SUBARU TRIBECA 2009 1.G Service Workshop Manual

Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 2001 of 2453

PM-18

Front & Rear Differential Oil

PERIODIC MAINTENANCE SERVICES

12.Front & Rear Differential Oil

A: REPLACEMENT

1. FRONT DIFFERENTIAL

1) Drain the differential gear oil by removing drain

plug using TORX® BIT T70.

NOTE:

•Before starting work, cool off the differential gear

oil well.

•If front differential gear oil adheres to the exhaust

pipe, wipe it off completely.

2) Replace the gasket with new one, and then tight-

en the drain plug to specified torque.

Tightening torque:

70 N·m (7.1 kgf-m, 51.6 ft-lb)

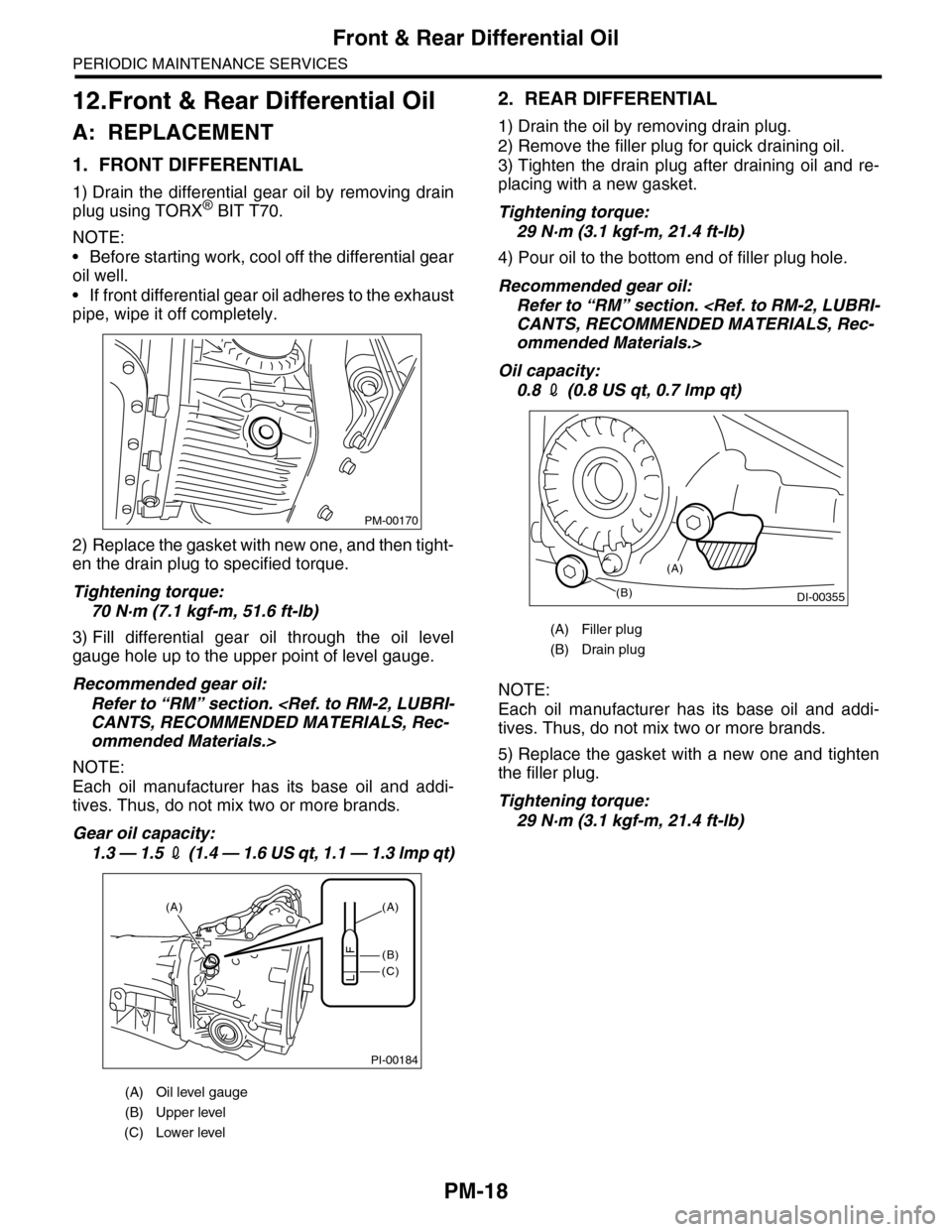

3) Fill differential gear oil through the oil level

gauge hole up to the upper point of level gauge.

Recommended gear oil:

Refer to “RM” section.

ommended Materials.>

NOTE:

Each oil manufacturer has its base oil and addi-

tives. Thus, do not mix two or more brands.

Gear oil capacity:

1.3 — 1.5 2 (1 . 4 — 1 .6 U S q t , 1 . 1 — 1 .3 lmp q t)

