TOYOTA CAMRY V20 1986 Service Information

Manufacturer: TOYOTA, Model Year: 1986, Model line: CAMRY V20, Model: TOYOTA CAMRY V20 1986Pages: 2389, PDF Size: 84.44 MB

Page 421 of 2389

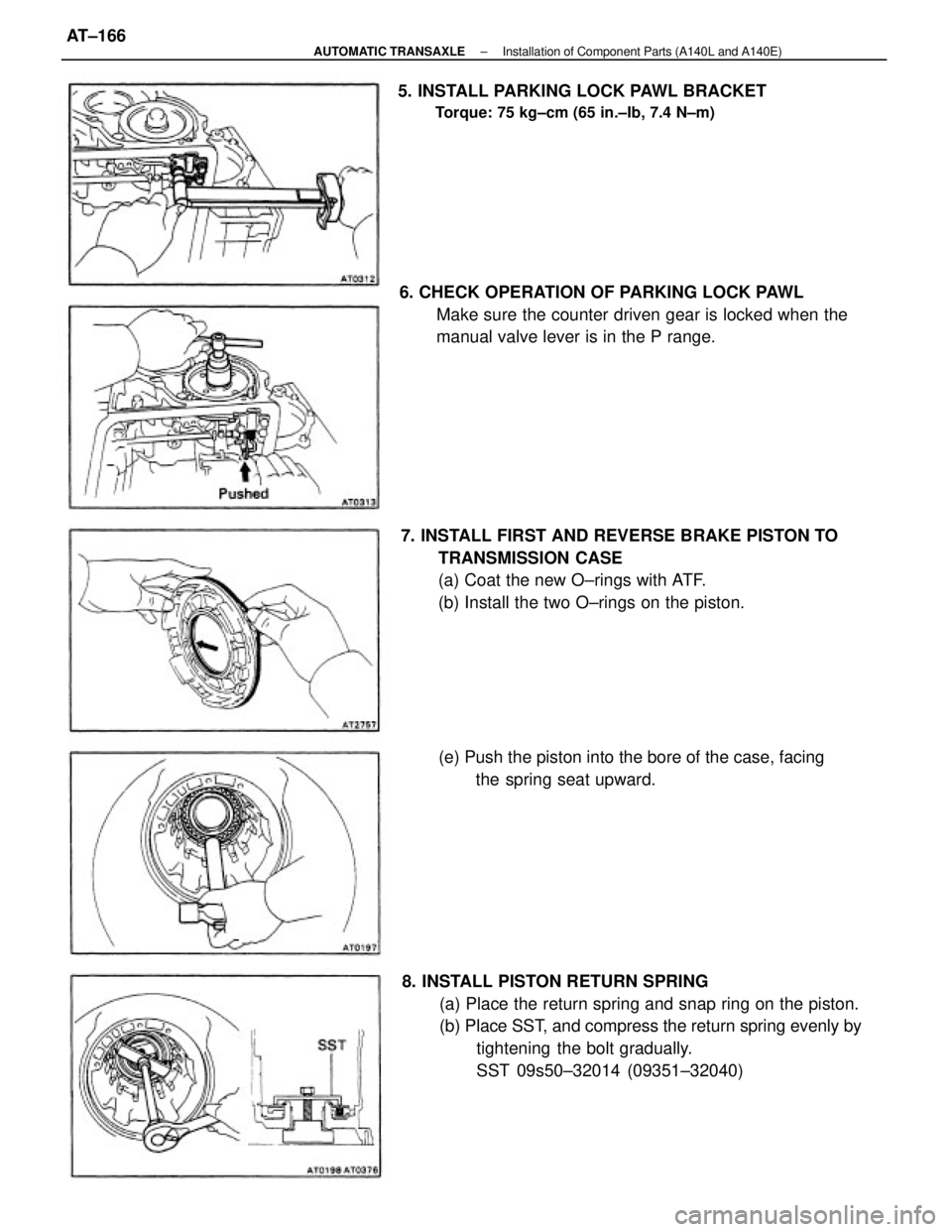

8. INSTALL PISTON RETURN SPRING

(a) Place the return spring and snap ring on the piston.

(b) Place SST, and compress the return spring evenly by

tightening the bolt gradually.

SST 09s50±32014 (09351±32040) 6. CHECK OPERATION OF PARKING LOCK PAWL

Make sure the counter driven gear is locked when the

manual valve lever is in the P range.

7. INSTALL FIRST AND REVERSE BRAKE PISTON TO

TRANSMISSION CASE

(a) Coat the new O±rings with ATF.

(b) Install the two O±rings on the piston.

(e) Push the piston into the bore of the case, facing

the spring seat upward. 5. INSTALL PARKING LOCK PAWL BRACKET

Torque: 75 kg±cm (65 in.±Ib, 7.4 N±m)

