sensor SUBARU TRIBECA 2009 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 1158 of 2453

EC(H6DO)-10

Fuel Tank Pressure Sensor

EMISSION CONTROL (AUX. EMISSION CONTROL DEVICES)

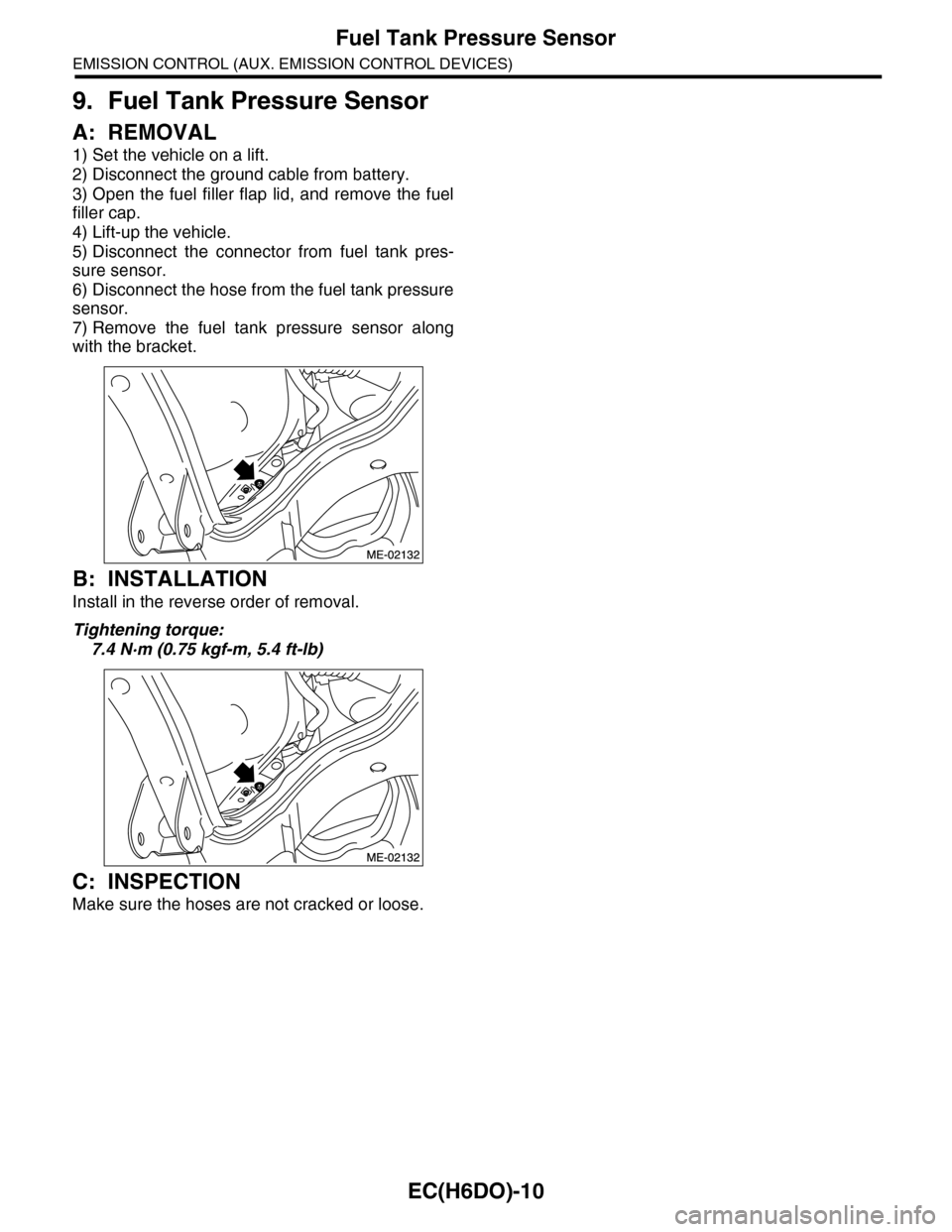

9. Fuel Tank Pressure Sensor

A: REMOVAL

1) Set the vehicle on a lift.

2) Disconnect the ground cable from battery.

3) Open the fuel filler flap lid, and remove the fuel

filler cap.

4) Lift-up the vehicle.

5) Disconnect the connector from fuel tank pres-

sure sensor.

6) Disconnect the hose from the fuel tank pressure

sensor.

7) Remove the fuel tank pressure sensor along

with the bracket.

B: INSTALLATION

Install in the reverse order of removal.

Tightening torque:

7.4 N·m (0.75 kgf-m, 5.4 ft-lb)

C: INSPECTION

Make sure the hoses are not cracked or loose.

Page 1166 of 2453

EN(H6DO)(diag)-5

General Description

ENGINE (DIAGNOSTICS)

3. General Description

A: CAUTION

1) Airbag system wiring harness is routed near the

ECM, main relay and fuel pump relay.

CAUTION:

•All airbag system wiring harnesses and con-

nectors are colored yellow. Do not use electri-

cal test equipment on these circuits.

•Be careful not to damage the airbag system

wiring harness when servicing the ECM, TCM,

main relay and fuel pump relay.

2) Never connect the battery in reverse polarity.

•The ECM will be destroyed instantly.

•The fuel injector and other parts will be dam-

aged.

3) Do not disconnect the battery terminals while the

engine is running.

A large counter electromotive force will be generat-

ed in the generator, and this voltage may damage

electronic parts such as ECM etc.

4) Before disconnecting the connectors of each

sensor and ECM, be sure to turn the ignition switch

to OFF. Perform the clear memory mode after con-

necting the connectors.

5) Poor contact has been identified as a primary

cause of this problem. Measure the voltage or re-

sistance of individual sensor or all electrical control

modules using a tapered pin with a diameter of less

than 0.64 mm (0.025 in). Do not insert the pin more

than 5 mm (0.20 in) into the part.

6) Remove the ECM from the located position after

disconnecting two cables on battery.

Otherwise, the ECM may be damaged.

CAUTION:

When replacing the ECM, be careful not to use

the wrong spec. ECM to avoid any damage on

the fuel injection system.

7) Connectors of each sensor in the engine com-

partment and the harness connectors on the en-

gine side and body side are all designed to be

waterproof. Even if the connectors are waterproof,

take care not to allow water to get into them when

washing the vehicle, or when servicing the vehicle

in rainy weather.

8) Use ECM mounting stud bolts as the grounding

point to chassis when measuring voltage and resis-

tance in the passenger compartment.

9) Use the engine ground terminal or engine as-

sembly as the grounding point to chassis when

measuring the voltage and resistance in engine

compartment.

10) Every MFI-related part is a precision part. Do

not drop them.

