SUBARU TRIBECA 2009 1.G Service Workshop Manual

Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 1901 of 2453

ME(H6DO)-35

Engine Assembly

MECHANICAL

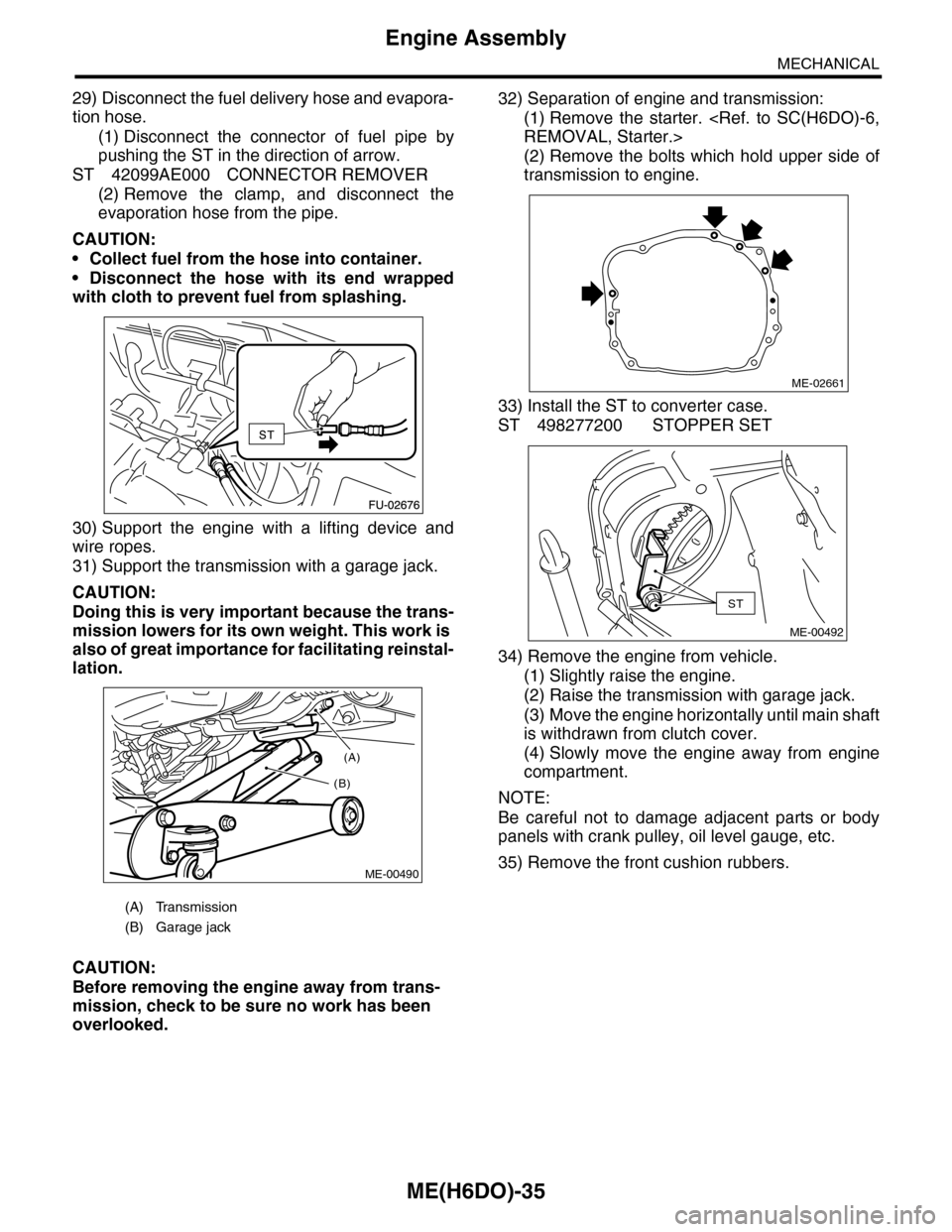

29) Disconnect the fuel delivery hose and evapora-

tion hose.

(1) Disconnect the connector of fuel pipe by

pushing the ST in the direction of arrow.

ST 42099AE000 CONNECTOR REMOVER

(2) Remove the clamp, and disconnect the

evaporation hose from the pipe.

CAUTION:

•Collect fuel from the hose into container.

•Disconnect the hose with its end wrapped

with cloth to prevent fuel from splashing.

