SUBARU TRIBECA 2009 1.G Service Workshop Manual

Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 1911 of 2453

ME(H6DO)-45

Timing Chain Assembly

MECHANICAL

13) Remove the idler sprocket (upper).

14) Remove the timing chain (LH).

15) Remove the idler sprocket (lower).

B: INSTALLATION

NOTE:

•Be careful that the foreign matter is not into or

onto assembled component during installation.

•Apply engine oil to the chain guide, chain ten-

sioner lever and idler sprocket when installing.

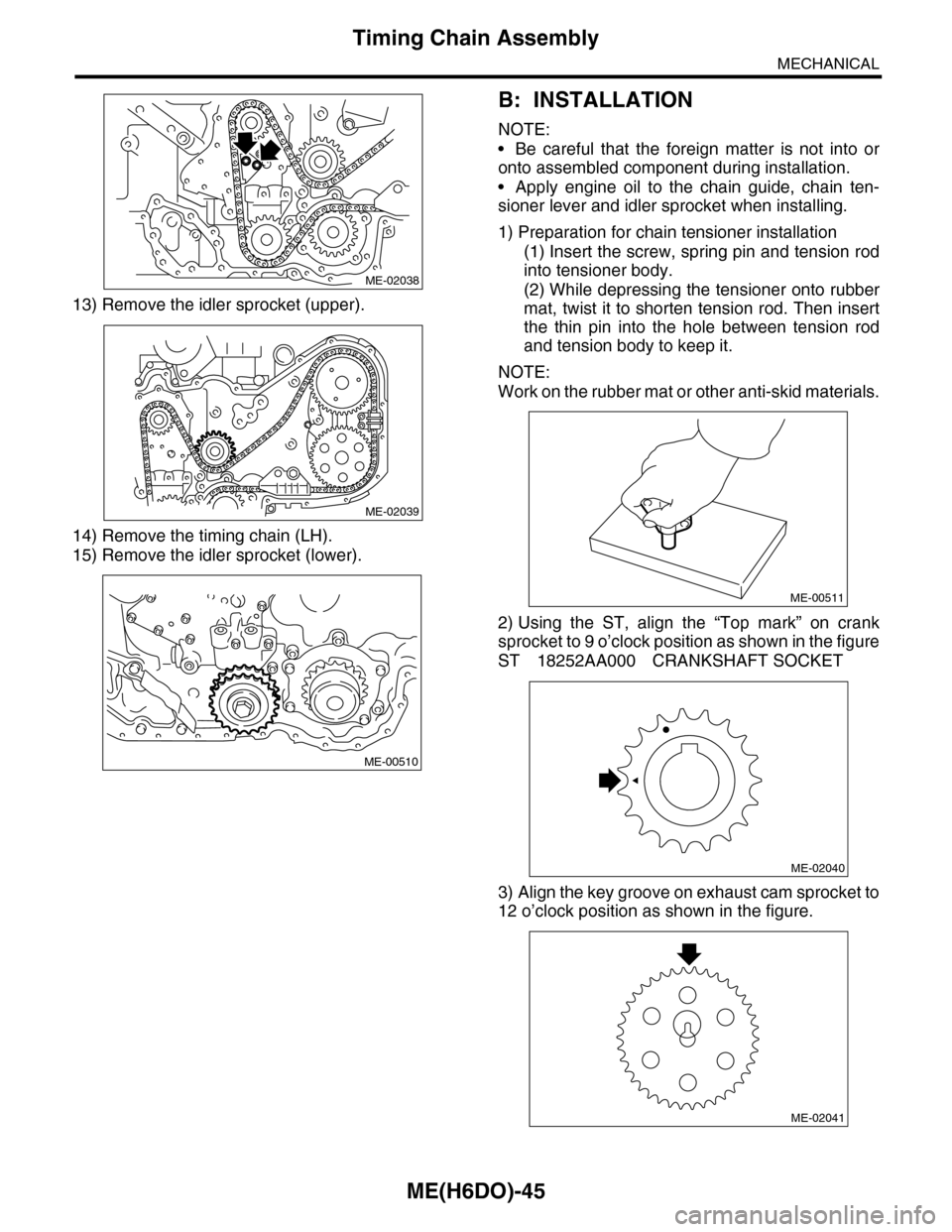

1) Preparation for chain tensioner installation

(1) Insert the screw, spring pin and tension rod

into tensioner body.

(2) While depressing the tensioner onto rubber

mat, twist it to shorten tension rod. Then insert

the thin pin into the hole between tension rod

and tension body to keep it.

NOTE:

Work on the rubber mat or other anti-skid materials.

2) Using the ST, align the “Top mark” on crank

sprocket to 9 o’clock position as shown in the figure

ST 18252AA000 CRANKSHAFT SOCKET

3) Align the key groove on exhaust cam sprocket to

12 o’clock position as shown in the figure.

