SUBARU LEGACY 1999 Service Repair Manual

Manufacturer: SUBARU, Model Year: 1999, Model line: LEGACY, Model: SUBARU LEGACY 1999Pages: 1456, PDF Size: 59.93 MB

Page 1251 of 1456

5) Remove attaching screws and take out wiper

motor assembly.

CAUTION:

Be careful not to damage O-ring when remov-

ing wiper motor assembly.

B6M0114

6) Installation is in the reverse order of removal.

Tightening torque:

5.9

±1.5 N´m (0.6±0.15 kg-m, 4.3±1.1 ft-lb)

4. WASHER TANK AND WASHER MOTOR

Remove and install washer tank and washer

motor.

5. COMBINATION SWITCH

Remove and install combination switch.

C: DISASSEMBLY AND ASSEMBLY

1. COMBINATION SWITCH

Disassembly and assembly combination switch.

D: INSPECTION

1. COMBINATION SWITCH (ON-CAR)

1) Remove instrument panel lower cover.

2) Remove lower column cover.

3) Unfasten holddown clip which secures harness,

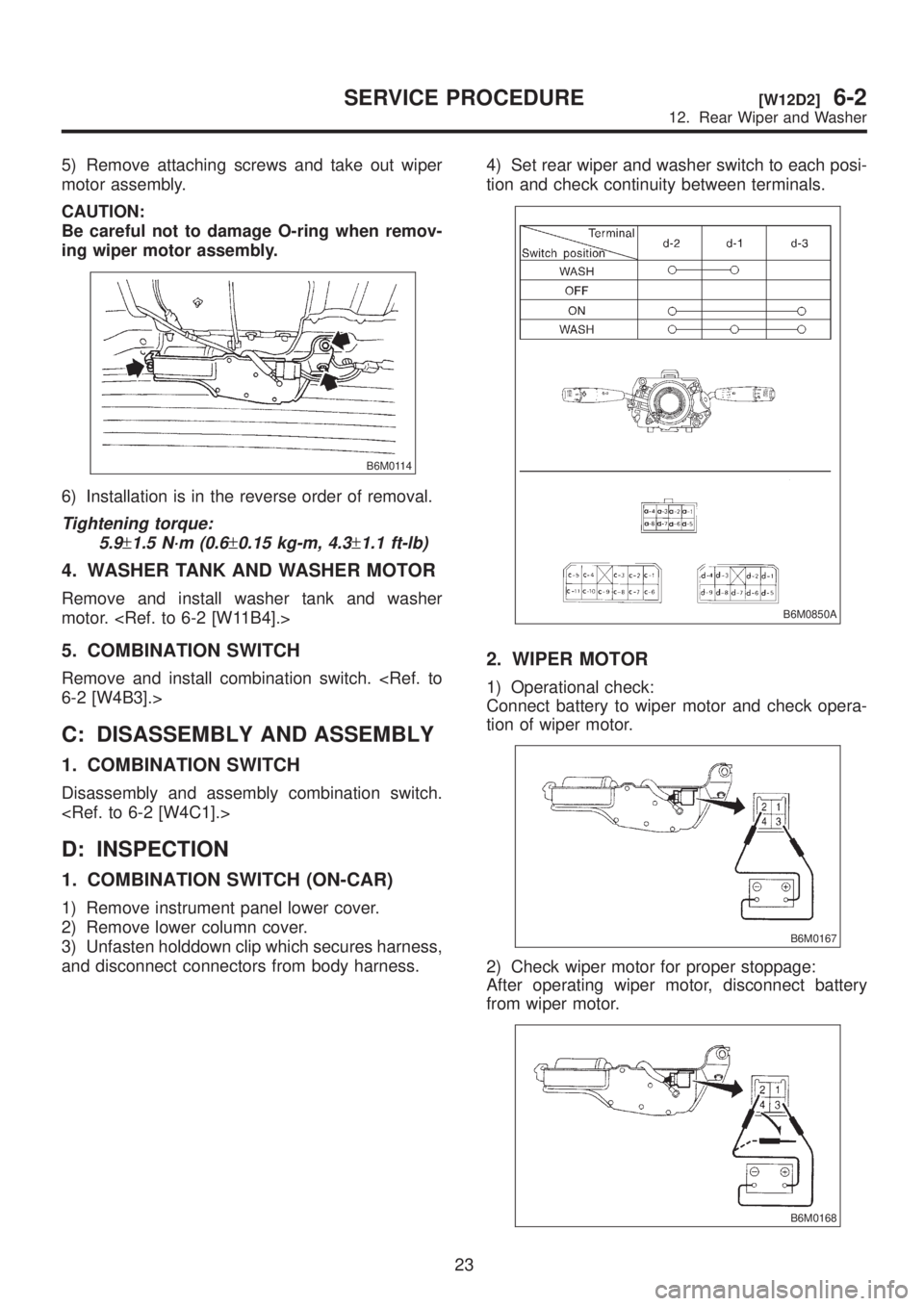

and disconnect connectors from body harness.4) Set rear wiper and washer switch to each posi-

tion and check continuity between terminals.

B6M0850A

2. WIPER MOTOR

1) Operational check:

Connect battery to wiper motor and check opera-

tion of wiper motor.

B6M0167

2) Check wiper motor for proper stoppage:

After operating wiper motor, disconnect battery

from wiper motor.

B6M0168

23

[W12D2]6-2SERVICE PROCEDURE

12. Rear Wiper and Washer

Page 1252 of 1456

3) Reconnect battery and ensure that wiper motor

stops at ªAUTO STOPº after it has been operated.

