SUBARU LEGACY 1999 Service Repair Manual

Manufacturer: SUBARU, Model Year: 1999, Model line: LEGACY, Model: SUBARU LEGACY 1999Pages: 1456, PDF Size: 59.93 MB

Page 1211 of 1456

NOTE:

ILength L1 is important in making for easy

removal.

IIt may be necessary to wrap points (A) and (B)

with vinyl tape to prevent them separating while

working.

If they do separate, spark plug socket is left on the

spark plug and it is very difficult to remove.

IAn approximately 250 mm (9.84 in) long exten-

sion is recommended to be connected to ratchet.

IFor spark plug socket, extension and Universal

Joint, it is recommended to use the following tools.

Spark plug socket : PROTO 5020-50

Extension : SNAP-ON FX1

Universal Joint : SNAP-ON FU80B

B6M0568B

9) Set (D) extension and (E) ratchet in turn onto

the connected tools in plug hole, and remove spark

plug using them.

B6M0567B

(A) Spark plug socket 16 mm (5/8 in)

(B) Extension

(C) Universal Joint

(D) Extension

(E) Ratchet

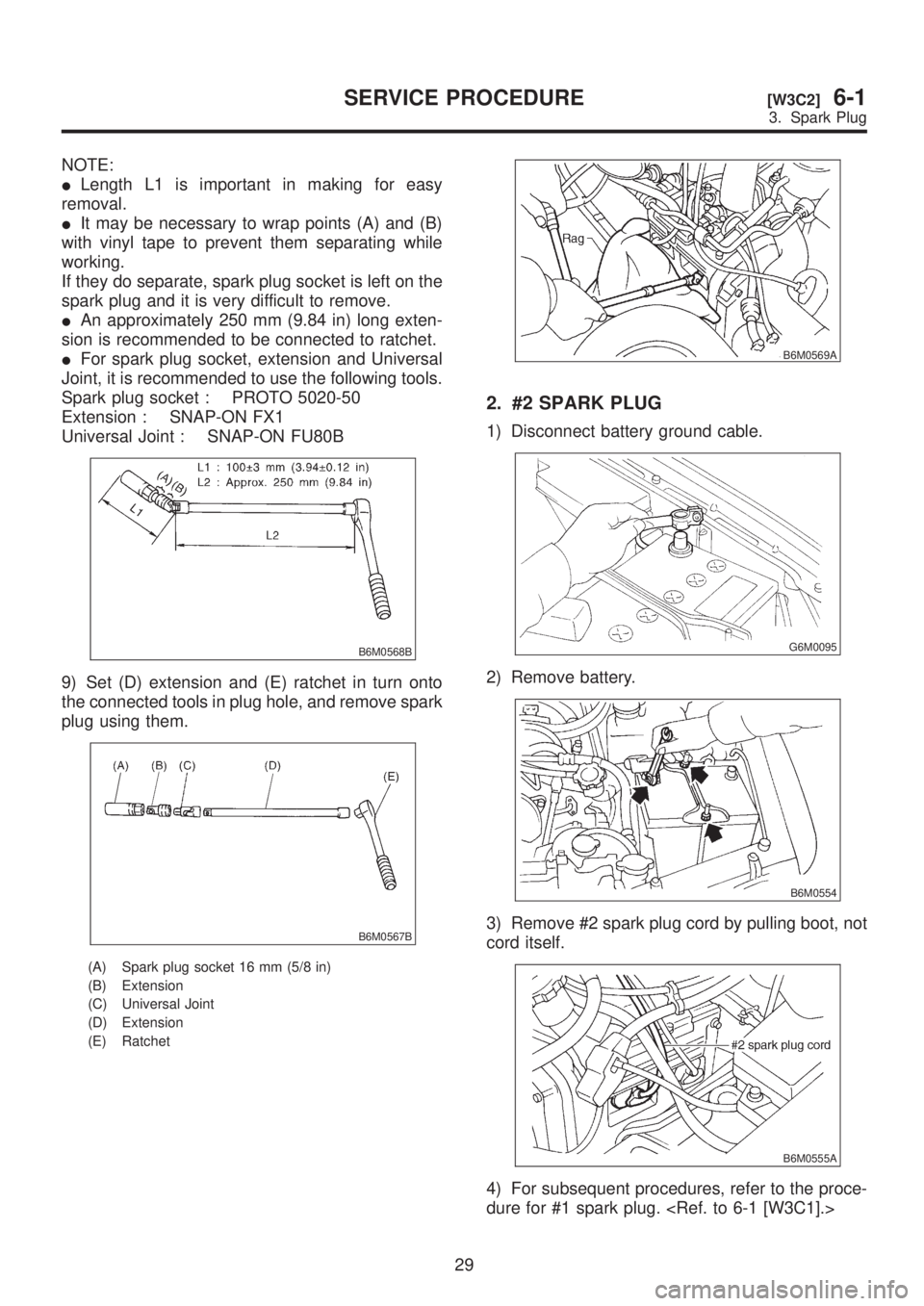

B6M0569A

2. #2 SPARK PLUG

1) Disconnect battery ground cable.

G6M0095

2) Remove battery.

B6M0554

3) Remove #2 spark plug cord by pulling boot, not

cord itself.

B6M0555A

4) For subsequent procedures, refer to the proce-

dure for #1 spark plug.

