TOYOTA RAV4 1996 Service Repair Manual

Manufacturer: TOYOTA, Model Year: 1996, Model line: RAV4, Model: TOYOTA RAV4 1996Pages: 1632, PDF Size: 41.64 MB

Page 761 of 1632

13. On all models, remove front wheels. Drain transaxle fluid. On models with Anti-Lock Brake System

(ABS), remove bolt and pull ABS speed sensor from front of axle carrier.

14. On all models, remove cotter pin and retainer from end of axle shaft. Loosen axle shaft nut while

applying brakes. Remove axle shaft nut.

15. Remove nut, and separate tie rod from steering knuckle. Disconnect stabilizer bar link from lower control

arm. Remove ball joint-to-lower control arm bolts/nuts.

16. Using soft-face hammer, tap axle shaft from hub assembly. Pull steering knuckle outward and separate

axle shaft from hub assembly.

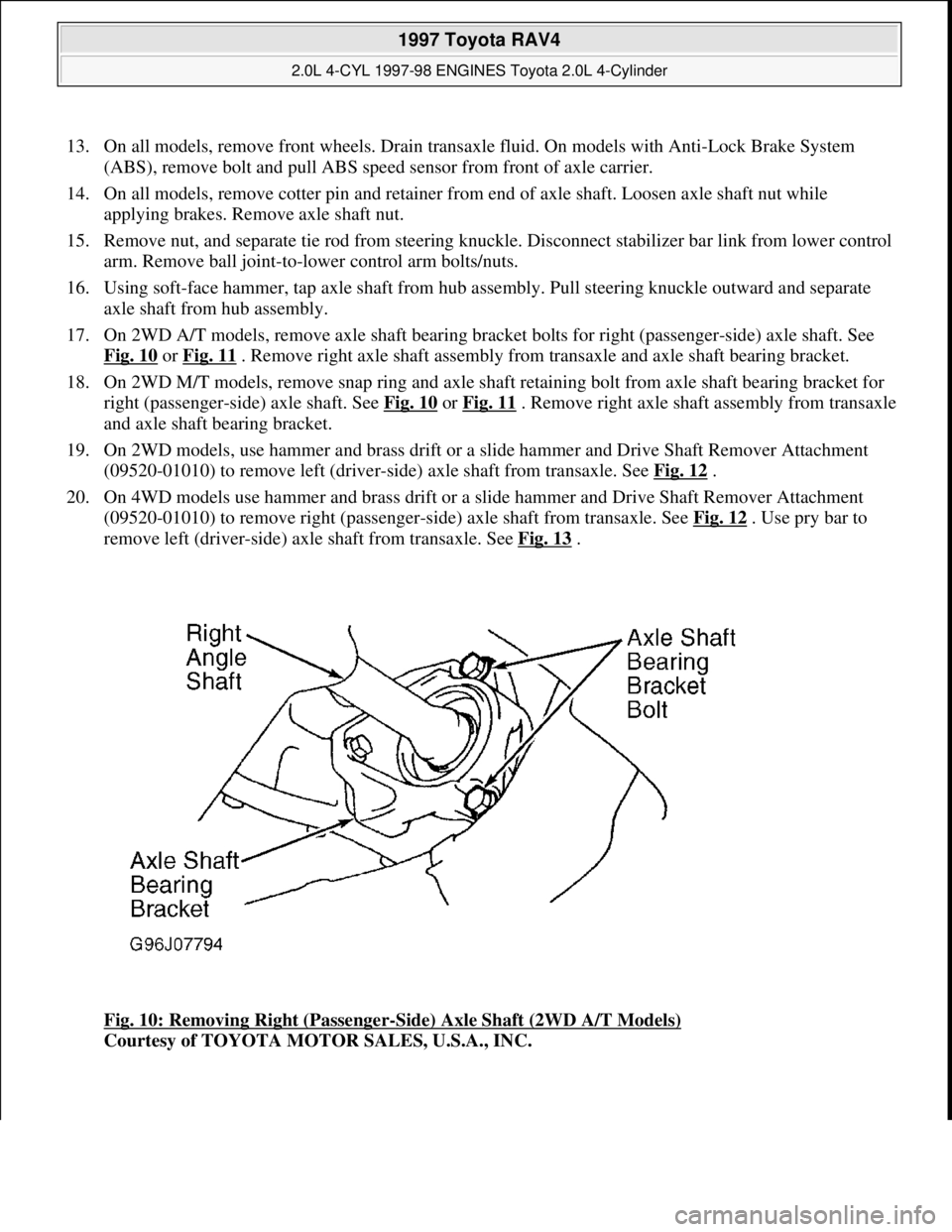

17. On 2WD A/T models, remove axle shaft bearing bracket bolts for right (passenger-side) axle shaft. See

Fig. 10

or Fig. 11 . Remove right axle shaft assembly from transaxle and axle shaft bearing bracket.