B6M0169

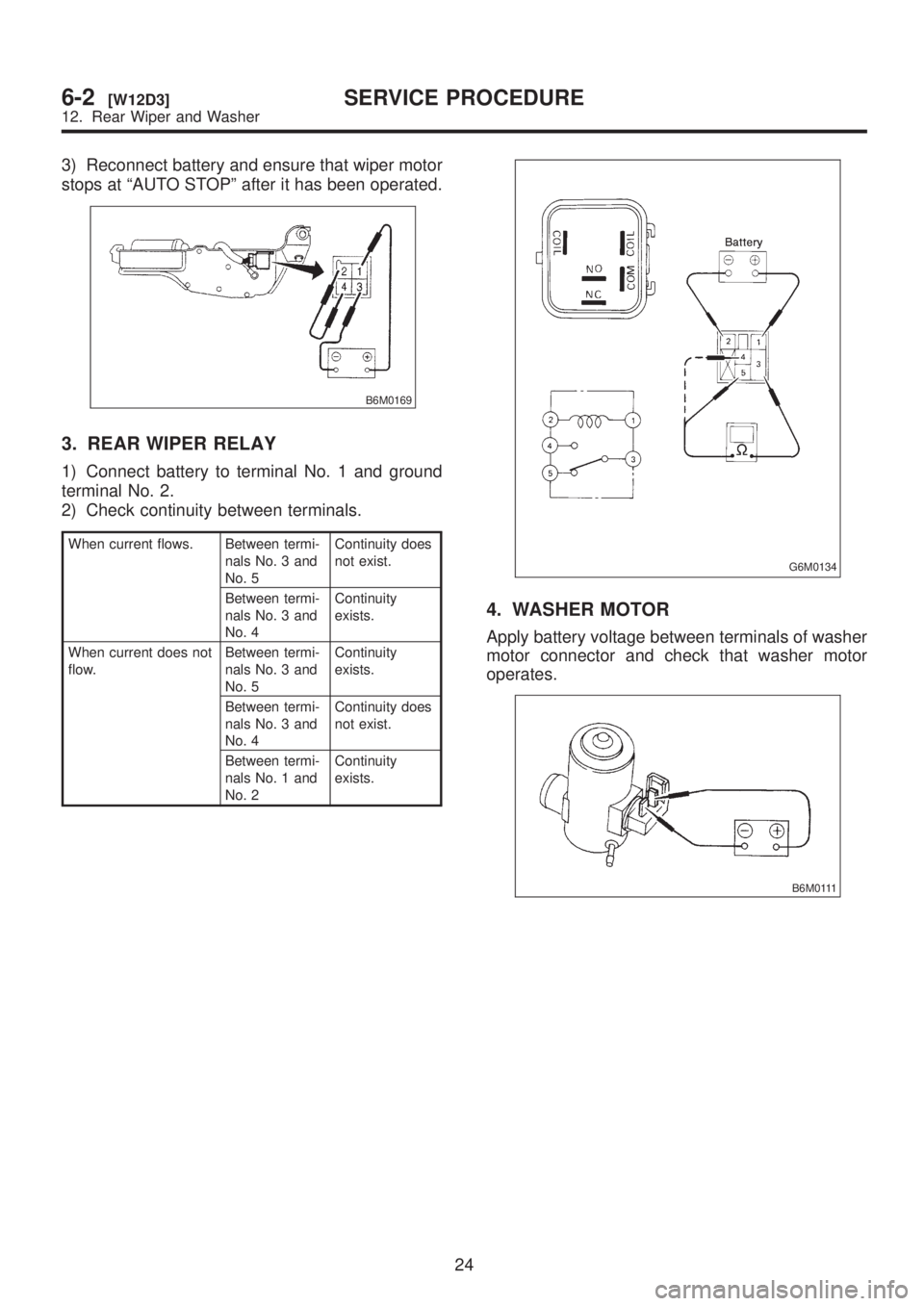

3. REAR WIPER RELAY

1) Connect battery to terminal No. 1 and ground

terminal No. 2.

2) Check continuity between terminals.

When current flows. Between termi-

nals No. 3 and

No. 5Continuity does

not exist.

Between termi-

nals No. 3 and

No. 4Continuity

exists.

When current does not

flow.Between termi-

nals No. 3 and

No. 5Continuity

exists.

Between termi-

nals No. 3 and

No. 4Continuity does

not exist.

Between termi-

nals No. 1 and

No. 2Continuity

exists.

G6M0134

4. WASHER MOTOR

Apply battery voltage between terminals of washer

motor connector and check that washer motor

operates.

B6M0111

24

6-2[W12D3]SERVICE PROCEDURE

12. Rear Wiper and Washer

Page 1253 of 1456

13. Rear Window Defogger

A: REMOVAL AND INSTALLATION

1. DEFOGGER SWITCH

1) Remove screws which secure meter visor.

2) Remove meter visor from instrument panel

while disconnecting connectors.

3) Remove rear window defogger switch from

meter visor.

4) Installation is in the reverse order of removal.

