SUBARU LEGACY 1999 Service Repair Manual

Manufacturer: SUBARU, Model Year: 1999, Model line: LEGACY, Model: SUBARU LEGACY 1999Pages: 1456, PDF Size: 59.93 MB

Page 1221 of 1456

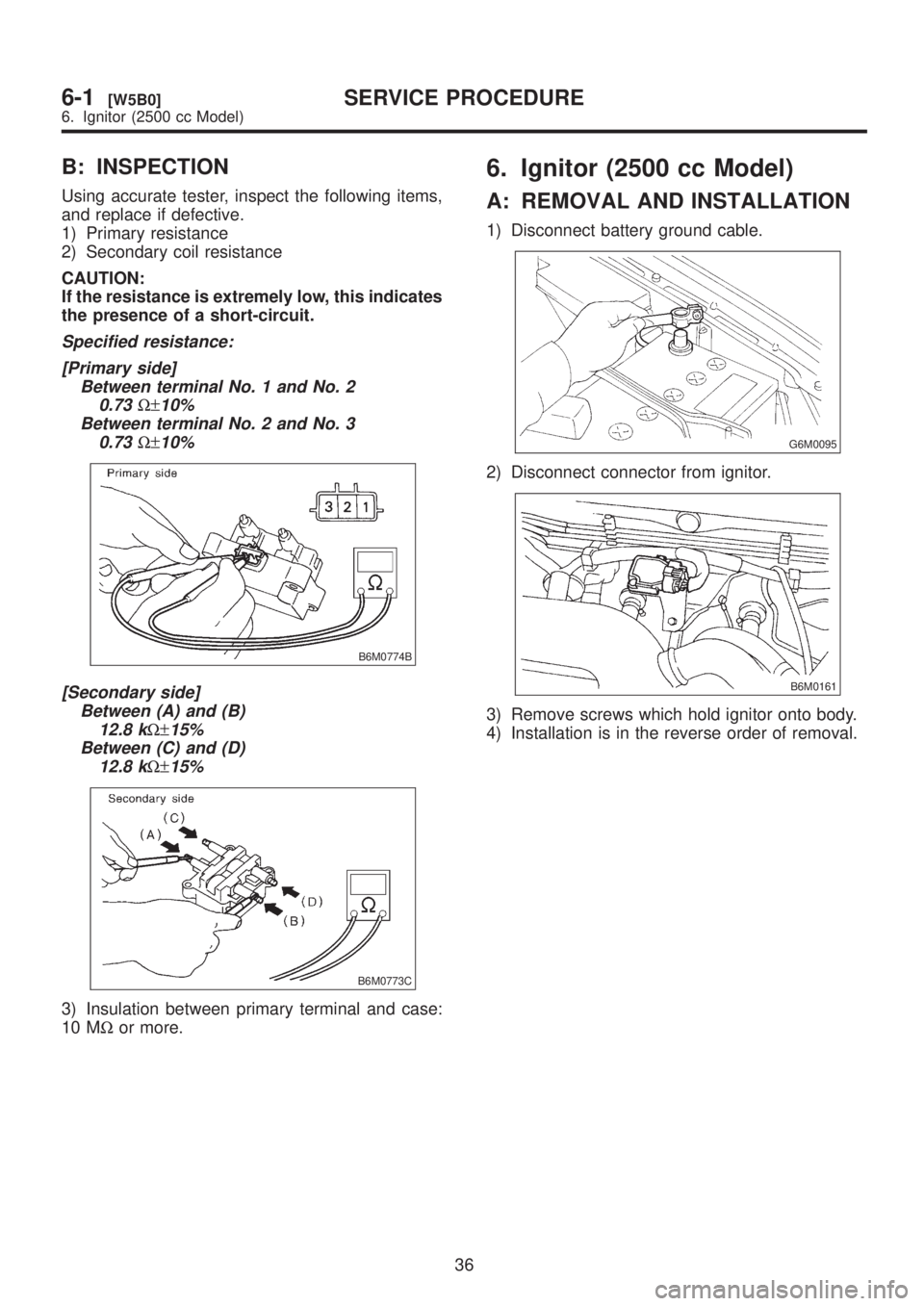

B: INSPECTION

Using accurate tester, inspect the following items,

and replace if defective.

1) Primary resistance

2) Secondary coil resistance

CAUTION:

If the resistance is extremely low, this indicates

the presence of a short-circuit.

Specified resistance:

[Primary side]

Between terminal No. 1 and No. 2

0.73

W±10%

Between terminal No. 2 and No. 3

0.73

W±10%

B6M0774B

[Secondary side]

Between (A) and (B)

12.8 k

W±15%

Between (C) and (D)

12.8 k

W±15%

B6M0773C

3) Insulation between primary terminal and case:

10 MWor more.

6. Ignitor (2500 cc Model)

A: REMOVAL AND INSTALLATION

1) Disconnect battery ground cable.

G6M0095

2) Disconnect connector from ignitor.

B6M0161

3) Remove screws which hold ignitor onto body.

4) Installation is in the reverse order of removal.

