sensor SUBARU TRIBECA 2009 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 1731 of 2453

GD(H6DO)-119

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

3. ENABLE CONDITIONS

4. GENERAL DRIVING CYCLE

Always perform the diagnosis continuously.

5. DIAGNOSTIC METHOD

Abnormality Judgment

If a condition where the number of camshaft position sensor signals for 2 engine revolutions is not 3 times,

continues for more than 3 seconds.

Judge as OK and clear the NG when the following criteria are not established.

Time Needed for Diagnosis: 8 seconds

Malfunction Indicator Light: Illuminates as soon as a malfunction occurs.

Normality Judgment

Judge as OK and clear the NG when the malfunction criteria below are met.

6. DTC CLEAR CONDITION

•When the OK idling cycle is completed 40 times in a row

•When “Clear Memory” is performed

7. MALFUNCTION INDICATOR LIGHT CLEAR CONDITIONS

•When the OK driving cycle is completed 3 times in a row

•When “Clear Memory” is performed

8. FAIL SAFE

Make the oil flow control solenoid valve driving duty a predetermined value (9.36%).

9. ECM OPERATION AT DTC SETTING

Memorize the freeze frame data. (For test mode $02)

Secondary Parameters Enable Conditions

Battery voltage≥ 8 V

Judgment Value

Malfunction Criteria Threshold Value

Amount of camshaft sensor signal during

2 revs.

≠ 3

Judgment Value

Malfunction Criteria Threshold Value

Camshaft position sensor signal = 3

Page 1732 of 2453

GD(H6DO)-120

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

CA:DTC P0345 CAMSHAFT POSITION SENSOR “A” CIRCUIT (BANK 2)

1. OUTLINE OF DIAGNOSIS

NOTE:

For the diagnostic procedure, refer to DTC P0340.

