TOYOTA RAV4 1996 Service Repair Manual

Manufacturer: TOYOTA, Model Year: 1996, Model line: RAV4, Model: TOYOTA RAV4 1996Pages: 1632, PDF Size: 41.64 MB

Page 771 of 1632

Removal

1. Disconnect negative battery cable. Remove power steering fluid reservoir with mounting bracket.

Remove accessory drive belts. Remove generator and generator mounting bracket. Remove wiring

brackets for access to timing belt covers.

2. On models with Anti-Lock Brake System (ABS), disconnect electrical connectors and brake lines from

ABS actuator. ABS actuator is located in front of passenger-side strut tower. Remove ABS actuator

mounting bracket-to-body bolts/nuts. Remove ABS actuator with mounting bracket.

3. On all models, raise and support vehicle. Remove passenger-side lower engine cover. Remove passenger-

side front wheel.

4. Using floor jack, slightly raise engine to remove weight from right (timing belt side) engine mount at

timing belt cover. Remove right (timing belt side) engine mount from body and mounting bracket on

cylinder block for access to timing belt covers.

5. Remove spark plugs. Remove crankshaft pulley bolt. Using puller, remove crankshaft pulley. Remove

right (timing belt side) engine mounting bracket from front of cylinder block.

6. Disconnect engine wiring harness protector from rear of No. 2 timing belt cover. When disconnecting

engine wiring harness protector, remove bolt on intake manifold side of engine first and then bolt on

exhaust manifold side of engine.

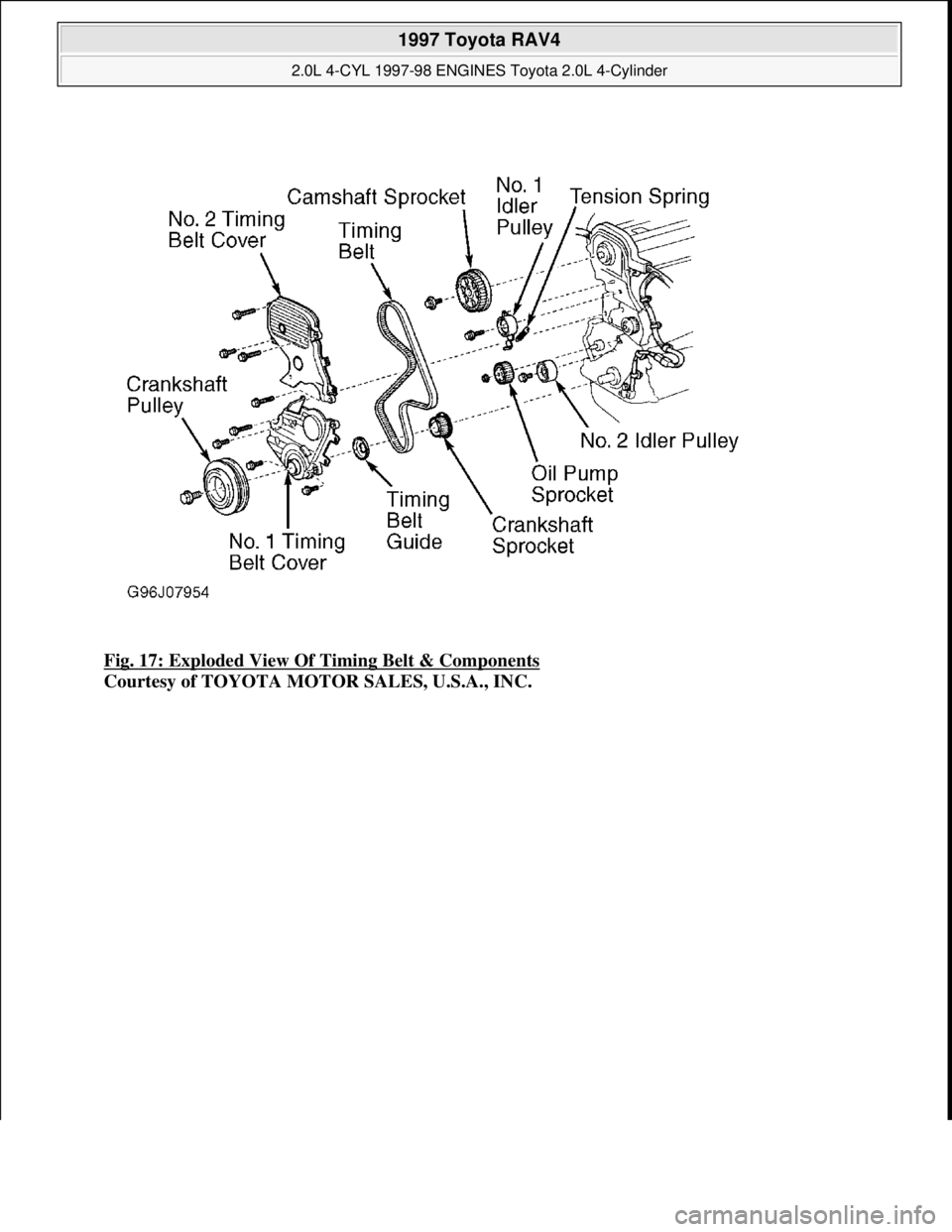

7. Remove No. 2 timing belt cover. See Fig. 17

. Install crankshaft pulley on crankshaft. Temporarily install

crankshaft pulley bolt.

8. Rotate crankshaft clockwise, viewed from timing belt end of engine, so cylinder No. 1 is at TDC on

compression stroke and timing mark on crankshaft pulley aligns with "0" mark on timing belt cover.

Cylinder No. 1 is front cylinder at timing belt end of engine.

