TOYOTA CAMRY V20 1986 Service Information

Manufacturer: TOYOTA, Model Year: 1986, Model line: CAMRY V20, Model: TOYOTA CAMRY V20 1986Pages: 2389, PDF Size: 84.44 MB

Page 821 of 2389

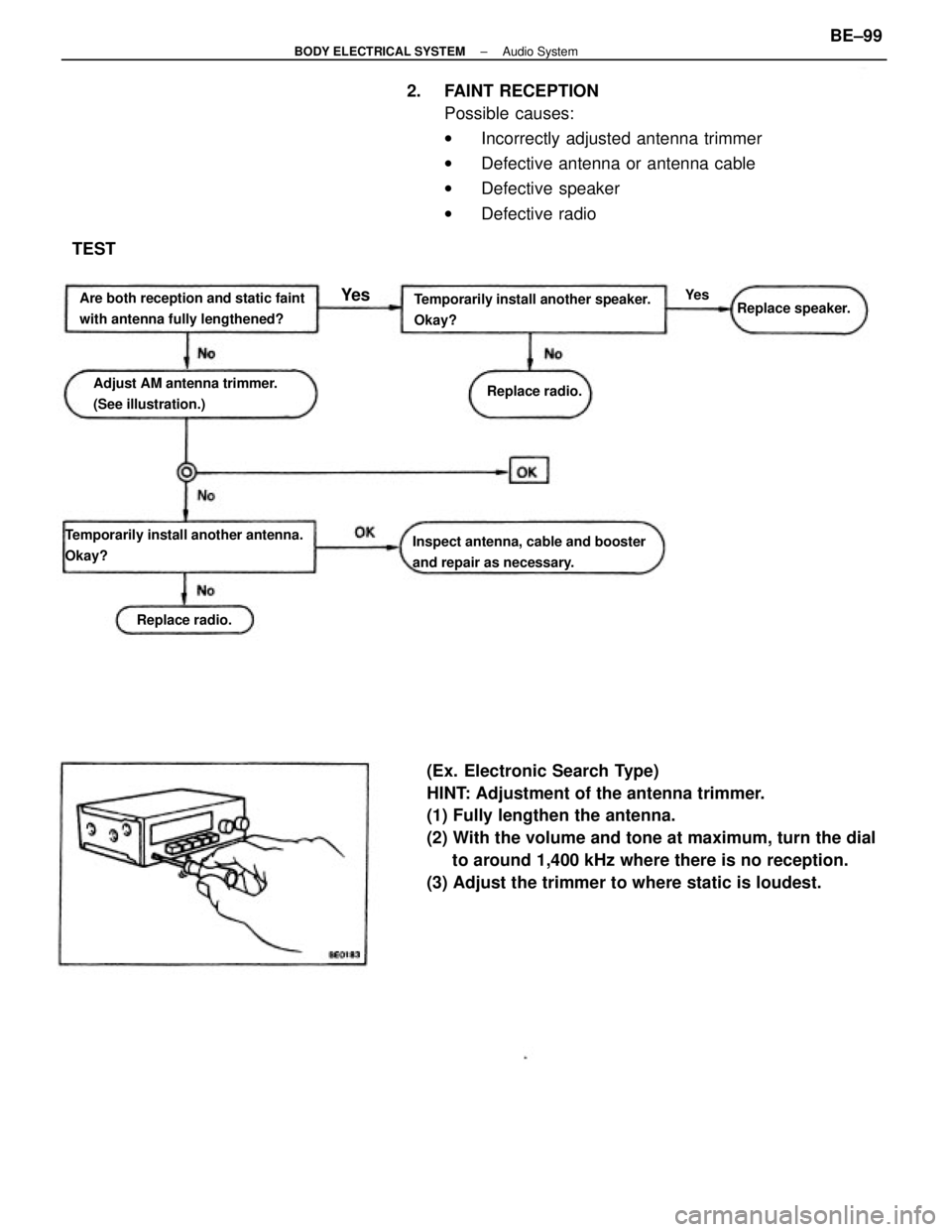

(Ex. Electronic Search Type)

HINT: Adjustment of the antenna trimmer.

(1) Fully lengthen the antenna.

(2) With the volume and tone at maximum, turn the dial

to around 1,400 kHz where there is no reception.

(3) Adjust the trimmer to where static is loudest. 2. FAINT RECEPTION

Possible causes:

wIncorrectly adjusted antenna trimmer

wDefective antenna or antenna cable

wDefective speaker

wDefective radio

Temporarily install another speaker.

Okay?

Temporarily install another antenna.

Okay?Inspect antenna, cable and booster

and repair as necessary. Are both reception and static faint

with antenna fully lengthened?

Adjust AM antenna trimmer.

(See illustration.)Replace speaker.

Replace radio.

Replace radio.