29

[W3C2]6-1SERVICE PROCEDURE

3. Spark Plug

Page 1212 of 1456

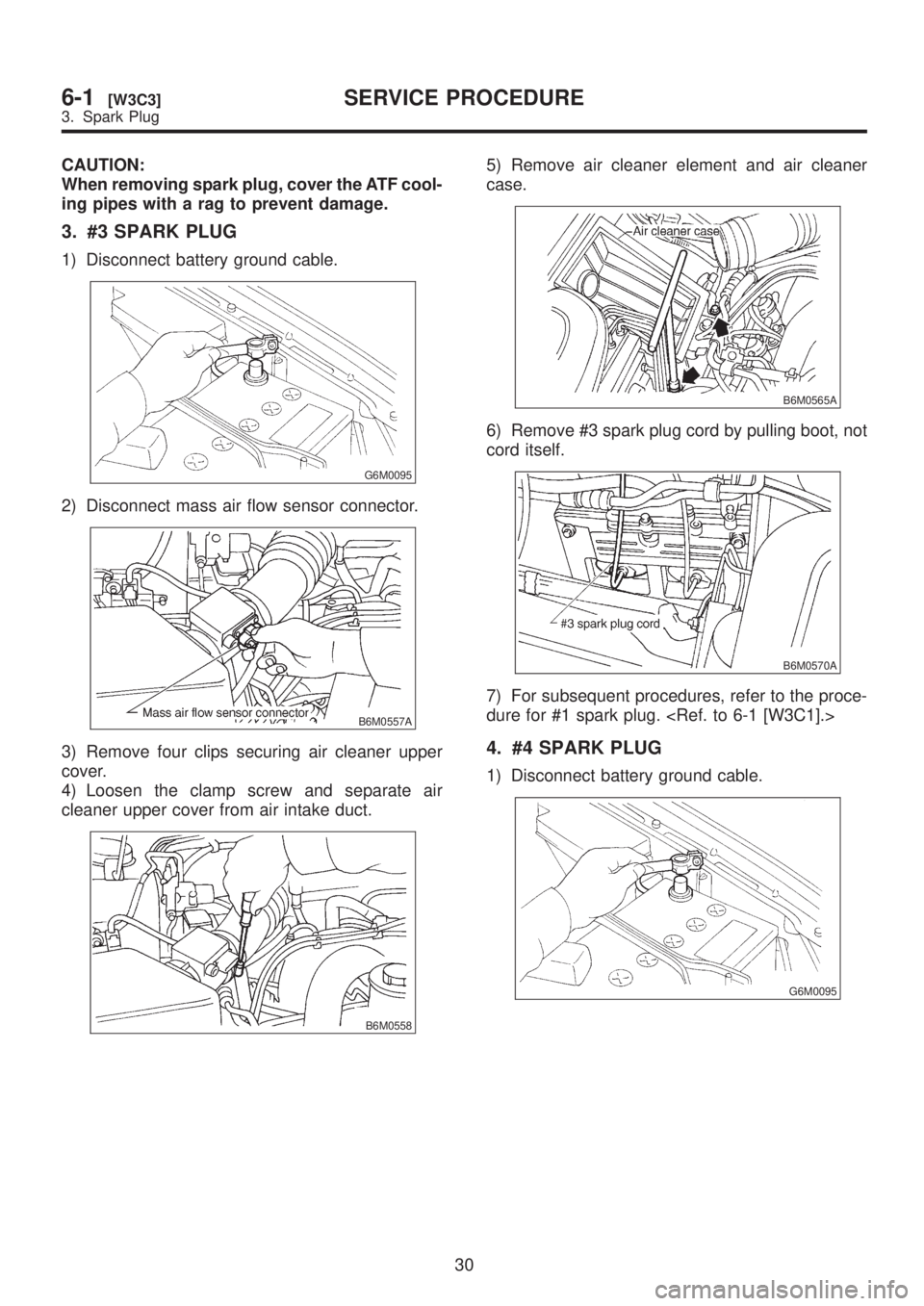

CAUTION:

When removing spark plug, cover the ATF cool-

ing pipes with a rag to prevent damage.

3. #3 SPARK PLUG

1) Disconnect battery ground cable.

G6M0095

2) Disconnect mass air flow sensor connector.

B6M0557A

3) Remove four clips securing air cleaner upper

cover.

4) Loosen the clamp screw and separate air

cleaner upper cover from air intake duct.

B6M0558

5) Remove air cleaner element and air cleaner

case.

B6M0565A

6) Remove #3 spark plug cord by pulling boot, not

cord itself.

B6M0570A

7) For subsequent procedures, refer to the proce-

dure for #1 spark plug.

4. #4 SPARK PLUG

1) Disconnect battery ground cable.

