TOYOTA CAMRY V20 1986 Service Information

Manufacturer: TOYOTA, Model Year: 1986, Model line: CAMRY V20, Model: TOYOTA CAMRY V20 1986Pages: 2389, PDF Size: 84.44 MB

Page 851 of 2389

BRAKE SYSTEM

± BRAKE SYSTEMBR±1

Page 852 of 2389

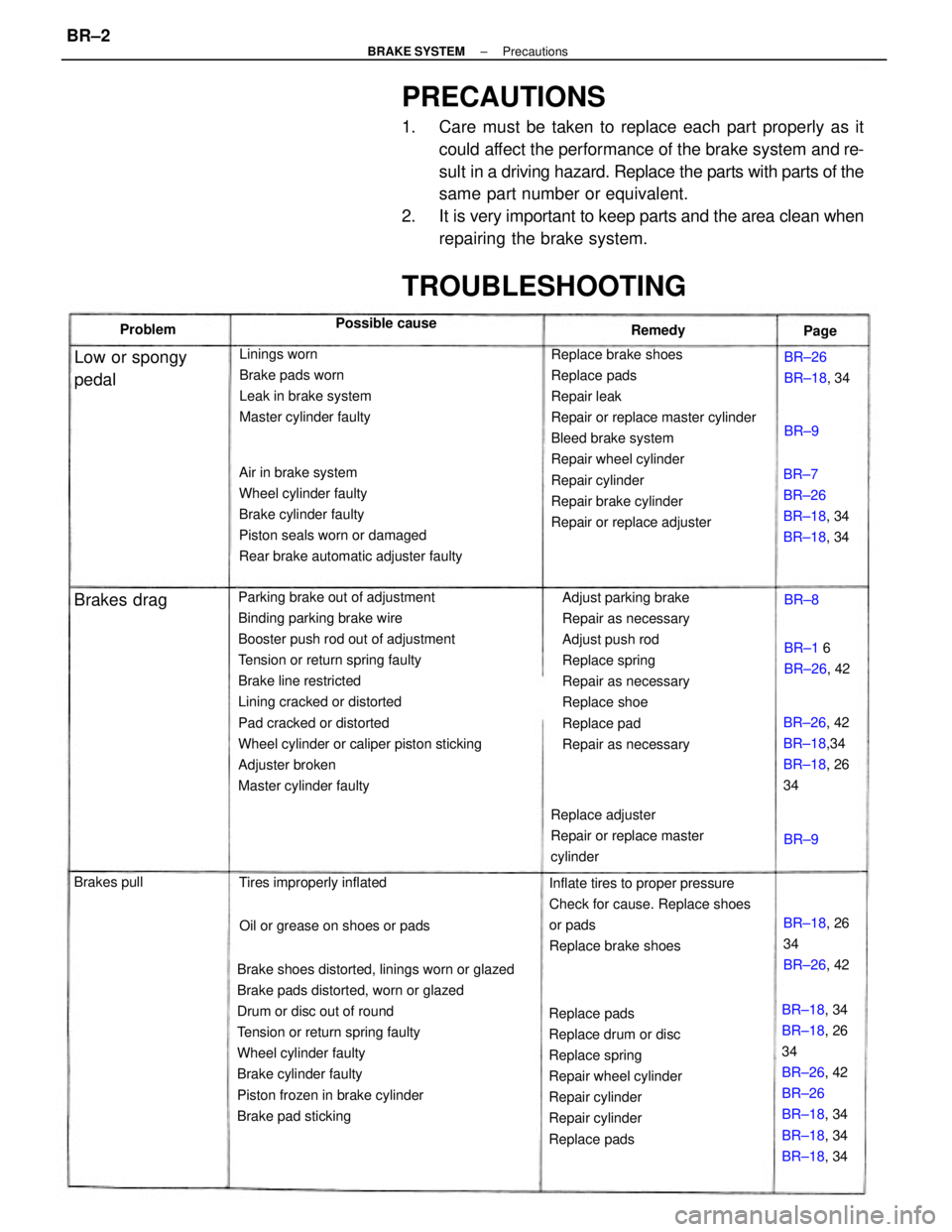

PRECAUTIONS

1. Care must be taken to replace each part properly as it

could affect the performance of the brake system and re-

sult in a driving hazard. Replace the parts with parts of the

same part number or equivalent.

2. It is very important to keep parts and the area clean when

repairing the brake system.