2. REAR DIFFERENTIAL

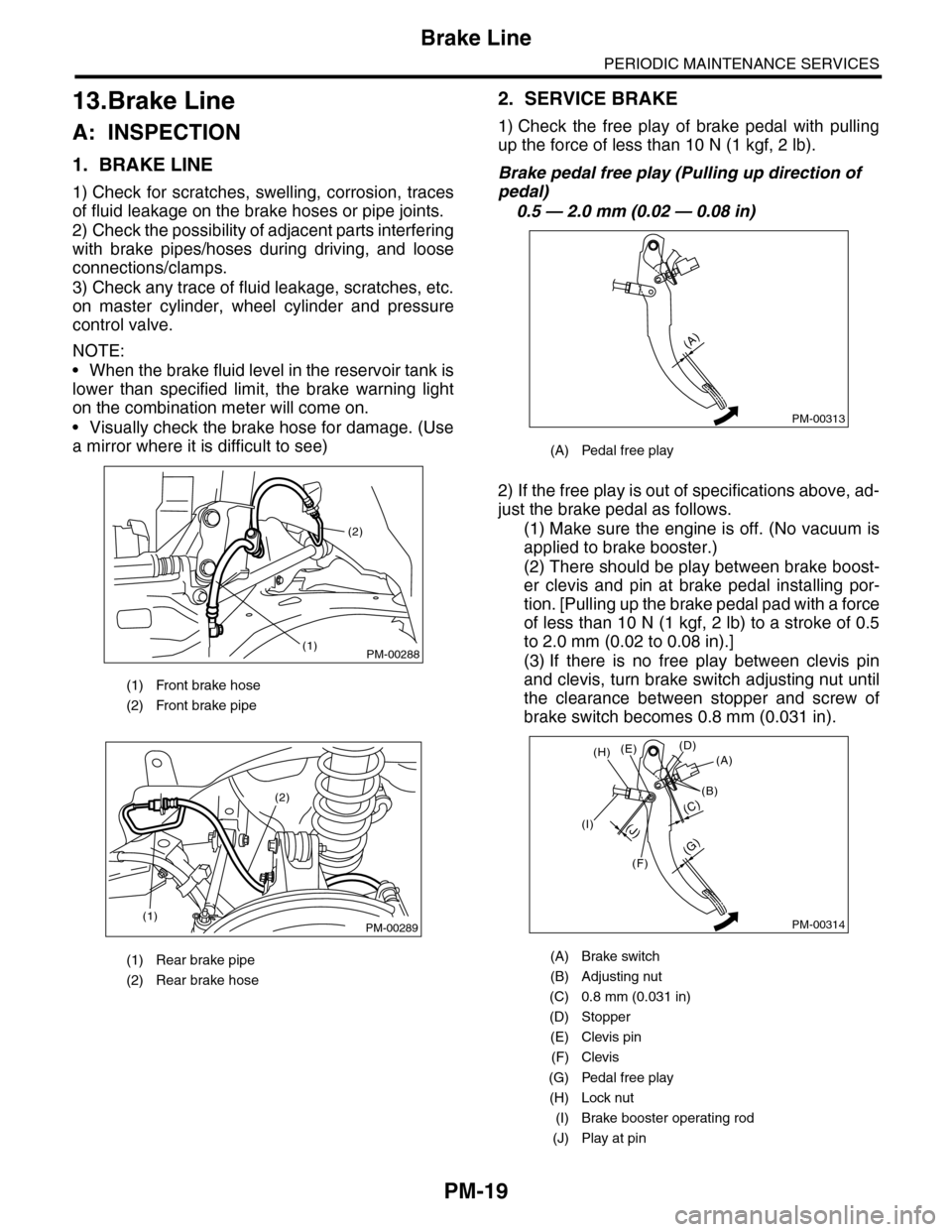

1) Drain the oil by removing drain plug.

2) Remove the filler plug for quick draining oil.

3) Tighten the drain plug after draining oil and re-

placing with a new gasket.

Tightening torque:

29 N·m (3.1 kgf-m, 21.4 ft-lb)

4) Pour oil to the bottom end of filler plug hole.

Recommended gear oil:

Refer to “RM” section.

ommended Materials.>

Oil capacity:

0.8 2 (0.8 US qt, 0.7 lmp qt)

NOTE:

Each oil manufacturer has its base oil and addi-

tives. Thus, do not mix two or more brands.

5) Replace the gasket with a new one and tighten

the filler plug.

Tightening torque:

29 N·m (3.1 kgf-m, 21.4 ft-lb)

(A) Oil level gauge

(B) Upper level

(C) Lower level

PM-00170

PI-00184

(A)

(C)

(B)

(A)

F

L

(A) Filler plug

(B) Drain plug

(B)DI-00355

(A)

Page 2002 of 2453

PM-19

Brake Line

PERIODIC MAINTENANCE SERVICES

13.Brake Line

A: INSPECTION

1. BRAKE LINE

1) Check for scratches, swelling, corrosion, traces

of fluid leakage on the brake hoses or pipe joints.

2) Check the possibility of adjacent parts interfering

with brake pipes/hoses during driving, and loose

connections/clamps.

3) Check any trace of fluid leakage, scratches, etc.

on master cylinder, wheel cylinder and pressure

control valve.

NOTE:

•When the brake fluid level in the reservoir tank is

lower than specified limit, the brake warning light

on the combination meter will come on.

•Visually check the brake hose for damage. (Use

a mirror where it is difficult to see)

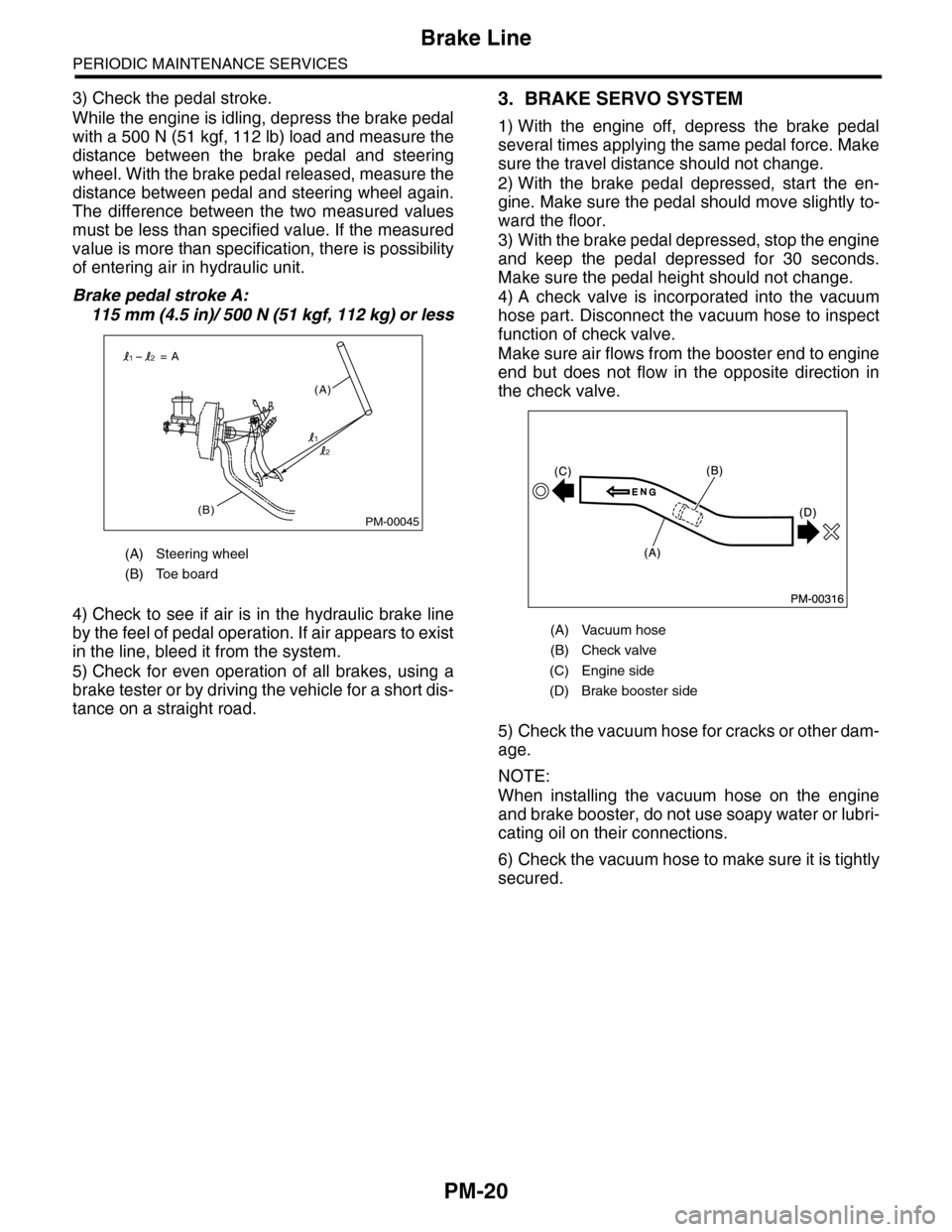

2. SERVICE BRAKE

1) Check the free play of brake pedal with pulling

up the force of less than 10 N (1 kgf, 2 lb).

