SUBARU TRIBECA 2009 1.G Service Workshop Manual

Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 1981 of 2453

SC(H6DO)-23

Generator

STARTING/CHARGING SYSTEMS

2. ROTOR

1) Slip ring surface

Inspect the slip rings for contamination or any

roughness on the sliding surface. Repair the slip

ring surface using a lathe or sand paper.

2) Slip ring outer diameter

Measure the slip ring outer diameter. If the slip ring

is worn, replace the rotor assembly.

Slip ring outer diameter:

Standard

22.7 mm (0.894 in)

Limit

22.1 mm (0.870 in)

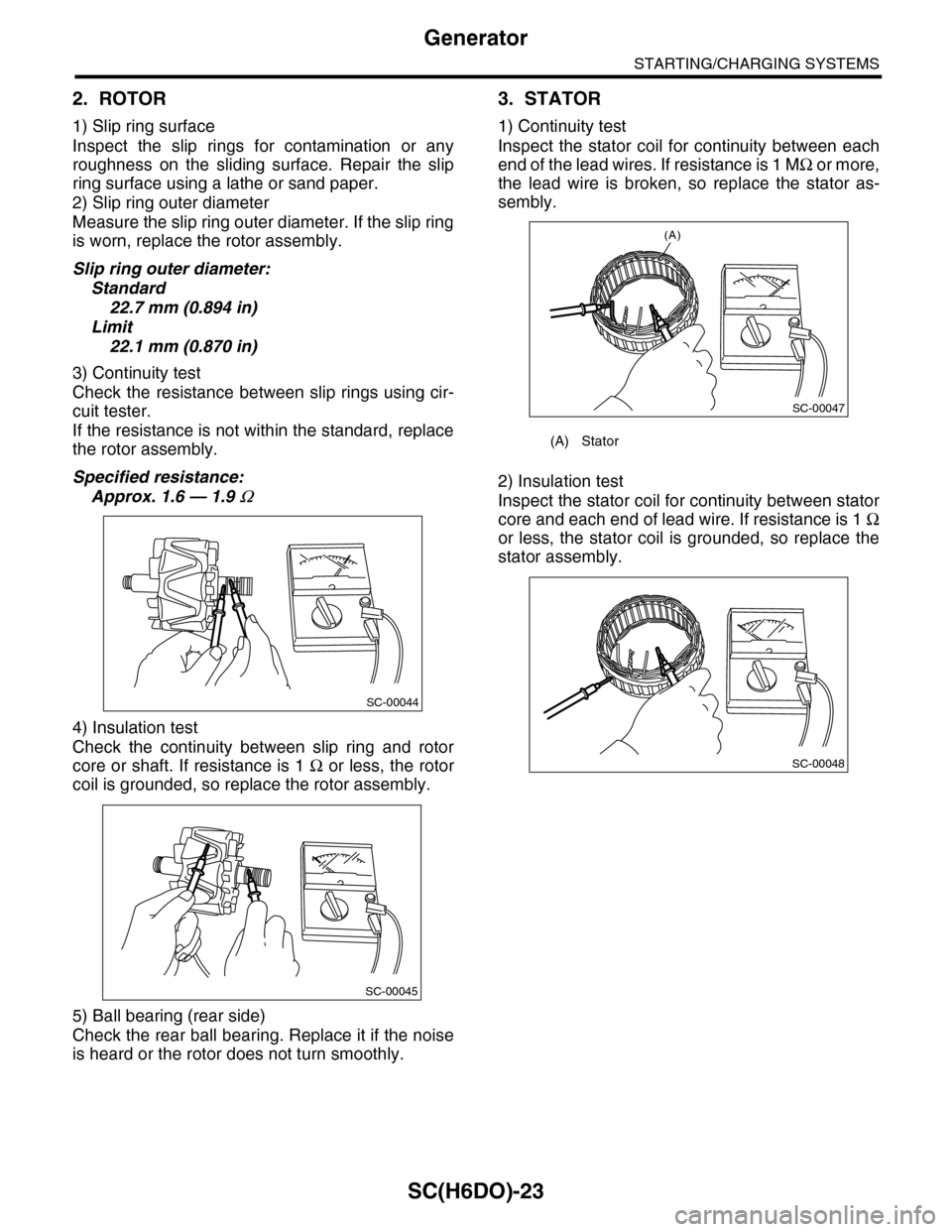

3) Continuity test

Check the resistance between slip rings using cir-

cuit tester.

If the resistance is not within the standard, replace

the rotor assembly.

Specified resistance:

Approx. 1.6 — 1.9 Ω

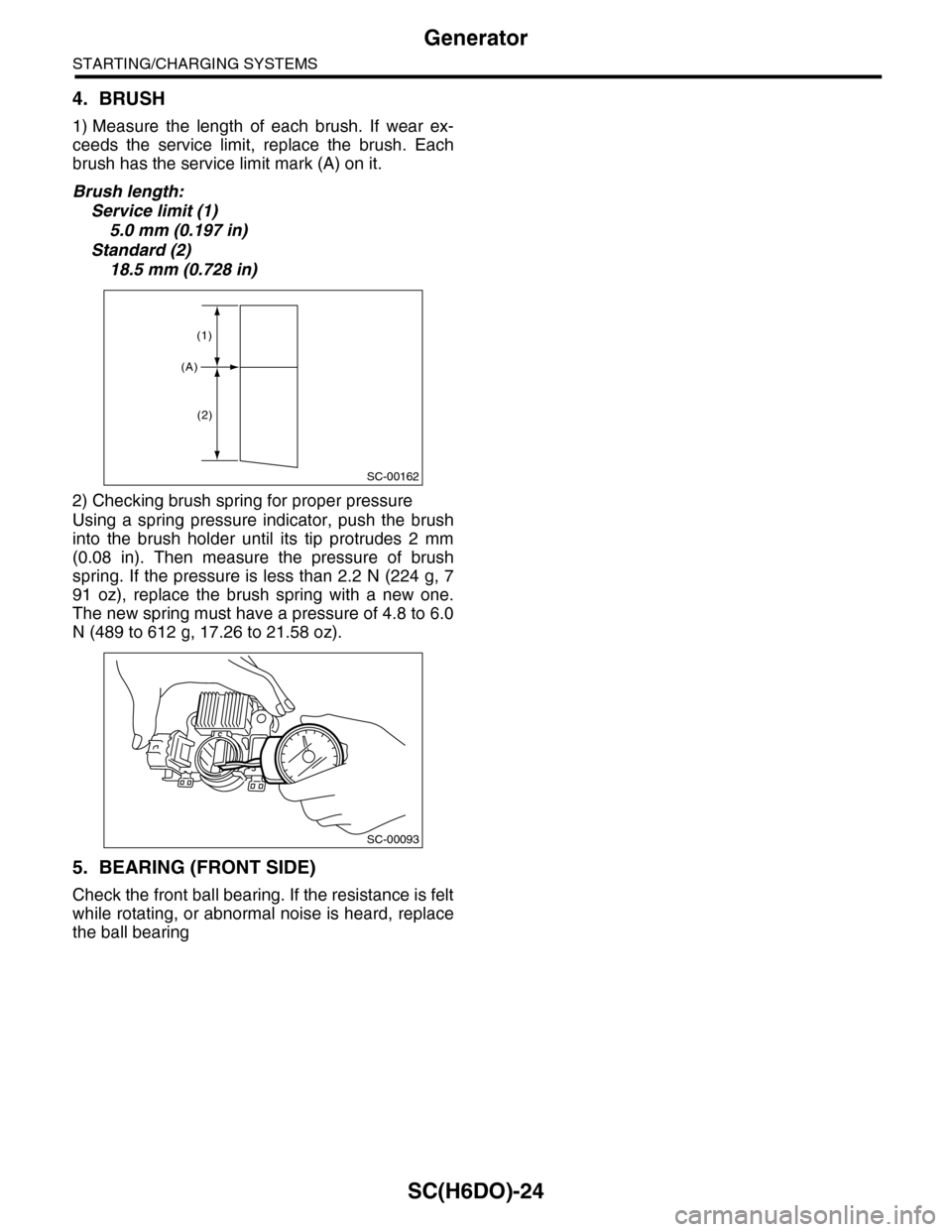

4) Insulation test

Check the continuity between slip ring and rotor

core or shaft. If resistance is 1 Ω or less, the rotor

coil is grounded, so replace the rotor assembly.

5) Ball bearing (rear side)

Check the rear ball bearing. Replace it if the noise

is heard or the rotor does not turn smoothly.

3. STATOR

1) Continuity test

Inspect the stator coil for continuity between each

end of the lead wires. If resistance is 1 MΩ o r m o r e ,

the lead wire is broken, so replace the stator as-

sembly.

2) Insulation test

Inspect the stator coil for continuity between stator

core and each end of lead wire. If resistance is 1 Ω

or less, the stator coil is grounded, so replace the

stator assembly.

SC-00044

SC-00045

(A) Stator

(A)

SC-00047

SC-00048

Page 1982 of 2453

SC(H6DO)-24

Generator

STARTING/CHARGING SYSTEMS

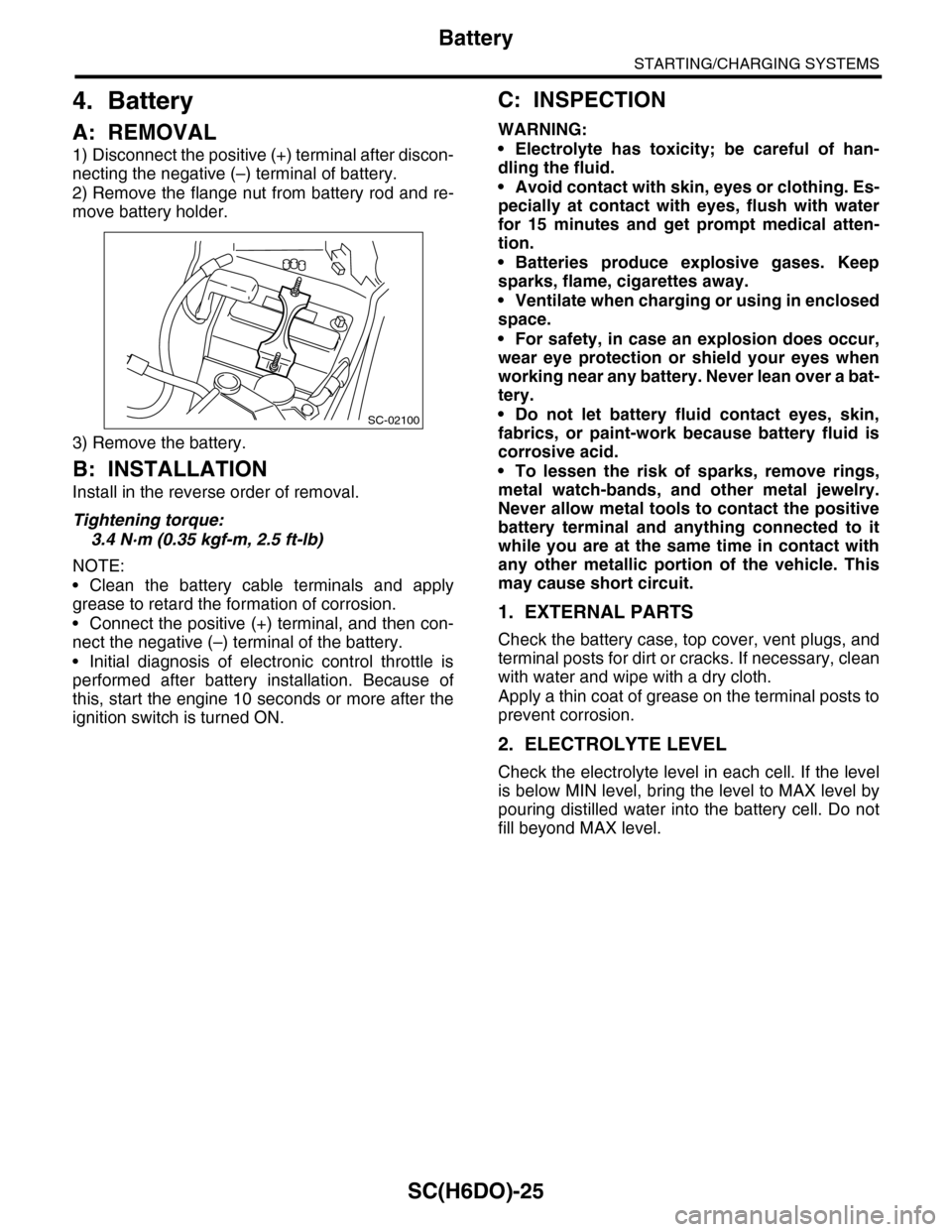

4. BRUSH

1) Measure the length of each brush. If wear ex-

ceeds the service limit, replace the brush. Each

brush has the service limit mark (A) on it.