Parking brake out of adjustment

Binding parking brake wire

Booster push rod out of adjustment

Tension or return spring faulty

Brake line restricted

Lining cracked or distorted

Pad cracked or distorted

Wheel cylinder or caliper piston sticking

Adjuster broken

Master cylinder faulty

Brake shoes distorted, linings worn or glazed

Brake pads distorted, worn or glazed

Drum or disc out of round

Tension or return spring faulty

Wheel cylinder faulty

Brake cylinder faulty

Piston frozen in brake cylinder

Brake pad stickingReplace brake shoes

Replace pads

Repair leak

Repair or replace master cylinder

Bleed brake system

Repair wheel cylinder

Repair cylinder

Repair brake cylinder

Repair or replace adjuster Air in brake system

Wheel cylinder faulty

Brake cylinder faulty

Piston seals worn or damaged

Rear brake automatic adjuster faulty

Adjust parking brake

Repair as necessary

Adjust push rod

Replace spring

Repair as necessary

Replace shoe

Replace pad

Repair as necessary

Replace pads

Replace drum or disc

Replace spring

Repair wheel cylinder

Repair cylinder

Repair cylinder

Replace padsInflate tires to proper pressure

Check for cause. Replace shoes

or pads

Replace brake shoes Linings worn

Brake pads worn

Leak in brake system

Master cylinder faulty

BR±18, 34

BR±18, 26

34

BR±26, 42

BR±26

BR±18, 34

BR±18, 34

BR±18, 34 Replace adjuster

Repair or replace master

cylinder

TROUBLESHOOTING

BR±7

BR±26

BR±18, 34

BR±18, 34

BR±26, 42

BR±18,34

BR±18, 26

34

Oil or grease on shoes or pads Tires improperly inflated

BR±18, 26

34

BR±26, 42

Low or spongy

pedalBR±26

BR±18, 34

BR±1 6

BR±26, 42 Possible cause

Brakes drag

Brakes pullRemedy Problem

Page

BR±8

BR±9BR±9

± BRAKE SYSTEMPrecautionsBR±2

Page 853 of 2389

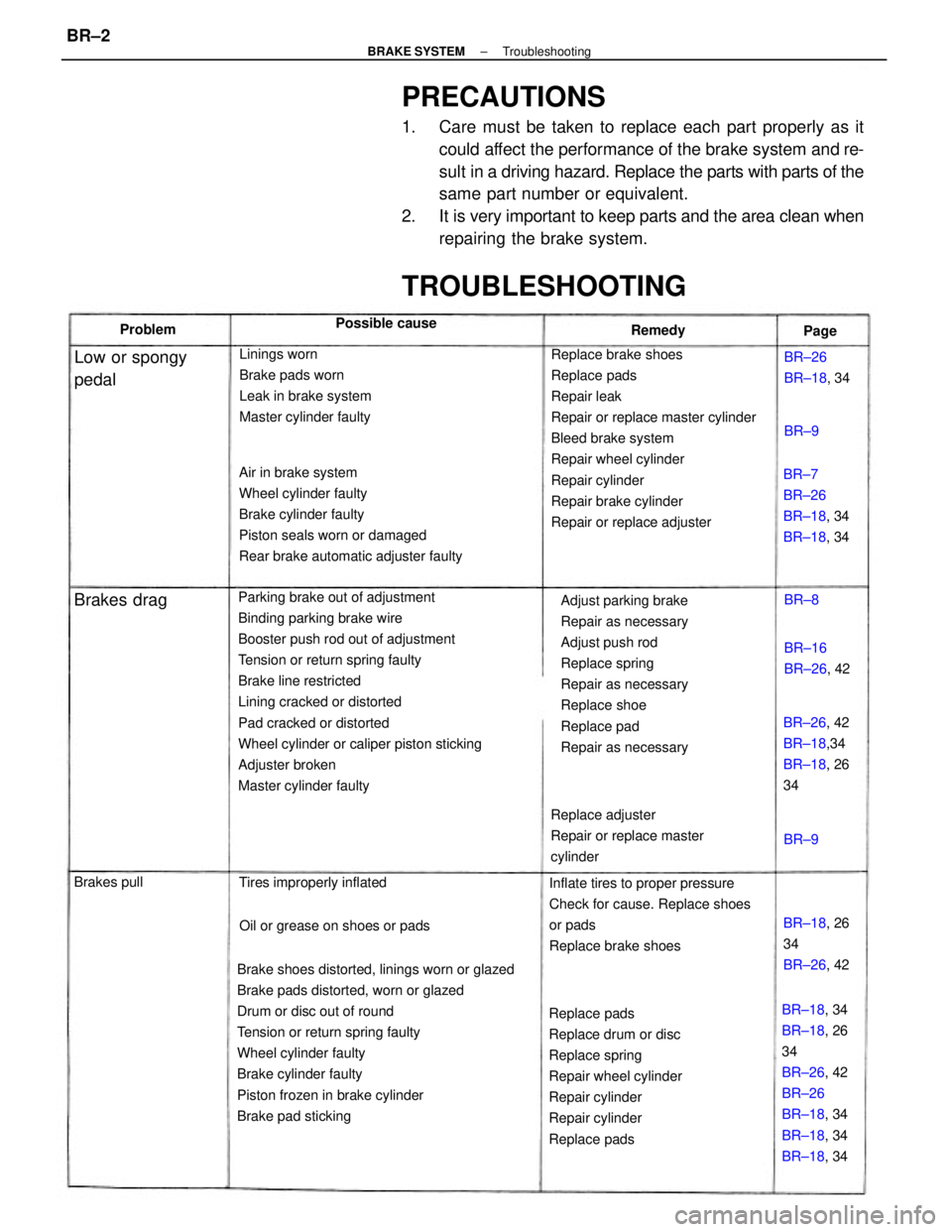

PRECAUTIONS

1. Care must be taken to replace each part properly as it

could affect the performance of the brake system and re-

sult in a driving hazard. Replace the parts with parts of the

same part number or equivalent.

2. It is very important to keep parts and the area clean when

repairing the brake system.

