SUBARU LEGACY 1999 Service Repair Manual

Manufacturer: SUBARU, Model Year: 1999, Model line: LEGACY, Model: SUBARU LEGACY 1999Pages: 1456, PDF Size: 59.93 MB

Page 1181 of 1456

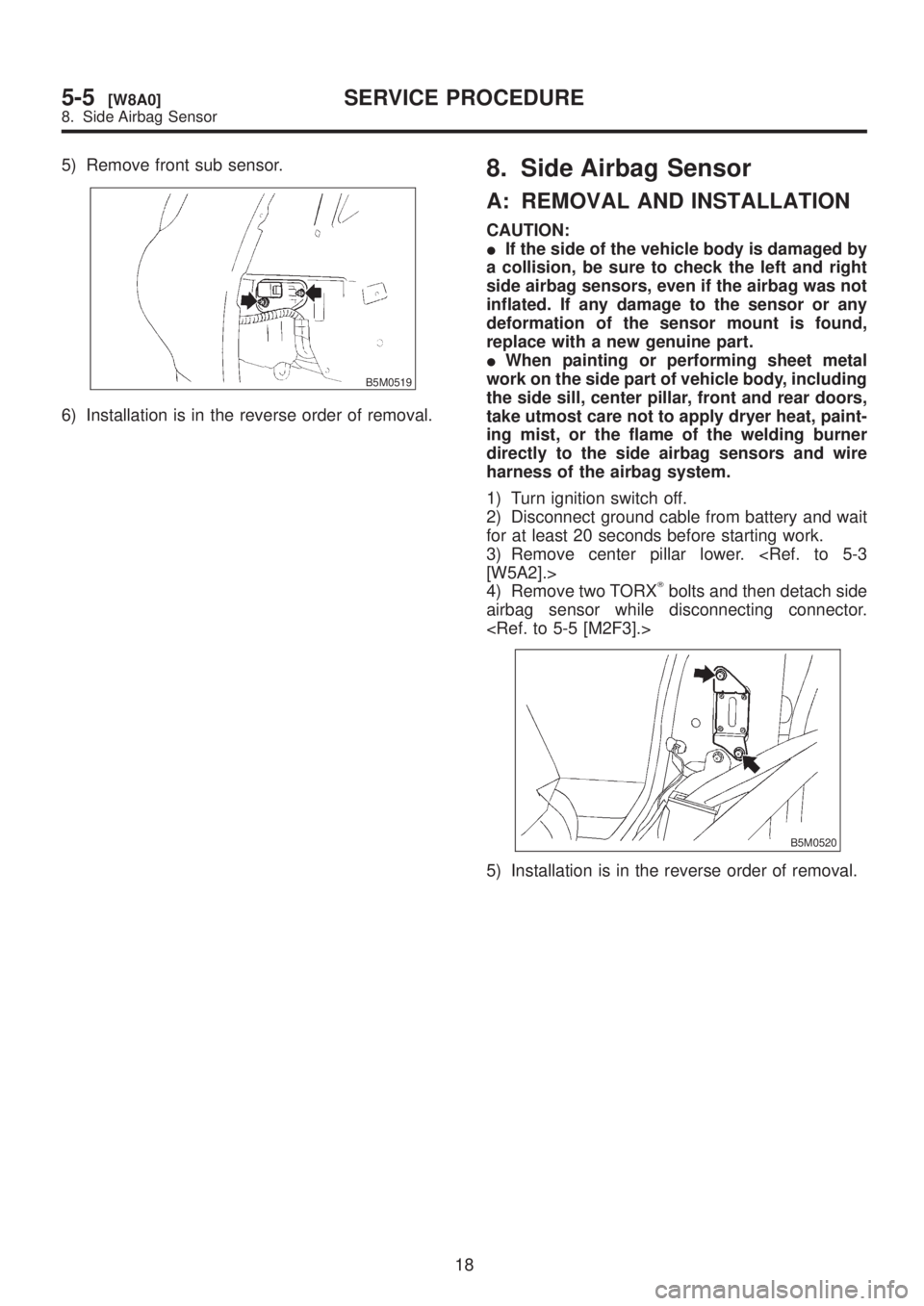

5) Remove front sub sensor.

B5M0519

6) Installation is in the reverse order of removal.

8. Side Airbag Sensor

A: REMOVAL AND INSTALLATION

CAUTION:

IIf the side of the vehicle body is damaged by

a collision, be sure to check the left and right

side airbag sensors, even if the airbag was not

inflated. If any damage to the sensor or any

deformation of the sensor mount is found,

replace with a new genuine part.

IWhen painting or performing sheet metal

work on the side part of vehicle body, including

the side sill, center pillar, front and rear doors,

take utmost care not to apply dryer heat, paint-

ing mist, or the flame of the welding burner

directly to the side airbag sensors and wire

harness of the airbag system.

1) Turn ignition switch off.

2) Disconnect ground cable from battery and wait

for at least 20 seconds before starting work.

3) Remove center pillar lower.