Criteria.>

Page 1733 of 2453

GD(H6DO)-121

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

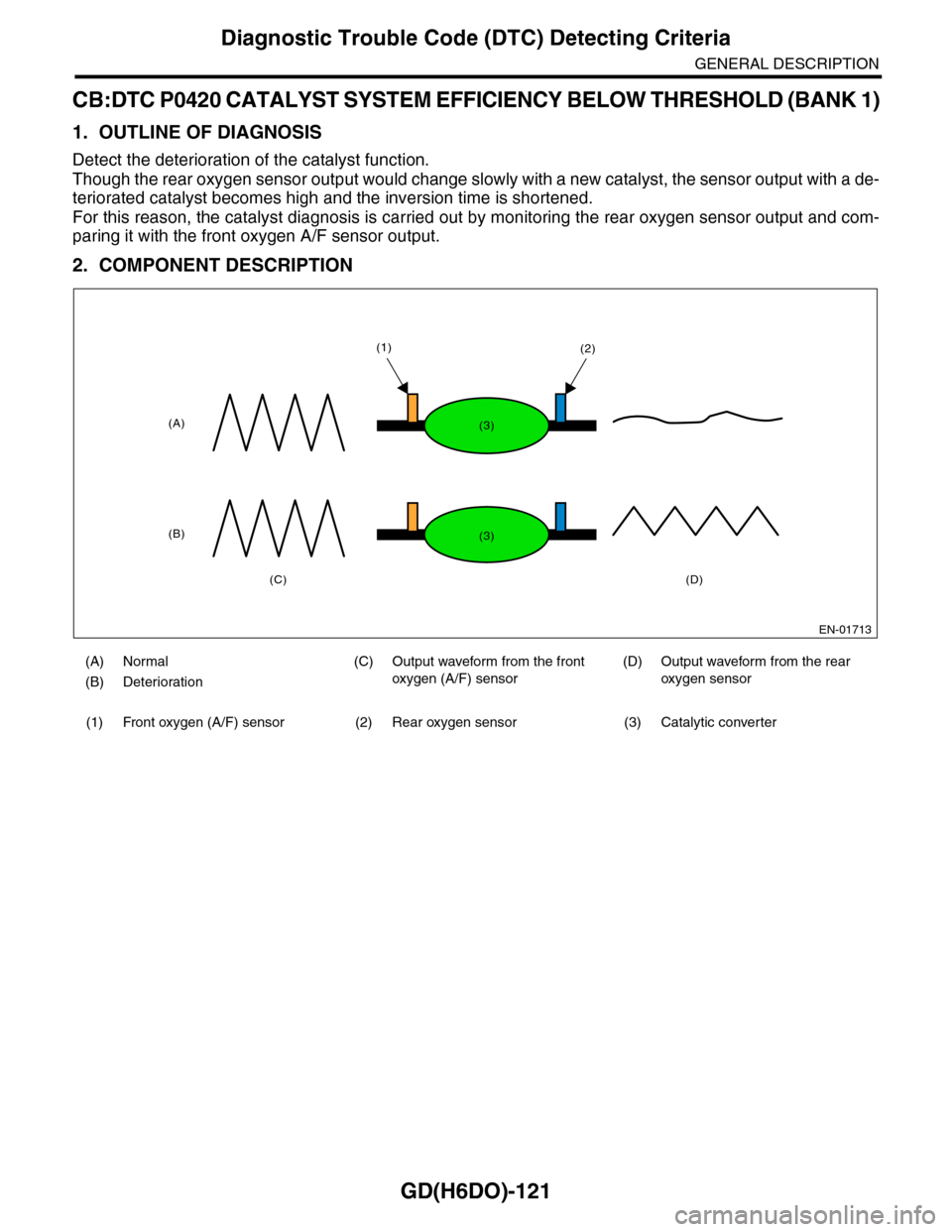

CB:DTC P0420 CATALYST SYSTEM EFFICIENCY BELOW THRESHOLD (BANK 1)

1. OUTLINE OF DIAGNOSIS

Detect the deterioration of the catalyst function.

Though the rear oxygen sensor output would change slowly with a new catalyst, the sensor output with a de-

teriorated catalyst becomes high and the inversion time is shortened.

For this reason, the catalyst diagnosis is carried out by monitoring the rear oxygen sensor output and com-

paring it with the front oxygen A/F sensor output.

2. COMPONENT DESCRIPTION

(A) Normal (C) Output waveform from the front

oxygen (A/F) sensor

(D) Output waveform from the rear

oxygen sensor(B) Deterioration

(1) Front oxygen (A/F) sensor (2) Rear oxygen sensor (3) Catalytic converter

EN-01713

(A)

(B)

(C)(D)

(1)(2)

(3)

(3)

Page 1734 of 2453

GD(H6DO)-122

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

3. ENABLE CONDITIONS

Map 2

Add the following value every 512 milliseconds.

4. GENERAL DRIVING CYCLE

Perform the diagnosis only once at a constant 70 km/h (43 MPH) or higher.

5. DIAGNOSTIC METHOD

After the execution criteria are established, calculate the output fluctuation value of front oxygen (A/F) sensor

(averaged for the right and left) and output fluctuation value of rear oxygen sensor. Calculate the diagnosis

value when the front oxygen (A/F) sensor output fluctuation value is more than specified value. A/F response

properties and diagnosis values are parameters for the judgment value.

Judge as NG when the malfunction criteria below are met. Judge as OK if the criteria below are not met.

Time Needed for Diagnosis: 30 to 55 seconds

Malfunction Indicator Light Illumination: Illuminates when malfunctions occur in 2 continuous driving cy-

cles.

Secondary Parameters Enable Conditions

Battery voltage > 10.9 V

Atmospheric pressure > 75.1 kPa (563

mmHg, 22.2 inHg)

Engine coolant temperature≥ 75°C (167°F)

Catalyst warm-up counter (Map 2)≥ 8000

Misfire detection every 200 rotations < 5 times

Sub feedback In operation

Evaporative system diagnosis Not in operation

Time of difference (< 0.10) between

actual and target lambda

1000 milliseconds or

more

Ve h i c l e s p e e d≥ 70 km/h (43 MPH)

Amount of intake air 15 ←→ 50 g (0.53

←→ 1.76 oz)/s

Rear O2 output change from lower than

to higher than 600 mV

Experienced after fuel

cut

Load change absolute value < 0.02 g (0.007 oz)/rev

To t a l t i m e o f c a n i s t e r p u r g e o p e r a t i o n≥ 5 sec.

Learning value of evaporation gas den-

sity

≤ 0.12

After engine starting≥ 205 sec.