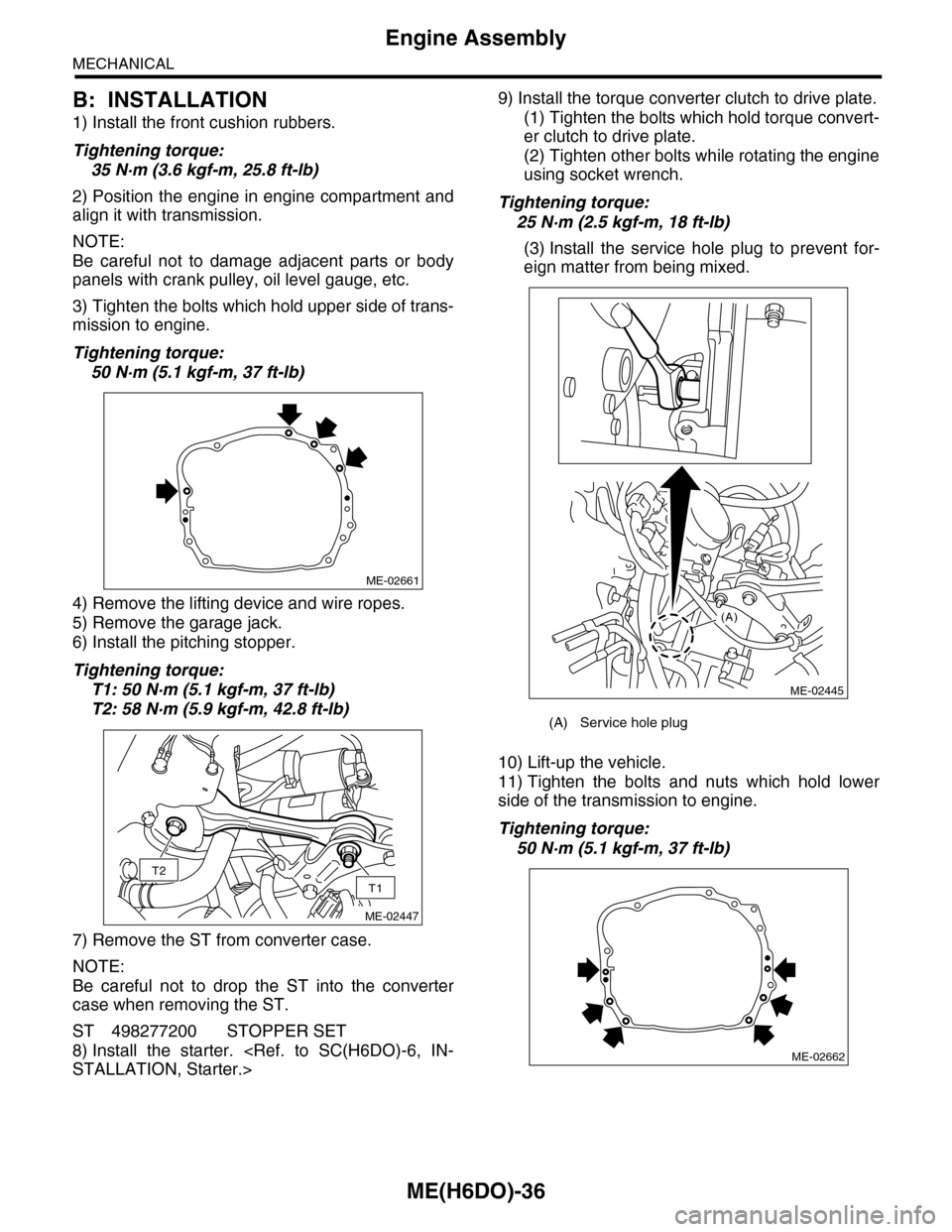

30) Support the engine with a lifting device and

wire ropes.

31) Support the transmission with a garage jack.

CAUTION:

Doing this is very important because the trans-

mission lowers for its own weight. This work is

also of great importance for facilitating reinstal-

lation.

CAUTION:

Before removing the engine away from trans-

mission, check to be sure no work has been

overlooked.

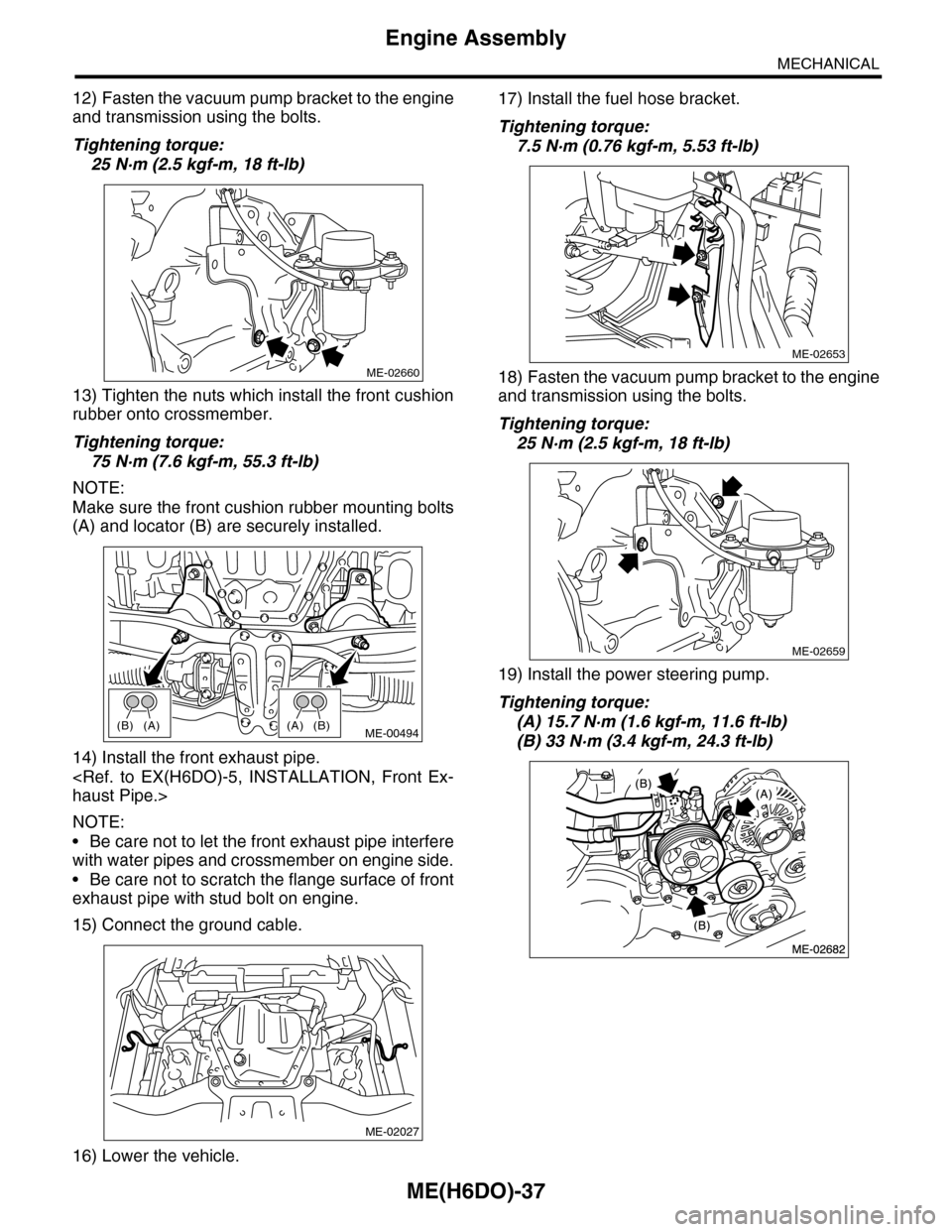

32) Separation of engine and transmission:

(1) Remove the starter.

(2) Remove the bolts which hold upper side of

transmission to engine.

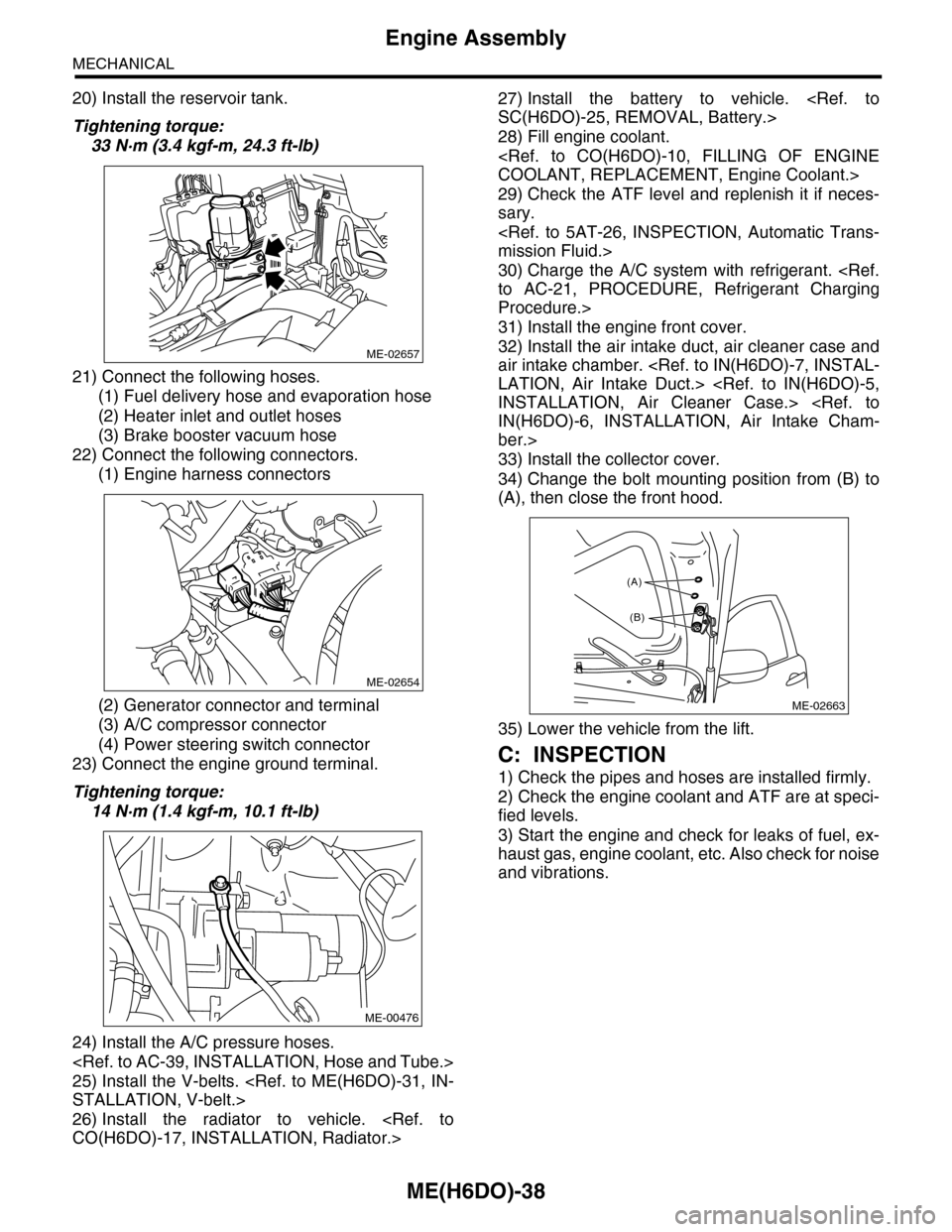

33) Install the ST to converter case.

ST 498277200 STOPPER SET

34) Remove the engine from vehicle.

(1) Slightly raise the engine.

(2) Raise the transmission with garage jack.

(3) Move the engine horizontally until main shaft

is withdrawn from clutch cover.

(4) Slowly move the engine away from engine

compartment.

NOTE:

Be careful not to damage adjacent parts or body

panels with crank pulley, oil level gauge, etc.

35) Remove the front cushion rubbers.

(A) Transmission

(B) Garage jack

(A)

(B)

ME-00490

ME-02661

ST

ME-00492

Page 1902 of 2453

ME(H6DO)-36

Engine Assembly

MECHANICAL

B: INSTALLATION

1) Install the front cushion rubbers.

Tightening torque:

35 N·m (3.6 kgf-m, 25.8 ft-lb)

2) Position the engine in engine compartment and

align it with transmission.

NOTE:

Be careful not to damage adjacent parts or body

panels with crank pulley, oil level gauge, etc.

