SUBARU TRIBECA 2009 1.G Service Workshop Manual

Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 1961 of 2453

SC(H6DO)-3

General Description

STARTING/CHARGING SYSTEMS

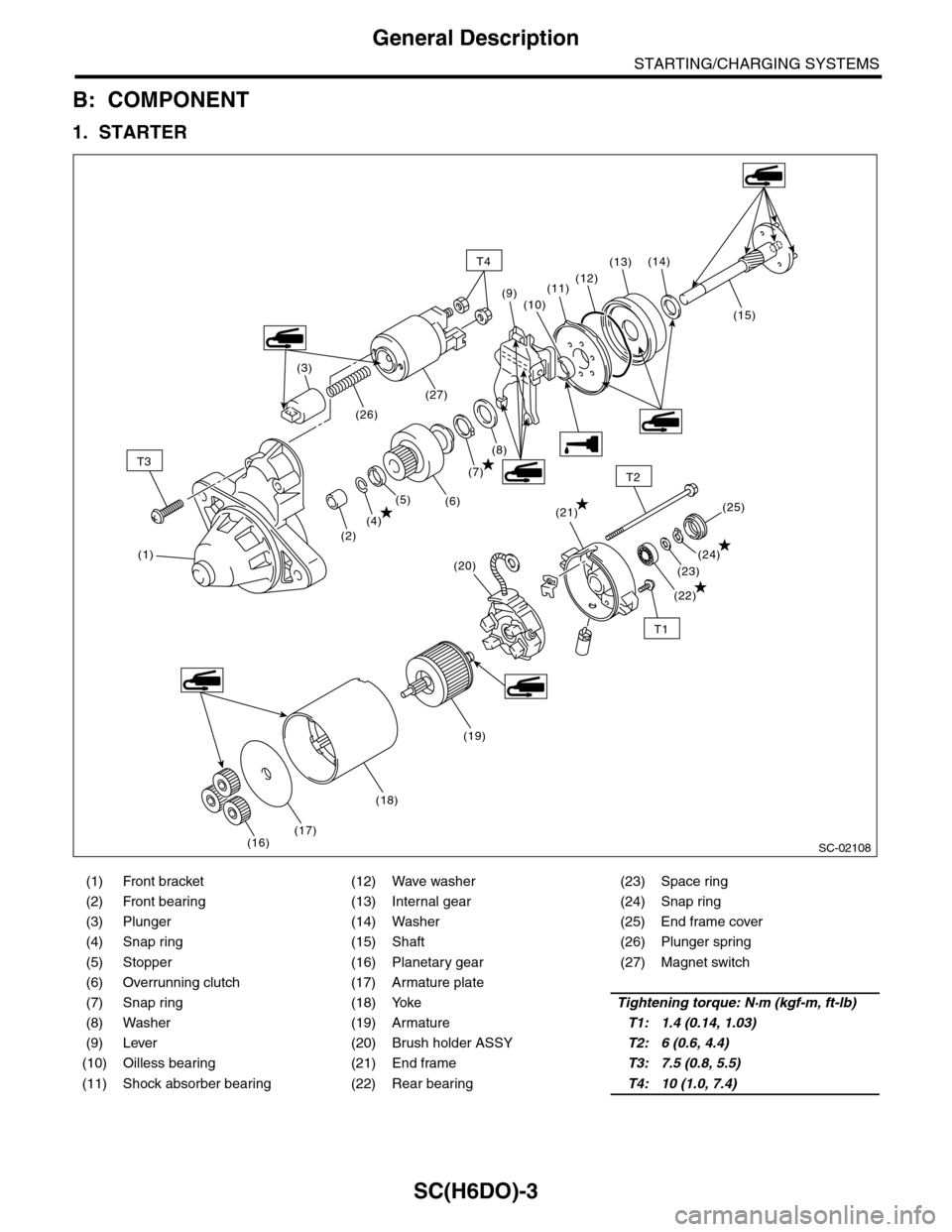

B: COMPONENT

1. STARTER

(1) Front bracket (12) Wave washer (23) Space ring

(2) Front bearing (13) Internal gear (24) Snap ring

(3) Plunger (14) Washer (25) End frame cover

(4) Snap ring (15) Shaft (26) Plunger spring

(5) Stopper (16) Planetary gear (27) Magnet switch

(6) Overrunning clutch (17) Armature plate

(7) Snap ring (18) YokeTightening torque: N·m (kgf-m, ft-lb)

(8) Washer (19) ArmatureT1: 1.4 (0.14, 1.03)

(9) Lever (20) Brush holder ASSYT2: 6 (0.6, 4.4)

(10) Oilless bearing (21) End frameT3: 7.5 (0.8, 5.5)

(11) Shock absorber bearing (22) Rear bearingT4: 10 (1.0, 7.4)

SC-02108

T3

T1

T2

(1)

(2)

T4

(4)(21)

(22)

(23)

(24)

(25)(5)(6)

(7)

(8)

(15)

(14)(13)

(12)(11)

(10)(9)

(3)

(26)

(27)

(16)(17)

(18)

(19)

(20)