11) Observe the following cautions when installing

a radio in MFI equipped models.

CAUTION:

•The antenna must be kept as far apart as pos-

sible from control unit. (The ECM is located un-

der the steering column, inside of the

instrument panel lower trim panel.)

•The antenna feeder must be placed as far apart

as possible from the ECM and MFI harness.

•Carefully adjust the antenna for correct

matching.

•When mounting a large power type radio, pay

special attention to the three items mentioned

above.

•Incorrect installation of the radio may affect

the operation of ECM.

12) Release the pressure in the fuel system before

disconnecting the fuel hose. If engine starts during

this operation, run it until it stops.

13) For the model with ABS, the ABS warning light

may illuminate when performing driving test with

jacked-up or lifted-up condition, but this is not a

system malfunction. The reason for this is the

speed difference between the front and rear

wheels. After diagnosis of engine control system,

perform the ABS memory clear procedure of self-

diagnosis function.

B: INSPECTION

Before performing diagnostics, check the following

item which might affect engine problems.

1. BATTERY

1) Measure the battery voltage and specific gravity

of electrolyte.

Standard voltage: 12 V

Specific gravity: Above 1.260

2) Check the condition of the main and other fuses,

and harnesses and connectors. Also check for

proper grounding.

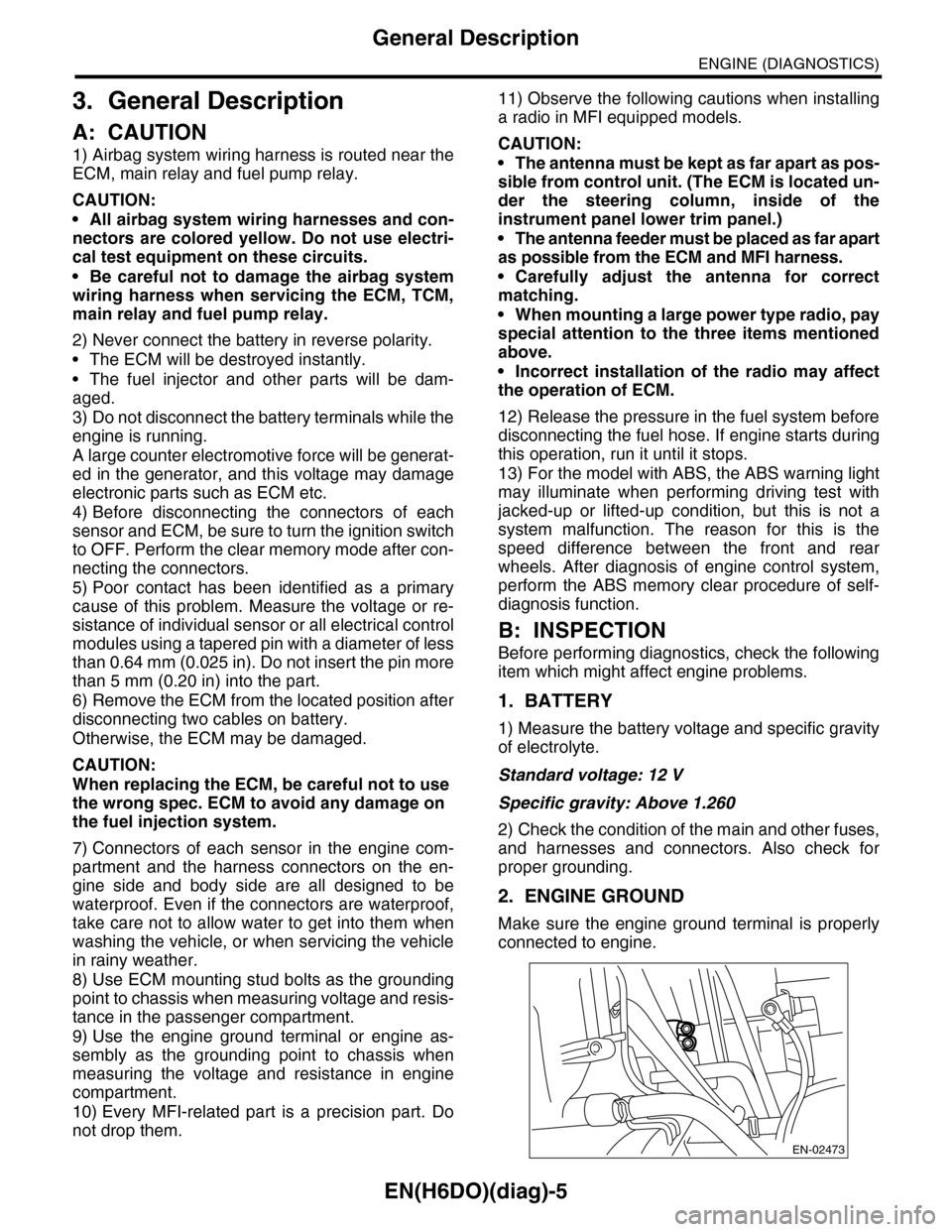

2. ENGINE GROUND

Make sure the engine ground terminal is properly

connected to engine.

EN-02473

Page 1167 of 2453

EN(H6DO)(diag)-6

General Description

ENGINE (DIAGNOSTICS)

C: NOTE

1. GENERAL DESCRIPTION

•The on-board diagnostics (OBD) system detects

and indicates a fault in various inputs and outputs

of the complex electronic control. Malfunction indi-

cator light in the combination meter indicates oc-

currence of a fault or trouble.

•Further, against such a failure or sensors as may

disable the drive, the fail-safe function is provided

to ensure the minimal drivability.

•The OBD system incorporated with the vehicles

within this engine family complies with OBD-II Reg-

ulations. The OBD system monitors the compo-

nents and the system malfunction listed in Engine

Section which affects on emissions.

•When the system decides that a malfunction oc-

curs, malfunction indicator light illuminates. At the

same time of the malfunction indicator light illumi-

nation or blinking, a DTC and a freeze frame en-

gine conditions are stored into on-board computer.

•The OBD system stores freeze frame engine

condition data (engine load, engine coolant tem-

perature, fuel trim, engine speed and vehicle

speed, etc.) into on-board computer when it detects

a malfunction first.

•If the OBD system detects the various malfunc-

tions including the fault of fuel trim or misfire, the

OBD system first stores freeze frame engine condi-

tions about fuel trim or misfire.

•When the malfunction does not occur again for

three consecutive driving cycles, malfunction indi-

cator light is turned off, but DTC remains at on-

board computer.

•When troubleshooting the vehicle which com-

plies with OBD-II Regulations, connect the Subaru

Select Monitor or general scan tool to the vehicle.