Parking brake out of adjustment

Binding parking brake wire

Booster push rod out of adjustment

Tension or return spring faulty

Brake line restricted

Lining cracked or distorted

Pad cracked or distorted

Wheel cylinder or caliper piston sticking

Adjuster broken

Master cylinder faulty

Brake shoes distorted, linings worn or glazed

Brake pads distorted, worn or glazed

Drum or disc out of round

Tension or return spring faulty

Wheel cylinder faulty

Brake cylinder faulty

Piston frozen in brake cylinder

Brake pad stickingReplace brake shoes

Replace pads

Repair leak

Repair or replace master cylinder

Bleed brake system

Repair wheel cylinder

Repair cylinder

Repair brake cylinder

Repair or replace adjuster Air in brake system

Wheel cylinder faulty

Brake cylinder faulty

Piston seals worn or damaged

Rear brake automatic adjuster faulty

Adjust parking brake

Repair as necessary

Adjust push rod

Replace spring

Repair as necessary

Replace shoe

Replace pad

Repair as necessary

Replace pads

Replace drum or disc

Replace spring

Repair wheel cylinder

Repair cylinder

Repair cylinder

Replace padsInflate tires to proper pressure

Check for cause. Replace shoes

or pads

Replace brake shoes Linings worn

Brake pads worn

Leak in brake system

Master cylinder faulty

BR±18, 34

BR±18, 26

34

BR±26, 42

BR±26

BR±18, 34

BR±18, 34

BR±18, 34 Replace adjuster

Repair or replace master

cylinder

TROUBLESHOOTING

BR±7

BR±26

BR±18, 34

BR±18, 34

BR±26, 42

BR±18,34

BR±18, 26

34

Oil or grease on shoes or pads Tires improperly inflated

BR±18, 26

34

BR±26, 42

Low or spongy

pedalBR±26

BR±18, 34

BR±16

BR±26, 42 Possible cause

Brakes drag

Brakes pullRemedy Problem

Page

BR±8

BR±9BR±9

± BRAKE SYSTEMTroubleshootingBR±2

Page 854 of 2389

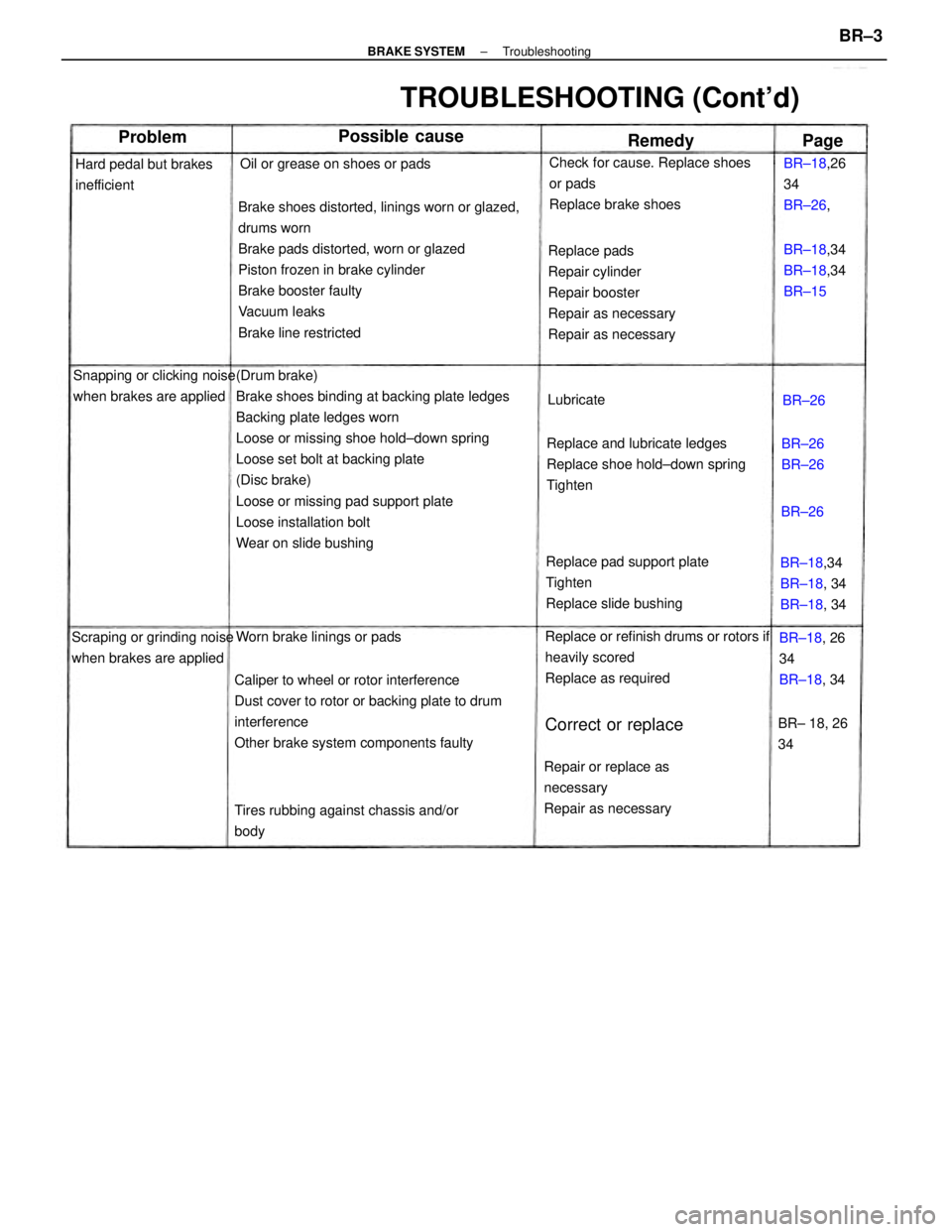

(Drum brake)

Brake shoes binding at backing plate ledges

Backing plate ledges worn

Loose or missing shoe hold±down spring

Loose set bolt at backing plate

(Disc brake)

Loose or missing pad support plate

Loose installation bolt

Wear on slide bushingBrake shoes distorted, linings worn or glazed,

drums worn

Brake pads distorted, worn or glazed

Piston frozen in brake cylinder

Brake booster faulty

Vacuum leaks

Brake line restricted

Caliper to wheel or rotor interference

Dust cover to rotor or backing plate to drum

interference

Other brake system components faultyReplace and lubricate ledges

Replace shoe hold±down spring

TightenReplace pads

Repair cylinder

Repair booster

Repair as necessary

Repair as necessary

Replace pad support plate

Tighten

Replace slide bushing

Replace or refinish drums or rotors if

heavily scored

Replace as required

TROUBLESHOOTING (Cont'd)