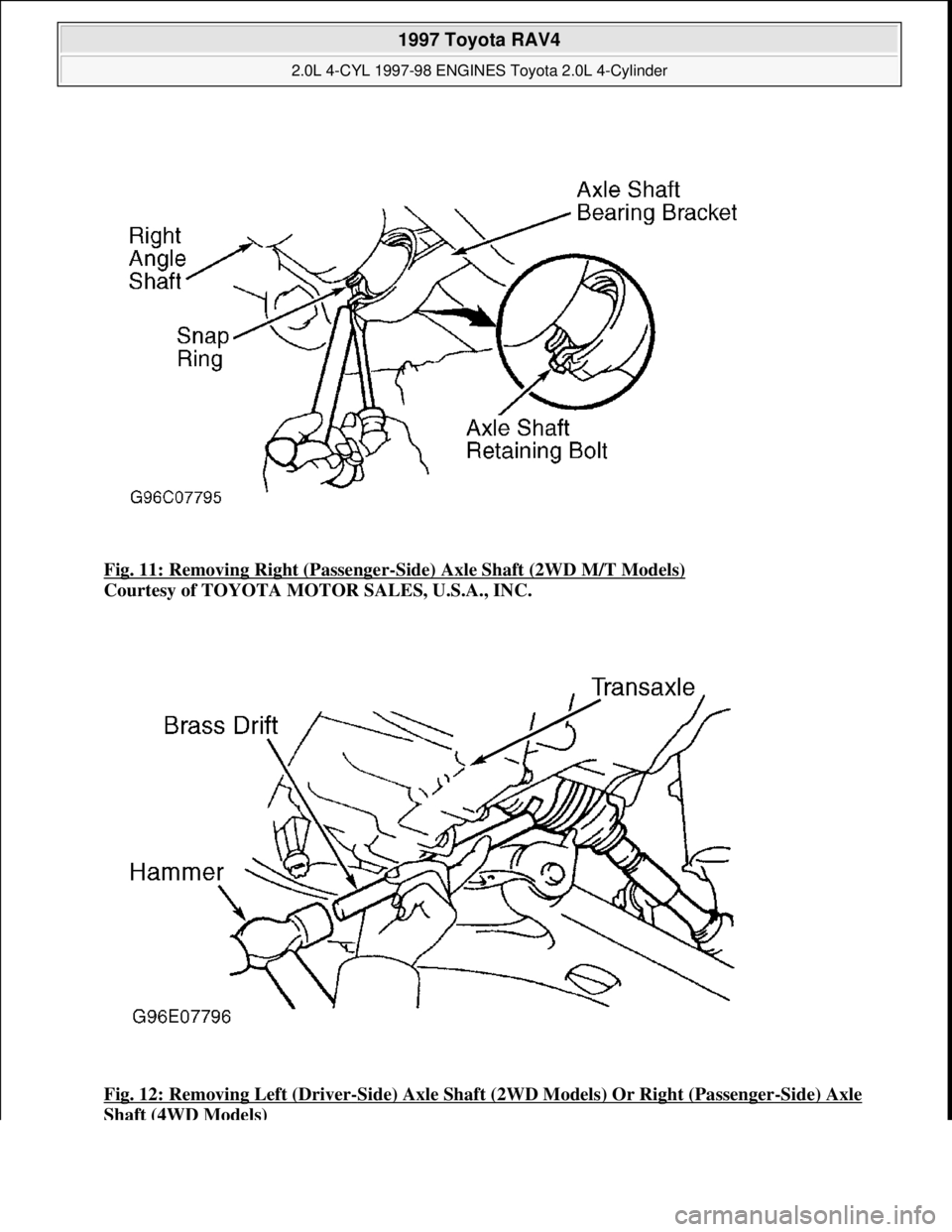

18. On 2WD M/T models, remove snap ring and axle shaft retaining bolt from axle shaft bearing bracket for

right (passenger-side) axle shaft. See Fig. 10

or Fig. 11. Remove right axle shaft assembly from transaxle

and axle shaft bearing bracket.

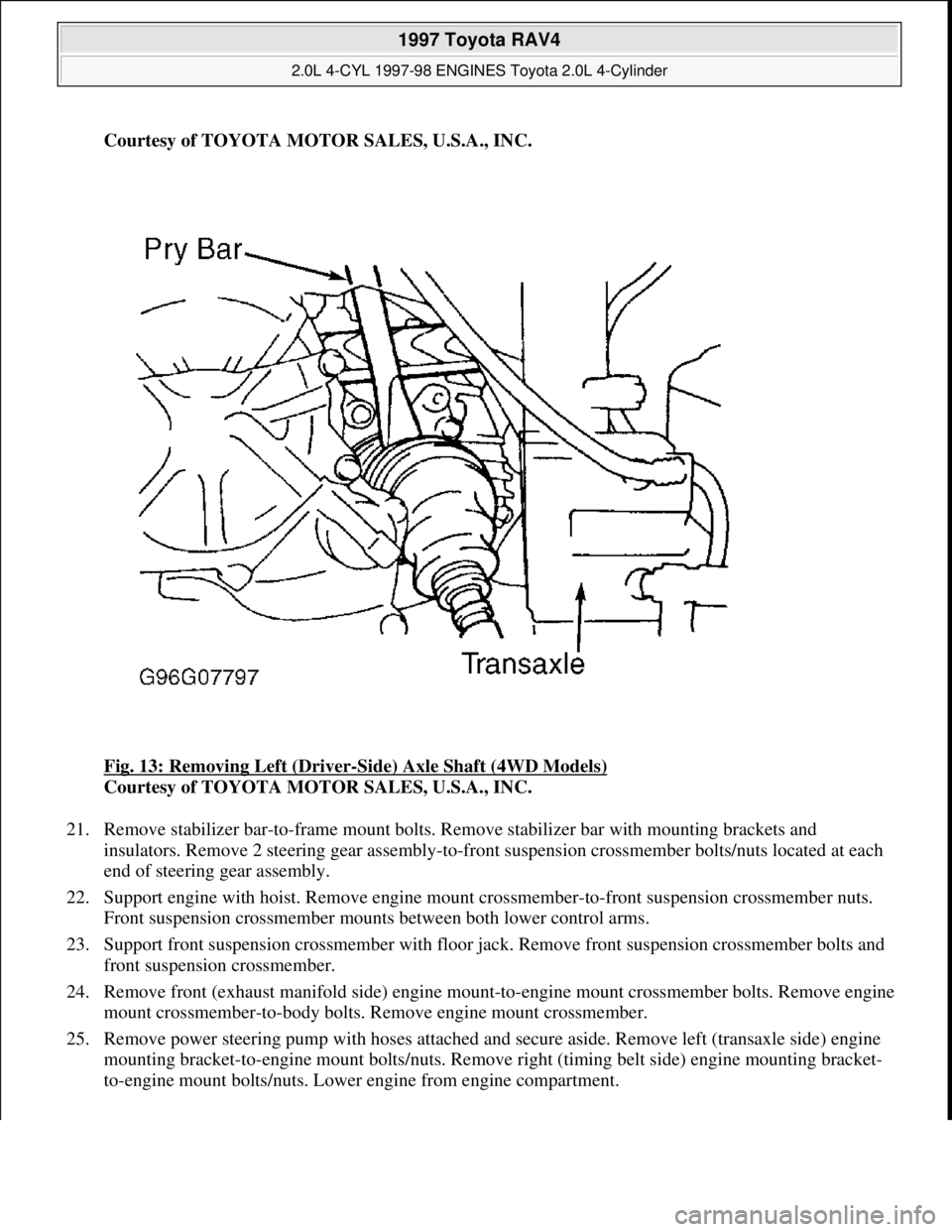

19. On 2WD models, use hammer and brass drift or a slide hammer and Drive Shaft Remover Attachment

(09520-01010) to remove left (driver-side) axle shaft from transaxle. See Fig. 12

.