B: INSPECTION

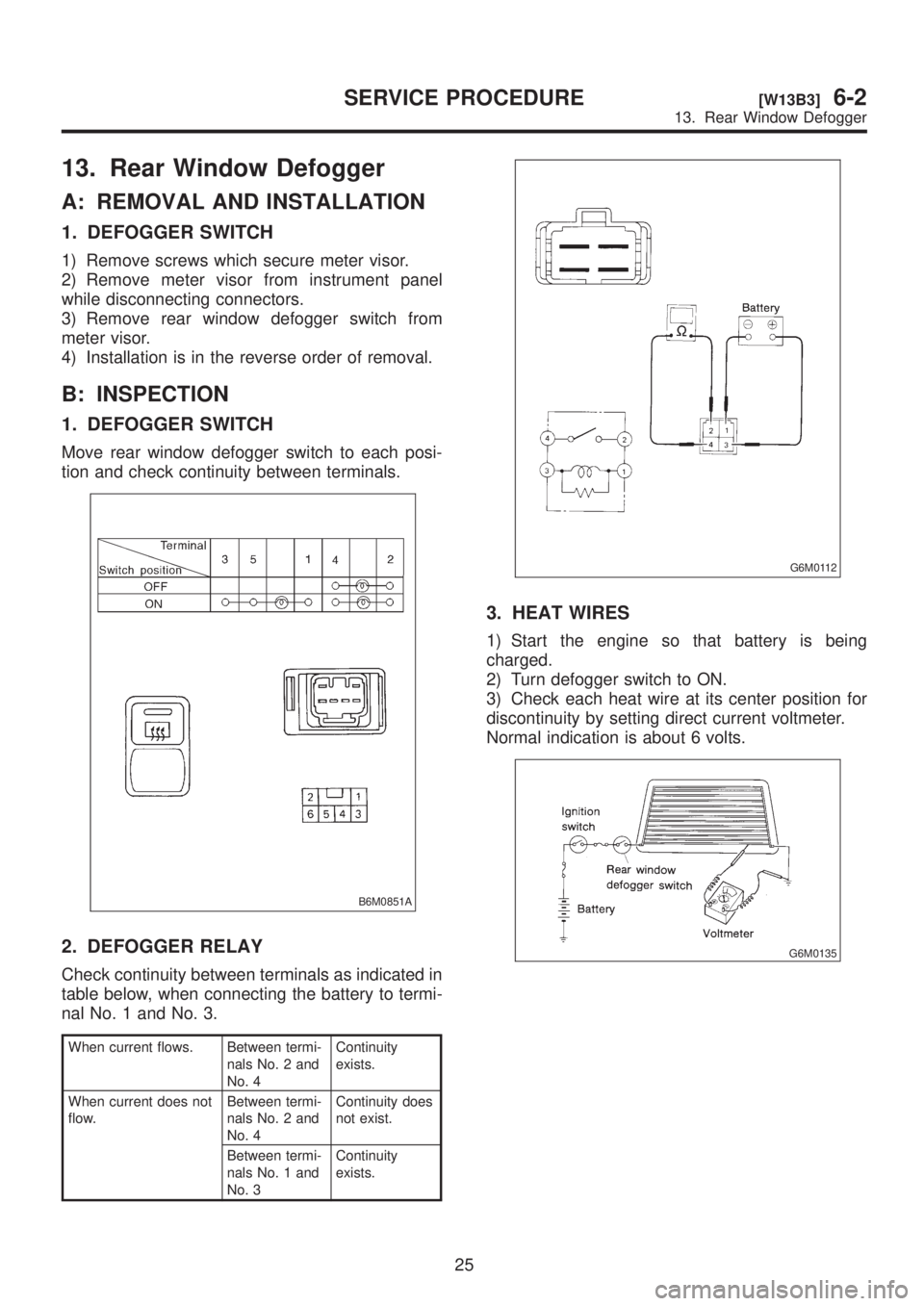

1. DEFOGGER SWITCH

Move rear window defogger switch to each posi-

tion and check continuity between terminals.

B6M0851A

2. DEFOGGER RELAY

Check continuity between terminals as indicated in

table below, when connecting the battery to termi-

nal No. 1 and No. 3.

When current flows. Between termi-

nals No. 2 and

No. 4Continuity

exists.

When current does not

flow.Between termi-

nals No. 2 and

No. 4Continuity does

not exist.

Between termi-

nals No. 1 and

No. 3Continuity

exists.

G6M0112

3. HEAT WIRES

1) Start the engine so that battery is being

charged.

2) Turn defogger switch to ON.

3) Check each heat wire at its center position for

discontinuity by setting direct current voltmeter.

Normal indication is about 6 volts.