± AUTOMATIC TRANSAXLEInstallation of Component Parts (A140L and A140E)AT±166

Page 422 of 2389

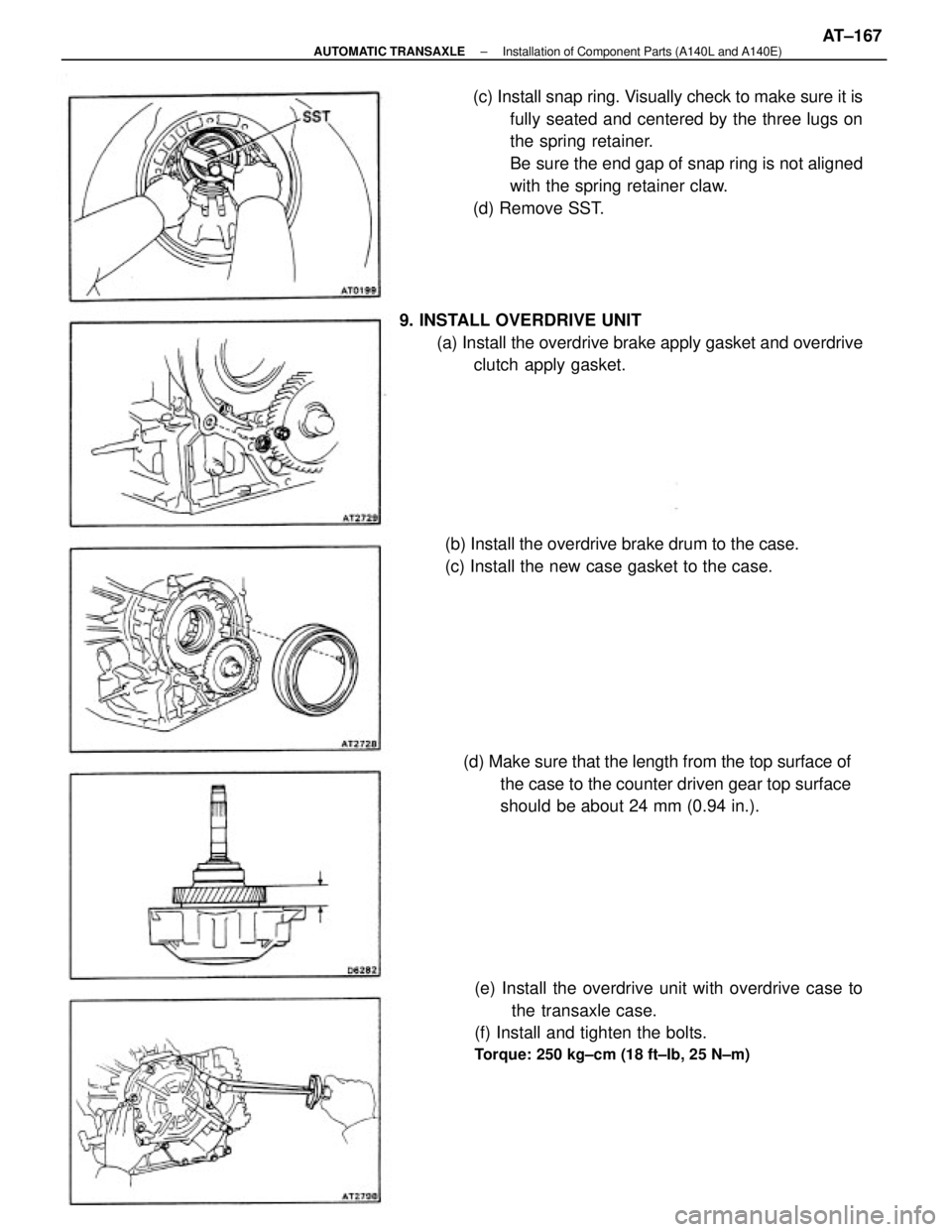

(c) Install snap ring. Visually check to make sure it is

fully seated and centered by the three lugs on

the spring retainer.

Be sure the end gap of snap ring is not aligned

with the spring retainer claw.

(d) Remove SST.

(e) Install the overdrive unit with overdrive case to

the transaxle case.

(f) Install and tighten the bolts.

Torque: 250 kg±cm (18 ft±Ib, 25 N±m)

9. INSTALL OVERDRIVE UNIT

(a) Install the overdrive brake apply gasket and overdrive

clutch apply gasket.

(d) Make sure that the length from the top surface of

the case to the counter driven gear top surface

should be about 24 mm (0.94 in.). (b) Install the overdrive brake drum to the case.

(c) Install the new case gasket to the case.