20. On 4WD models use hammer and brass drift or a slide hammer and Drive Shaft Remover Attachment

(09520-01010) to remove right (passenger-side) axle shaft from transaxle. See Fig. 12

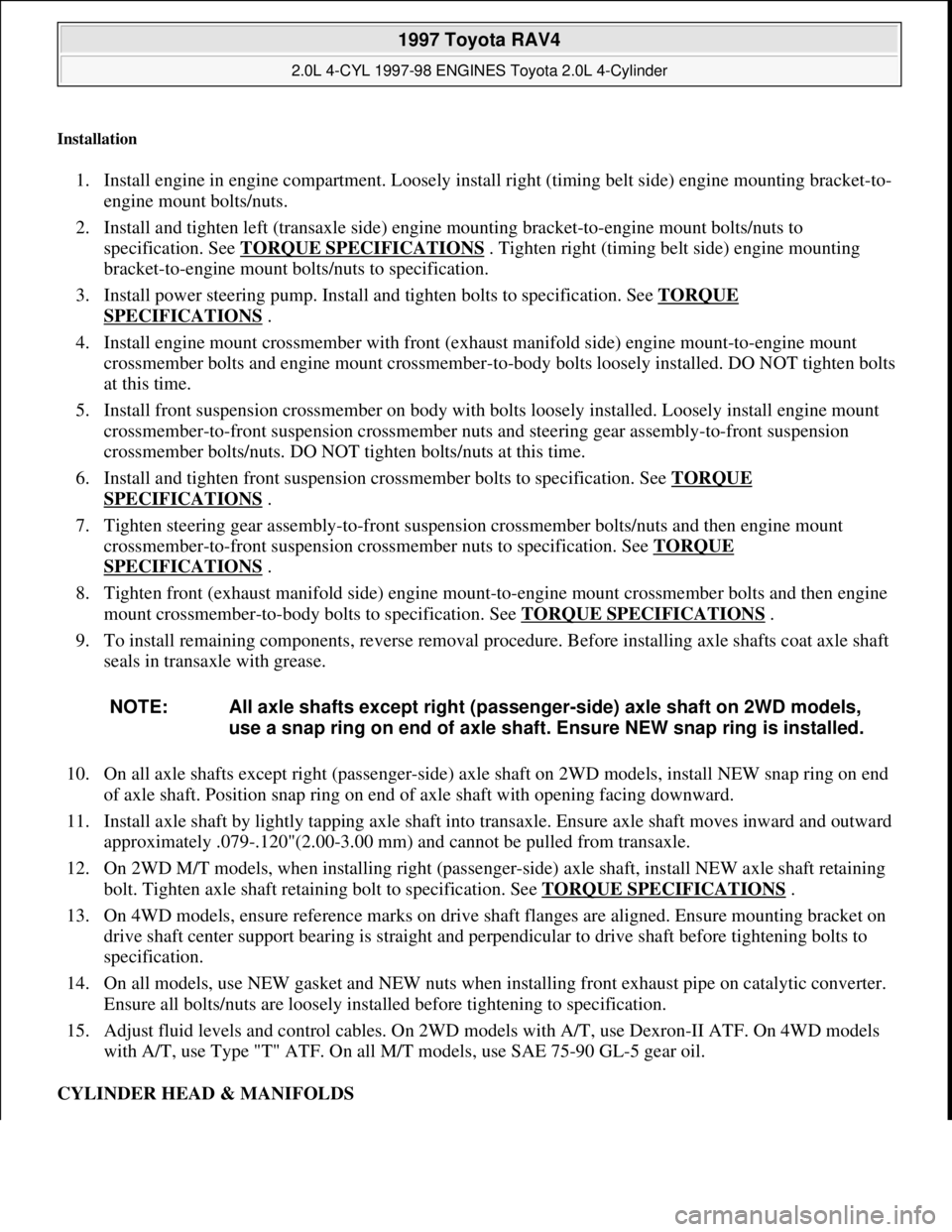

. Use pry bar to

remove left (driver-side) axle shaft from transaxle. See Fig. 13

.

Fig. 10: Removing Right (Passenger

-Side) Axle Shaft (2WD A/T Models)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

1997 Toyota RAV4

2.0L 4-CYL 1997-98 ENGINES Toyota 2.0L 4-Cylinder

Microsoft

Sunday, November 22, 2009 10:23:31 AMPage 13 © 2005 Mitchell Repair Information Company, LLC.

Page 762 of 1632

Fig. 11: Removing Right (Passenger-Side) Axle Shaft (2WD M/T Models)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Fig. 12: Removing Left (Driver

-Side) Axle Shaft (2WD Models) Or Right (Passenger-Side) Axle

Shaft (4WD Models)

1997 Toyota RAV4

2.0L 4-CYL 1997-98 ENGINES Toyota 2.0L 4-Cylinder

Microsoft

Sunday, November 22, 2009 10:23:31 AMPage 14 © 2005 Mitchell Repair Information Company, LLC.

Page 763 of 1632

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Fig. 13: Removing Left (Driver

-Side) Axle Shaft (4WD Models)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

21. Remove stabilizer bar-to-frame mount bolts. Remove stabilizer bar with mounting brackets and

insulators. Remove 2 steering gear assembly-to-front suspension crossmember bolts/nuts located at each

end of steering gear assembly.

22. Support engine with hoist. Remove engine mount crossmember-to-front suspension crossmember nuts.

Front suspension crossmember mounts between both lower control arms.

23. Support front suspension crossmember with floor jack. Remove front suspension crossmember bolts and

front suspension crossmember.

24. Remove front (exhaust manifold side) engine mount-to-engine mount crossmember bolts. Remove engine

mount crossmember-to-body bolts. Remove engine mount crossmember.

25. Remove power steering pump with hoses attached and secure aside. Remove left (transaxle side) engine

mounting bracket-to-engine mount bolts/nuts. Remove right (timing belt side) engine mounting bracket-

to-en

gine mount bolts/nuts. Lower engine from engine compartment.

1997 Toyota RAV4

2.0L 4-CYL 1997-98 ENGINES Toyota 2.0L 4-Cylinder

Microsoft

Sunday, November 22, 2009 10:23:31 AMPage 15 © 2005 Mitchell Repair Information Company, LLC.

Page 764 of 1632

Installation

1. Install engine in engine compartment. Loosely install right (timing belt side) engine mounting bracket-to-

engine mount bolts/nuts.

2. Install and tighten left (transaxle side) engine mounting bracket-to-engine mount bolts/nuts to

specification. See TORQUE SPECIFICATIONS

. Tighten right (timing belt side) engine mounting

bracket-to-engine mount bolts/nuts to specification.

3. Install power steering pump. Install and tighten bolts to specification. See TORQUE

SPECIFICATIONS .

4. Install engine mount crossmember with front (exhaust manifold side) engine mount-to-engine mount

crossmember bolts and engine mount crossmember-to-

body bolts loosely installed. DO NOT tighten bolts

at this time.