Brush length:

Service limit (1)

5.0 mm (0.197 in)

Standard (2)

18.5 mm (0.728 in)

2) Checking brush spring for proper pressure

Using a spring pressure indicator, push the brush

into the brush holder until its tip protrudes 2 mm

(0.08 in). Then measure the pressure of brush

spring. If the pressure is less than 2.2 N (224 g, 7

91 oz), replace the brush spring with a new one.

The new spring must have a pressure of 4.8 to 6.0

N (489 to 612 g, 17.26 to 21.58 oz).

5. BEARING (FRONT SIDE)

Check the front ball bearing. If the resistance is felt

while rotating, or abnormal noise is heard, replace

the ball bearing

SC-00162

(A)

(1)

(2)

SC-00093

Page 1983 of 2453

SC(H6DO)-25

Battery

STARTING/CHARGING SYSTEMS

4. Battery

A: REMOVAL

1) Disconnect the positive (+) terminal after discon-

necting the negative (–) terminal of battery.

2) Remove the flange nut from battery rod and re-

move battery holder.

3) Remove the battery.

B: INSTALLATION

Install in the reverse order of removal.

Tightening torque:

3.4 N·m (0.35 kgf-m, 2.5 ft-lb)

NOTE:

•Clean the battery cable terminals and apply

grease to retard the formation of corrosion.

•Connect the positive (+) terminal, and then con-

nect the negative (–) terminal of the battery.

•Initial diagnosis of electronic control throttle is

performed after battery installation. Because of

this, start the engine 10 seconds or more after the

ignition switch is turned ON.

C: INSPECTION

WARNING:

•Electrolyte has toxicity; be careful of han-

dling the fluid.

•Avoid contact with skin, eyes or clothing. Es-

pecially at contact with eyes, flush with water

for 15 minutes and get prompt medical atten-

tion.

•Batteries produce explosive gases. Keep

sparks, flame, cigarettes away.

•Ventilate when charging or using in enclosed

space.

•For safety, in case an explosion does occur,

wear eye protection or shield your eyes when

working near any battery. Never lean over a bat-

tery.

•Do not let battery fluid contact eyes, skin,

fabrics, or paint-work because battery fluid is

corrosive acid.

•To lessen the risk of sparks, remove rings,

metal watch-bands, and other metal jewelry.

Never allow metal tools to contact the positive

battery terminal and anything connected to it

while you are at the same time in contact with

any other metallic portion of the vehicle. This

may cause short circuit.

1. EXTERNAL PARTS

Check the battery case, top cover, vent plugs, and

terminal posts for dirt or cracks. If necessary, clean

with water and wipe with a dry cloth.

Apply a thin coat of grease on the terminal posts to

prevent corrosion.

2. ELECTROLYTE LEVEL

Check the electrolyte level in each cell. If the level

is below MIN level, bring the level to MAX level by

pouring distilled water into the battery cell. Do not

fill beyond MAX level.

SC-02100

Page 1984 of 2453

SC(H6DO)-26

Battery

STARTING/CHARGING SYSTEMS

3. SPECIFIC GRAVITY OF ELECTROLYTE

1) Measure specific gravity of electrolyte using a

hydrometer and a thermometer.

Specific gravity varies with temperature of electro-

lyte so that it must be corrected at 20°C (68°F) us-

ing the following equation:

S20 = St + 0.0007 × (t – 20)

S20: Specific gravity corrected at electrolyte

temperature of 20°C (68°F)

St: Measured specific gravity

t: Measured temperature (°C)

Determine whether or not battery must be

charged, according to corrected specific

gravity.

Standard specific gravity: 1.220 — 1.290

[20°C (68°F)]

