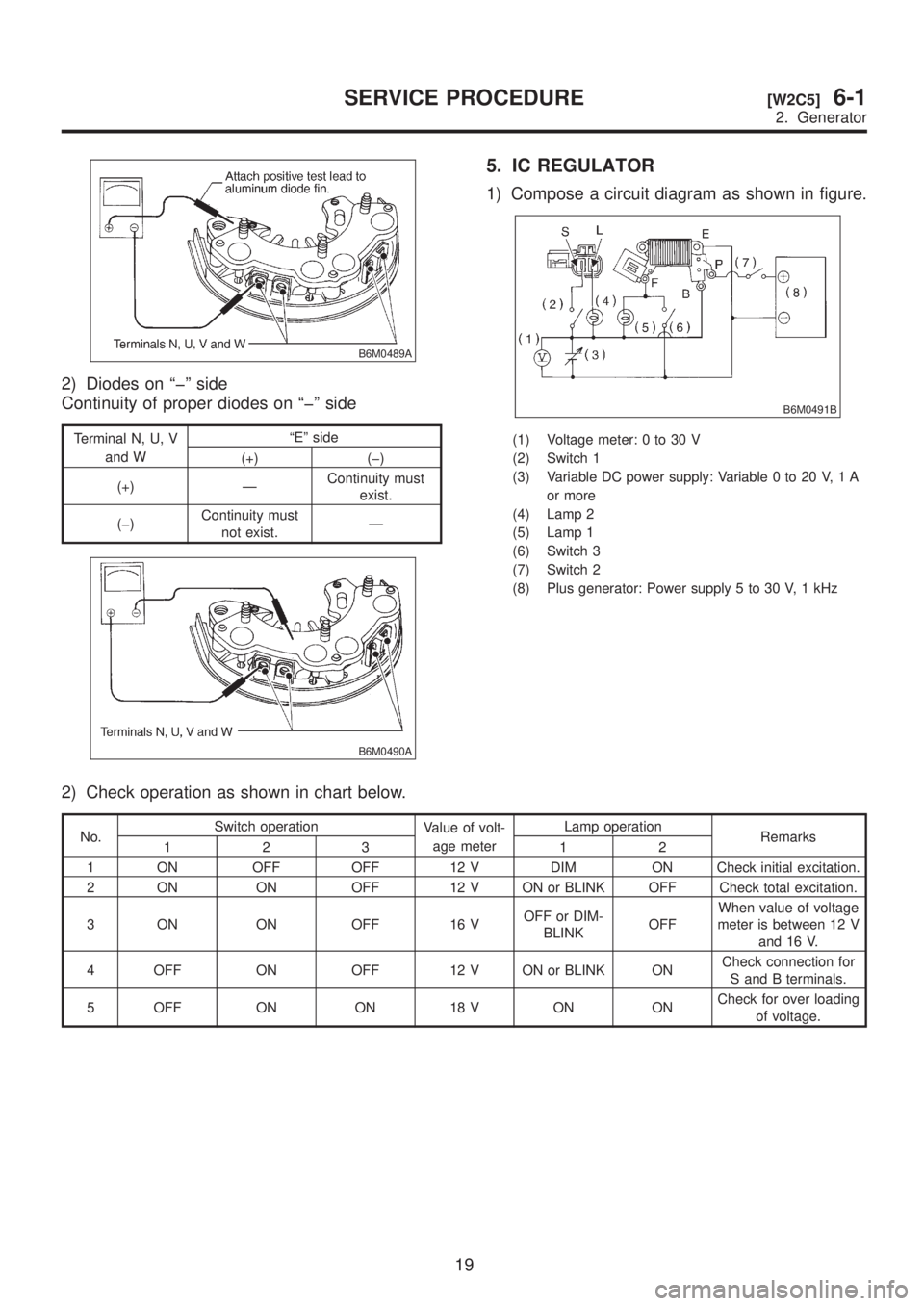

5. IC REGULATOR

1) Compose a circuit diagram as shown in figure.

B6M0491B

(1) Voltage meter: 0 to 30 V

(2) Switch 1

(3) Variable DC power supply: Variable 0 to 20 V, 1 A

or more

(4) Lamp 2

(5) Lamp 1

(6) Switch 3

(7) Switch 2

(8) Plus generator: Power supply 5 to 30 V, 1 kHz

2) Check operation as shown in chart below.

No.Switch operation

Value of volt-

age meterLamp operation

Remarks

123 12

1 ON OFF OFF 12 V DIM ON Check initial excitation.

2 ON ON OFF 12 V ON or BLINK OFF Check total excitation.

3 ON ON OFF 16 VOFF or DIM-

BLINKOFFWhen value of voltage

meter is between 12 V

and 16 V.

4 OFF ON OFF 12 V ON or BLINK ONCheck connection for

S and B terminals.

5 OFF ON ON 18 V ON ONCheck for over loading

of voltage.

19

[W2C5]6-1SERVICE PROCEDURE

2. Generator