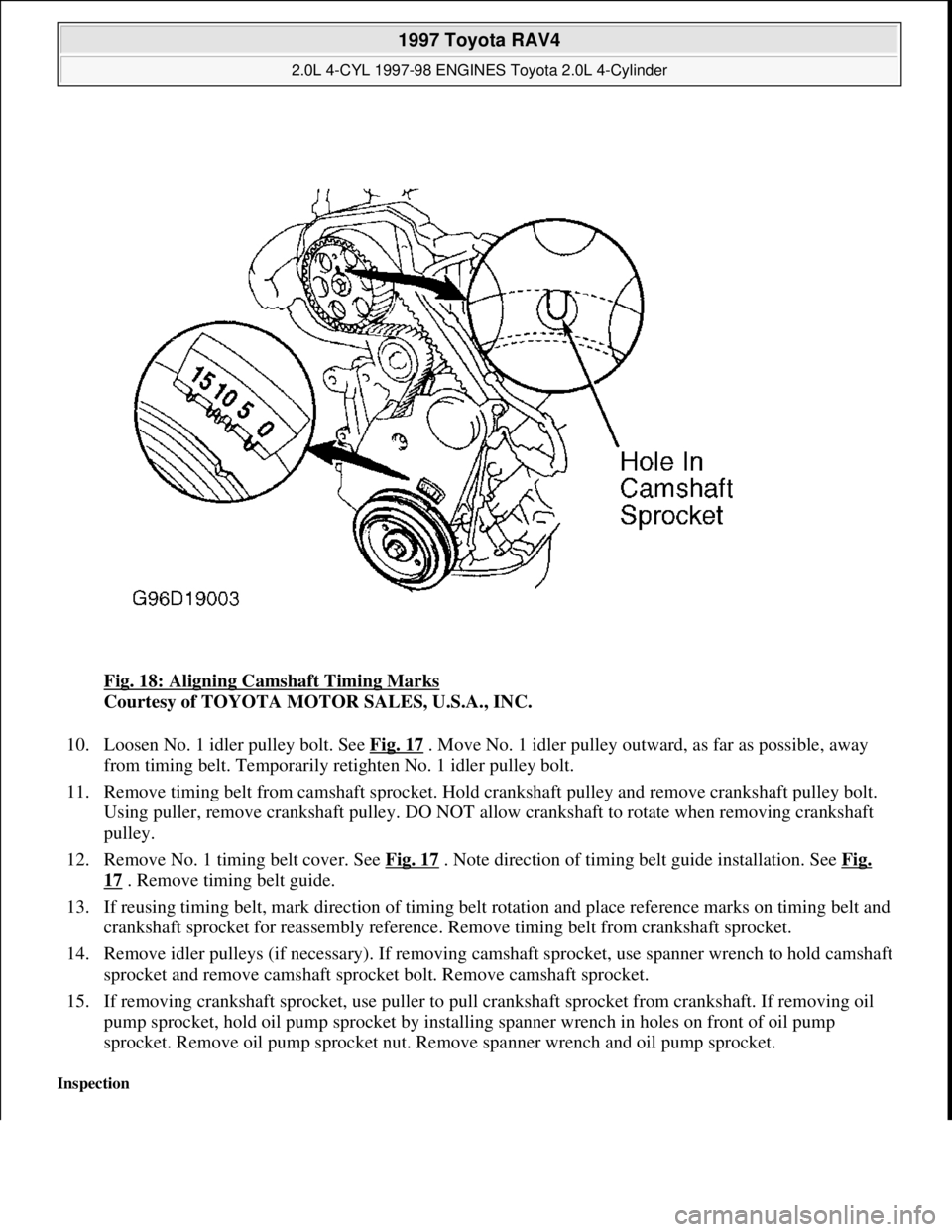

9. Ensure hole in camshaft sprocket aligns with alignment mark on camshaft bearing cap. See Fig. 18

. If

hole in camshaft sprocket is not aligned with alignment mark, rotate crankshaft clockwise one full

revolution.

1997 Toyota RAV4

2.0L 4-CYL 1997-98 ENGINES Toyota 2.0L 4-Cylinder

Microsoft

Sunday, November 22, 2009 10:23:31 AMPage 23 © 2005 Mitchell Repair Information Company, LLC.

Page 772 of 1632

Fig. 17: Exploded View Of Timing Belt & Components

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

1997 Toyota RAV4

2.0L 4-CYL 1997-98 ENGINES Toyota 2.0L 4-Cylinder

Microsoft

Sunday, November 22, 2009 10:23:31 AMPage 24 © 2005 Mitchell Repair Information Company, LLC.

Page 773 of 1632

Fig. 18: Aligning Camshaft Timing Marks

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

10. Loosen No. 1 idler pulley bolt. See Fig. 17

. Move No. 1 idler pulley outward, as far as possible, away

from timing belt. Temporarily retighten No. 1 idler pulley bolt.

11. Remove timing belt from camshaft sprocket. Hold crankshaft pulley and remove crankshaft pulley bolt.

Using puller, remove crankshaft pulley. DO NOT allow crankshaft to rotate when removing crankshaft

pulley.

12. Remove No. 1 timing belt cover. See Fig. 17

. Note direction of timing belt guide installation. See Fig.

17 . Remove timing belt guide.

13. If reusing timing belt, mark direction of timing belt rotation and place reference marks on timing belt and

crankshaft sprocket for reassembly reference. Remove timing belt from crankshaft sprocket.

14. Remove idler pulleys (if necessary). If removing camshaft sprocket, use spanner wrench to hold camshaft

sprocket and remove camshaft sprocket bolt. Remove camshaft sprocket.

15. If removing crankshaft sprocket, use puller to pull crankshaft sprocket from crankshaft. If removing oil

pump sprocket, hold oil pump sprocket by installing spanner wrench in holes on front of oil pump

sprocket. Remove oil pump sprocket nut. Remove spanner wrench and oil pump sprocket.