TEST

Ye sYe s

± BODY ELECTRICAL SYSTEMAudio SystemBE±99

Page 822 of 2389

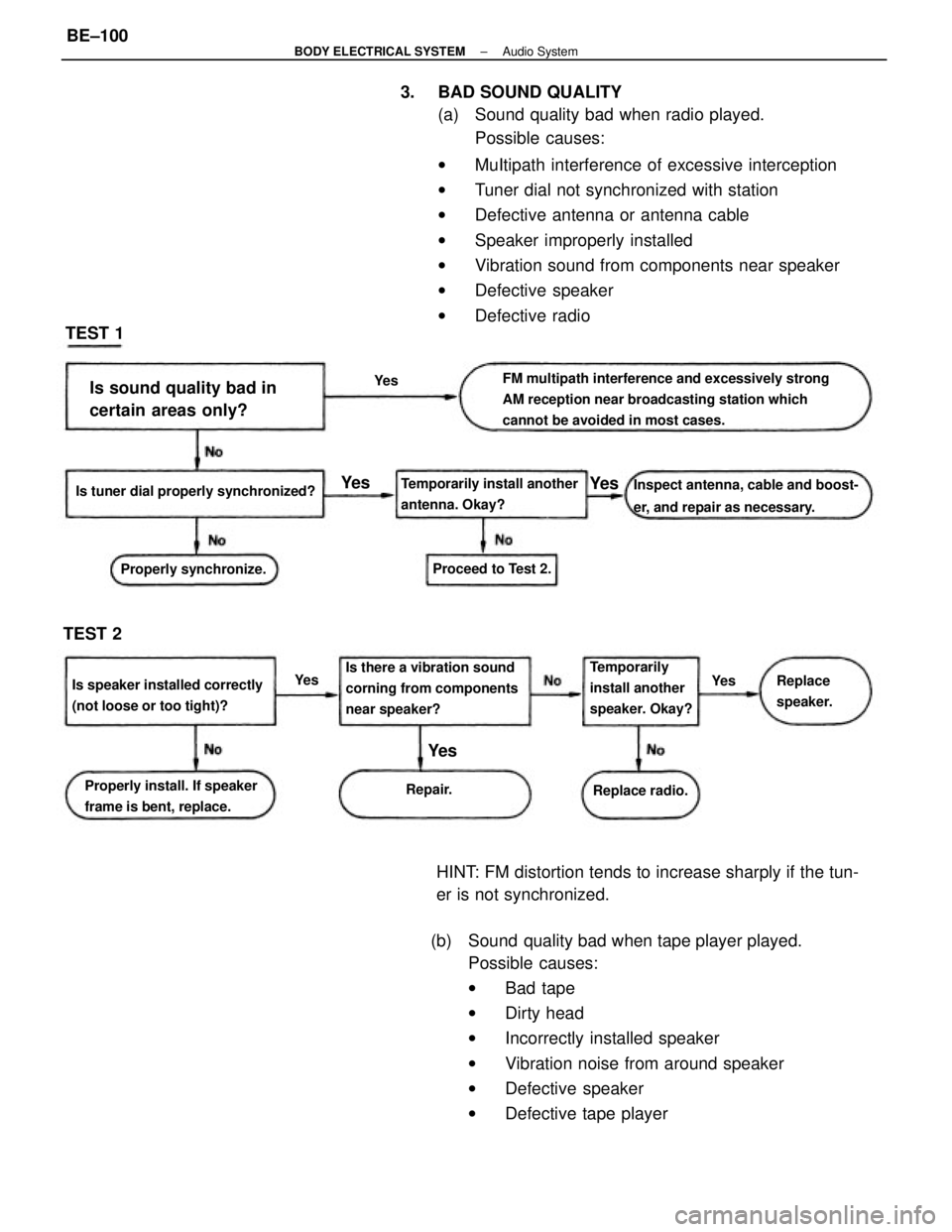

3. BAD SOUND QUALITY

(a) Sound quality bad when radio played.

Possible causes:

wMuItipath interference of excessive interception

wTuner dial not synchronized with station

wDefective antenna or antenna cable

wSpeaker improperly installed

wVibration sound from components near speaker

wDefective speaker

wDefective radio

(b) Sound quality bad when tape player played.

Possible causes:

wBad tape

wDirty head

wIncorrectly installed speaker

wVibration noise from around speaker

wDefective speaker

wDefective tape player HINT: FM distortion tends to increase sharply if the tun-

er is not synchronized.

FM multipath interference and excessively strong

AM reception near broadcasting station which

cannot be avoided in most cases.

Is there a vibration sound

corning from components

near speaker?Inspect antenna, cable and boost-

er, and repair as necessary.Is sound quality bad in

certain areas only?

Is speaker installed correctly

(not loose or too tight)?Temporarily install another

antenna. Okay?

Properly install. If speaker

frame is bent, replace. Is tuner dial properly synchronized?

Temporarily

install another

speaker. Okay? Properly synchronize.Proceed to Test 2.

Replace radio.Replace

speaker.

TEST 2TEST 1

Repair.