5. Install front suspension crossmember on body with bolts loosely installed. Loosely install engine mount

crossmember-to-front suspension crossmember nuts and steering gear assembly-to-front suspension

crossmember bolts/nuts. DO NOT tighten bolts/nuts at this time.

6. Install and tighten front suspension crossmember bolts to specification. See TORQUE

SPECIFICATIONS .

7. Tighten steering gear assembly-to-front suspension crossmember bolts/nuts and then engine mount

crossmember-to-front suspension crossmember nuts to specification. See TORQUE

SPECIFICATIONS .

8. Tighten front (exhaust manifold side) engine mount-to-engine mount crossmember bolts and then engine

mount crossmember-to-body bolts to specification. See TORQUE SPECIFICATIONS

.

9. To install remaining components, reverse removal procedure. Before installing axle shafts coat axle shaft

seals in transaxle with grease.

10. On all axle shafts except right (passenger-side) axle shaft on 2WD models, install NEW snap ring on end

of axle shaft. Position snap ring on end of axle shaft with opening facing downward.

11. Install axle shaft by lightly tapping axle shaft into transaxle. Ensure axle shaft moves inward and outward

approximately .079-.120"(2.00-3.00 mm) and cannot be pulled from transaxle.

12. On 2WD M/T models, when installing right (passenger-side) axle shaft, install NEW axle shaft retaining

bolt. Tighten axle shaft retaining bolt to specification. See TORQUE SPECIFICATIONS

.

13. On 4WD models, ensure reference marks on drive shaft flanges are aligned. Ensure mounting bracket on

drive shaft center support bearing is straight and perpendicular to drive shaft before tightening bolts to

specification.

14. On all models, use NEW gasket and NEW nuts when installing front exhaust pipe on catalytic converter.

Ensure all bolts/nuts are loosely installed before tightening to specification.

15. Adjust fluid levels and control cables. On 2WD models with A/T, use Dexron-II ATF. On 4WD models

with A/T, use Type "T" ATF. On all M/T models, use SAE 75-90 GL-5 gear oil.

CYLINDER HEAD & MANIFOLDS NOTE: All axle shafts except right (passenger-side) axle shaft on 2WD models,

use a snap ring on end of axle shaft. Ensure NEW snap ring is installed.

1997 Toyota RAV4

2.0L 4-CYL 1997-98 ENGINES Toyota 2.0L 4-Cylinder

Microsoft

Sunday, November 22, 2009 10:23:31 AMPage 16 © 2005 Mitchell Repair Information Company, LLC.

Page 765 of 1632

Removal

1. Release fuel pressure. See FUEL PRESSURE RELEASE . Drain cooling system. Raise and support

vehicle. Remove right lower engine cover.

2. Disconnect control cables at throttle body. Remove air cleaner assembly and air cleaner case. Remove

accessory drive belt and generator. On 1997 models, remove distributor with spark plug wires. On 1998

models, remove front exhaust pipe.