Page 1962 of 2453

SC(H6DO)-4

General Description

STARTING/CHARGING SYSTEMS

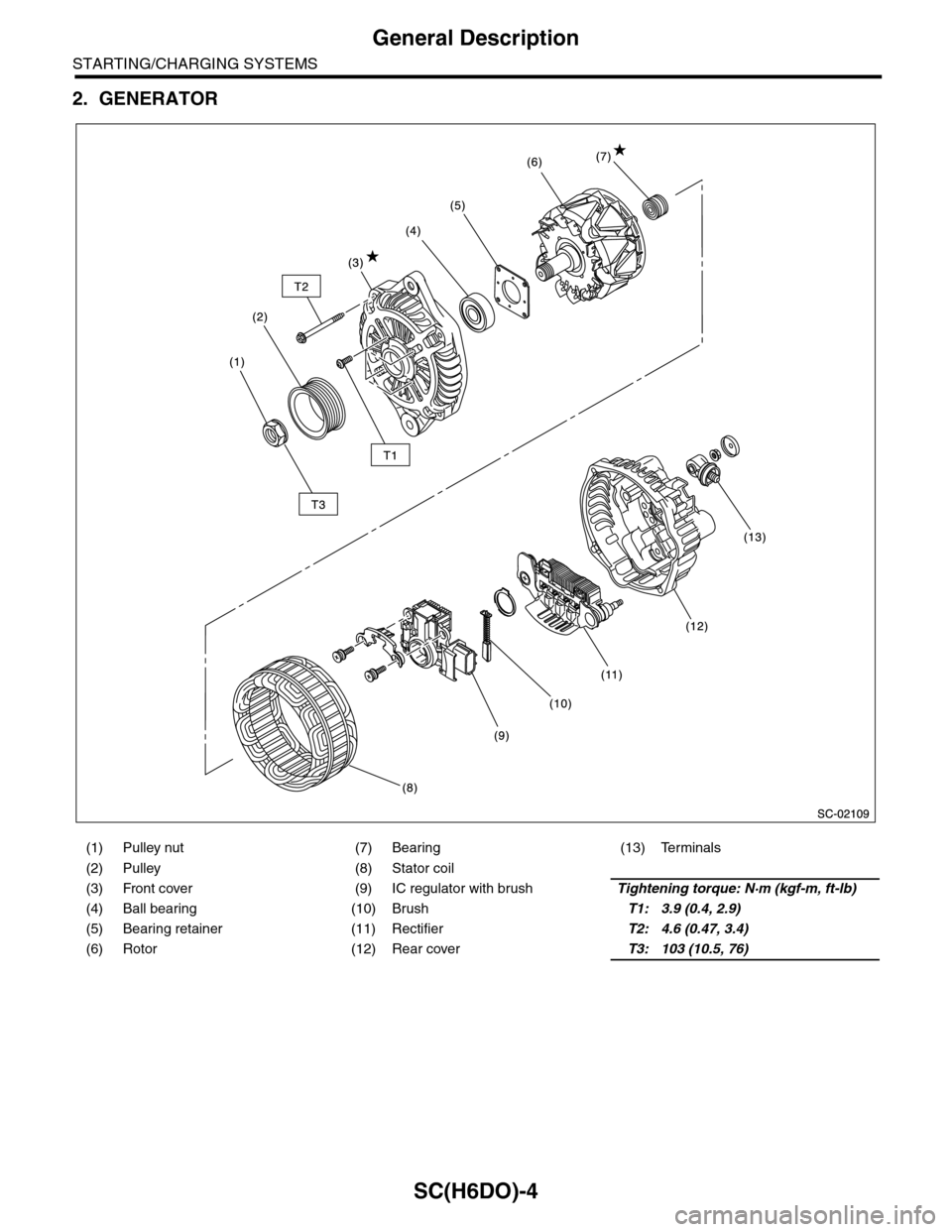

2. GENERATOR

(1) Pulley nut (7) Bearing (13) Terminals

(2) Pulley (8) Stator coil

(3) Front cover (9) IC regulator with brushTightening torque: N·m (kgf-m, ft-lb)

(4) Ball bearing (10) BrushT1: 3.9 (0.4, 2.9)

(5) Bearing retainer (11) RectifierT2: 4.6 (0.47, 3.4)

(6) Rotor (12) Rear coverT3: 103 (10.5, 76)

Page 1963 of 2453

SC(H6DO)-5

General Description

STARTING/CHARGING SYSTEMS

C: CAUTION

•Wear work clothing, including a cap, protective

goggles and protective shoes during operation.

•Remove contamination including dirt and corro-

sion before removal, installation or disassembly.

•Keep the disassembled parts in order and pro-

tect them from dust and dirt.

•Before removal, installation or disassembly, be

sure to clarify the failure. Avoid unnecessary re-

moval, installation, disassembly and replacement.

•Be careful not to burn yourself, because each

part on the vehicle is hot after running.

•Be sure to tighten fasteners including bolts and

nuts to the specified torque.

•Place shop jacks or rigid racks at the specified

points.

•Before disconnecting connectors of sensors or

units, be sure to disconnect the ground cable from

battery.