Inspection

1997 Toyota RAV4

2.0L 4-CYL 1997-98 ENGINES Toyota 2.0L 4-Cylinder

Microsoft

Sunday, November 22, 2009 10:23:31 AMPage 25 © 2005 Mitchell Repair Information Company, LLC.

Page 774 of 1632

1. Inspect timing belt for damaged teeth, cracking or oil contamination. Ensure idler pulleys rotate freely.

Replace components if damaged or worn.

2. Ensure free length of tension spring is within specification. See TENSION SPRING

SPECIFICATIONS . Measure tension required to extend tension spring to specified installed length.

Replace tension spring if tension is not within specification. See TENSION SPRING

SPECIFICATIONS .

TENSION SPRING SPECIFICATIONS

Installation

1. If installing oil pump sprocket, align cutout areas on oil pump sprocket with areas on oil pump shaft.

Install oil pump sprocket. Install and tighten oil pump sprocket nut to specification while holding oil

pump sprocket with spanner wrench. See TORQUE SPECIFICATIONS

.

2. If installing crankshaft sprocket, align crankshaft sprocket with key in crankshaft. Install crankshaft

sprocket with flange toward cylinder block. See Fig. 17

.

3. Install No. 2 idler pulley (if removed). Install and tighten bolt to specification. See TORQUE

SPECIFICATIONS . Ensure idler pulley is clean and rotates smoothly.

4. Install No. 1 idler pulley and tension spring (if removed). DO NOT tighten bolt at this time. Ensure pivot

hole on No. 1 idler pulley mounting flange engages with pin on front of cylinder block.

5. Move idler pulley away from timing belt area as far as possible. Temporarily tighten No. 1 idler pulley

bolt. Ensure idler pulley is clean and rotates smoothly.

6. If installing camshaft sprocket, align pin groove in camshaft sprocket with pin in camshaft. Install

camshaft sprocket. Install and tighten camshaft sprocket bolt to specification. See TORQUE

SPECIFICATIONS . Using crankshaft pulley bolt, rotate crankshaft so key on crankshaft is at 12

o'clock position.

7. Ensure all sprockets and idler pulleys are clean. Install timing belt on crankshaft sprocket, oil pump

sprocket, water pump sprocket,No. 1 idler pulley and then No. 2 idler pulley.

8. Install timing belt guide with cupped side away from crankshaft sprocket and flat side toward timing belt.

Install No. 1 timing belt cover.

ApplicationSpecification

Free Length

19971.811" (46.00 mm)

19981.654" (42.00 mm)

Tension At Spring Installed Length (1)

19975.0-6.1 lbs. (2.27-2.77 kg)

19987.0-8.5 lbs. (3.18-3.86 kg)

(1)Installed length of spring is 1.988" (50.5 mm).

CAUTION: If reusing timing belt, ensure reference mark on timing belt aligns

with reference mark placed on crankshaft sprocket and timing belt is

installed in original direction of rotation.

1997 Toyota RAV4

2.0L 4-CYL 1997-98 ENGINES Toyota 2.0L 4-Cylinder

Microsoft

Sunday, November 22, 2009 10:23:31 AMPage 26 © 2005 Mitchell Repair Information Company, LLC.

Page 775 of 1632

9. Remove crankshaft pulley bolt. Align crankshaft pulley key groove with key in crankshaft. Install

crankshaft pulley. Temporarily install and tighten crankshaft pulley bolt.

10. Rotate camshaft and align hole in camshaft sprocket with alignment mark on camshaft bearing cap. See

Fig. 18

.

11. If using NEW timing belt, go to step 16). If reusing timing belt, ensure reference mark placed on timing

belt aligns with upper edge of No. 1 timing belt cover when timing mark on crankshaft pulley aligns with

"0" mark on No. 1 timing belt cover. If reference mark is aligned, proceed to step 16).

12. If reference mark is below surface of No. 1 timing belt cover, pull upward on water pump side of timing

belt while rotating crankshaft pulley counterclockwise. Align reference mark with surface of No. 1 timing

belt cover.

13. Pull upward on water pump side of timing belt. Rotate crankshaft pulley clockwise so timing mark on

crankshaft pulley aligns with "0" mark on No. 1 timing belt cover.

14. If reference mark is above surface of No. 1 timing belt cover, pull upward on No. 1 idler pulley side of

timing belt while rotating crankshaft pulley clockwise. Align reference mark with surface of No. 1 timing

belt cover.

15. Pull upward on No. 1 idler pulley side of timing belt. Rotate crankshaft pulley counterclockwise so timing

mark on crankshaft pulley aligns with "0" mark on No. 1 timing belt cover.

16. Install timing belt on camshaft sprocket. If reusing timing belt, ensure reference mark on timing belt

aligns with reference mark placed on camshaft sprocket. Ensure tension exists on timing belt between

crankshaft and camshaft sprockets.

17. Loosen No. 1 idler pulley bolt 1/2 turn. Rotate crankshaft pulley 2 full revolutions clockwise from TDC

to TDC. DO NOT rotate crankshaft counterclockwise.

18. Ensure timing mark on crankshaft pulley aligns with "0" mark on No. 1 timing belt cover and hole in

camshaft sprocket aligns with alignment mark on camshaft bearing cap. See Fig. 18

. If timing marks are

not aligned, remove timing belt and reinstall.