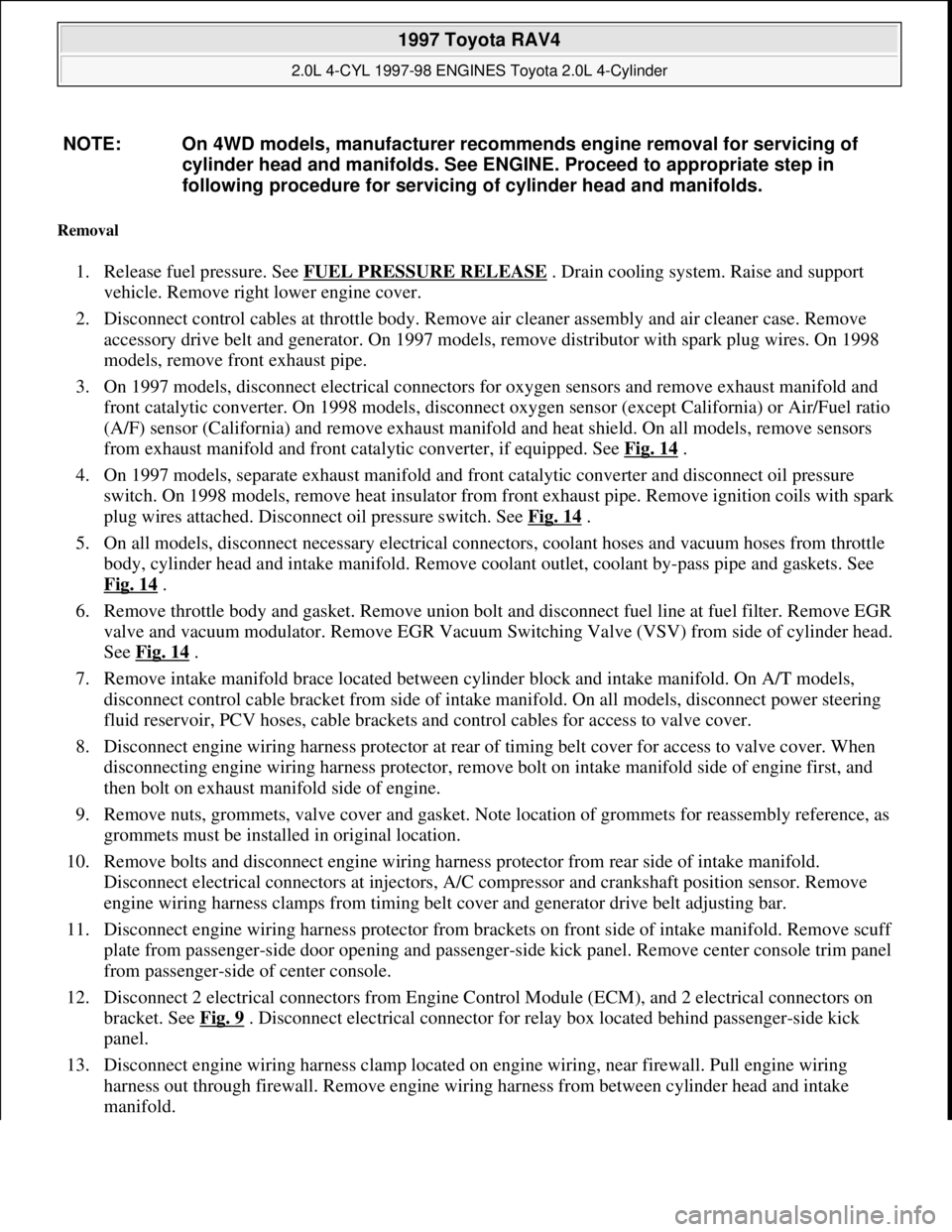

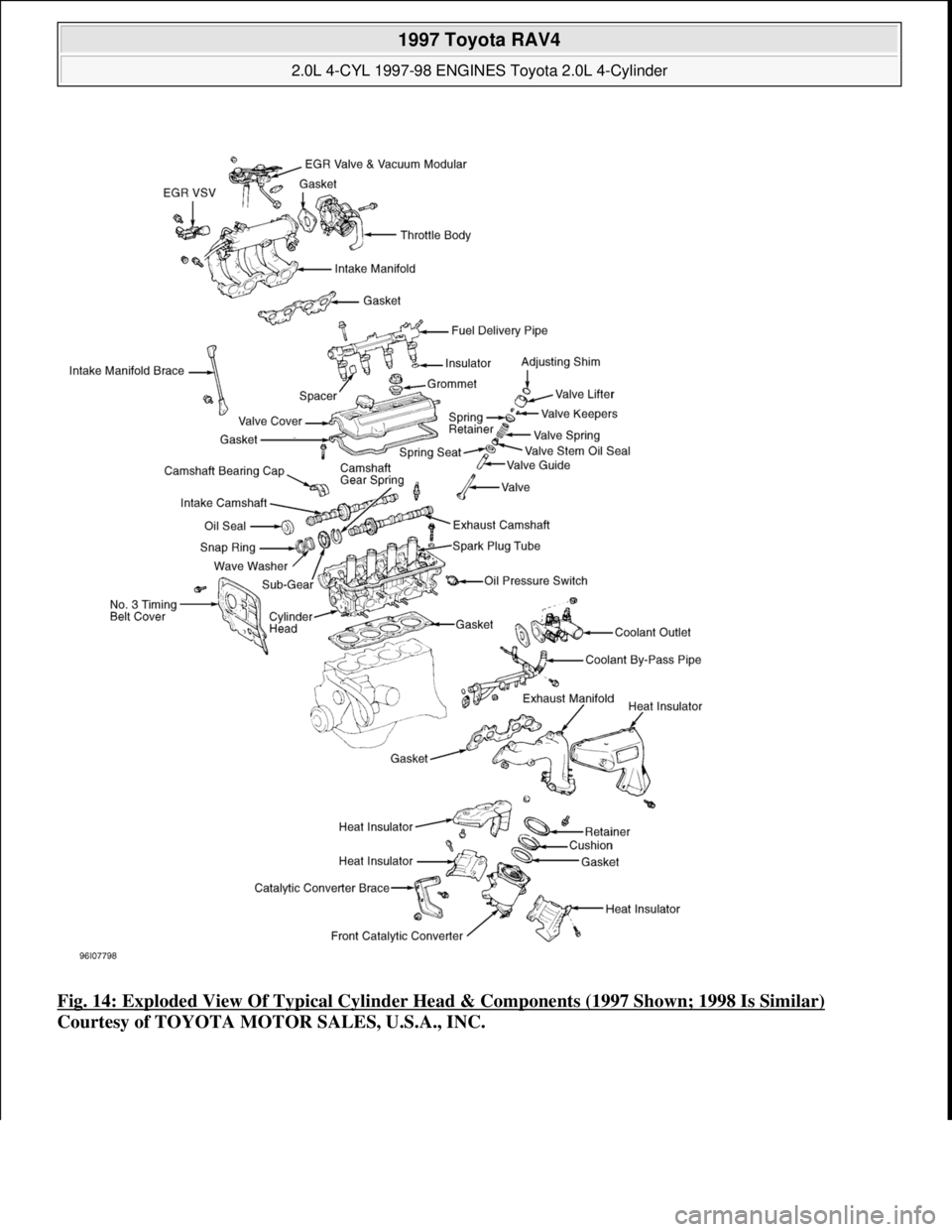

3. On 1997 models, disconnect electrical connectors for oxygen sensors and remove exhaust manifold and

front catalytic converter. On 1998 models, disconnect oxygen sensor (except California) or Air/Fuel ratio

(A/F) sensor (California) and remove exhaust manifold and heat shield. On all models, remove sensors

from exhaust manifold and front catalytic converter, if equipped. See Fig. 14

.

4. On 1997 models, separate exhaust manifold and front catalytic converter and disconnect oil pressure

switch. On 1998 models, remove heat insulator from front exhaust pipe. Remove ignition coils with spark

plug wires attached. Disconnect oil pressure switch. See Fig. 14

.

5. On all models, disconnect necessary electrical connectors, coolant hoses and vacuum hoses from throttle

body, cylinder head and intake manifold. Remove coolant outlet, coolant by-pass pipe and gaskets. See

Fig. 14

.

6. Remove throttle body and gasket. Remove union bolt and disconnect fuel line at fuel filter. Remove EGR

valve and vacuum modulator. Remove EGR Vacuum Switching Valve (VSV) from side of cylinder head.

See Fig. 14

.

7. Remove intake manifold brace located between cylinder block and intake manifold. On A/T models,

disconnect control cable bracket from side of intake manifold. On all models, disconnect power steering

fluid reservoir, PCV hoses, cable brackets and control cables for access to valve cover.

8. Disconnect engine wiring harness protector at rear of timing belt cover for access to valve cover. When

disconnecting engine wiring harness protector, remove bolt on intake manifold side of engine first, and

then bolt on exhaust manifold side of engine.

9. Remove nuts, grommets, valve cover and gasket. Note location of grommets for reassembly reference, as

grommets must be installed in original location.

10. Remove bolts and disconnect engine wiring harness protector from rear side of intake manifold.

Disconnect electrical connectors at injectors, A/C compressor and crankshaft position sensor. Remove

engine wiring harness clamps from timing belt cover and generator drive belt adjusting bar.

11. Disconnect engine wiring harness protector from brackets on front side of intake manifold. Remove scuff

plate from passenger-side door opening and passenger-side kick panel. Remove center console trim panel

from passenger-side of center console.

12. Disconnect 2 electrical connectors from Engine Control Module (ECM), and 2 electrical connectors on

bracket. See Fig. 9

. Disconnect electrical connector for relay box located behind passenger-side kick

panel.

13. Disconnect engine wiring harness clamp located on engine wiring, near firewall. Pull engine wiring

harness out through firewall. Remove engine wiring harness from between cylinder head and intake

manifold. NOTE: On 4WD models, manufacturer recommends engine removal for servicing of

cylinder head and manifolds. See ENGINE. Proceed to appropriate step in

following procedure for servicing of cylinder head and manifolds.

1997 Toyota RAV4

2.0L 4-CYL 1997-98 ENGINES Toyota 2.0L 4-Cylinder

Microsoft

Sunday, November 22, 2009 10:23:31 AMPage 17 © 2005 Mitchell Repair Information Company, LLC.