Page 1964 of 2453

SC(H6DO)-6

Starter

STARTING/CHARGING SYSTEMS

2. Starter

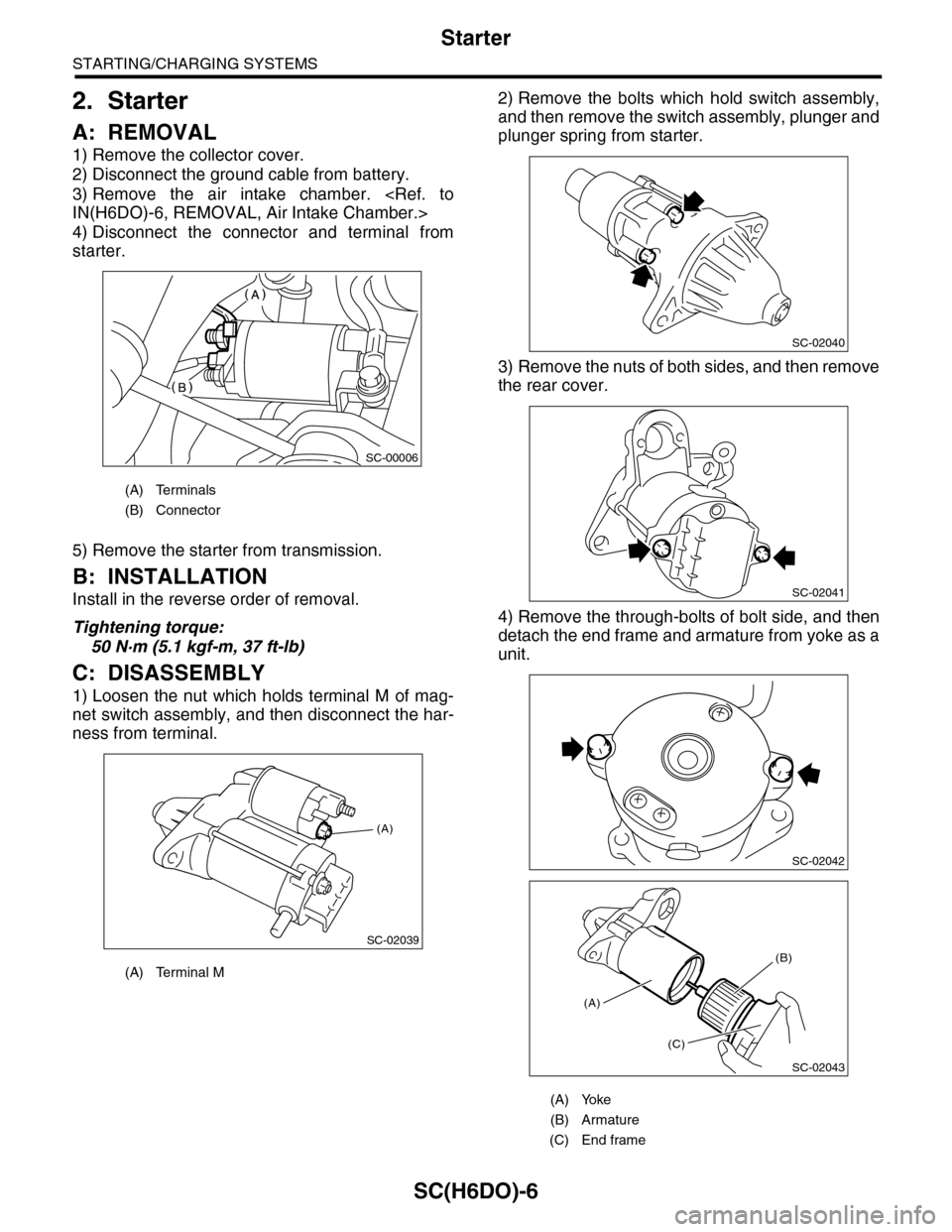

A: REMOVAL

1) Remove the collector cover.

2) Disconnect the ground cable from battery.

3) Remove the air intake chamber.

4) Disconnect the connector and terminal from

starter.

5) Remove the starter from transmission.

B: INSTALLATION

Install in the reverse order of removal.

Tightening torque:

50 N·m (5.1 kgf-m, 37 ft-lb)

C: DISASSEMBLY

1) Loosen the nut which holds terminal M of mag-

net switch assembly, and then disconnect the har-

ness from terminal.

2) Remove the bolts which hold switch assembly,

and then remove the switch assembly, plunger and

plunger spring from starter.

3) Remove the nuts of both sides, and then remove

the rear cover.

4) Remove the through-bolts of bolt side, and then

detach the end frame and armature from yoke as a

unit.

(A) Terminals

(B) Connector

(A) Terminal M

SC-00006

(A)

SC-02039

(A) Yoke

(B) Armature

(C) End frame

SC-02040

SC-02041

SC-02042

SC-02043

(A)

(C)

(B)

