TOYOTA RAV4 2006 Service Repair Manual

Manufacturer: TOYOTA, Model Year: 2006,

Model line: RAV4,

Model: TOYOTA RAV4 2006

Pages: 2000, PDF Size: 45.84 MB

TOYOTA RAV4 2006 Service Repair Manual

RAV4 2006

TOYOTA

TOYOTA

https://www.carmanualsonline.info/img/14/57463/w960_57463-0.png

TOYOTA RAV4 2006 Service Repair Manual

Trending: transmission oil, charging, fuel filter, change wheel, Wheel bearing, transmission, parking sensors

Page 421 of 2000

STEERING COLUMN – STEERING SYSTEMSR–3

SR

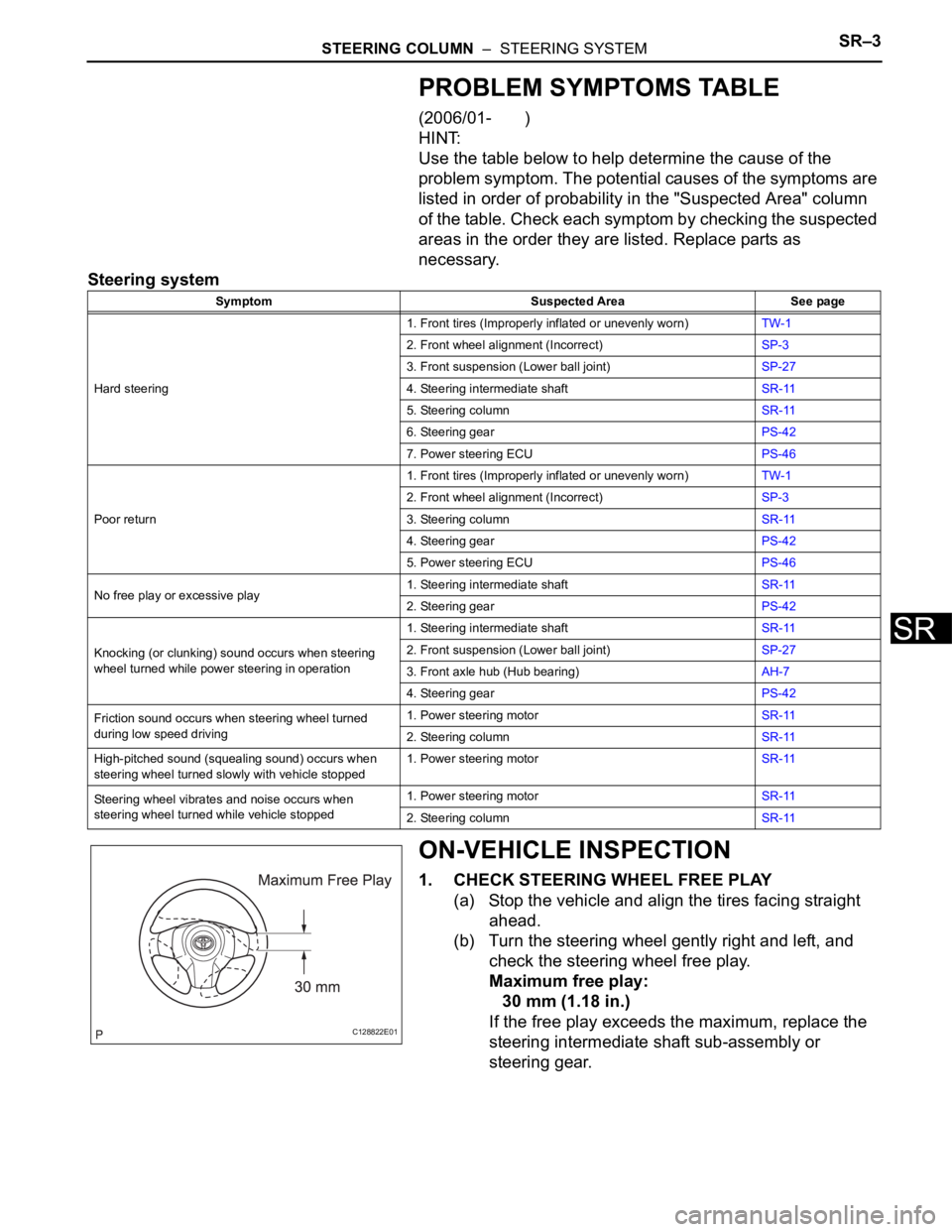

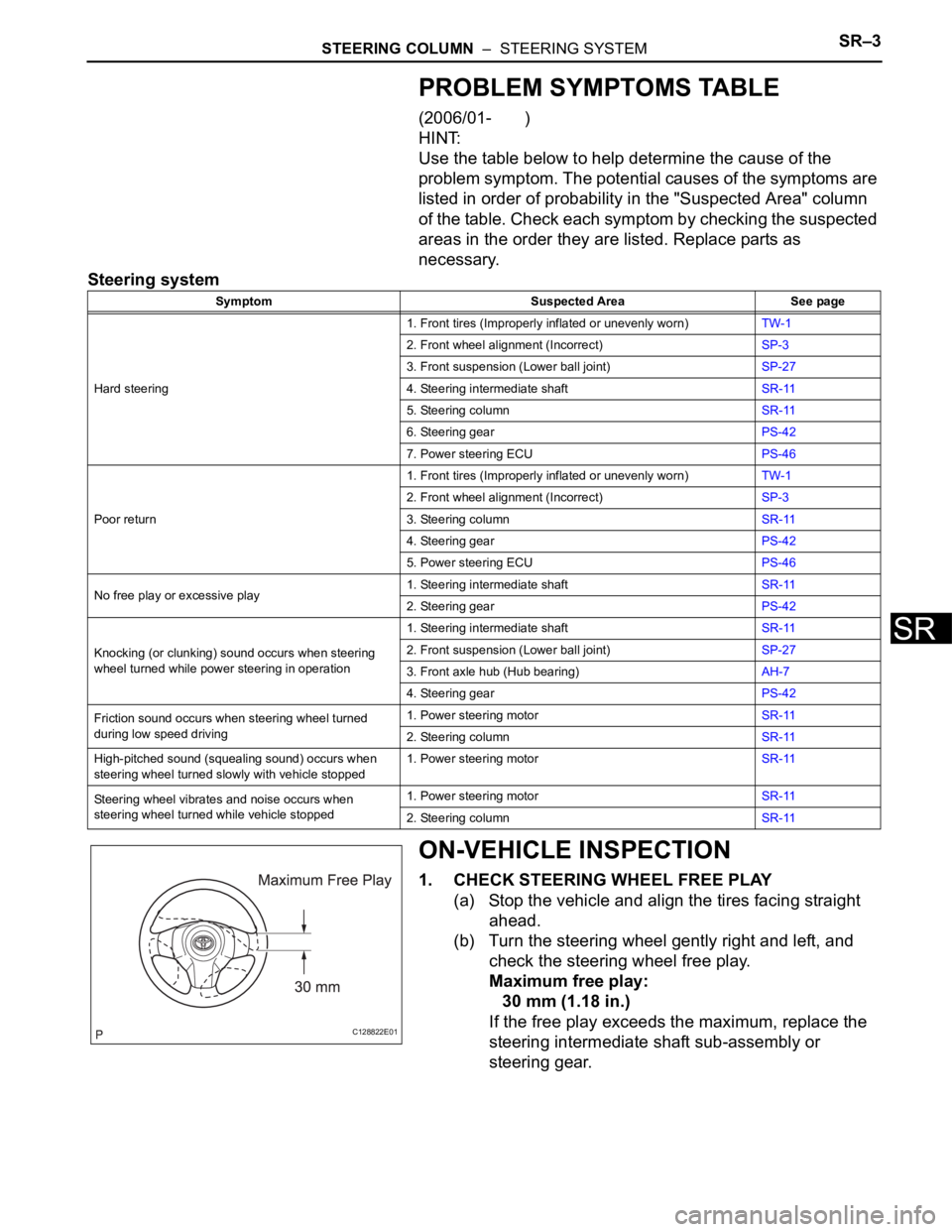

PROBLEM SYMPTOMS TABLE

(2006/01- )

HINT:

Use the table below to help determine the cause of the

problem symptom. The potential causes of the symptoms are

listed in order of probability in the "Suspected Area" column

of the table. Check each symptom by checking the suspected

areas in the order they are listed. Replace parts as

necessary.

Steering system

ON-VEHICLE INSPECTION

1. CHECK STEERING WHEEL FREE PLAY

(a) Stop the vehicle and align the tires facing straight

ahead.

(b) Turn the steering wheel gently right and left, and

check the steering wheel free play.

Maximum free play:

30 mm (1.18 in.)

If the free play exceeds the maximum, replace the

steering intermediate shaft sub-assembly or

