TOYOTA CAMRY V20 1986 Service Information

CAMRY V20 1986

TOYOTA

TOYOTA

https://www.carmanualsonline.info/img/14/57449/w960_57449-0.png

TOYOTA CAMRY V20 1986 Service Information

Trending: wheel alignment, compression ratio, parking brake, fog light, fuses, trunk release, coolant

Page 431 of 2389

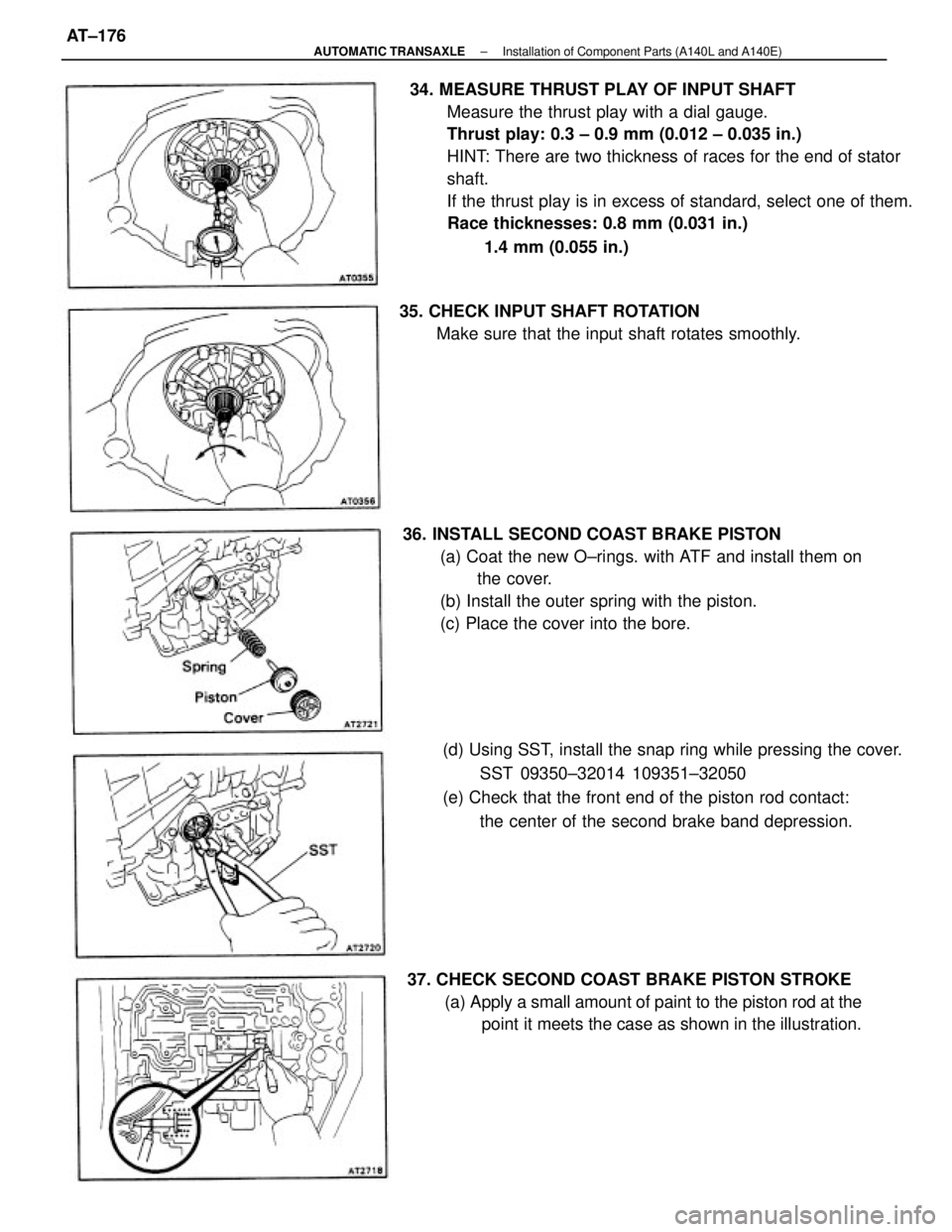

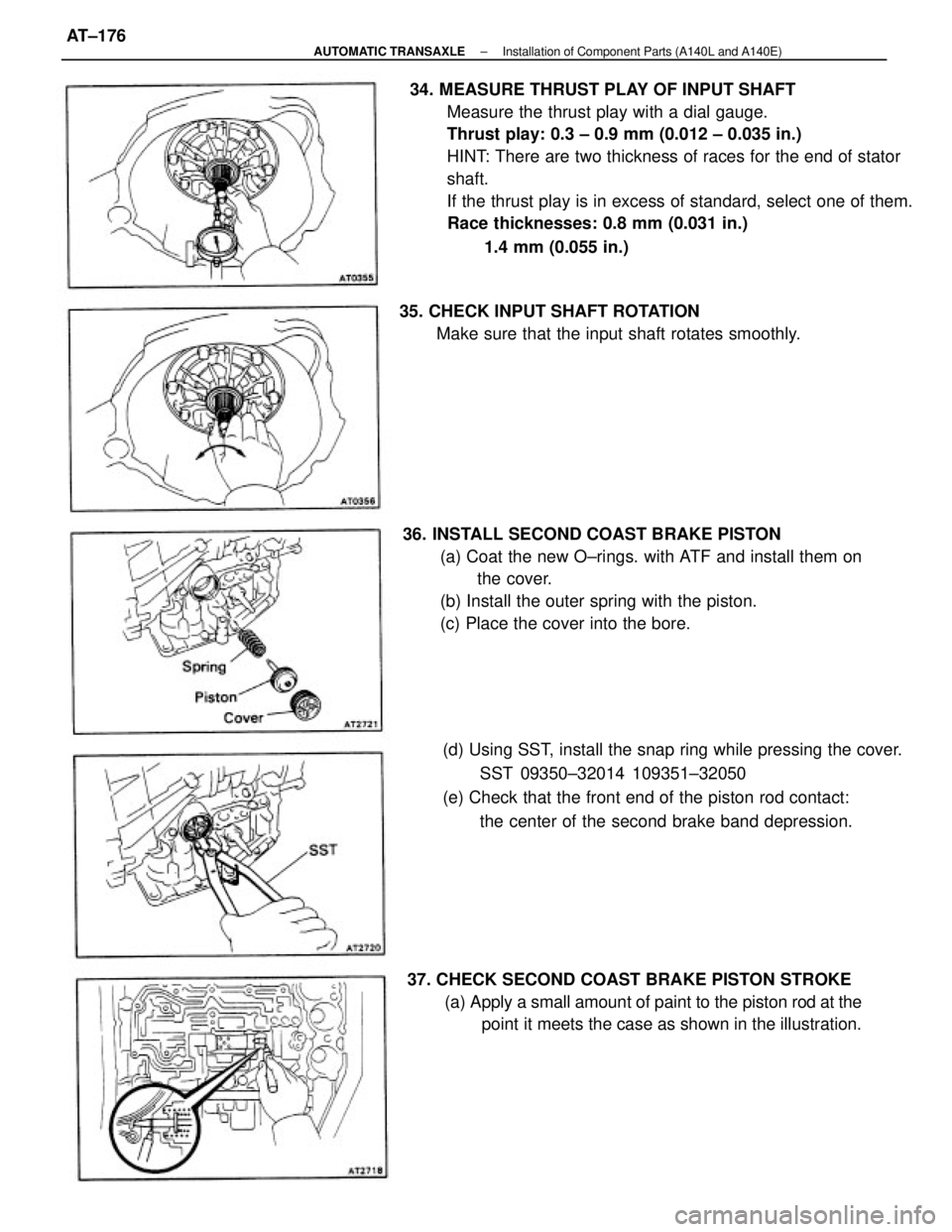

34. MEASURE THRUST PLAY OF INPUT SHAFT

Measure the thrust play with a dial gauge.

Thrust play: 0.3 ± 0.9 mm (0.012 ± 0.035 in.)

HINT: There are two thickness of races for the end of stator

shaft.

If the thrust play is in excess of standard, select one of them.

Race thicknesses: 0.8 mm (0.031 in.)

1.4 mm (0.055 in.)

36. INSTALL SECOND COAST BRAKE PISTON

(a) Coat the new O±rings. with ATF and install them on

the cover.

(b) Install the outer spring with the piston.

(c) Place the cover into the bore.

(d) Using SST, install the snap ring while pressing the cover.

SST 09350±32014 109351±32050

(e) Check that the front end of the piston rod contact:

the center of the second brake band depression.

37. CHECK SECOND COAST BRAKE PISTON STROKE

(a) Apply a small amount of paint to the piston rod at the

point it meets the case as shown in the illustration. 35. CHECK INPUT SHAFT ROTATION

Make sure that the input shaft rotates smoothly.