Page 1965 of 2453

SC(H6DO)-7

Starter

STARTING/CHARGING SYSTEMS

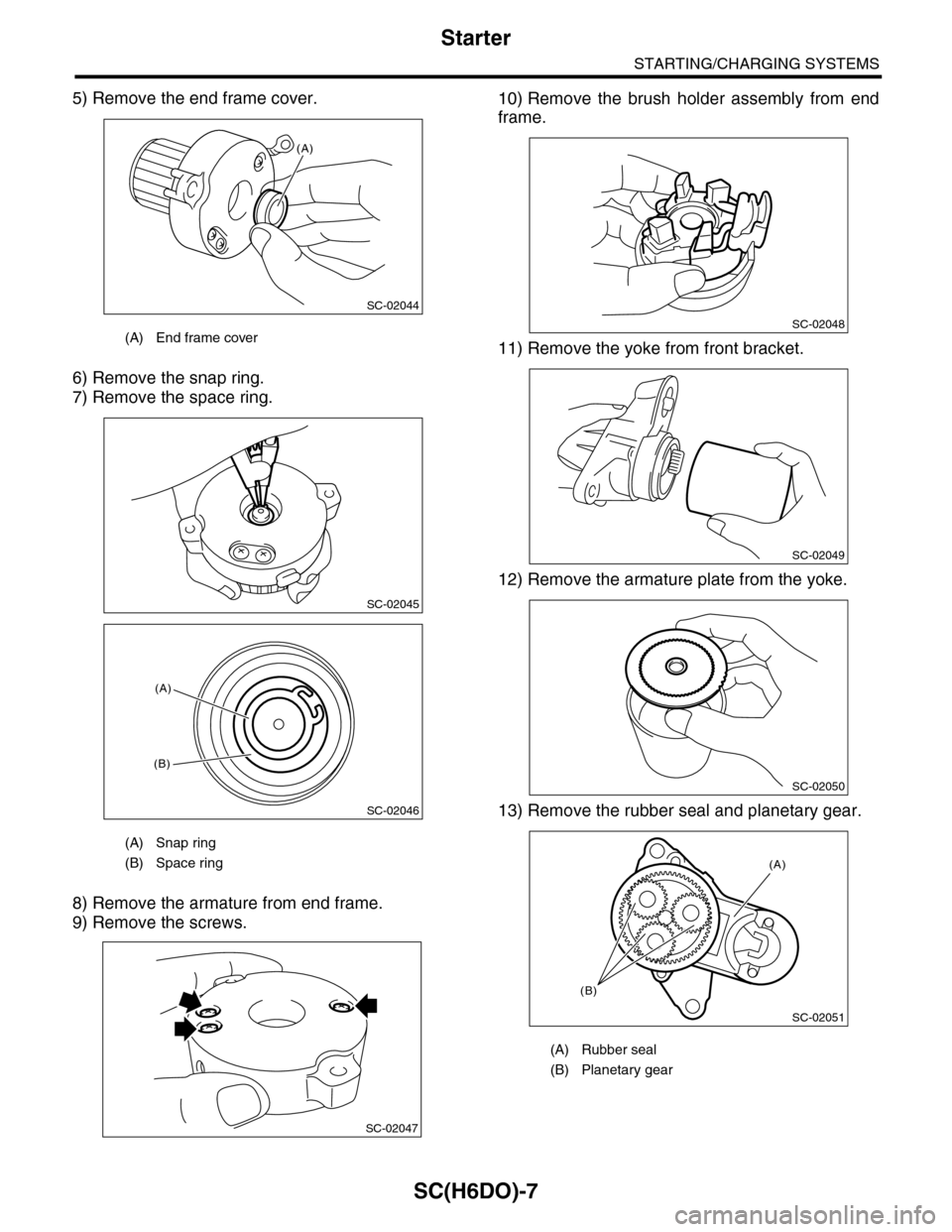

5) Remove the end frame cover.

6) Remove the snap ring.

7) Remove the space ring.

8) Remove the armature from end frame.

9) Remove the screws.

10) Remove the brush holder assembly from end

frame.

11) Remove the yoke from front bracket.

12) Remove the armature plate from the yoke.

13) Remove the rubber seal and planetary gear.

(A) End frame cover

(A) Snap ring

(B) Space ring

(A)

SC-02044

SC-02045

SC-02046

(A)

(B)

SC-02047

(A) Rubber seal

(B) Planetary gear

SC-02048

SC-02049

SC-02050

SC-02051

(A)

(B)