ME-02038

ME-02039

ME-00510

ME-00511

ME-02040

ME-02041

Page 1912 of 2453

ME(H6DO)-46

Timing Chain Assembly

MECHANICAL

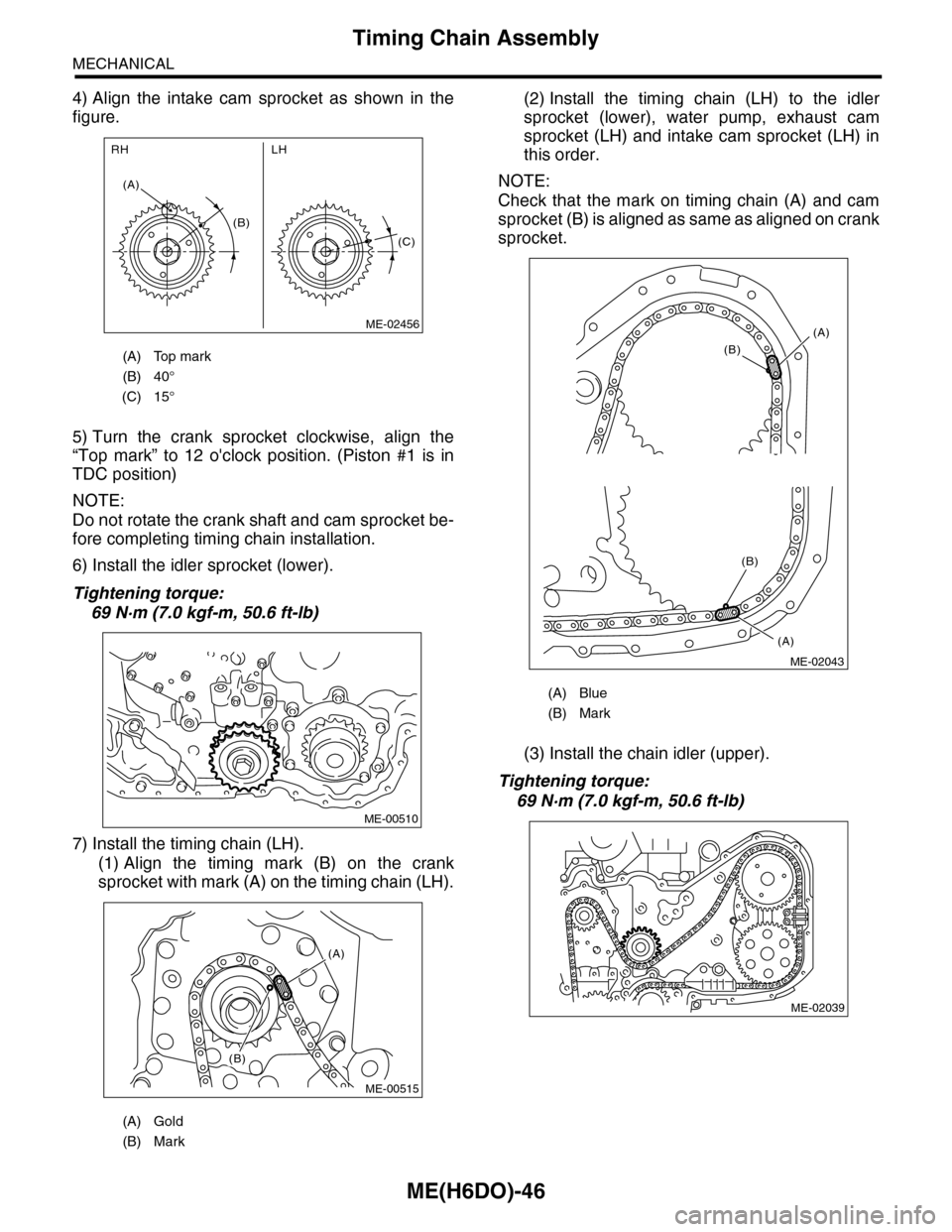

4) Align the intake cam sprocket as shown in the

figure.

5) Turn the crank sprocket clockwise, align the

“Top mark” to 12 o'clock position. (Piston #1 is in

TDC position)

NOTE:

Do not rotate the crank shaft and cam sprocket be-

fore completing timing chain installation.

6) Install the idler sprocket (lower).

Tightening torque:

69 N·m (7.0 kgf-m, 50.6 ft-lb)

7) Install the timing chain (LH).

(1) Align the timing mark (B) on the crank

sprocket with mark (A) on the timing chain (LH).

(2) Install the timing chain (LH) to the idler

sprocket (lower), water pump, exhaust cam

sprocket (LH) and intake cam sprocket (LH) in

this order.

NOTE:

Check that the mark on timing chain (A) and cam

sprocket (B) is aligned as same as aligned on crank

sprocket.

(3) Install the chain idler (upper).

Tightening torque:

69 N·m (7.0 kgf-m, 50.6 ft-lb)

(A) Top mark

(B) 40°

(C) 15°

(A) Gold

(B) Mark

(B)

(A)

LHRH

(C)

ME-02456

ME-00510

(A)

(B)

ME-00515

(A) Blue

(B) Mark

(A)

(B)

(A)

(B)