Check for cause. Replace shoes

or pads

Replace brake shoes

Repair or replace as

necessary

Repair as necessary

Tires rubbing against chassis and/or

body Snapping or clicking noise

when brakes are applied

Scraping or grinding noise

when brakes are appliedOil or grease on shoes or pads

Hard pedal but brakes

inefficient

Worn brake linings or padsBR±18,34

BR±18, 34

BR±18, 34 BR±18,34

BR±18,34

BR±15 BR±18,26

34

BR±26,

BR±18, 26

34

BR±18, 34

Correct or replaceBR± 18, 26

34

Possible cause

BR±26

BR±26 Lubricate

Problem

Remedy

BR±26

Page

BR±26

± BRAKE SYSTEMTroubleshootingBR±3

Page 855 of 2389

Maladjustment of brake pedal or booster push

rod

Poor return of brake booster or master cylinder or

wheel cylinder

(Disc brake)

Rusted or stuck piston

Improper positioning of pad in caliper

Rotor rubbing against caliper housing

Improper installation of disc brake pad support

plate

Pad wear and pad wear indicator making contact

with the rotor

(Drum brake)

Weak, damaged or incorrect shoe hold±down

springs

Grooved backing plate ledges

Bent or warped backing plate causing

interference with drum

Improper machining of drum causing interference

with backing plate or shoe

Other brake system components:

Loose or extra parts in brakes

Rear drum adjustment too tight causing lining to

glaze

Worn, damaged or insufficiently lubricated wheel

bearings Brake drums and linings, rotors and pads

worn or scored

Dirty, greased, contaminated or glazed

linings or pads

Improper linings or pads using

Maladjustment of brake pedal or booster

push rod

(Disc brake)

Missing or damaged brake pad

anti±squeal shim

Pad wear and pad wear indicator making

contact with the rotor

Burred or rusted calipers

(Drum brake)

Weak damaged or incorrect shoe

hold±down springs, loose or damaged

shoe hold±down spring pins and springs

and grooved backing plate ledges Squeaking, squealing

groaning or chattering

noise when brakes are

applied

Note: Brake friction

materials inherently

generate noise and heat in

order to dissipate eniergy.

As a result, occasional

squeal is normal and is

aggravated by severe

environmental conditions

such as cold,' heat,

wetness, snow, salt, mud,

etc. This occasional squeal

is not a functional problem

and does not indicate any

loss of brake effectivenessInspect, repair or replace

Clean or replace

Inspect for correct usage or

replace

Inspect and adjust

Inspect and lubricate as

necessary

Repair or replace

Repair or replace

Repair or replace

Replace

Replace

Repair or replace

Repair or replace

Replace drum

TROUBLESHOOTING (Cont'd)

Replace

Replace

Clean or deburr

Inspect and adjust

Inspect, repair or replace Squealing and

squeaking noise when

brakes are not applied

BR±26, 42

BR±26, 42

BR±26, 42

BR±26, 42 BR±18,34

BR±18, 34

BR±18, 34

BR±18, 34

Inspect, repair or replace as

necessaryBR±18, 34

BR±18, 34

BR±18, 34 BR±18, 26,

34

BR±18, 26

34

±Inspect, repair or replace

BR±9,15

26 Possible cause

BR± 18, 34 BR±6,16 . Page Remedy

BR±6, 16 Problem

BR±26

± BRAKE SYSTEMTroubleshootingBR±4

Page 856 of 2389

Maladjustment of brake pedal or booster push

rod

worn, damaged or dry wheel bearings

(Disc brake)

Loose or missing anti±rattle spring or pad

support plate or rimping on outer pad

Failure of shim

Wear on slide bushing

Loose installation bolt

Poor return of piston

(Drum brake)

Loose or extra partsInspect , replace if necessary

Inspect , replace if necessary

Inspect , tighten if necessary

Inspect , repair or replaceTighten to correct torque

Replace if stud holes are

elongated

Inspect and adjust Stones or foreign material trapped inside

wheel covers

Loose wheel nuts

TROUBLESHOOTING (Cont'd)