19. Rotate crankshaft clockwise 1 7/8 revolutions and align crankshaft pulley "0" mark with 45-degree

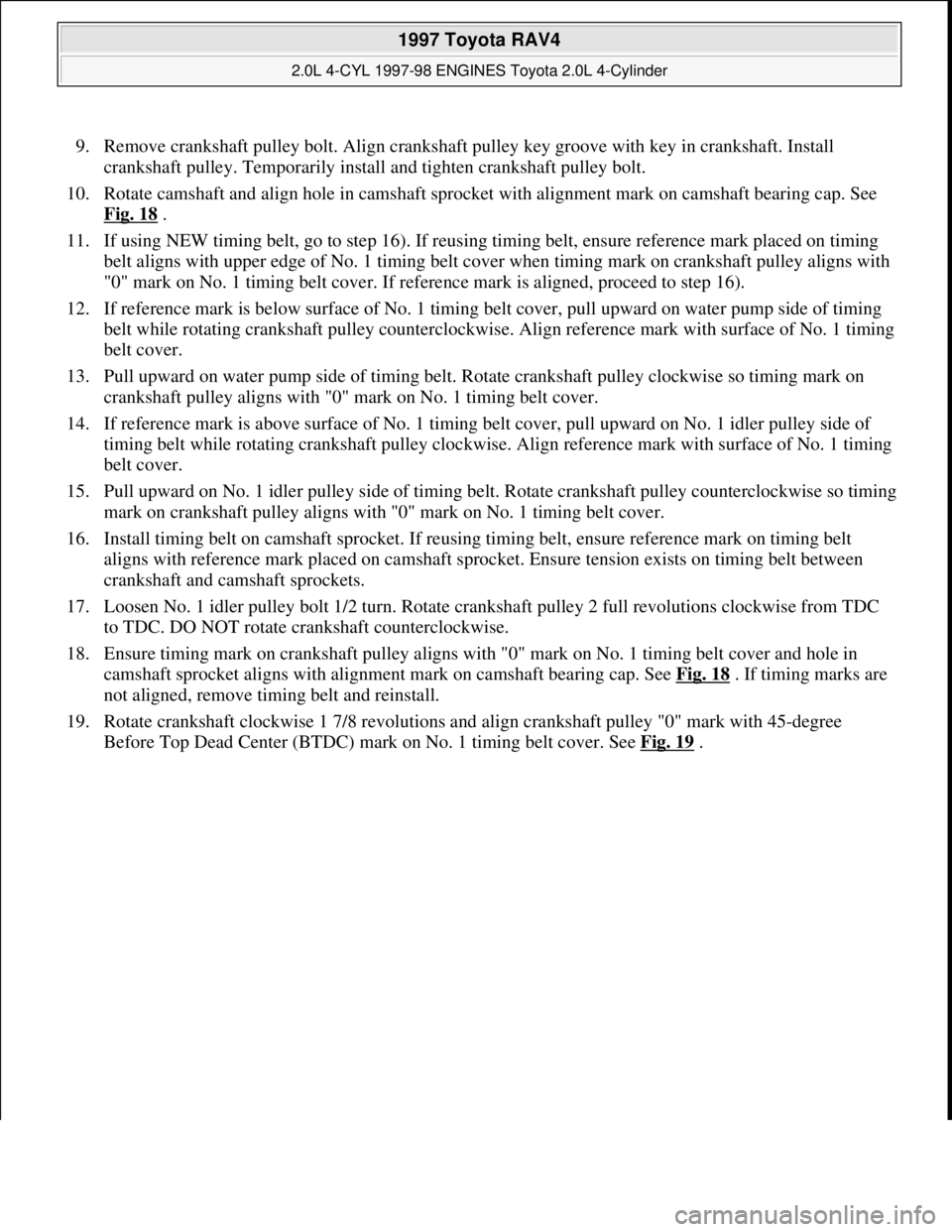

Before Top Dead Center (BTDC) mark on No. 1 timing belt cover. See Fig. 19

.

1997 Toyota RAV4

2.0L 4-CYL 1997-98 ENGINES Toyota 2.0L 4-Cylinder

Microsoft

Sunday, November 22, 2009 10:23:31 AMPage 27 © 2005 Mitchell Repair Information Company, LLC.