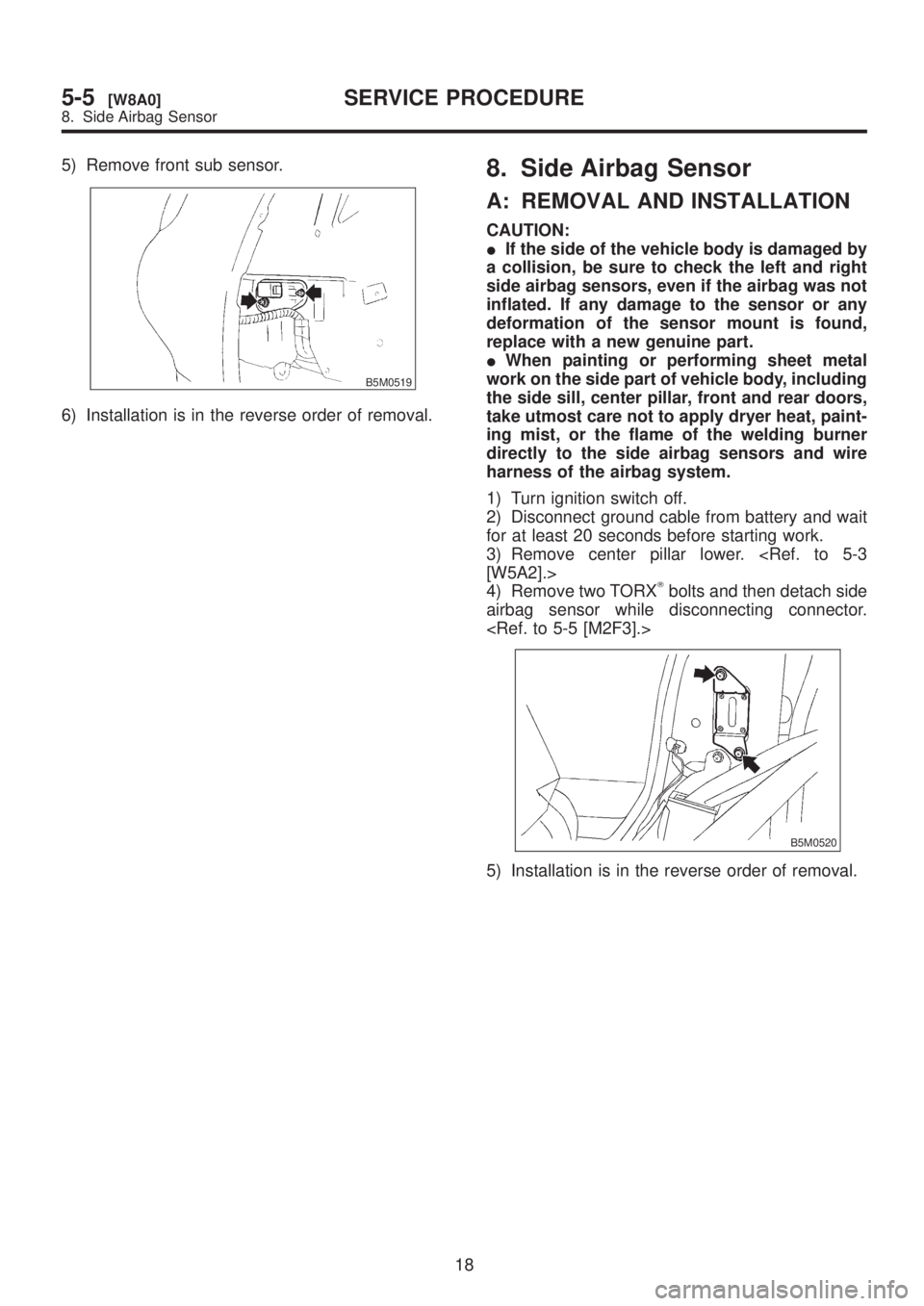

4) Remove two TORX

Tbolts and then detach side

airbag sensor while disconnecting connector.

B5M0520

5) Installation is in the reverse order of removal.

18

5-5[W8A0]SERVICE PROCEDURE

8. Side Airbag Sensor

Page 1182 of 1456

5) Remove front sub sensor.

B5M0519

6) Installation is in the reverse order of removal.

8. Side Airbag Sensor

A: REMOVAL AND INSTALLATION

CAUTION:

IIf the side of the vehicle body is damaged by

a collision, be sure to check the left and right

side airbag sensors, even if the airbag was not

inflated. If any damage to the sensor or any

deformation of the sensor mount is found,

replace with a new genuine part.

IWhen painting or performing sheet metal

work on the side part of vehicle body, including

the side sill, center pillar, front and rear doors,

take utmost care not to apply dryer heat, paint-

ing mist, or the flame of the welding burner

directly to the side airbag sensors and wire

harness of the airbag system.

1) Turn ignition switch off.

2) Disconnect ground cable from battery and wait

for at least 20 seconds before starting work.

3) Remove center pillar lower.

4) Remove two TORX

Tbolts and then detach side

airbag sensor while disconnecting connector.

B5M0520

5) Installation is in the reverse order of removal.