Page 766 of 1632

14. Remove timing belt from camshaft sprocket. Remove camshaft sprocket, No. 1 idler pulley and tension

spring. See TIMING BELT

. Remove No. 3 timing belt cover from cylinder head. See Fig. 14 . Remove

camshafts. See CAMSHAFTS

.

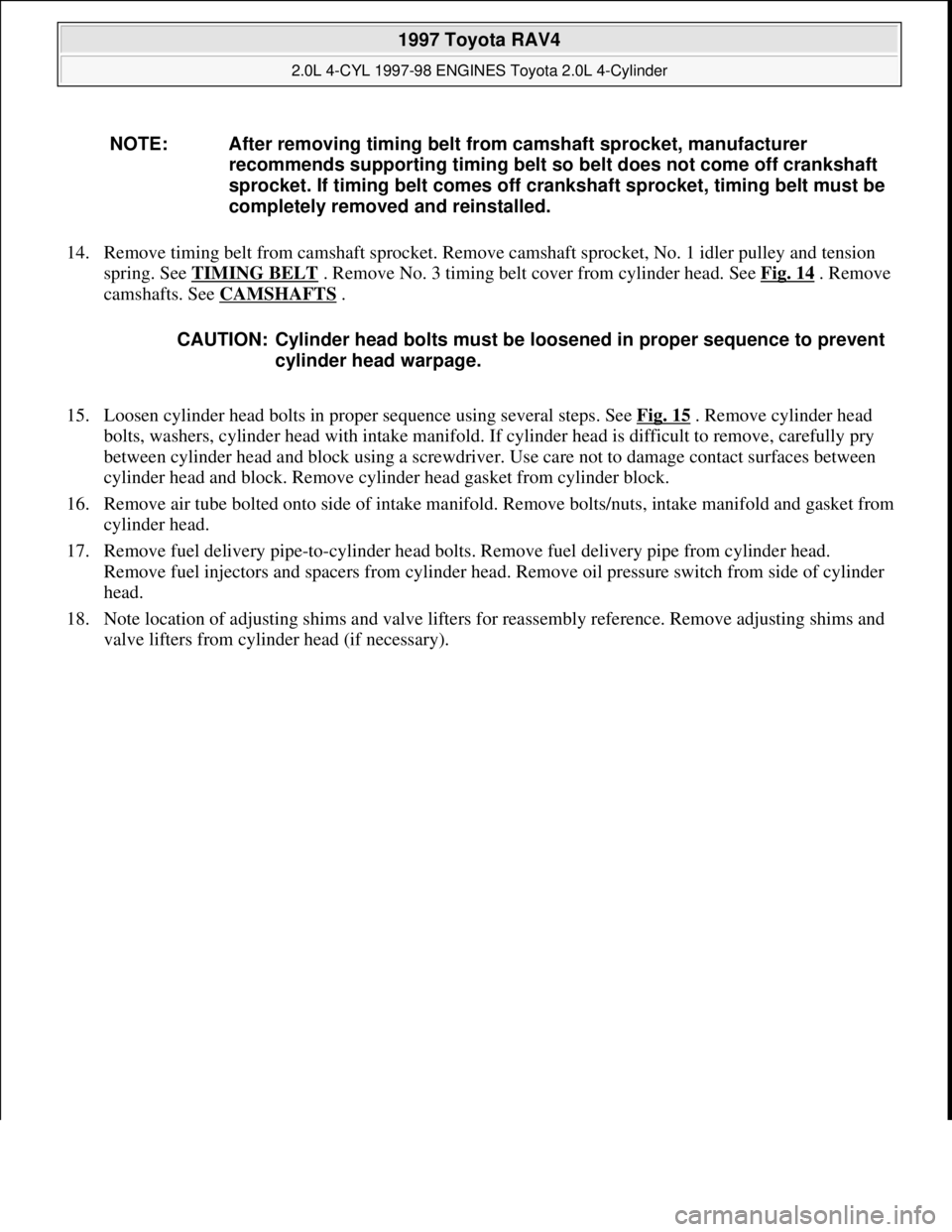

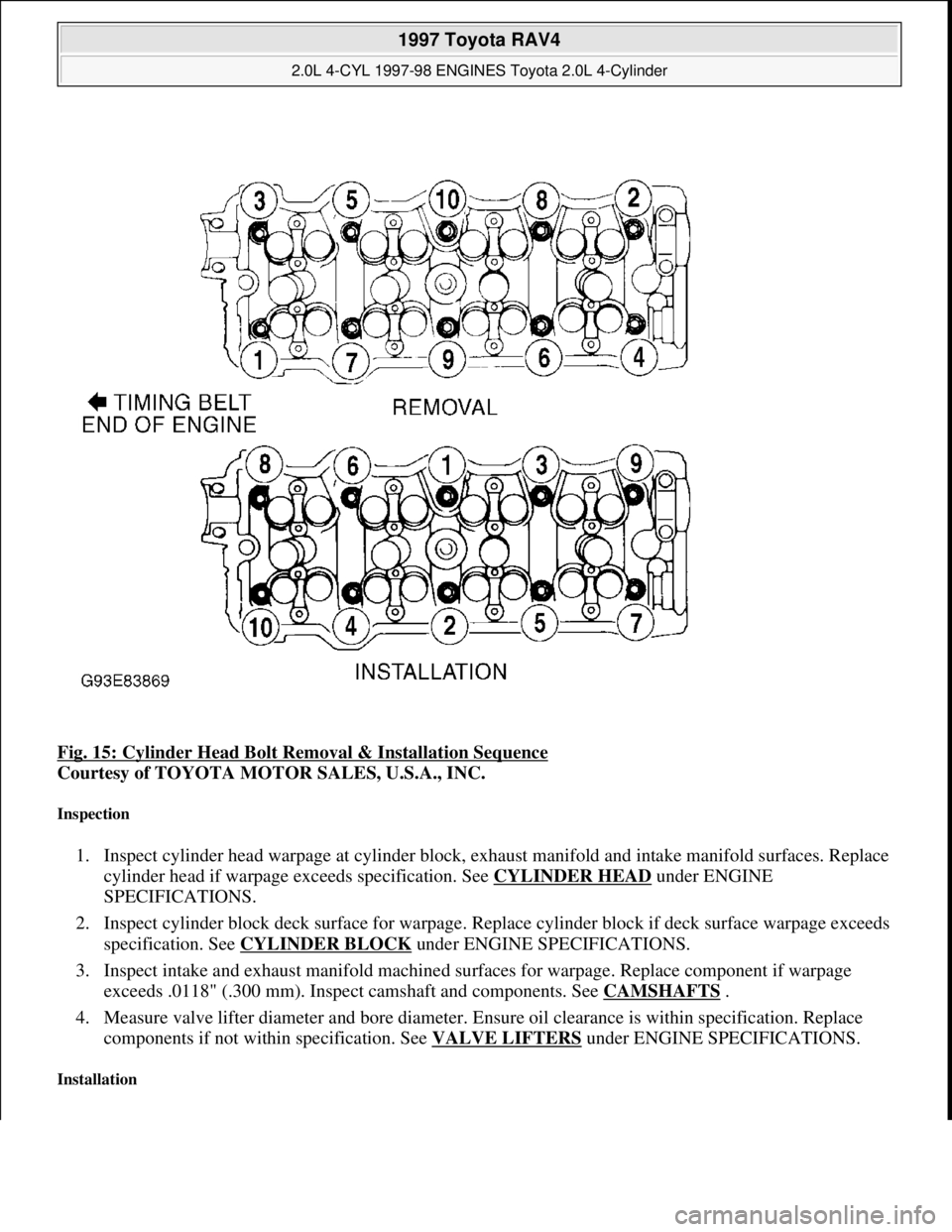

15. Loosen cylinder head bolts in proper sequence using several steps. See Fig. 15

. Remove cylinder head

bolts, washers, cylinder head with intake manifold. If cylinder head is difficult to remove, carefully pry

between cylinder head and block using a screwdriver. Use care not to damage contact surfaces between

cylinder head and block. Remove cylinder head gasket from cylinder block.

16. Remove air tube bolted onto side of intake manifold. Remove bolts/nuts, intake manifold and gasket from

cylinder head.

17. Remove fuel delivery pipe-to-cylinder head bolts. Remove fuel delivery pipe from cylinder head.

Remove fuel injectors and spacers from cylinder head. Remove oil pressure switch from side of cylinder

head.

18. Note location of adjusting shims and valve lifters for reassembly reference. Remove adjusting shims and

valve lifters from c

ylinder head (if necessary). NOTE: After removing timing belt from camshaft sprocket, manufacturer

recommends supporting timing belt so belt does not come off crankshaft

sprocket. If timing belt comes off crankshaft sprocket, timing belt must be

completely removed and reinstalled.

CAUTION: Cylinder head bolts must be loosened in proper sequence to prevent

cylinder head warpage.

1997 Toyota RAV4

2.0L 4-CYL 1997-98 ENGINES Toyota 2.0L 4-Cylinder

Microsoft

Sunday, November 22, 2009 10:23:31 AMPage 18 © 2005 Mitchell Repair Information Company, LLC.

Page 767 of 1632

Fig. 14: Exploded View Of Typical Cylinder Head & Components (1997 Shown; 1998 Is Similar)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

1997 Toyota RAV4

2.0L 4-CYL 1997-98 ENGINES Toyota 2.0L 4-Cylinder

Microsoft

Sunday, November 22, 2009 10:23:31 AMPage 19 © 2005 Mitchell Repair Information Company, LLC.

Page 768 of 1632

Fig. 15: Cylinder Head Bolt Removal & Installation Sequence

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Inspection

1. Inspect cylinder head warpage at cylinder block, exhaust manifold and intake manifold surfaces. Replace

cylinder head if warpage exceeds specification. See CYLINDER HEAD

under ENGINE

SPECIFICATIONS.

2. Inspect cylinder block deck surface for warpage. Replace cylinder block if deck surface warpage exceeds

specification. See CYLINDER BLOCK

under ENGINE SPECIFICATIONS.

3. Inspect intake and exhaust manifold machined surfaces for warpage. Replace component if warpage

exceeds .0118" (.300 mm). Inspect camshaft and components. See CAMSHAFTS