G6M0135

25

[W13B3]6-2SERVICE PROCEDURE

13. Rear Window Defogger

Page 1254 of 1456

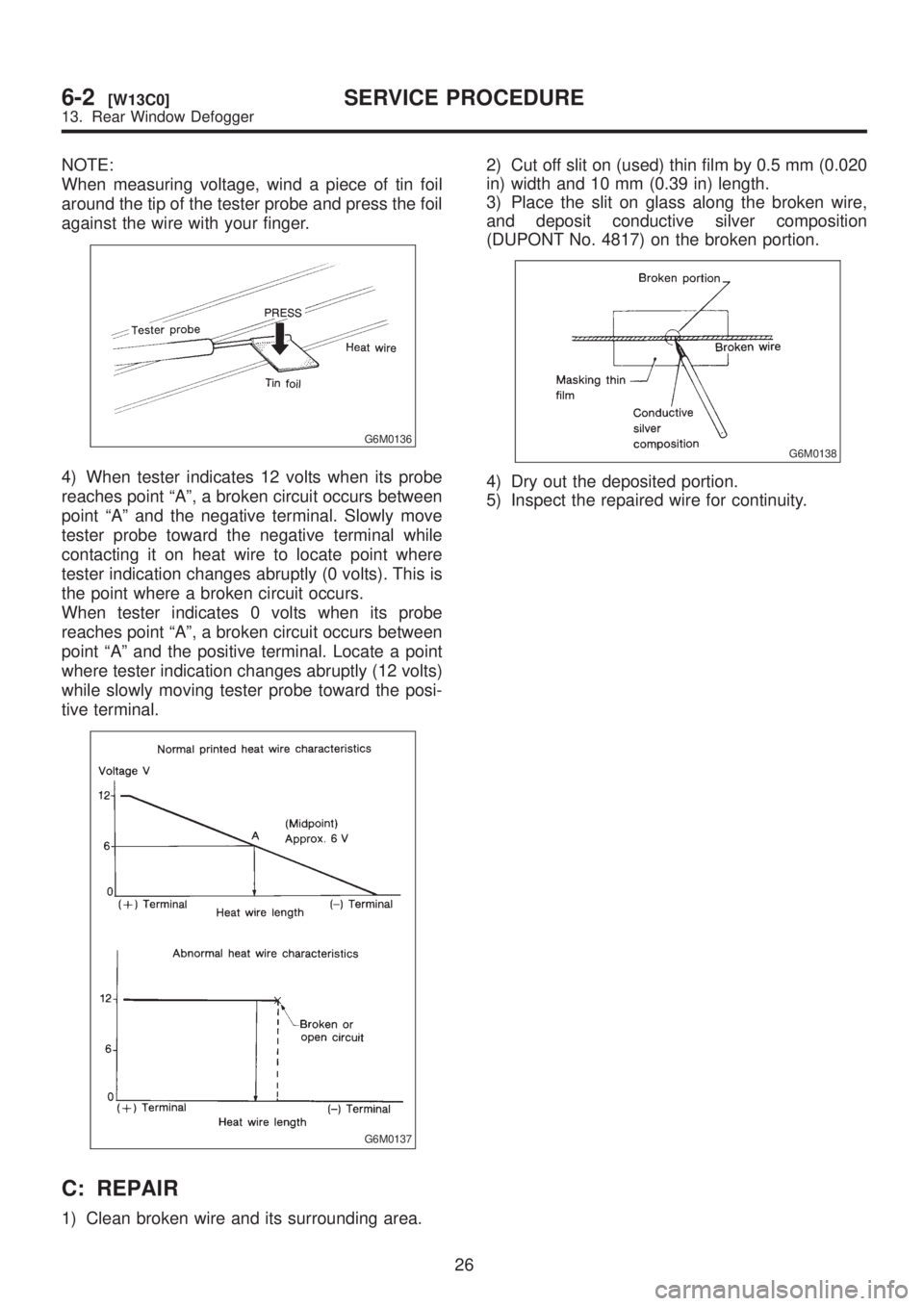

NOTE:

When measuring voltage, wind a piece of tin foil

around the tip of the tester probe and press the foil

against the wire with your finger.

G6M0136

4) When tester indicates 12 volts when its probe

reaches point ªAº, a broken circuit occurs between

point ªAº and the negative terminal. Slowly move

tester probe toward the negative terminal while

contacting it on heat wire to locate point where

tester indication changes abruptly (0 volts). This is

the point where a broken circuit occurs.

When tester indicates 0 volts when its probe

reaches point ªAº, a broken circuit occurs between

point ªAº and the positive terminal. Locate a point

where tester indication changes abruptly (12 volts)

while slowly moving tester probe toward the posi-

tive terminal.

G6M0137

C: REPAIR

1) Clean broken wire and its surrounding area.2) Cut off slit on (used) thin film by 0.5 mm (0.020

in) width and 10 mm (0.39 in) length.

3) Place the slit on glass along the broken wire,

and deposit conductive silver composition

(DUPONT No. 4817) on the broken portion.

G6M0138

4) Dry out the deposited portion.

5) Inspect the repaired wire for continuity.

26

6-2[W13C0]SERVICE PROCEDURE

13. Rear Window Defogger

Page 1255 of 1456

14. Combination Meter

A: REMOVAL AND INSTALLATION

1. COMBINATION METER

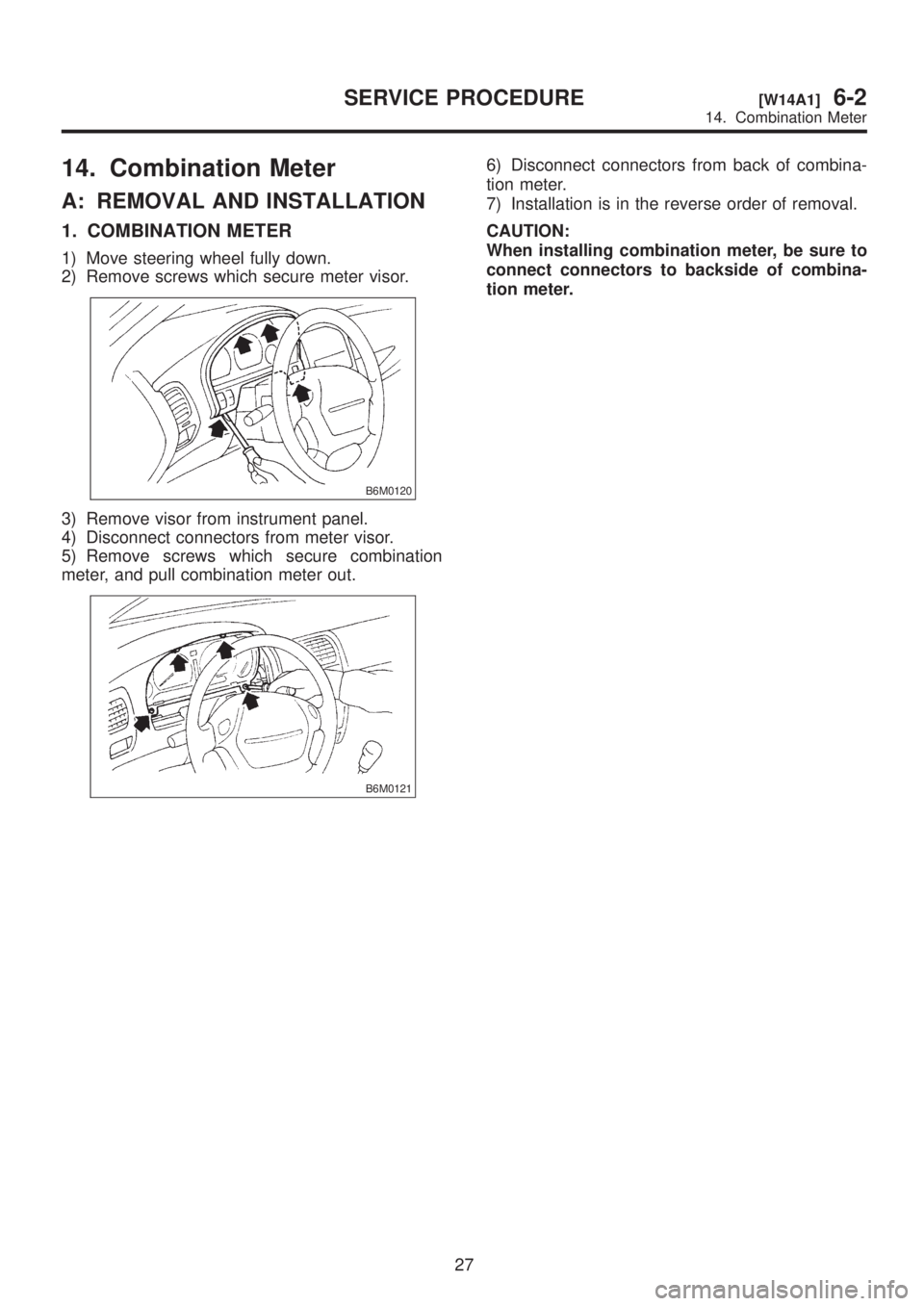

1) Move steering wheel fully down.