Amount of intake

air (g(oz)/s)0 (0)3.2

(0.113)

6.4

(0.226)

9.6

(0.339)

12.8

(0.451)

16

(0.564)

19.2

(0.677)

22.4

(0.790)

25.6

(0.903)

28.8

(1.016)

32

(1.129)

35.2

(1.242)

To t a l v a l u e f o r

warm-up counter–19 –8 11 19 30 44 61 81 104 130 159 161

Judgment Value

Malfunction Criteria Threshold Value

Accumulated variation of output voltage

of rear oxygen sensor per 32 millisec-

onds × 4 divided by accumulated varia-

tion of lambda of front oxygen (A/F)

sensor per 32 milliseconds × 4

≥ 30

Page 1736 of 2453

GD(H6DO)-124

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

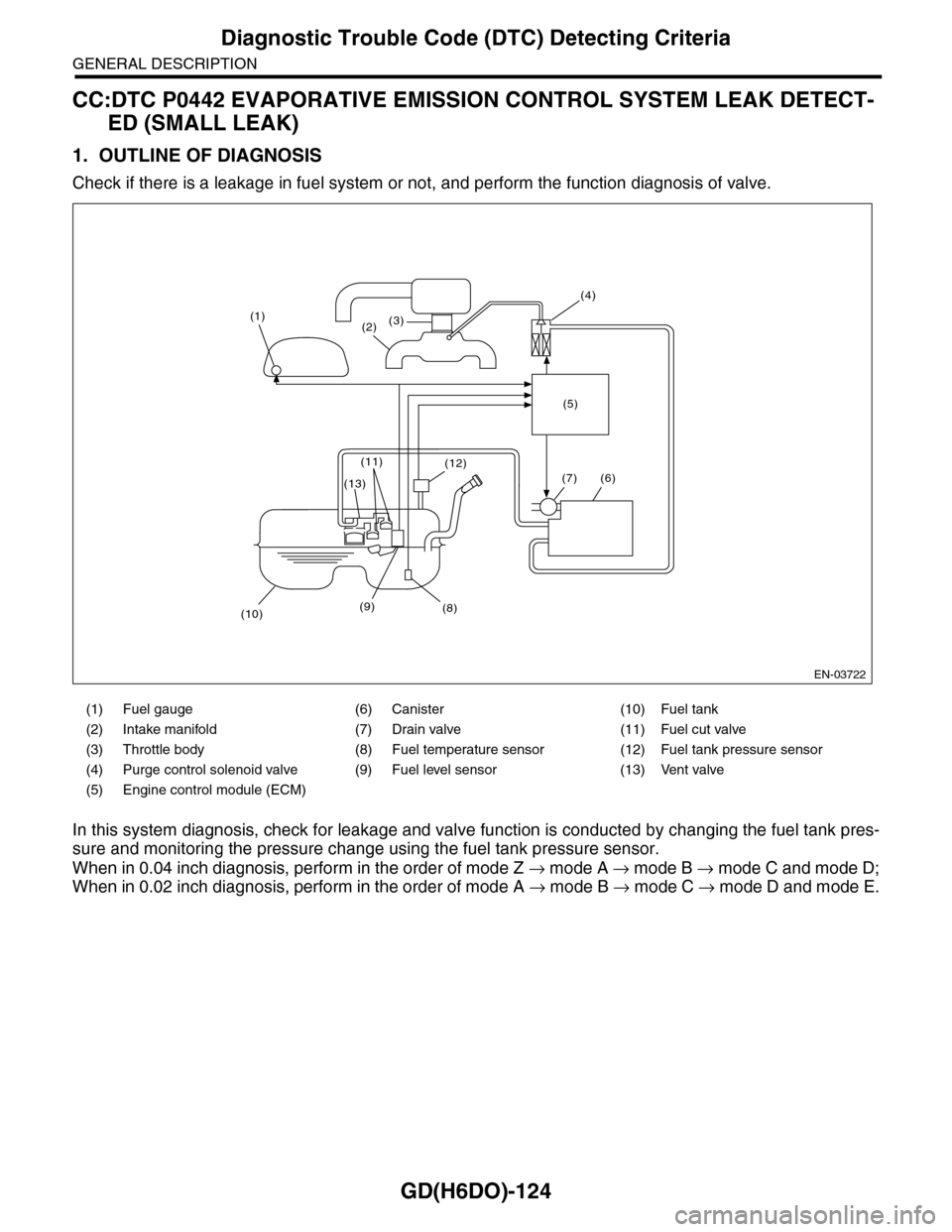

CC:DTC P0442 EVAPORATIVE EMISSION CONTROL SYSTEM LEAK DETECT-

ED (SMALL LEAK)

1. OUTLINE OF DIAGNOSIS

Check if there is a leakage in fuel system or not, and perform the function diagnosis of valve.