G6M0095

30

6-1[W3C3]SERVICE PROCEDURE

3. Spark Plug

Page 1213 of 1456

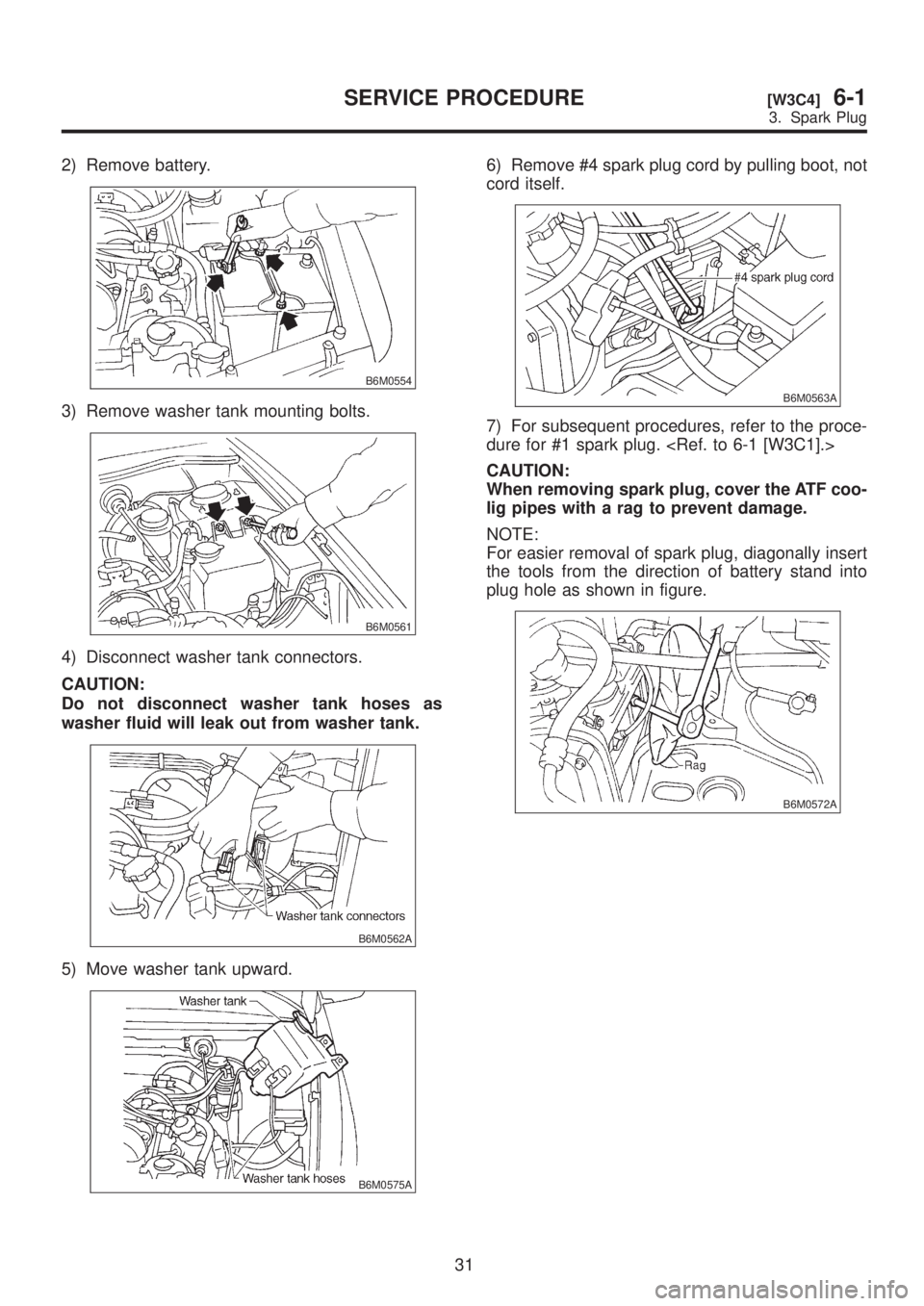

2) Remove battery.

B6M0554

3) Remove washer tank mounting bolts.

B6M0561

4) Disconnect washer tank connectors.

CAUTION:

Do not disconnect washer tank hoses as

washer fluid will leak out from washer tank.

B6M0562A

5) Move washer tank upward.

B6M0575A

6) Remove #4 spark plug cord by pulling boot, not

cord itself.

B6M0563A

7) For subsequent procedures, refer to the proce-

dure for #1 spark plug.

CAUTION:

When removing spark plug, cover the ATF coo-

lig pipes with a rag to prevent damage.

NOTE:

For easier removal of spark plug, diagonally insert

the tools from the direction of battery stand into

plug hole as shown in figure.

B6M0572A

31

[W3C4]6-1SERVICE PROCEDURE

3. Spark Plug

Page 1214 of 1456

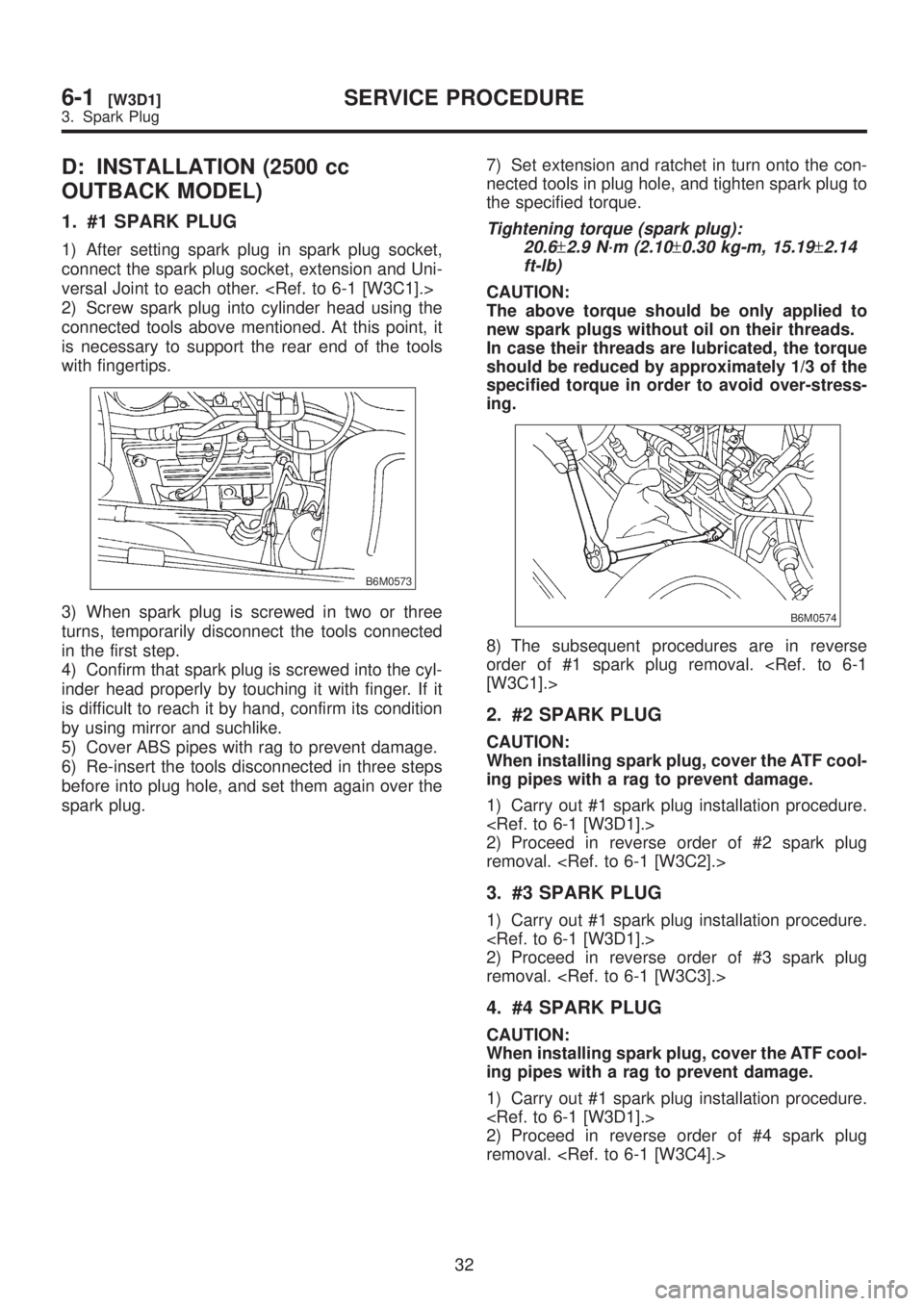

D: INSTALLATION (2500 cc

OUTBACK MODEL)

1. #1 SPARK PLUG

1) After setting spark plug in spark plug socket,

connect the spark plug socket, extension and Uni-

versal Joint to each other.

2) Screw spark plug into cylinder head using the

connected tools above mentioned. At this point, it

is necessary to support the rear end of the tools

with fingertips.