ME-02043

ME-02039

Page 1913 of 2453

ME(H6DO)-47

Timing Chain Assembly

MECHANICAL

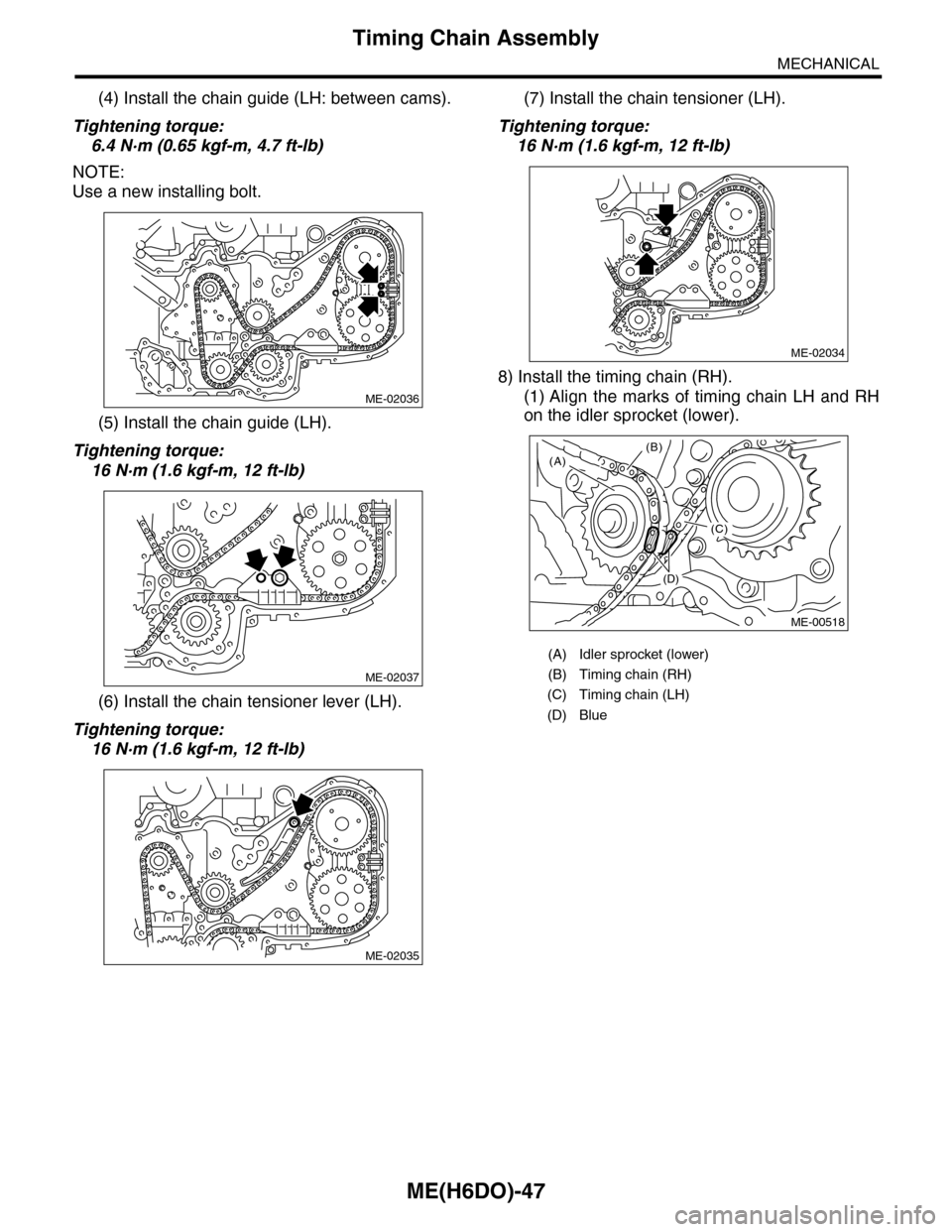

(4) Install the chain guide (LH: between cams).

Tightening torque:

6.4 N·m (0.65 kgf-m, 4.7 ft-lb)

NOTE:

Use a new installing bolt.

(5) Install the chain guide (LH).

Tightening torque:

16 N·m (1.6 kgf-m, 12 ft-lb)

(6) Install the chain tensioner lever (LH).

Tightening torque:

16 N·m (1.6 kgf-m, 12 ft-lb)

(7) Install the chain tensioner (LH).

Tightening torque:

16 N·m (1.6 kgf-m, 12 ft-lb)

8) Install the timing chain (RH).

(1) Align the marks of timing chain LH and RH

on the idler sprocket (lower).

ME-02036

ME-02037

ME-02035

(A) Idler sprocket (lower)

(B) Timing chain (RH)

(C) Timing chain (LH)

(D) Blue

ME-02034

(A)(B)

(C)

(D)

ME-00518

Page 1914 of 2453

ME(H6DO)-48

Timing Chain Assembly

MECHANICAL

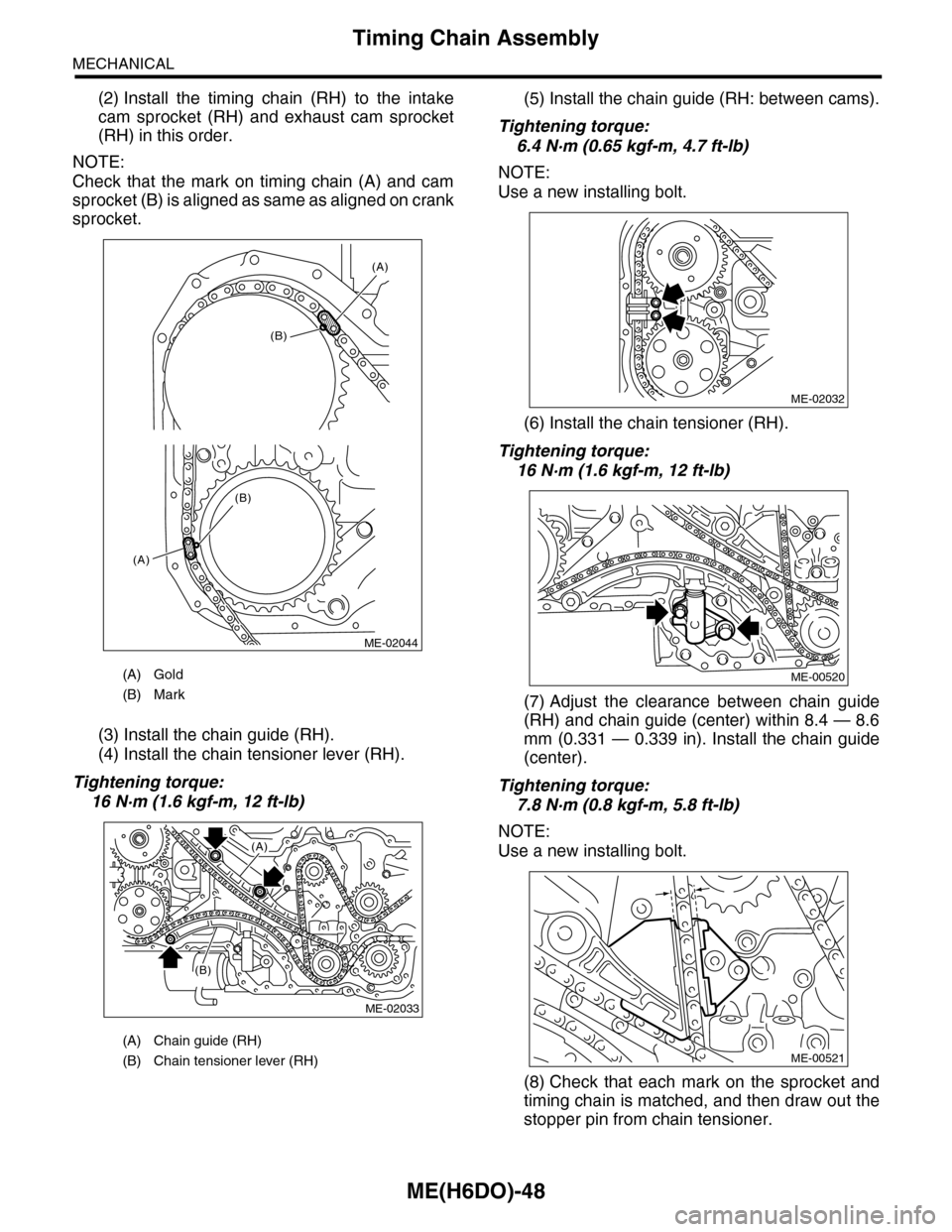

(2) Install the timing chain (RH) to the intake

cam sprocket (RH) and exhaust cam sprocket

(RH) in this order.

NOTE:

Check that the mark on timing chain (A) and cam

sprocket (B) is aligned as same as aligned on crank

sprocket.