Page 776 of 1632

Fig. 19: Aligning Crankshaft Pulley With 45-Degree BTDC Mark

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

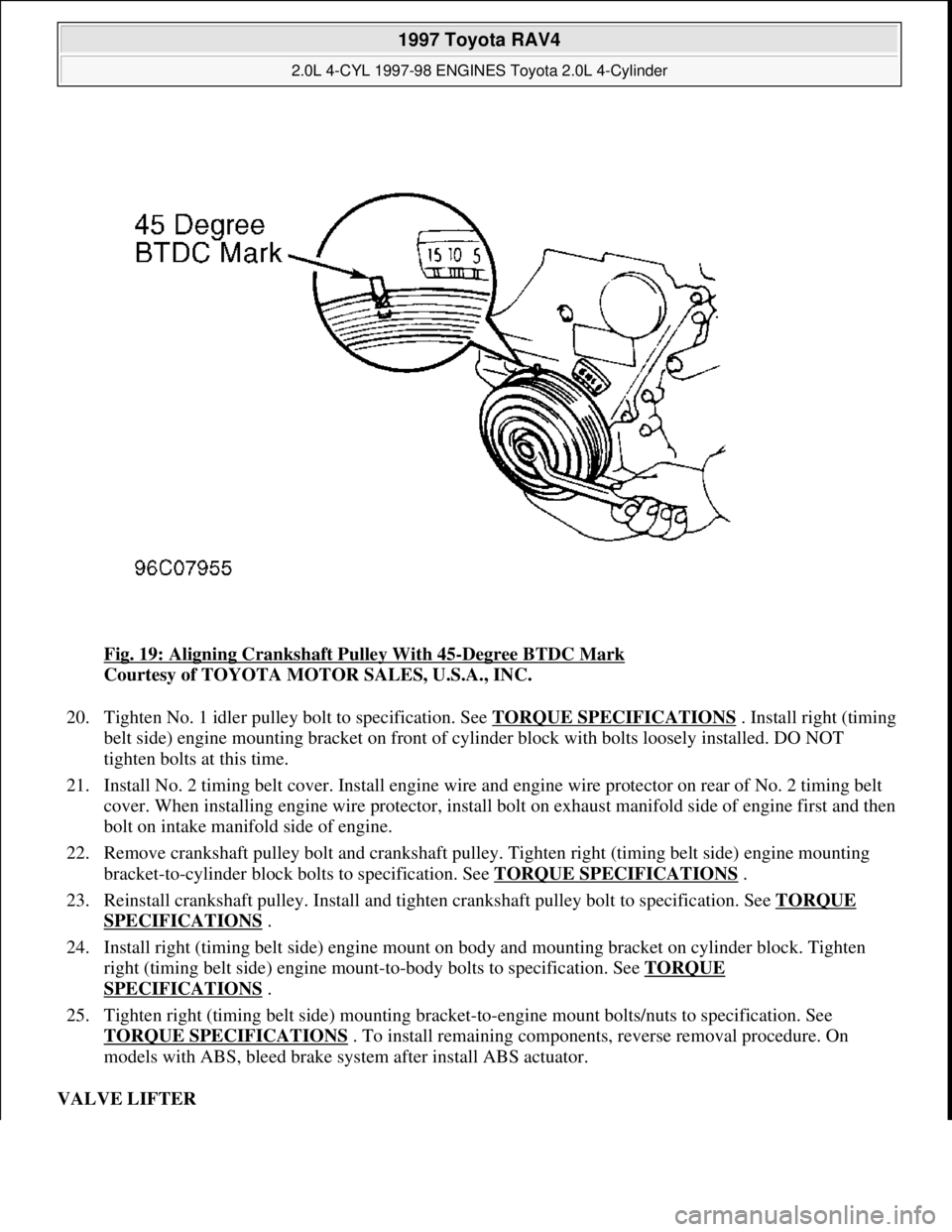

20. Tighten No. 1 idler pulley bolt to specification. See TORQUE SPECIFICATIONS

. Install right (timing

belt side) engine mounting bracket on front of cylinder block with bolts loosely installed. DO NOT

tighten bolts at this time.

21. Install No. 2 timing belt cover. Install engine wire and engine wire protector on rear of No. 2 timing belt

cover. When installing engine wire protector, install bolt on exhaust manifold side of engine first and then

bolt on intake manifold side of engine.

22. Remove crankshaft pulley bolt and crankshaft pulley. Tighten right (timing belt side) engine mounting

bracket-to-cylinder block bolts to specification. See TORQUE SPECIFICATIONS

.

23. Reinstall crankshaft pulley. Install and tighten crankshaft pulley bolt to specification. See TORQUE

SPECIFICATIONS .

24. Install right (timing belt side) engine mount on body and mounting bracket on cylinder block. Tighten

right (timing belt side) engine mount-to-body bolts to specification. See TORQUE

SPECIFICATIONS .

25. Tighten right (timing belt side) mounting bracket-to-engine mount bolts/nuts to specification. See

TORQUE SPECIFICATIONS

. To install remaining components, reverse removal procedure. On

models with ABS, bleed brake system after install ABS actuator.

VALVE LIFTER

1997 Toyota RAV4

2.0L 4-CYL 1997-98 ENGINES Toyota 2.0L 4-Cylinder

Microsoft

Sunday, November 22, 2009 10:23:31 AMPage 28 © 2005 Mitchell Repair Information Company, LLC.