Groaning, clicking or

rattling noise when

brakes are not applied

Inspect and lubricate or

replace

BR±21, 37

BR±21, 37

BR±21, 37

BR±21, 37 Inspect, repair or replaceRemove foreign material

Inspect and repair

Possible cause

BR±21, 37

BR±26, 42 BR±6,16

Problem

Remedy

Page

± BRAKE SYSTEMTroubleshootingBR±5

Page 857 of 2389

CHECKS AND ADJUSTMENTS

CHECK AND ADJUSTMENT OF BRAKE

PEDAL

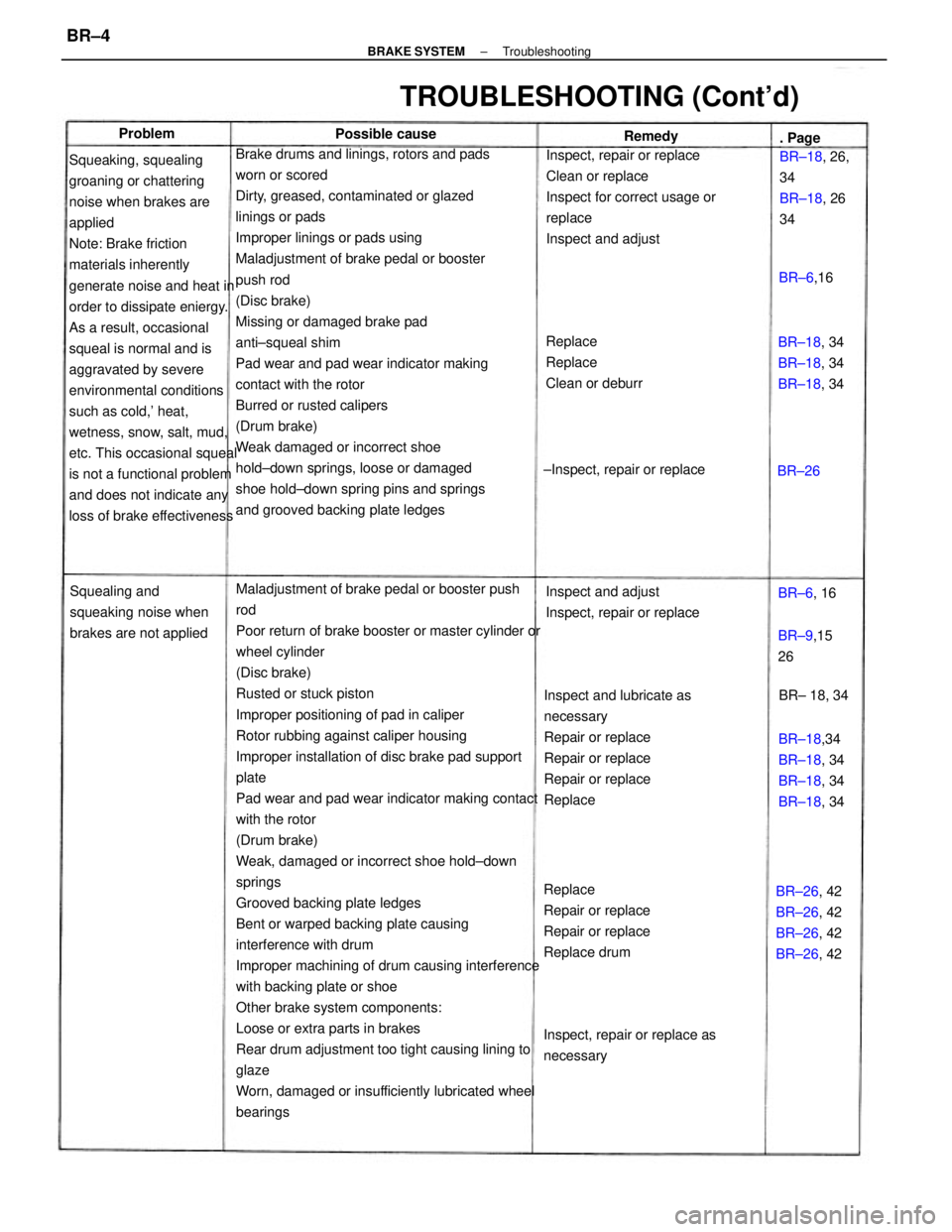

1. CHECK THAT PEDAL HEIGHT IS CORRECT

Pedal height from asphalt sheet:

177.5 ± 187.5 mm (6.988 ± 7.382 in.)

If incorrect, adjust the pedal height.

2. IF NECESSARY, ADJUST PEDAL HEIGHT

(a) If necessary, remove the instrument lower finish pan-

el and air duct.

(b) Loosen the stop light switch lock nut.

(e) Sufficiently loosen the stop light switch.

(d) Loosen the push rod lock nut.

(e) Adjust the pedal height by turning the pedal push

rod.

(f) Return the stop light switch until it lightly contacts the

pedal stopper.

(g) Tighten the two lock nuts.

(h) Check that the stop lights light when the brake pedal

depressed.

(i) After adjusting the pedal height, check and adjust

the pedal freeplay.