Ye s

Ye s

Ye s

Ye s

Ye s

Ye s

± BODY ELECTRICAL SYSTEMAudio SystemBE±100

Page 823 of 2389

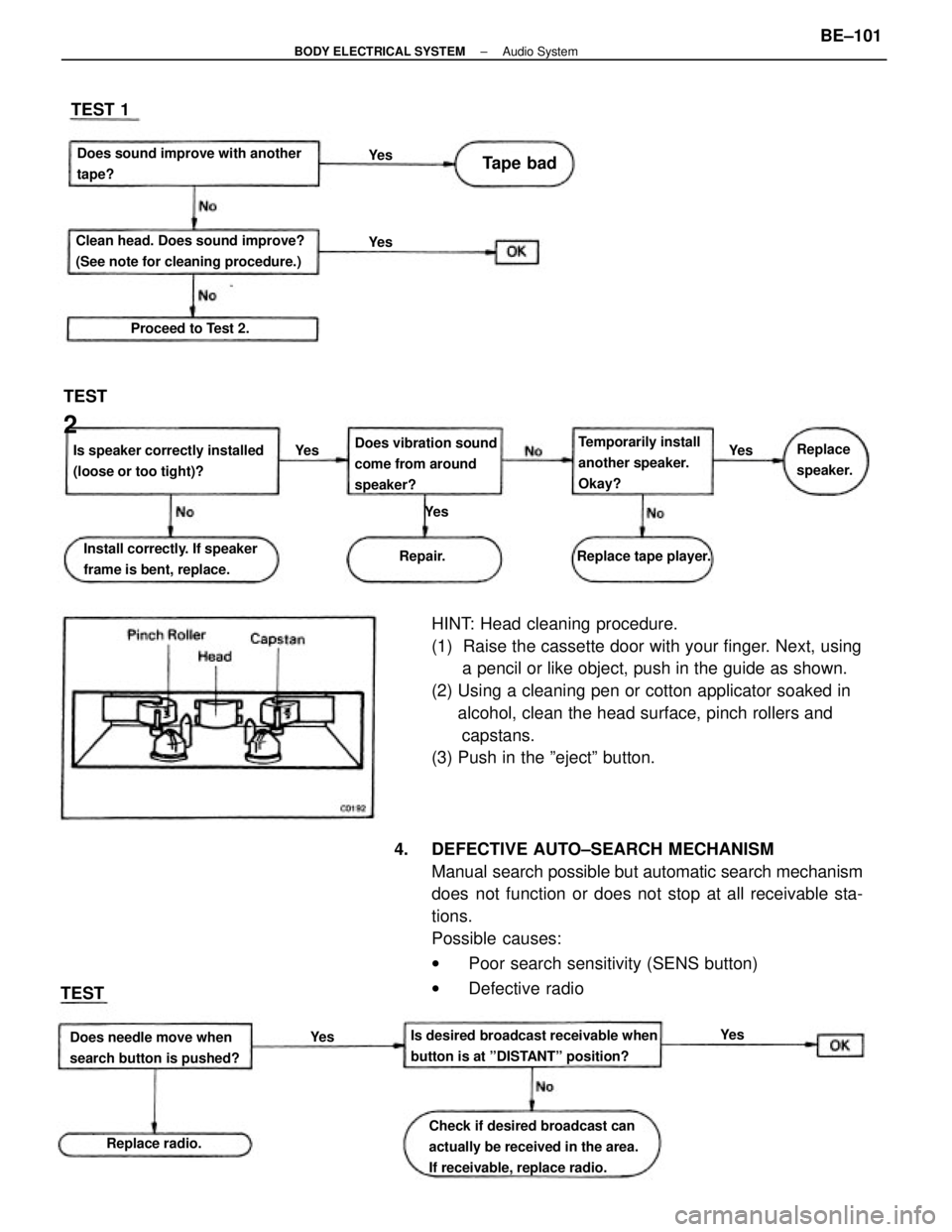

HINT: Head cleaning procedure.

(1) Raise the cassette door with your finger. Next, using

a pencil or like object, push in the guide as shown.

(2) Using a cleaning pen or cotton applicator soaked in

alcohol, clean the head surface, pinch rollers and

capstans.

(3) Push in the ºejectº button.

4. DEFECTIVE AUTO±SEARCH MECHANISM

Manual search possible but automatic search mechanism

does not function or does not stop at all receivable sta-

tions.

Possible causes:

wPoor search sensitivity (SENS button)

wDefective radio

Check if desired broadcast can

actually be received in the area.

If receivable, replace radio. Is desired broadcast receivable when

button is at ºDISTANTº position? Clean head. Does sound improve?

(See note for cleaning procedure.)Does sound improve with another

tape?

Is speaker correctly installed

(loose or too tight)?Does vibration sound

come from around

speaker?

Install correctly. If speaker

frame is bent, replace.Temporarily install

another speaker.

Okay?

Does needle move when

search button is pushed?Replace tape player. Proceed to Test 2.

Replace radio.Replace

speaker.

TEST

2

Tape bad TEST 1

Repair.