Page 1966 of 2453

SC(H6DO)-8

Starter

STARTING/CHARGING SYSTEMS

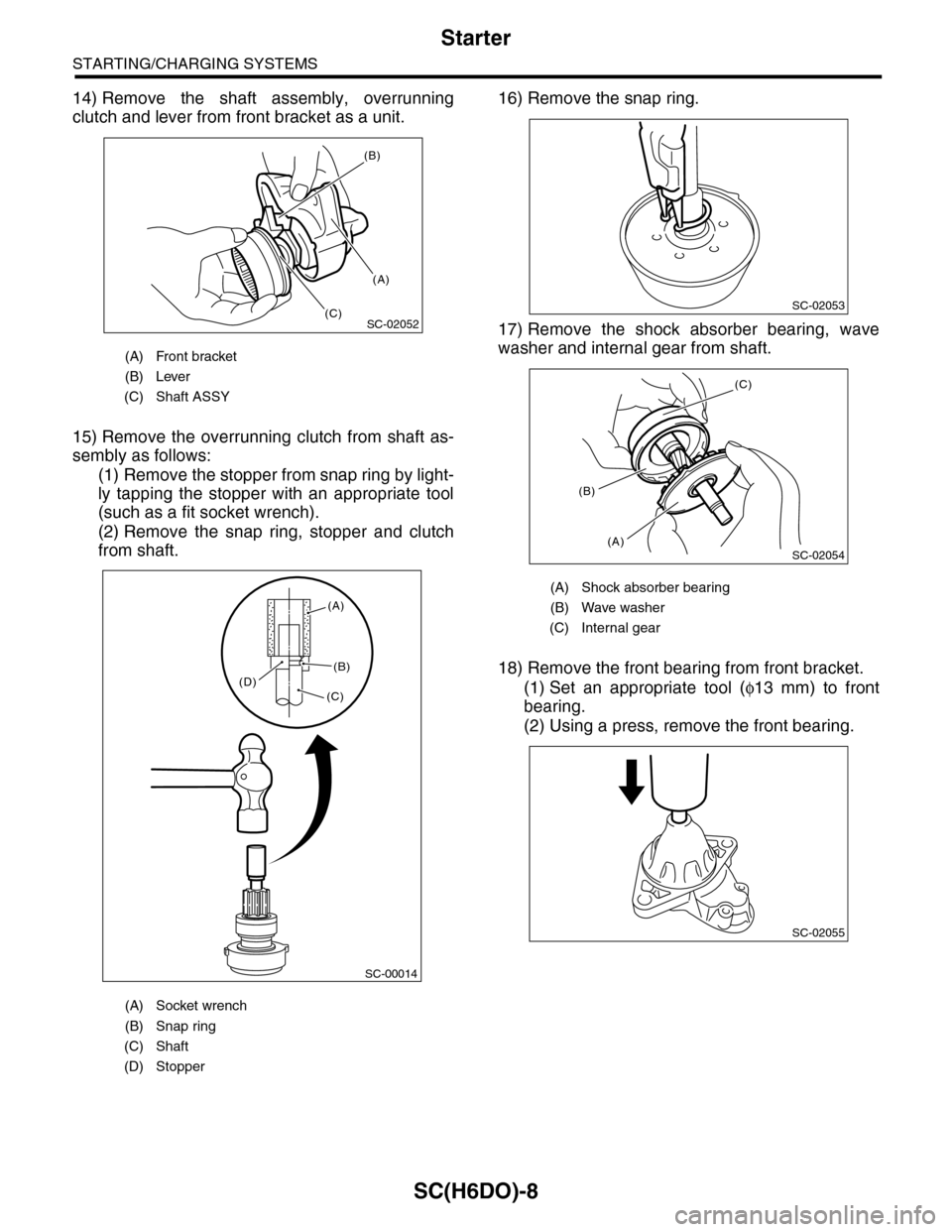

14) Remove the shaft assembly, overrunning

clutch and lever from front bracket as a unit.

15) Remove the overrunning clutch from shaft as-

sembly as follows:

(1) Remove the stopper from snap ring by light-

ly tapping the stopper with an appropriate tool

(such as a fit socket wrench).

(2) Remove the snap ring, stopper and clutch

from shaft.

16) Remove the snap ring.

17) Remove the shock absorber bearing, wave

washer and internal gear from shaft.

18) Remove the front bearing from front bracket.

(1) Set an appropriate tool (φ13 mm) to front

bearing.

(2) Using a press, remove the front bearing.

(A) Front bracket

(B) Lever

(C) Shaft ASSY

(A) Socket wrench

(B) Snap ring

(C) Shaft

(D) Stopper

SC-02052

(B)

(A)

(C)

SC-00014

(A)

(B)

(C)(D)

(A) Shock absorber bearing

(B) Wave washer

(C) Internal gear

SC-02053

SC-02054

(C)

(A)

(B)

SC-02055

Page 1967 of 2453

SC(H6DO)-9

Starter

STARTING/CHARGING SYSTEMS

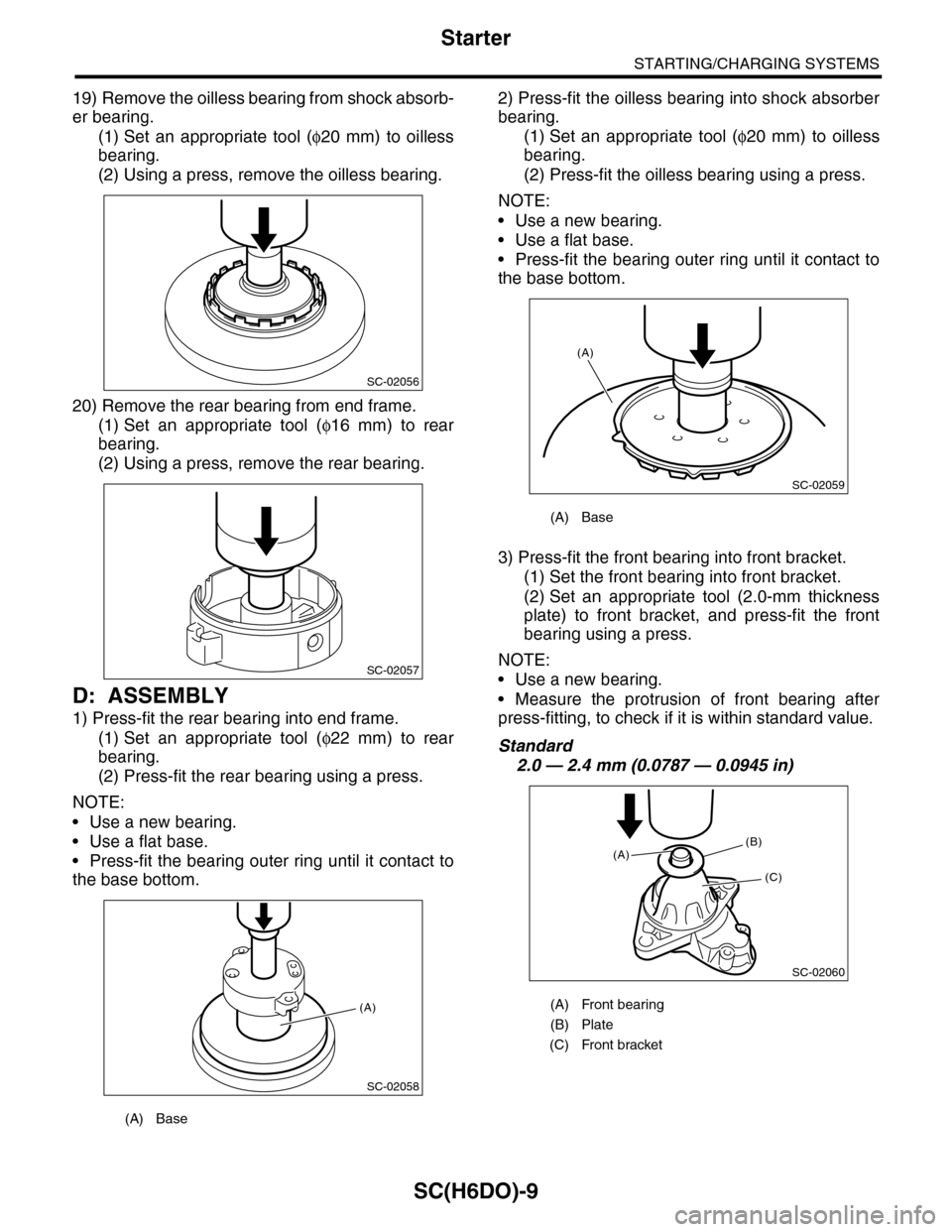

19) Remove the oilless bearing from shock absorb-

er bearing.