In this system diagnosis, check for leakage and valve function is conducted by changing the fuel tank pres-

sure and monitoring the pressure change using the fuel tank pressure sensor.

When in 0.04 inch diagnosis, perform in the order of mode Z → mode A → mode B → mode C and mode D;

When in 0.02 inch diagnosis, perform in the order of mode A → mode B → mode C → mode D and mode E.

(1) Fuel gauge (6) Canister (10) Fuel tank

(2) Intake manifold (7) Drain valve (11) Fuel cut valve

(3) Throttle body (8) Fuel temperature sensor (12) Fuel tank pressure sensor

(4) Purge control solenoid valve (9) Fuel level sensor (13) Vent valve

(5) Engine control module (ECM)

EN-03722

(1)(2)(3)

(4)

(5)

(6)

(8)

(12)

(9)(10)

(13)

(11)

(7)

Page 1741 of 2453

GD(H6DO)-129

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

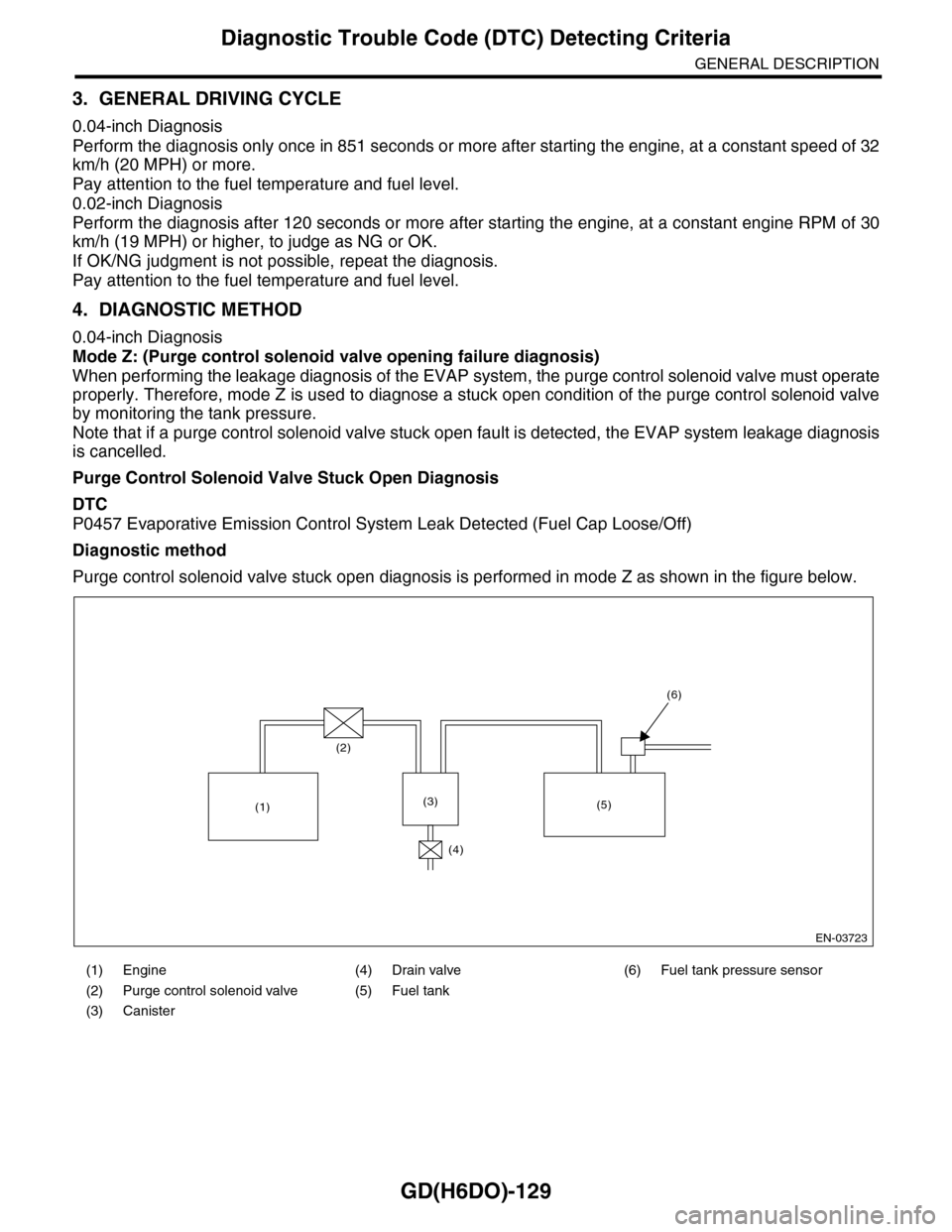

3. GENERAL DRIVING CYCLE

0.04-inch Diagnosis

Perform the diagnosis only once in 851 seconds or more after starting the engine, at a constant speed of 32

km/h (20 MPH) or more.