18

5-5[W8A0]SERVICE PROCEDURE

8. Side Airbag Sensor

Page 1183 of 1456

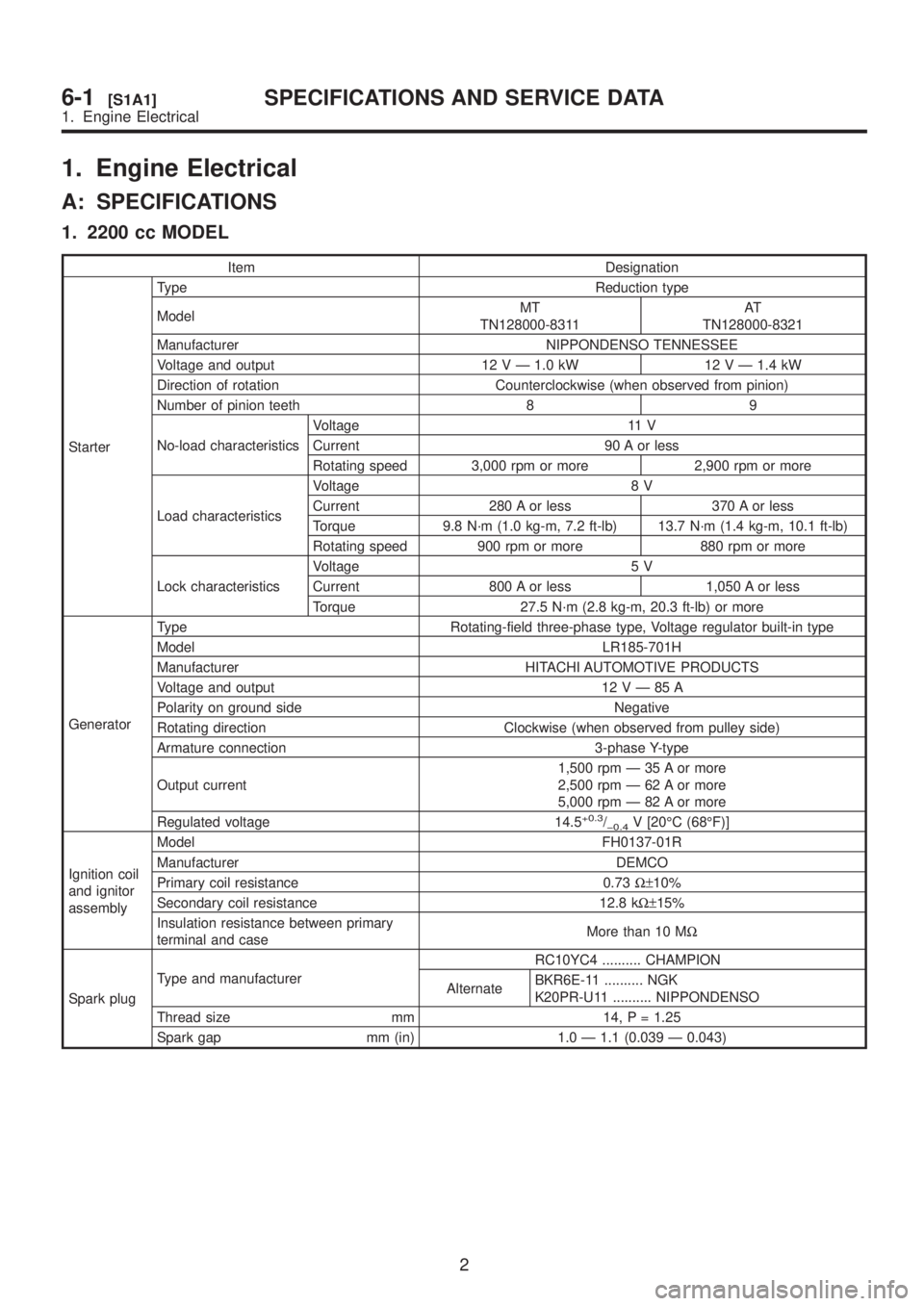

1. Engine Electrical

A: SPECIFICATIONS

1. 2200 cc MODEL

Item Designation

StarterType Reduction type

ModelMT

TN128000-8311AT

TN128000-8321

Manufacturer NIPPONDENSO TENNESSEE

Voltage and output 12 V Ð 1.0 kW 12 V Ð 1.4 kW

Direction of rotation Counterclockwise (when observed from pinion)

Number of pinion teeth 8 9

No-load characteristicsVoltage 11 V

Current 90 A or less

Rotating speed 3,000 rpm or more 2,900 rpm or more

Load characteristicsVoltage 8 V

Current 280 A or less 370 A or less

Torque 9.8 N´m (1.0 kg-m, 7.2 ft-lb) 13.7 N´m (1.4 kg-m, 10.1 ft-lb)

Rotating speed 900 rpm or more 880 rpm or more

Lock characteristicsVoltage 5 V

Current 800 A or less 1,050 A or less

Torque 27.5 N´m (2.8 kg-m, 20.3 ft-lb) or more

GeneratorType Rotating-field three-phase type, Voltage regulator built-in type

Model LR185-701H

Manufacturer HITACHI AUTOMOTIVE PRODUCTS

Voltage and output 12VÐ85A

Polarity on ground side Negative

Rotating direction Clockwise (when observed from pulley side)

Armature connection 3-phase Y-type

Output current1,500 rpm Ð 35 A or more

2,500 rpm Ð 62 A or more

5,000 rpm Ð 82 A or more

Regulated voltage 14.5

+0.3/þ0.4V [20ÉC (68ÉF)]

Ignition coil

and ignitor

assemblyModel FH0137-01R

Manufacturer DEMCO

Primary coil resistance 0.73W±10%

Secondary coil resistance 12.8 kW±15%

Insulation resistance between primary

terminal and caseMore than 10 MW

Spark plugType and manufacturerRC10YC4 .......... CHAMPION

AlternateBKR6E-11 .......... NGK

K20PR-U11 .......... NIPPONDENSO

Thread size mm 14, P = 1.25

Spark gap mm (in) 1.0 Ð 1.1 (0.039 Ð 0.043)