Brake pedal free play (Pulling up direction of

pedal)

0.5 — 2.0 mm (0.02 — 0.08 in)

2) If the free play is out of specifications above, ad-

just the brake pedal as follows.

(1) Make sure the engine is off. (No vacuum is

applied to brake booster.)

(2) There should be play between brake boost-

er clevis and pin at brake pedal installing por-

tion. [Pulling up the brake pedal pad with a force

of less than 10 N (1 kgf, 2 lb) to a stroke of 0.5

to 2.0 mm (0.02 to 0.08 in).]

(3) If there is no free play between clevis pin

and clevis, turn brake switch adjusting nut until

the clearance between stopper and screw of

brake switch becomes 0.8 mm (0.031 in).

(1) Front brake hose

(2) Front brake pipe

(1) Rear brake pipe

(2) Rear brake hose

PM-00288

(2)

(1)

PM-00289(1)

(2)

(A) Pedal free play

(A) Brake switch

(B) Adjusting nut

(C) 0.8 mm (0.031 in)

(D) Stopper

(E) Clevis pin

(F) Clevis

(G) Pedal free play

(H) Lock nut

(I) Brake booster operating rod

(J) Play at pin

PM-00313

(A)

PM-00314

(G)

(A)(D)(E)

(B)

(C)

(F)

(J)(I)

(H)

Page 2003 of 2453

PM-20

Brake Line

PERIODIC MAINTENANCE SERVICES

3) Check the pedal stroke.

While the engine is idling, depress the brake pedal

with a 500 N (51 kgf, 112 lb) load and measure the

distance between the brake pedal and steering

wheel. With the brake pedal released, measure the

distance between pedal and steering wheel again.

The difference between the two measured values

must be less than specified value. If the measured

value is more than specification, there is possibility

of entering air in hydraulic unit.

Brake pedal stroke A:

115 mm (4.5 in)/ 500 N (51 kgf, 112 kg) or less

4) Check to see if air is in the hydraulic brake line

by the feel of pedal operation. If air appears to exist

in the line, bleed it from the system.

5) Check for even operation of all brakes, using a

brake tester or by driving the vehicle for a short dis-

tance on a straight road.

3. BRAKE SERVO SYSTEM

1) With the engine off, depress the brake pedal

several times applying the same pedal force. Make

sure the travel distance should not change.

2) With the brake pedal depressed, start the en-

gine. Make sure the pedal should move slightly to-

ward the floor.

3) With the brake pedal depressed, stop the engine

and keep the pedal depressed for 30 seconds.

Make sure the pedal height should not change.

4) A check valve is incorporated into the vacuum

hose part. Disconnect the vacuum hose to inspect

function of check valve.

Make sure air flows from the booster end to engine

end but does not flow in the opposite direction in

the check valve.

5) Check the vacuum hose for cracks or other dam-

age.

NOTE:

When installing the vacuum hose on the engine

and brake booster, do not use soapy water or lubri-

cating oil on their connections.

6) Check the vacuum hose to make sure it is tightly

secured.

(A) Steering wheel

(B) Toe board

PM-00045(B)

(A)

= A

1

12

2

(A) Vacuum hose

(B) Check valve

(C) Engine side

(D) Brake booster side

Page 2004 of 2453

PM-21

Brake Fluid

PERIODIC MAINTENANCE SERVICES

14.Brake Fluid

A: REPLACEMENT

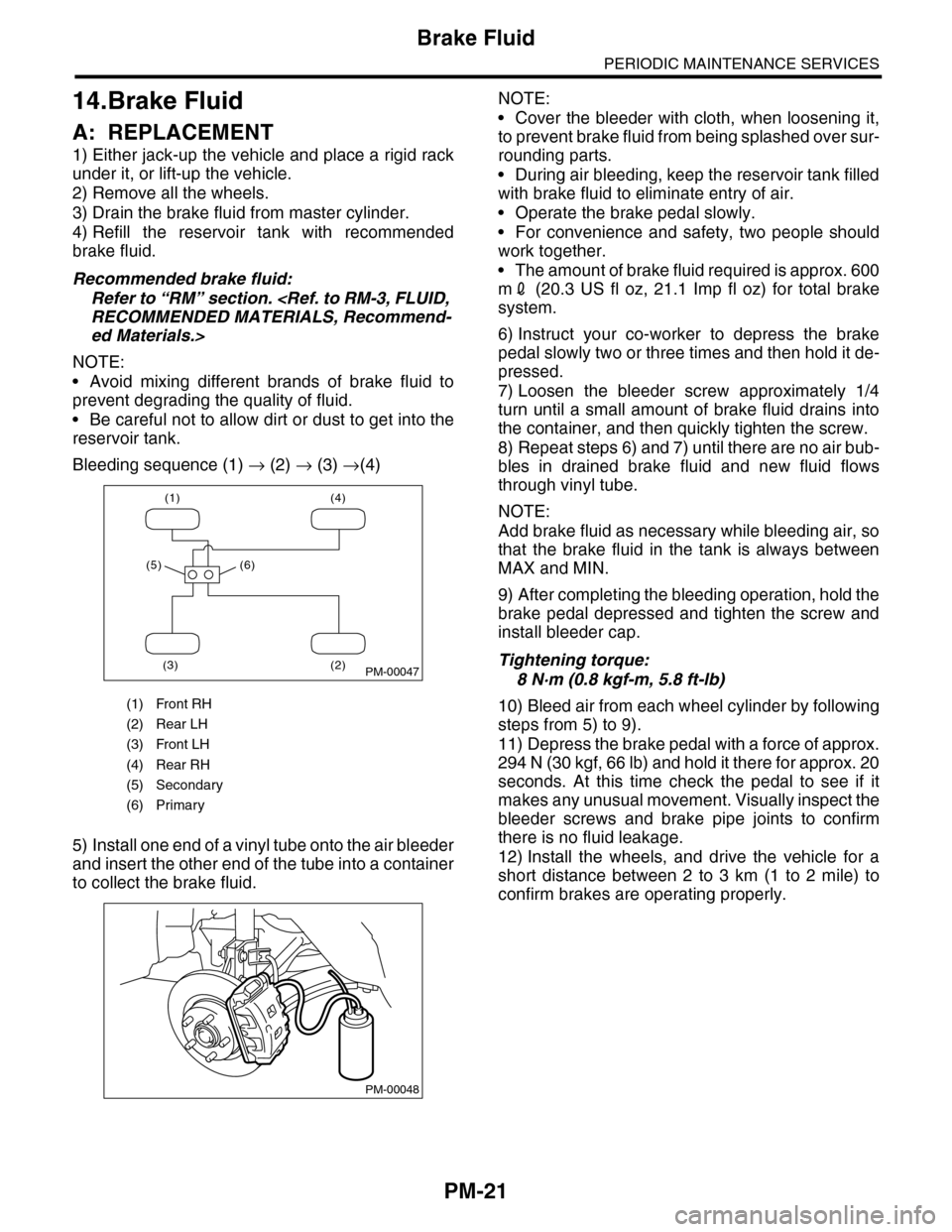

1) Either jack-up the vehicle and place a rigid rack

under it, or lift-up the vehicle.