(1) Set an appropriate tool (φ20 mm) to oilless

bearing.

(2) Using a press, remove the oilless bearing.

20) Remove the rear bearing from end frame.

(1) Set an appropriate tool (φ16 mm) to rear

bearing.

(2) Using a press, remove the rear bearing.

D: ASSEMBLY

1) Press-fit the rear bearing into end frame.

(1) Set an appropriate tool (φ22 mm) to rear

bearing.

(2) Press-fit the rear bearing using a press.

NOTE:

•Use a new bearing.

•Use a flat base.

•Press-fit the bearing outer ring until it contact to

the base bottom.

2) Press-fit the oilless bearing into shock absorber

bearing.

(1) Set an appropriate tool (φ20 mm) to oilless

bearing.

(2) Press-fit the oilless bearing using a press.

NOTE:

•Use a new bearing.

•Use a flat base.

•Press-fit the bearing outer ring until it contact to

the base bottom.

3) Press-fit the front bearing into front bracket.

(1) Set the front bearing into front bracket.

(2) Set an appropriate tool (2.0-mm thickness

plate) to front bracket, and press-fit the front

bearing using a press.

NOTE:

•Use a new bearing.

•Measure the protrusion of front bearing after

press-fitting, to check if it is within standard value.

Standard

2.0 — 2.4 mm (0.0787 — 0.0945 in)

(A) Base

SC-02056

SC-02057

SC-02058

(A)

(A) Base

(A) Front bearing

(B) Plate

(C) Front bracket

SC-02059

(A)

SC-02060

(B)

(C)

(A)

Page 1968 of 2453

SC(H6DO)-10

Starter

STARTING/CHARGING SYSTEMS

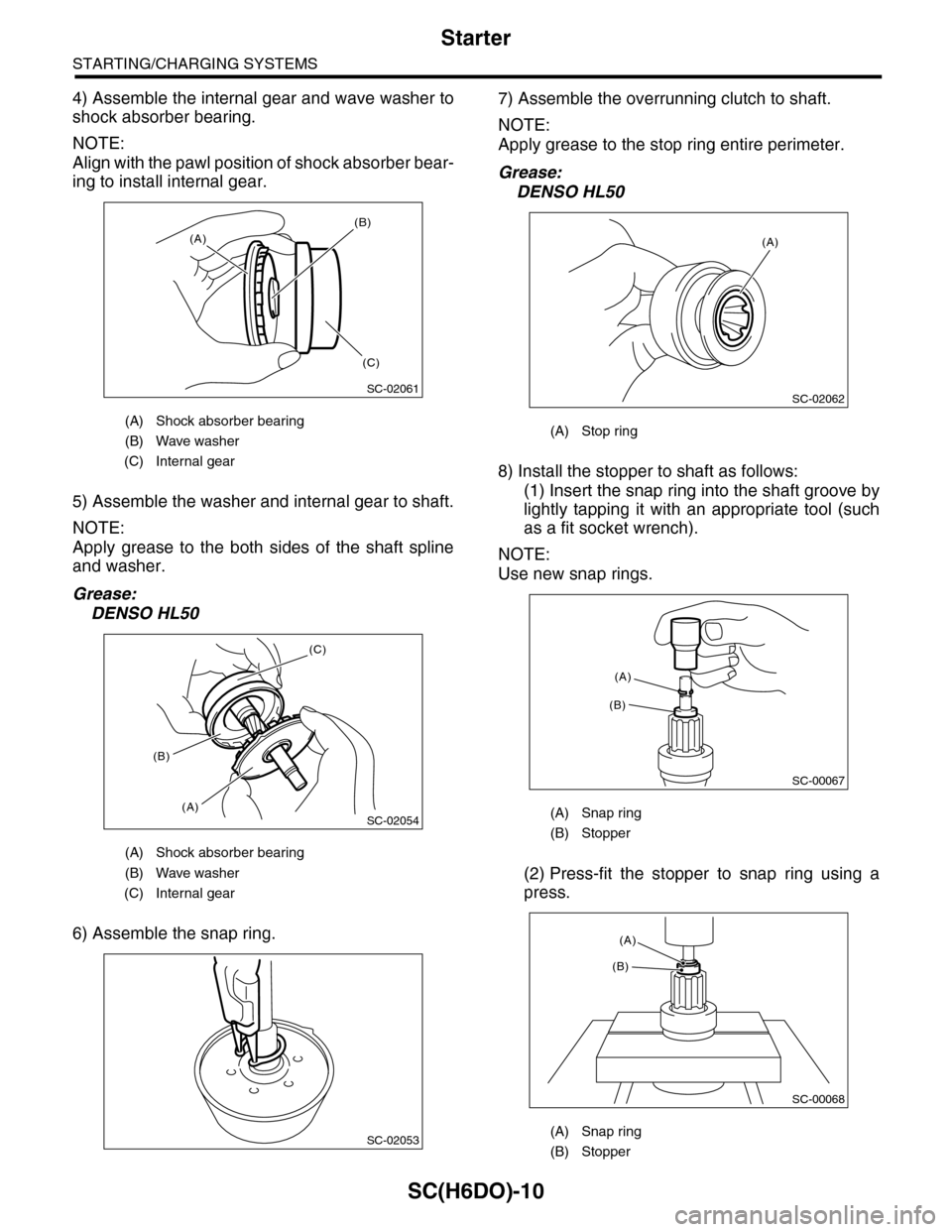

4) Assemble the internal gear and wave washer to

shock absorber bearing.