.

4. Measure valve lifter diameter and bore diameter. Ensure oil clearance is within specification. Replace

components if not within specification. See VALVE LIFTERS

under ENGINE SPECIFICATIONS.

Installation

1997 Toyota RAV4

2.0L 4-CYL 1997-98 ENGINES Toyota 2.0L 4-Cylinder

Microsoft

Sunday, November 22, 2009 10:23:31 AMPage 20 © 2005 Mitchell Repair Information Company, LLC.

Page 769 of 1632

1. Install NEW insulator at bottom of fuel injector and NEW grommet on top of fuel injector. Coat NEW

"O" rings with gasoline and install on fuel injector.

2. Install 2 spacers on cylinder head. Install fuel injectors on cylinder head. Install fuel delivery pipe on fuel

injectors. Using twisting motion, push fuel injectors into fuel delivery pipe.

3. Install and slightly tighten fuel delivery pipe-to-cylinder head bolts. Ensure all fuel injectors rotate

smoothly. If fuel injector fails to rotate smoothly, check for improperly installed or damaged "O" rings.

4. Position electrical connector on fuel injector facing toward top of engine. Tighten fuel delivery pipe-to-

cylinder head bolts to specification. See TORQUE SPECIFICATIONS

.

5. Using NEW gasket, install intake manifold. Install and tighten bolts/nuts to specification. See TORQUE

SPECIFICATIONS . Install air tube on side of intake manifold.

6. Install adjusting shims and valve lifters in original location on cylinder head (if removed). Ensure valve

lifters rotate smoothly in cylinder head.

7. Install NEW gasket for cylinder head on cylinder block. Ensure all holes in gasket align with holes in

cylinder block.

8. Install cylinder head. Coat threads and bolt-to-cylinder contact surfaces on cylinder head bolts with

engine oil. Install and tighten cylinder head bolts to specification in sequence. See Fig. 15

. See

TORQUE SPECIFICATIONS

.

9. Install camshafts using proper procedure. See CAMSHAFTS. Install No. 3 timing belt cover. Install and

tighten bolts to specification. See TORQUE SPECIFICATIONS

.

10. To install remaining components, reverse removal procedure. If camshaft or cylinder head components

are serviced, adjust valve clearance. See VALVE CLEARANCE ADJUSTMENT

under

ADJUSTMENTS.

11. Before installing gasket and valve cover, apply sealant at front and rear valve cover areas on cylinder

head. See Fig. 4

. Using NEW gasket, install valve cover.

12. Install grommets in original location with marking on grommet aligned in designated area. See Fig. 5

.

Install and tighten valve cover nuts to specification. See TORQUE SPECIFICATIONS

.

13. Install NEW throttle body gasket with protruding area on gasket facing toward bottom of throttle body.

On throttle bodies using 4 mounting bolts, ensure longer bolts are installed in 2 lower bolt holes.