2) Remove all the wheels.

3) Drain the brake fluid from master cylinder.

4) Refill the reservoir tank with recommended

brake fluid.

Recommended brake fluid:

Refer to “RM” section.

ed Materials.>

NOTE:

•Avoid mixing different brands of brake fluid to

prevent degrading the quality of fluid.

•Be careful not to allow dirt or dust to get into the

reservoir tank.

Bleeding sequence (1) → (2) → (3) →(4)

5) Install one end of a vinyl tube onto the air bleeder

and insert the other end of the tube into a container

to collect the brake fluid.

NOTE:

•Cover the bleeder with cloth, when loosening it,

to prevent brake fluid from being splashed over sur-

rounding parts.

•During air bleeding, keep the reservoir tank filled

with brake fluid to eliminate entry of air.

•Operate the brake pedal slowly.

•For convenience and safety, two people should

work together.

•The amount of brake fluid required is approx. 600

m2 (20.3 US fl oz, 21.1 Imp fl oz) for total brake

system.

6) Instruct your co-worker to depress the brake

pedal slowly two or three times and then hold it de-

pressed.

7) Loosen the bleeder screw approximately 1/4

turn until a small amount of brake fluid drains into

the container, and then quickly tighten the screw.

8) Repeat steps 6) and 7) until there are no air bub-

bles in drained brake fluid and new fluid flows

through vinyl tube.

NOTE:

Add brake fluid as necessary while bleeding air, so

that the brake fluid in the tank is always between

MAX and MIN.

9) After completing the bleeding operation, hold the

brake pedal depressed and tighten the screw and

install bleeder cap.

Tightening torque:

8 N·m (0.8 kgf-m, 5.8 ft-lb)

10) Bleed air from each wheel cylinder by following

steps from 5) to 9).

11) Depress the brake pedal with a force of approx.

294 N (30 kgf, 66 lb) and hold it there for approx. 20

seconds. At this time check the pedal to see if it

makes any unusual movement. Visually inspect the

bleeder screws and brake pipe joints to confirm

there is no fluid leakage.

12) Install the wheels, and drive the vehicle for a

short distance between 2 to 3 km (1 to 2 mile) to

confirm brakes are operating properly.

(1) Front RH

(2) Rear LH

(3) Front LH

(4) Rear RH

(5) Secondary

(6) Primary

(1) (4)

(2)(3)

(5) (6)

PM-00047

PM-00048

Page 2005 of 2453

PM-22

Disc Brake Pad & Disc

PERIODIC MAINTENANCE SERVICES

15.Disc Brake Pad & Disc

A: INSPECTION

1) Jack-up the vehicle and support with rigid racks.

Then remove the wheels.

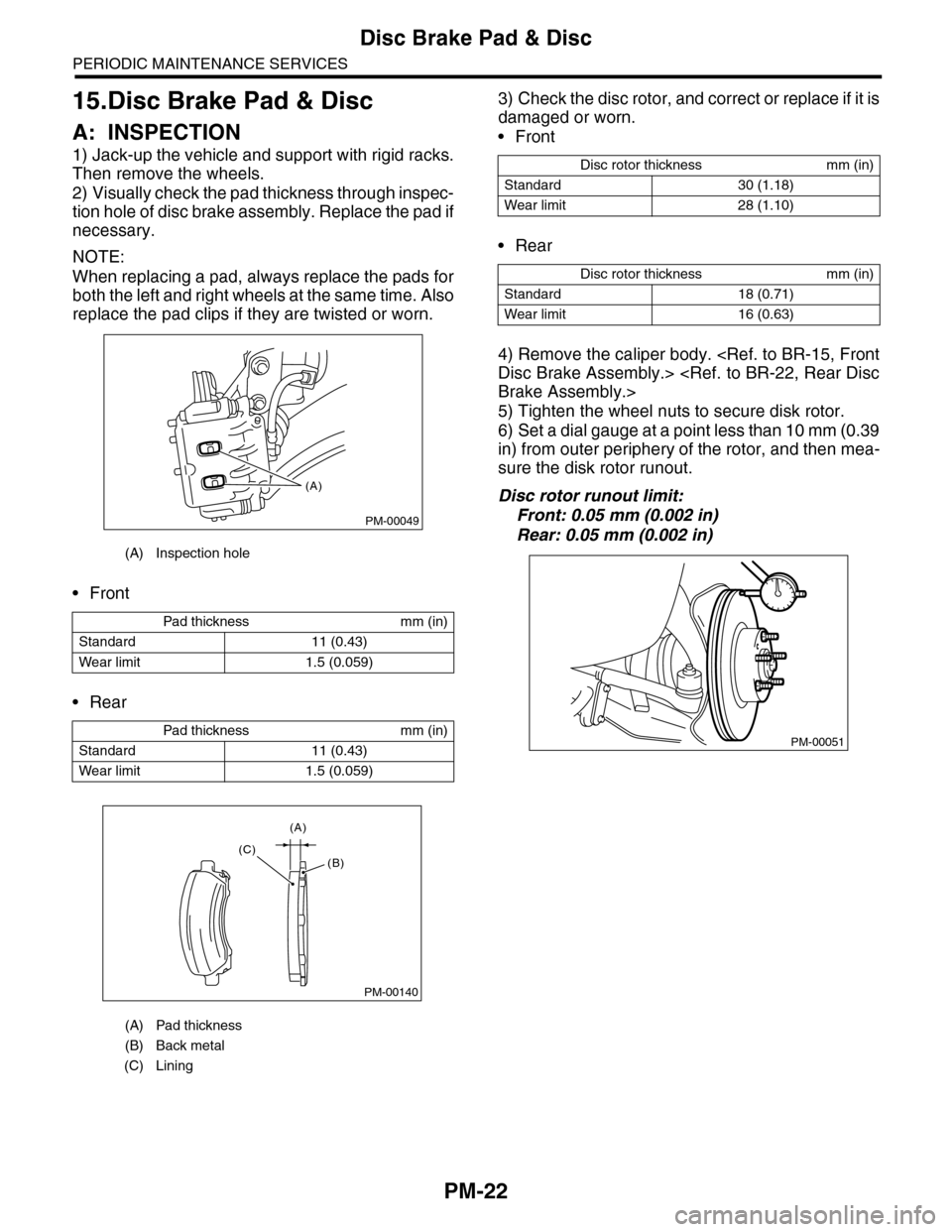

2) Visually check the pad thickness through inspec-

tion hole of disc brake assembly. Replace the pad if

necessary.

NOTE:

When replacing a pad, always replace the pads for

both the left and right wheels at the same time. Also

replace the pad clips if they are twisted or worn.

•Front

•Rear

3) Check the disc rotor, and correct or replace if it is

damaged or worn.

•Front

•Rear

4) Remove the caliper body.