2) Remove screws which secure meter visor.

B6M0120

3) Remove visor from instrument panel.

4) Disconnect connectors from meter visor.

5) Remove screws which secure combination

meter, and pull combination meter out.

B6M0121

6) Disconnect connectors from back of combina-

tion meter.

7) Installation is in the reverse order of removal.

CAUTION:

When installing combination meter, be sure to

connect connectors to backside of combina-

tion meter.

27

[W14A1]6-2SERVICE PROCEDURE

14. Combination Meter

Page 1256 of 1456

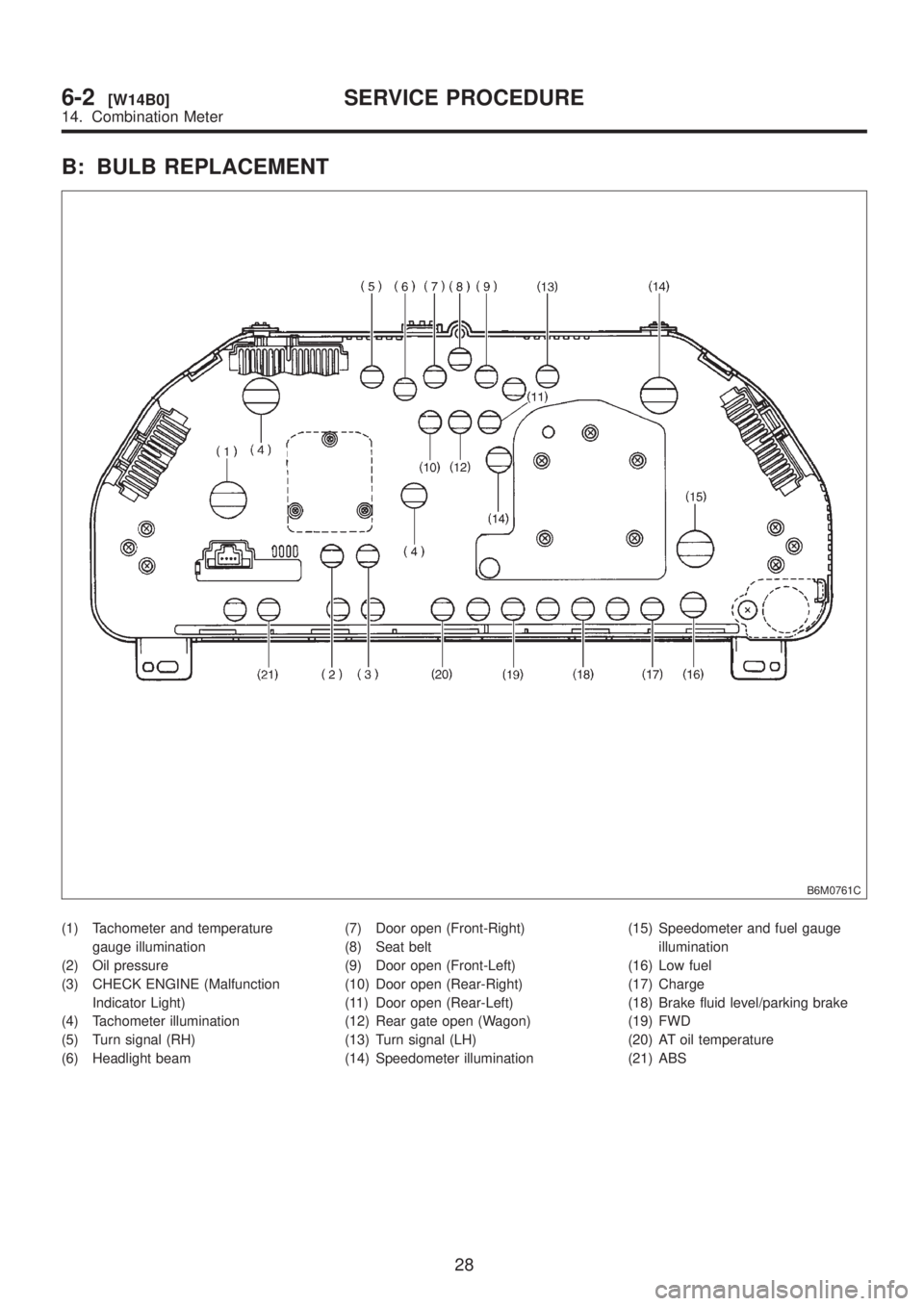

B: BULB REPLACEMENT

B6M0761C

(1) Tachometer and temperature

gauge illumination

(2) Oil pressure

(3) CHECK ENGINE (Malfunction

Indicator Light)

(4) Tachometer illumination

(5) Turn signal (RH)

(6) Headlight beam(7) Door open (Front-Right)

(8) Seat belt

(9) Door open (Front-Left)

(10) Door open (Rear-Right)

(11) Door open (Rear-Left)

(12) Rear gate open (Wagon)

(13) Turn signal (LH)

(14) Speedometer illumination(15) Speedometer and fuel gauge

illumination

(16) Low fuel

(17) Charge

(18) Brake fluid level/parking brake

(19) FWD

(20) AT oil temperature

(21) ABS

28

6-2[W14B0]SERVICE PROCEDURE

14. Combination Meter

Page 1257 of 1456

15. Vehicle Speed Sensor 2

A: GENERAL PRECAUTIONS

(1) Be careful not to drop or bump sensor as this

may break built-in magnet.