36

6-1[W5B0]SERVICE PROCEDURE

6. Ignitor (2500 cc Model)

Page 1222 of 1456

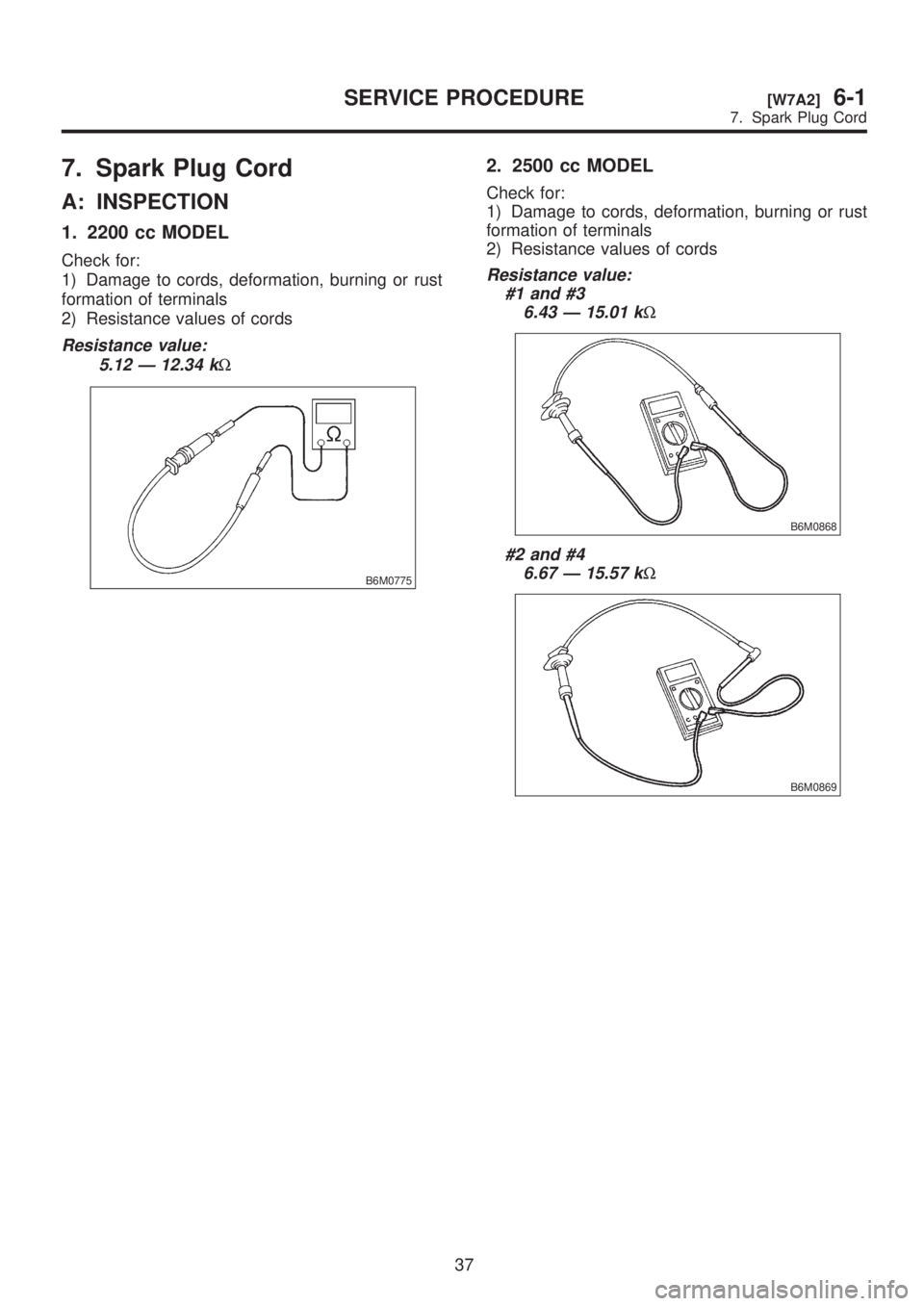

7. Spark Plug Cord

A: INSPECTION

1. 2200 cc MODEL

Check for:

1) Damage to cords, deformation, burning or rust

formation of terminals

2) Resistance values of cords

Resistance value:

5.12 Ð 12.34 k

W

B6M0775

2. 2500 cc MODEL

Check for:

1) Damage to cords, deformation, burning or rust

formation of terminals

2) Resistance values of cords

Resistance value:

#1 and #3

6.43 Ð 15.01 k

W

B6M0868

#2 and #4

6.67 Ð 15.57 k

W

B6M0869

37

[W7A2]6-1SERVICE PROCEDURE

7. Spark Plug Cord

Page 1223 of 1456

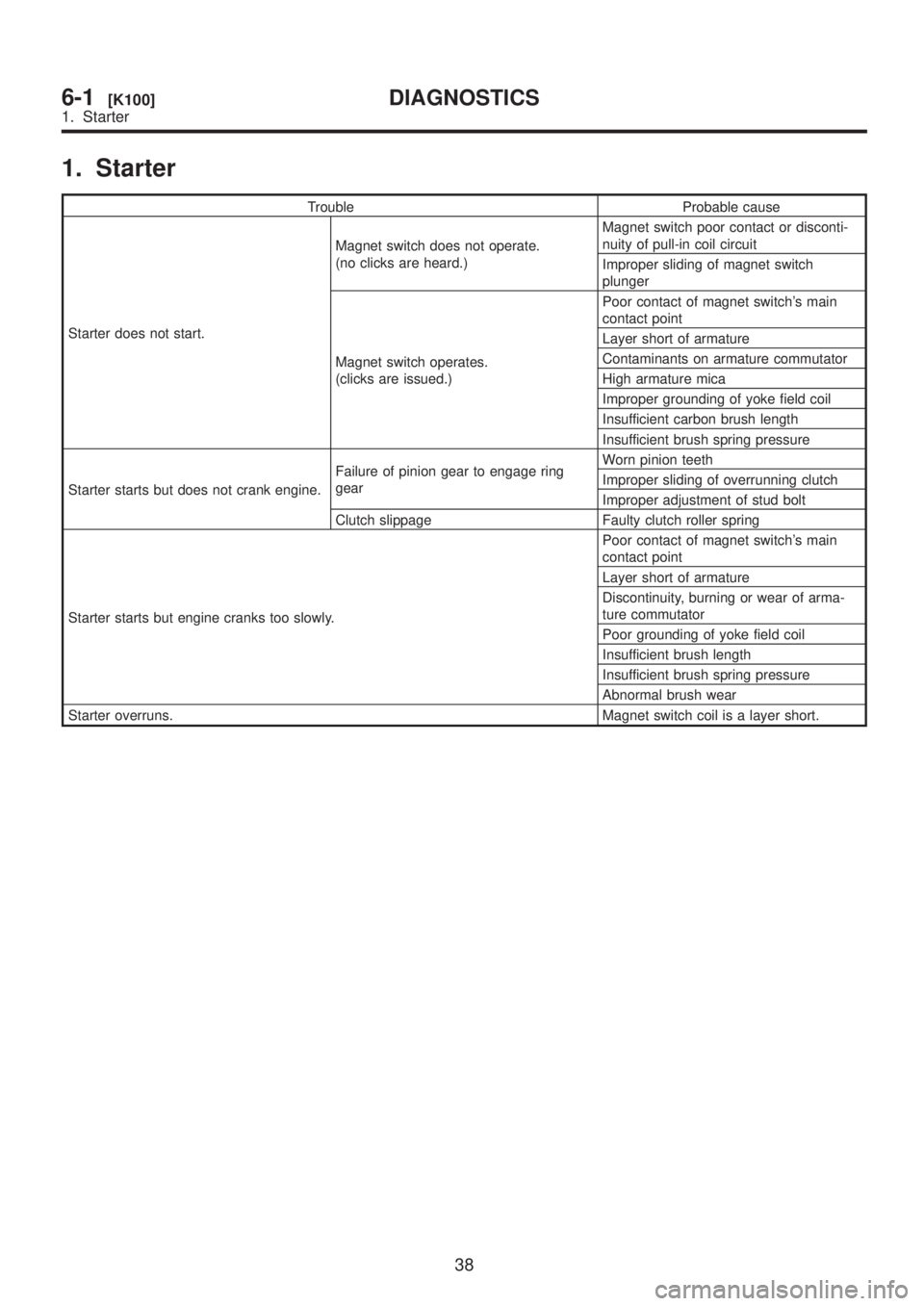

1. Starter

Trouble Probable cause

Starter does not start.Magnet switch does not operate.

(no clicks are heard.)Magnet switch poor contact or disconti-

nuity of pull-in coil circuit

Improper sliding of magnet switch

plunger

Magnet switch operates.

(clicks are issued.)Poor contact of magnet switch's main

contact point

Layer short of armature

Contaminants on armature commutator

High armature mica

Improper grounding of yoke field coil

Insufficient carbon brush length

Insufficient brush spring pressure

Starter starts but does not crank engine.Failure of pinion gear to engage ring

gearWorn pinion teeth

Improper sliding of overrunning clutch

Improper adjustment of stud bolt

Clutch slippage Faulty clutch roller spring

Starter starts but engine cranks too slowly.Poor contact of magnet switch's main

contact point

Layer short of armature

Discontinuity, burning or wear of arma-

ture commutator

Poor grounding of yoke field coil

Insufficient brush length

Insufficient brush spring pressure

Abnormal brush wear

Starter overruns. Magnet switch coil is a layer short.

38

6-1[K100]DIAGNOSTICS

1. Starter

Page 1224 of 1456

![SUBARU LEGACY 1999 Service Repair Manual 2. Generator

B6M0771

39

[K200]6-1DIAGNOSTICS

2. Generator SUBARU LEGACY 1999 Service Repair Manual 2. Generator

B6M0771

39

[K200]6-1DIAGNOSTICS

2. Generator](/img/17/57435/w960_57435-1223.png)

2. Generator

B6M0771

39

[K200]6-1DIAGNOSTICS

2. Generator

Page 1225 of 1456

MEMO:

40

6-1DIAGNOSTICS

Page 1226 of 1456

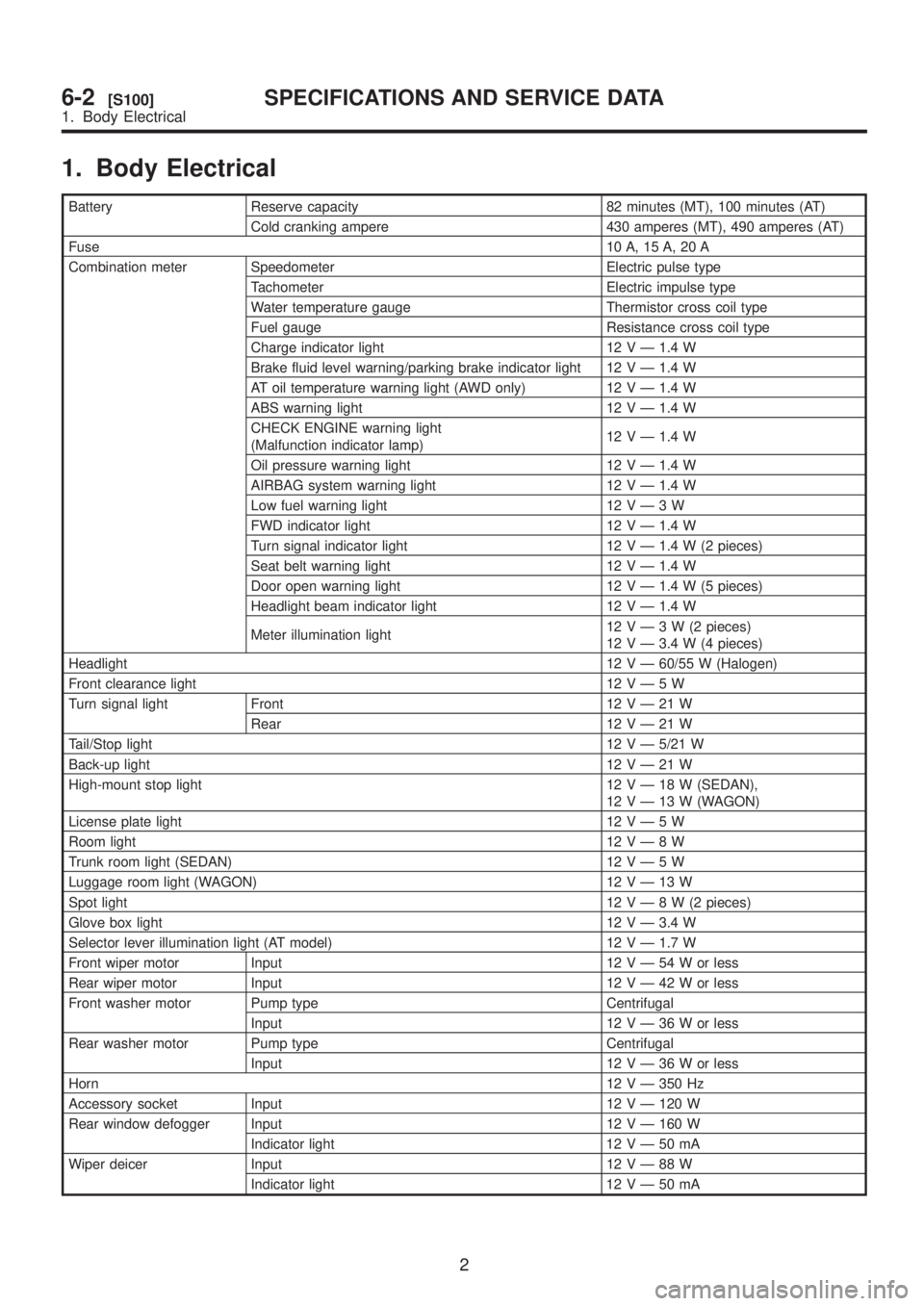

1. Body Electrical

Battery Reserve capacity 82 minutes (MT), 100 minutes (AT)

Cold cranking ampere 430 amperes (MT), 490 amperes (AT)

Fuse10 A, 15 A, 20 A

Combination meter Speedometer Electric pulse type

Tachometer Electric impulse type

Water temperature gauge Thermistor cross coil type

Fuel gauge Resistance cross coil type

Charge indicator light 12 V Ð 1.4 W

Brake fluid level warning/parking brake indicator light 12 V Ð 1.4 W

AT oil temperature warning light (AWD only) 12 V Ð 1.4 W

ABS warning light 12 V Ð 1.4 W

CHECK ENGINE warning light

(Malfunction indicator lamp)12 V Ð 1.4 W

Oil pressure warning light 12 V Ð 1.4 W

AIRBAG system warning light 12 V Ð 1.4 W

Low fuel warning light 12VÐ3W

FWD indicator light 12 V Ð 1.4 W

Turn signal indicator light 12 V Ð 1.4 W (2 pieces)

Seat belt warning light 12 V Ð 1.4 W

Door open warning light 12 V Ð 1.4 W (5 pieces)

Headlight beam indicator light 12 V Ð 1.4 W

Meter illumination light12VÐ3W(2pieces)

12 V Ð 3.4 W (4 pieces)

Headlight12 V Ð 60/55 W (Halogen)

Front clearance light 12VÐ5W

Turn signal light Front 12VÐ21W

Rear 12VÐ21W

Tail/Stop light12 V Ð 5/21 W

Back-up light12VÐ21W

High-mount stop light 12VÐ18W(SEDAN),

12VÐ13W(WAGON)

License plate light 12VÐ5W

Room light12VÐ8W

Trunk room light (SEDAN) 12VÐ5W

Luggage room light (WAGON) 12VÐ13W

Spot light12VÐ8W(2pieces)

Glove box light 12 V Ð 3.4 W

Selector lever illumination light (AT model) 12 V Ð 1.7 W

Front wiper motor Input 12VÐ54Worless

Rear wiper motor Input 12VÐ42Worless

Front washer motor Pump type Centrifugal

Input 12VÐ36Worless

Rear washer motor Pump type Centrifugal

Input 12VÐ36Worless

Horn12 V Ð 350 Hz

Accessory socket Input 12 V Ð 120 W

Rear window defogger Input 12 V Ð 160 W

Indicator light 12VÐ50mA

Wiper deicer Input 12VÐ88W

Indicator light 12VÐ50mA

2

6-2[S100]SPECIFICATIONS AND SERVICE DATA

1. Body Electrical

Page 1227 of 1456

1. Precaution

IBefore disassembling or reassembling parts,

always disconnect battery ground cable. When

repairing radio, control modules, etc. which are

provided with memory functions, record

memory contents before disconnecting battery

ground cable. Otherwise, these contents are

cancelled upon disconnection.

IReassemble parts in reverse order of disas-

sembly procedure unless otherwise indicated.

IAdjust parts to specifications contained in

this manual if so designated.

IConnect connectors and hoses securely dur-

ing reassembly.

IAfter reassembly, ensure functional parts

operate smoothly.

CAUTION:

IAirbag system wiring harness is routed near

the electrical parts and switch.

IAll Airbag system wiring harness and con-

nectors are colored yellow. Do not use electri-

cal test equipment on these circuits.

IBe careful not to damage Airbag system wir-

ing harness when servicing the ignition key

cylinder.