± AUTOMATIC TRANSAXLEInstallation of Component Parts (A140L and A140E)AT±176

Page 432 of 2389

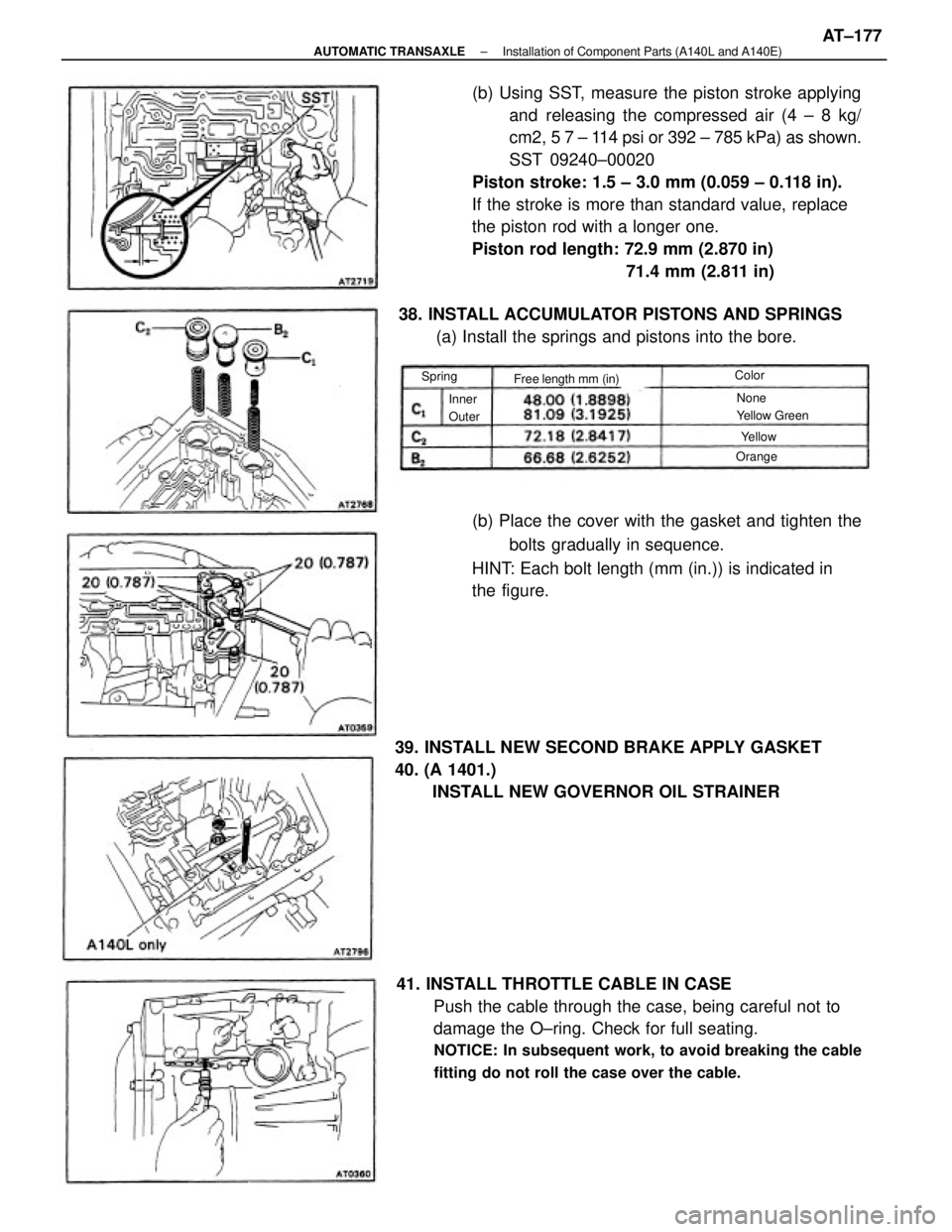

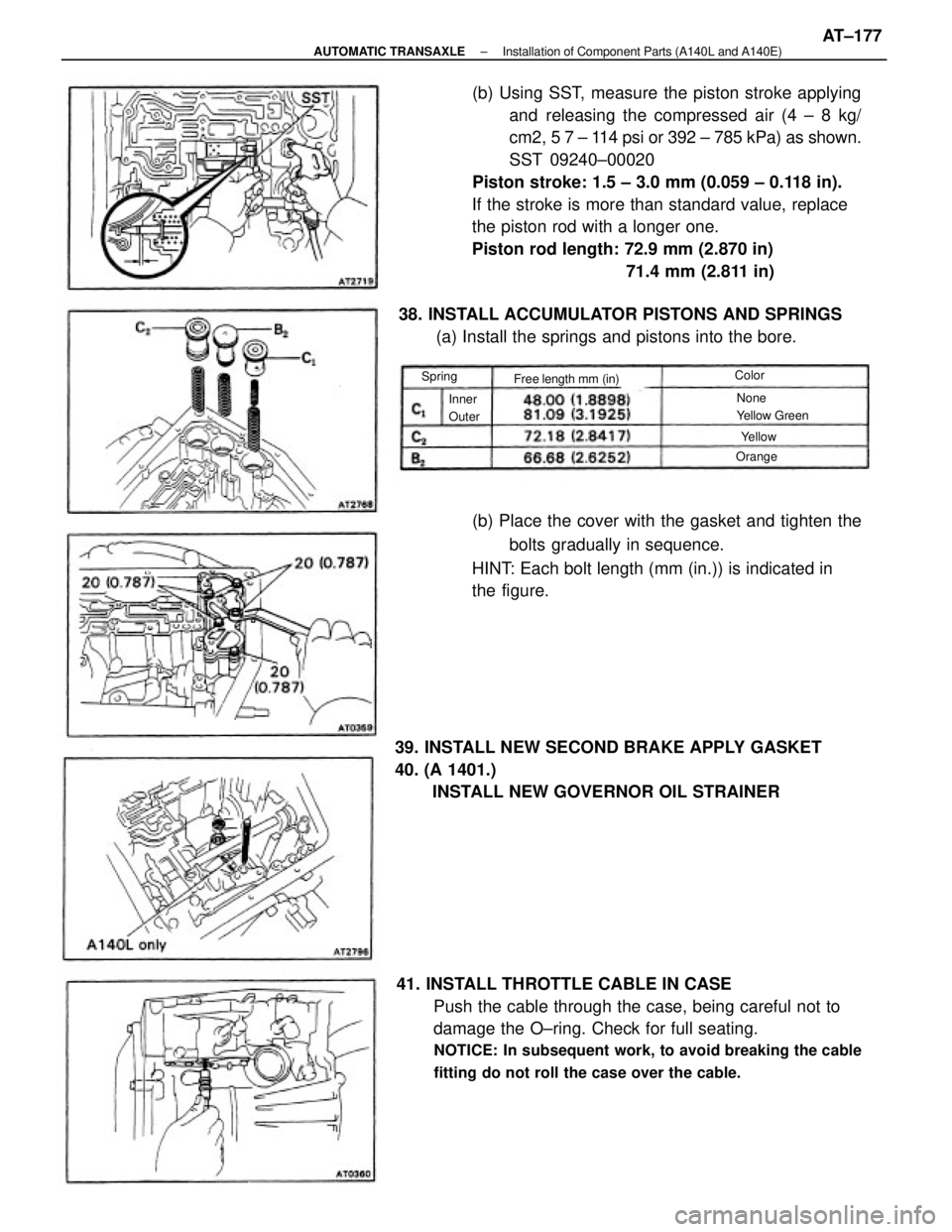

(b) Using SST, measure the piston stroke applying

and releasing the compressed air (4 ± 8 kg/

cm2, 5 7 ± 114 psi or 392 ± 785 kPa) as shown.

SST 09240±00020

Piston stroke: 1.5 ± 3.0 mm (0.059 ± 0.118 in).

If the stroke is more than standard value, replace

the piston rod with a longer one.

Piston rod length: 72.9 mm (2.870 in)

71.4 mm (2.811 in)

41. INSTALL THROTTLE CABLE IN CASE

Push the cable through the case, being careful not to

damage the O±ring. Check for full seating.

NOTICE: In subsequent work, to avoid breaking the cable

fitting do not roll the case over the cable.

(b) Place the cover with the gasket and tighten the

bolts gradually in sequence.

HINT: Each bolt length (mm (in.)) is indicated in

the figure.

39. INSTALL NEW SECOND BRAKE APPLY GASKET

40. (A 1401.)

INSTALL NEW GOVERNOR OIL STRAINER 38. INSTALL ACCUMULATOR PISTONS AND SPRINGS

(a) Install the springs and pistons into the bore.

Free length mm (in)