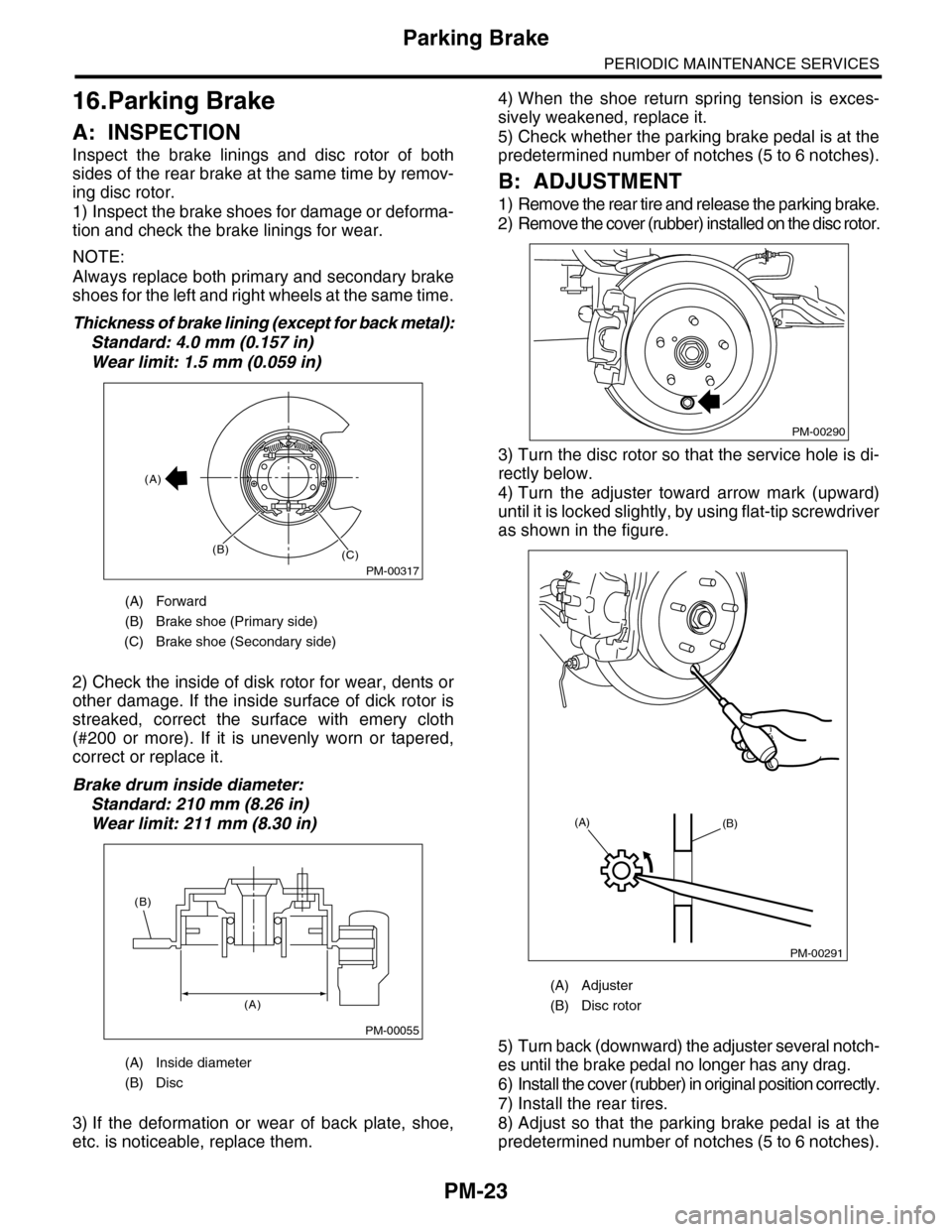

5) Tighten the wheel nuts to secure disk rotor.

6) Set a dial gauge at a point less than 10 mm (0.39

in) from outer periphery of the rotor, and then mea-

sure the disk rotor runout.

Disc rotor runout limit:

Front: 0.05 mm (0.002 in)

Rear: 0.05 mm (0.002 in)

(A) Inspection hole

Pad thickness mm (in)

Standard 11 (0.43)

Wear limit 1.5 (0.059)

Pad thickness mm (in)

Standard 11 (0.43)

Wear limit 1.5 (0.059)

(A) Pad thickness

(B) Back metal

(C) Lining

PM-00049

(A)

PM-00140

(A)

(C)(B)

Disc rotor thickness mm (in)

Standard 30 (1.18)

Wear limit 28 (1.10)

Disc rotor thickness mm (in)

Standard 18 (0.71)

Wear limit 16 (0.63)