(3) Install the chain guide (RH).

(4) Install the chain tensioner lever (RH).

Tightening torque:

16 N·m (1.6 kgf-m, 12 ft-lb)

(5) Install the chain guide (RH: between cams).

Tightening torque:

6.4 N·m (0.65 kgf-m, 4.7 ft-lb)

NOTE:

Use a new installing bolt.

(6) Install the chain tensioner (RH).

Tightening torque:

16 N·m (1.6 kgf-m, 12 ft-lb)

(7) Adjust the clearance between chain guide

(RH) and chain guide (center) within 8.4 — 8.6

mm (0.331 — 0.339 in). Install the chain guide

(center).

Tightening torque:

7.8 N·m (0.8 kgf-m, 5.8 ft-lb)

NOTE:

Use a new installing bolt.

(8) Check that each mark on the sprocket and

timing chain is matched, and then draw out the

stopper pin from chain tensioner.

(A) Gold

(B) Mark

(A) Chain guide (RH)

(B) Chain tensioner lever (RH)

(A)

(A)

(B)

(B)

ME-02044

ME-02033

(A)

(B)

ME-02032

ME-00520

ME-00521

Page 1915 of 2453

ME(H6DO)-49

Cam Sprocket

MECHANICAL

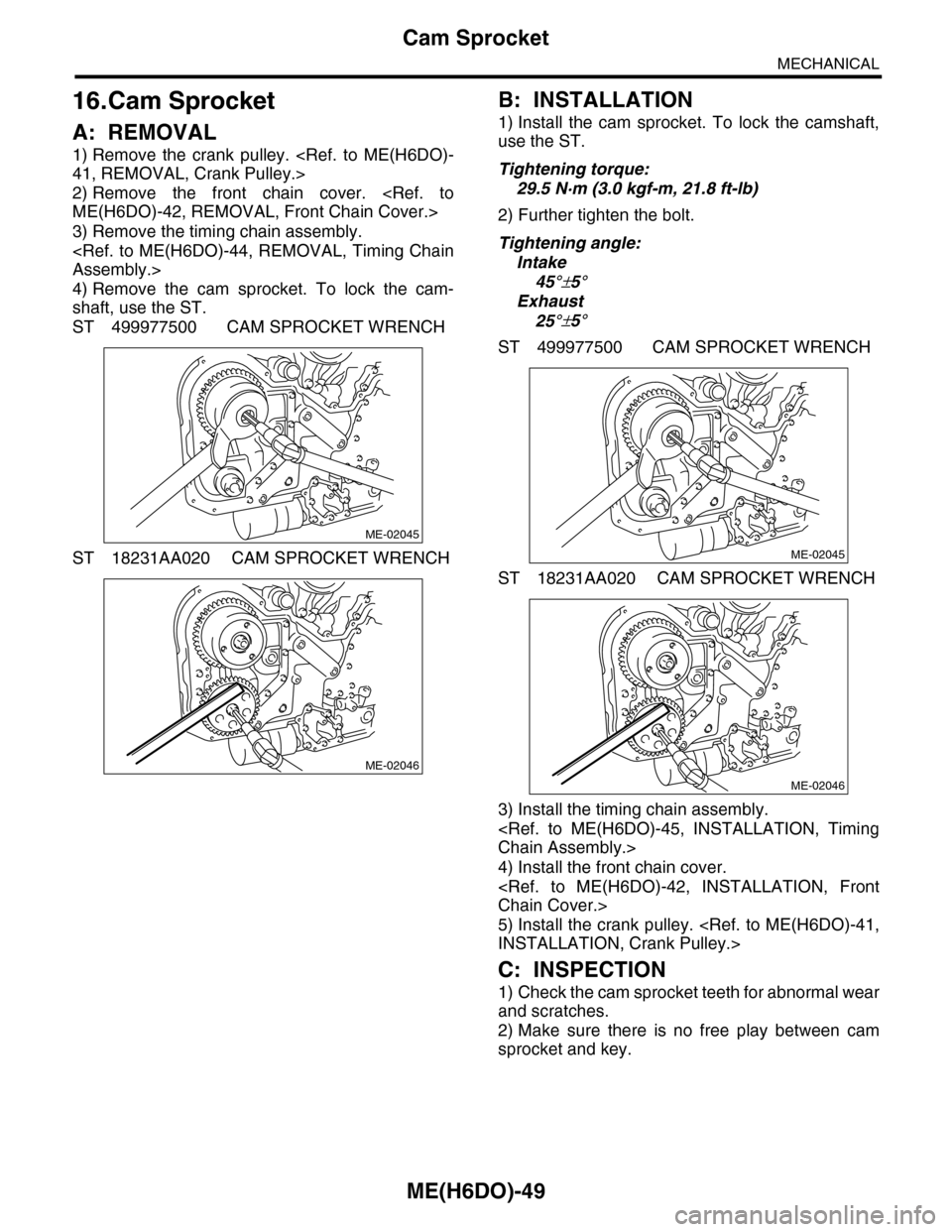

16.Cam Sprocket

A: REMOVAL

1) Remove the crank pulley.

2) Remove the front chain cover.

3) Remove the timing chain assembly.

4) Remove the cam sprocket. To lock the cam-

shaft, use the ST.

ST 499977500 CAM SPROCKET WRENCH

ST 18231AA020 CAM SPROCKET WRENCH

B: INSTALLATION

1) Install the cam sprocket. To lock the camshaft,

use the ST.

Tightening torque:

29.5 N·m (3.0 kgf-m, 21.8 ft-lb)

2) Further tighten the bolt.

Tightening angle:

Intake

45°±5°

Exhaust

25°±5°

ST 499977500 CAM SPROCKET WRENCH

ST 18231AA020 CAM SPROCKET WRENCH

3) Install the timing chain assembly.

4) Install the front chain cover.

5) Install the crank pulley.

C: INSPECTION

1) Check the cam sprocket teeth for abnormal wear

and scratches.

2) Make sure there is no free play between cam

sprocket and key.