± AUTOMATIC TRANSAXLEInstallation of Component Parts (A140L and A140E)AT±167

Page 423 of 2389

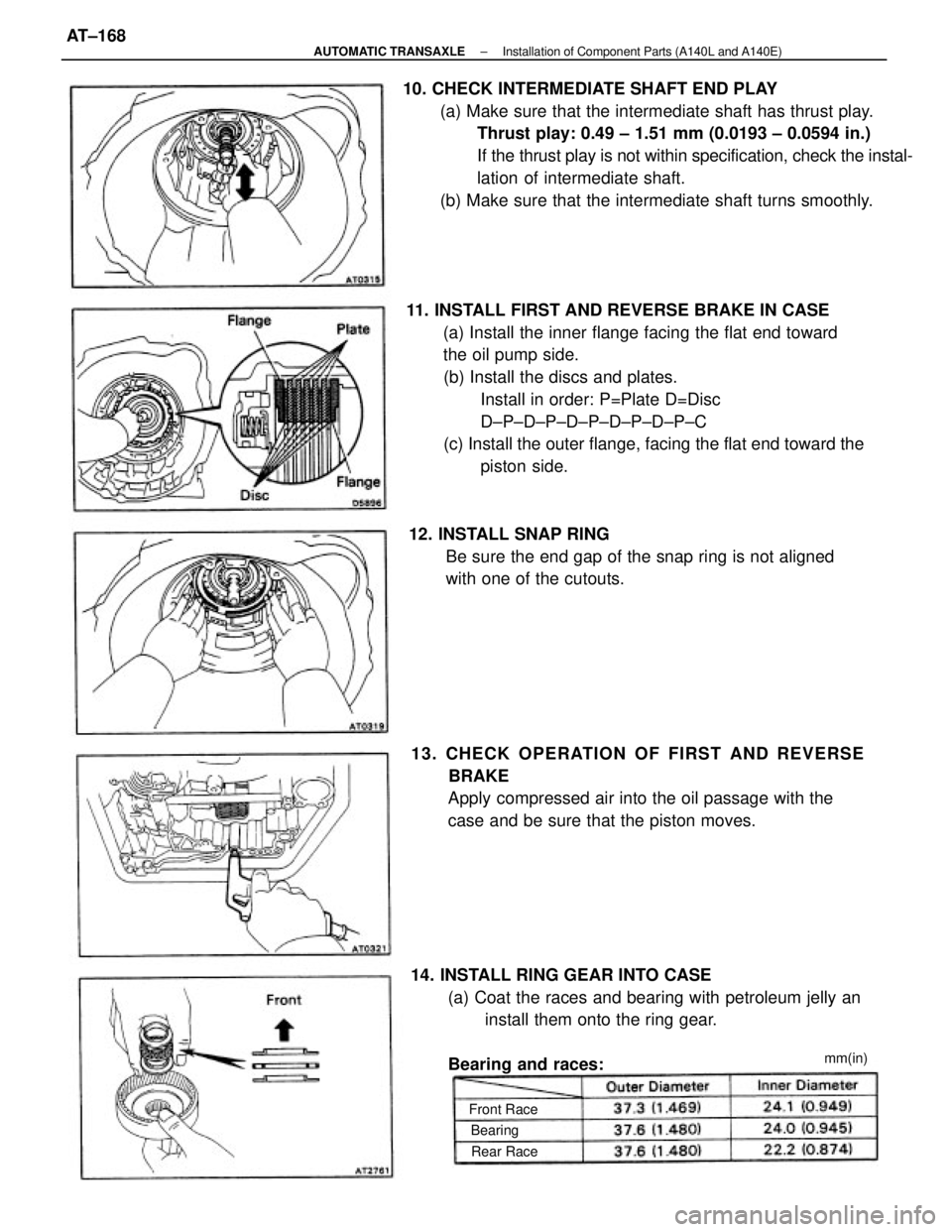

11. INSTALL FIRST AND REVERSE BRAKE IN CASE

(a) Install the inner flange facing the flat end toward

the oil pump side.

(b) Install the discs and plates.

Install in order: P=Plate D=Disc

D±P±D±P±D±P±D±P±D±P±C

(c) Install the outer flange, facing the flat end toward the

piston side. 10. CHECK INTERMEDIATE SHAFT END PLAY

(a) Make sure that the intermediate shaft has thrust play.

Thrust play: 0.49 ± 1.51 mm (0.0193 ± 0.0594 in.)

If the thrust play is not within specification, check the instal-

lation of intermediate shaft.

(b) Make sure that the intermediate shaft turns smoothly.

14. INSTALL RING GEAR INTO CASE

(a) Coat the races and bearing with petroleum jelly an

install them onto the ring gear.

Bearing and races: 13. CHECK OPERATION OF FIRST AND REVERSE

BRAKE

Apply compressed air into the oil passage with the

case and be sure that the piston moves. 12. INSTALL SNAP RING

Be sure the end gap of the snap ring is not aligned

with one of the cutouts.

Front Race

Rear Racemm(in)

Bearing

± AUTOMATIC TRANSAXLEInstallation of Component Parts (A140L and A140E)AT±168

Page 424 of 2389

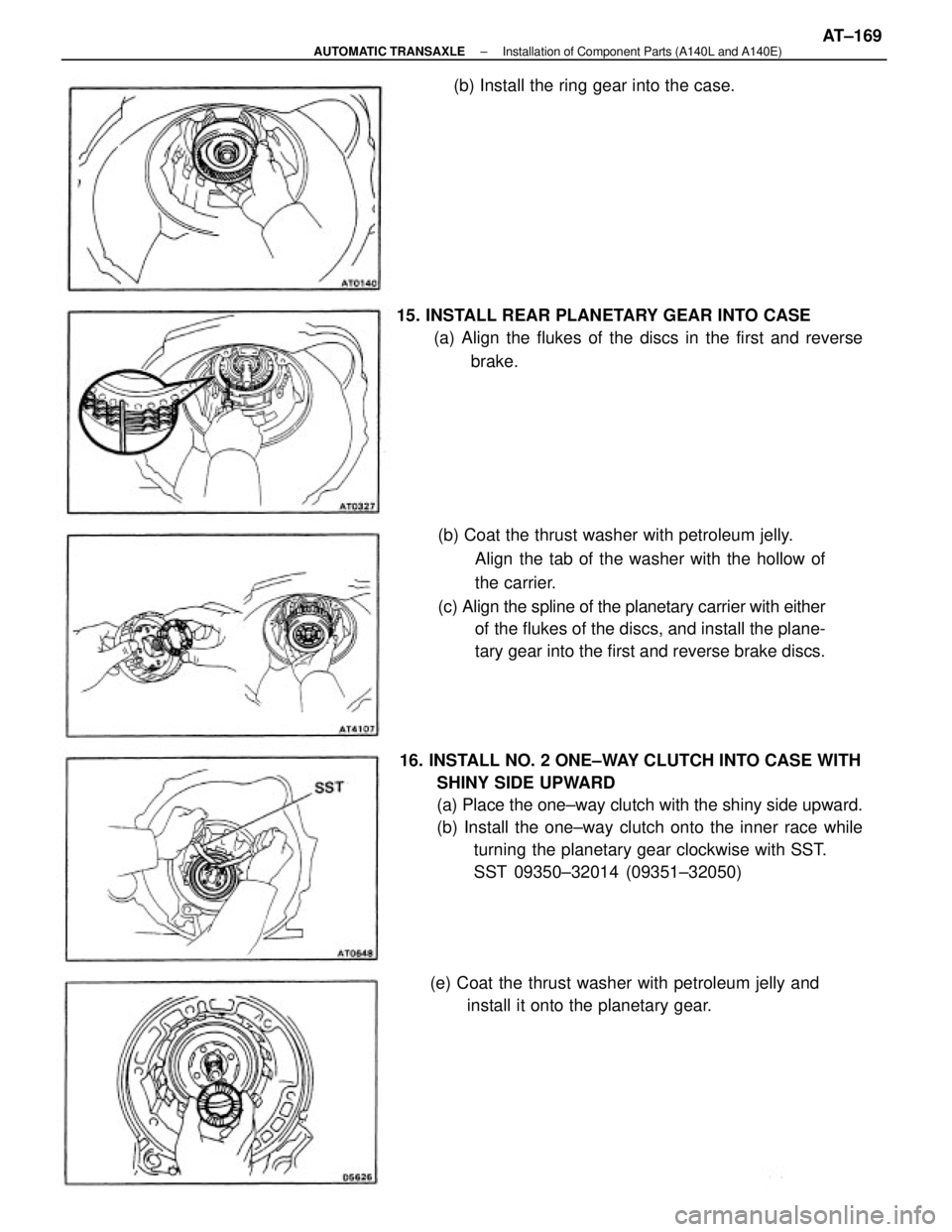

16. INSTALL NO. 2 ONE±WAY CLUTCH INTO CASE WITH

SHINY SIDE UPWARD

(a) Place the one±way clutch with the shiny side upward.