2. ENGINE AND EMISSION CONTROL SYS-

TEM

•The Multipoint Fuel Injection (MFI) system is a

system that supplies the optimum air-fuel mixture

to the engine for all the various operating condi-

tions through the use of the latest electronic tech-

nology.

With this system fuel, which is pressurized at a con-

stant pressure, is injected into the intake air pas-

sage of the cylinder head. The injection quantity of

fuel is controlled by an intermittent injection system

where the electro-magnetic injection valve (fuel in-

jector) opens only for a short period of time, de-

pending on the quantity of air required for one cycle

of operation. In actual operation, the injection quan-

tity is determined by the duration of an electric

pulse applied to the fuel injector and this permits

simple, yet highly precise metering of the fuel.

•Further, all the operating conditions of the engine

are converted into electric signals, and this results

in additional features of the system, such as large

improved adaptability, easier addition of compen-

sating element etc.

The MFI system also has the following features:

•Reduced emission of harmful exhaust gases.

•Reduced in fuel consumption.

•Increased engine output.

•Superior acceleration and deceleration.

•Superior startability and warm-up perfor-

mance in cold weather since compensation is

made for coolant and intake air temperature.

Page 1170 of 2453

EN(H6DO)(diag)-9

Electrical Component Location

ENGINE (DIAGNOSTICS)

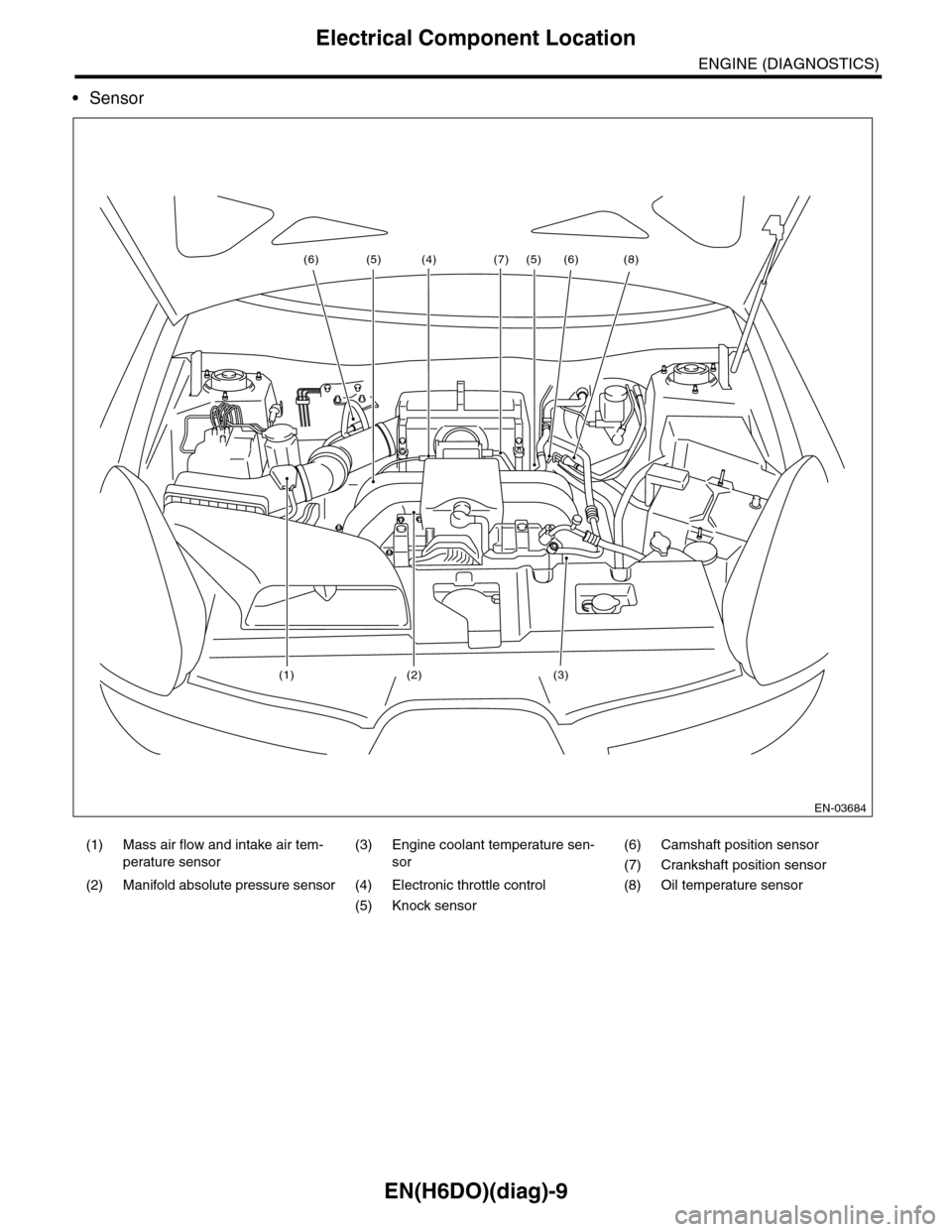

•Sensor

(1) Mass air flow and intake air tem-

perature sensor

(3) Engine coolant temperature sen-

sor

(6) Camshaft position sensor

(7) Crankshaft position sensor

(2) Manifold absolute pressure sensor (4) Electronic throttle control (8) Oil temperature sensor

(5) Knock sensor

EN-03684

(6)(6) (8)

(3)(2)

(7)

(1)

(4) (5)(5)

Page 1172 of 2453

EN(H6DO)(diag)-11

Electrical Component Location

ENGINE (DIAGNOSTICS)