None

Yellow Green Inner

Outer

Orange Spring

Yellow Color

± AUTOMATIC TRANSAXLEInstallation of Component Parts (A140L and A140E)AT±177

Page 433 of 2389

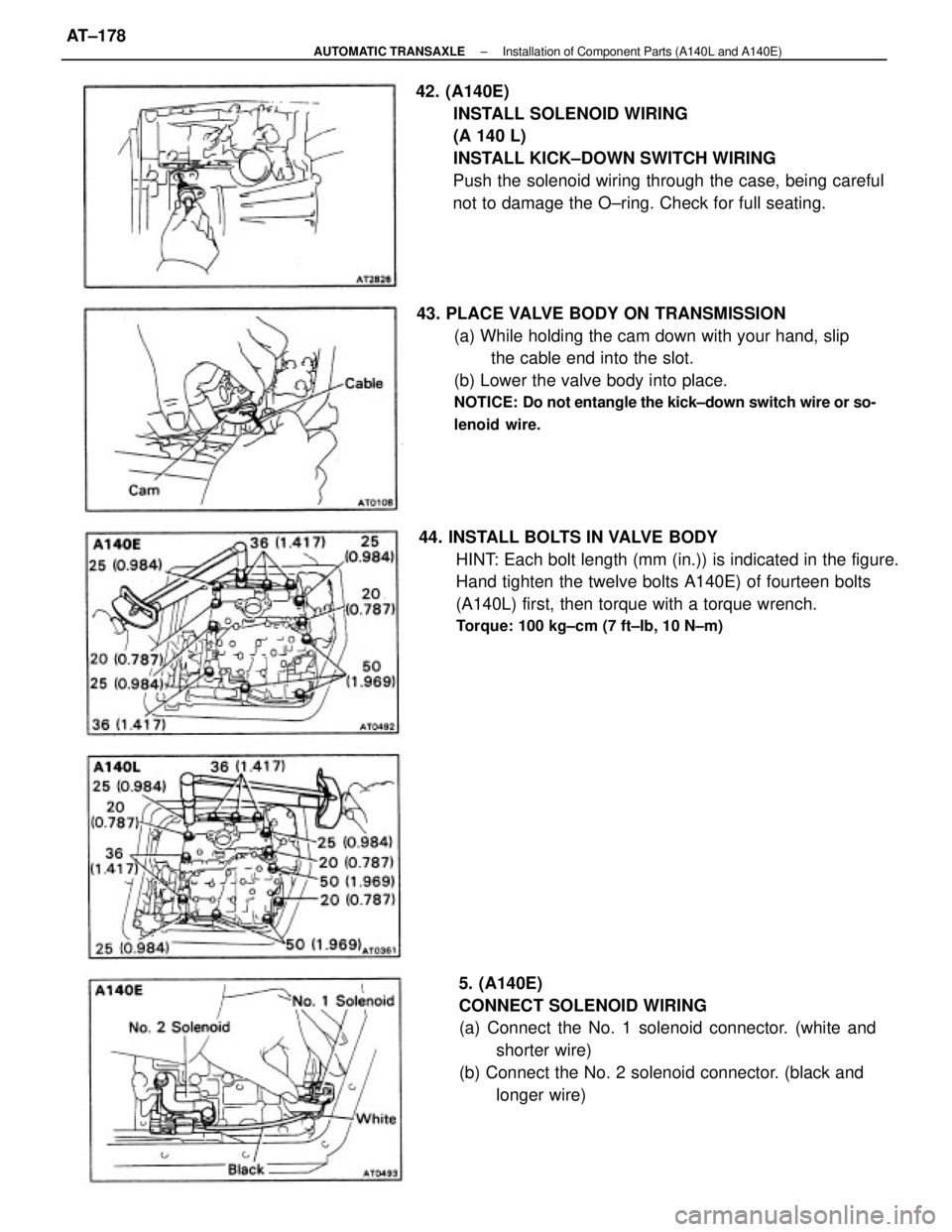

42. (A140E)

INSTALL SOLENOID WIRING

(A 140 L)

INSTALL KICK±DOWN SWITCH WIRING

Push the solenoid wiring through the case, being careful

not to damage the O±ring. Check for full seating.

44. INSTALL BOLTS IN VALVE BODY

HINT: Each bolt length (mm (in.)) is indicated in the figure.

Hand tighten the twelve bolts A140E) of fourteen bolts

(A140L) first, then torque with a torque wrench.

Torque: 100 kg±cm (7 ft±Ib, 10 N±m)

43. PLACE VALVE BODY ON TRANSMISSION

(a) While holding the cam down with your hand, slip

the cable end into the slot.

(b) Lower the valve body into place.

NOTICE: Do not entangle the kick±down switch wire or so-

lenoid wire.

5. (A140E)

CONNECT SOLENOID WIRING

(a) Connect the No. 1 solenoid connector. (white and

shorter wire)

(b) Connect the No. 2 solenoid connector. (black and

longer wire)