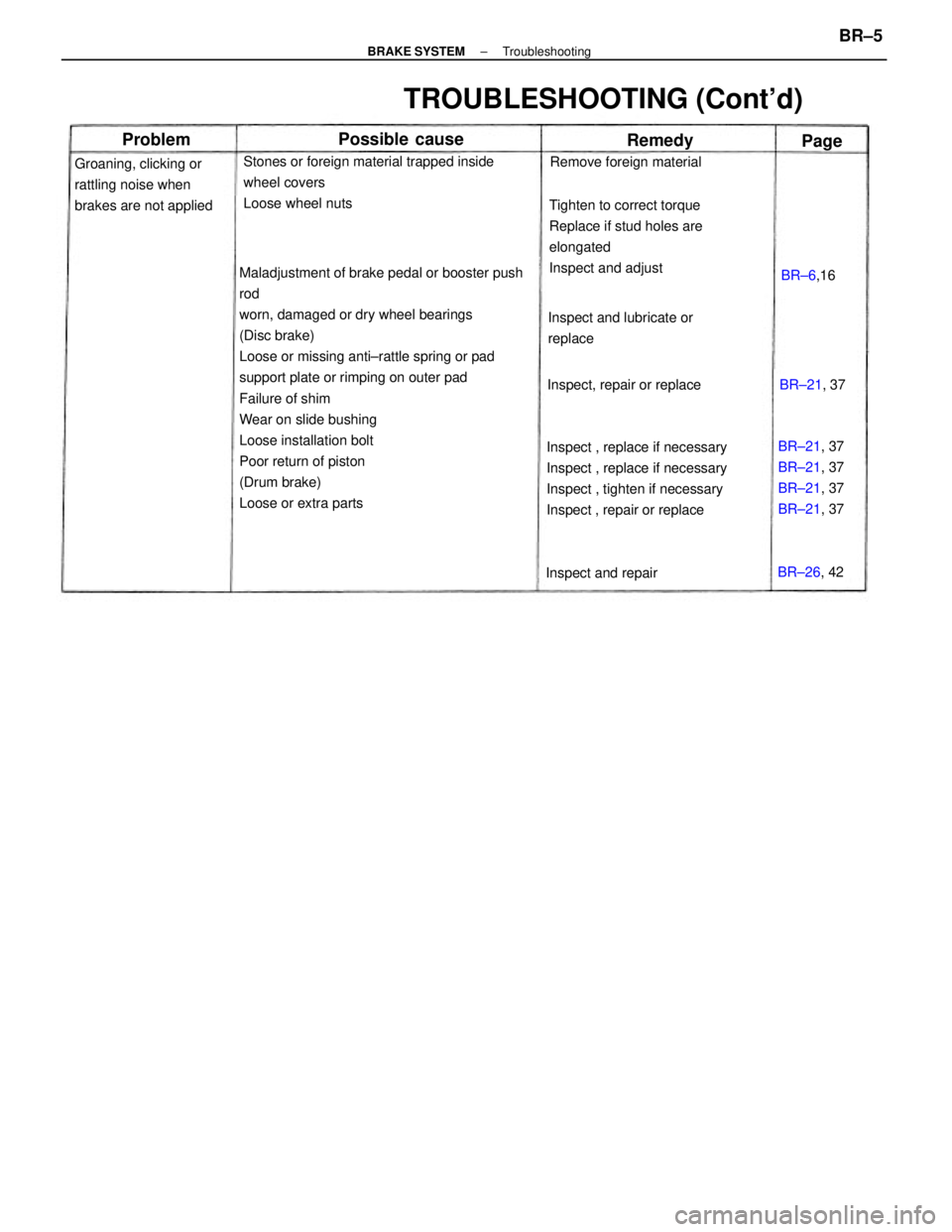

3. CHECK THAT PEDAL FREEPLAY IS CORRECT

(a) Stop the engine and depress the brake pedal sever-

al times until there is no more vacuum left in the

booster.

(b) Push in the pedal until the beginning of resistance

is felt. Measure the distance, as shown.

Pedal freeplay: 3 ±6 mm (0.12 ± 0.24 in.)

HINT: The freeplay to the first resistance is due to the play

between the clevis and pin. And it is 1 3 mm (0.04±

0.12 in.) on the pedal.

4. IF NECESSARY, ADJUST PEDAL FREEPLAY

(a) If incorrect, adjust the pedal freeplay by turning the

pedal push rod.

(b) Start the engine and confirm that pedal freepiay ex-

ists.

(e) After adjusting the pedal freeplay, check the pedal

height.

(d) Install the air duct and instrument lower finish panel.

± BRAKE SYSTEMChecks and AdjustmentsBR±6

Page 858 of 2389

OPERATIONAL TEST OF BRAKE

BOOSTER

HINT: If there is leakage or lack of vacuum, repair before

testing. If available, use a brake booster tester to check the

booster operating condition.

1. OPERATING CHECK

(a) Depress the brake pedal several times with the en-

gine stopped, and check that is no change in the ped-

al reserve distance.

(b) Depress the brake pedal and start the engine. If the

pedal goes down slightly, operation is normal.

2. AIR TIGHTNESS CHECK

(a) Start the engine and stop it after one or two minutes.

Depress the brake pedal several times slowly. If the

pedal goes down furtherest the first time, but gradual-

ly rises after the second or third time, the booster is air

tight.

(b) Depress the brake pedal while the engine is running,

and stop it with the pedal depressed. If there is no

change in pedal reserve travel after holding the pedal

for thirty seconds, the booster is air tight.

BLEEDING OF BRAKE SYSTEM

HINT: If any work is done on the brake system or if air is sus-

pected in the brake lines, bleed the system of air.

NOTICE: Do not let brake fluid remain on a painted surface.

Wash it off immediately.

1. FILL BRAKE RESERVOIR WITH BRAKE FLUID

Check the fluid level in the reservoir. If necessary, add

brake fluid. 5. CHECK THAT PEDAL RESERVE DISTANCE IS

CORRECT

Release the parking brake. With engine running, depress

the pedal and measure the pedal reserve distance, as

shown.

Pedal reserve distance from asphalt sheet at 50 kg

(110.2 1b): More than 85 mm, (3.35 in.)

If incorrect, troubleshoot the brake system.