3) Tighten the bolts which hold upper side of trans-

mission to engine.

Tightening torque:

50 N·m (5.1 kgf-m, 37 ft-lb)

4) Remove the lifting device and wire ropes.

5) Remove the garage jack.

6) Install the pitching stopper.

Tightening torque:

T1: 50 N·m (5.1 kgf-m, 37 ft-lb)

T2: 58 N·m (5.9 kgf-m, 42.8 ft-lb)

7) Remove the ST from converter case.

NOTE:

Be careful not to drop the ST into the converter

case when removing the ST.

ST 498277200 STOPPER SET

8) Install the starter.

9) Install the torque converter clutch to drive plate.

(1) Tighten the bolts which hold torque convert-

er clutch to drive plate.

(2) Tighten other bolts while rotating the engine

using socket wrench.

Tightening torque:

25 N·m (2.5 kgf-m, 18 ft-lb)

(3) Install the service hole plug to prevent for-

eign matter from being mixed.

10) Lift-up the vehicle.

11) Tighten the bolts and nuts which hold lower

side of the transmission to engine.

Tightening torque:

50 N·m (5.1 kgf-m, 37 ft-lb)

ME-02661

T2

T1

ME-02447

(A) Service hole plug

(A)

ME-02445

ME-02662

Page 1903 of 2453

ME(H6DO)-37

Engine Assembly

MECHANICAL

12) Fasten the vacuum pump bracket to the engine

and transmission using the bolts.

Tightening torque:

25 N·m (2.5 kgf-m, 18 ft-lb)

13) Tighten the nuts which install the front cushion

rubber onto crossmember.

Tightening torque:

75 N·m (7.6 kgf-m, 55.3 ft-lb)

NOTE:

Make sure the front cushion rubber mounting bolts

(A) and locator (B) are securely installed.

14) Install the front exhaust pipe.

NOTE:

•Be care not to let the front exhaust pipe interfere

with water pipes and crossmember on engine side.

•Be care not to scratch the flange surface of front

exhaust pipe with stud bolt on engine.

15) Connect the ground cable.

16) Lower the vehicle.

17) Install the fuel hose bracket.

Tightening torque:

7.5 N·m (0.76 kgf-m, 5.53 ft-lb)

18) Fasten the vacuum pump bracket to the engine

and transmission using the bolts.

Tightening torque:

25 N·m (2.5 kgf-m, 18 ft-lb)

19) Install the power steering pump.

Tightening torque:

(A) 15.7 N·m (1.6 kgf-m, 11.6 ft-lb)

(B) 33 N·m (3.4 kgf-m, 24.3 ft-lb)

ME-02660

(A)(B)(B)(A)ME-00494

ME-02027

ME-02653

ME-02659

Page 1904 of 2453

ME(H6DO)-38

Engine Assembly

MECHANICAL

20) Install the reservoir tank.

Tightening torque:

33 N·m (3.4 kgf-m, 24.3 ft-lb)

21) Connect the following hoses.

(1) Fuel delivery hose and evaporation hose

(2) Heater inlet and outlet hoses

(3) Brake booster vacuum hose

22) Connect the following connectors.

(1) Engine harness connectors

(2) Generator connector and terminal

(3) A/C compressor connector

(4) Power steering switch connector

23) Connect the engine ground terminal.

Tightening torque:

14 N·m (1.4 kgf-m, 10.1 ft-lb)

24) Install the A/C pressure hoses.

25) Install the V-belts.

26) Install the radiator to vehicle.

27) Install the battery to vehicle.

28) Fill engine coolant.

29) Check the ATF level and replenish it if neces-

sary.

30) Charge the A/C system with refrigerant.

Procedure.>

31) Install the engine front cover.

32) Install the air intake duct, air cleaner case and

air intake chamber.

ber.>

33) Install the collector cover.

34) Change the bolt mounting position from (B) to

(A), then close the front hood.

35) Lower the vehicle from the lift.

C: INSPECTION

1) Check the pipes and hoses are installed firmly.

2) Check the engine coolant and ATF are at speci-

fied levels.

3) Start the engine and check for leaks of fuel, ex-

haust gas, engine coolant, etc. Also check for noise

and vibrations.

ME-02657

ME-02654

ME-00476

ME-02663

(A)

(B)

Page 1905 of 2453

ME(H6DO)-39

Engine Mounting

MECHANICAL

11.Engine Mounting

A: REMOVAL

1) Remove the engine unit.

2) Remove the engine mounting from engine as-

sembly.

B: INSTALLATION

Install in the reverse order of removal.

Tightening torque:

Engine mounting:

35 N·m (3.6 kgf-m, 25.8 ft-lb)

C: INSPECTION

Make sure that there are no cracks or other damag-

es.