± AUTOMATIC TRANSAXLEInstallation of Component Parts (A140L and A140E)AT±178

Page 434 of 2389

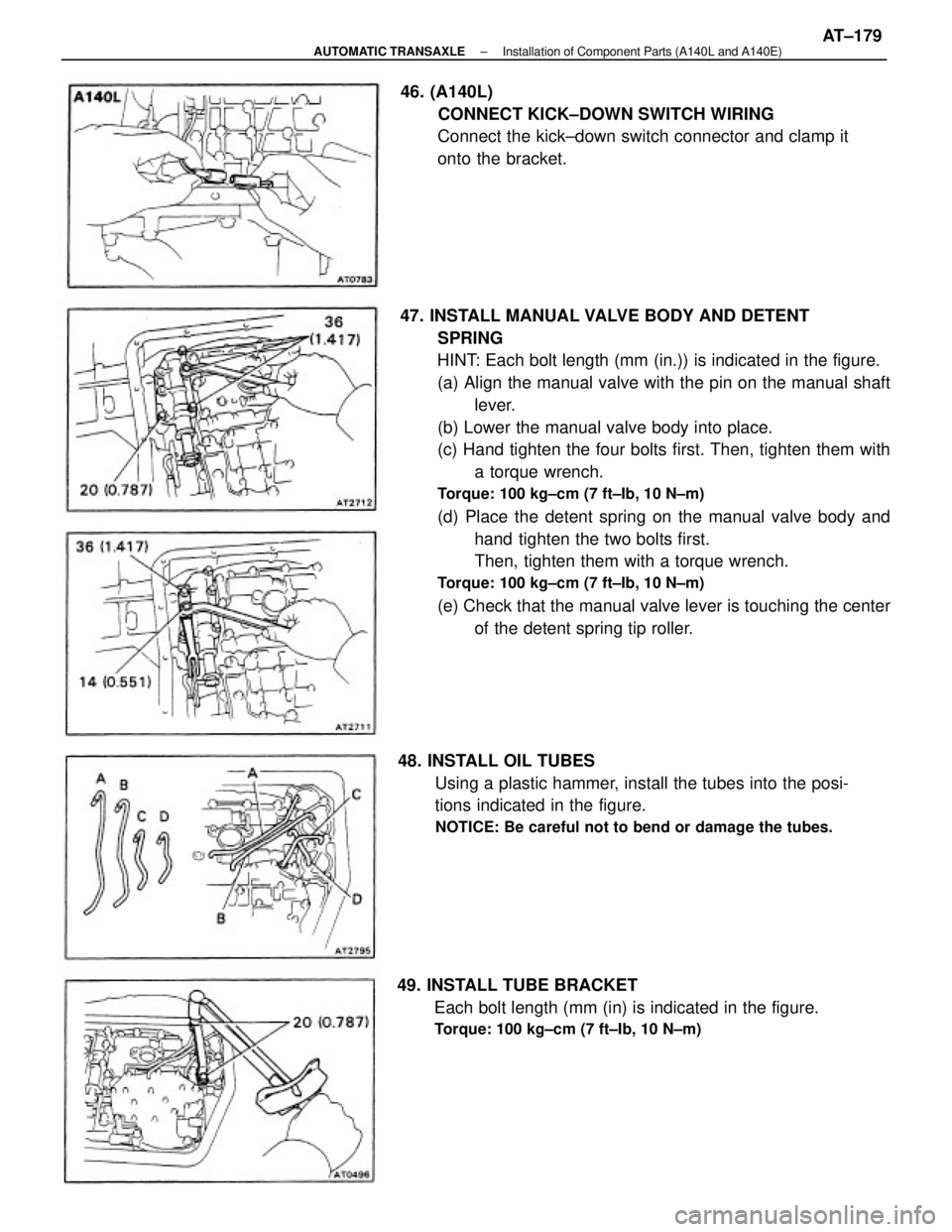

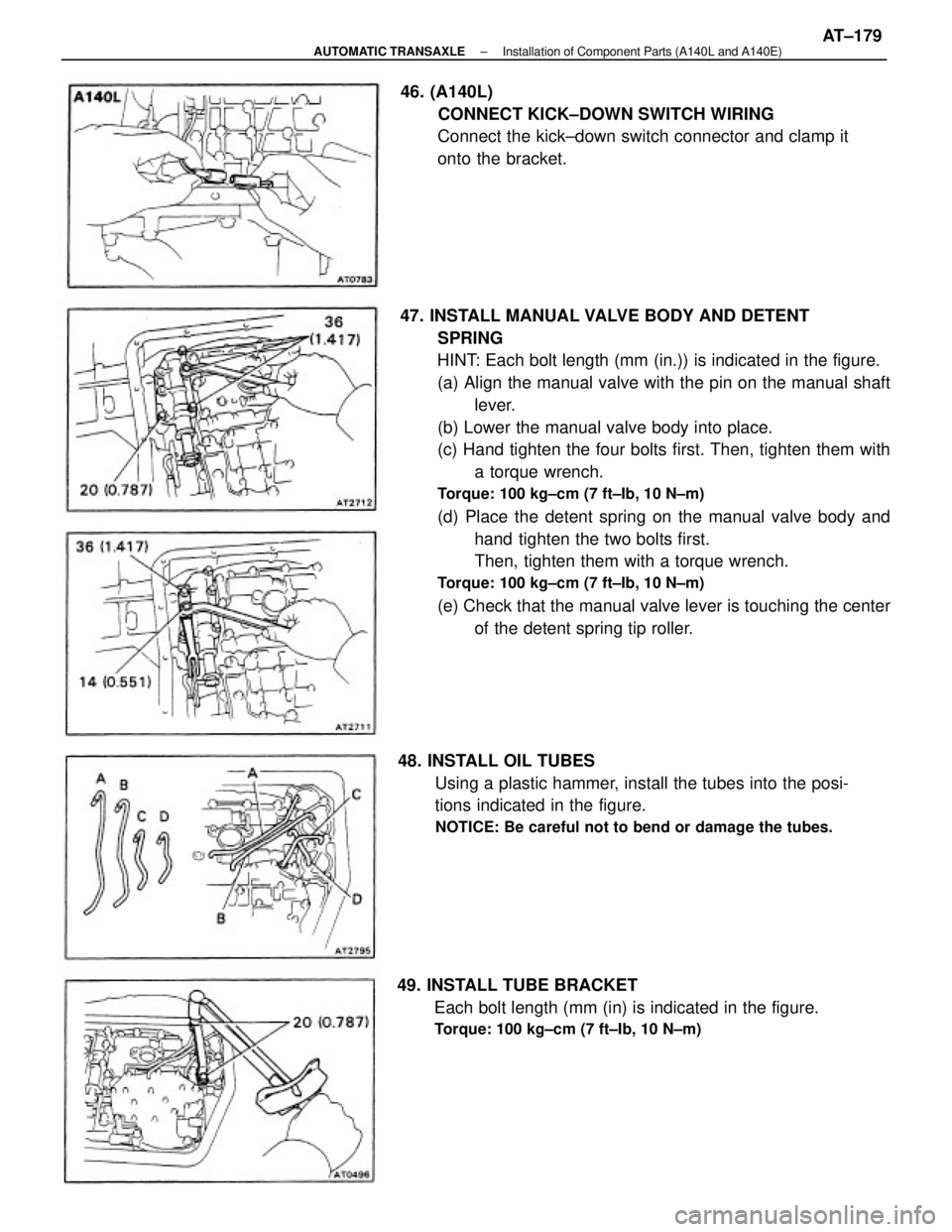

47. INSTALL MANUAL VALVE BODY AND DETENT

SPRING

HINT: Each bolt length (mm (in.)) is indicated in the figure.

(a) Align the manual valve with the pin on the manual shaft

lever.

(b) Lower the manual valve body into place.

(c) Hand tighten the four bolts first. Then, tighten them with

a torque wrench.

Torque: 100 kg±cm (7 ft±Ib, 10 N±m)

(d) Place the detent spring on the manual valve body and

hand tighten the two bolts first.

Then, tighten them with a torque wrench.

Torque: 100 kg±cm (7 ft±Ib, 10 N±m)

(e) Check that the manual valve lever is touching the center

of the detent spring tip roller.

48. INSTALL OIL TUBES

Using a plastic hammer, install the tubes into the posi-

tions indicated in the figure.

NOTICE: Be careful not to bend or damage the tubes.

46. (A140L)

CONNECT KICK±DOWN SWITCH WIRING

Connect the kick±down switch connector and clamp it

onto the bracket.

49. INSTALL TUBE BRACKET

Each bolt length (mm (in) is indicated in the figure.

Torque: 100 kg±cm (7 ft±Ib, 10 N±m)

± AUTOMATIC TRANSAXLEInstallation of Component Parts (A140L and A140E)AT±179

Page 435 of 2389

54. (140L)

INSTALL GOVERNOR BODY

(a) Install the governor body adaptor.

(b) Install the governor body with the plate washer.

(c) Install the thrust washer onto the governor body.

(d) Install the new O±ring to the cover.

(e) Install the cover to the case. 53. (A140E)

INSTALL NO. 2 SPEED SENSOR

(a) Install the speed sensor with a new O±ring.