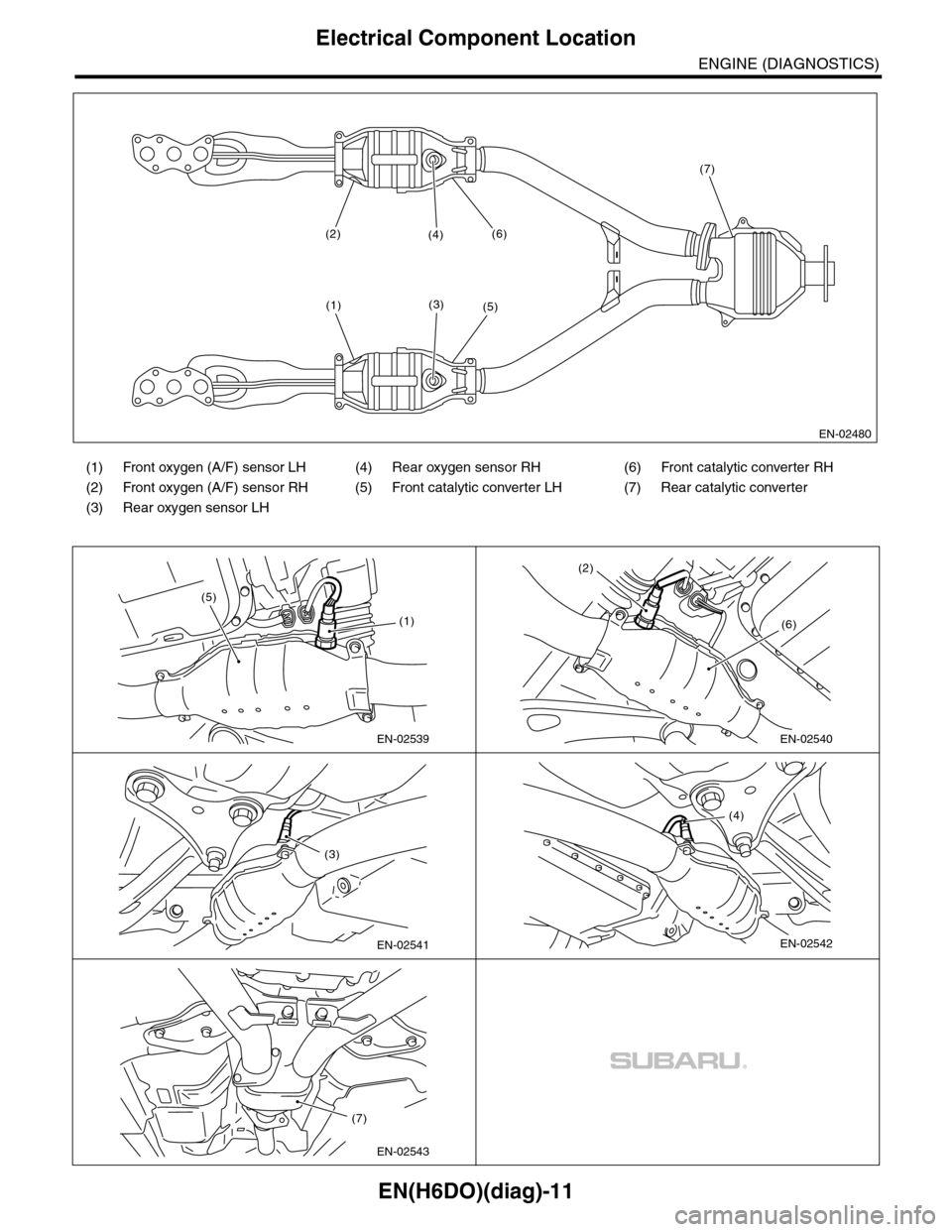

(1) Front oxygen (A/F) sensor LH (4) Rear oxygen sensor RH (6) Front catalytic converter RH

(2) Front oxygen (A/F) sensor RH (5) Front catalytic converter LH (7) Rear catalytic converter

(3) Rear oxygen sensor LH

EN-02480

(2)

(1)(3)

(4)(6)

(7)

(5)

EN-02539

(5)

(1)

EN-02540

(2)

(6)

EN-02541

(3)

EN-02542

(4)

(7)

EN-02543

Page 1173 of 2453

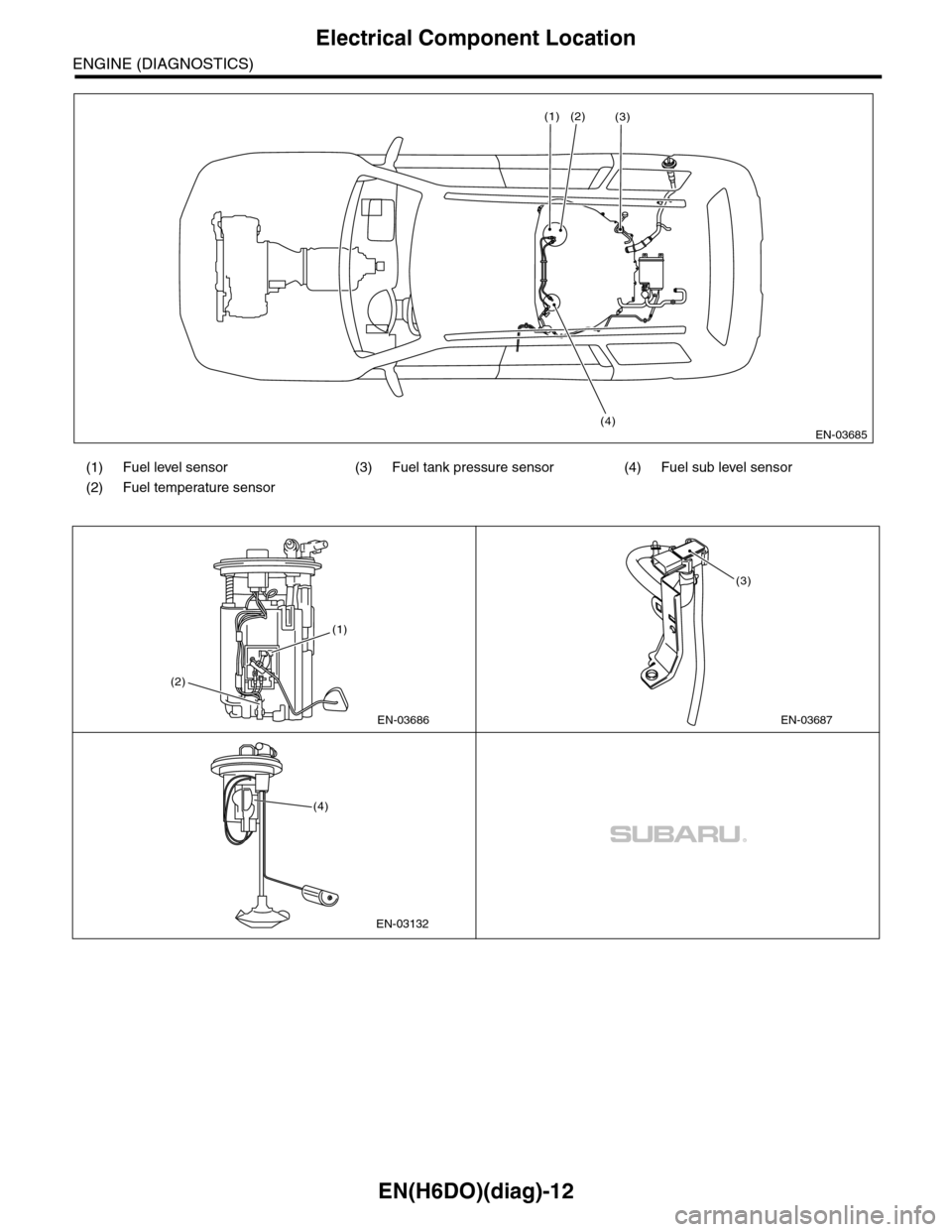

EN(H6DO)(diag)-12

Electrical Component Location

ENGINE (DIAGNOSTICS)