Page 777 of 1632

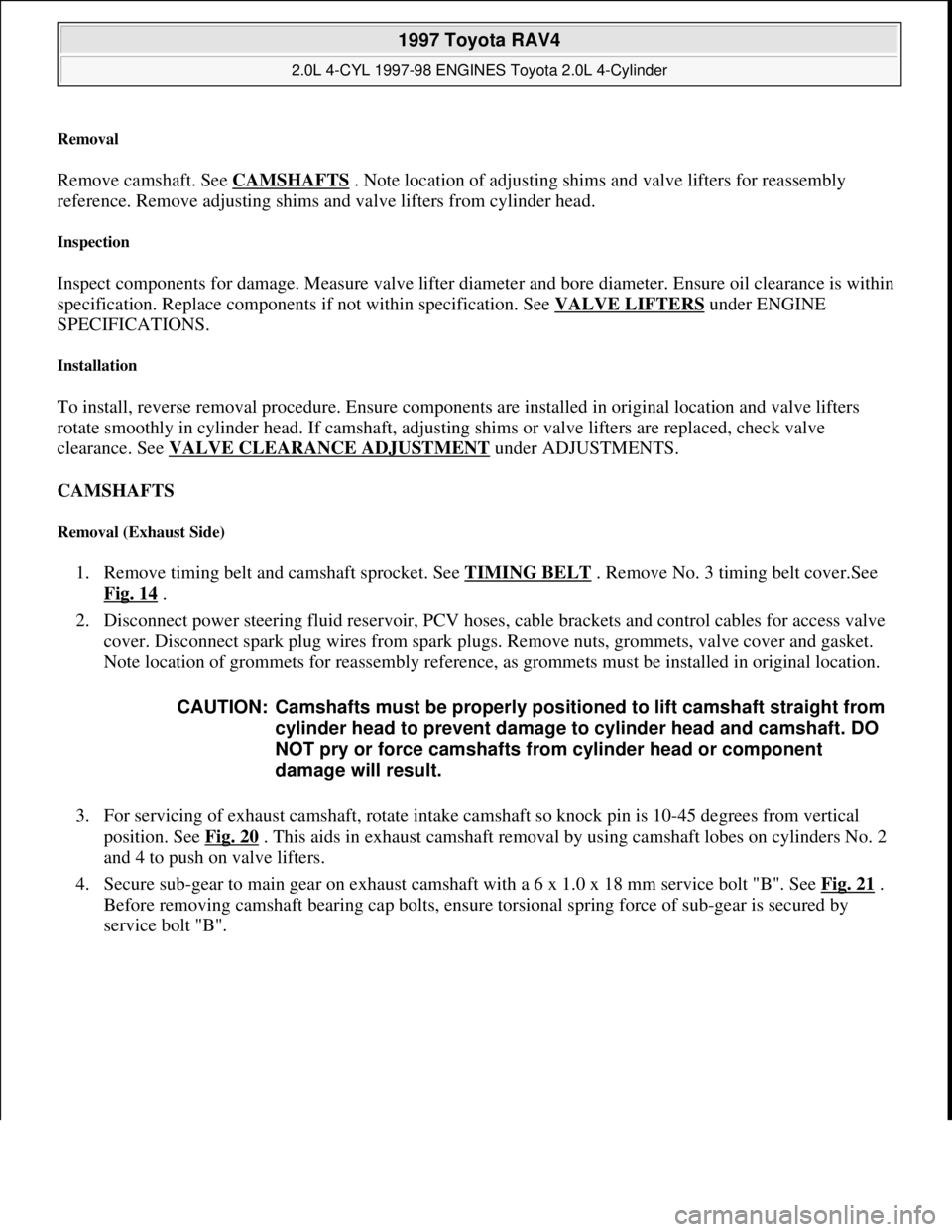

Removal

Remove camshaft. See CAMSHAFTS . Note location of adjusting shims and valve lifters for reassembly

reference. Remove adjusting shims and valve lifters from cylinder head.

Inspection

Inspect components for damage. Measure valve lifter diameter and bore diameter. Ensure oil clearance is within

specification. Replace components if not within specification. See VALVE LIFTERS

under ENGINE

SPECIFICATIONS.

Installation

To install, reverse removal procedure. Ensure components are installed in original location and valve lifters

rotate smoothly in cylinder head. If camshaft, adjusting shims or valve lifters are replaced, check valve

clearance. See VALVE CLEARANCE ADJUSTMENT

under ADJUSTMENTS.

CAMSHAFTS

Removal (Exhaust Side)

1. Remove timing belt and camshaft sprocket. See TIMING BELT . Remove No. 3 timing belt cover.See

Fig. 14

.

2. Disconnect power steering fluid reservoir, PCV hoses, cable brackets and control cables for access valve

cover. Disconnect spark plug wires from spark plugs. Remove nuts, grommets, valve cover and gasket.

Note location of grommets for reassembly reference, as grommets must be installed in original location.

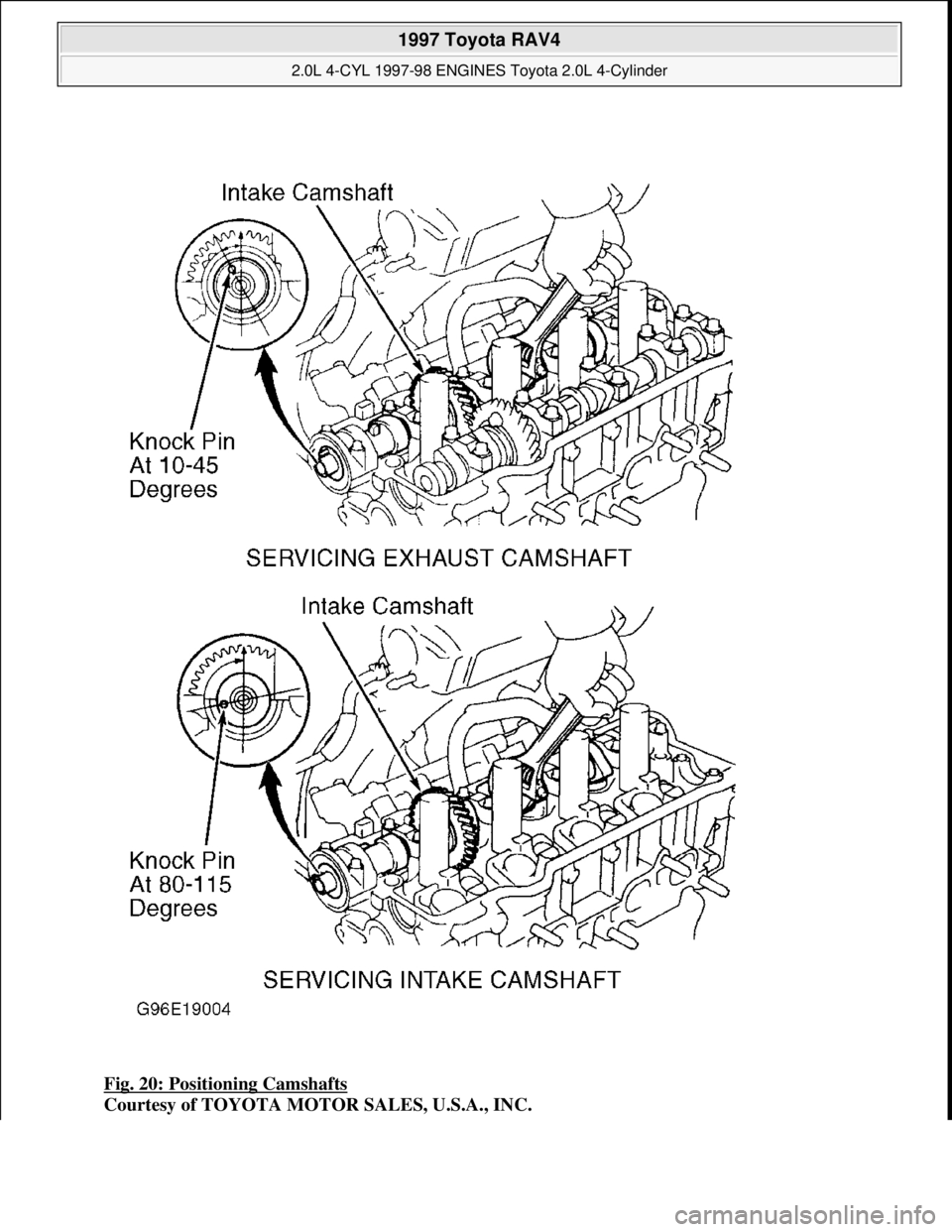

3. For servicing of exhaust camshaft, rotate intake camshaft so knock pin is 10-45 degrees from vertical

position. See Fig. 20

. This aids in exhaust camshaft removal by using camshaft lobes on cylinders No. 2

and 4 to push on valve lifters.