B6M0573

3) When spark plug is screwed in two or three

turns, temporarily disconnect the tools connected

in the first step.

4) Confirm that spark plug is screwed into the cyl-

inder head properly by touching it with finger. If it

is difficult to reach it by hand, confirm its condition

by using mirror and suchlike.

5) Cover ABS pipes with rag to prevent damage.

6) Re-insert the tools disconnected in three steps

before into plug hole, and set them again over the

spark plug.7) Set extension and ratchet in turn onto the con-

nected tools in plug hole, and tighten spark plug to

the specified torque.

Tightening torque (spark plug):

20.6

±2.9 N´m (2.10±0.30 kg-m, 15.19±2.14

ft-lb)

CAUTION:

The above torque should be only applied to

new spark plugs without oil on their threads.

In case their threads are lubricated, the torque

should be reduced by approximately 1/3 of the

specified torque in order to avoid over-stress-

ing.

B6M0574

8) The subsequent procedures are in reverse

order of #1 spark plug removal.

2. #2 SPARK PLUG

CAUTION:

When installing spark plug, cover the ATF cool-

ing pipes with a rag to prevent damage.

1) Carry out #1 spark plug installation procedure.

2) Proceed in reverse order of #2 spark plug

removal.

3. #3 SPARK PLUG

1) Carry out #1 spark plug installation procedure.

2) Proceed in reverse order of #3 spark plug

removal.

4. #4 SPARK PLUG

CAUTION:

When installing spark plug, cover the ATF cool-

ing pipes with a rag to prevent damage.

1) Carry out #1 spark plug installation procedure.

2) Proceed in reverse order of #4 spark plug

removal.

32

6-1[W3D1]SERVICE PROCEDURE

3. Spark Plug

Page 1215 of 1456

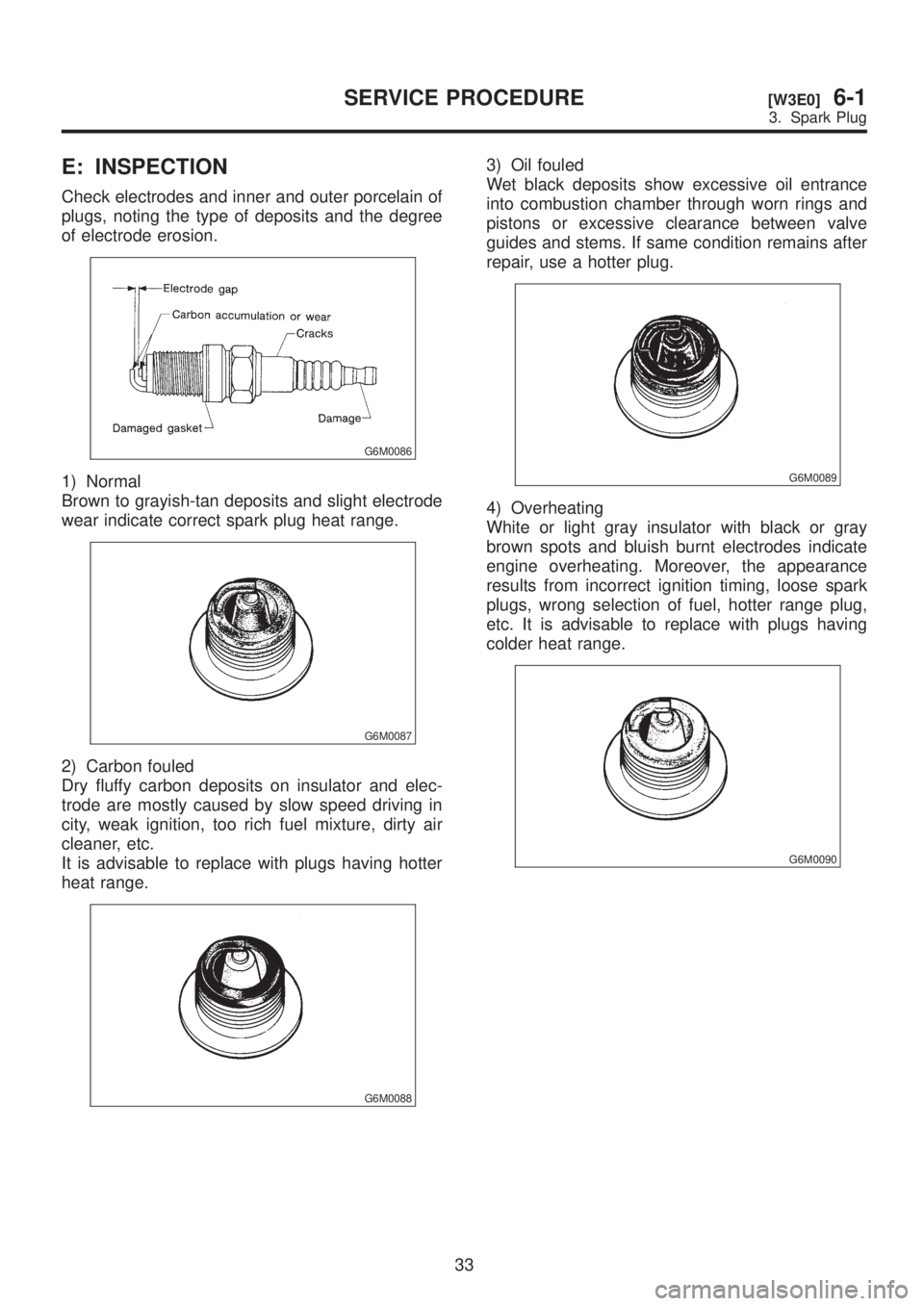

E: INSPECTION

Check electrodes and inner and outer porcelain of

plugs, noting the type of deposits and the degree

of electrode erosion.

G6M0086

1) Normal

Brown to grayish-tan deposits and slight electrode

wear indicate correct spark plug heat range.

G6M0087

2) Carbon fouled

Dry fluffy carbon deposits on insulator and elec-

trode are mostly caused by slow speed driving in

city, weak ignition, too rich fuel mixture, dirty air

cleaner, etc.

It is advisable to replace with plugs having hotter

heat range.

G6M0088

3) Oil fouled

Wet black deposits show excessive oil entrance

into combustion chamber through worn rings and

pistons or excessive clearance between valve

guides and stems. If same condition remains after

repair, use a hotter plug.