TEST

Ye s Ye s

Ye s Ye s

Ye s

Ye s

Ye s

± BODY ELECTRICAL SYSTEMAudio SystemBE±101

Page 824 of 2389

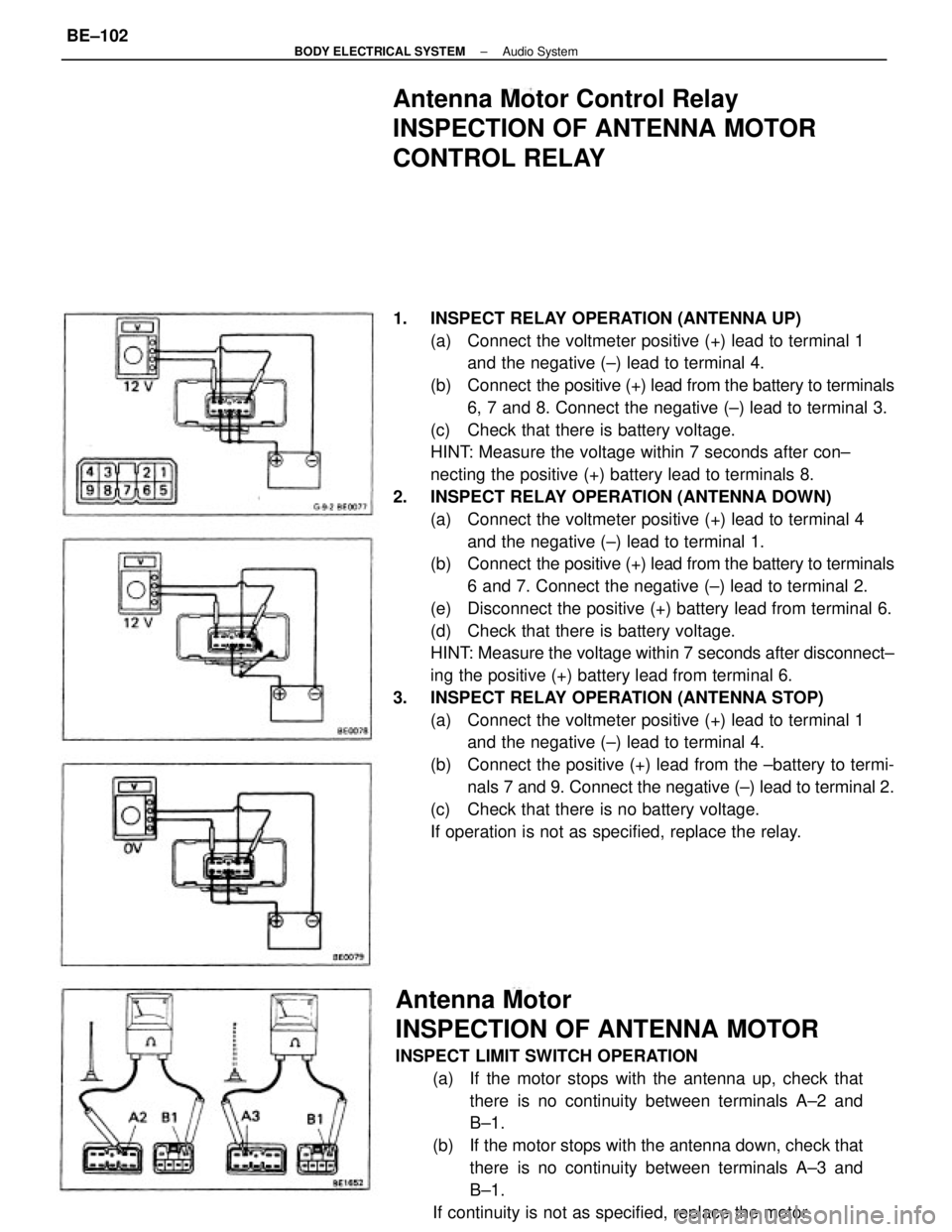

1. INSPECT RELAY OPERATION (ANTENNA UP)

(a) Connect the voltmeter positive (+) lead to terminal 1

and the negative (±) lead to terminal 4.

(b) Connect the positive (+) lead from the battery to terminals

6, 7 and 8. Connect the negative (±) lead to terminal 3.

(c) Check that there is battery voltage.

HINT: Measure the voltage within 7 seconds after con±

necting the positive (+) battery lead to terminals 8.

2. INSPECT RELAY OPERATION (ANTENNA DOWN)

(a) Connect the voltmeter positive (+) lead to terminal 4

and the negative (±) lead to terminal 1.

(b) Connect the positive (+) lead from the battery to terminals

6 and 7. Connect the negative (±) lead to terminal 2.

(e) Disconnect the positive (+) battery lead from terminal 6.

(d) Check that there is battery voltage.

HINT: Measure the voltage within 7 seconds after disconnect±

ing the positive (+) battery lead from terminal 6.

3. INSPECT RELAY OPERATION (ANTENNA STOP)

(a) Connect the voltmeter positive (+) lead to terminal 1

and the negative (±) lead to terminal 4.

(b) Connect the positive (+) lead from the ±battery to termi-

nals 7 and 9. Connect the negative (±) lead to terminal 2.

(c) Check that there is no battery voltage.

If operation is not as specified, replace the relay.

Antenna Motor

INSPECTION OF ANTENNA MOTOR

INSPECT LIMIT SWITCH OPERATION

(a) If the motor stops with the antenna up, check that

there is no continuity between terminals A±2 and

B±1.

(b) If the motor stops with the antenna down, check that

there is no continuity between terminals A±3 and

B±1.

If continuity is not as specified, replace the motor.

Antenna Motor Control Relay

INSPECTION OF ANTENNA MOTOR

CONTROL RELAY

± BODY ELECTRICAL SYSTEMAudio SystemBE±102

Page 825 of 2389

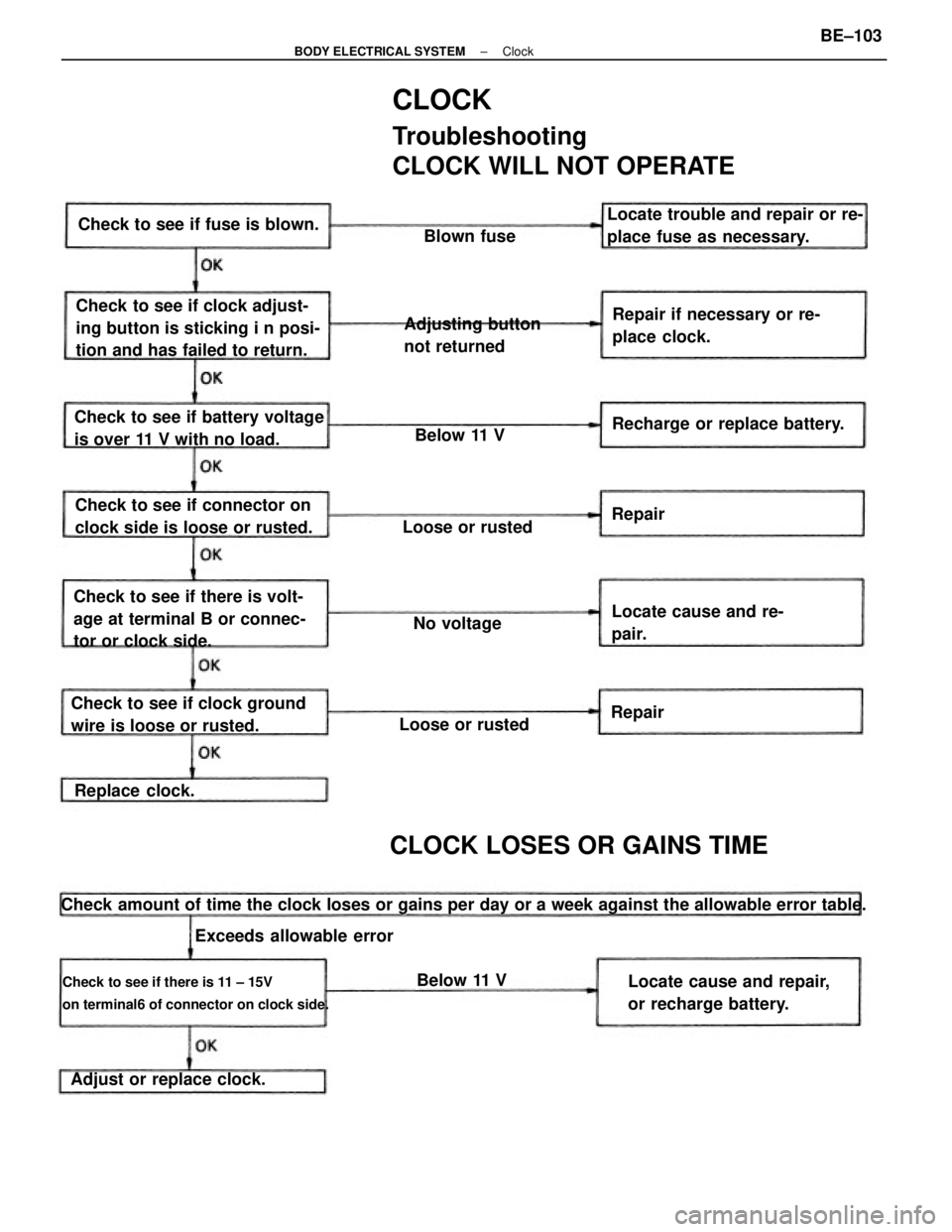

CLOCK

Troubleshooting

CLOCK WILL NOT OPERATE

Check amount of time the clock loses or gains per day or a week against the allowable error table.