ME-02045

ME-02046

ME-02045

ME-02046

Page 1916 of 2453

ME(H6DO)-50

Crank Sprocket

MECHANICAL

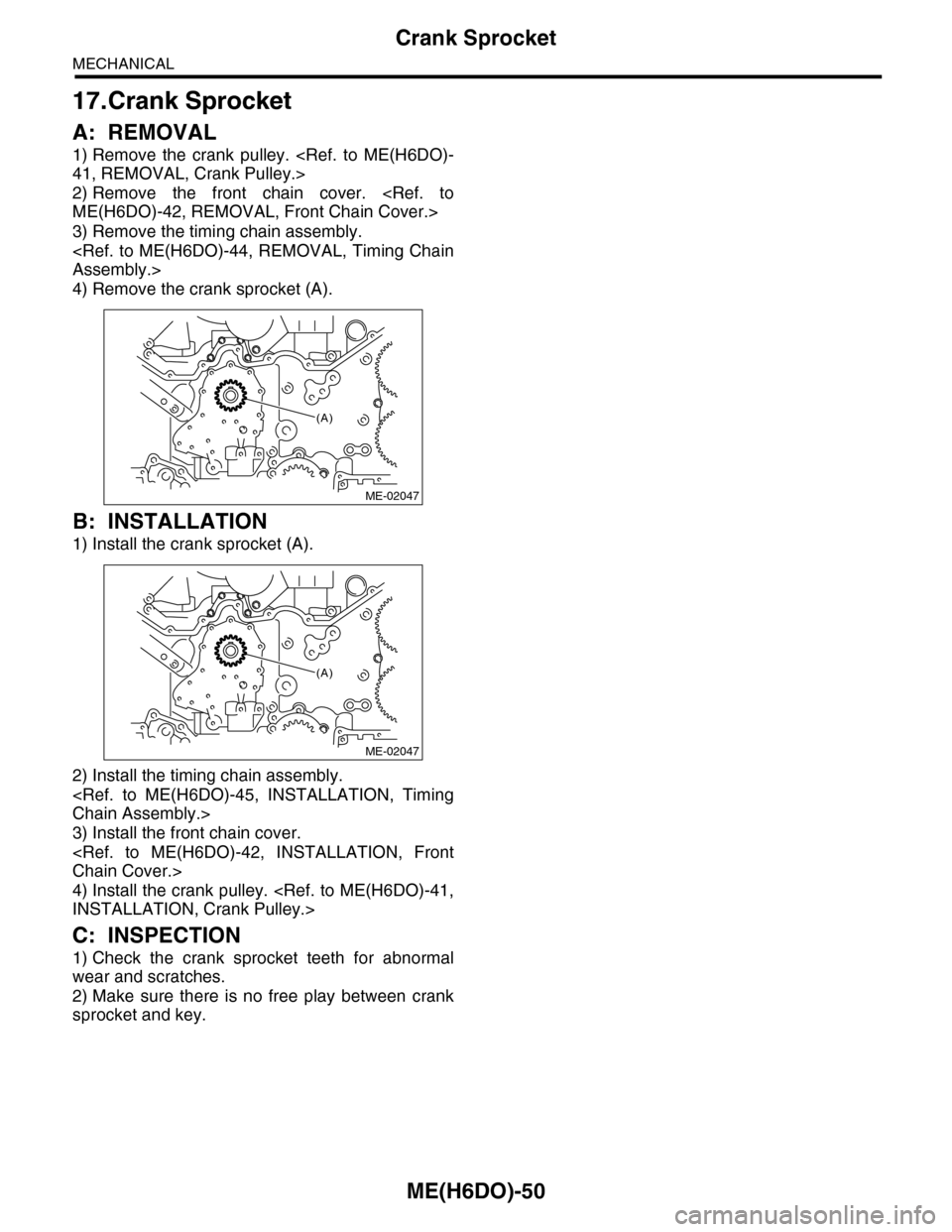

17.Crank Sprocket

A: REMOVAL

1) Remove the crank pulley.

2) Remove the front chain cover.

3) Remove the timing chain assembly.

4) Remove the crank sprocket (A).

B: INSTALLATION

1) Install the crank sprocket (A).

2) Install the timing chain assembly.

3) Install the front chain cover.

4) Install the crank pulley.

C: INSPECTION

1) Check the crank sprocket teeth for abnormal

wear and scratches.

2) Make sure there is no free play between crank

sprocket and key.

ME-02047

(A)

ME-02047

(A)