(1) Fuel level sensor (3) Fuel tank pressure sensor (4) Fuel sub level sensor

(2) Fuel temperature sensor

EN-03685

(1)

(4)

(2)(3)

EN-03686

(2)

(1)

EN-03687

(3)

EN-03132

(4)

Page 1177 of 2453

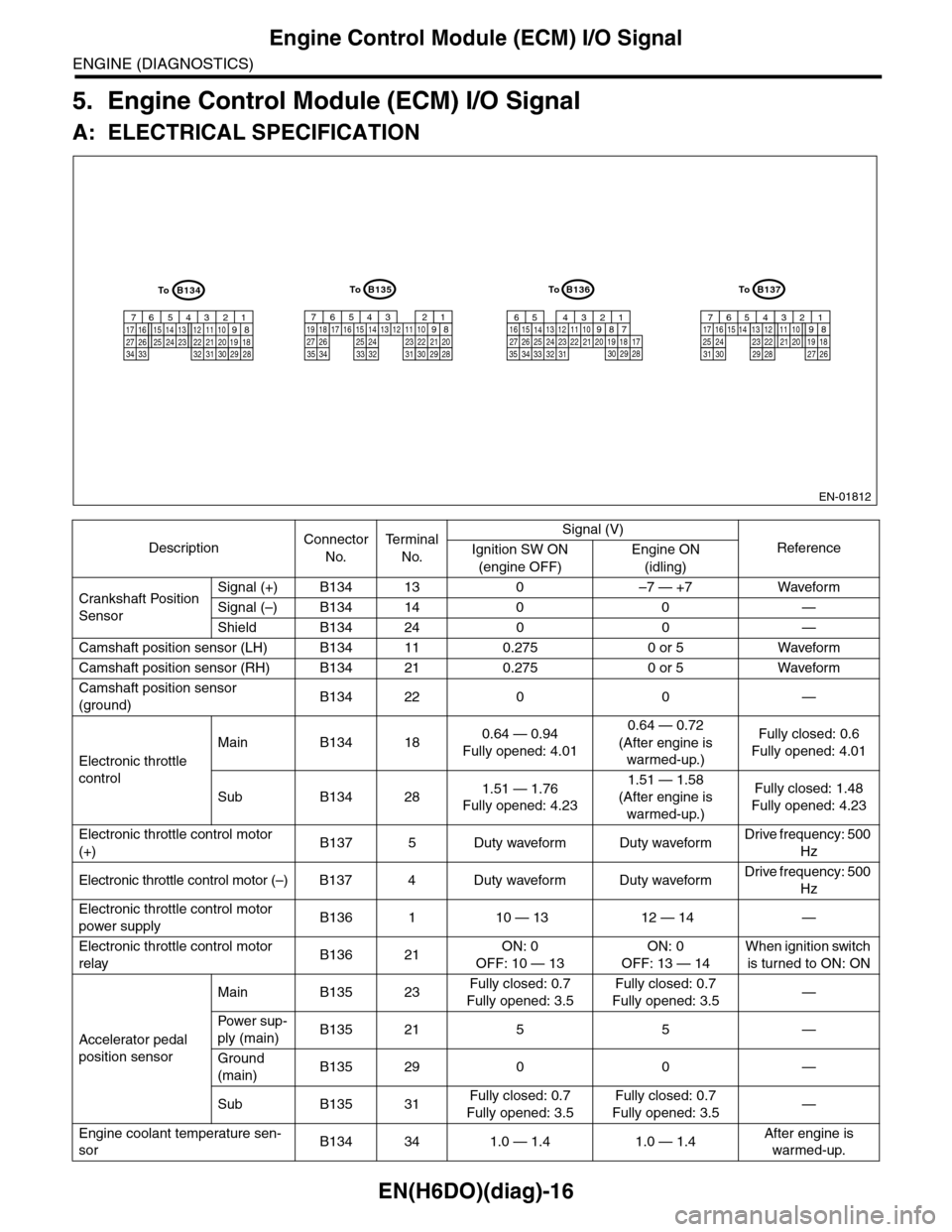

EN(H6DO)(diag)-16

Engine Control Module (ECM) I/O Signal

ENGINE (DIAGNOSTICS)

5. Engine Control Module (ECM) I/O Signal

A: ELECTRICAL SPECIFICATION

DescriptionConnector

No.

Te r m i n a l

No.

Signal (V)

ReferenceIgnition SW ON

(engine OFF)

Engine ON

(idling)

Crankshaft Position

Sensor

Signal (+) B134 13 0 –7 — +7 Waveform

Signal (–) B134 14 0 0 —

Shield B134 24 0 0 —

Camshaft position sensor (LH) B134 11 0.275 0 or 5 Waveform

Camshaft position sensor (RH) B134 21 0.275 0 or 5 Waveform

Camshaft position sensor

(ground)B134 22 0 0 —

Electronic throttle

control

Main B134 180.64 — 0.94

Fully opened: 4.01

0.64 — 0.72

(After engine is

warmed-up.)

Fully closed: 0.6

Fully opened: 4.01

Sub B134 281.51 — 1.76

Fully opened: 4.23

1.51 — 1.58

(After engine is

warmed-up.)

Fully closed: 1.48

Fully opened: 4.23

Electronic throttle control motor

(+)B137 5 Duty waveform Duty waveformDrive frequency: 500

Hz

Electronic throttle control motor (–) B137 4 Duty waveform Duty waveformDrive frequency: 500

Hz

Electronic throttle control motor

power supplyB136 1 10 — 13 12 — 14 —

Electronic throttle control motor

relayB136 21ON: 0

OFF: 10 — 13

ON: 0

OFF: 13 — 14

When ignition switch

is turned to ON: ON

Accelerator pedal

position sensor

Main B135 23Fully closed: 0.7

Fully opened: 3.5

Fully closed: 0.7

Fully opened: 3.5—

Powe r s up -

ply (main)B135 21 5 5 —

Ground

(main)B135 29 0 0 —

Sub B135 31Fully closed: 0.7

Fully opened: 3.5

Fully closed: 0.7

Fully opened: 3.5—

Engine coolant temperature sen-

sorB134 34 1.0 — 1.4 1.0 — 1.4After engine is

warmed-up.