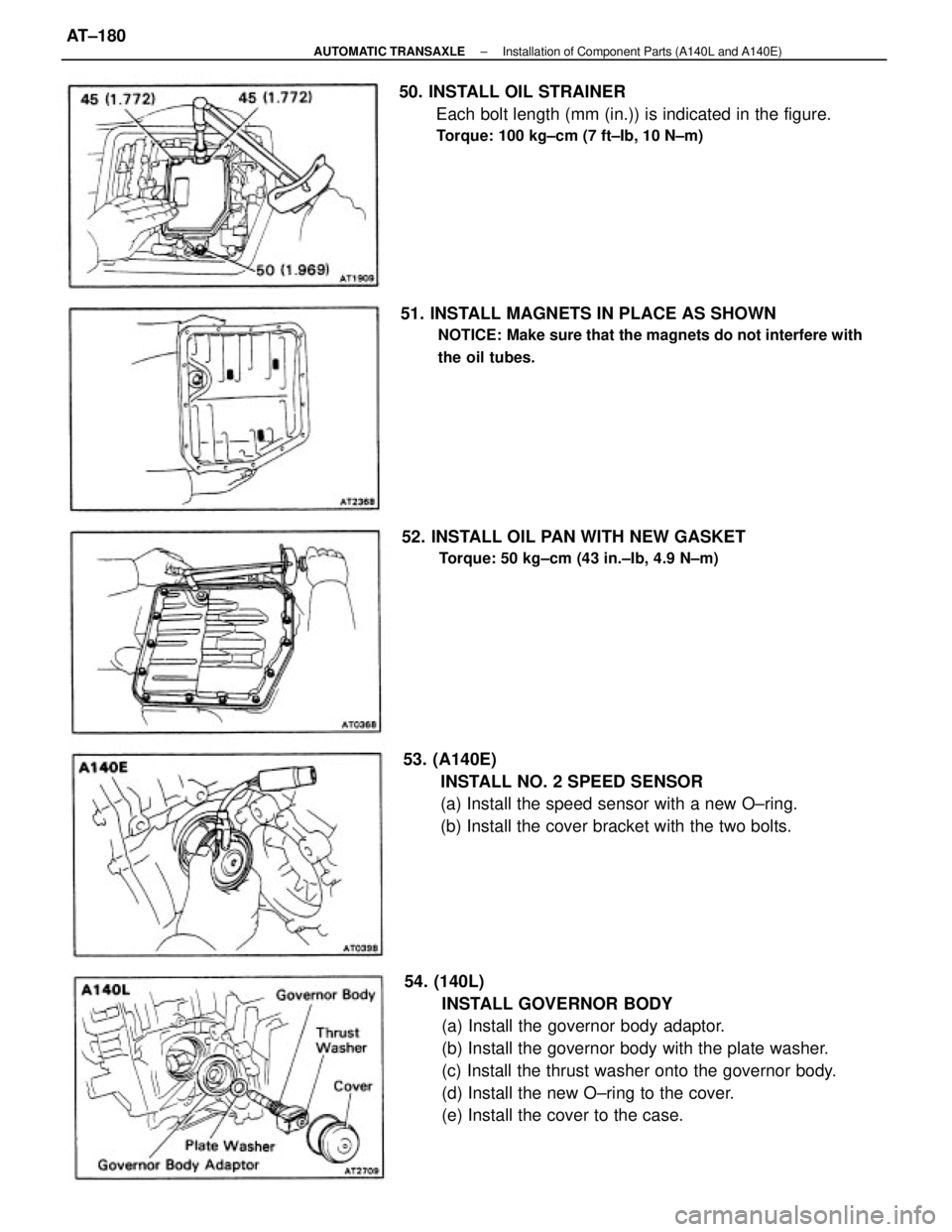

(b) Install the cover bracket with the two bolts. 50. INSTALL OIL STRAINER

Each bolt length (mm (in.)) is indicated in the figure.

Torque: 100 kg±cm (7 ft±Ib, 10 N±m)

51. INSTALL MAGNETS IN PLACE AS SHOWN

NOTICE: Make sure that the magnets do not interfere with

the oil tubes.

52. INSTALL OIL PAN WITH NEW GASKET

Torque: 50 kg±cm (43 in.±Ib, 4.9 N±m)

± AUTOMATIC TRANSAXLEInstallation of Component Parts (A140L and A140E)AT±180

Page 436 of 2389

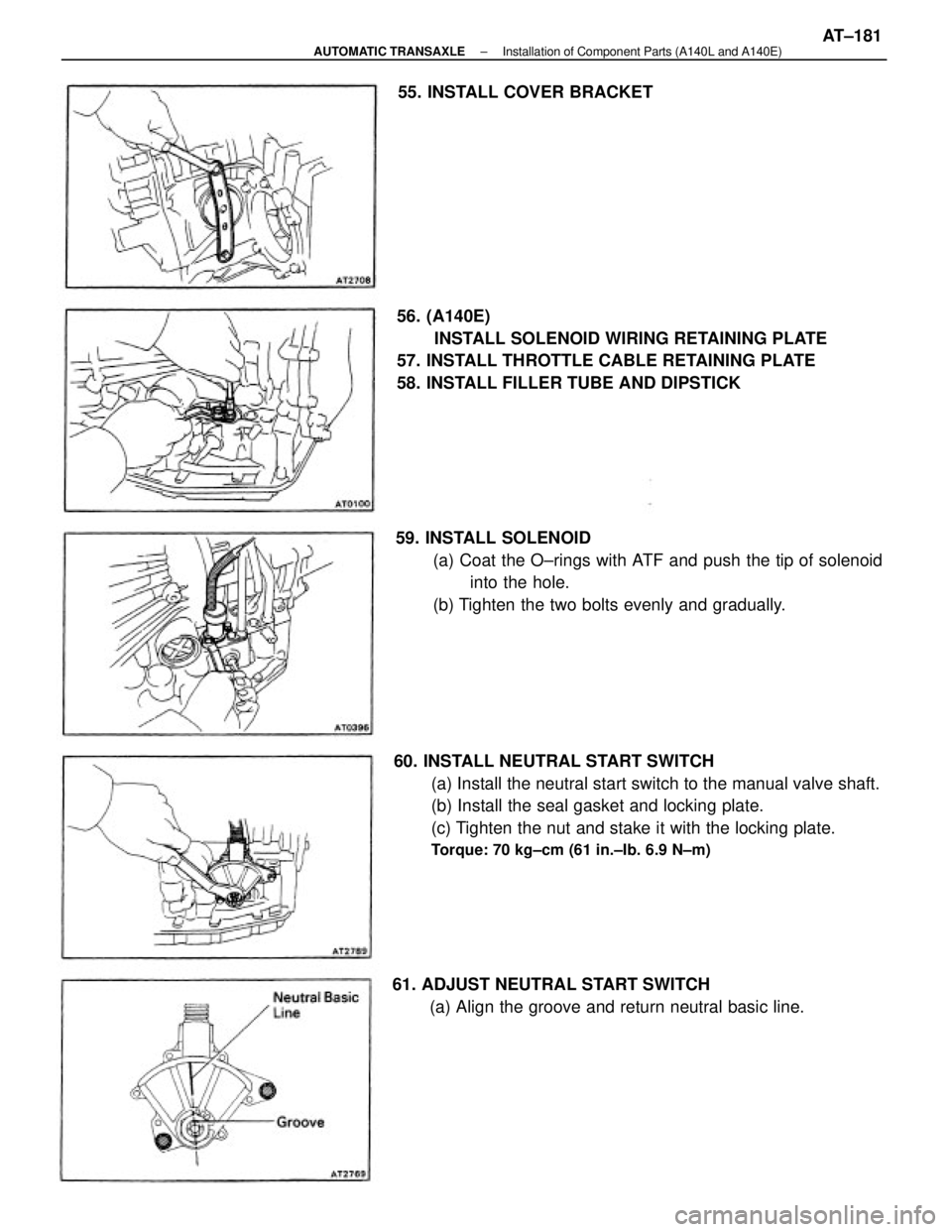

60. INSTALL NEUTRAL START SWITCH

(a) Install the neutral start switch to the manual valve shaft.

(b) Install the seal gasket and locking plate.

(c) Tighten the nut and stake it with the locking plate.

Torque: 70 kg±cm (61 in.±Ib. 6.9 N±m)

56. (A140E)

INSTALL SOLENOID WIRING RETAINING PLATE

57. INSTALL THROTTLE CABLE RETAINING PLATE

58. INSTALL FILLER TUBE AND DIPSTICK

59. INSTALL SOLENOID

(a) Coat the O±rings with ATF and push the tip of solenoid

into the hole.

(b) Tighten the two bolts evenly and gradually.