Pay attention to the fuel temperature and fuel level.

0.02-inch Diagnosis

Perform the diagnosis after 120 seconds or more after starting the engine, at a constant engine RPM of 30

km/h (19 MPH) or higher, to judge as NG or OK.

If OK/NG judgment is not possible, repeat the diagnosis.

Pay attention to the fuel temperature and fuel level.

4. DIAGNOSTIC METHOD

0.04-inch Diagnosis

Mode Z: (Purge control solenoid valve opening failure diagnosis)

When performing the leakage diagnosis of the EVAP system, the purge control solenoid valve must operate

properly. Therefore, mode Z is used to diagnose a stuck open condition of the purge control solenoid valve

by monitoring the tank pressure.

Note that if a purge control solenoid valve stuck open fault is detected, the EVAP system leakage diagnosis

is cancelled.

Purge Control Solenoid Valve Stuck Open Diagnosis

DTC

P0457 Evaporative Emission Control System Leak Detected (Fuel Cap Loose/Off)

Diagnostic method

Purge control solenoid valve stuck open diagnosis is performed in mode Z as shown in the figure below.

(1) Engine (4) Drain valve (6) Fuel tank pressure sensor

(2) Purge control solenoid valve (5) Fuel tank

(3) Canister

EN-03723

(2)

(1)(3)

(4)

(5)

(6)

Page 1752 of 2453

GD(H6DO)-140

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

CF:DTC P0451 EVAPORATIVE EMISSION CONTROL SYSTEM PRESSURE

SENSOR

1. OUTLINE OF DIAGNOSIS

Detect the tank pressure sensor output property abnormality.

Judge NG when there is no pressure variation, which should exist in the tank, considering the engine status.

2. COMPONENT DESCRIPTION

3. ENABLE CONDITIONS

4. GENERAL DRIVING CYCLE

•Always perform the diagnosis continuously in 60 seconds after starting the engine.

•Be sure to check the fuel level and fuel temperature.

5. DIAGNOSTIC METHOD

Abnormality Judgment

Judge as NG when the malfunction criteria below are met.

(A) Output voltage (C) To fuel tank (D) To atmosphere

(B) Input voltage

(1) Connector (2) Terminals

Secondary Parameters Enable Conditions

After engine starting 60 seconds or more

Fuel level≥ 9.6 2 (2.45 US gal,

2.11 Imp gal)

Fuel temperature < 35°C (95°F)

Battery voltage≥ 10.9 V

Atmospheric pressure > 75.1 kPa (563

mmHg, 22.2 inHg)

Engine speed < 7000 rpm

EN-03141

(A)

(B)

(2)(1)

(D)

(C)