EN-01812

B134

5678219431024 2223251112131415262728

1617181920213334 2932 3031

B136

5678219431024 2223251112131415262728

16171819202133342932303135

B135

5678219431024 2223251112131415262728

16171819202129303132333435

B137

5678219431022231112131415242526

1617181920212728293031

ToToToTo

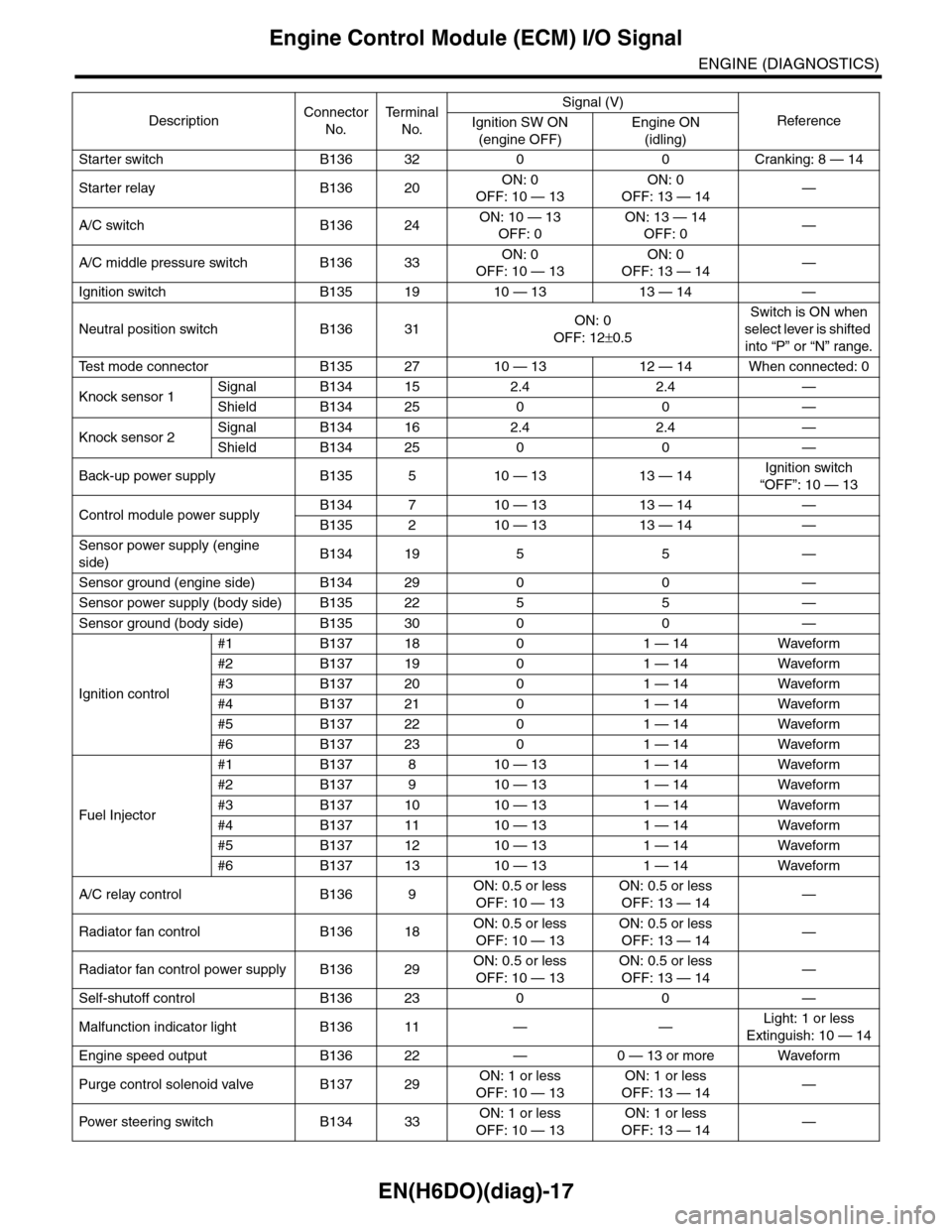

Page 1178 of 2453

EN(H6DO)(diag)-17

Engine Control Module (ECM) I/O Signal

ENGINE (DIAGNOSTICS)

Starter switch B136 32 0 0 Cranking: 8 — 14

Starter relay B136 20ON: 0

OFF: 10 — 13

ON: 0

OFF: 13 — 14—

A/C switch B136 24ON: 10 — 13

OFF: 0

ON: 13 — 14

OFF: 0—

A/C middle pressure switch B136 33ON: 0

OFF: 10 — 13

ON: 0

OFF: 13 — 14—

Ignition switch B135 19 10 — 13 13 — 14 —

Neutral position switch B136 31ON: 0

OFF: 12±0.5

Switch is ON when

select lever is shifted

into “P” or “N” range.

Te s t m o d e c o n n e c t o r B 1 3 5 2 7 1 0 — 1 3 1 2 — 1 4 W h e n c o n n e c t e d : 0

Knock sensor 1Signal B134 15 2.4 2.4 —

Shield B134 25 0 0 —

Knock sensor 2Signal B134 16 2.4 2.4 —

Shield B134 25 0 0 —

Back-up power supply B135 5 10 — 13 13 — 14Ignition switch

“OFF”: 10 — 13

Control module power supplyB134 7 10 — 13 13 — 14 —

B135 2 10 — 13 13 — 14 —

Sensor power supply (engine

side)B134 19 5 5 —

Sensor ground (engine side) B134 29 0 0 —

Sensor power supply (body side) B135 22 5 5 —

Sensor ground (body side) B135 30 0 0 —

Ignition control

#1 B137 18 0 1 — 14 Waveform

#2 B137 19 0 1 — 14 Waveform

#3 B137 20 0 1 — 14 Waveform

#4 B137 21 0 1 — 14 Waveform

#5 B137 22 0 1 — 14 Waveform

#6 B137 23 0 1 — 14 Waveform

Fuel Injector

#1 B137 8 10 — 13 1 — 14 Waveform

#2 B137 9 10 — 13 1 — 14 Waveform

#3 B137 10 10 — 13 1 — 14 Waveform

#4 B137 11 10 — 13 1 — 14 Waveform

#5 B137 12 10 — 13 1 — 14 Waveform

#6 B137 13 10 — 13 1 — 14 Waveform

A/C relay control B136 9ON: 0.5 or less

OFF: 10 — 13

ON: 0.5 or less

OFF: 13 — 14—

Radiator fan control B136 18ON: 0.5 or less

OFF: 10 — 13

ON: 0.5 or less

OFF: 13 — 14—

Radiator fan control power supply B136 29ON: 0.5 or less

OFF: 10 — 13

ON: 0.5 or less

OFF: 13 — 14—

Self-shutoff control B136 23 0 0 —

Malfunction indicator light B136 11 — —Light: 1 or less

Extinguish: 10 — 14

Engine speed output B136 22 — 0 — 13 or more Waveform

Purge control solenoid valve B137 29ON: 1 or less

OFF: 10 — 13

ON: 1 or less

OFF: 13 — 14—

Pow er s te e r in g sw it c h B 1 3 4 33ON: 1 or less

OFF: 10 — 13

ON: 1 or less

OFF: 13 — 14—

DescriptionConnector

No.