G6M0089

4) Overheating

White or light gray insulator with black or gray

brown spots and bluish burnt electrodes indicate

engine overheating. Moreover, the appearance

results from incorrect ignition timing, loose spark

plugs, wrong selection of fuel, hotter range plug,

etc. It is advisable to replace with plugs having

colder heat range.

G6M0090

33

[W3E0]6-1SERVICE PROCEDURE

3. Spark Plug

Page 1216 of 1456

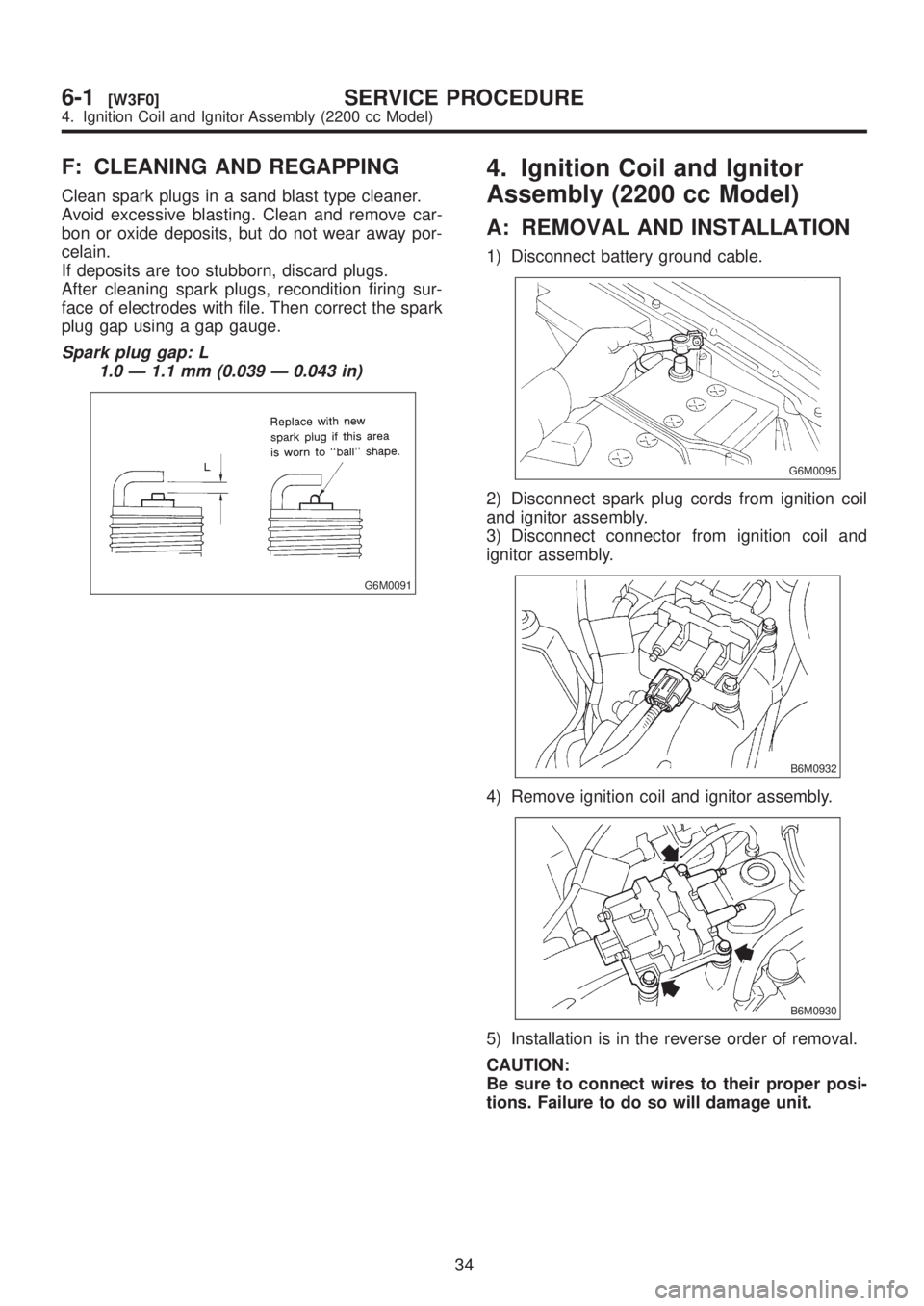

F: CLEANING AND REGAPPING

Clean spark plugs in a sand blast type cleaner.

Avoid excessive blasting. Clean and remove car-

bon or oxide deposits, but do not wear away por-

celain.

If deposits are too stubborn, discard plugs.

After cleaning spark plugs, recondition firing sur-

face of electrodes with file. Then correct the spark

plug gap using a gap gauge.

Spark plug gap: L

1.0 Ð 1.1 mm (0.039 Ð 0.043 in)