2

6-1[S1A1]SPECIFICATIONS AND SERVICE DATA

1. Engine Electrical

Page 1184 of 1456

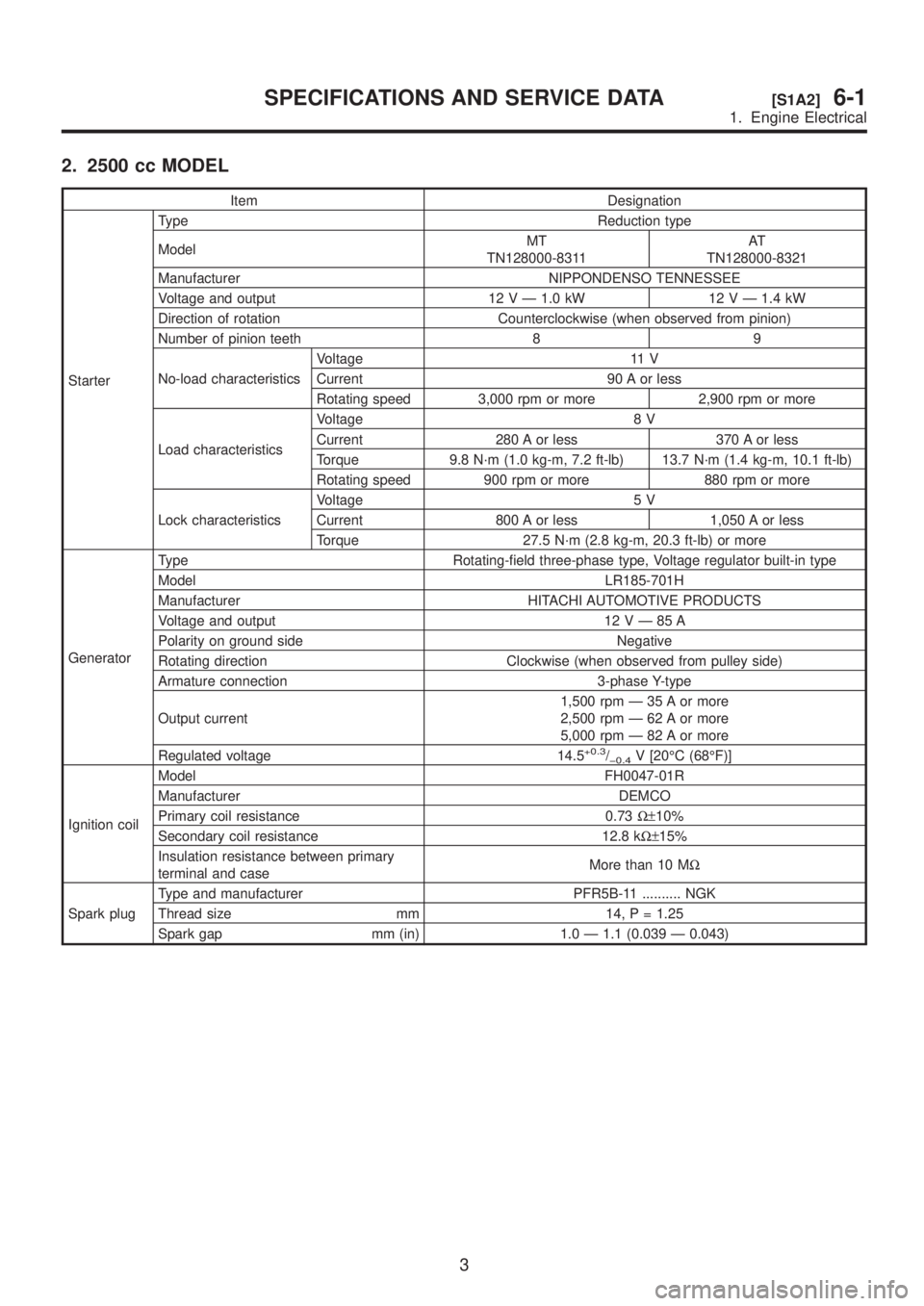

2. 2500 cc MODEL

Item Designation

StarterType Reduction type

ModelMT

TN128000-8311AT

TN128000-8321

Manufacturer NIPPONDENSO TENNESSEE

Voltage and output 12 V Ð 1.0 kW 12 V Ð 1.4 kW

Direction of rotation Counterclockwise (when observed from pinion)

Number of pinion teeth 8 9

No-load characteristicsVoltage 11 V

Current 90 A or less

Rotating speed 3,000 rpm or more 2,900 rpm or more

Load characteristicsVoltage 8 V

Current 280 A or less 370 A or less

Torque 9.8 N´m (1.0 kg-m, 7.2 ft-lb) 13.7 N´m (1.4 kg-m, 10.1 ft-lb)

Rotating speed 900 rpm or more 880 rpm or more

Lock characteristicsVoltage 5 V

Current 800 A or less 1,050 A or less

Torque 27.5 N´m (2.8 kg-m, 20.3 ft-lb) or more

GeneratorType Rotating-field three-phase type, Voltage regulator built-in type

Model LR185-701H

Manufacturer HITACHI AUTOMOTIVE PRODUCTS

Voltage and output 12VÐ85A

Polarity on ground side Negative

Rotating direction Clockwise (when observed from pulley side)

Armature connection 3-phase Y-type

Output current1,500 rpm Ð 35 A or more

2,500 rpm Ð 62 A or more

5,000 rpm Ð 82 A or more

Regulated voltage 14.5

+0.3/þ0.4V [20ÉC (68ÉF)]

Ignition coilModel FH0047-01R

Manufacturer DEMCO

Primary coil resistance 0.73W±10%

Secondary coil resistance 12.8 kW±15%

Insulation resistance between primary

terminal and caseMore than 10 MW

Spark plugType and manufacturer PFR5B-11 .......... NGK

Thread size mm 14, P = 1.25

Spark gap mm (in) 1.0 Ð 1.1 (0.039 Ð 0.043)