Page 1906 of 2453

ME(H6DO)-40

Preparation for Overhaul

MECHANICAL

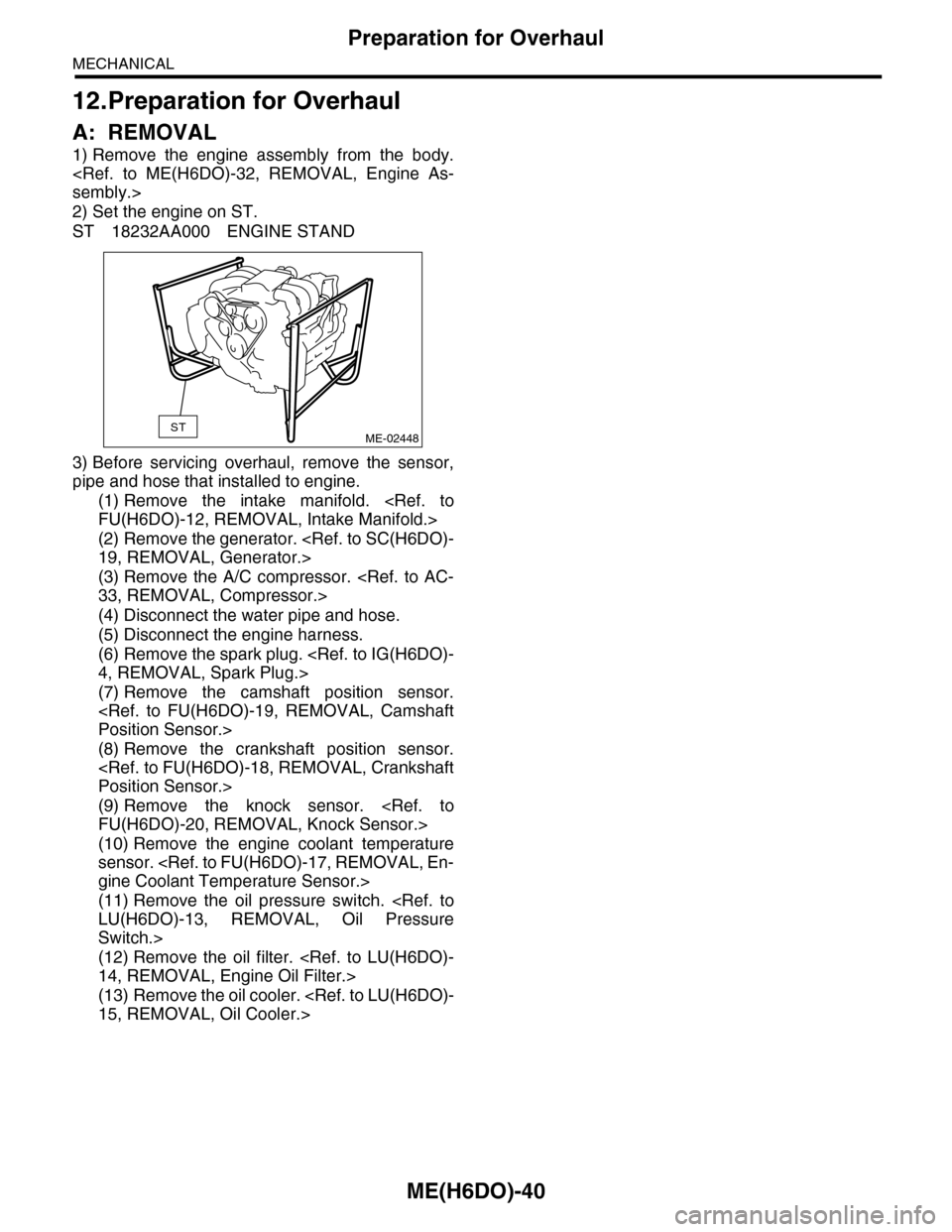

12.Preparation for Overhaul

A: REMOVAL

1) Remove the engine assembly from the body.

2) Set the engine on ST.

ST 18232AA000 ENGINE STAND

3) Before servicing overhaul, remove the sensor,

pipe and hose that installed to engine.

(1) Remove the intake manifold.

(2) Remove the generator.

(3) Remove the A/C compressor.

(4) Disconnect the water pipe and hose.

(5) Disconnect the engine harness.

(6) Remove the spark plug.

(7) Remove the camshaft position sensor.

(8) Remove the crankshaft position sensor.

(9) Remove the knock sensor.

(10) Remove the engine coolant temperature

sensor.

(11) Remove the oil pressure switch.

Switch.>

(12) Remove the oil filter.

(13) Remove the oil cooler.