Page 1917 of 2453

ME(H6DO)-51

Rear Chain Cover

MECHANICAL

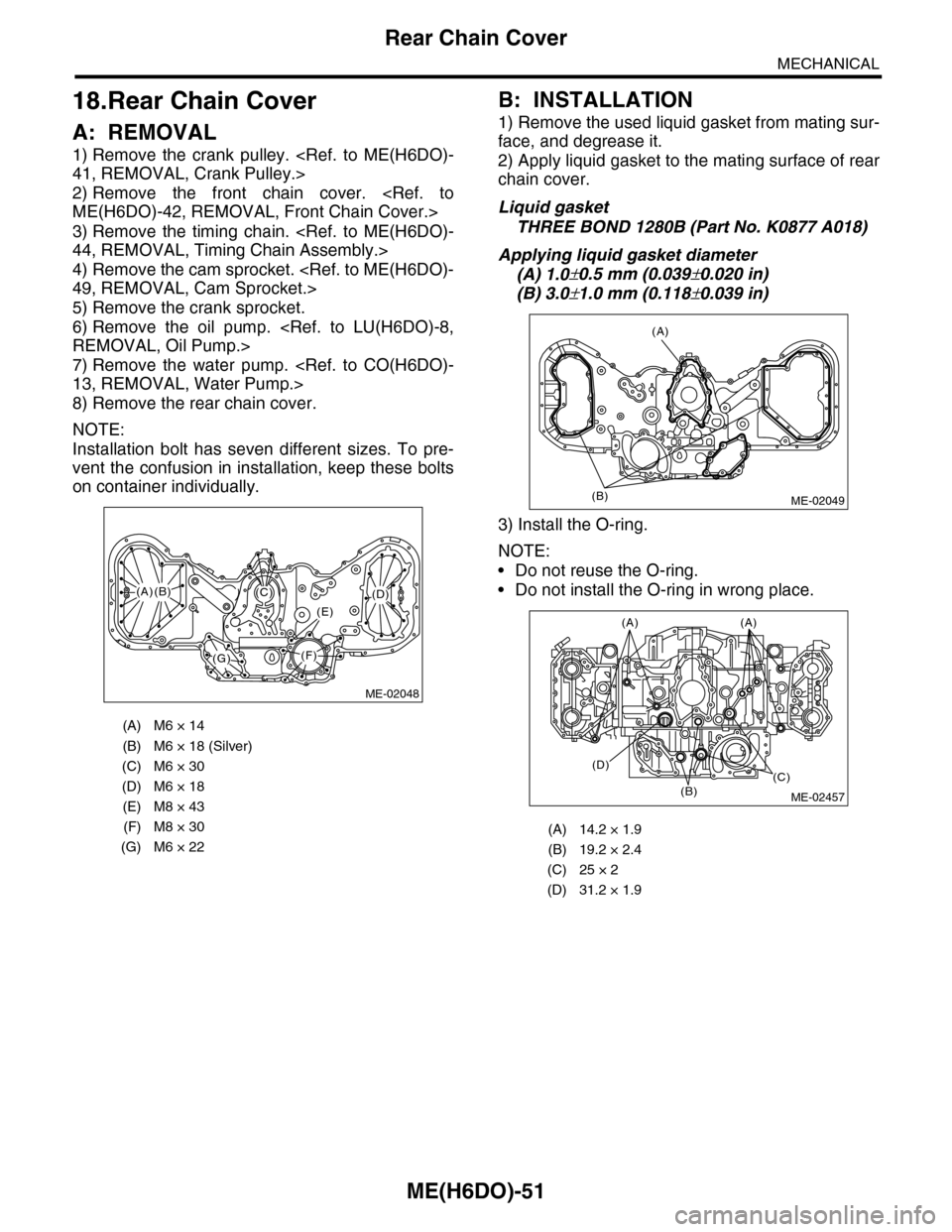

18.Rear Chain Cover

A: REMOVAL

1) Remove the crank pulley.

2) Remove the front chain cover.

3) Remove the timing chain.

4) Remove the cam sprocket.

5) Remove the crank sprocket.

6) Remove the oil pump.

7) Remove the water pump.

8) Remove the rear chain cover.

NOTE:

Installation bolt has seven different sizes. To pre-

vent the confusion in installation, keep these bolts

on container individually.

B: INSTALLATION

1) Remove the used liquid gasket from mating sur-

face, and degrease it.

2) Apply liquid gasket to the mating surface of rear

chain cover.

Liquid gasket

THREE BOND 1280B (Part No. K0877 A018)

Applying liquid gasket diameter

(A) 1.0±0.5 mm (0.039±0.020 in)

(B) 3.0±1.0 mm (0.118±0.039 in)

3) Install the O-ring.

NOTE:

•Do not reuse the O-ring.

•Do not install the O-ring in wrong place.

(A) M6 × 14

(B) M6 × 18 (Silver)

(C) M6 × 30

(D) M6 × 18

(E) M8 × 43

(F) M8 × 30

(G) M6 × 22

ME-02048

(F)

(C)(D)

(E)

(G)

(A)(B)

(A) 14.2 × 1.9

(B) 19.2 × 2.4

(C) 25 × 2

(D) 31.2 × 1.9

(A)

(B)ME-02049

(B)

(D)(C)

(A)(A)

ME-02457

Page 1918 of 2453

ME(H6DO)-52

Rear Chain Cover

MECHANICAL

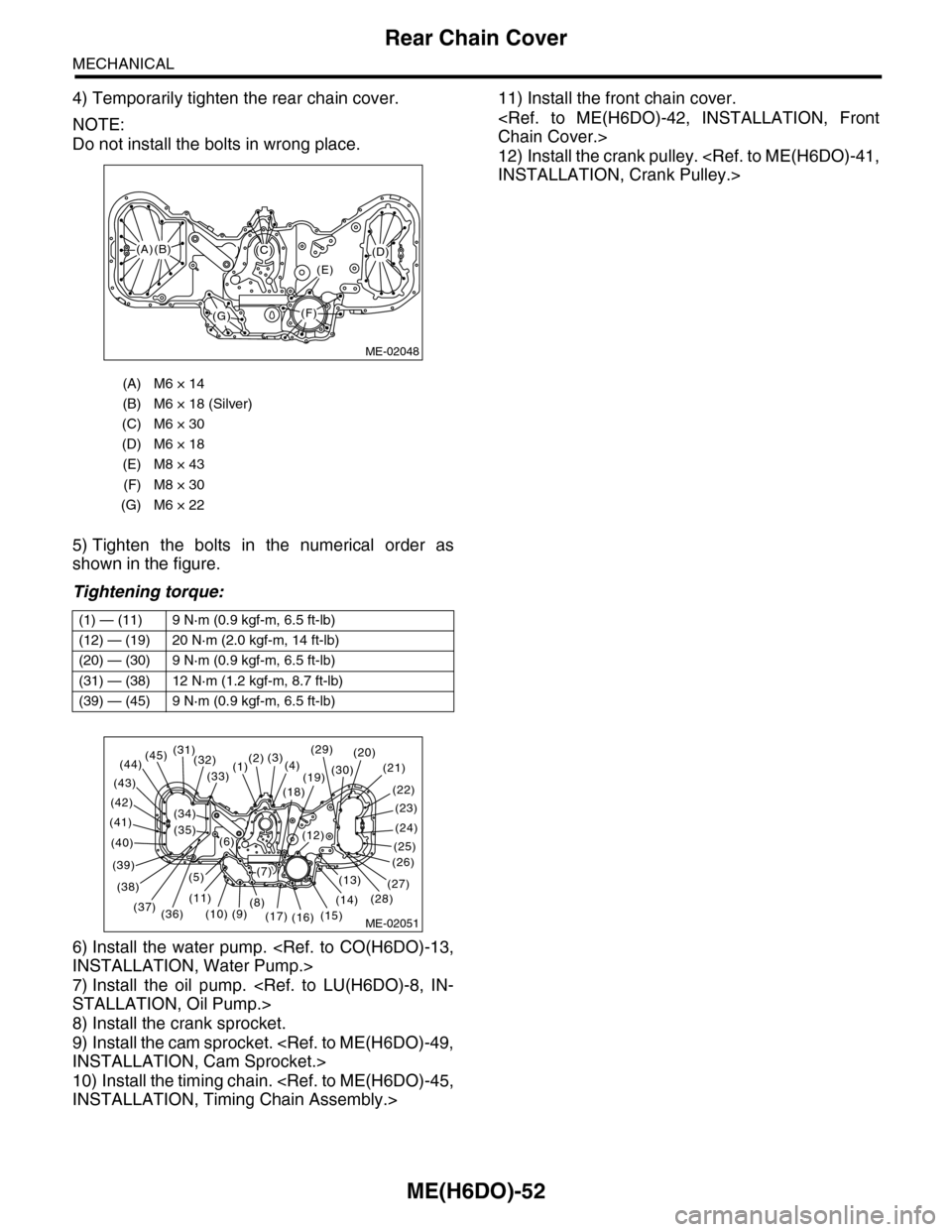

4) Temporarily tighten the rear chain cover.