Page 1754 of 2453

GD(H6DO)-142

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

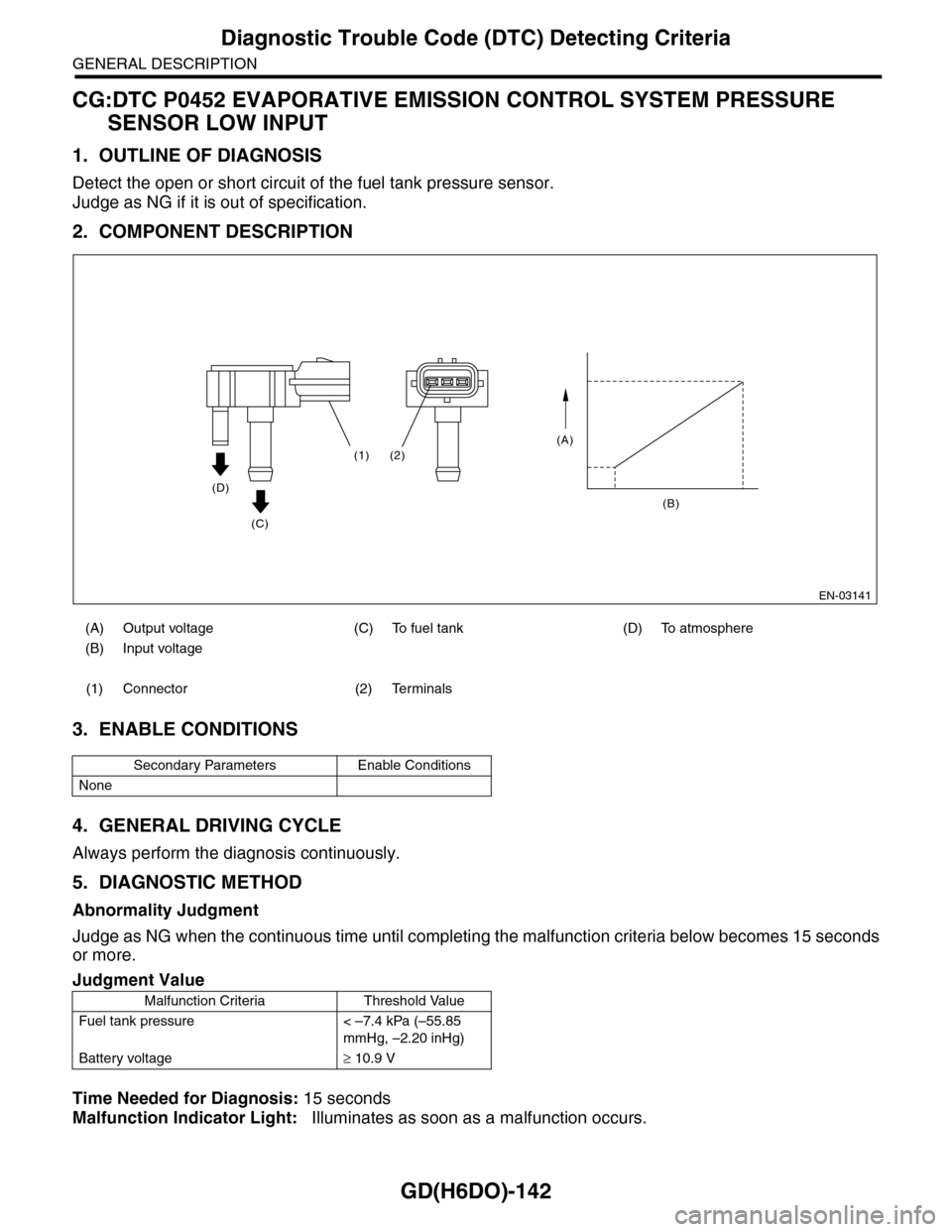

CG:DTC P0452 EVAPORATIVE EMISSION CONTROL SYSTEM PRESSURE

SENSOR LOW INPUT

1. OUTLINE OF DIAGNOSIS

Detect the open or short circuit of the fuel tank pressure sensor.

Judge as NG if it is out of specification.

2. COMPONENT DESCRIPTION

3. ENABLE CONDITIONS

4. GENERAL DRIVING CYCLE

Always perform the diagnosis continuously.

5. DIAGNOSTIC METHOD

Abnormality Judgment

Judge as NG when the continuous time until completing the malfunction criteria below becomes 15 seconds

or more.

Time Needed for Diagnosis: 15 seconds

Malfunction Indicator Light: Illuminates as soon as a malfunction occurs.

(A) Output voltage (C) To fuel tank (D) To atmosphere

(B) Input voltage

(1) Connector (2) Terminals

Secondary Parameters Enable Conditions

None

Judgment Value

Malfunction Criteria Threshold Value

Fuel tank pressure < –7.4 kPa (–55.85

mmHg, –2.20 inHg)

Battery voltage≥ 10.9 V

EN-03141

(A)

(B)

(2)(1)

(D)

(C)