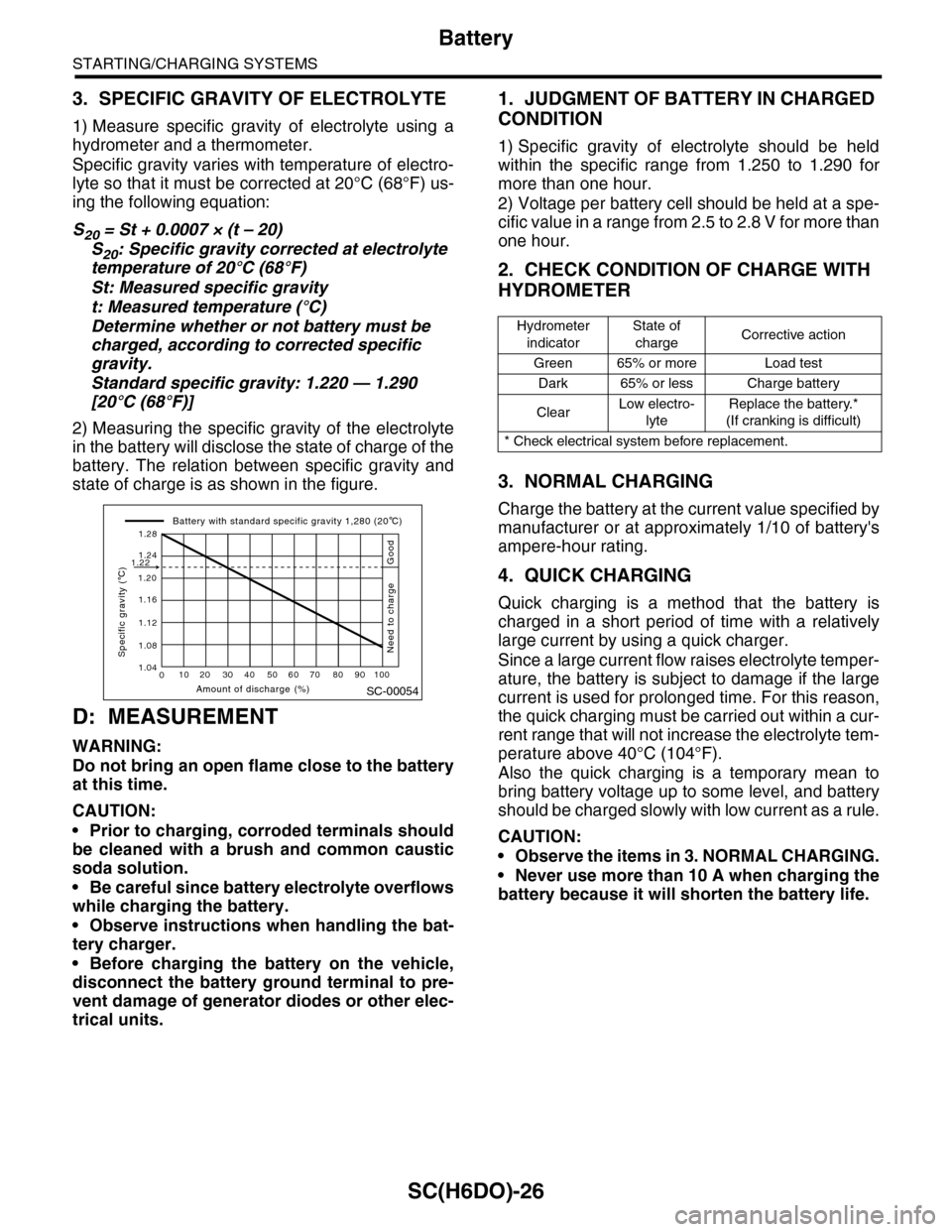

2) Measuring the specific gravity of the electrolyte

in the battery will disclose the state of charge of the

battery. The relation between specific gravity and

state of charge is as shown in the figure.

D: MEASUREMENT

WARNING:

Do not bring an open flame close to the battery

at this time.

CAUTION:

•Prior to charging, corroded terminals should

be cleaned with a brush and common caustic

soda solution.

•Be careful since battery electrolyte overflows

while charging the battery.

•Observe instructions when handling the bat-

tery charger.

•Before charging the battery on the vehicle,

disconnect the battery ground terminal to pre-

vent damage of generator diodes or other elec-

trical units.

1. JUDGMENT OF BATTERY IN CHARGED

CONDITION

1) Specific gravity of electrolyte should be held

within the specific range from 1.250 to 1.290 for

more than one hour.

2) Voltage per battery cell should be held at a spe-

cific value in a range from 2.5 to 2.8 V for more than

one hour.

2. CHECK CONDITION OF CHARGE WITH

HYDROMETER

3. NORMAL CHARGING

Charge the battery at the current value specified by

manufacturer or at approximately 1/10 of battery's

ampere-hour rating.

4. QUICK CHARGING

Quick charging is a method that the battery is

charged in a short period of time with a relatively

large current by using a quick charger.

Since a large current flow raises electrolyte temper-

ature, the battery is subject to damage if the large

current is used for prolonged time. For this reason,

the quick charging must be carried out within a cur-

rent range that will not increase the electrolyte tem-

perature above 40°C (104°F).

Also the quick charging is a temporary mean to

bring battery voltage up to some level, and battery

should be charged slowly with low current as a rule.

CAUTION:

•Observe the items in 3. NORMAL CHARGING.

•Never use more than 10 A when charging the

battery because it will shorten the battery life.

SC-00054

010 20 30 40 50 60 70 80 90 100

1.12

1.20

1.16

1.24

1.28

1.22

1.08

1.04

Amount of discharge (%)

Specific gravity ( C)

Battery with standard specific gravity 1,280 (20 C)

Good

Need to charge

Hydrometer

indicator

State of

chargeCorrective action

Green 65% or more Load test

Dark 65% or less Charge battery

ClearLow electro-

lyte

Replace the battery.*

(If cranking is difficult)

* Check electrical system before replacement.

Page 1985 of 2453

PM-2

General Description

PERIODIC MAINTENANCE SERVICES

1. General Description

A: GENERAL DESCRIPTION

Be sure to perform periodic maintenance in order to

maintain vehicle performance and find problems

before they occur.