(b) Install the one±way clutch onto the inner race while

turning the planetary gear clockwise with SST.

SST 09350±32014 (09351±32050) (b) Coat the thrust washer with petroleum jelly.

Align the tab of the washer with the hollow of

the carrier.

(c) Align the spline of the planetary carrier with either

of the flukes of the discs, and install the plane-

tary gear into the first and reverse brake discs. 15. INSTALL REAR PLANETARY GEAR INTO CASE

(a) Align the flukes of the discs in the first and reverse

brake.

(e) Coat the thrust washer with petroleum jelly and

install it onto the planetary gear. (b) Install the ring gear into the case.

± AUTOMATIC TRANSAXLEInstallation of Component Parts (A140L and A140E)AT±169

Page 425 of 2389

20. INSTALL SECOND BRAKE INTO CASE

(a) Install the flange, facing the flat end toward the oil

pump side.

(b) Install the discs and plates.

Install in order: P=Plate D=Disc

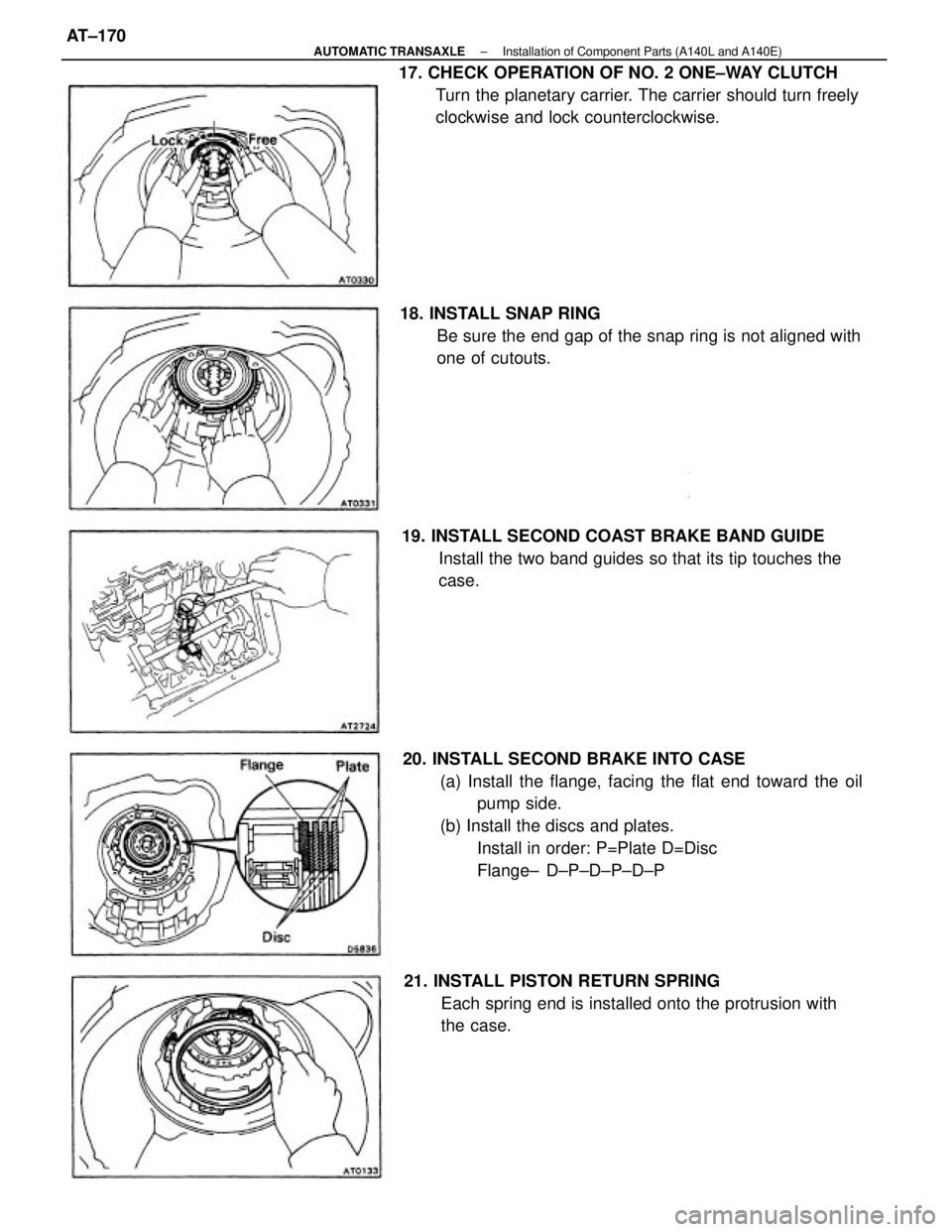

Flange± D±P±D±P±D±P 17. CHECK OPERATION OF NO. 2 ONE±WAY CLUTCH

Turn the planetary carrier. The carrier should turn freely

clockwise and lock counterclockwise.

18. INSTALL SNAP RING

Be sure the end gap of the snap ring is not aligned with

one of cutouts.

21. INSTALL PISTON RETURN SPRING

Each spring end is installed onto the protrusion with

the case. 19. INSTALL SECOND COAST BRAKE BAND GUIDE

Install the two band guides so that its tip touches the

case.