61. ADJUST NEUTRAL START SWITCH

(a) Align the groove and return neutral basic line. 55. INSTALL COVER BRACKET

± AUTOMATIC TRANSAXLEInstallation of Component Parts (A140L and A140E)AT±181

Page 437 of 2389

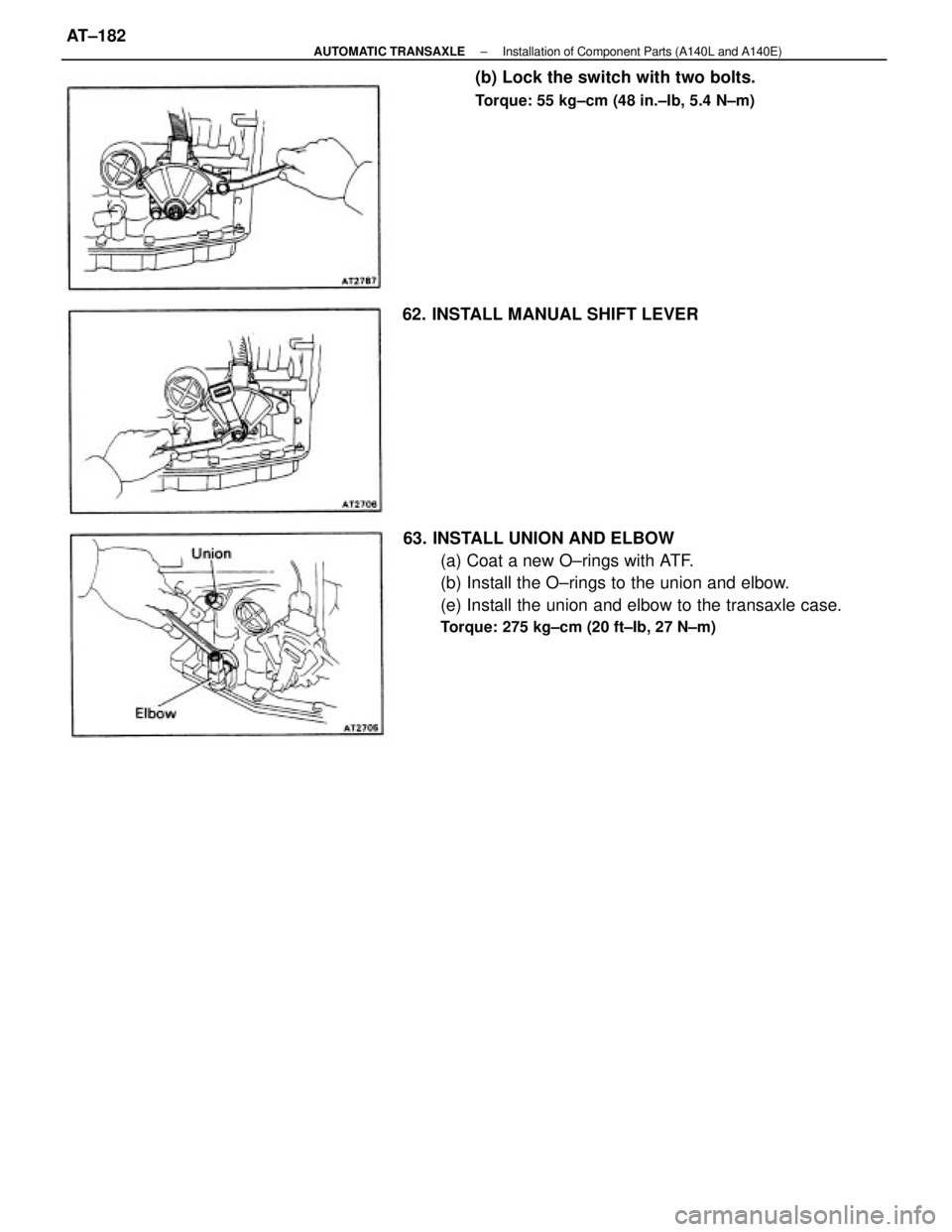

63. INSTALL UNION AND ELBOW

(a) Coat a new O±rings with ATF.

(b) Install the O±rings to the union and elbow.

(e) Install the union and elbow to the transaxle case.

Torque: 275 kg±cm (20 ft±Ib, 27 N±m)

(b) Lock the switch with two bolts.

Torque: 55 kg±cm (48 in.±Ib, 5.4 N±m)