Page 1986 of 2453

PM-3

Schedule

PERIODIC MAINTENANCE SERVICES

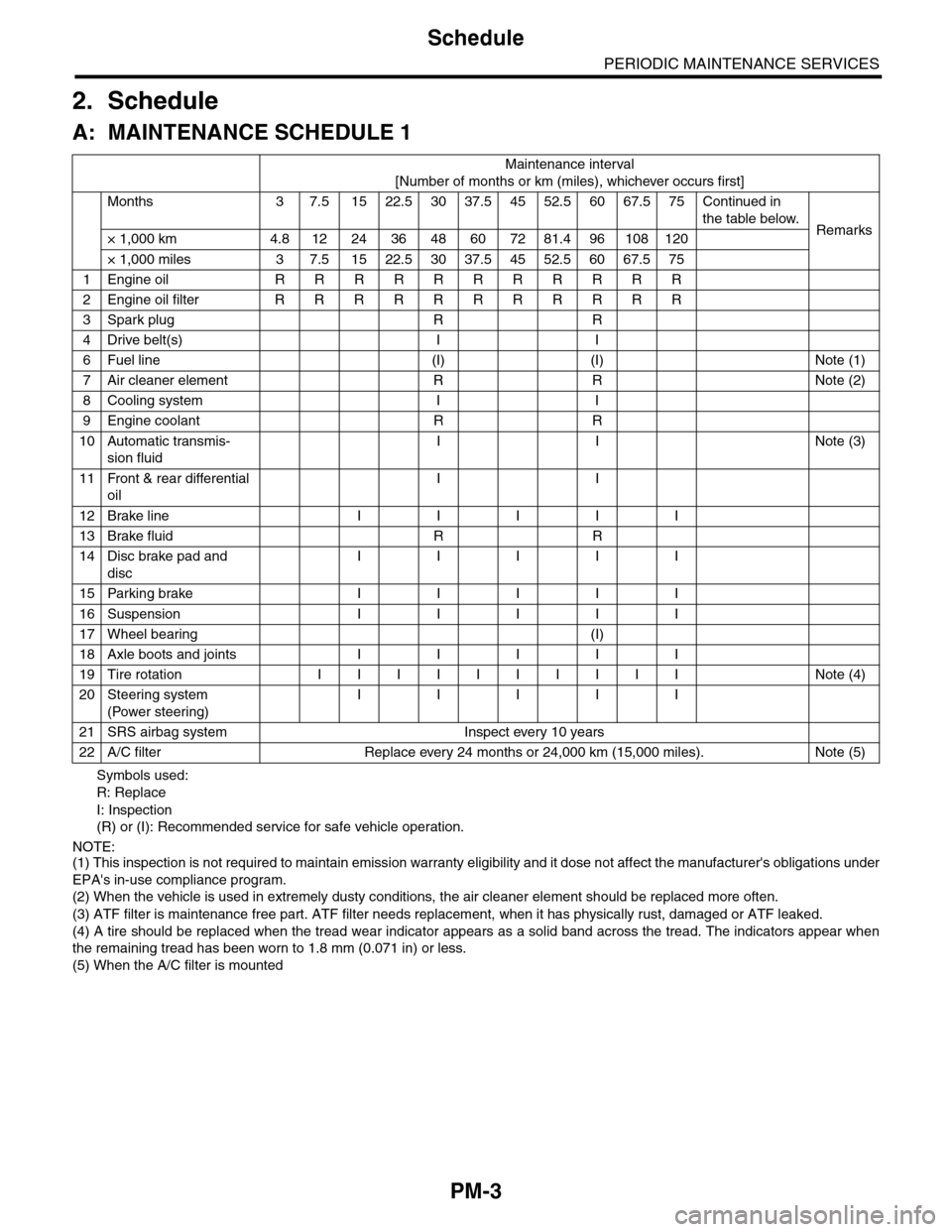

2. Schedule

A: MAINTENANCE SCHEDULE 1

Symbols used:

R: Replace

I: Inspection

(R) or (I): Recommended service for safe vehicle operation.

NOTE:(1) This inspection is not required to maintain emission warranty eligibility and it dose not affect the manufacturer's obligations under

EPA's in-use compliance program.

(2) When the vehicle is used in extremely dusty conditions, the air cleaner element should be replaced more often.

(3) ATF filter is maintenance free part. ATF filter needs replacement, when it has physically rust, damaged or ATF leaked.

(4) A tire should be replaced when the tread wear indicator appears as a solid band across the tread. The indicators appear when

the remaining tread has been worn to 1.8 mm (0.071 in) or less.

(5) When the A/C filter is mounted

Maintenance interval

[Number of months or km (miles), whichever occurs first]

Months 3 7.51522.53037.54552.56067.575Continued in

the table below.Remarks× 1,000 km 4.8 12 24 36 48 60 72 81.4 96 108 120

× 1,000 miles 3 7.5 15 22.5 30 37.5 45 52.5 60 67.5 75

1Engine oil R R R R R R R R R R R

2Engine oil filter R R R R R R R R R R R

3Spark plug R R

4Drive belt(s) I I

6Fuel line (I) (I) Note (1)

7Air cleaner element R R Note (2)

8Cooling system I I

9Engine coolant R R

10 Automatic transmis-

sion fluid

I I Note (3)

11 Front & rear differential

oil

I I

12 Brake line I I I I I

13 Brake fluid R R

14 Disc brake pad and

disc

I I I I I

15 Parking brake I I I I I

16 Suspension I I I I I

17 Wheel bearing (I)

18 Axle boots and joints I I I I I

19 Tire rotation I I I I I I I I I I Note (4)

20 Steering system

(Power steering)