± AUTOMATIC TRANSAXLEInstallation of Component Parts (A140L and A140E)AT±170

Page 426 of 2389

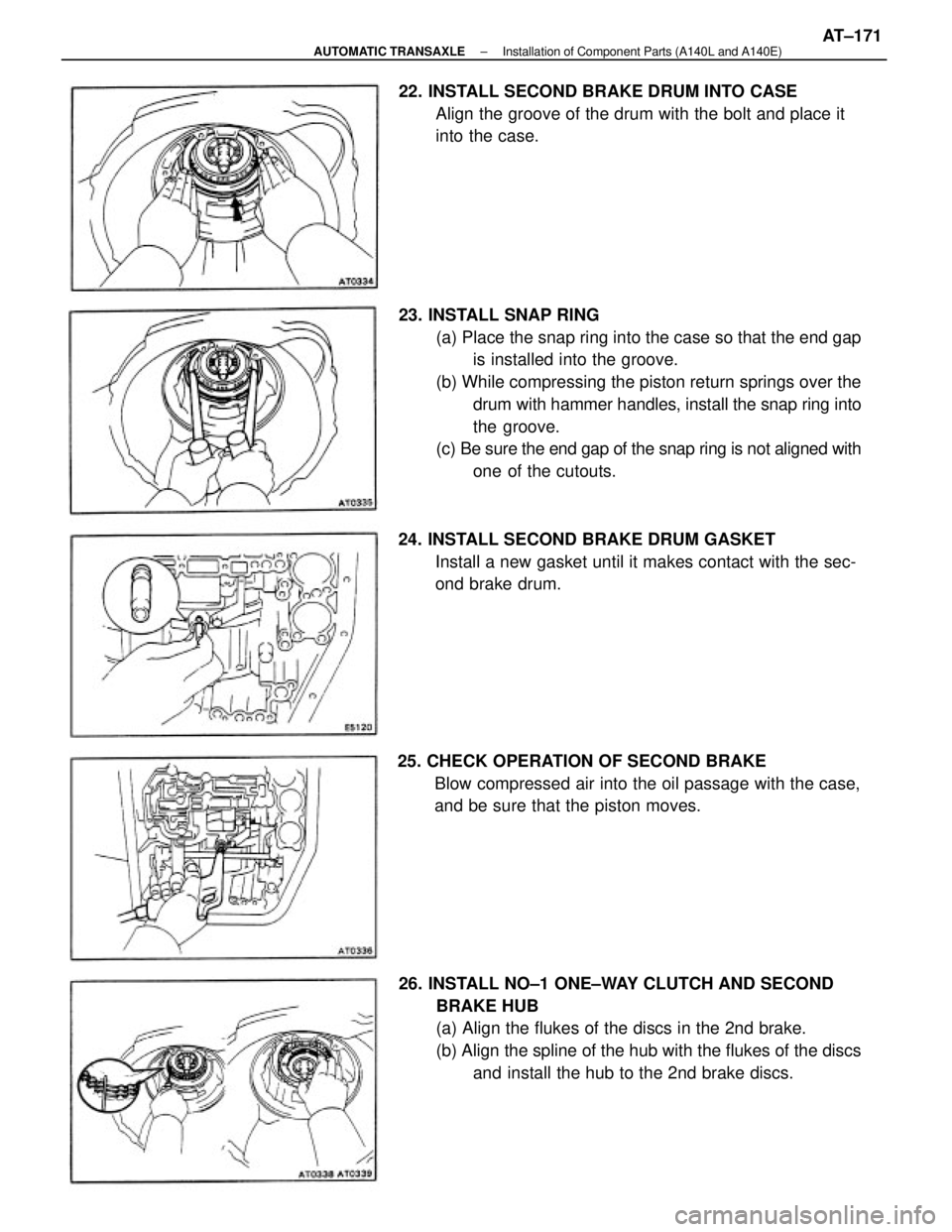

23. INSTALL SNAP RING

(a) Place the snap ring into the case so that the end gap

is installed into the groove.

(b) While compressing the piston return springs over the

drum with hammer handles, install the snap ring into

the groove.

(c) Be sure the end gap of the snap ring is not aligned with

one of the cutouts.

26. INSTALL NO±1 ONE±WAY CLUTCH AND SECOND

BRAKE HUB

(a) Align the flukes of the discs in the 2nd brake.

(b) Align the spline of the hub with the flukes of the discs

and install the hub to the 2nd brake discs. 25. CHECK OPERATION OF SECOND BRAKE

Blow compressed air into the oil passage with the case,

and be sure that the piston moves. 22. INSTALL SECOND BRAKE DRUM INTO CASE

Align the groove of the drum with the bolt and place it

into the case.

24. INSTALL SECOND BRAKE DRUM GASKET

Install a new gasket until it makes contact with the sec-

ond brake drum.