Check to see if there is 11 ± 15V

on terminal6 of connector on clock side.

Check to see if clock adjust-

ing button is sticking i n posi-

tion and has failed to return.

Check to see if there is volt-

age at terminal B or connec-

tor or clock side.

Check to see if clock ground

wire is loose or rusted.Check to see if battery voltage

is over 11 V with no load.Repair if necessary or re-

place clock. Locate trouble and repair or re-

place fuse as necessary.

Locate cause and repair,

or recharge battery. Check to see if connector on

clock side is loose or rusted.

CLOCK LOSES OR GAINS TIME

Adjusting button

not returned Check to see if fuse is blown.

Recharge or replace battery.

Adjust or replace clock.Locate cause and re-

pair.

Exceeds allowable errorLoose or rustedLoose or rusted

Replace clock.No voltageBlown fuse

Below 11 V

Below 11 VRepair

Repair

± BODY ELECTRICAL SYSTEMClockBE±103

Page 826 of 2389

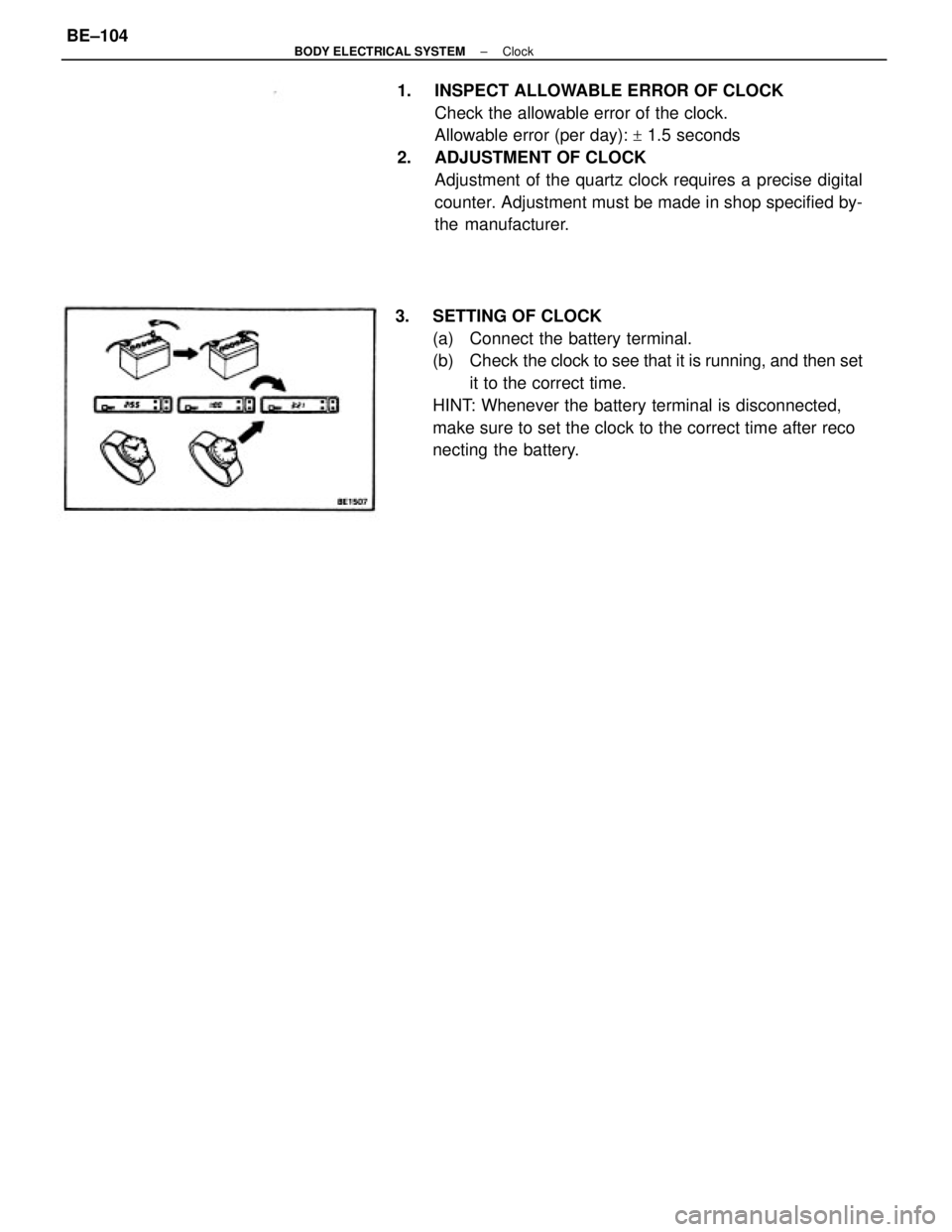

1. INSPECT ALLOWABLE ERROR OF CLOCK

Check the allowable error of the clock.

Allowable error (per day):

+ 1.5 seconds

2. ADJUSTMENT OF CLOCK

Adjustment of the quartz clock requires a precise digital

counter. Adjustment must be made in shop specified by-

the manufacturer.

3. SETTING OF CLOCK

(a) Connect the battery terminal.

(b) Check the clock to see that it is running, and then set

it to the correct time.

HINT: Whenever the battery terminal is disconnected,

make sure to set the clock to the correct time after reco

necting the battery.