I I I I I

21 SRS airbag system Inspect every 10 years

22 A/C filter Replace every 24 months or 24,000 km (15,000 miles). Note (5)

Page 1987 of 2453

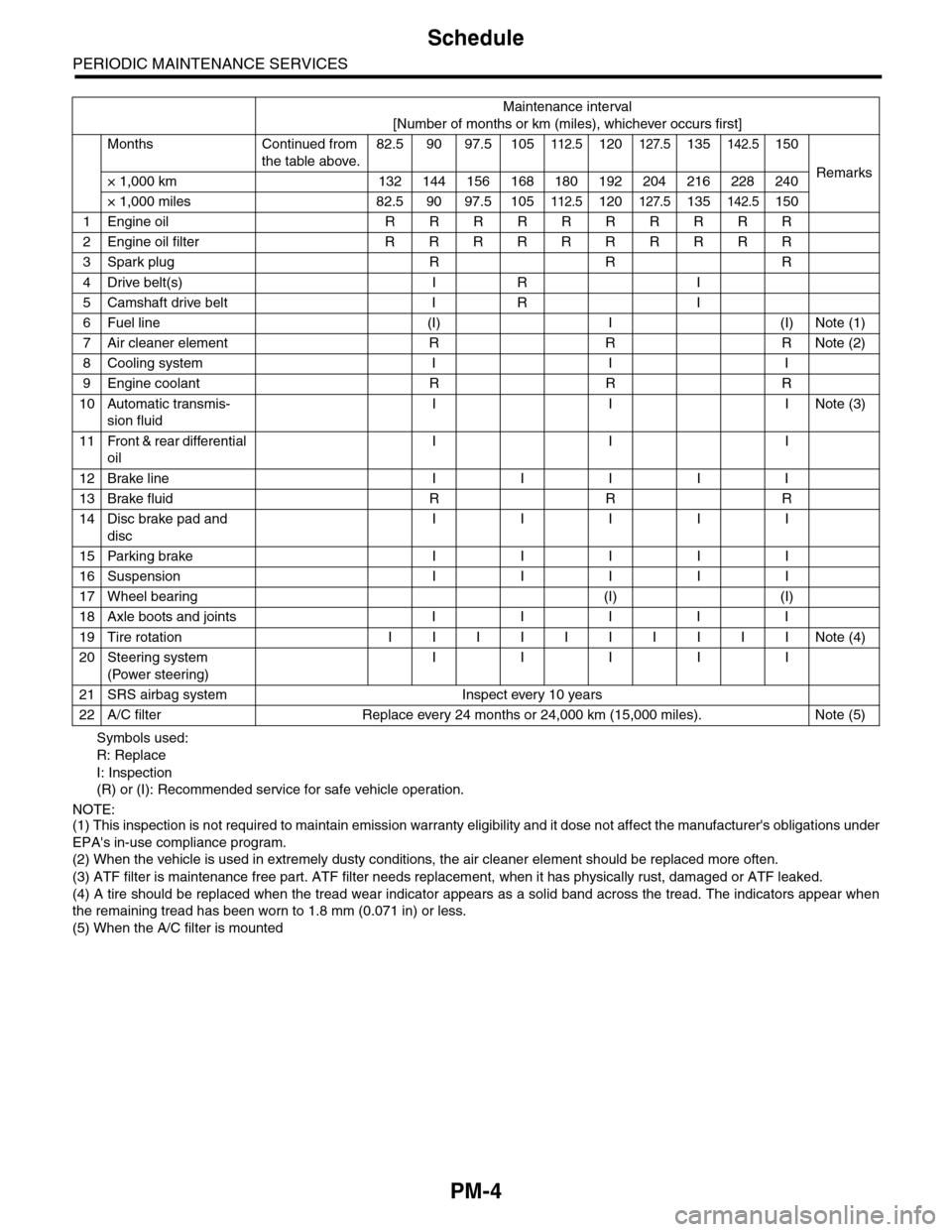

PM-4

Schedule

PERIODIC MAINTENANCE SERVICES

Symbols used:

R: Replace

I: Inspection

(R) or (I): Recommended service for safe vehicle operation.

NOTE:(1) This inspection is not required to maintain emission warranty eligibility and it dose not affect the manufacturer's obligations under

EPA's in-use compliance program.

(2) When the vehicle is used in extremely dusty conditions, the air cleaner element should be replaced more often.

(3) ATF filter is maintenance free part. ATF filter needs replacement, when it has physically rust, damaged or ATF leaked.

(4) A tire should be replaced when the tread wear indicator appears as a solid band across the tread. The indicators appear when

the remaining tread has been worn to 1.8 mm (0.071 in) or less.

(5) When the A/C filter is mounted

Maintenance interval

[Number of months or km (miles), whichever occurs first]

Months Continued from

the table above.

82.5 90 97.5 105112.5120127.5135142.5150

Remarks× 1,000 km 132 144 156 168 180 192 204 216 228 240

× 1,000 miles 82.5 90 97.5 105112.5120127.5135142.5150

1Engine oil R R R R R R R R R R

2Engine oil filter R R R R R R R R R R

3Spark plug R R R

4Drive belt(s) I R I

5Camshaft drive belt I R I

6Fuel line (I) I (I) Note (1)

7Air cleaner element R R R Note (2)

8Cooling system I I I

9Engine coolant R R R

10 Automatic transmis-

sion fluid

I I INote (3)

11 Front & rear differential

oil

I I I

12 Brake line I I I I I

13 Brake fluid R R R

14 Disc brake pad and

disc

I I I I I

15 Parking brake I I I I I

16 Suspension I I I I I

17 Wheel bearing (I) (I)

18 Axle boots and joints I I I I I

19 Tire rotation I I I I I I I I I I Note (4)

20 Steering system

(Power steering)