NOTE:

Do not install the bolts in wrong place.

5) Tighten the bolts in the numerical order as

shown in the figure.

Tightening torque:

6) Install the water pump.

7) Install the oil pump.

8) Install the crank sprocket.

9) Install the cam sprocket.

10) Install the timing chain.

11) Install the front chain cover.

12) Install the crank pulley.

(A) M6 × 14

(B) M6 × 18 (Silver)

(C) M6 × 30

(D) M6 × 18

(E) M8 × 43

(F) M8 × 30

(G) M6 × 22

(1) — (11) 9 N·m (0.9 kgf-m, 6.5 ft-lb)

(12) — (19) 20 N·m (2.0 kgf-m, 14 ft-lb)

(20) — (30) 9 N·m (0.9 kgf-m, 6.5 ft-lb)

(31) — (38) 12 N·m (1.2 kgf-m, 8.7 ft-lb)

(39) — (45) 9 N·m (0.9 kgf-m, 6.5 ft-lb)

ME-02048

(F)

(C)(D)

(E)

(G)

(A)(B)

ME-02051(15)

(14)

(26)

(27)(13)

(25)

(24)

(23)

(22)

(21)(20)

(16)(17)

(12)

(19)(30)

(18)

(4)(3)(2)(1)(33)

(8)(9)(10)

(11)

(32)(31)(45)(44)

(43)

(42)

(41)

(40)

(39)

(38)

(37)(36)

(5)

(6)

(7)

(29)

(28)

(35)

(34)

Page 1919 of 2453

ME(H6DO)-53

Camshaft

MECHANICAL

19.Camshaft

A: REMOVAL

1) Remove the crank pulley.

2) Remove the front chain cover.

3) Remove the timing chain assembly.

4) Remove the cam sprocket.

5) Remove the crank sprocket.

6) Remove the rear chain cover.

7) Disconnect the oil pipe.

8) Remove the rocker cover (LH).

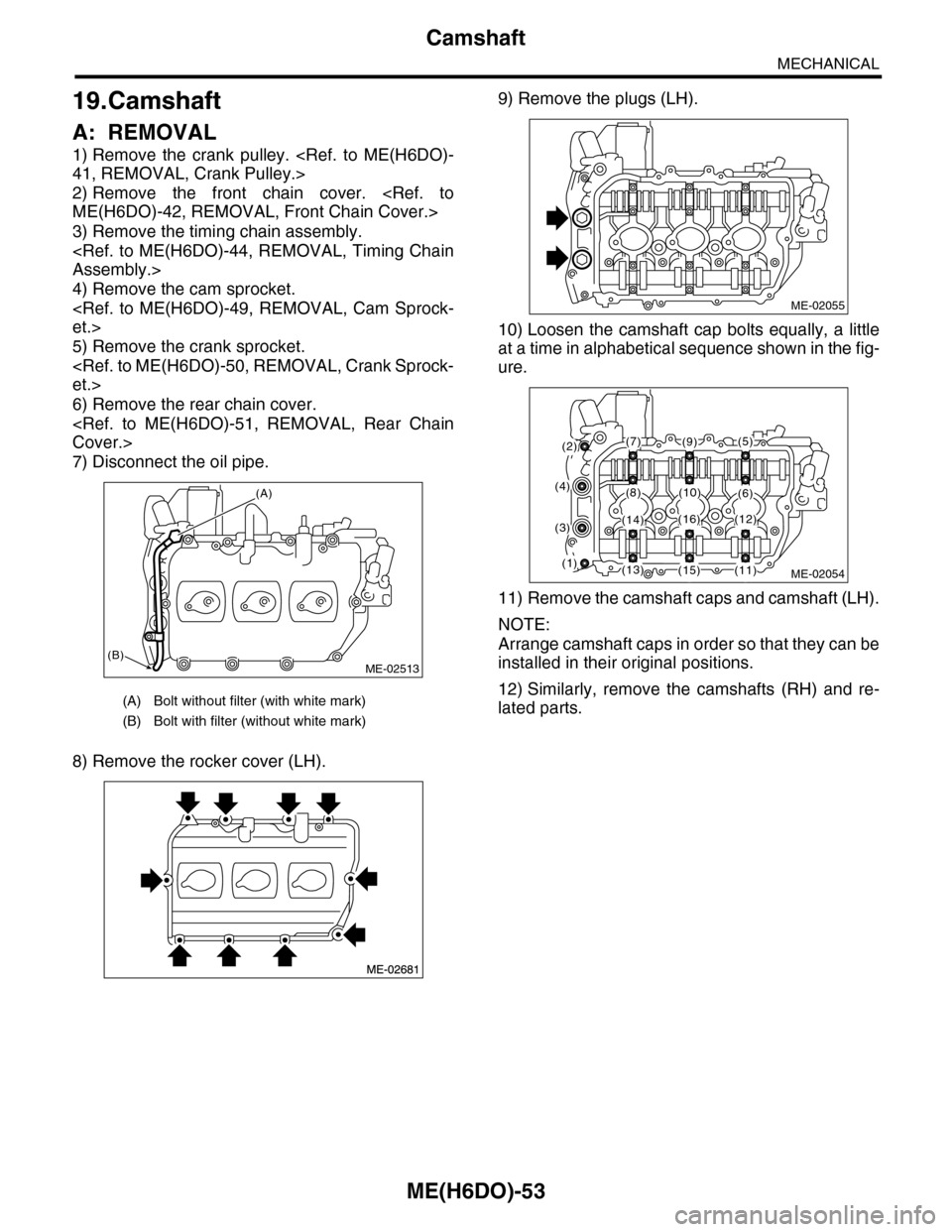

9) Remove the plugs (LH).