STME-02448

Page 1907 of 2453

ME(H6DO)-41

Crank Pulley

MECHANICAL

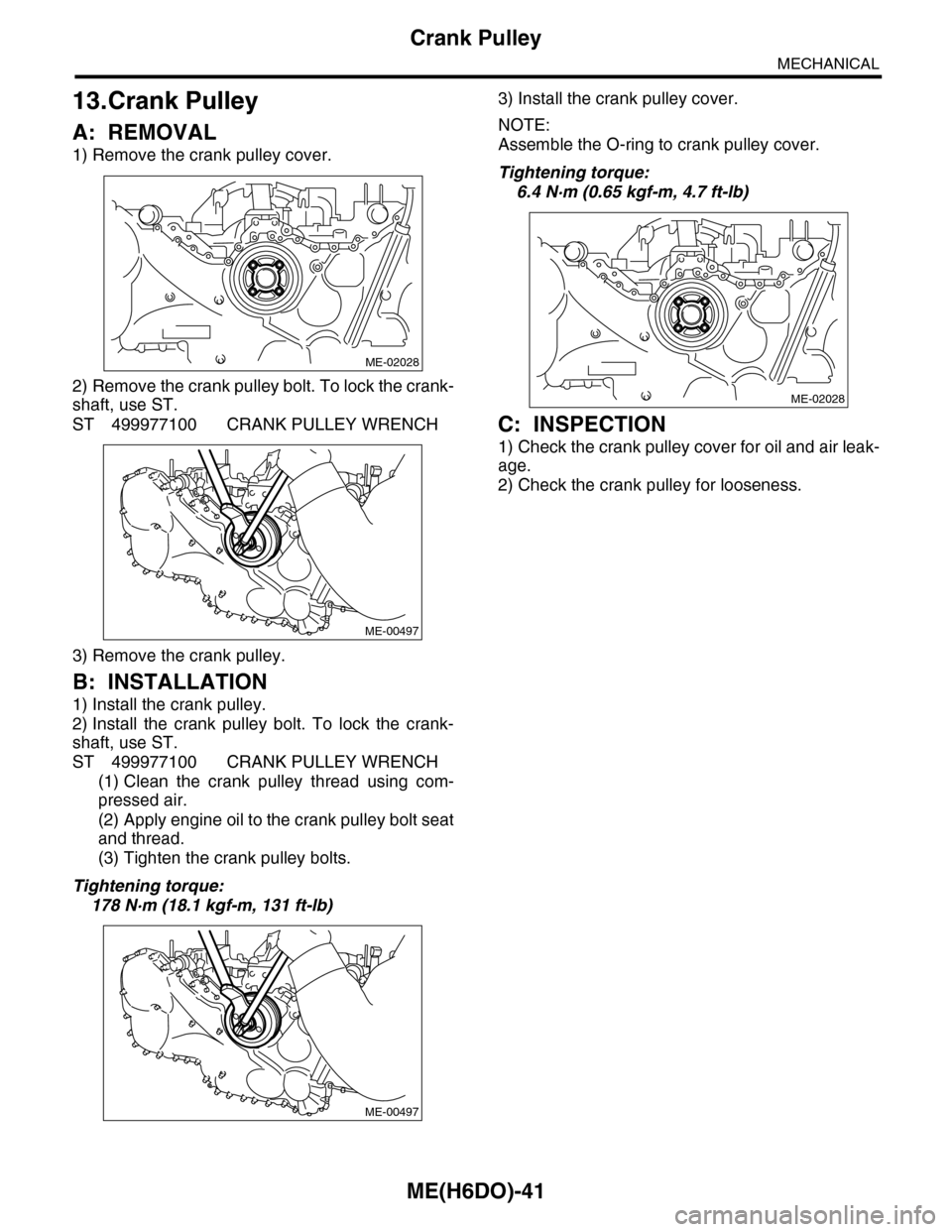

13.Crank Pulley

A: REMOVAL

1) Remove the crank pulley cover.

2) Remove the crank pulley bolt. To lock the crank-

shaft, use ST.

ST 499977100 CRANK PULLEY WRENCH

3) Remove the crank pulley.

B: INSTALLATION

1) Install the crank pulley.

2) Install the crank pulley bolt. To lock the crank-

shaft, use ST.

ST 499977100 CRANK PULLEY WRENCH

(1) Clean the crank pulley thread using com-

pressed air.

(2) Apply engine oil to the crank pulley bolt seat

and thread.

(3) Tighten the crank pulley bolts.

Tightening torque:

178 N·m (18.1 kgf-m, 131 ft-lb)

3) Install the crank pulley cover.

NOTE:

Assemble the O-ring to crank pulley cover.

Tightening torque:

6.4 N·m (0.65 kgf-m, 4.7 ft-lb)

C: INSPECTION

1) Check the crank pulley cover for oil and air leak-

age.

2) Check the crank pulley for looseness.