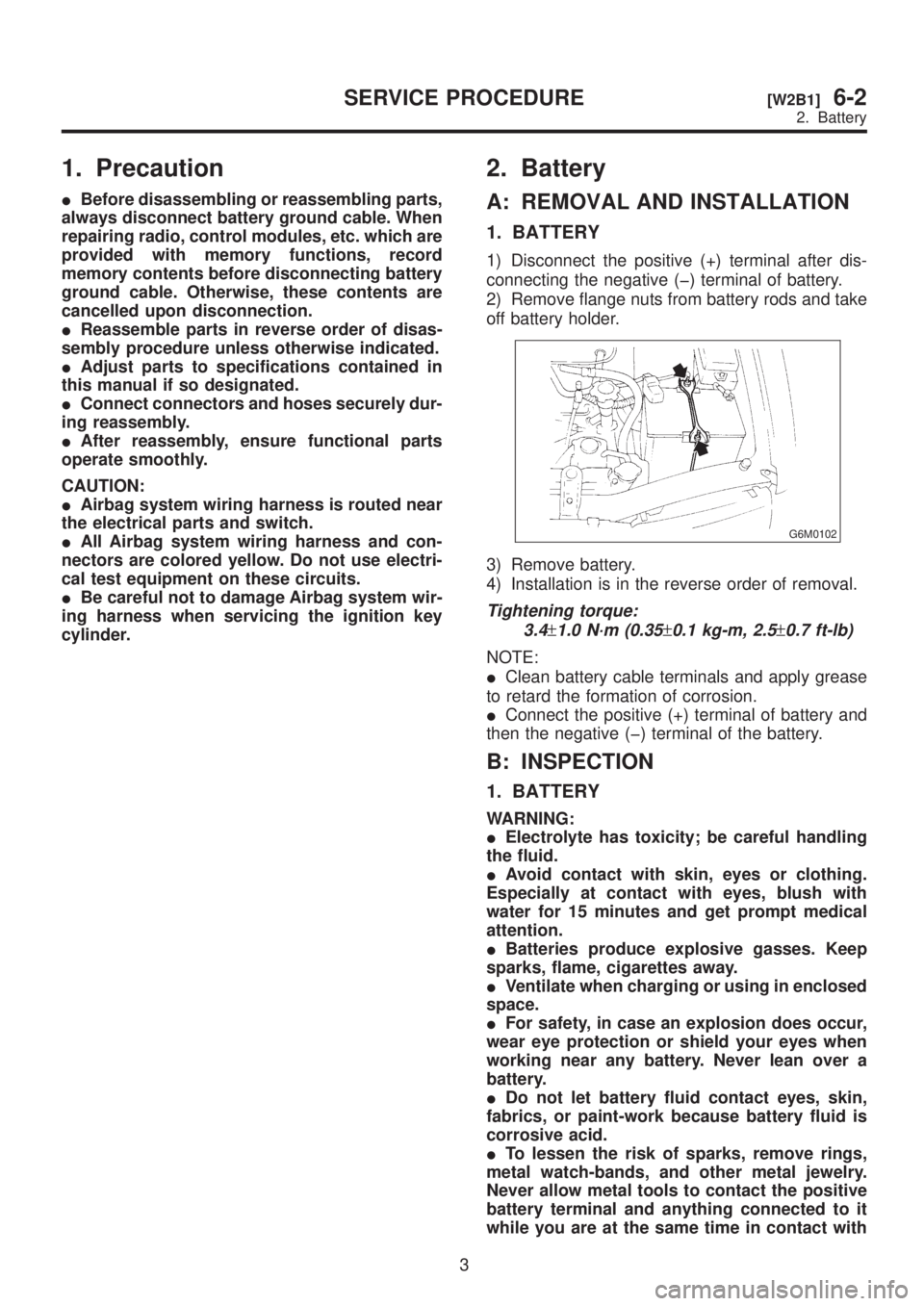

2. Battery

A: REMOVAL AND INSTALLATION

1. BATTERY

1) Disconnect the positive (+) terminal after dis-

connecting the negative (þ) terminal of battery.

2) Remove flange nuts from battery rods and take

off battery holder.

G6M0102

3) Remove battery.

4) Installation is in the reverse order of removal.

Tightening torque:

3.4

±1.0 N´m (0.35±0.1 kg-m, 2.5±0.7 ft-lb)

NOTE:

IClean battery cable terminals and apply grease

to retard the formation of corrosion.

IConnect the positive (+) terminal of battery and

then the negative (þ) terminal of the battery.

B: INSPECTION

1. BATTERY

WARNING:

IElectrolyte has toxicity; be careful handling

the fluid.

IAvoid contact with skin, eyes or clothing.

Especially at contact with eyes, blush with

water for 15 minutes and get prompt medical

attention.

IBatteries produce explosive gasses. Keep

sparks, flame, cigarettes away.

IVentilate when charging or using in enclosed

space.

IFor safety, in case an explosion does occur,

wear eye protection or shield your eyes when

working near any battery. Never lean over a

battery.

IDo not let battery fluid contact eyes, skin,

fabrics, or paint-work because battery fluid is

corrosive acid.

ITo lessen the risk of sparks, remove rings,

metal watch-bands, and other metal jewelry.

Never allow metal tools to contact the positive

battery terminal and anything connected to it

while you are at the same time in contact with

3

[W2B1]6-2SERVICE PROCEDURE

2. Battery

Page 1228 of 1456

1. Precaution

IBefore disassembling or reassembling parts,

always disconnect battery ground cable. When

repairing radio, control modules, etc. which are

provided with memory functions, record

memory contents before disconnecting battery

ground cable. Otherwise, these contents are

cancelled upon disconnection.

IReassemble parts in reverse order of disas-

sembly procedure unless otherwise indicated.

IAdjust parts to specifications contained in

this manual if so designated.

IConnect connectors and hoses securely dur-

ing reassembly.

IAfter reassembly, ensure functional parts

operate smoothly.

CAUTION:

IAirbag system wiring harness is routed near

the electrical parts and switch.

IAll Airbag system wiring harness and con-

nectors are colored yellow. Do not use electri-

cal test equipment on these circuits.

IBe careful not to damage Airbag system wir-

ing harness when servicing the ignition key

cylinder.