NOTE:

Align with the pawl position of shock absorber bear-

ing to install internal gear.

5) Assemble the washer and internal gear to shaft.

NOTE:

Apply grease to the both sides of the shaft spline

and washer.

Grease:

DENSO HL50

6) Assemble the snap ring.

7) Assemble the overrunning clutch to shaft.

NOTE:

Apply grease to the stop ring entire perimeter.

Grease:

DENSO HL50

8) Install the stopper to shaft as follows:

(1) Insert the snap ring into the shaft groove by

lightly tapping it with an appropriate tool (such

as a fit socket wrench).

NOTE:

Use new snap rings.

(2) Press-fit the stopper to snap ring using a

press.

(A) Shock absorber bearing

(B) Wave washer

(C) Internal gear

(A) Shock absorber bearing

(B) Wave washer

(C) Internal gear

SC-02061

(A)

(B)

(C)

SC-02054

(C)

(A)

(B)

SC-02053

(A) Stop ring

(A) Snap ring

(B) Stopper

(A) Snap ring

(B) Stopper

SC-02062

(A)

SC-00067

(B)

(A)

SC-00068

(A)

(B)

Page 1969 of 2453

SC(H6DO)-11

Starter

STARTING/CHARGING SYSTEMS

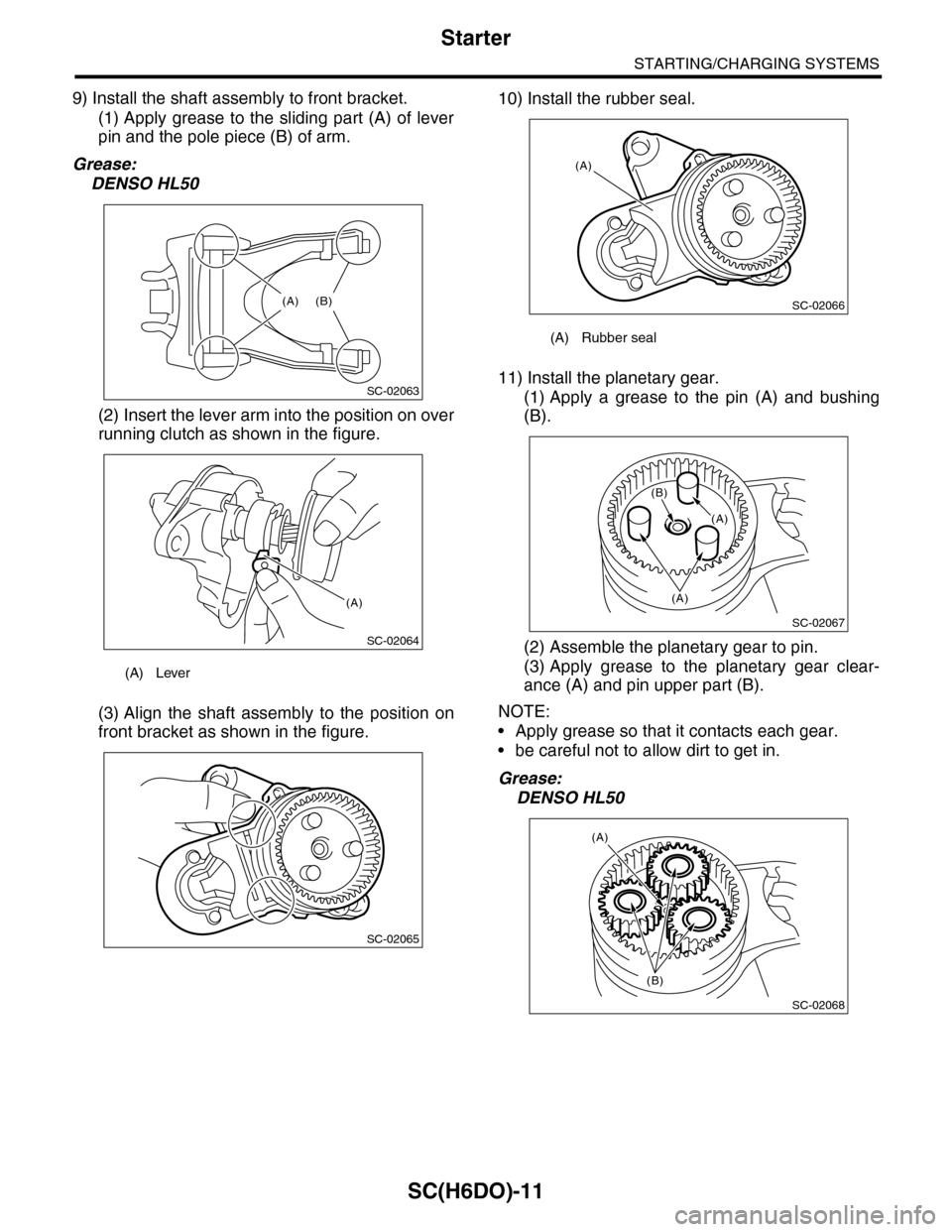

9) Install the shaft assembly to front bracket.