14. Install NEW "O" ring on coolant by-pass pipe and NEW gasket on water pump cover before installing

coolant by-pass pipe. Apply soapy water solution on "O" ring before installing coolant by-pass pipe. Use

NEW gasket when installing catalytic converter on exhaust manifold.

15. Use NEW gasket and NEW nuts when installing front exhaust pipe on front catalytic converter. Ensure

all bolts/nuts are loosely installed on front exhaust pipe before tightening to specification. See TORQUE

SPECIFICATIONS .

16. Install NEW "O" ring on distributor. Coat "O" ring with engine oil. Rotate crankshaft clockwise, as

viewed from timing belt end of engine, so cylinder No. 1 is at TDC on compression stroke and timing

mark on crankshaft pulley aligns with "0" mark on timing belt cover. Cylinder No. 1 is front cylinder at

timing belt end of engine.

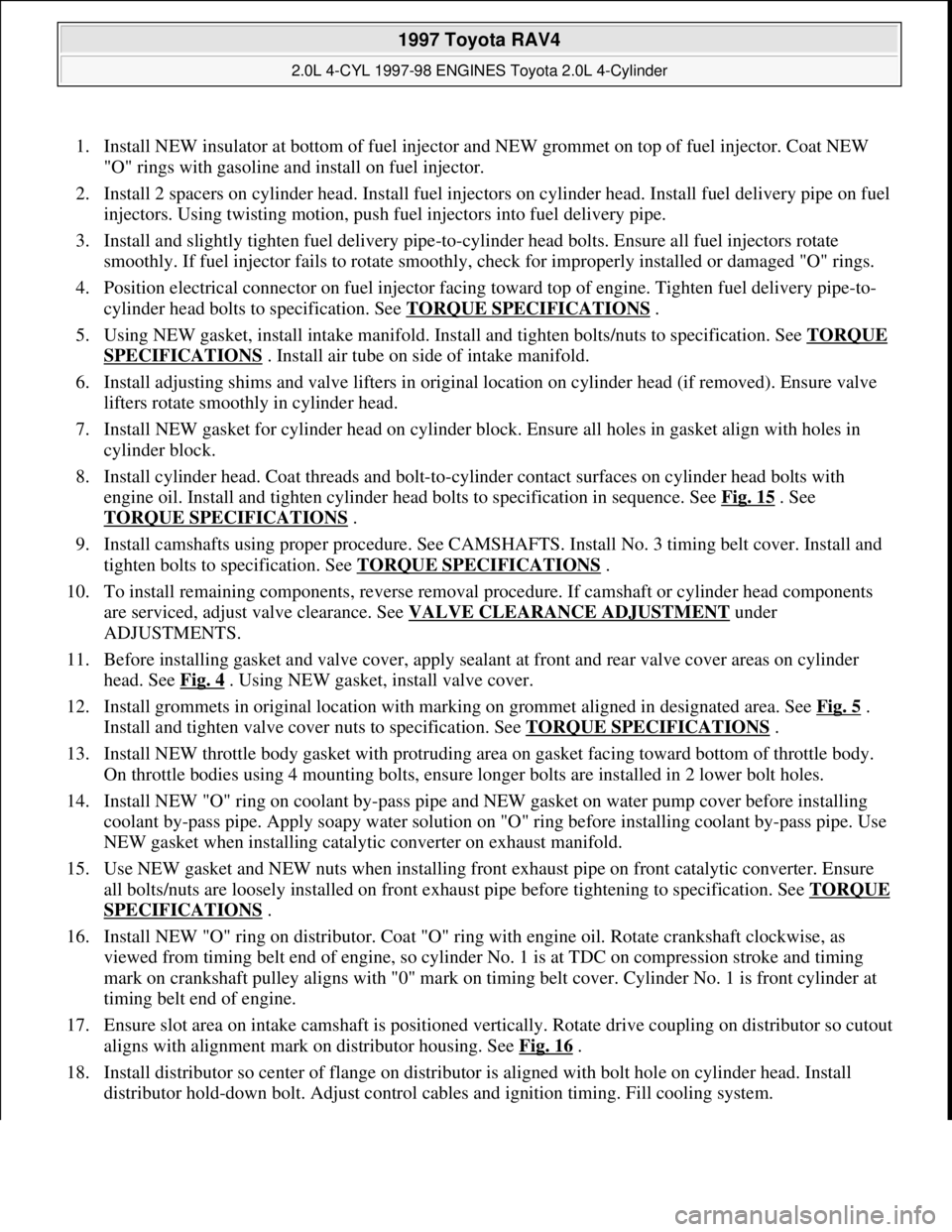

17. Ensure slot area on intake camshaft is positioned vertically. Rotate drive coupling on distributor so cutout

aligns with alignment mark on distributor housing. See Fig. 16

.

18. Install distributor so center of flange on distributor is aligned with bolt hole on cylinder head. Install

distributor hol

d-down bolt. Adjust control cables and ignition timing. Fill cooling system.

1997 Toyota RAV4

2.0L 4-CYL 1997-98 ENGINES Toyota 2.0L 4-Cylinder

Microsoft

Sunday, November 22, 2009 10:23:31 AMPage 21 © 2005 Mitchell Repair Information Company, LLC.

Page 770 of 1632

Fig. 16: Installing Distributor (1997)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

CRANKSHAFT FRONT SEAL

Removal & Installation (Oil Pump Installed)

1. Remove timing belt and crankshaft sprocket. See TIMING BELT. Using a knife, cut lip from seal. Pry

seal from oil pump housing. DO NOT damage sealing surfaces.

2. To install, apply grease to lip of NEW seal. Using hammer and Seal Installer (SST 09226-10010), install

seal until seal surface is even with oil pump housing. To install remaining components, reverse removal

procedure.

Removal & Installation (Oil Pump Removed)

Using hammer and drift, remove seal from oil pump housing. To install, use hammer and Seal Installer (SST

09226-10010). Install seal until seal surface is even with oil pump housing. Apply grease to lip of NEW seal.

TIMING BELT

CAUTION: If reusing timing belt, mark direction of timing belt rotation and place

reference mark on timing belt at camshaft sprocket for reassembly

reference. Also place reference mark on timing belt at upper edge of No. 1

timing belt cover. DO NOT bend, twist or turn timing belt inside out. DO

NOT expose timing to oil, water or steam.

1997 Toyota RAV4

2.0L 4-CYL 1997-98 ENGINES Toyota 2.0L 4-Cylinder

Microsoft

Sunday, November 22, 2009 10:23:31 AMPage 22 © 2005 Mitchell Repair Information Company, LLC.