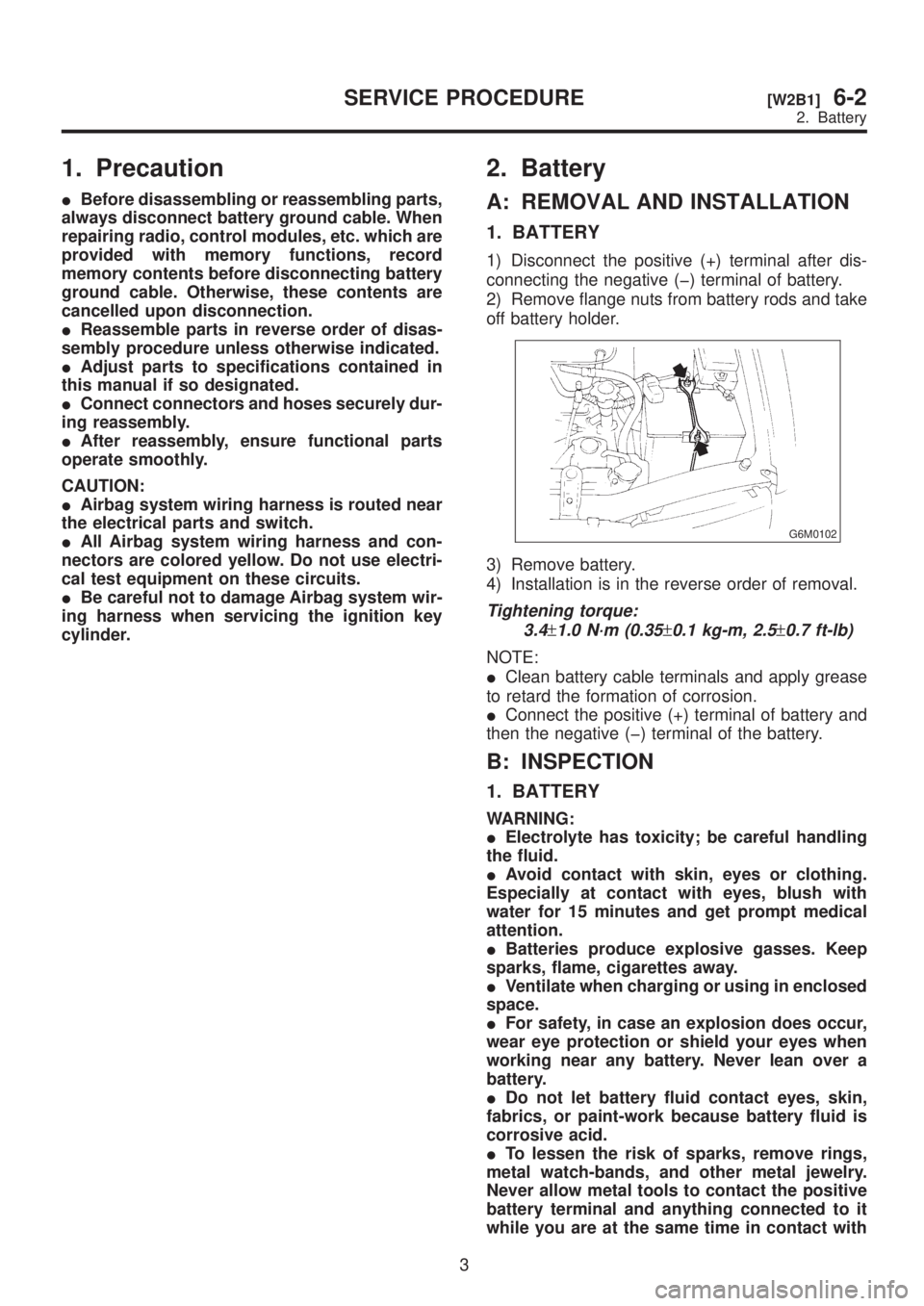

2. Battery

A: REMOVAL AND INSTALLATION

1. BATTERY

1) Disconnect the positive (+) terminal after dis-

connecting the negative (þ) terminal of battery.

2) Remove flange nuts from battery rods and take

off battery holder.

G6M0102

3) Remove battery.

4) Installation is in the reverse order of removal.

Tightening torque:

3.4

±1.0 N´m (0.35±0.1 kg-m, 2.5±0.7 ft-lb)

NOTE:

IClean battery cable terminals and apply grease

to retard the formation of corrosion.

IConnect the positive (+) terminal of battery and

then the negative (þ) terminal of the battery.

B: INSPECTION

1. BATTERY

WARNING:

IElectrolyte has toxicity; be careful handling

the fluid.

IAvoid contact with skin, eyes or clothing.

Especially at contact with eyes, blush with

water for 15 minutes and get prompt medical

attention.

IBatteries produce explosive gasses. Keep

sparks, flame, cigarettes away.

IVentilate when charging or using in enclosed

space.

IFor safety, in case an explosion does occur,

wear eye protection or shield your eyes when

working near any battery. Never lean over a

battery.

IDo not let battery fluid contact eyes, skin,

fabrics, or paint-work because battery fluid is

corrosive acid.

ITo lessen the risk of sparks, remove rings,

metal watch-bands, and other metal jewelry.

Never allow metal tools to contact the positive

battery terminal and anything connected to it

while you are at the same time in contact with

3

[W2B1]6-2SERVICE PROCEDURE

2. Battery

Page 1229 of 1456

any other metallic portion of the vehicle

because a short circuit will be caused.

1) External parts:

Check for the existence of dirt or cracks on the

battery case, top cover, vent plugs, and terminal

posts. If necessary, clean with water and wipe with

a dry cloth. Apply a thin coat of grease on the ter-

minal posts to prevent corrosion.