G6M0091

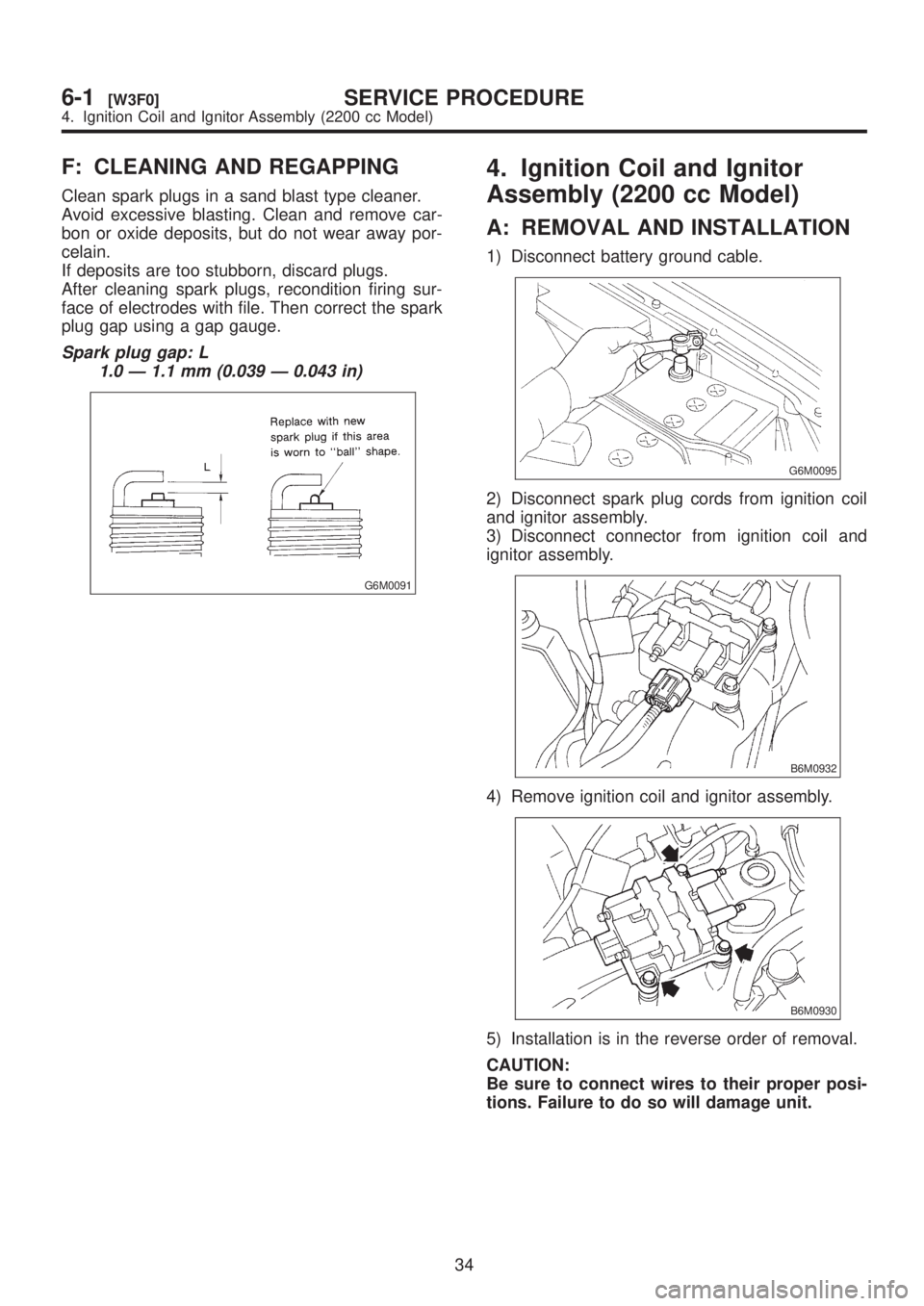

4. Ignition Coil and Ignitor

Assembly (2200 cc Model)

A: REMOVAL AND INSTALLATION

1) Disconnect battery ground cable.

G6M0095

2) Disconnect spark plug cords from ignition coil

and ignitor assembly.

3) Disconnect connector from ignition coil and

ignitor assembly.

B6M0932

4) Remove ignition coil and ignitor assembly.

B6M0930

5) Installation is in the reverse order of removal.

CAUTION:

Be sure to connect wires to their proper posi-

tions. Failure to do so will damage unit.

34

6-1[W3F0]SERVICE PROCEDURE

4. Ignition Coil and Ignitor Assembly (2200 cc Model)

Page 1217 of 1456

F: CLEANING AND REGAPPING

Clean spark plugs in a sand blast type cleaner.

Avoid excessive blasting. Clean and remove car-

bon or oxide deposits, but do not wear away por-

celain.

If deposits are too stubborn, discard plugs.

After cleaning spark plugs, recondition firing sur-

face of electrodes with file. Then correct the spark

plug gap using a gap gauge.

Spark plug gap: L

1.0 Ð 1.1 mm (0.039 Ð 0.043 in)

G6M0091

4. Ignition Coil and Ignitor

Assembly (2200 cc Model)

A: REMOVAL AND INSTALLATION

1) Disconnect battery ground cable.

G6M0095

2) Disconnect spark plug cords from ignition coil

and ignitor assembly.

3) Disconnect connector from ignition coil and

ignitor assembly.

B6M0932

4) Remove ignition coil and ignitor assembly.

B6M0930

5) Installation is in the reverse order of removal.

CAUTION:

Be sure to connect wires to their proper posi-

tions. Failure to do so will damage unit.