(2) Drive key is designed to separate from vehicle

speed sensor 2. Be careful not to lose it or forget

to install.

(3) Vehicle speed sensor 2 is installed in part

(which contains bearings, etc., finished to a high

degree of accuracy). Do not allow foreign matter

(filings, sand, etc.) to get into it.

(4) When checking output of vehicle speed sensor

2 as a single unit, ensure test leads are connected

to their correct terminals. Failure to do this may

damage internal IC.

(5) Discard vehicle speed sensor 2 after removal;

replace with new one.

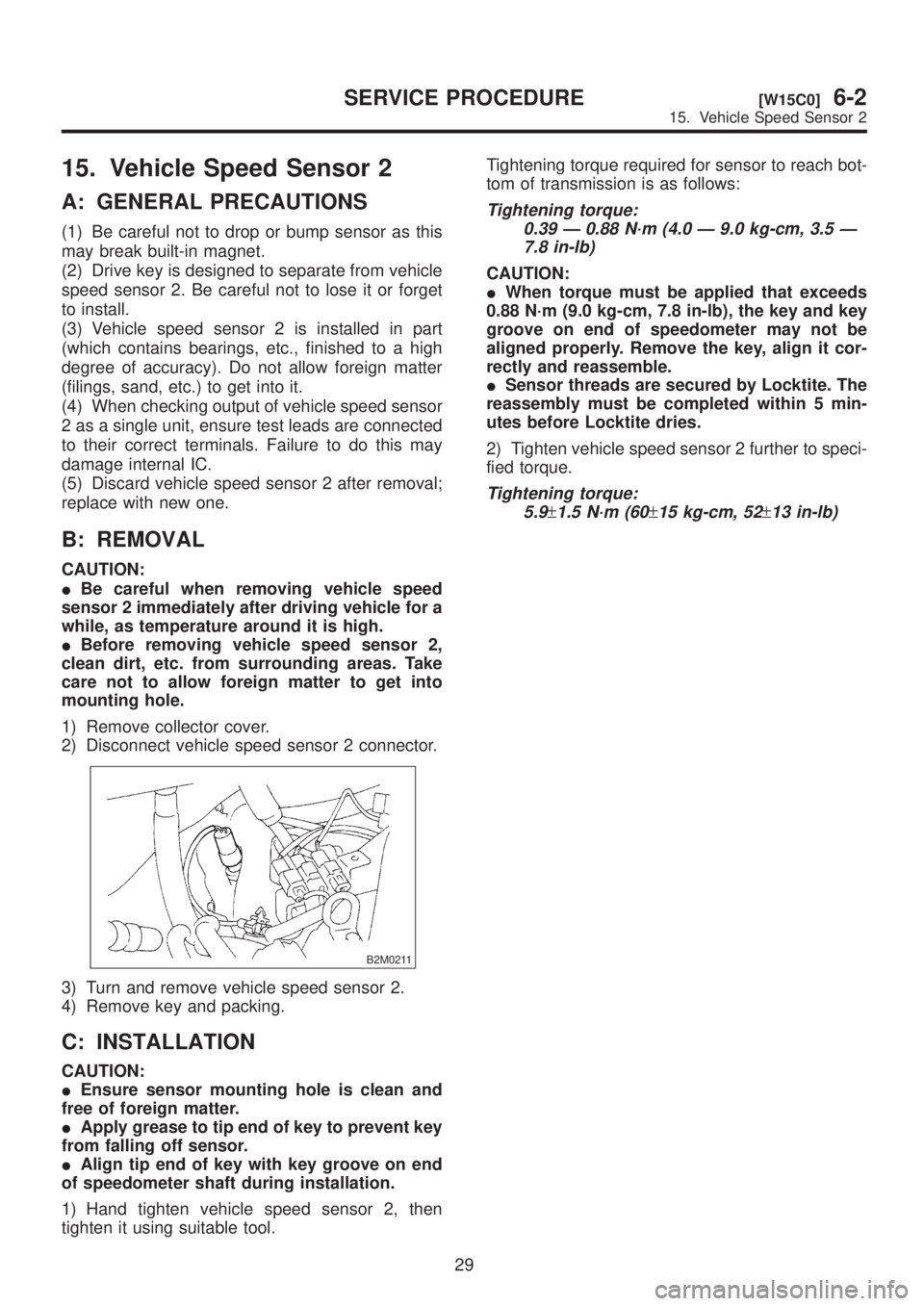

B: REMOVAL

CAUTION:

IBe careful when removing vehicle speed

sensor 2 immediately after driving vehicle for a

while, as temperature around it is high.

IBefore removing vehicle speed sensor 2,

clean dirt, etc. from surrounding areas. Take

care not to allow foreign matter to get into

mounting hole.

1) Remove collector cover.

2) Disconnect vehicle speed sensor 2 connector.

B2M0211

3) Turn and remove vehicle speed sensor 2.

4) Remove key and packing.

C: INSTALLATION

CAUTION:

IEnsure sensor mounting hole is clean and

free of foreign matter.

IApply grease to tip end of key to prevent key

from falling off sensor.

IAlign tip end of key with key groove on end

of speedometer shaft during installation.

1) Hand tighten vehicle speed sensor 2, then

tighten it using suitable tool.Tightening torque required for sensor to reach bot-

tom of transmission is as follows:

Tightening torque:

0.39 Ð 0.88 N´m (4.0 Ð 9.0 kg-cm, 3.5 Ð

7.8 in-lb)

CAUTION:

IWhen torque must be applied that exceeds

0.88 N´m (9.0 kg-cm, 7.8 in-lb), the key and key

groove on end of speedometer may not be

aligned properly. Remove the key, align it cor-

rectly and reassemble.

ISensor threads are secured by Locktite. The

reassembly must be completed within 5 min-

utes before Locktite dries.

2) Tighten vehicle speed sensor 2 further to speci-

fied torque.