2) Electrolyte level:

Check the electrolyte level in each cell. If the level

is below MIN LEVEL, bring the level to MAX

LEVEL by pouring distilled water into the battery

cell. Do not fill beyond MAX LEVEL.

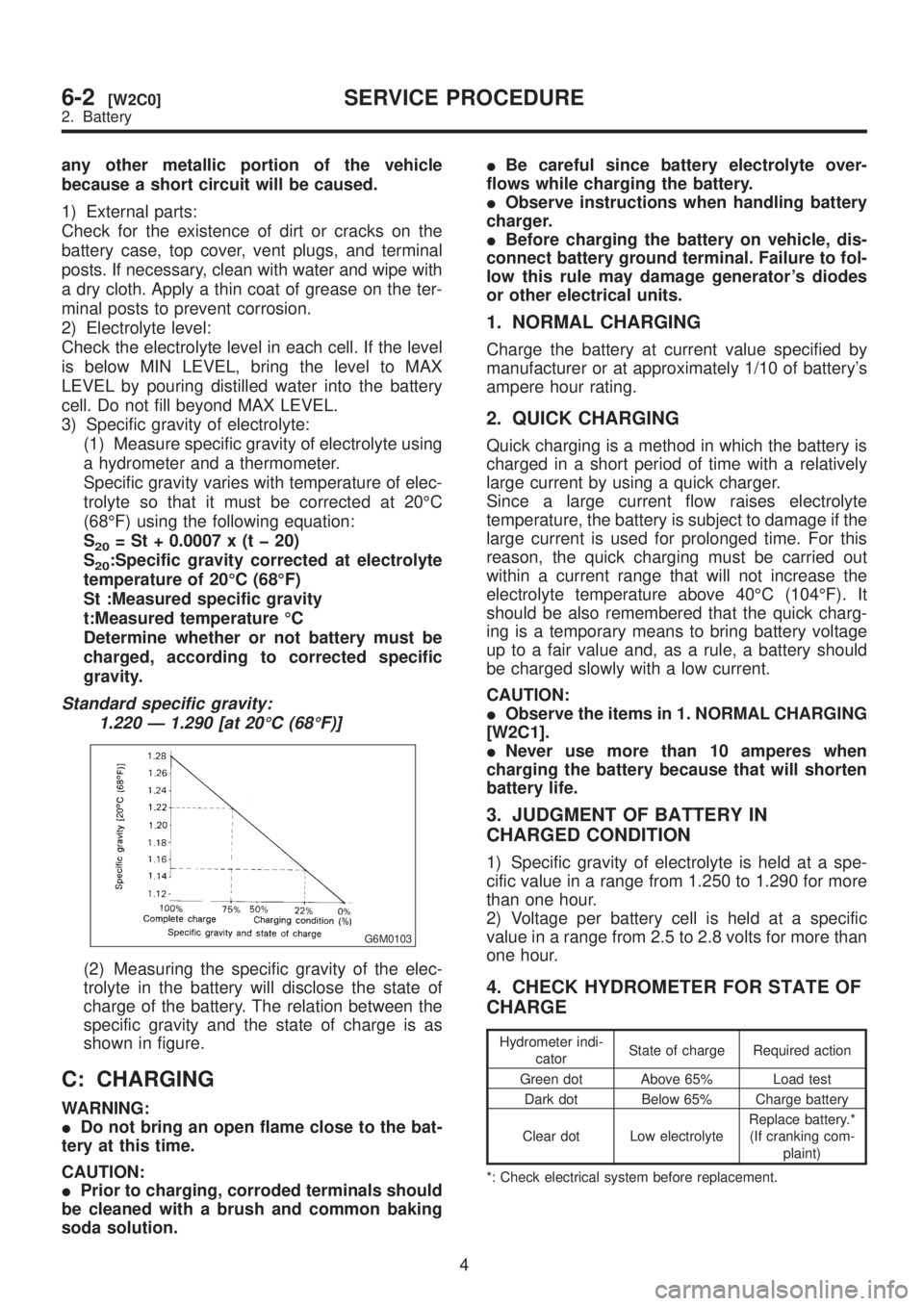

3) Specific gravity of electrolyte:

(1) Measure specific gravity of electrolyte using

a hydrometer and a thermometer.

Specific gravity varies with temperature of elec-

trolyte so that it must be corrected at 20ÉC

(68ÉF) using the following equation:

S

20= St + 0.0007 x (t þ 20)

S

20:Specific gravity corrected at electrolyte

temperature of 20ÉC (68ÉF)

St :Measured specific gravity

t:Measured temperature ÉC

Determine whether or not battery must be

charged, according to corrected specific

gravity.

Standard specific gravity:

1.220 Ð 1.290 [at 20ÉC (68ÉF)]

G6M0103

(2) Measuring the specific gravity of the elec-

trolyte in the battery will disclose the state of

charge of the battery. The relation between the

specific gravity and the state of charge is as

shown in figure.

C: CHARGING

WARNING:

IDo not bring an open flame close to the bat-

tery at this time.

CAUTION:

IPrior to charging, corroded terminals should

be cleaned with a brush and common baking

soda solution.IBe careful since battery electrolyte over-

flows while charging the battery.

IObserve instructions when handling battery

charger.

IBefore charging the battery on vehicle, dis-

connect battery ground terminal. Failure to fol-

low this rule may damage generator's diodes

or other electrical units.

1. NORMAL CHARGING

Charge the battery at current value specified by

manufacturer or at approximately 1/10 of battery's

ampere hour rating.

2. QUICK CHARGING

Quick charging is a method in which the battery is

charged in a short period of time with a relatively

large current by using a quick charger.

Since a large current flow raises electrolyte

temperature, the battery is subject to damage if the

large current is used for prolonged time. For this

reason, the quick charging must be carried out

within a current range that will not increase the

electrolyte temperature above 40ÉC (104ÉF). It

should be also remembered that the quick charg-

ing is a temporary means to bring battery voltage

up to a fair value and, as a rule, a battery should

be charged slowly with a low current.