ME-02028

ME-00497

ME-00497

ME-02028

Page 1908 of 2453

ME(H6DO)-42

Front Chain Cover

MECHANICAL

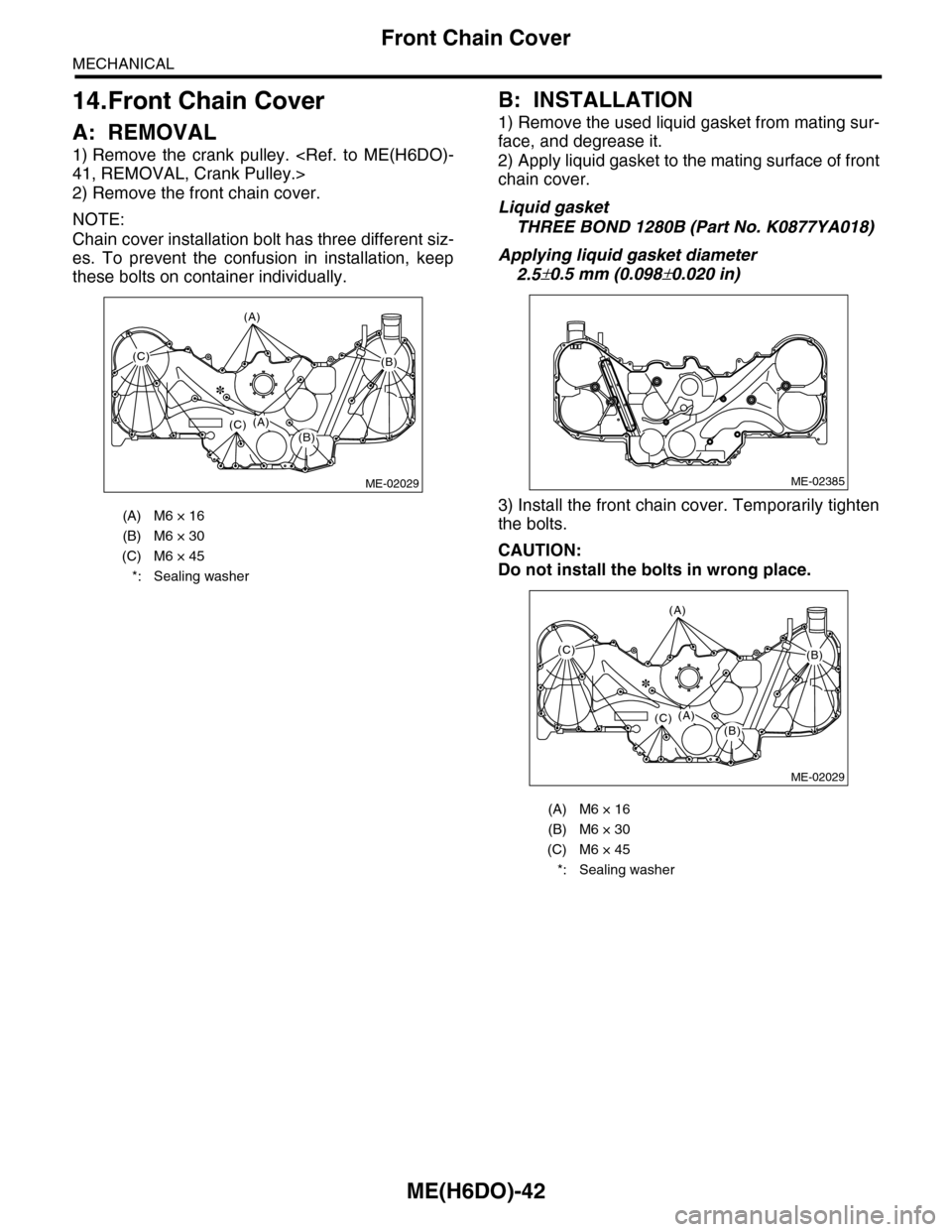

14.Front Chain Cover

A: REMOVAL

1) Remove the crank pulley.

2) Remove the front chain cover.

NOTE:

Chain cover installation bolt has three different siz-

es. To prevent the confusion in installation, keep

these bolts on container individually.

B: INSTALLATION

1) Remove the used liquid gasket from mating sur-

face, and degrease it.

2) Apply liquid gasket to the mating surface of front

chain cover.

Liquid gasket

THREE BOND 1280B (Part No. K0877YA018)

Applying liquid gasket diameter

2.5±0.5 mm (0.098±0.020 in)

3) Install the front chain cover. Temporarily tighten

the bolts.

CAUTION:

Do not install the bolts in wrong place.

(A) M6 × 16

(B) M6 × 30

(C) M6 × 45

*: Sealing washer

(C)

(C)

(A)

(B)

(B)

ME-02029

(A)

(A) M6 × 16

(B) M6 × 30

(C) M6 × 45

*: Sealing washer

ME-02385

(C)

(C)

(A)

(B)

(B)

ME-02029

(A)

Page 1909 of 2453

ME(H6DO)-43

Front Chain Cover

MECHANICAL

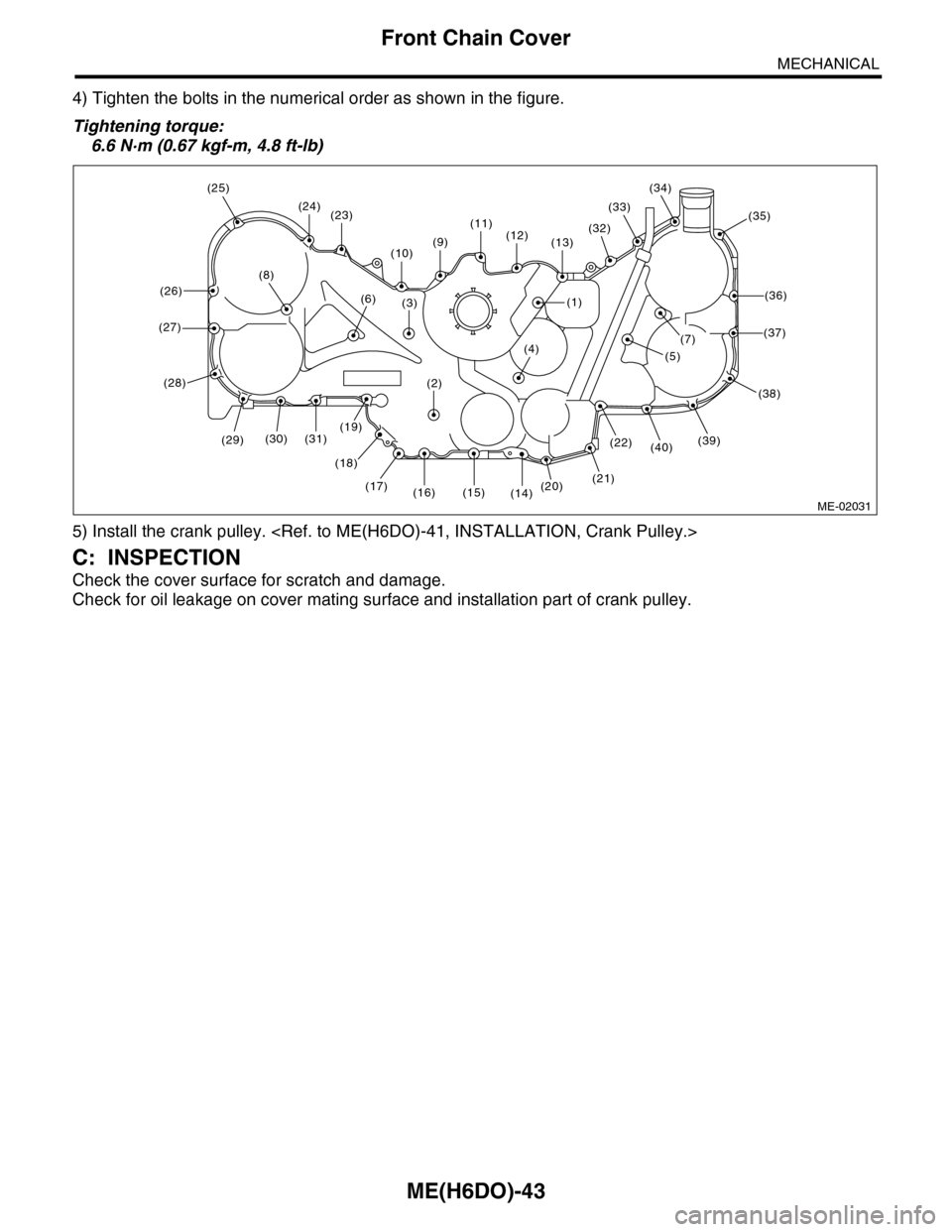

4) Tighten the bolts in the numerical order as shown in the figure.