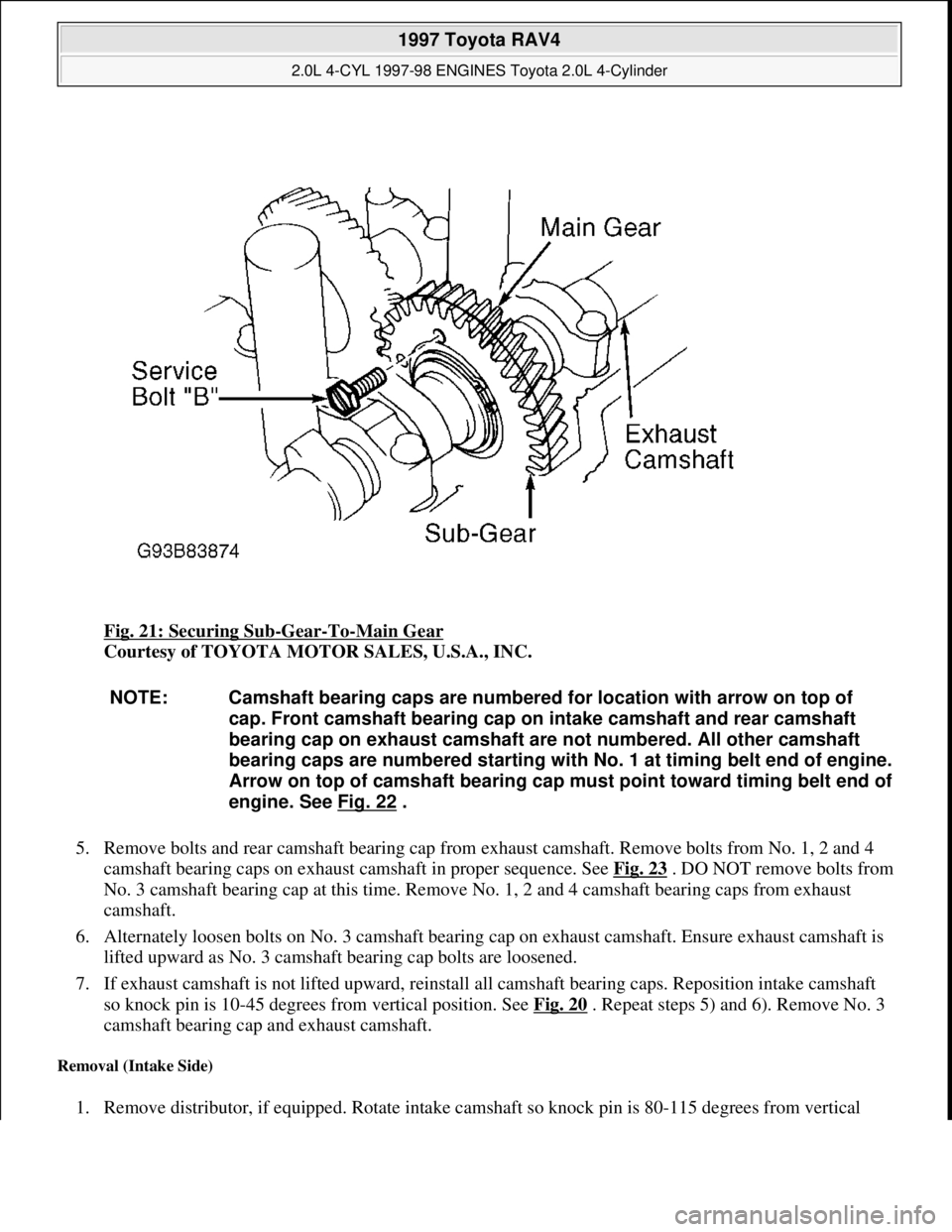

4. Secure sub-gear to main gear on exhaust camshaft with a 6 x 1.0 x 18 mm service bolt "B". See Fig. 21

.

Before removing camshaft bearing cap bolts, ensure torsional spring force of sub-gear is secured by

service bolt "B". CAUTION: Camshafts must be properly positioned to lift camshaft straight from

cylinder head to prevent damage to cylinder head and camshaft. DO

NOT pry or force camshafts from cylinder head or component

damage will result.

1997 Toyota RAV4

2.0L 4-CYL 1997-98 ENGINES Toyota 2.0L 4-Cylinder

Microsoft

Sunday, November 22, 2009 10:23:31 AMPage 29 © 2005 Mitchell Repair Information Company, LLC.

Page 778 of 1632

Fig. 20: Positioning Camshafts

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

1997 Toyota RAV4

2.0L 4-CYL 1997-98 ENGINES Toyota 2.0L 4-Cylinder

Microsoft

Sunday, November 22, 2009 10:23:31 AMPage 30 © 2005 Mitchell Repair Information Company, LLC.

Page 779 of 1632

Fig. 21: Securing Sub-Gear-To-Main Gear

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

5. Remove bolts and rear camshaft bearing cap from exhaust camshaft. Remove bolts from No. 1, 2 and 4

camshaft bearing caps on exhaust camshaft in proper sequence. See Fig. 23

. DO NOT remove bolts from

No. 3 camshaft bearing cap at this time. Remove No. 1, 2 and 4 camshaft bearing caps from exhaust

camshaft.