I I I I I

21 SRS airbag system Inspect every 10 years

22 A/C filter Replace every 24 months or 24,000 km (15,000 miles). Note (5)

Page 1988 of 2453

PM-5

Schedule

PERIODIC MAINTENANCE SERVICES

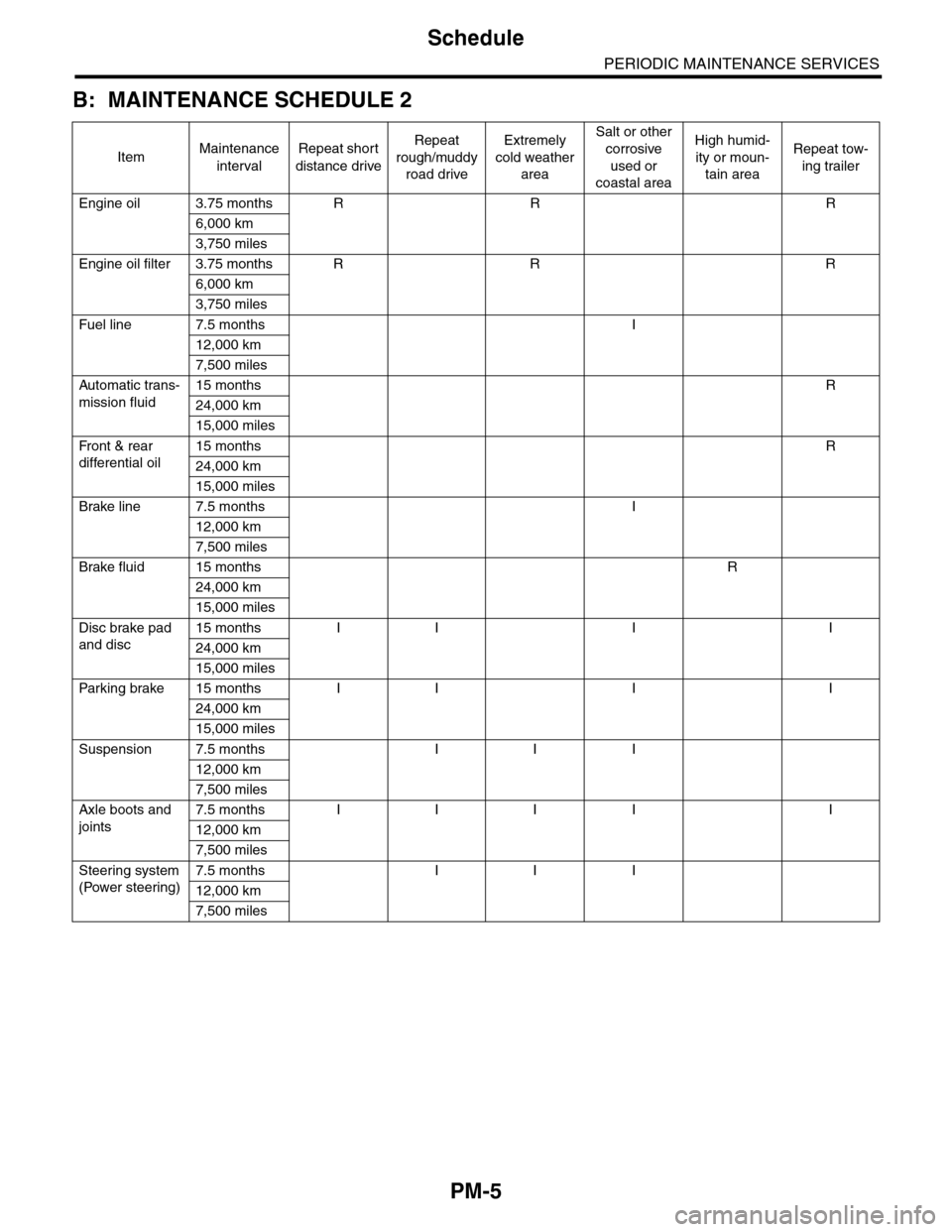

B: MAINTENANCE SCHEDULE 2

ItemMaintenance

interval

Repeat short

distance drive

Repeat

rough/muddy

road drive

Extremely

cold weather

area

Salt or other

corrosive

used or

coastal area

High humid-

ity or moun-

tain area

Repeat tow-

ing trailer

Engine oil 3.75 months R R R

6,000 km

3,750 miles

Engine oil filter 3.75 months R R R

6,000 km

3,750 miles

Fuel line 7.5 months I

12,000 km

7,500 miles

Automatic trans-

mission fluid

15 months R

24,000 km

15,000 miles

Fr o nt & r ea r

differential oil

15 months R

24,000 km

15,000 miles

Brake line 7.5 months I

12,000 km

7,500 miles

Brake fluid 15 months R

24,000 km

15,000 miles

Disc brake pad

and disc

15 months I I I I

24,000 km

15,000 miles

Par king brake 15 months I I I I

24,000 km

15,000 miles

Suspension 7.5 months I I I

12,000 km

7,500 miles

Axle boots and

joints

7.5 months I I I I I

12,000 km

7,500 miles

Steering system

(Power steering)

7.5 months I I I

12,000 km

7,500 miles

Page 1989 of 2453

PM-6

Engine Oil

PERIODIC MAINTENANCE SERVICES

3. Engine Oil

A: REPLACEMENT

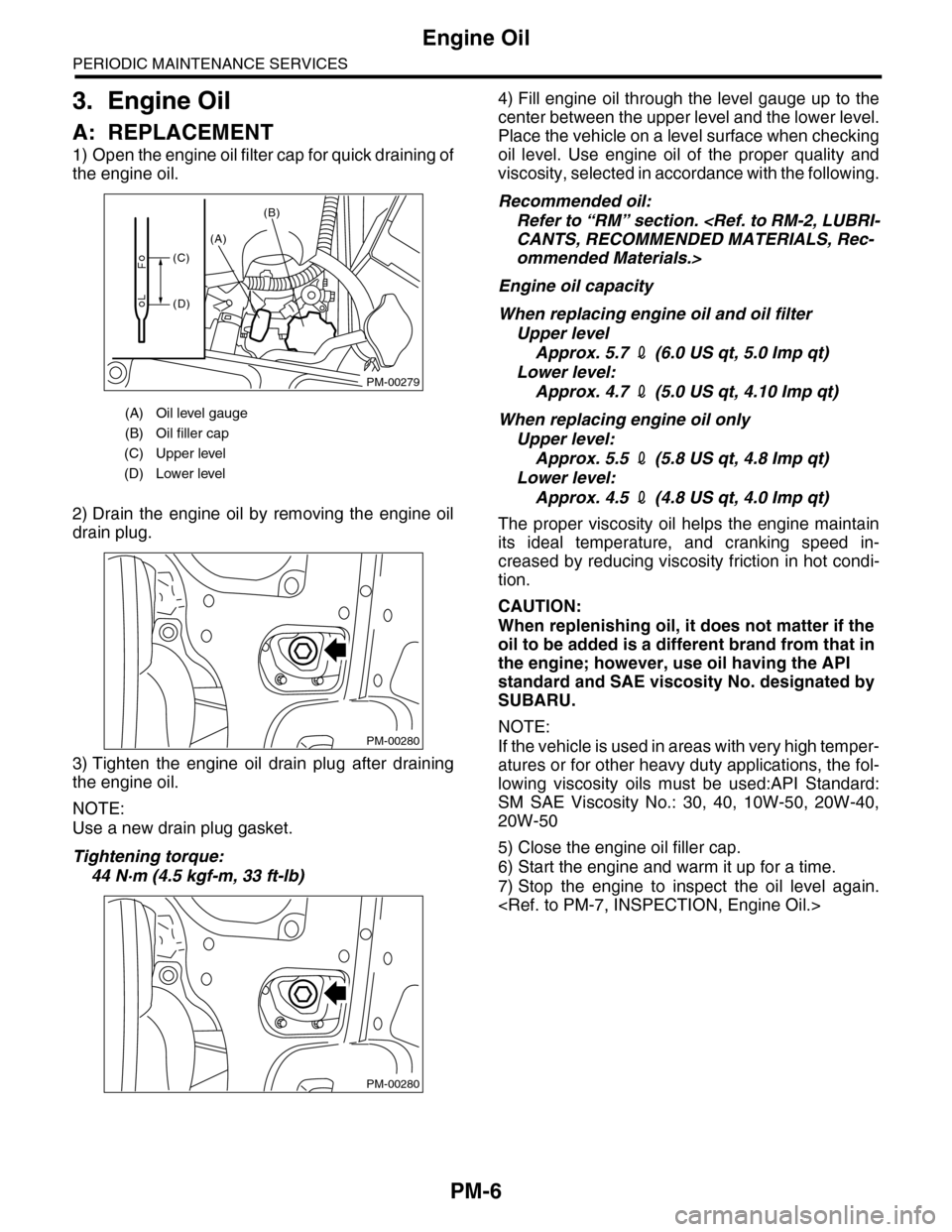

1) Open the engine oil filter cap for quick draining of

the engine oil.

2) Drain the engine oil by removing the engine oil

drain plug.

3) Tighten the engine oil drain plug after draining

the engine oil.

NOTE:

Use a new drain plug gasket.

Tightening torque:

44 N·m (4.5 kgf-m, 33 ft-lb)

4) Fill engine oil through the level gauge up to the

center between the upper level and the lower level.