± BODY ELECTRICAL SYSTEMClockBE±104

Page 827 of 2389

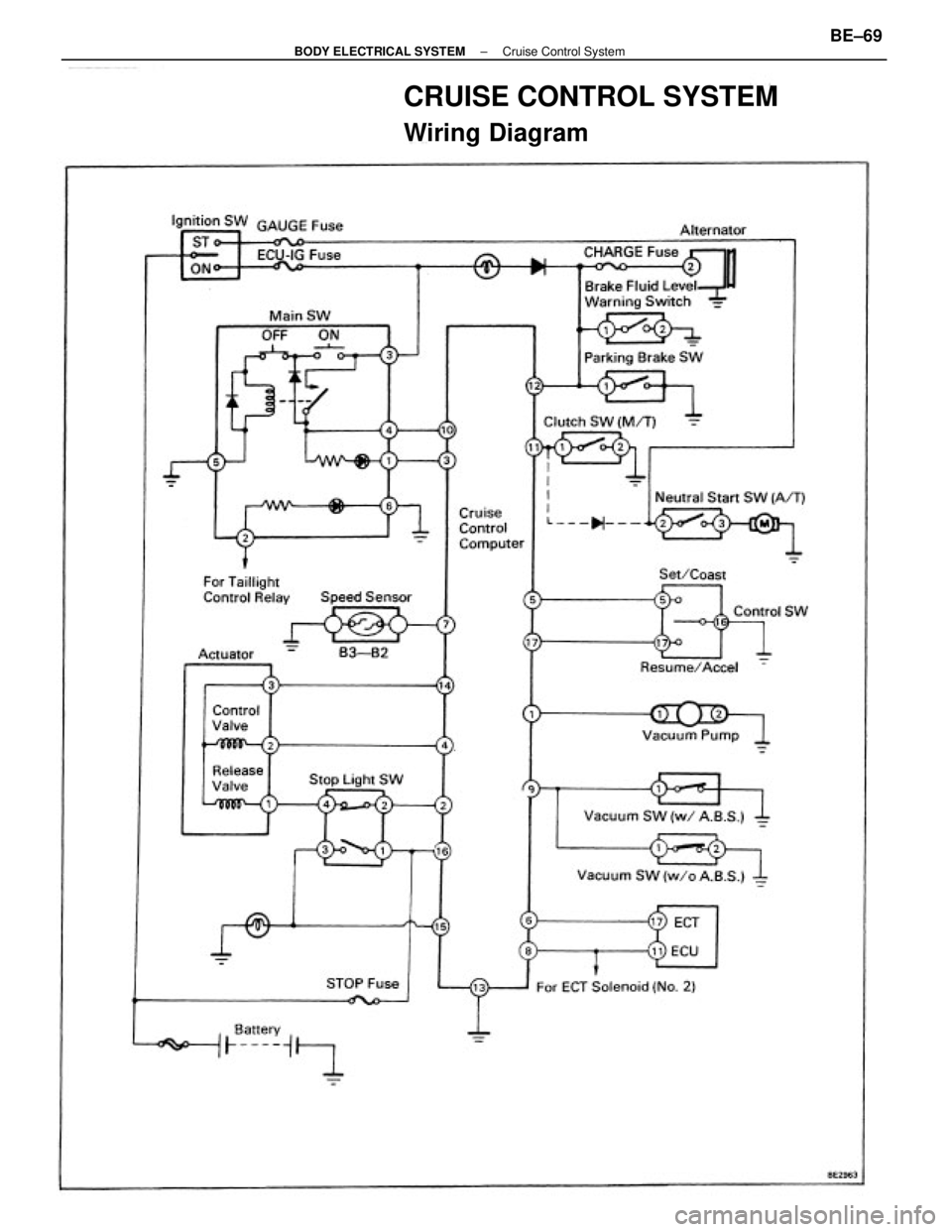

CRUISE CONTROL SYSTEM

Wiring Diagram

± BODY ELECTRICAL SYSTEMCruise Control SystemBE±69

Page 828 of 2389

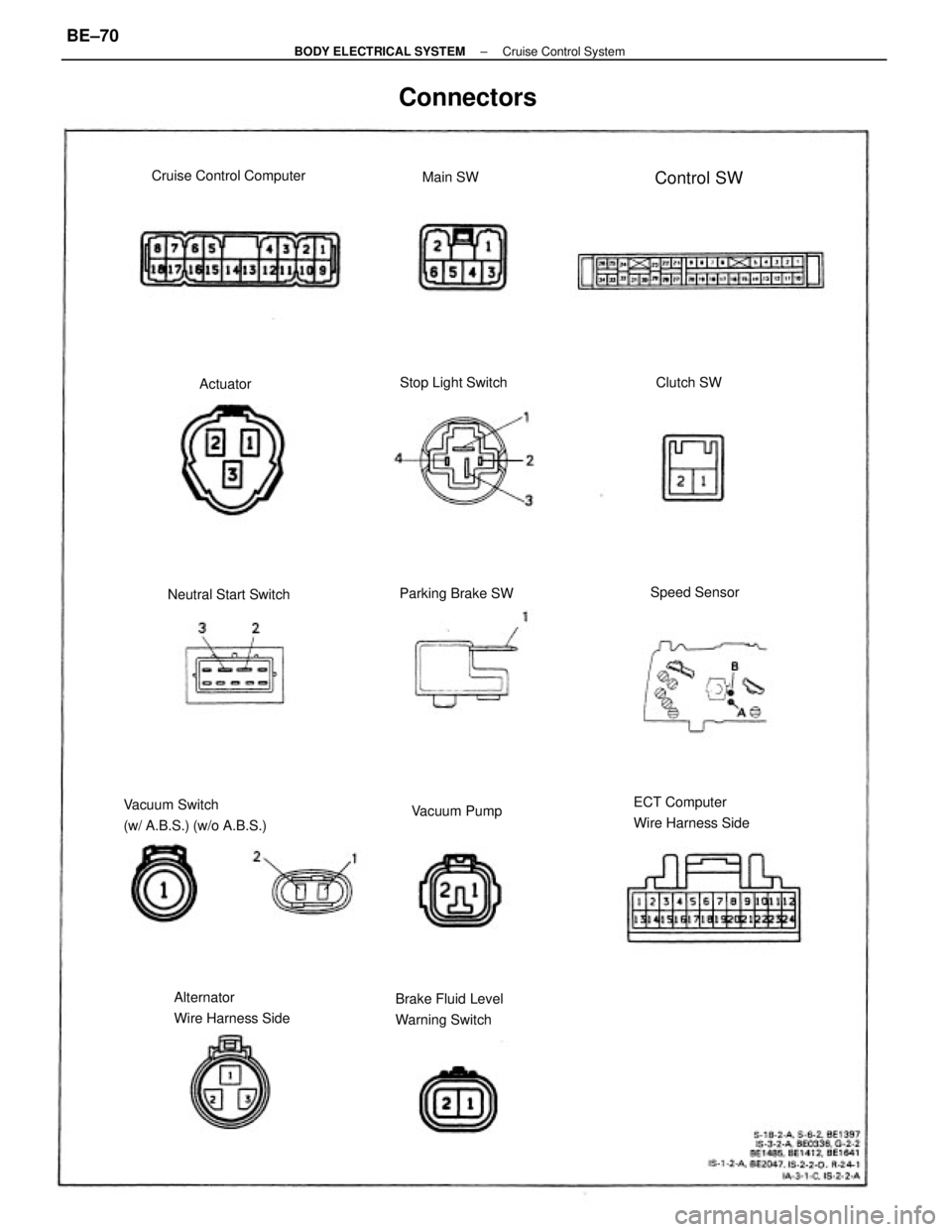

Vacuum Switch

(w/ A.B.S.) (w/o A.B.S.)ECT Computer

Wire Harness Side

Alternator

Wire Harness SideBrake Fluid Level

Warning Switch

Connectors

Cruise Control Computer