Te r m i n a l

No.

Signal (V)

ReferenceIgnition SW ON

(engine OFF)

Engine ON

(idling)

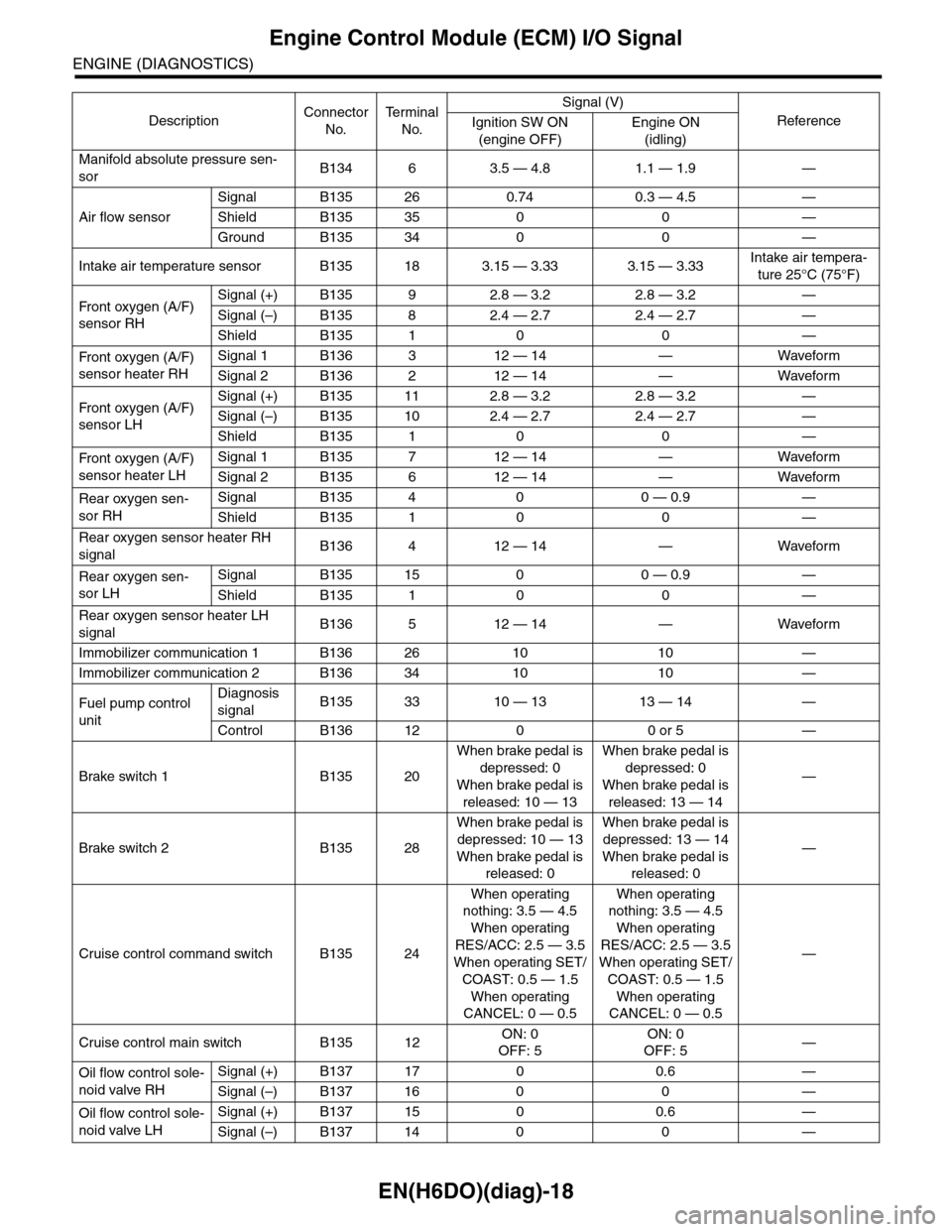

Page 1179 of 2453

EN(H6DO)(diag)-18

Engine Control Module (ECM) I/O Signal

ENGINE (DIAGNOSTICS)

Manifold absolute pressure sen-

sorB134 6 3.5 — 4.8 1.1 — 1.9 —

Air flow sensor

Signal B135 26 0.74 0.3 — 4.5 —

Shield B135 35 0 0 —

Ground B135 34 0 0 —

Intake air temperature sensor B135 18 3.15 — 3.33 3.15 — 3.33Intake air tempera-

ture 25°C (75°F)

Fr o nt ox yg e n ( A / F)

sensor RH

Signal (+) B135 9 2.8 — 3.2 2.8 — 3.2 —

Signal (–) B135 8 2.4 — 2.7 2.4 — 2.7 —

Shield B135 1 0 0 —

Fr o nt ox yg e n ( A / F)

sensor heater RH

Signal 1 B136 3 12 — 14 — Waveform

Signal 2 B136 2 12 — 14 — Waveform

Fr o nt ox yg e n ( A / F)

sensor LH

Signal (+) B135 11 2.8 — 3.2 2.8 — 3.2 —

Signal (–) B135 10 2.4 — 2.7 2.4 — 2.7 —

Shield B135 1 0 0 —

Fr o nt ox yg e n ( A / F)

sensor heater LH

Signal 1 B135 7 12 — 14 — Waveform

Signal 2 B135 6 12 — 14 — Waveform

Rear oxygen sen-

sor RH

Signal B135 4 0 0 — 0.9 —

Shield B135 1 0 0 —

Rear oxygen sensor heater RH

signalB136 4 12 — 14 — Waveform

Rear oxygen sen-

sor LH

Signal B135 15 0 0 — 0.9 —

Shield B135 1 0 0 —

Rear oxygen sensor heater LH

signalB136 5 12 — 14 — Waveform

Immobilizer communication 1 B136 26 10 10 —

Immobilizer communication 2 B136 34 10 10 —

Fuel pump control

unit

Diagnosis

signalB135 33 10 — 13 13 — 14 —

Control B136 12 0 0 or 5 —

Brake switch 1 B135 20

When brake pedal is

depressed: 0

When brake pedal is

released: 10 — 13

When brake pedal is

depressed: 0

When brake pedal is

released: 13 — 14

—

Brake switch 2 B135 28

When brake pedal is

depressed: 10 — 13

When brake pedal is

released: 0

When brake pedal is

depressed: 13 — 14

When brake pedal is

released: 0

—

Cruise control command switch B135 24

When operating

nothing: 3.5 — 4.5

When operating

RES/ACC: 2.5 — 3.5

When operating SET/

COAST: 0.5 — 1.5

When operating

CANCEL: 0 — 0.5

When operating

nothing: 3.5 — 4.5

When operating

RES/ACC: 2.5 — 3.5

When operating SET/

COAST: 0.5 — 1.5

When operating

CANCEL: 0 — 0.5

—

Cruise control main switch B135 12ON: 0

OFF: 5

ON: 0

OFF: 5—

Oil flow control sole-

noid valve RH

Signal (+) B137 17 0 0.6 —

Signal (–) B137 16 0 0 —

Oil flow control sole-

noid valve LH

Signal (+) B137 15 0 0.6 —

Signal (–) B137 14 0 0 —

DescriptionConnector

No.