34

6-1[W3F0]SERVICE PROCEDURE

4. Ignition Coil and Ignitor Assembly (2200 cc Model)

Page 1218 of 1456

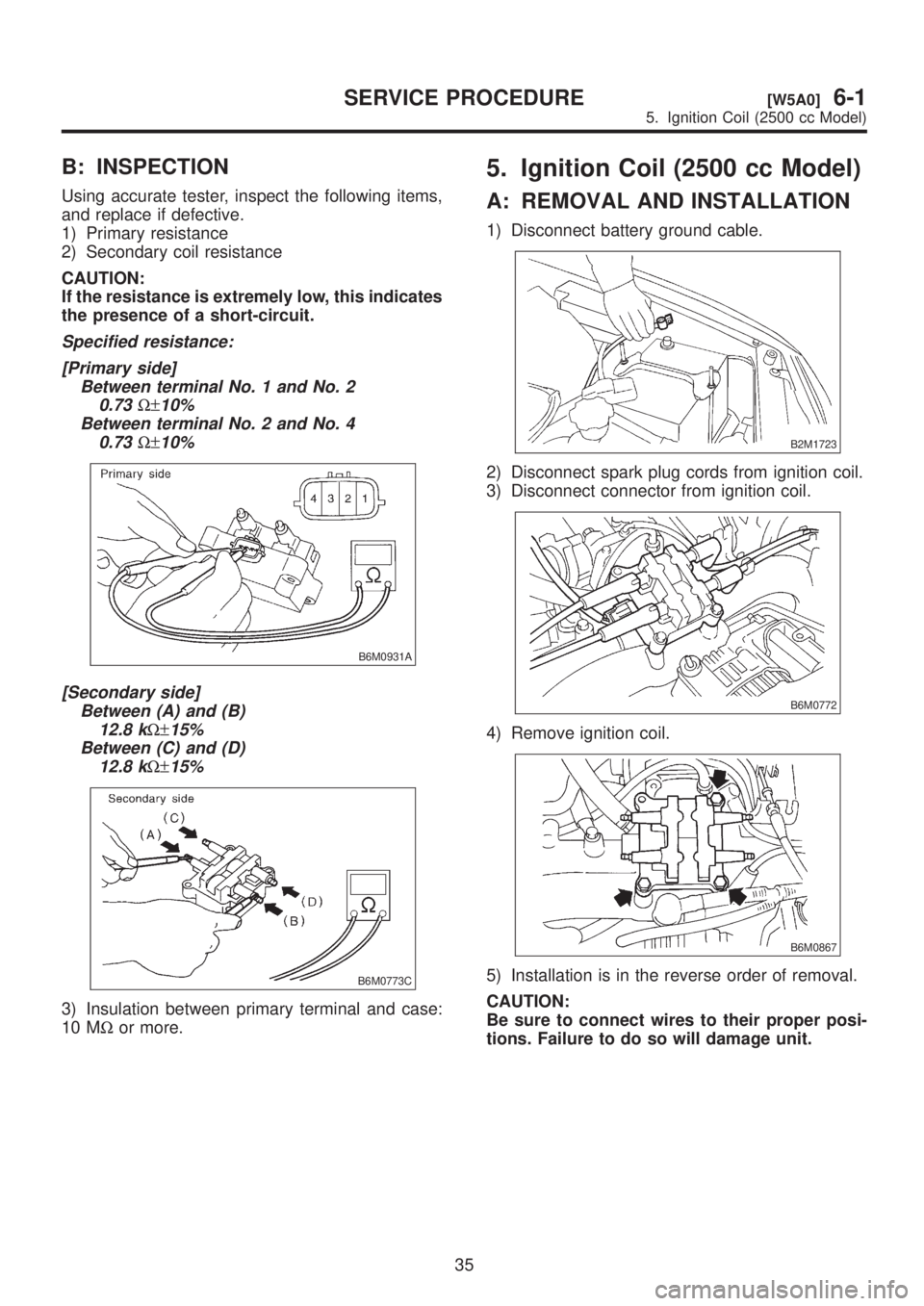

B: INSPECTION

Using accurate tester, inspect the following items,

and replace if defective.

1) Primary resistance

2) Secondary coil resistance

CAUTION:

If the resistance is extremely low, this indicates

the presence of a short-circuit.

Specified resistance:

[Primary side]

Between terminal No. 1 and No. 2

0.73

W±10%

Between terminal No. 2 and No. 4

0.73

W±10%

B6M0931A

[Secondary side]

Between (A) and (B)

12.8 k

W±15%

Between (C) and (D)

12.8 k

W±15%

B6M0773C

3) Insulation between primary terminal and case:

10 MWor more.

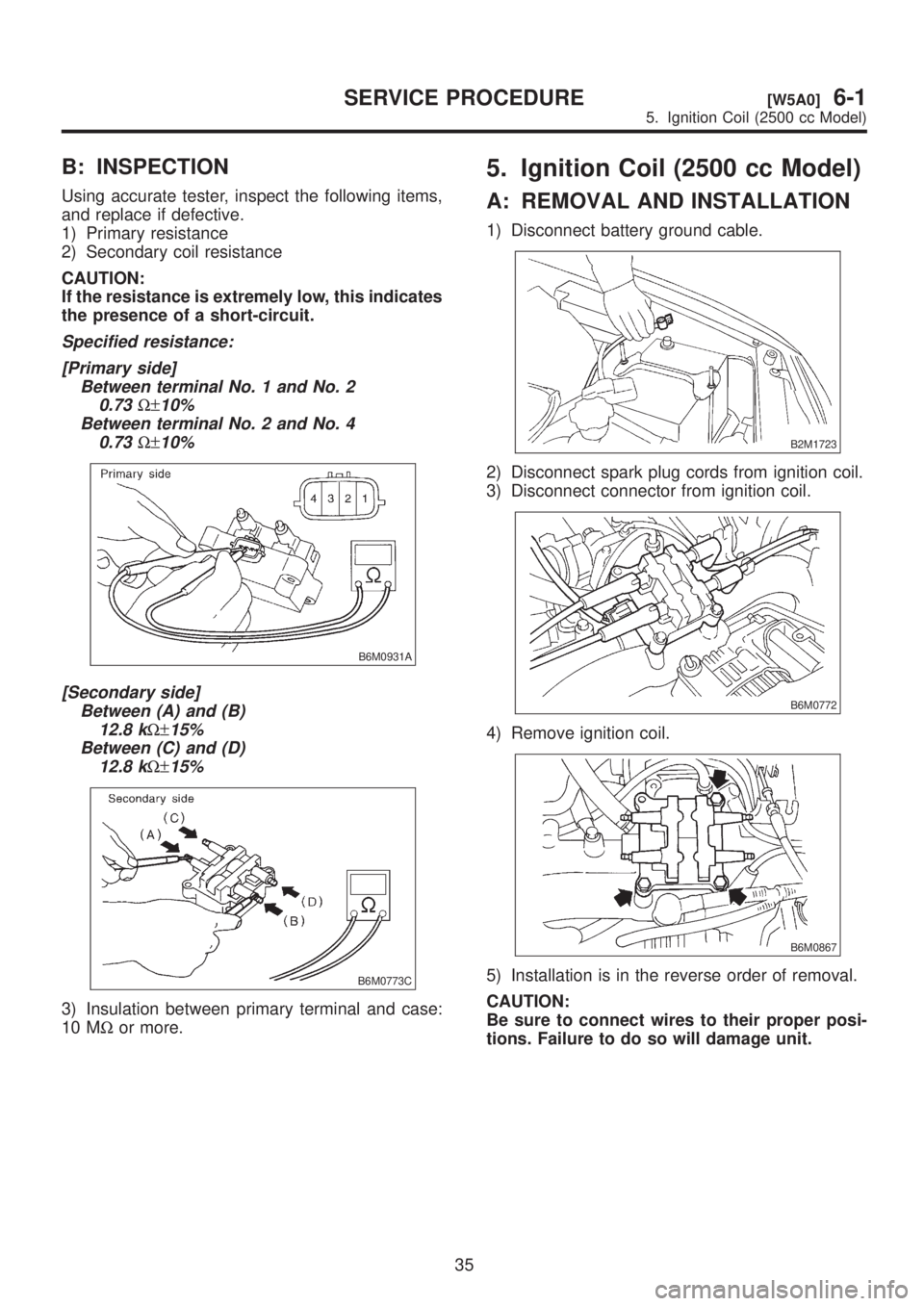

5. Ignition Coil (2500 cc Model)

A: REMOVAL AND INSTALLATION

1) Disconnect battery ground cable.

B2M1723

2) Disconnect spark plug cords from ignition coil.

3) Disconnect connector from ignition coil.