Page 1756 of 2453

GD(H6DO)-144

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

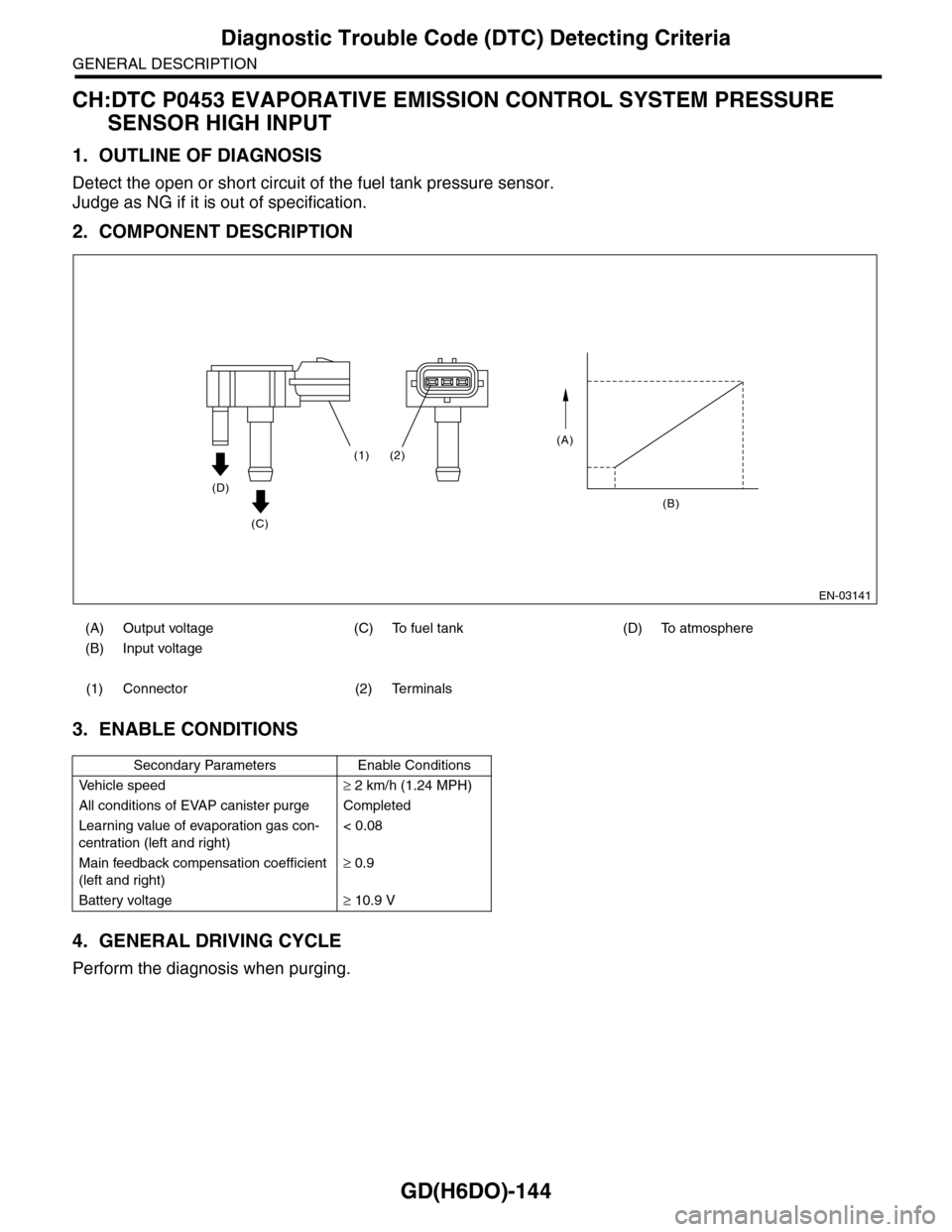

CH:DTC P0453 EVAPORATIVE EMISSION CONTROL SYSTEM PRESSURE

SENSOR HIGH INPUT

1. OUTLINE OF DIAGNOSIS

Detect the open or short circuit of the fuel tank pressure sensor.

Judge as NG if it is out of specification.

2. COMPONENT DESCRIPTION

3. ENABLE CONDITIONS

4. GENERAL DRIVING CYCLE

Perform the diagnosis when purging.

(A) Output voltage (C) To fuel tank (D) To atmosphere

(B) Input voltage

(1) Connector (2) Terminals

Secondary Parameters Enable Conditions

Ve h i c l e s p e e d≥ 2 km/h (1.24 MPH)

All conditions of EVAP canister purge Completed

Learning value of evaporation gas con-

centration (left and right)

< 0.08

Main feedback compensation coefficient

(left and right)

≥ 0.9

Battery voltage≥ 10.9 V

EN-03141

(A)

(B)

(2)(1)

(D)

(C)