3

[S1A2]6-1SPECIFICATIONS AND SERVICE DATA

1. Engine Electrical

Page 1185 of 1456

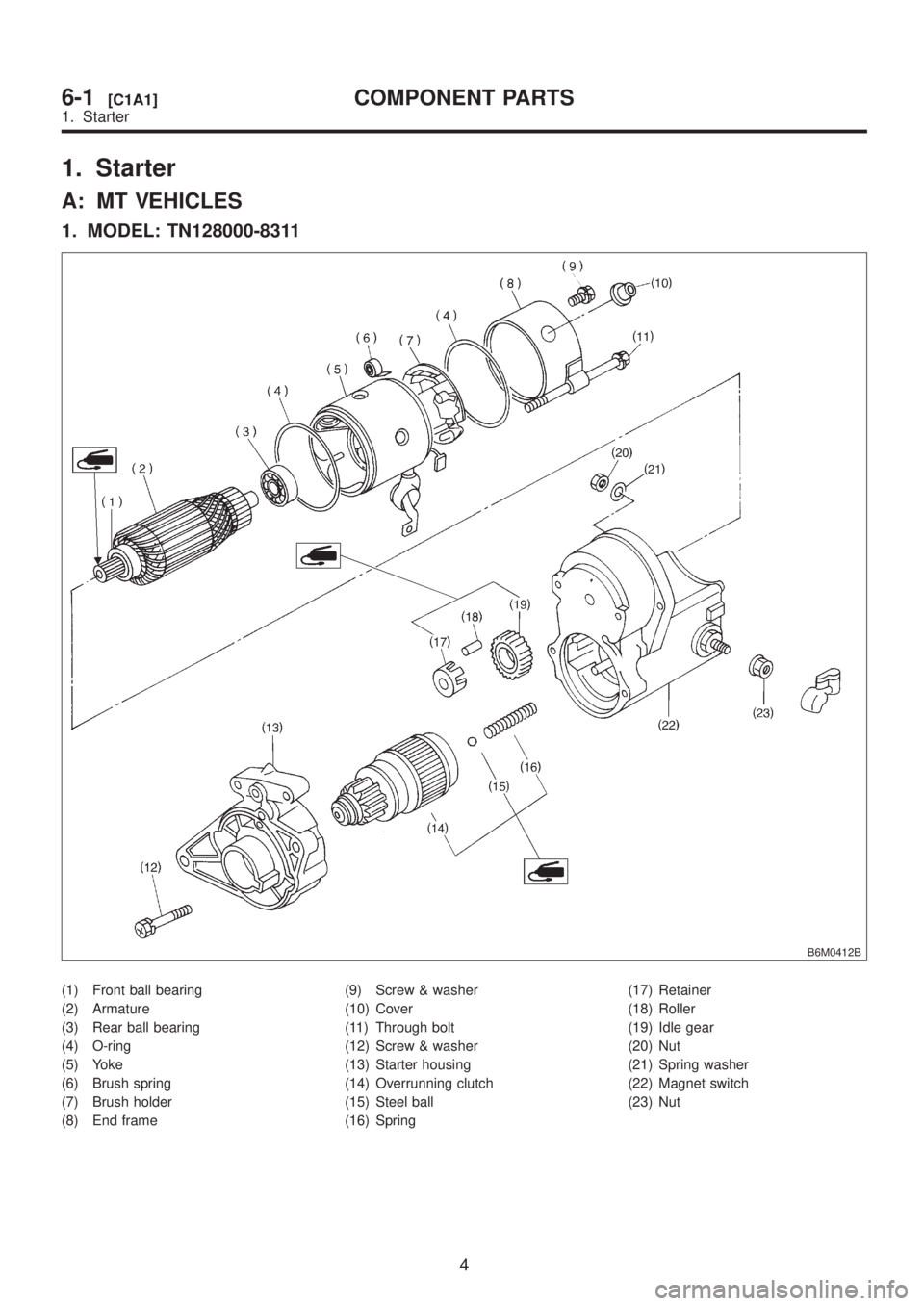

1. Starter

A: MT VEHICLES

1. MODEL: TN128000-8311

B6M0412B

(1) Front ball bearing

(2) Armature

(3) Rear ball bearing

(4) O-ring

(5) Yoke

(6) Brush spring

(7) Brush holder

(8) End frame(9) Screw & washer

(10) Cover

(11) Through bolt

(12) Screw & washer

(13) Starter housing

(14) Overrunning clutch

(15) Steel ball

(16) Spring(17) Retainer

(18) Roller

(19) Idle gear

(20) Nut

(21) Spring washer

(22) Magnet switch

(23) Nut

4

6-1[C1A1]COMPONENT PARTS

1. Starter

Page 1186 of 1456

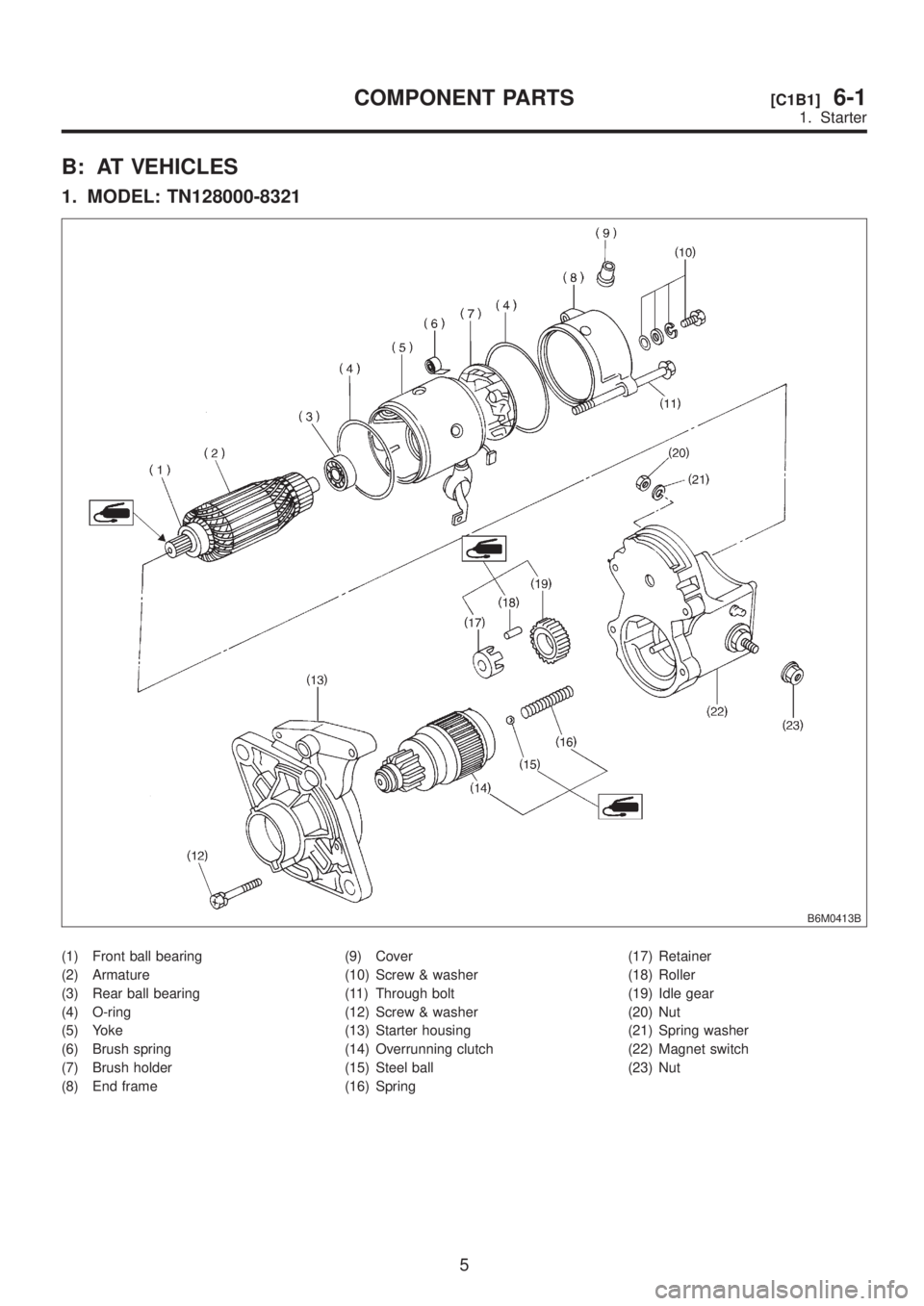

B: AT VEHICLES

1. MODEL: TN128000-8321

B6M0413B

(1) Front ball bearing

(2) Armature

(3) Rear ball bearing

(4) O-ring

(5) Yoke

(6) Brush spring

(7) Brush holder

(8) End frame(9) Cover

(10) Screw & washer

(11) Through bolt

(12) Screw & washer

(13) Starter housing

(14) Overrunning clutch

(15) Steel ball

(16) Spring(17) Retainer

(18) Roller

(19) Idle gear