Te r m i n a l

No.

Signal (V)

ReferenceIgnition SW ON

(engine OFF)

Engine ON

(idling)

Page 1180 of 2453

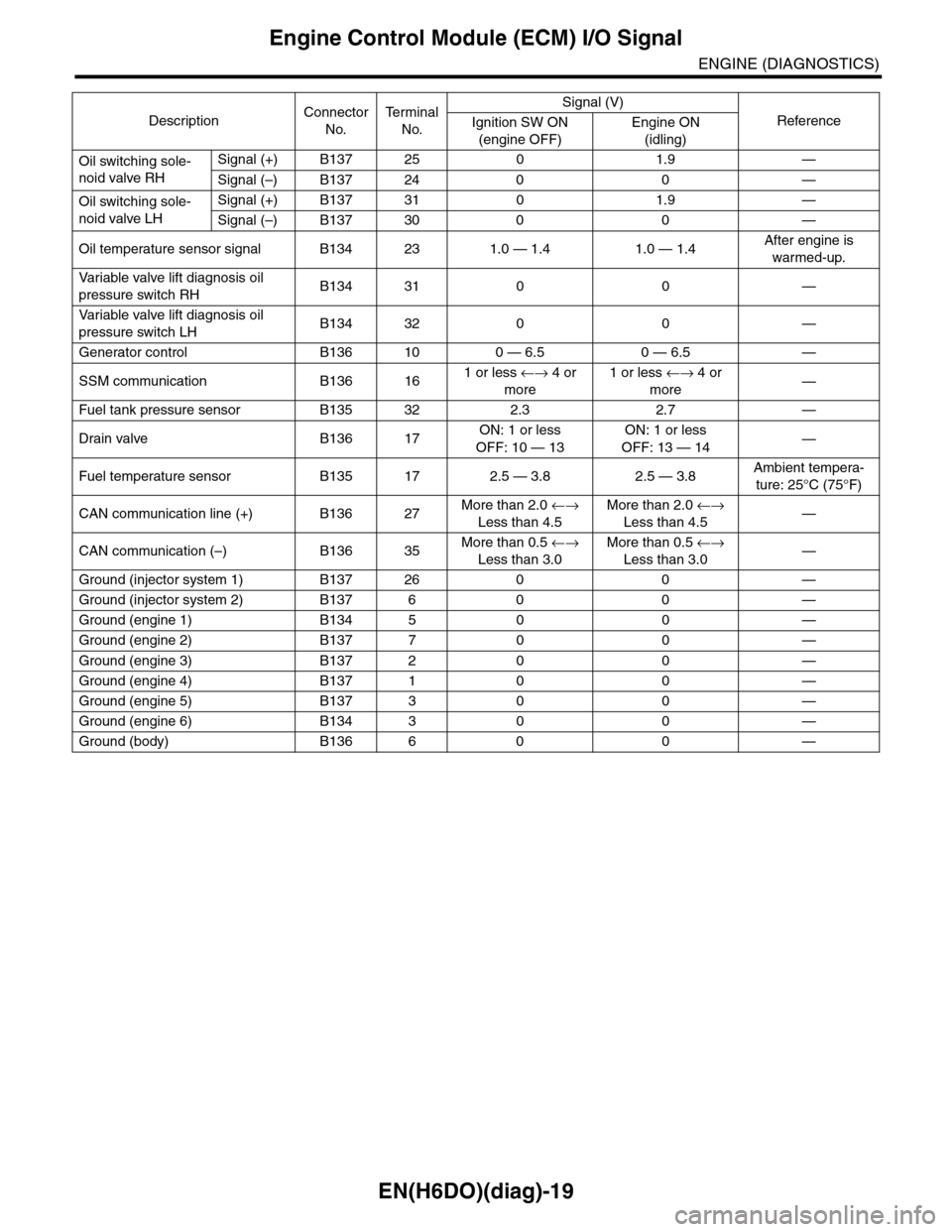

EN(H6DO)(diag)-19

Engine Control Module (ECM) I/O Signal

ENGINE (DIAGNOSTICS)

Oil switching sole-

noid valve RH

Signal (+) B137 25 0 1.9 —

Signal (–) B137 24 0 0 —

Oil switching sole-

noid valve LH

Signal (+) B137 31 0 1.9 —

Signal (–) B137 30 0 0 —

Oil temperature sensor signal B134 23 1.0 — 1.4 1.0 — 1.4After engine is

warmed-up.

Va r i a b l e va l v e l i f t d i a g n o s i s o i l

pressure switch RHB134 31 0 0 —

Va r i a b l e va l v e l i f t d i a g n o s i s o i l

pressure switch LHB134 32 0 0 —

Generator control B136 10 0 — 6.5 0 — 6.5 —

SSM communication B136 161 or less ←→ 4 or

more

1 or less ←→ 4 or

more—

Fuel tank pressure sensor B135 32 2.3 2.7 —

Drain valve B136 17ON: 1 or less

OFF: 10 — 13

ON: 1 or less

OFF: 13 — 14—

Fuel temperature sensor B135 17 2.5 — 3.8 2.5 — 3.8Ambient tempera-

ture: 25°C (75°F)

CAN communication line (+) B136 27More than 2.0 ←→

Less than 4.5

More than 2.0 ←→

Less than 4.5—

CAN communication (–) B136 35More than 0.5 ←→

Less than 3.0

More than 0.5 ←→

Less than 3.0—

Ground (injector system 1) B137 26 0 0 —

Ground (injector system 2) B137 6 0 0 —

Ground (engine 1) B134 5 0 0 —

Ground (engine 2) B137 7 0 0 —

Ground (engine 3) B137 2 0 0 —

Ground (engine 4) B137 1 0 0 —

Ground (engine 5) B137 3 0 0 —

Ground (engine 6) B134 3 0 0 —

Ground (body) B136 6 0 0 —

DescriptionConnector

No.

Te r m i n a l

No.

Signal (V)

ReferenceIgnition SW ON

(engine OFF)

Engine ON

(idling)