10) Loosen the camshaft cap bolts equally, a little

at a time in alphabetical sequence shown in the fig-

ure.

11) Remove the camshaft caps and camshaft (LH).

NOTE:

Arrange camshaft caps in order so that they can be

installed in their original positions.

12) Similarly, remove the camshafts (RH) and re-

lated parts.(A) Bolt without filter (with white mark)

(B) Bolt with filter (without white mark)

ME-02513

(A)

(B)

ME-02055

ME-02054(1)

(2)

(8)

(7)(9)

(3)

(4)

(5)

(6)(10)

(11)(13)

(14)(12)

(15)

(16)

Page 1920 of 2453

ME(H6DO)-54

Camshaft

MECHANICAL

B: INSTALLATION

1) Apply engine oil to camshaft journals, and install

the camshaft.

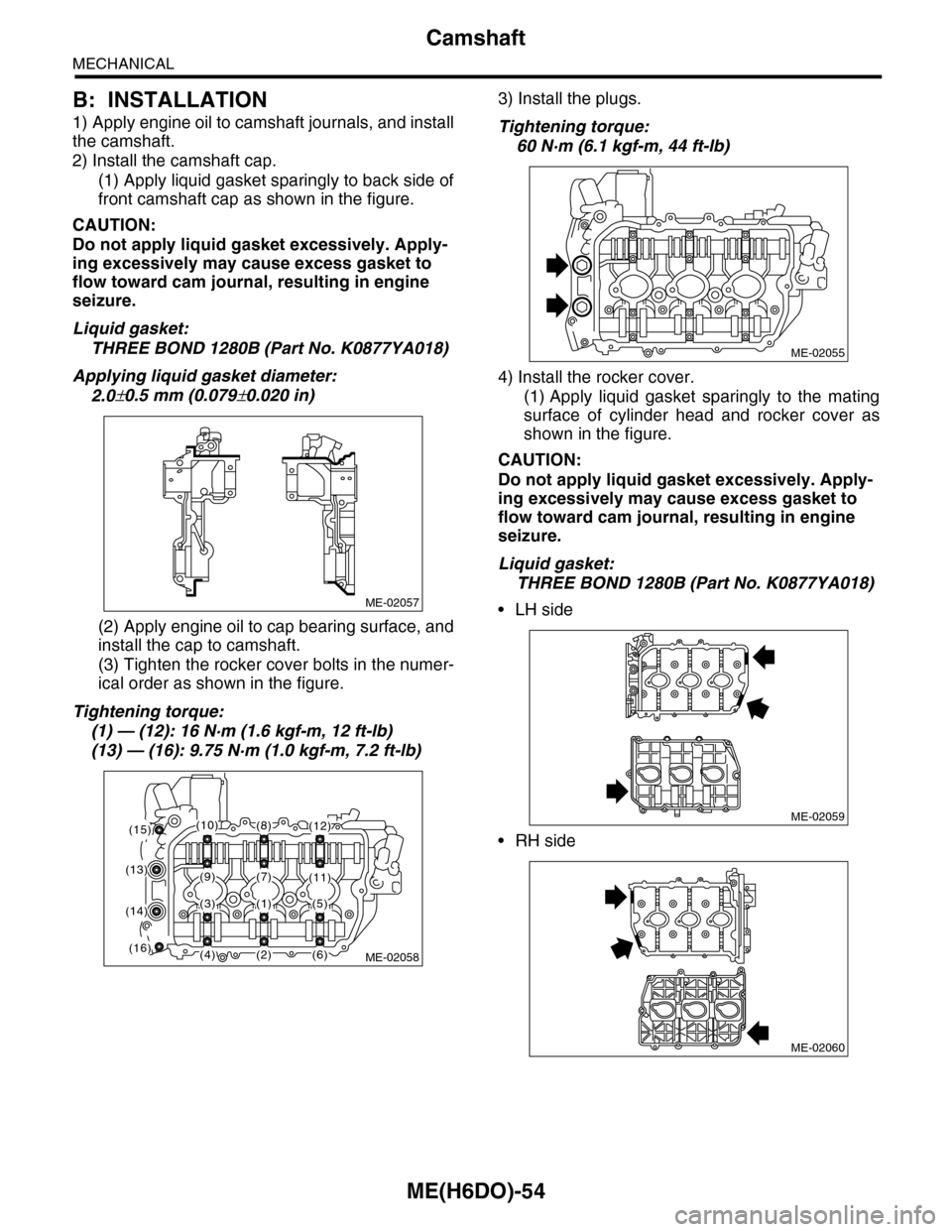

2) Install the camshaft cap.

(1) Apply liquid gasket sparingly to back side of

front camshaft cap as shown in the figure.

CAUTION:

Do not apply liquid gasket excessively. Apply-

ing excessively may cause excess gasket to

flow toward cam journal, resulting in engine

seizure.

Liquid gasket:

THREE BOND 1280B (Part No. K0877YA018)

Applying liquid gasket diameter:

2.0±0.5 mm (0.079±0.020 in)

(2) Apply engine oil to cap bearing surface, and

install the cap to camshaft.

(3) Tighten the rocker cover bolts in the numer-

ical order as shown in the figure.

Tightening torque:

(1) — (12): 16 N·m (1.6 kgf-m, 12 ft-lb)

(13) — (16): 9.75 N·m (1.0 kgf-m, 7.2 ft-lb)

3) Install the plugs.

Tightening torque:

60 N·m (6.1 kgf-m, 44 ft-lb)

4) Install the rocker cover.

(1) Apply liquid gasket sparingly to the mating

surface of cylinder head and rocker cover as

shown in the figure.

CAUTION:

Do not apply liquid gasket excessively. Apply-

ing excessively may cause excess gasket to

flow toward cam journal, resulting in engine

seizure.

Liquid gasket:

THREE BOND 1280B (Part No. K0877YA018)

•LH side

•RH side

ME-02057

ME-02058

(1)

(2)

(8)

(7)(9)

(3)

(4)

(5)

(6)

(10)

(11)(13)

(14)

(15)

(16)

(12)

ME-02055

ME-02059

ME-02060