(20) Nut

(21) Spring washer

(22) Magnet switch

(23) Nut

5

[C1B1]6-1COMPONENT PARTS

1. Starter

Page 1187 of 1456

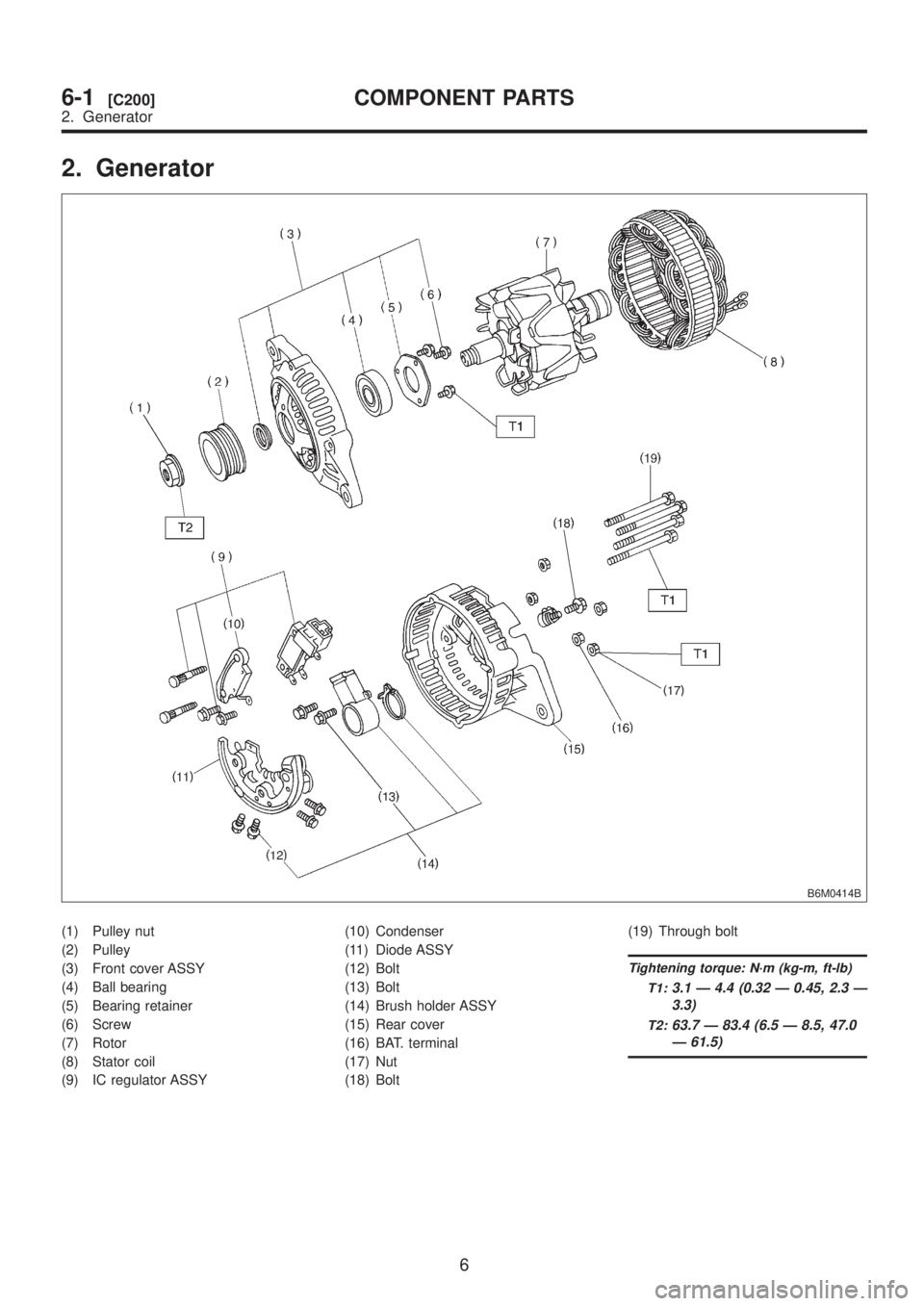

2. Generator

B6M0414B

(1) Pulley nut

(2) Pulley

(3) Front cover ASSY

(4) Ball bearing

(5) Bearing retainer

(6) Screw

(7) Rotor

(8) Stator coil

(9) IC regulator ASSY(10) Condenser

(11) Diode ASSY

(12) Bolt

(13) Bolt

(14) Brush holder ASSY

(15) Rear cover

(16) BAT. terminal

(17) Nut

(18) Bolt(19) Through bolt

Tightening torque: N´m (kg-m, ft-lb)

T1:

3.1 Ð 4.4 (0.32 Ð 0.45, 2.3 Ð

3.3)

T2:63.7 Ð 83.4 (6.5 Ð 8.5, 47.0

Ð 61.5)

6

6-1[C200]COMPONENT PARTS

2. Generator

Page 1188 of 1456

![SUBARU LEGACY 1999 Service Repair Manual 1. Starter

A: REMOVAL AND INSTALLATION

1) Disconnect battery ground cable.

B2M1723

2) Remove air intake chamber. <Ref. to 2-7

[W18A0].>

S6M0007

3) Remove air intake chamber stay. (AT vehicles

only)

S6 SUBARU LEGACY 1999 Service Repair Manual 1. Starter

A: REMOVAL AND INSTALLATION

1) Disconnect battery ground cable.