CAUTION:

IObserve the items in 1. NORMAL CHARGING

[W2C1].

INever use more than 10 amperes when

charging the battery because that will shorten

battery life.

3. JUDGMENT OF BATTERY IN

CHARGED CONDITION

1) Specific gravity of electrolyte is held at a spe-

cific value in a range from 1.250 to 1.290 for more

than one hour.

2) Voltage per battery cell is held at a specific

value in a range from 2.5 to 2.8 volts for more than

one hour.

4. CHECK HYDROMETER FOR STATE OF

CHARGE

Hydrometer indi-

catorState of charge Required action

Green dot Above 65% Load test

Dark dot Below 65% Charge battery

Clear dot Low electrolyteReplace battery.*

(If cranking com-

plaint)

*: Check electrical system before replacement.

4

6-2[W2C0]SERVICE PROCEDURE

2. Battery

Page 1230 of 1456

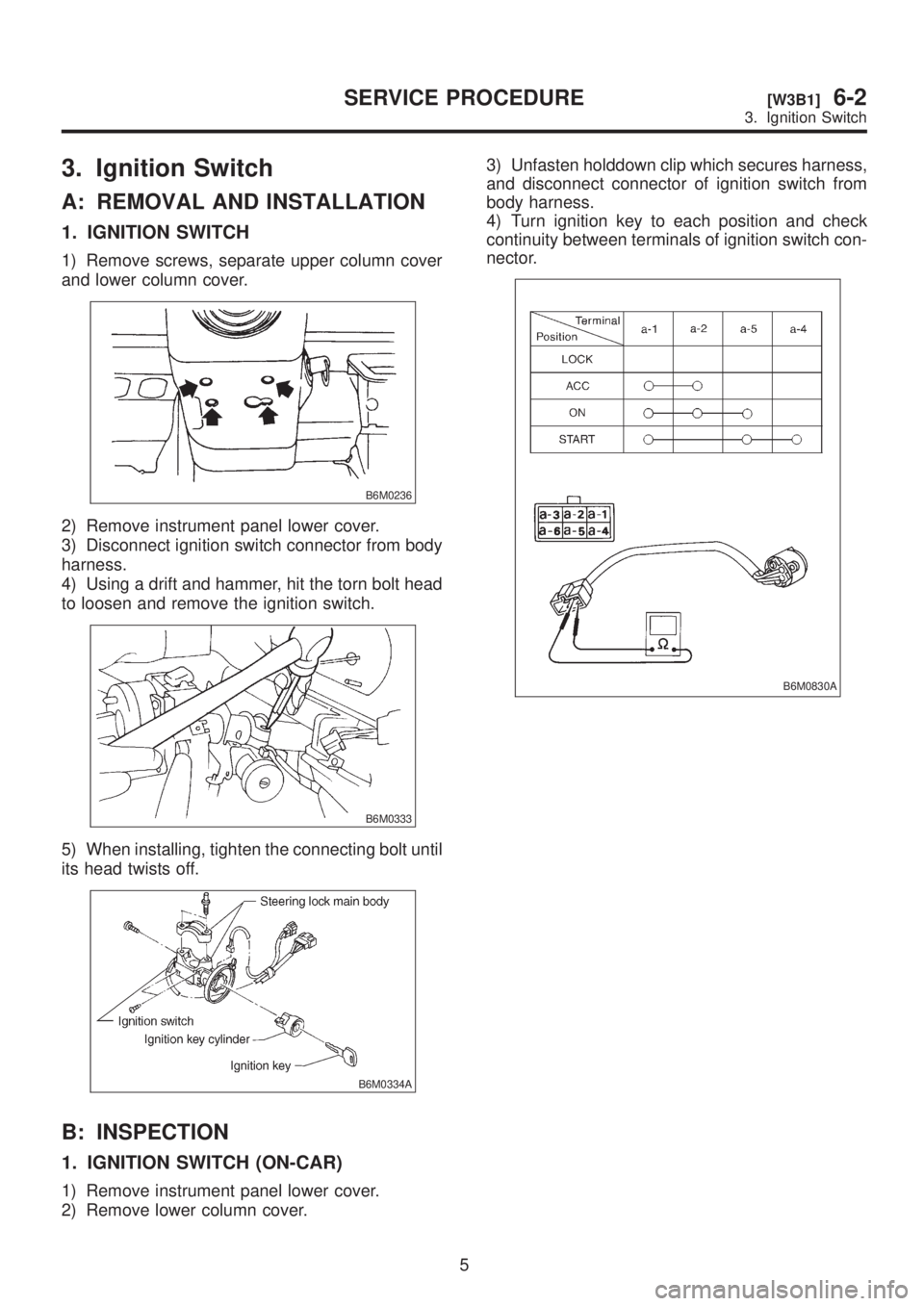

3. Ignition Switch

A: REMOVAL AND INSTALLATION

1. IGNITION SWITCH

1) Remove screws, separate upper column cover

and lower column cover.

B6M0236

2) Remove instrument panel lower cover.

3) Disconnect ignition switch connector from body

harness.

4) Using a drift and hammer, hit the torn bolt head

to loosen and remove the ignition switch.

B6M0333

5) When installing, tighten the connecting bolt until

its head twists off.

B6M0334A

B: INSPECTION

1. IGNITION SWITCH (ON-CAR)

1) Remove instrument panel lower cover.

2) Remove lower column cover.3) Unfasten holddown clip which secures harness,

and disconnect connector of ignition switch from

body harness.

4) Turn ignition key to each position and check

continuity between terminals of ignition switch con-

nector.

B6M0830A

5

[W3B1]6-2SERVICE PROCEDURE

3. Ignition Switch