± AUTOMATIC TRANSAXLEInstallation of Component Parts (A140L and A140E)AT±171

Page 427 of 2389

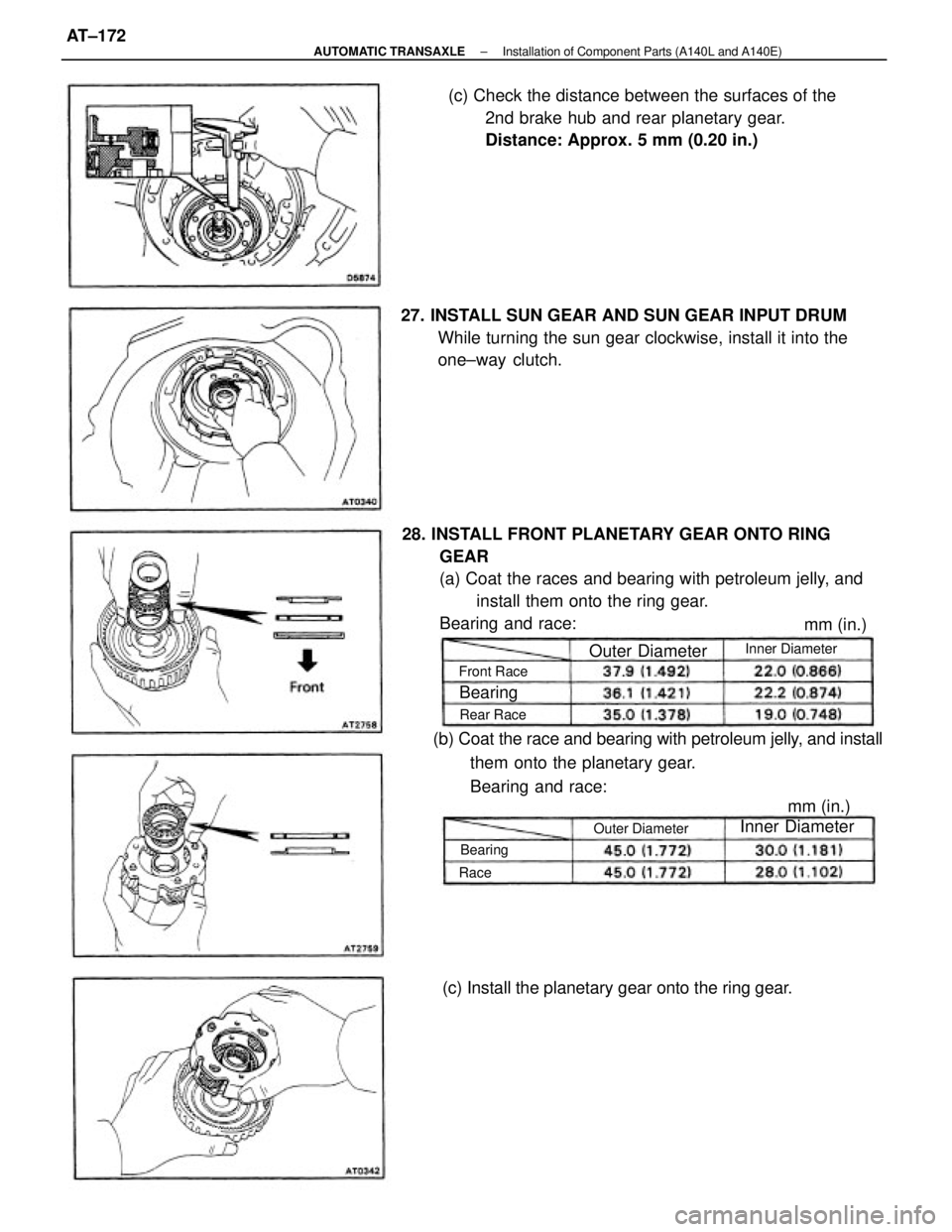

28. INSTALL FRONT PLANETARY GEAR ONTO RING

GEAR

(a) Coat the races and bearing with petroleum jelly, and

install them onto the ring gear.

Bearing and race:(c) Check the distance between the surfaces of the

2nd brake hub and rear planetary gear.

Distance: Approx. 5 mm (0.20 in.)

(b) Coat the race and bearing with petroleum jelly, and install

them onto the planetary gear.

Bearing and race: 27. INSTALL SUN GEAR AND SUN GEAR INPUT DRUM

While turning the sun gear clockwise, install it into the

one±way clutch.

(c) Install the planetary gear onto the ring gear.Outer Diameter

Outer DiameterInner DiameterInner Diameter

Front Race

mm (in.)

Rear Race

mm (in.)