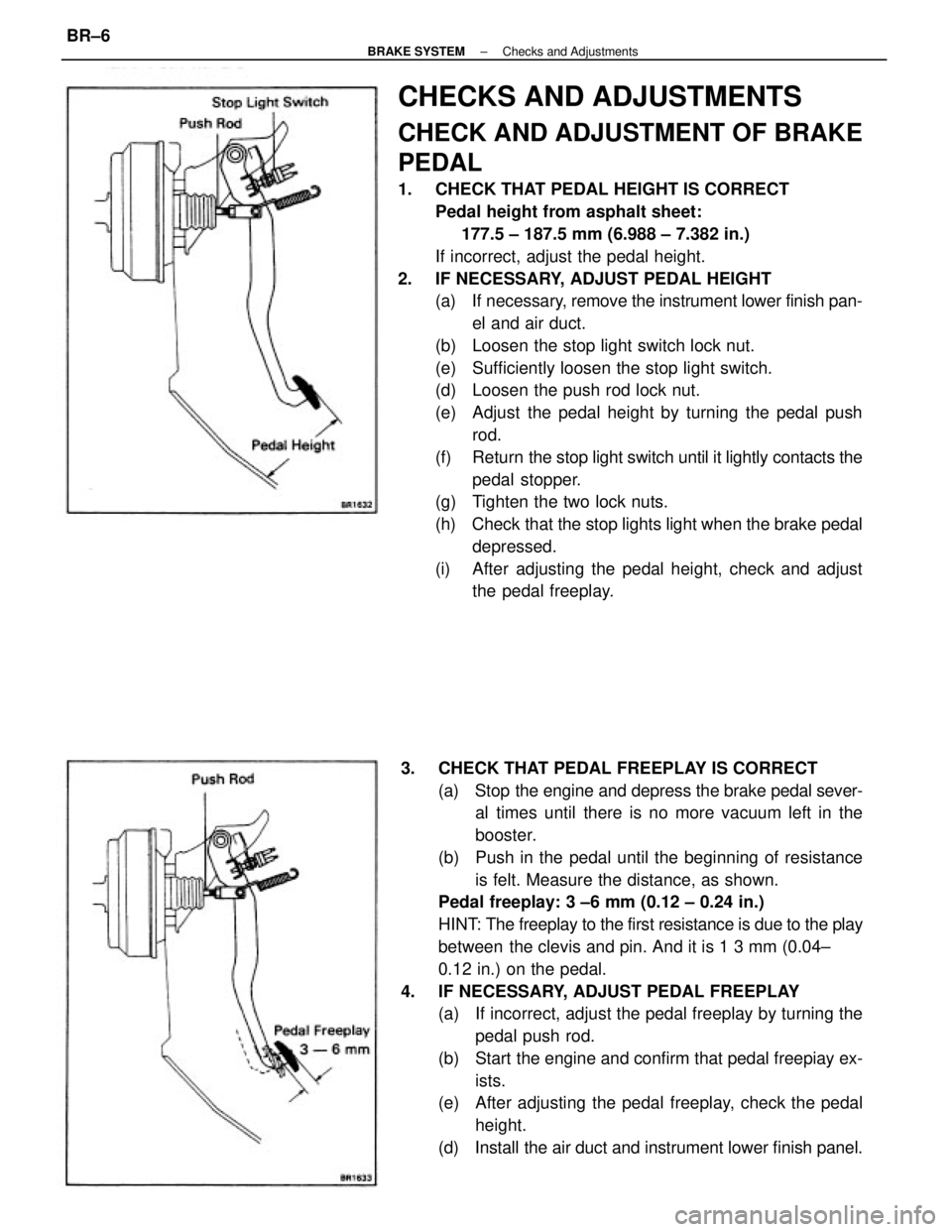

2. BLEED MASTER CYLINDER

HINT: If the master cylinder was disassembled or if the res-

ervoir becomes empty, bleed the air from the master cylin-

der.

(a) Disconnect the brake tubes from the master cylinder.

(b) Depress the brake pedal and hold it.

± BRAKE SYSTEMChecks and AdjustmentsBR±7

Page 859 of 2389

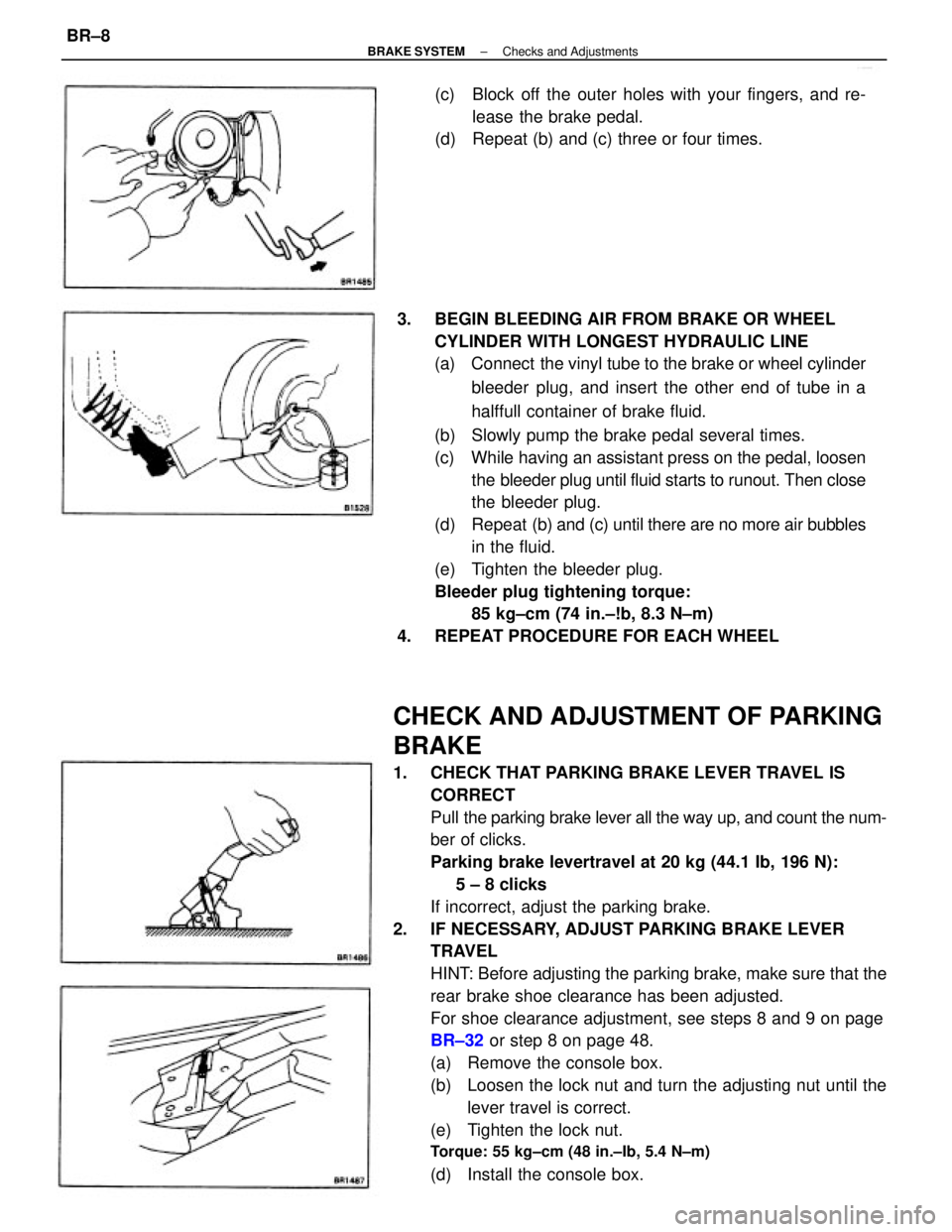

CHECK AND ADJUSTMENT OF PARKING

BRAKE

1. CHECK THAT PARKING BRAKE LEVER TRAVEL IS

CORRECT

Pull the parking brake lever all the way up, and count the num-

ber of clicks.

Parking brake levertravel at 20 kg (44.1 Ib, 196 N):

5 ± 8 clicks

If incorrect, adjust the parking brake.