6. Alternately loosen bolts on No. 3 camshaft bearing cap on exhaust camshaft. Ensure exhaust camshaft is

lifted upward as No. 3 camshaft bearing cap bolts are loosened.

7. If exhaust camshaft is not lifted upward, reinstall all camshaft bearing caps. Reposition intake camshaft

so knock pin is 10-45 degrees from vertical position. See Fig. 20

. Repeat steps 5) and 6). Remove No. 3

camshaft bearing cap and exhaust camshaft.

Removal (Intake Side)

1. Remove distributor, if equipped. Rotate intake camshaft so knock pin is 80-115 degrees from vertical

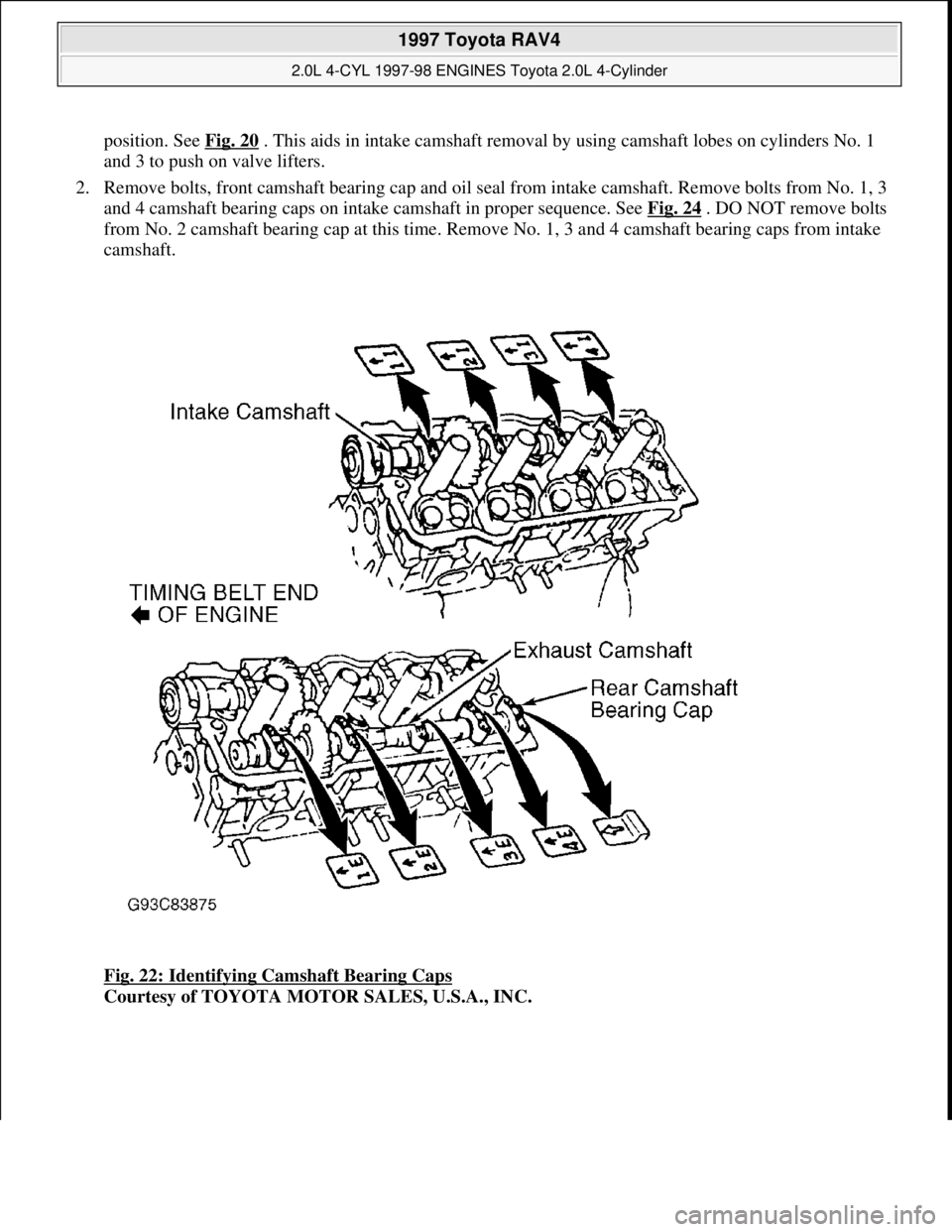

NOTE: Camshaft bearing caps are numbered for location with arrow on top of

cap. Front camshaft bearing cap on intake camshaft and rear camshaft

bearing cap on exhaust camshaft are not numbered. All other camshaft

bearing caps are numbered starting with No. 1 at timing belt end of engine.

Arrow on top of camshaft bearing cap must point toward timing belt end of

engine. See Fig. 22

.

1997 Toyota RAV4

2.0L 4-CYL 1997-98 ENGINES Toyota 2.0L 4-Cylinder

Microsoft

Sunday, November 22, 2009 10:23:31 AMPage 31 © 2005 Mitchell Repair Information Company, LLC.

Page 780 of 1632

position. See Fig. 20 . This aids in intake camshaft removal by using camshaft lobes on cylinders No. 1

and 3 to push on valve lifters.

2. Remove bolts, front camshaft bearing cap and oil seal from intake camshaft. Remove bolts from No. 1, 3

and 4 camshaft bearing caps on intake camshaft in proper sequence. See Fig. 24

. DO NOT remove bolts

from No. 2 camshaft bearing cap at this time. Remove No. 1, 3 and 4 camshaft bearing caps from intake

camshaft.

Fig. 22: Identifying Camshaft Bearing Caps

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

1997 Toyota RAV4

2.0L 4-CYL 1997-98 ENGINES Toyota 2.0L 4-Cylinder

Microsoft

Sunday, November 22, 2009 10:23:31 AMPage 32 © 2005 Mitchell Repair Information Company, LLC.