Bearing

Bearing

Race

± AUTOMATIC TRANSAXLEInstallation of Component Parts (A140L and A140E)AT±172

Page 428 of 2389

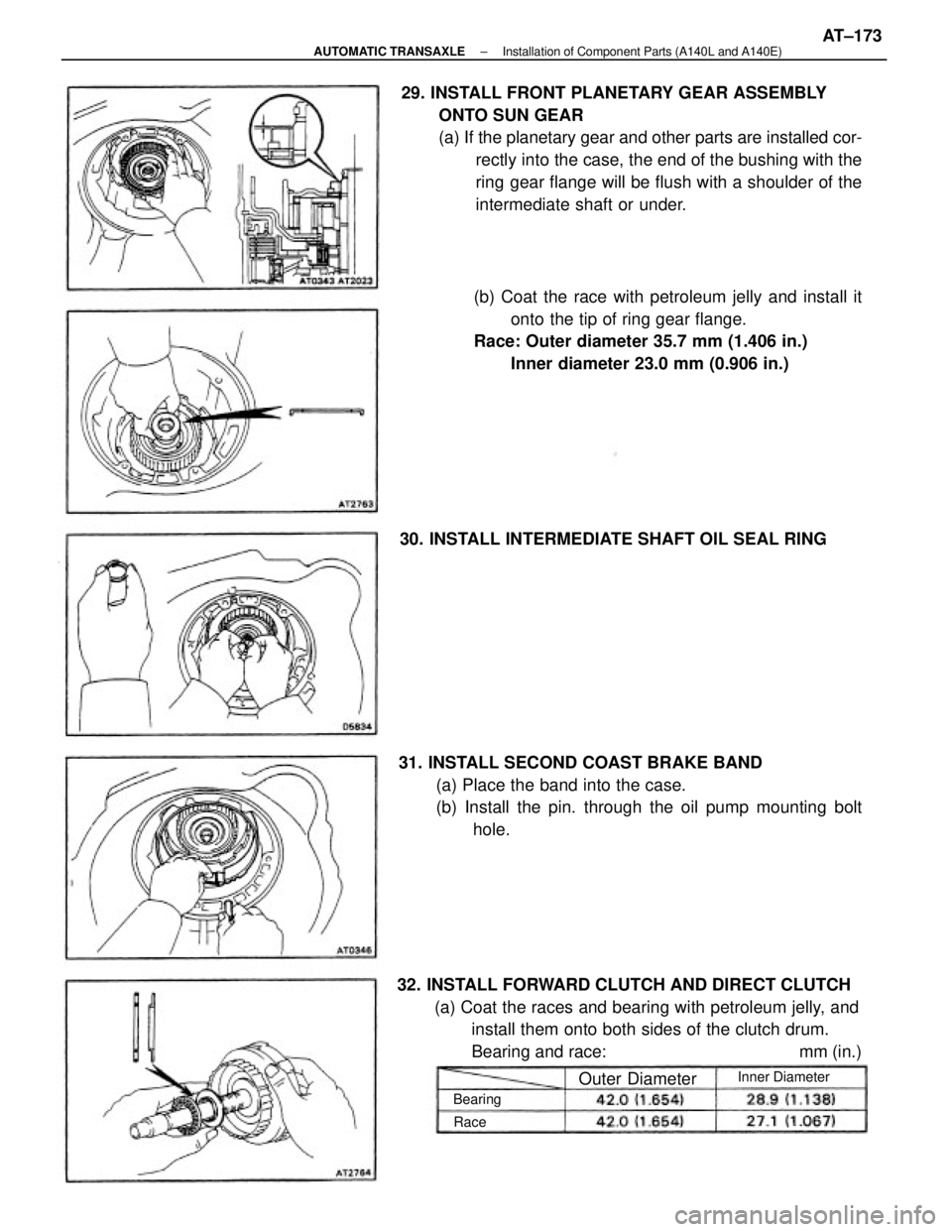

29. INSTALL FRONT PLANETARY GEAR ASSEMBLY

ONTO SUN GEAR

(a) If the planetary gear and other parts are installed cor-

rectly into the case, the end of the bushing with the

ring gear flange will be flush with a shoulder of the

intermediate shaft or under.

(b) Coat the race with petroleum jelly and install it

onto the tip of ring gear flange.

Race: Outer diameter 35.7 mm (1.406 in.)

Inner diameter 23.0 mm (0.906 in.)

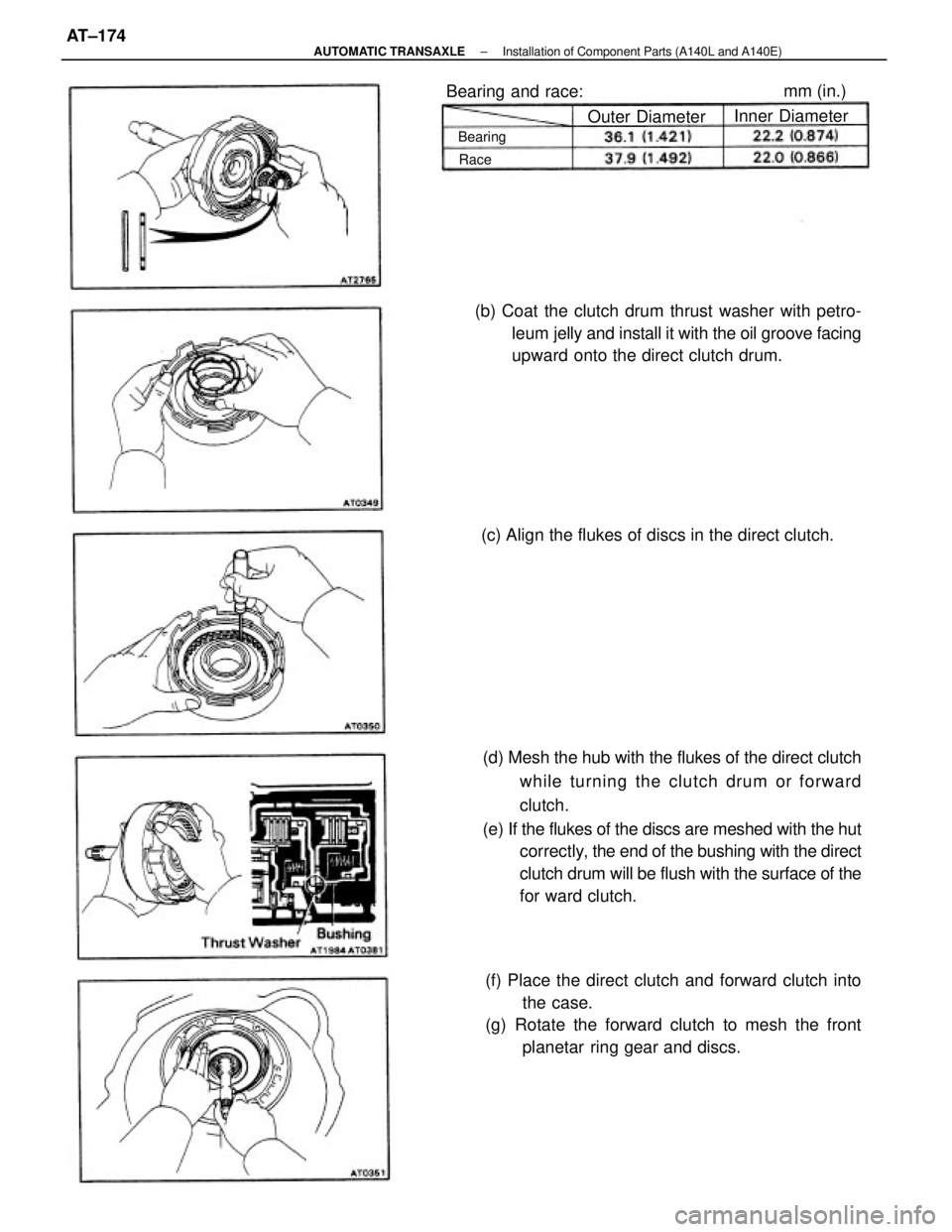

32. INSTALL FORWARD CLUTCH AND DIRECT CLUTCH

(a) Coat the races and bearing with petroleum jelly, and

install them onto both sides of the clutch drum.