Page 1763 of 2453

GD(H6DO)-151

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

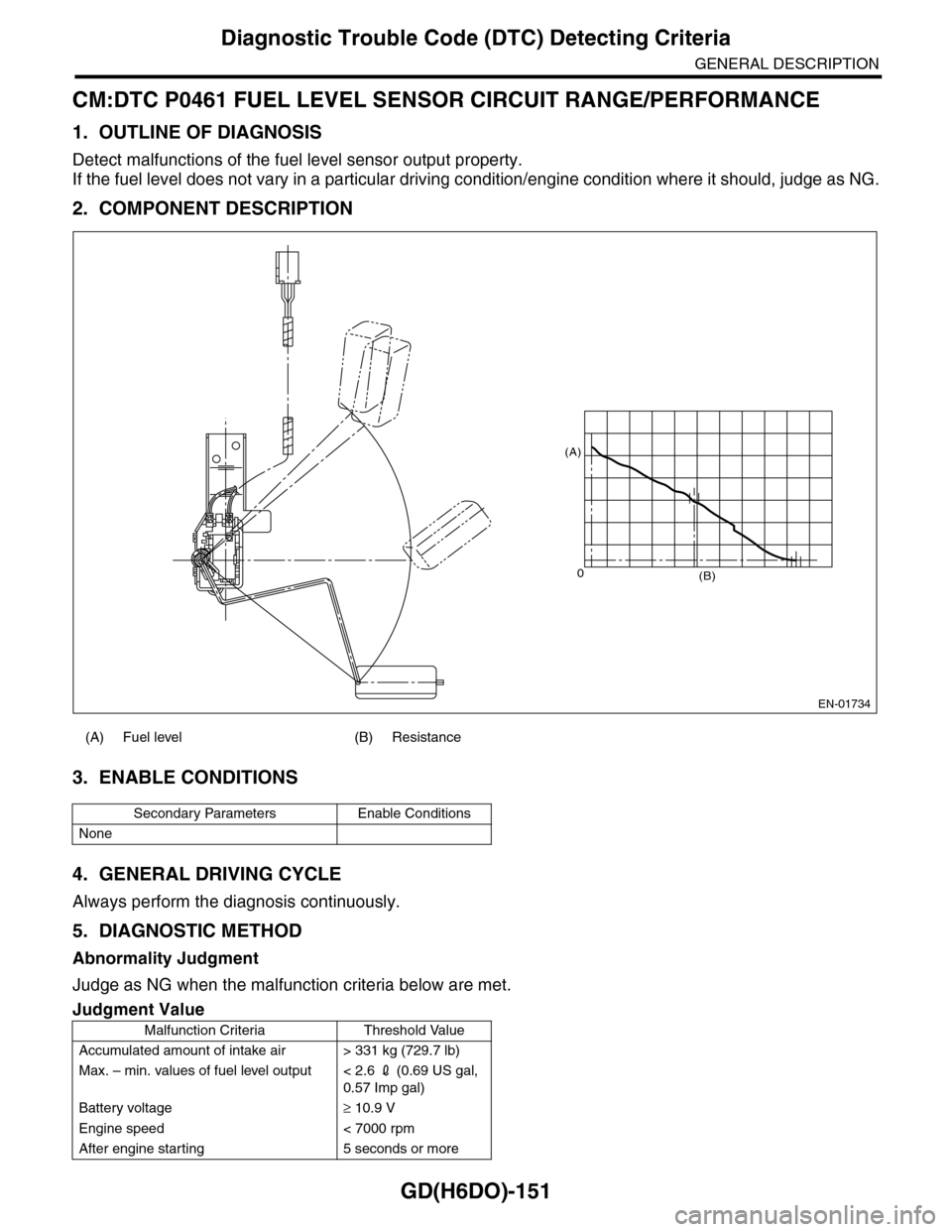

CM:DTC P0461 FUEL LEVEL SENSOR CIRCUIT RANGE/PERFORMANCE

1. OUTLINE OF DIAGNOSIS

Detect malfunctions of the fuel level sensor output property.

If the fuel level does not vary in a particular driving condition/engine condition where it should, judge as NG.

2. COMPONENT DESCRIPTION

3. ENABLE CONDITIONS

4. GENERAL DRIVING CYCLE

Always perform the diagnosis continuously.

5. DIAGNOSTIC METHOD

Abnormality Judgment

Judge as NG when the malfunction criteria below are met.

(A) Fuel level (B) Resistance

Secondary Parameters Enable Conditions

None

Judgment Value

Malfunction Criteria Threshold Value

Accumulated amount of intake air > 331 kg (729.7 lb)

Max. – min. values of fuel level output < 2.6 2 (0.69 US gal,

0.57 Imp gal)

Battery voltage≥ 10.9 V

Engine speed < 7000 rpm

After engine starting 5 seconds or more

EN-01734

0(B)

(A)