2. IF NECESSARY, ADJUST PARKING BRAKE LEVER

TRAVEL

HINT: Before adjusting the parking brake, make sure that the

rear brake shoe clearance has been adjusted.

For shoe clearance adjustment, see steps 8 and 9 on page

BR±32 or step 8 on page 48.

(a) Remove the console box.

(b) Loosen the lock nut and turn the adjusting nut until the

lever travel is correct.

(e) Tighten the lock nut.

Torque: 55 kg±cm (48 in.±Ib, 5.4 N±m)

(d) Install the console box. 3. BEGIN BLEEDING AIR FROM BRAKE OR WHEEL

CYLINDER WITH LONGEST HYDRAULIC LINE

(a) Connect the vinyl tube to the brake or wheel cylinder

bleeder plug, and insert the other end of tube in a

halffull container of brake fluid.

(b) Slowly pump the brake pedal several times.

(c) While having an assistant press on the pedal, loosen

the bleeder plug until fluid starts to runout. Then close

the bleeder plug.

(d) Repeat (b) and (c) until there are no more air bubbles

in the fluid.

(e) Tighten the bleeder plug.

Bleeder plug tightening torque:

85 kg±cm (74 in.±!b, 8.3 N±m)

4. REPEAT PROCEDURE FOR EACH WHEEL(c) Block off the outer holes with your fingers, and re-

lease the brake pedal.

(d) Repeat (b) and (c) three or four times.

± BRAKE SYSTEMChecks and AdjustmentsBR±8

Page 860 of 2389

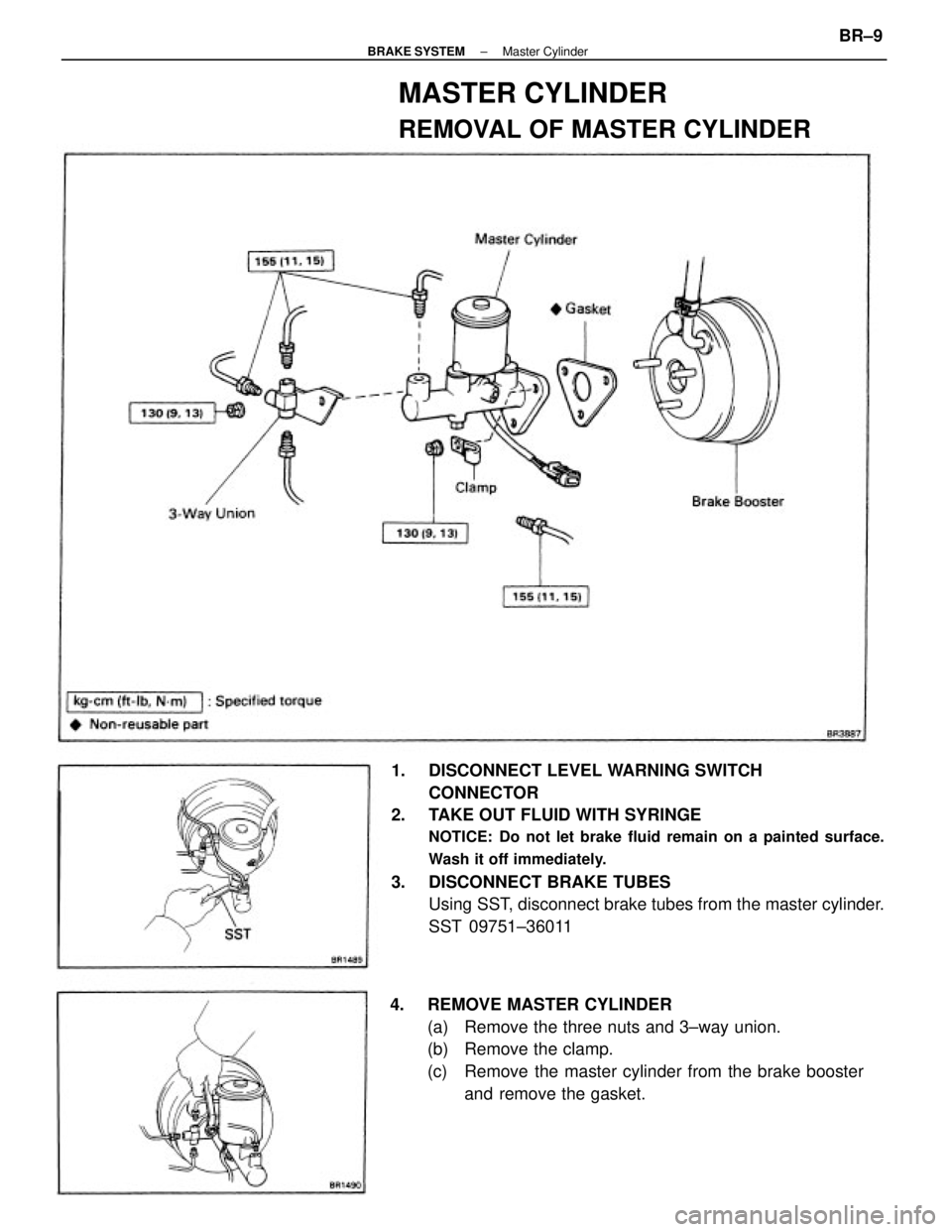

1. DISCONNECT LEVEL WARNING SWITCH

CONNECTOR

2. TAKE OUT FLUID WITH SYRINGE

NOTICE: Do not let brake fluid remain on a painted surface.

Wash it off immediately.

3. DISCONNECT BRAKE TUBES

Using SST, disconnect brake tubes from the master cylinder.

SST 09751±36011

4. REMOVE MASTER CYLINDER

(a) Remove the three nuts and 3±way union.

(b) Remove the clamp.

(c) Remove the master cylinder from the brake booster

and remove the gasket.

MASTER CYLINDER

REMOVAL OF MASTER CYLINDER

± BRAKE SYSTEMMaster CylinderBR±9