Bearing and race: mm (in.) 31. INSTALL SECOND COAST BRAKE BAND

(a) Place the band into the case.

(b) Install the pin. through the oil pump mounting bolt

hole. 30. INSTALL INTERMEDIATE SHAFT OIL SEAL RING

Outer Diameter

Inner Diameter

Bearing

Race

± AUTOMATIC TRANSAXLEInstallation of Component Parts (A140L and A140E)AT±173

Page 429 of 2389

(d) Mesh the hub with the flukes of the direct clutch

while turning the clutch drum or forward

clutch.

(e) If the flukes of the discs are meshed with the hut

correctly, the end of the bushing with the direct

clutch drum will be flush with the surface of the

for ward clutch.

(f) Place the direct clutch and forward clutch into

the case.

(g) Rotate the forward clutch to mesh the front

planetar ring gear and discs. (b) Coat the clutch drum thrust washer with petro-

leum jelly and install it with the oil groove facing

upward onto the direct clutch drum.

(c) Align the flukes of discs in the direct clutch. Bearing and race:

Outer DiameterInner Diametermm (in.)

Bearing

Race

± AUTOMATIC TRANSAXLEInstallation of Component Parts (A140L and A140E)AT±174

Page 430 of 2389

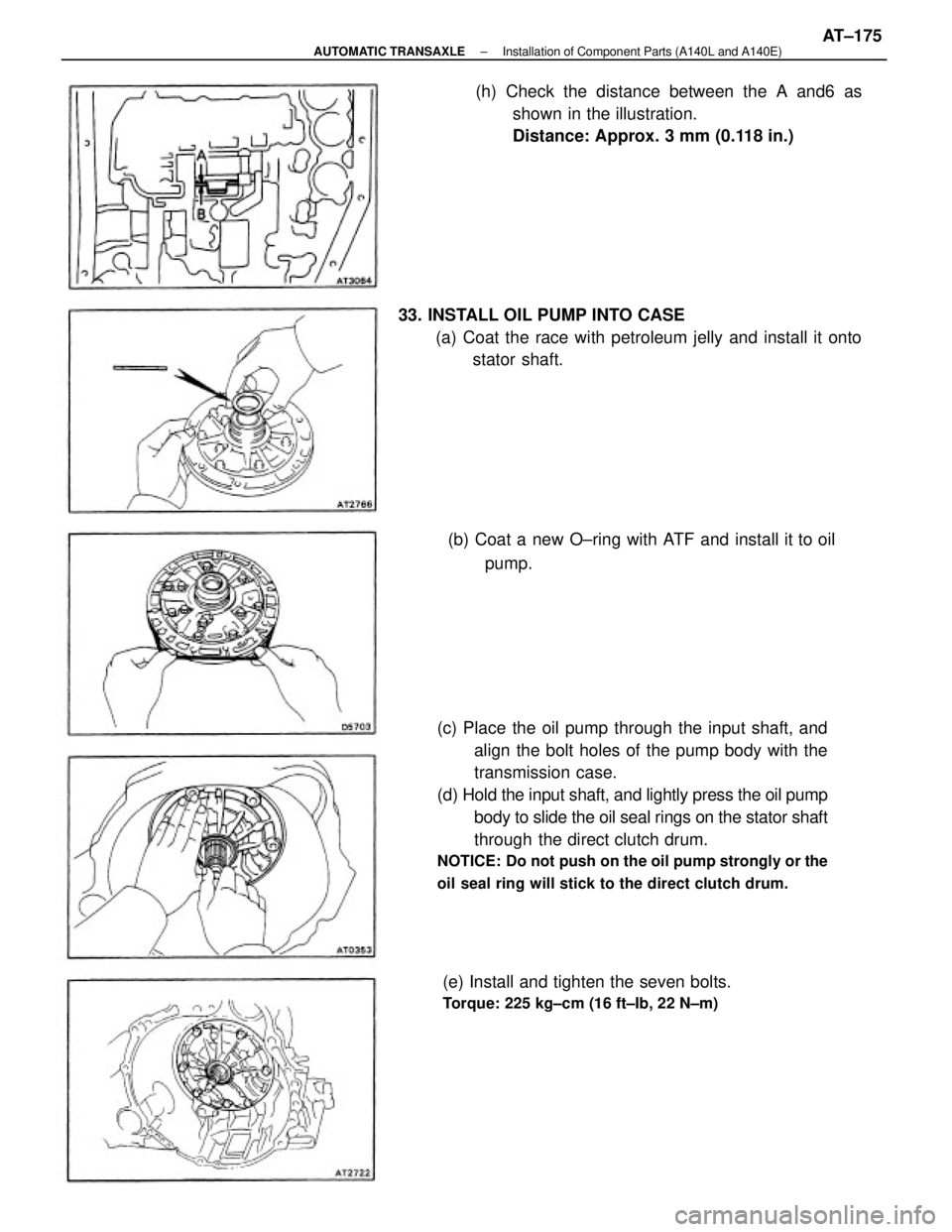

(c) Place the oil pump through the input shaft, and

align the bolt holes of the pump body with the

transmission case.

(d) Hold the input shaft, and lightly press the oil pump

body to slide the oil seal rings on the stator shaft

through the direct clutch drum.

NOTICE: Do not push on the oil pump strongly or the

oil seal ring will stick to the direct clutch drum.

33. INSTALL OIL PUMP INTO CASE

(a) Coat the race with petroleum jelly and install it onto

stator shaft.(h) Check the distance between the A and6 as

shown in the illustration.

Distance: Approx. 3 mm (0.118 in.)

(e) Install and tighten the seven bolts.

Torque: 225 kg±cm (16 ft±Ib, 22 N±m)

(b) Coat a new O±ring with ATF and install it to oil

pump.

± AUTOMATIC TRANSAXLEInstallation of Component Parts (A140L and A140E)AT±175