Tightening torque:

6.6 N·m (0.67 kgf-m, 4.8 ft-lb)

5) Install the crank pulley.

C: INSPECTION

Check the cover surface for scratch and damage.

Check for oil leakage on cover mating surface and installation part of crank pulley.

ME-02031

(21)

(22)(40)(39)

(38)

(37)

(36)

(35)

(34)

(33)

(32)(13)(12)(11)

(9)(10)

(23)(24)

(8)

(6)

(25)

(26)

(27)

(28)

(29)(30) (31)(19)

(18)

(17)(16) (15)(14)(20)

(3)

(2)

(4)(5)

(1)

(7)

Page 1910 of 2453

ME(H6DO)-44

Timing Chain Assembly

MECHANICAL

15.Timing Chain Assembly

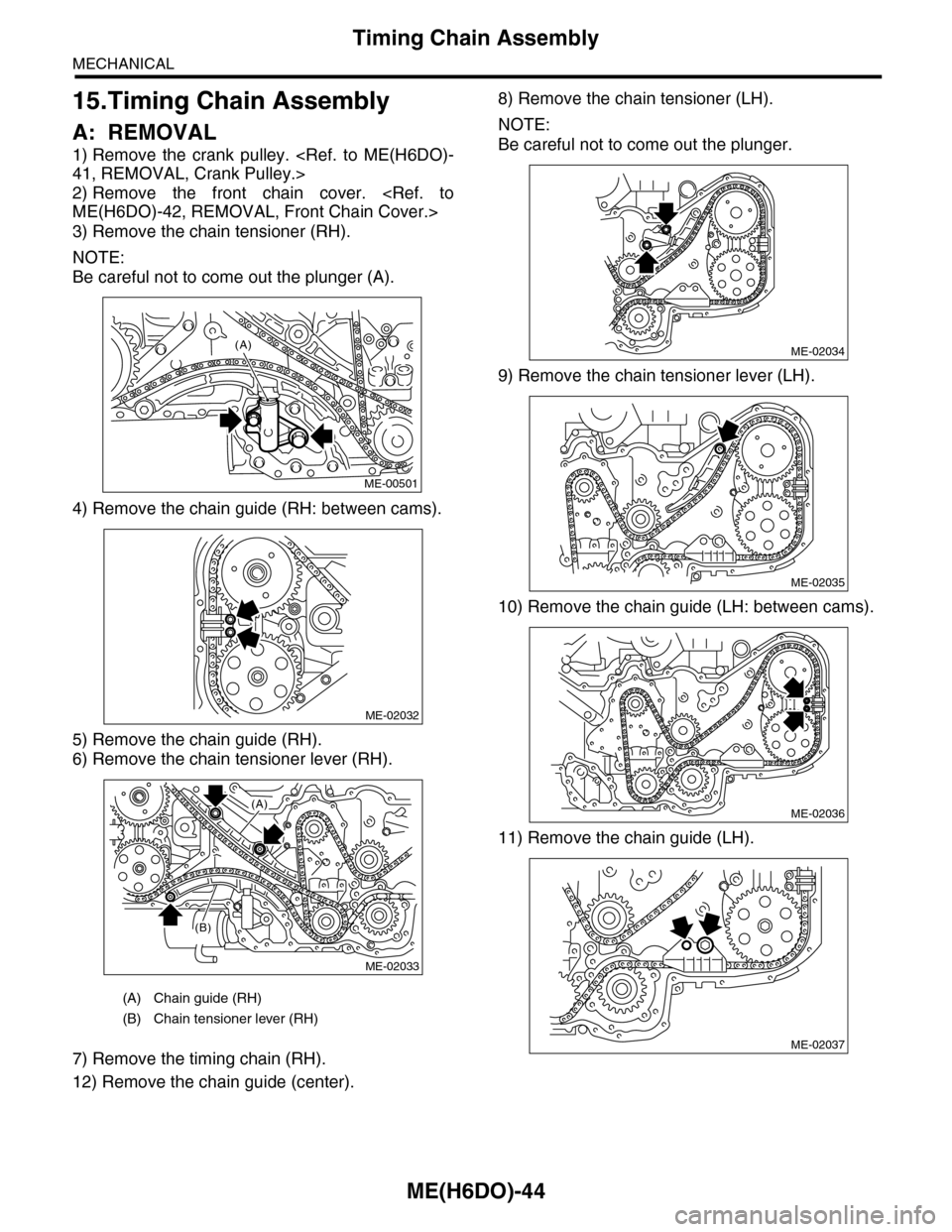

A: REMOVAL

1) Remove the crank pulley.

2) Remove the front chain cover.

3) Remove the chain tensioner (RH).

NOTE:

Be careful not to come out the plunger (A).

4) Remove the chain guide (RH: between cams).

5) Remove the chain guide (RH).

6) Remove the chain tensioner lever (RH).

7) Remove the timing chain (RH).

8) Remove the chain tensioner (LH).

NOTE:

Be careful not to come out the plunger.

9) Remove the chain tensioner lever (LH).

10) Remove the chain guide (LH: between cams).

11) Remove the chain guide (LH).

12) Remove the chain guide (center).

(A) Chain guide (RH)

(B) Chain tensioner lever (RH)

(A)

ME-00501

ME-02032

ME-02033

(A)

(B)

ME-02034

ME-02035

ME-02036

ME-02037