Tightening torque:

5.9

±1.5 N´m (60±15 kg-cm, 52±13 in-lb)

29

[W15C0]6-2SERVICE PROCEDURE

15. Vehicle Speed Sensor 2

Page 1258 of 1456

16. Horn and Cigarette Lighter

A: REMOVAL AND INSTALLATION

1. HORN

1) Open the engine hood.

2) Disconnect connector of horn.

3) Remove the horn.

4) Installation is in the reverse order of removal.

Tightening torque:

18

±5 N´m (1.8±0.5 kg-m, 13.0±3.6 ft-lb)

CAUTION:

After installing horn, connect connector, fit

firmly wiring harness to prevent from discon-

necting due to vibration.

B6M0349

2. HORN SWITCH (HORN PAD)

1) Remove screw which secures horn switch

(steering pad) to the base of steering wheel.

B6M0124

2) Remove horn switch (steering pad) from steer-

ing wheel while disconnecting connector.

3) Installation is in the reverse order of removal.

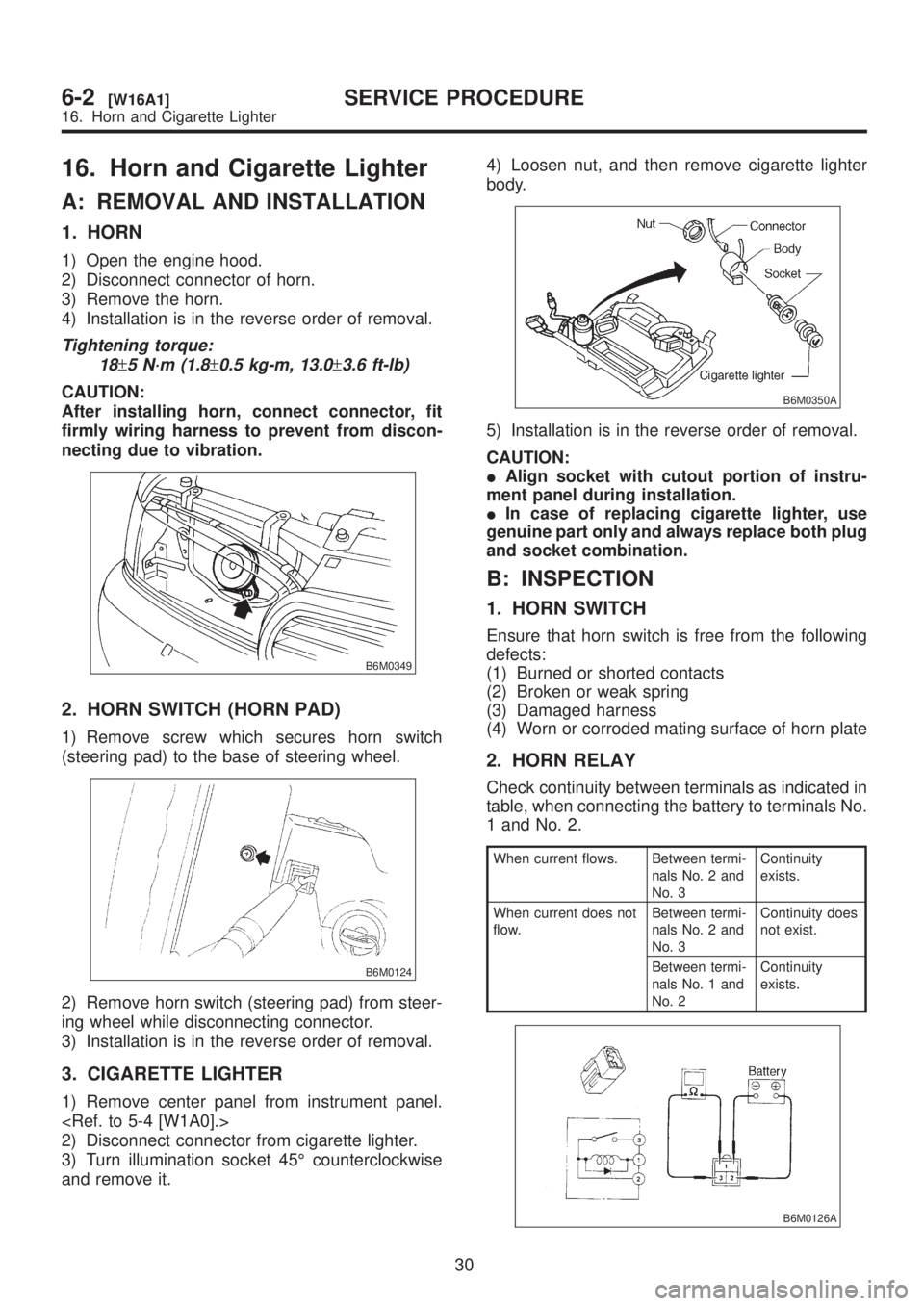

3. CIGARETTE LIGHTER

1) Remove center panel from instrument panel.

2) Disconnect connector from cigarette lighter.

3) Turn illumination socket 45É counterclockwise

and remove it.4) Loosen nut, and then remove cigarette lighter

body.

B6M0350A

5) Installation is in the reverse order of removal.

CAUTION:

IAlign socket with cutout portion of instru-

ment panel during installation.

IIn case of replacing cigarette lighter, use

genuine part only and always replace both plug

and socket combination.

B: INSPECTION

1. HORN SWITCH

Ensure that horn switch is free from the following

defects:

(1) Burned or shorted contacts

(2) Broken or weak spring

(3) Damaged harness

(4) Worn or corroded mating surface of horn plate

2. HORN RELAY

Check continuity between terminals as indicated in

table, when connecting the battery to terminals No.

1 and No. 2.

When current flows. Between termi-

nals No. 2 and

No. 3Continuity

exists.

When current does not

flow.Between termi-

nals No. 2 and

No. 3Continuity does

not exist.

Between termi-

nals No. 1 and

No. 2Continuity

exists.