Neutral Start SwitchStop Light Switch

Parking Brake SW

Vacuum PumpSpeed SensorControl SW

Clutch SW Main SW

Actuator

± BODY ELECTRICAL SYSTEMCruise Control SystemBE±70

Page 829 of 2389

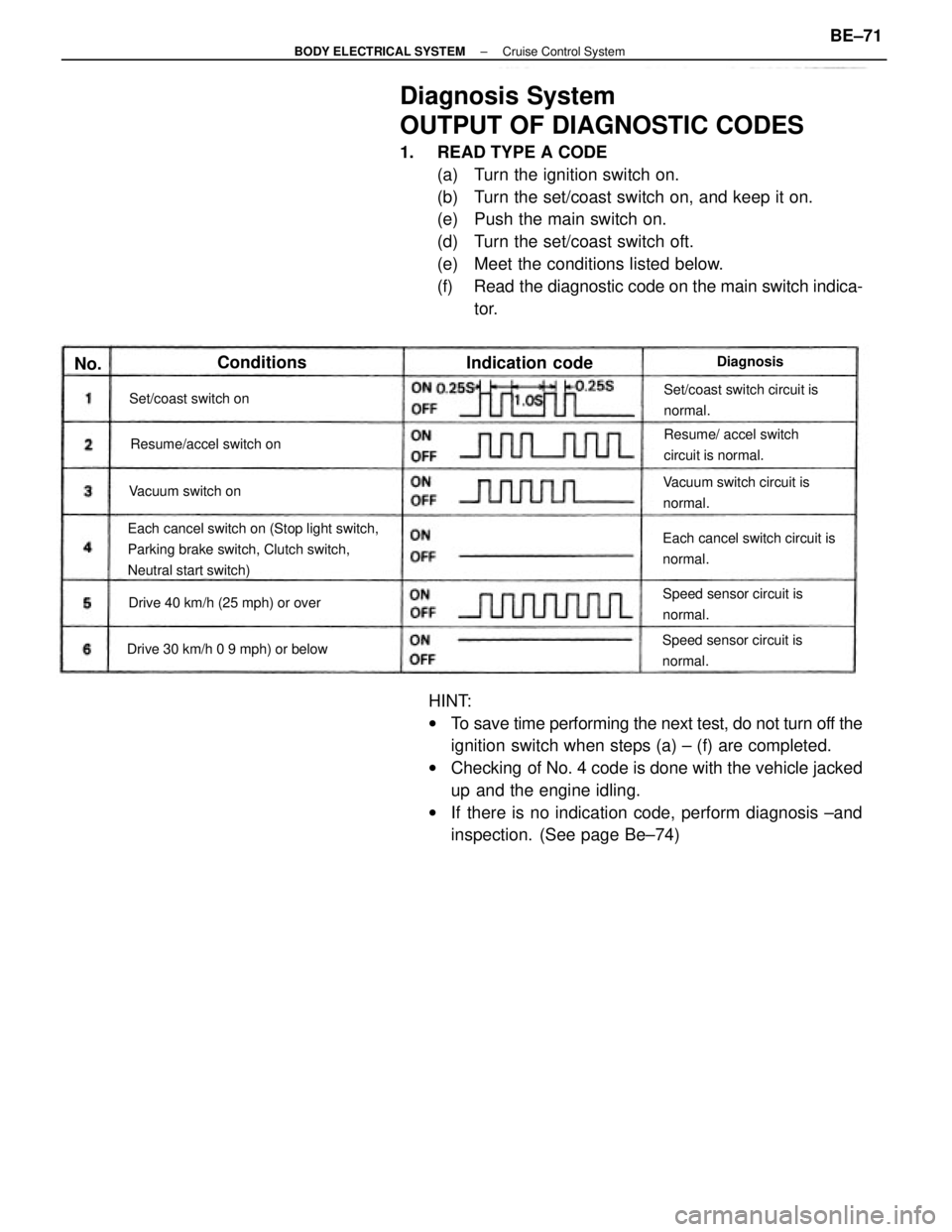

Diagnosis System

OUTPUT OF DIAGNOSTIC CODES

1. READ TYPE A CODE

(a) Turn the ignition switch on.

(b) Turn the set/coast switch on, and keep it on.

(e) Push the main switch on.

(d) Turn the set/coast switch oft.