B6M0772

4) Remove ignition coil.

B6M0867

5) Installation is in the reverse order of removal.

CAUTION:

Be sure to connect wires to their proper posi-

tions. Failure to do so will damage unit.

35

[W5A0]6-1SERVICE PROCEDURE

5. Ignition Coil (2500 cc Model)

Page 1219 of 1456

B: INSPECTION

Using accurate tester, inspect the following items,

and replace if defective.

1) Primary resistance

2) Secondary coil resistance

CAUTION:

If the resistance is extremely low, this indicates

the presence of a short-circuit.

Specified resistance:

[Primary side]

Between terminal No. 1 and No. 2

0.73

W±10%

Between terminal No. 2 and No. 4

0.73

W±10%

B6M0931A

[Secondary side]

Between (A) and (B)

12.8 k

W±15%

Between (C) and (D)

12.8 k

W±15%

B6M0773C

3) Insulation between primary terminal and case:

10 MWor more.

5. Ignition Coil (2500 cc Model)

A: REMOVAL AND INSTALLATION

1) Disconnect battery ground cable.

B2M1723

2) Disconnect spark plug cords from ignition coil.

3) Disconnect connector from ignition coil.

B6M0772

4) Remove ignition coil.

B6M0867

5) Installation is in the reverse order of removal.

CAUTION:

Be sure to connect wires to their proper posi-

tions. Failure to do so will damage unit.

35

[W5A0]6-1SERVICE PROCEDURE

5. Ignition Coil (2500 cc Model)

Page 1220 of 1456

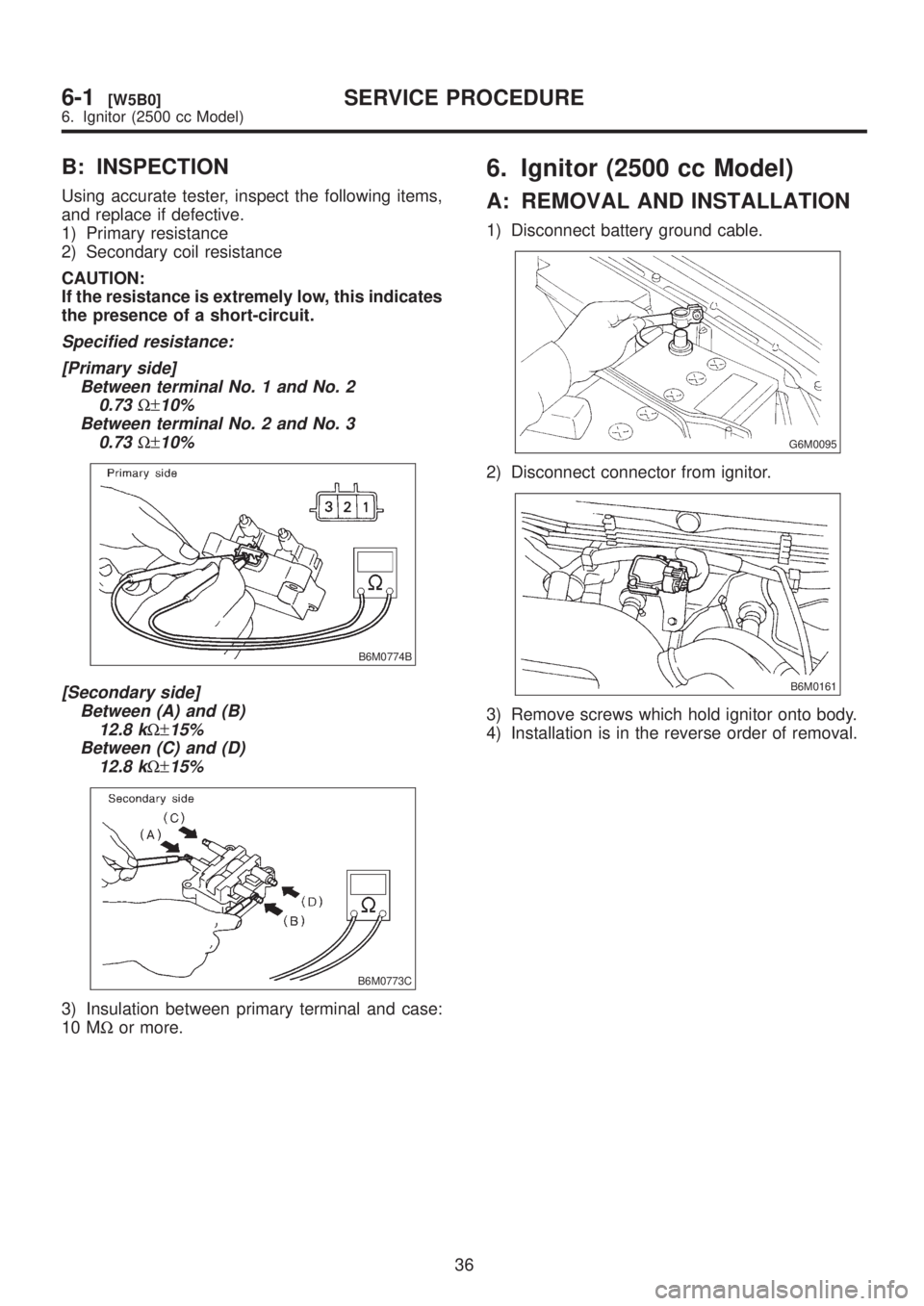

B: INSPECTION

Using accurate tester, inspect the following items,

and replace if defective.

1) Primary resistance

2) Secondary coil resistance

CAUTION:

If the resistance is extremely low, this indicates

the presence of a short-circuit.

Specified resistance:

[Primary side]

Between terminal No. 1 and No. 2

0.73

W±10%

Between terminal No. 2 and No. 3

0.73

W±10%

B6M0774B

[Secondary side]

Between (A) and (B)

12.8 k

W±15%

Between (C) and (D)

12.8 k

W±15%

B6M0773C

3) Insulation between primary terminal and case:

10 MWor more.

6. Ignitor (2500 cc Model)

A: REMOVAL AND INSTALLATION

1) Disconnect battery ground cable.

G6M0095

2) Disconnect connector from ignitor.

B6M0161

3) Remove screws which hold ignitor onto body.

4) Installation is in the reverse order of removal.

36

6-1[W5B0]SERVICE PROCEDURE

6. Ignitor (2500 cc Model)