B2M1723

2) Remove air intake chamber. <Ref. to 2-7

[W18A0].>

S6M0007

3) Remove air intake chamber stay. (AT vehicles

only)

S6](/img/17/57435/w960_57435-1187.png)

1. Starter

A: REMOVAL AND INSTALLATION

1) Disconnect battery ground cable.

B2M1723

2) Remove air intake chamber.

S6M0007

3) Remove air intake chamber stay. (AT vehicles

only)

S6M0023

4) Remove bolt which installs hill holder cable

bracket. (2200 cc MT model with hill holder)

B6M0891

5) Disconnect connector and terminal from starter.

S6M0002A

(A) Terminal

(B) Connector

6) Remove starter from transmission.

G2M0309

7) Installation is in the reverse order of removal.

Tightening torque:

50

±4 N´m (5.1±0.4 kg-m, 37±2.9 ft-lb)

G2M0309

7

[W1A0]6-1SERVICE PROCEDURE

1. Starter

Page 1189 of 1456

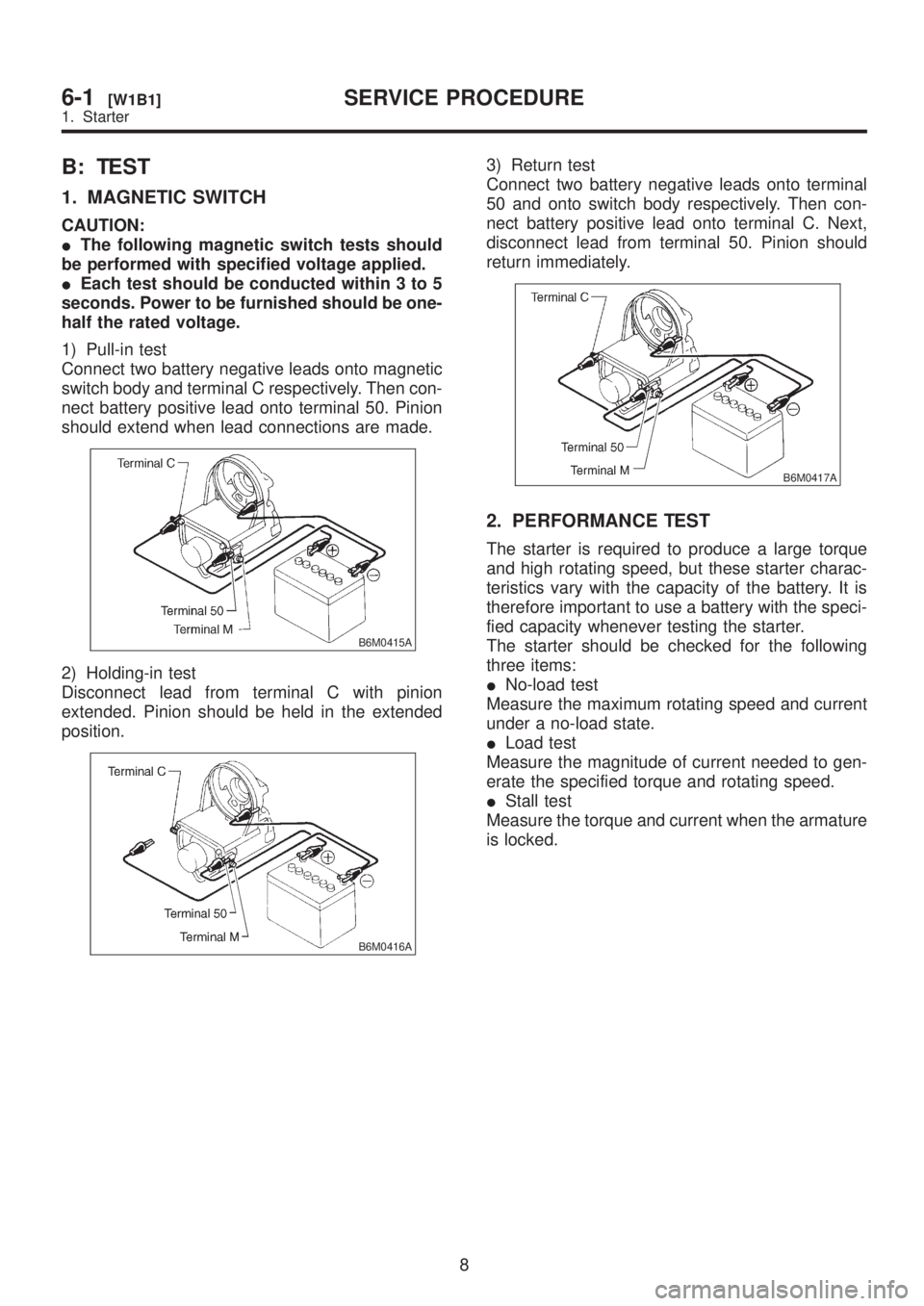

B: TEST

1. MAGNETIC SWITCH

CAUTION:

IThe following magnetic switch tests should

be performed with specified voltage applied.

IEach test should be conducted within 3 to 5

seconds. Power to be furnished should be one-

half the rated voltage.

1) Pull-in test

Connect two battery negative leads onto magnetic

switch body and terminal C respectively. Then con-

nect battery positive lead onto terminal 50. Pinion

should extend when lead connections are made.

B6M0415A

2) Holding-in test

Disconnect lead from terminal C with pinion

extended. Pinion should be held in the extended

position.

B6M0416A

3) Return test

Connect two battery negative leads onto terminal

50 and onto switch body respectively. Then con-

nect battery positive lead onto terminal C. Next,

disconnect lead from terminal 50. Pinion should

return immediately.

B6M0417A

2. PERFORMANCE TEST

The starter is required to produce a large torque

and high rotating speed, but these starter charac-

teristics vary with the capacity of the battery. It is

therefore important to use a battery with the speci-

fied capacity whenever testing the starter.

The starter should be checked for the following

three items:

INo-load test

Measure the maximum rotating speed and current

under a no-load state.

ILoad test

Measure the magnitude of current needed to gen-

erate the specified torque and rotating speed.

IStall test

Measure the torque and current when the armature

is locked.