PM-00051

Page 2006 of 2453

PM-23

Parking Brake

PERIODIC MAINTENANCE SERVICES

16.Parking Brake

A: INSPECTION

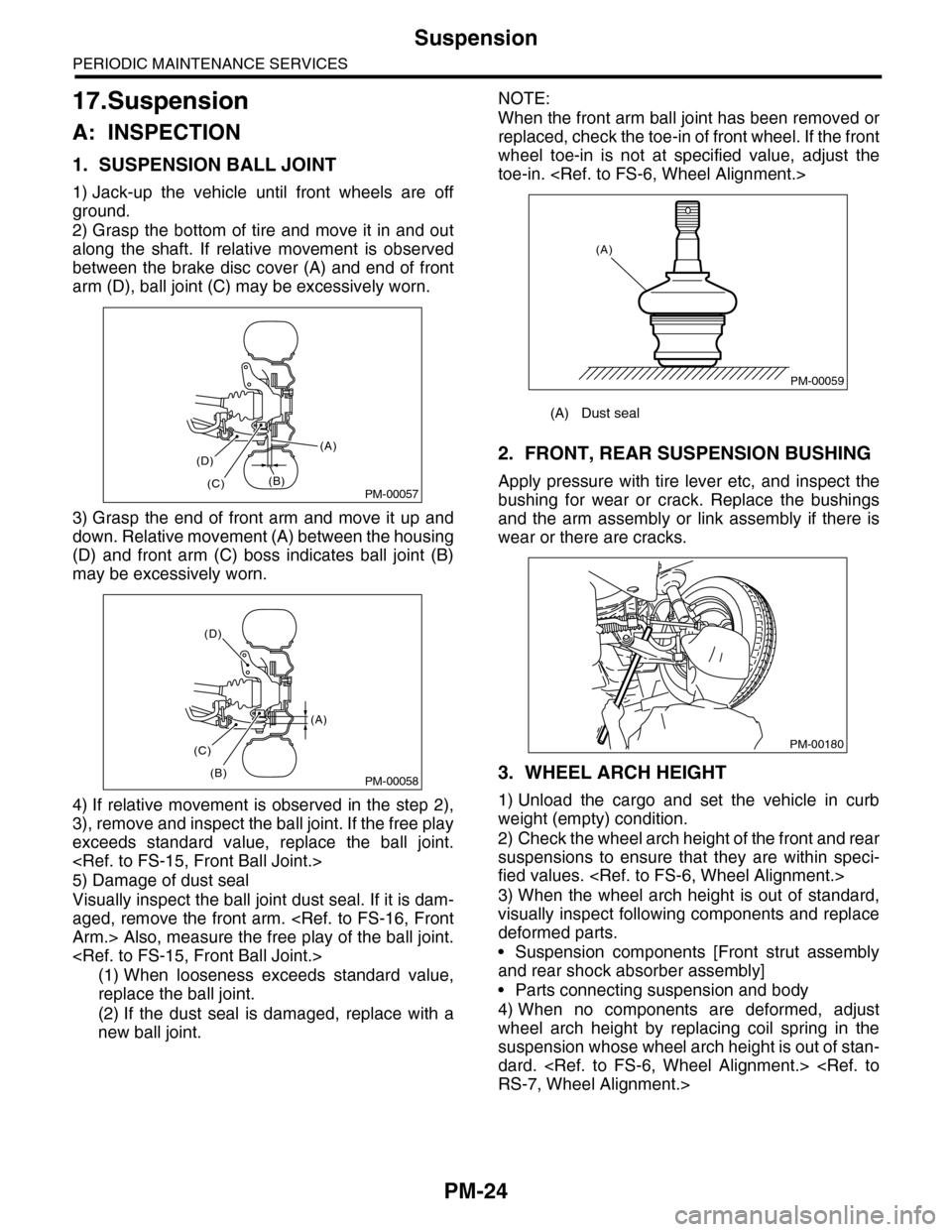

Inspect the brake linings and disc rotor of both

sides of the rear brake at the same time by remov-

ing disc rotor.

1) Inspect the brake shoes for damage or deforma-

tion and check the brake linings for wear.

NOTE:

Always replace both primary and secondary brake

shoes for the left and right wheels at the same time.

Thickness of brake lining (except for back metal):

Standard: 4.0 mm (0.157 in)

Wear limit: 1.5 mm (0.059 in)

2) Check the inside of disk rotor for wear, dents or

other damage. If the inside surface of dick rotor is

streaked, correct the surface with emery cloth

(#200 or more). If it is unevenly worn or tapered,

correct or replace it.

Brake drum inside diameter:

Standard: 210 mm (8.26 in)

Wear limit: 211 mm (8.30 in)

3) If the deformation or wear of back plate, shoe,

etc. is noticeable, replace them.

4) When the shoe return spring tension is exces-

sively weakened, replace it.

5) Check whether the parking brake pedal is at the

predetermined number of notches (5 to 6 notches).

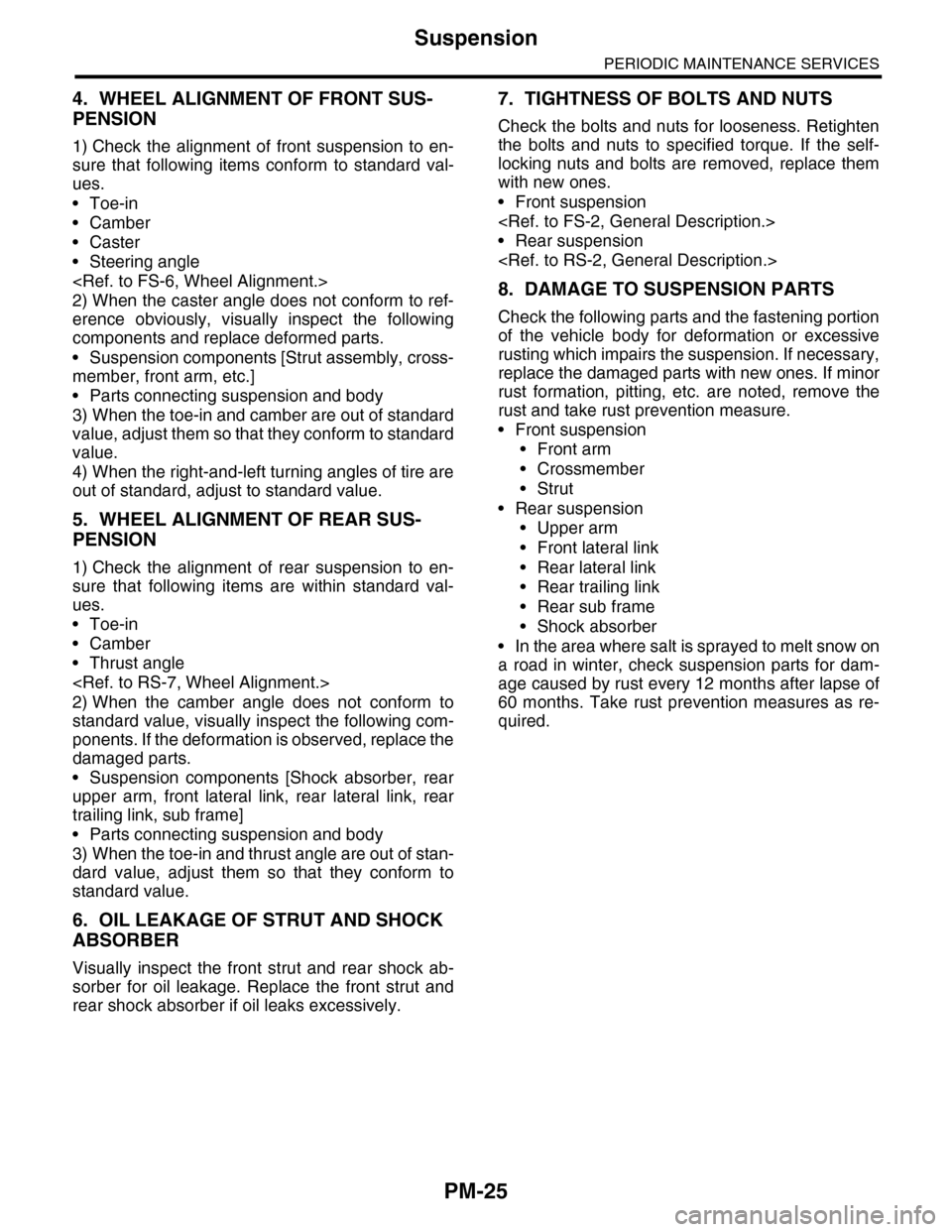

B: ADJUSTMENT

1) Remove the rear tire and release the parking brake.

2) Remove the cover (rubber) installed on the disc rotor.

3) Turn the disc rotor so that the service hole is di-

rectly below.

4) Turn the adjuster toward arrow mark (upward)

until it is locked slightly, by using flat-tip screwdriver

as shown in the figure.

5) Turn back (downward) the adjuster several notch-

es until the brake pedal no longer has any drag.

6) Install the cover (rubber) in original position correctly.

7) Install the rear tires.

8) Adjust so that the parking brake pedal is at the

predetermined number of notches (5 to 6 notches).

(A) Forward

(B) Brake shoe (Primary side)

(C) Brake shoe (Secondary side)

(A) Inside diameter

(B) Disc

PM-00317

(A)

(B)(C)

PM-00055

(A)

(B)

(A) Adjuster

(B) Disc rotor

PM-00290

PM-00291

(A)(B)

Page 2007 of 2453

PM-24

Suspension

PERIODIC MAINTENANCE SERVICES

17.Suspension

A: INSPECTION

1. SUSPENSION BALL JOINT

1) Jack-up the vehicle until front wheels are off

ground.