Place the vehicle on a level surface when checking

oil level. Use engine oil of the proper quality and

viscosity, selected in accordance with the following.

Recommended oil:

Refer to “RM” section.

ommended Materials.>

Engine oil capacity

When replacing engine oil and oil filter

Upper level

Approx. 5.7 2 (6.0 US qt, 5.0 Imp qt)

Lower level:

Approx. 4.7 2 (5.0 US qt, 4.10 Imp qt)

When replacing engine oil only

Upper level:

Approx. 5.5 2 (5.8 US qt, 4.8 Imp qt)

Lower level:

Approx. 4.5 2 (4.8 US qt, 4.0 Imp qt)

The proper viscosity oil helps the engine maintain

its ideal temperature, and cranking speed in-

creased by reducing viscosity friction in hot condi-

tion.

CAUTION:

When replenishing oil, it does not matter if the

oil to be added is a different brand from that in

the engine; however, use oil having the API

standard and SAE viscosity No. designated by

SUBARU.

NOTE:

If the vehicle is used in areas with very high temper-

atures or for other heavy duty applications, the fol-

lowing viscosity oils must be used:API Standard:

SM SAE Viscosity No.: 30, 40, 10W-50, 20W-40,

20W-50

5) Close the engine oil filler cap.

6) Start the engine and warm it up for a time.

7) Stop the engine to inspect the oil level again.

(A) Oil level gauge

(B) Oil filler cap

(C) Upper level

(D) Lower level

PM-00279

(A)

(B)

(C)

(D)

PM-00280

PM-00280

Page 1990 of 2453

PM-7

Engine Oil

PERIODIC MAINTENANCE SERVICES

B: INSPECTION

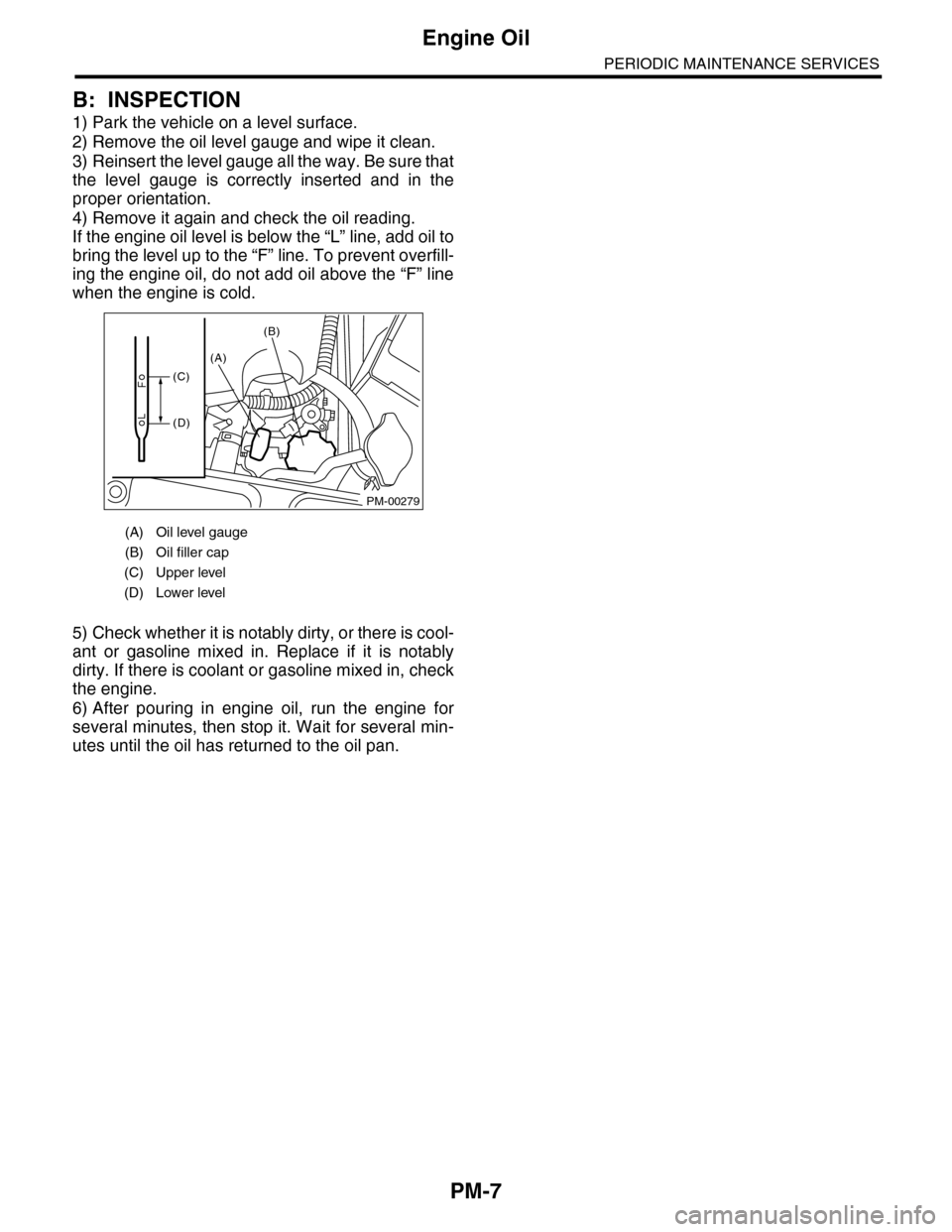

1) Park the vehicle on a level surface.

2) Remove the oil level gauge and wipe it clean.

3) Reinsert the level gauge all the way. Be sure that

the level gauge is correctly inserted and in the

proper orientation.

4) Remove it again and check the oil reading.

If the engine oil level is below the “L” line, add oil to

bring the level up to the “F” line. To prevent overfill-

ing the engine oil, do not add oil above the “F” line

when the engine is cold.

5) Check whether it is notably dirty, or there is cool-

ant or gasoline mixed in. Replace if it is notably

dirty. If there is coolant or gasoline mixed in, check

the engine.

6) After pouring in engine oil, run the engine for

several minutes, then stop it. Wait for several min-

utes until the oil has returned to the oil pan.

(A) Oil level gauge

(B) Oil filler cap

(C) Upper level

(D) Lower level

PM-00279

(A)

(B)

(C)

(D)