8

6-1[W1B1]SERVICE PROCEDURE

1. Starter

Page 1190 of 1456

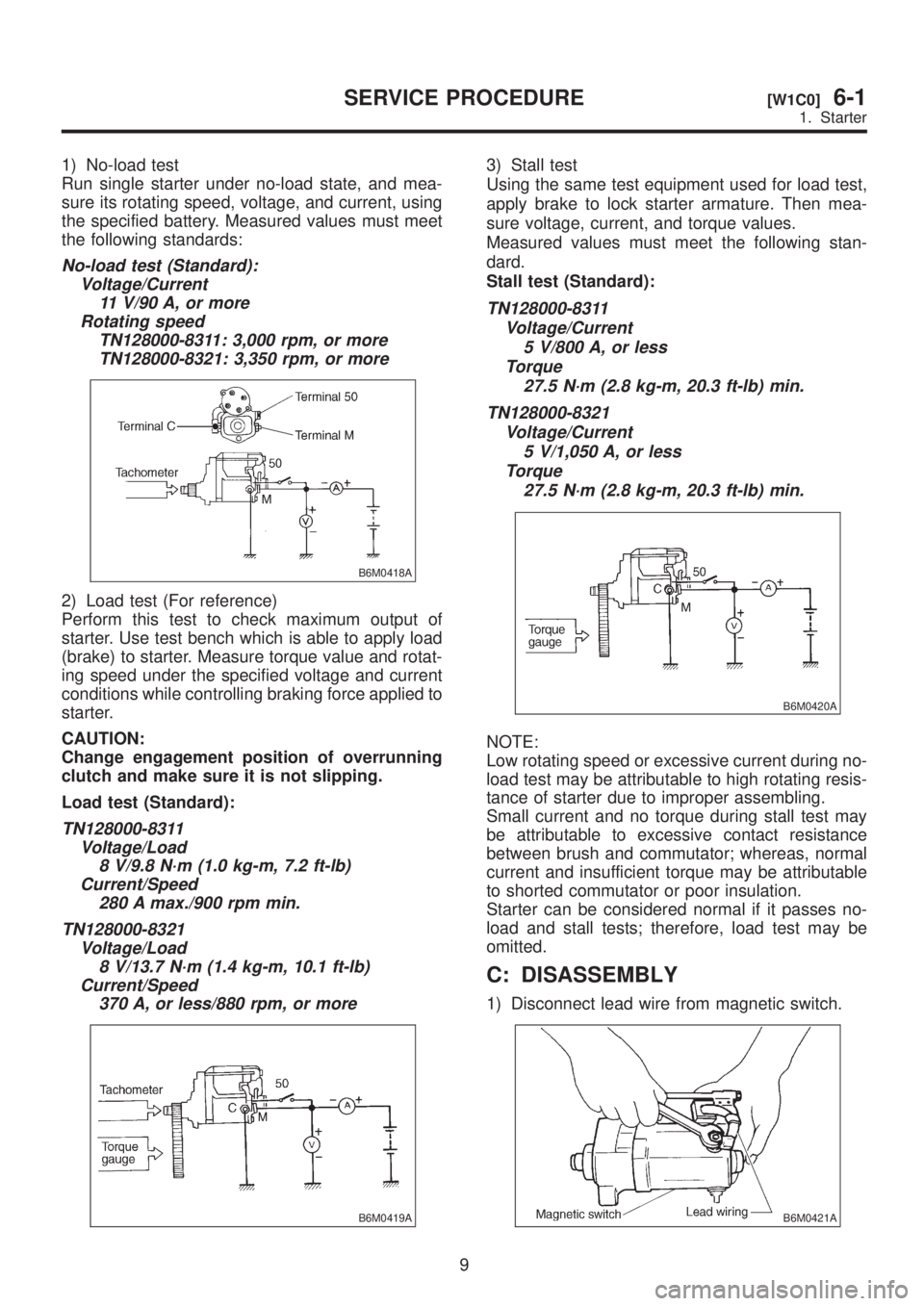

1) No-load test

Run single starter under no-load state, and mea-

sure its rotating speed, voltage, and current, using

the specified battery. Measured values must meet

the following standards:

No-load test (Standard):

Voltage/Current

11 V/90 A, or more

Rotating speed

TN128000-8311: 3,000 rpm, or more

TN128000-8321: 3,350 rpm, or more

B6M0418A

2) Load test (For reference)

Perform this test to check maximum output of

starter. Use test bench which is able to apply load

(brake) to starter. Measure torque value and rotat-

ing speed under the specified voltage and current

conditions while controlling braking force applied to

starter.

CAUTION:

Change engagement position of overrunning

clutch and make sure it is not slipping.

Load test (Standard):

TN128000-8311

Voltage/Load

8 V/9.8 N´m (1.0 kg-m, 7.2 ft-lb)

Current/Speed

280 A max./900 rpm min.

TN128000-8321

Voltage/Load

8 V/13.7 N´m (1.4 kg-m, 10.1 ft-lb)

Current/Speed

370 A, or less/880 rpm, or more

B6M0419A

3) Stall test

Using the same test equipment used for load test,

apply brake to lock starter armature. Then mea-

sure voltage, current, and torque values.

Measured values must meet the following stan-

dard.

Stall test (Standard):

TN128000-8311

Voltage/Current

5 V/800 A, or less

Torque

27.5 N´m (2.8 kg-m, 20.3 ft-lb) min.

TN128000-8321

Voltage/Current

5 V/1,050 A, or less

Torque

27.5 N´m (2.8 kg-m, 20.3 ft-lb) min.

B6M0420A

NOTE:

Low rotating speed or excessive current during no-

load test may be attributable to high rotating resis-

tance of starter due to improper assembling.

Small current and no torque during stall test may

be attributable to excessive contact resistance

between brush and commutator; whereas, normal

current and insufficient torque may be attributable

to shorted commutator or poor insulation.

Starter can be considered normal if it passes no-

load and stall tests; therefore, load test may be

omitted.

C: DISASSEMBLY

1) Disconnect lead wire from magnetic switch.

B6M0421A

9

[W1C0]6-1SERVICE PROCEDURE

1. Starter