B6M0126A

30

6-2[W16A1]SERVICE PROCEDURE

16. Horn and Cigarette Lighter

Page 1259 of 1456

3. HORN

Make sure that horn sounds when battery voltage

is applied between connector terminal and horn

body.

B6M0127

4. CIGARETTE LIGHTER

1) Remove plug. Then, check element's contact

for wear, and element for accumulation of ashes,

foreign particles, etc.

2) Check element for discontinuity.

3) Remove socket and clean element. Then,

check for wear or foreign particles on element's

contact and mating surface.

4) Ensure that cigarette lighter returns within 20

seconds after it is turned to ON.

17. Power Window

A: REMOVAL AND INSTALLATION

1. MAIN SWITCH, SUB SWITCH AND

POWER WINDOW MOTOR

Remove and install power window main switch,

sub switch and motor.

NOTE:

To remove the power window motor, it is necessary

to disassemble the door component parts.

B: INSPECTION

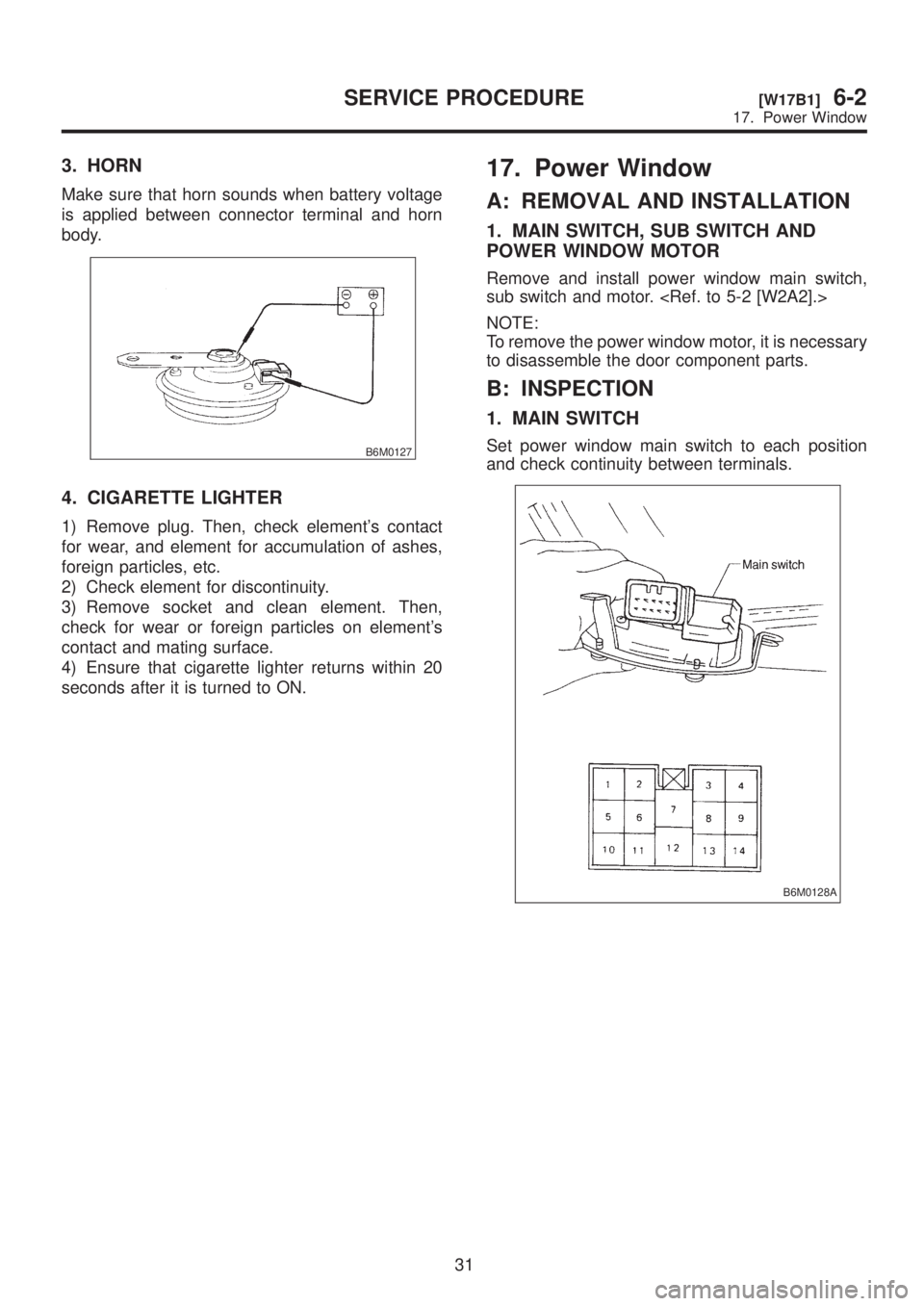

1. MAIN SWITCH

Set power window main switch to each position

and check continuity between terminals.

B6M0128A

31

[W17B1]6-2SERVICE PROCEDURE

17. Power Window

Page 1260 of 1456

3. HORN

Make sure that horn sounds when battery voltage

is applied between connector terminal and horn

body.

B6M0127

4. CIGARETTE LIGHTER

1) Remove plug. Then, check element's contact

for wear, and element for accumulation of ashes,

foreign particles, etc.

2) Check element for discontinuity.

3) Remove socket and clean element. Then,

check for wear or foreign particles on element's

contact and mating surface.

4) Ensure that cigarette lighter returns within 20

seconds after it is turned to ON.

17. Power Window

A: REMOVAL AND INSTALLATION

1. MAIN SWITCH, SUB SWITCH AND

POWER WINDOW MOTOR

Remove and install power window main switch,

sub switch and motor.

NOTE:

To remove the power window motor, it is necessary

to disassemble the door component parts.

B: INSPECTION

1. MAIN SWITCH

Set power window main switch to each position

and check continuity between terminals.

B6M0128A

31

[W17B1]6-2SERVICE PROCEDURE

17. Power Window