2) Grasp the bottom of tire and move it in and out

along the shaft. If relative movement is observed

between the brake disc cover (A) and end of front

arm (D), ball joint (C) may be excessively worn.

3) Grasp the end of front arm and move it up and

down. Relative movement (A) between the housing

(D) and front arm (C) boss indicates ball joint (B)

may be excessively worn.

4) If relative movement is observed in the step 2),

3), remove and inspect the ball joint. If the free play

exceeds standard value, replace the ball joint.

5) Damage of dust seal

Visually inspect the ball joint dust seal. If it is dam-

aged, remove the front arm.

(1) When looseness exceeds standard value,

replace the ball joint.

(2) If the dust seal is damaged, replace with a

new ball joint.

NOTE:

When the front arm ball joint has been removed or

replaced, check the toe-in of front wheel. If the front

wheel toe-in is not at specified value, adjust the

toe-in.

2. FRONT, REAR SUSPENSION BUSHING

Apply pressure with tire lever etc, and inspect the

bushing for wear or crack. Replace the bushings

and the arm assembly or link assembly if there is

wear or there are cracks.

3. WHEEL ARCH HEIGHT

1) Unload the cargo and set the vehicle in curb

weight (empty) condition.

2) Check the wheel arch height of the front and rear

suspensions to ensure that they are within speci-

fied values.

3) When the wheel arch height is out of standard,

visually inspect following components and replace

deformed parts.

•Suspension components [Front strut assembly

and rear shock absorber assembly]

•Parts connecting suspension and body

4) When no components are deformed, adjust

wheel arch height by replacing coil spring in the

suspension whose wheel arch height is out of stan-

dard.

PM-00057

(A)

(B)(C)

(D)

PM-00058

(A)

(B)

(C)

(D)

(A) Dust seal

PM-00059

(A)

PM-00180

Page 2008 of 2453

PM-25

Suspension

PERIODIC MAINTENANCE SERVICES

4. WHEEL ALIGNMENT OF FRONT SUS-

PENSION

1) Check the alignment of front suspension to en-

sure that following items conform to standard val-

ues.

•Toe-in

•Camber

•Caster

•Steering angle

2) When the caster angle does not conform to ref-

erence obviously, visually inspect the following

components and replace deformed parts.

•Suspension components [Strut assembly, cross-

member, front arm, etc.]

•Parts connecting suspension and body

3) When the toe-in and camber are out of standard

value, adjust them so that they conform to standard

value.

4) When the right-and-left turning angles of tire are

out of standard, adjust to standard value.

5. WHEEL ALIGNMENT OF REAR SUS-

PENSION

1) Check the alignment of rear suspension to en-

sure that following items are within standard val-

ues.

•Toe-in

•Camber

•Thrust angle

2) When the camber angle does not conform to

standard value, visually inspect the following com-

ponents. If the deformation is observed, replace the

damaged parts.

•Suspension components [Shock absorber, rear

upper arm, front lateral link, rear lateral link, rear

trailing link, sub frame]

•Parts connecting suspension and body

3) When the toe-in and thrust angle are out of stan-

dard value, adjust them so that they conform to

standard value.

6. OIL LEAKAGE OF STRUT AND SHOCK

ABSORBER

Visually inspect the front strut and rear shock ab-

sorber for oil leakage. Replace the front strut and

rear shock absorber if oil leaks excessively.

7. TIGHTNESS OF BOLTS AND NUTS

Check the bolts and nuts for looseness. Retighten

the bolts and nuts to specified torque. If the self-

locking nuts and bolts are removed, replace them

with new ones.

•Front suspension

•Rear suspension

8. DAMAGE TO SUSPENSION PARTS

Check the following parts and the fastening portion

of the vehicle body for deformation or excessive

rusting which impairs the suspension. If necessary,

replace the damaged parts with new ones. If minor

rust formation, pitting, etc. are noted, remove the

rust and take rust prevention measure.

•Front suspension

•Front arm

•Crossmember

•Strut

•Rear suspension

•Upper arm

•Front lateral link

•Rear lateral link

•Rear trailing link

•Rear sub frame

•Shock absorber

•In the area where salt is sprayed to melt snow on

a road in winter, check suspension parts for dam-

age caused by rust every 12 months after lapse of

60 months. Take rust prevention measures as re-

quired.