(e) Meet the conditions listed below.

(f) Read the diagnostic code on the main switch indica-

tor.

HINT:

wTo save time performing the next test, do not turn off the

ignition switch when steps (a) ± (f) are completed.

wChecking of No. 4 code is done with the vehicle jacked

up and the engine idling.

wIf there is no indication code, perform diagnosis ±and

inspection. (See page Be±74)

Each cancel switch on (Stop light switch,

Parking brake switch, Clutch switch,

Neutral start switch)Each cancel switch circuit is

normal.Set/coast switch circuit is

normal.

Vacuum switch circuit is

normal.Resume/ accel switch

circuit is normal.

Speed sensor circuit is

normal.Speed sensor circuit is

normal.

Drive 30 km/h 0 9 mph) or belowDrive 40 km/h (25 mph) or overResume/accel switch on Set/coast switch on

Vacuum switch on

Indication code ConditionsDiagnosisNo.

± BODY ELECTRICAL SYSTEMCruise Control SystemBE±71

Page 830 of 2389

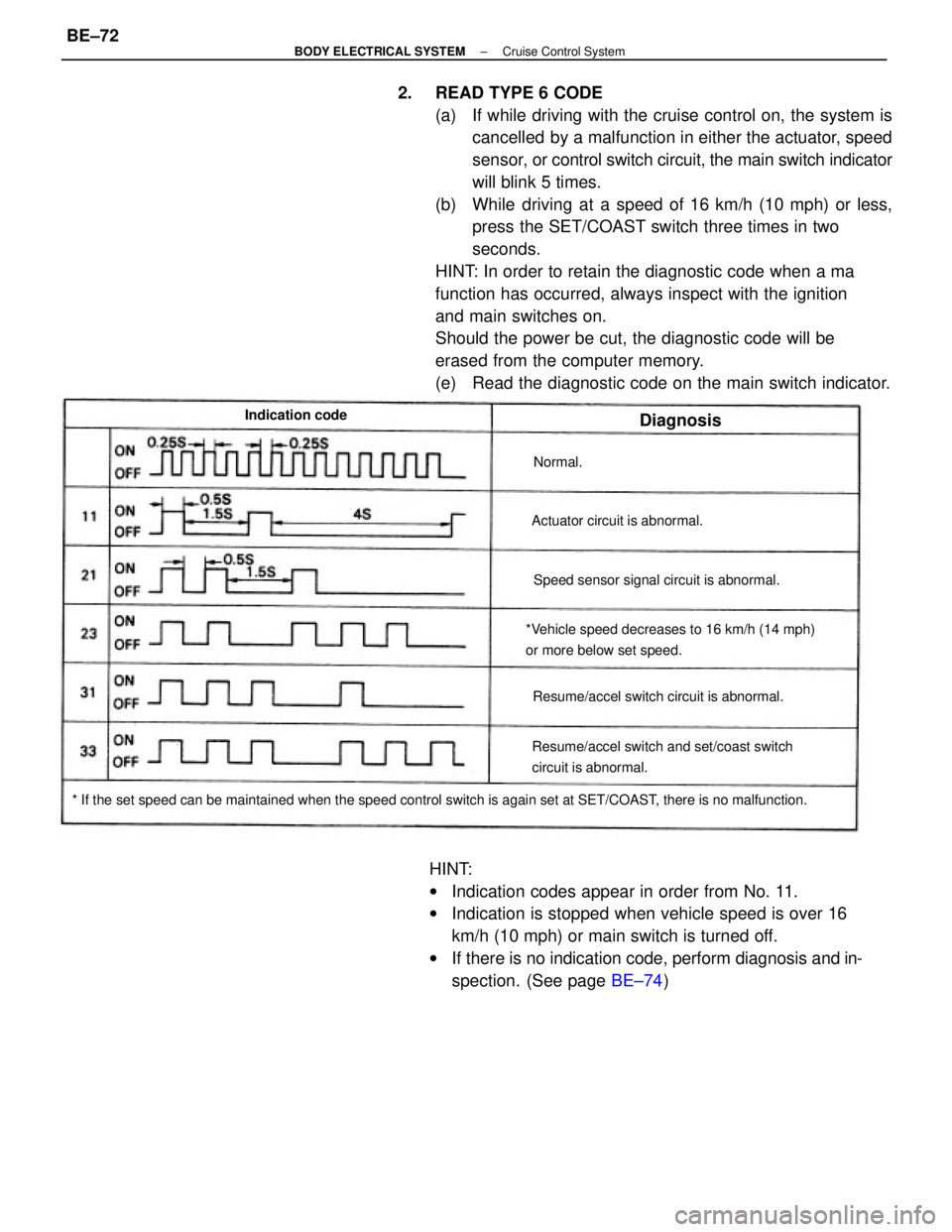

2. READ TYPE 6 CODE

(a) If while driving with the cruise control on, the system is

cancelled by a malfunction in either the actuator, speed

sensor, or control switch circuit, the main switch indicator

will blink 5 times.

(b) While driving at a speed of 16 km/h (10 mph) or less,

press the SET/COAST switch three times in two

seconds.

HINT: In order to retain the diagnostic code when a ma

function has occurred, always inspect with the ignition

and main switches on.

Should the power be cut, the diagnostic code will be

erased from the computer memory.

(e) Read the diagnostic code on the main switch indicator.

HINT:

wIndication codes appear in order from No. 11.

wIndication is stopped when vehicle speed is over 16

km/h (10 mph) or main switch is turned off.

wIf there is no indication code, perform diagnosis and in-

spection. (See page BE±74)

* If the set speed can be maintained when the speed control switch is again set at SET/COAST, there is no malfunction.*Vehicle speed decreases to 16 km/h (14 mph)

or more below set speed.

Resume/accel switch and set/coast switch

circuit is abnormal.Resume/accel switch circuit is abnormal.Speed sensor signal circuit is abnormal. Actuator circuit is abnormal. Indication code

Diagnosis

Normal.

± BODY ELECTRICAL SYSTEMCruise Control SystemBE±72