(1) Apply grease to the sliding part (A) of lever

pin and the pole piece (B) of arm.

Grease:

DENSO HL50

(2) Insert the lever arm into the position on over

running clutch as shown in the figure.

(3) Align the shaft assembly to the position on

front bracket as shown in the figure.

10) Install the rubber seal.

11) Install the planetary gear.

(1) Apply a grease to the pin (A) and bushing

(B).

(2) Assemble the planetary gear to pin.

(3) Apply grease to the planetary gear clear-

ance (A) and pin upper part (B).

NOTE:

•Apply grease so that it contacts each gear.

•be careful not to allow dirt to get in.

Grease:

DENSO HL50

(A) Lever

SC-02063

(A) (B)

SC-02064

(A)

SC-02065

(A) Rubber seal

SC-02066

(A)

SC-02067

(B)

(A)

(A)

SC-02068

(B)

(A)(A)

Page 1970 of 2453

SC(H6DO)-12

Starter

STARTING/CHARGING SYSTEMS

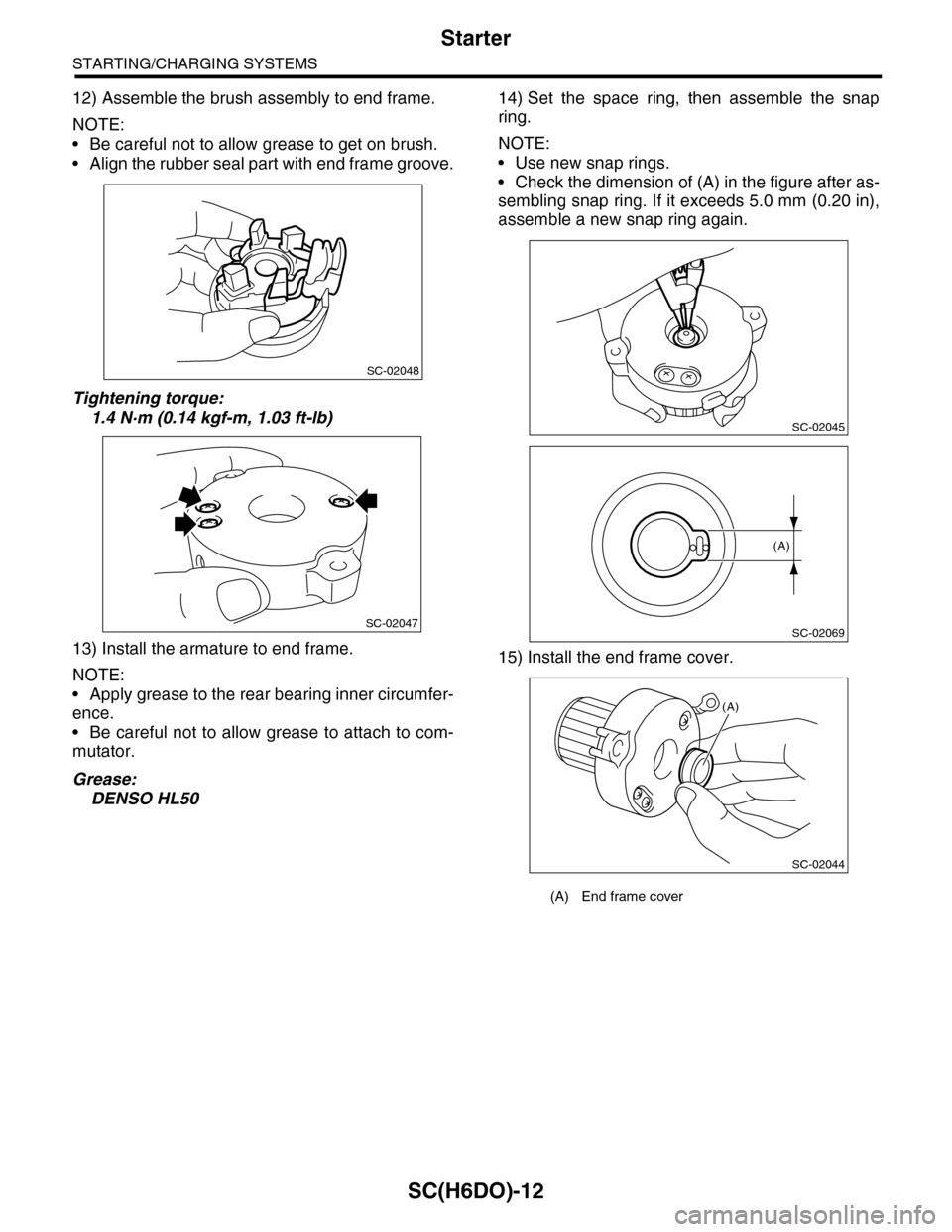

12) Assemble the brush assembly to end frame.

NOTE:

•Be careful not to allow grease to get on brush.

•Align the rubber seal part with end frame groove.

Tightening torque:

1.4 N·m (0.14 kgf-m, 1.03 ft-lb)

13) Install the armature to end frame.

NOTE:

•Apply grease to the rear bearing inner circumfer-

ence.

•Be careful not to allow grease to attach to com-

mutator.

Grease:

DENSO HL50

14) Set the space ring, then assemble the snap

ring.

NOTE:

•Use new snap rings.

•Check the dimension of (A) in the figure after as-

sembling snap ring. If it exceeds 5.0 mm (0.20 in),

assemble a new snap ring again.

15) Install the end frame cover.

SC-02048

SC-02047

(A) End frame cover

SC-02045

SC-02069

(A)

(A)

SC-02044