Page 2009 of 2453

PM-26

Wheel Bearing

PERIODIC MAINTENANCE SERVICES

18.Wheel Bearing

A: INSPECTION

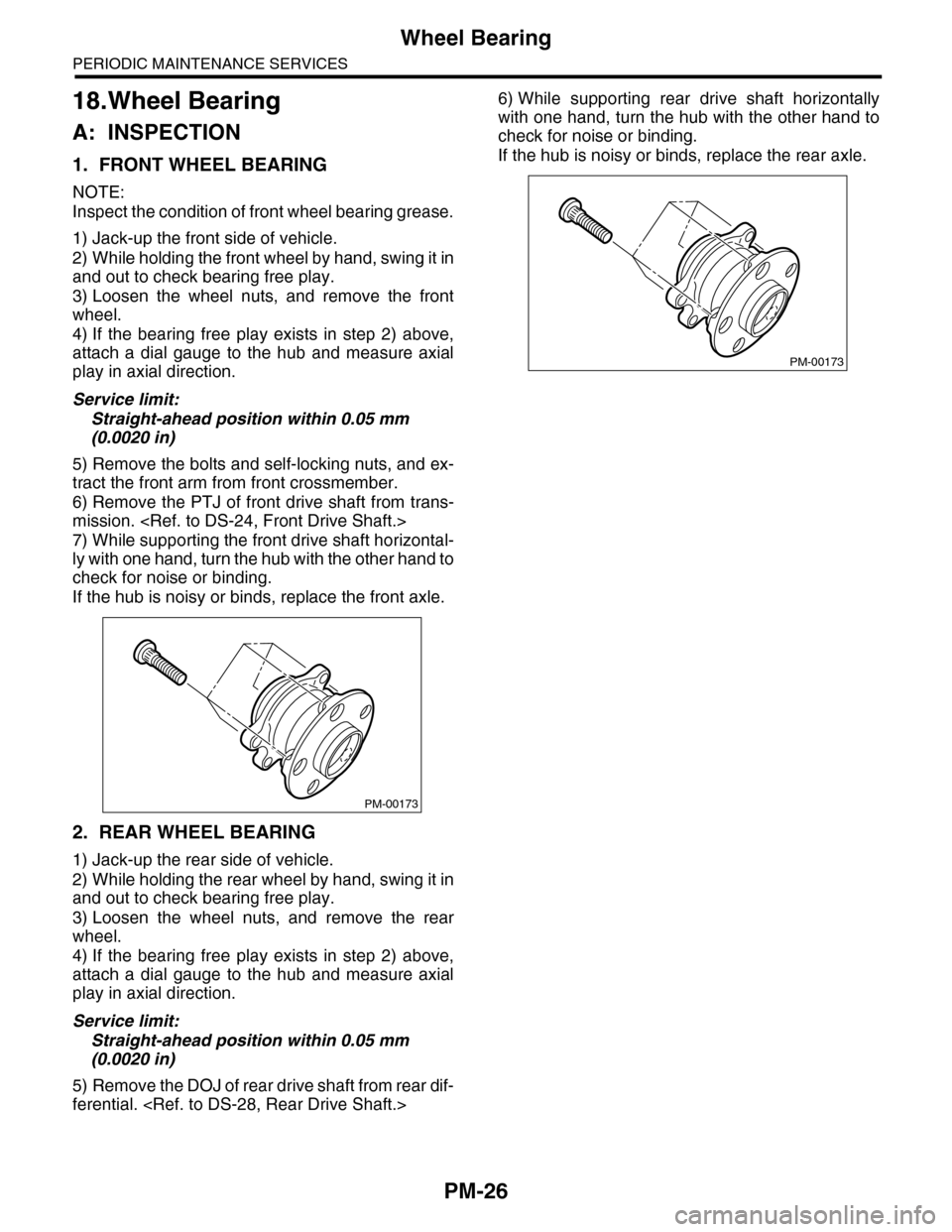

1. FRONT WHEEL BEARING

NOTE:

Inspect the condition of front wheel bearing grease.

1) Jack-up the front side of vehicle.

2) While holding the front wheel by hand, swing it in

and out to check bearing free play.

3) Loosen the wheel nuts, and remove the front

wheel.

4) If the bearing free play exists in step 2) above,

attach a dial gauge to the hub and measure axial

play in axial direction.

Service limit:

Straight-ahead position within 0.05 mm

(0.0020 in)

5) Remove the bolts and self-locking nuts, and ex-

tract the front arm from front crossmember.

6) Remove the PTJ of front drive shaft from trans-

mission.

7) While supporting the front drive shaft horizontal-

ly with one hand, turn the hub with the other hand to

check for noise or binding.

If the hub is noisy or binds, replace the front axle.

2. REAR WHEEL BEARING

1) Jack-up the rear side of vehicle.

2) While holding the rear wheel by hand, swing it in

and out to check bearing free play.

3) Loosen the wheel nuts, and remove the rear

wheel.

4) If the bearing free play exists in step 2) above,

attach a dial gauge to the hub and measure axial

play in axial direction.

Service limit:

Straight-ahead position within 0.05 mm

(0.0020 in)

5) Remove the DOJ of rear drive shaft from rear dif-

ferential.

6) While supporting rear drive shaft horizontally

with one hand, turn the hub with the other hand to

check for noise or binding.

If the hub is noisy or binds, replace the rear axle.

PM-00173

PM-00173

Page 2010 of 2453

PM-27

Axle Boots & Joints

PERIODIC MAINTENANCE SERVICES

19.Axle Boots & Joints

A: INSPECTION

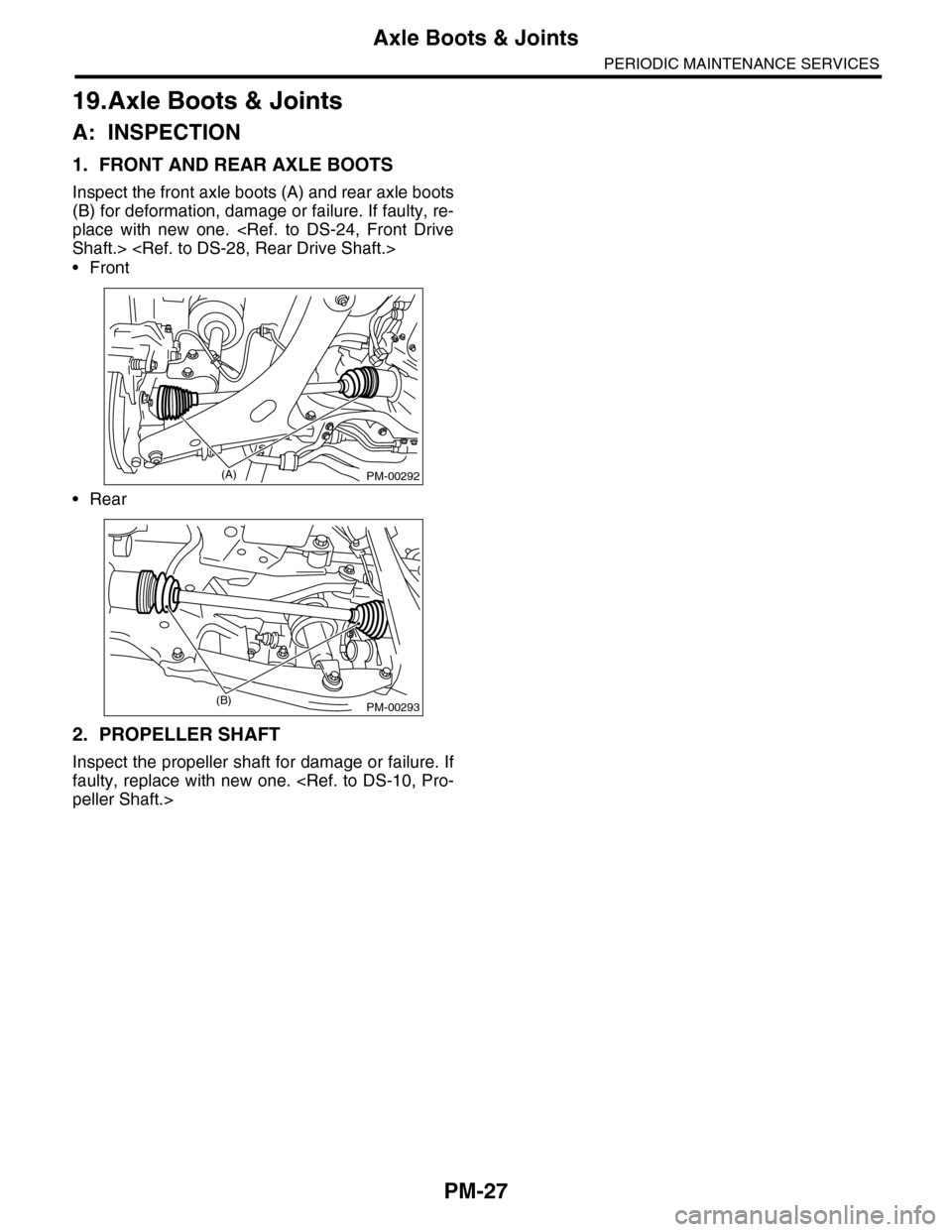

1. FRONT AND REAR AXLE BOOTS

Inspect the front axle boots (A) and rear axle boots

(B) for deformation, damage or failure. If faulty, re-

place with new one.

•Front

•Rear

2. PROPELLER SHAFT

Inspect the propeller shaft for damage or failure. If

faulty, replace with new one.

PM-00292(A)

PM-00293(B)