62. INSTALL MANUAL SHIFT LEVER

± AUTOMATIC TRANSAXLEInstallation of Component Parts (A140L and A140E)AT±182

Page 438 of 2389

A540E AND A540H

AUTOMATIC TRANSAXLE

AUTOMATIC TRANSAXLEAT±183

Page 439 of 2389

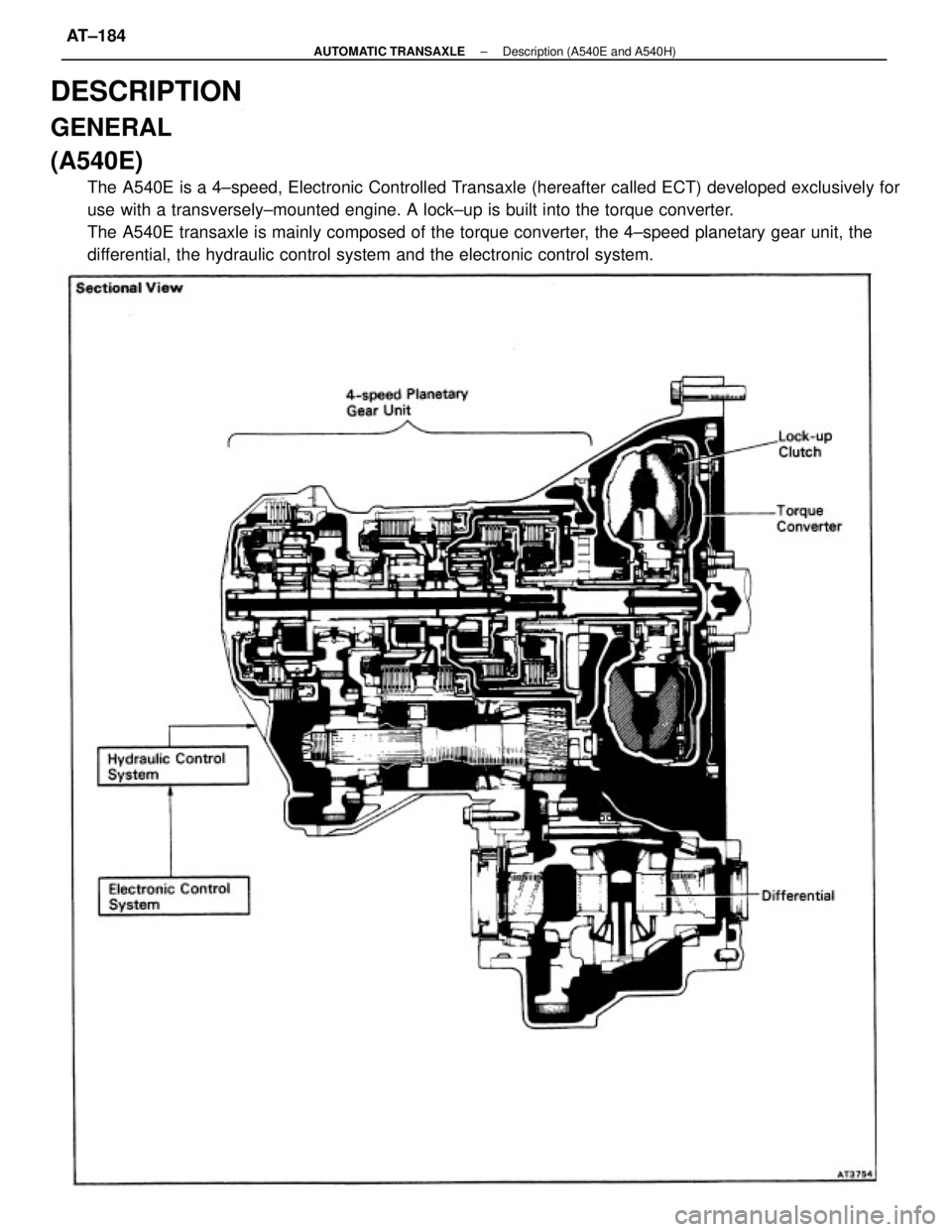

DESCRIPTION

GENERAL

(A540E)

The A540E is a 4±speed, Electronic Controlled Transaxle (hereafter called ECT) developed exclusively for

use with a transversely±mounted engine. A lock±up is built into the torque converter.

The A540E transaxle is mainly composed of the torque converter, the 4±speed planetary gear unit, the

differential, the hydraulic control system and the electronic control system.

± AUTOMATIC TRANSAXLEDescription (A540E and A540H)AT±184

Page 440 of 2389

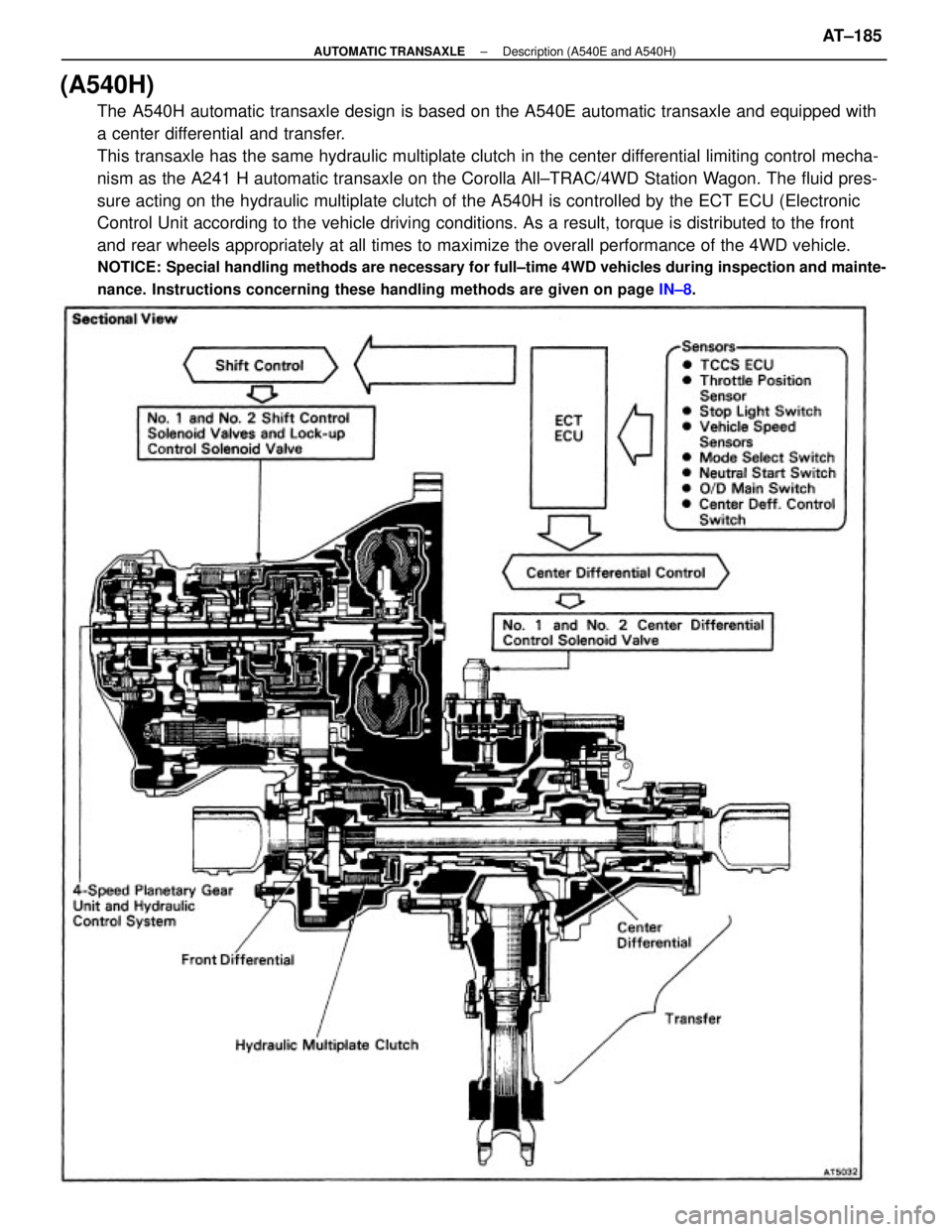

(A540H)

The A540H automatic transaxle design is based on the A540E automatic transaxle and equipped with

a center differential and transfer.

This transaxle has the same hydraulic multiplate clutch in the center differential limiting control mecha-

nism as the A241 H automatic transaxle on the Corolla All±TRAC/4WD Station Wagon. The fluid pres-

sure acting on the hydraulic multiplate clutch of the A540H is controlled by the ECT ECU (Electronic

Control Unit according to the vehicle driving conditions. As a result, torque is distributed to the front

and rear wheels appropriately at all times to maximize the overall performance of the 4WD vehicle.

NOTICE: Special handling methods are necessary for full±time 4WD vehicles during inspection and mainte-

nance. Instructions concerning these handling methods are given on page IN±8.

± AUTOMATIC TRANSAXLEDescription (A540E and A540H)AT±185

Trending: wheel size, fuel filter, clock reset, fuel pressure, change wheel, window, oil