steering gear.

Symptom Suspected Area See page

Hard steering1. Front tires (Improperly inflated or unevenly worn)TW-1

2. Front wheel alignment (Incorrect)SP-3

3. Front suspension (Lower ball joint)SP-27

4. Steering intermediate shaftSR-11

5. Steering columnSR-11

6. Steering gearPS-42

7. Power steering ECUPS-46

Poor return1. Front tires (Improperly inflated or unevenly worn)TW-1

2. Front wheel alignment (Incorrect)SP-3

3. Steering columnSR-11

4. Steering gearPS-42

5. Power steering ECUPS-46

No free play or excessive play1. Steering intermediate shaftSR-11

2. Steering gearPS-42

Knocking (or clunking) sound occurs when steering

wheel turned while power steering in operation1. Steering intermediate shaftSR-11

2. Front suspension (Lower ball joint)SP-27

3. Front axle hub (Hub bearing)AH-7

4. Steering gearPS-42

Friction sound occurs when steering wheel turned

during low speed driving1. Power steering motorSR-11

2. Steering columnSR-11

High-pitched sound (squealing sound) occurs when

steering wheel turned slowly with vehicle stopped1. Power steering motorSR-11

Steering wheel vibrates and noise occurs when

steering wheel turned while vehicle stopped1. Power steering motorSR-11

2. Steering columnSR-11

C128822E01

Page 422 of 2000

SR–4STEERING COLUMN – STEERING SYSTEM

SR

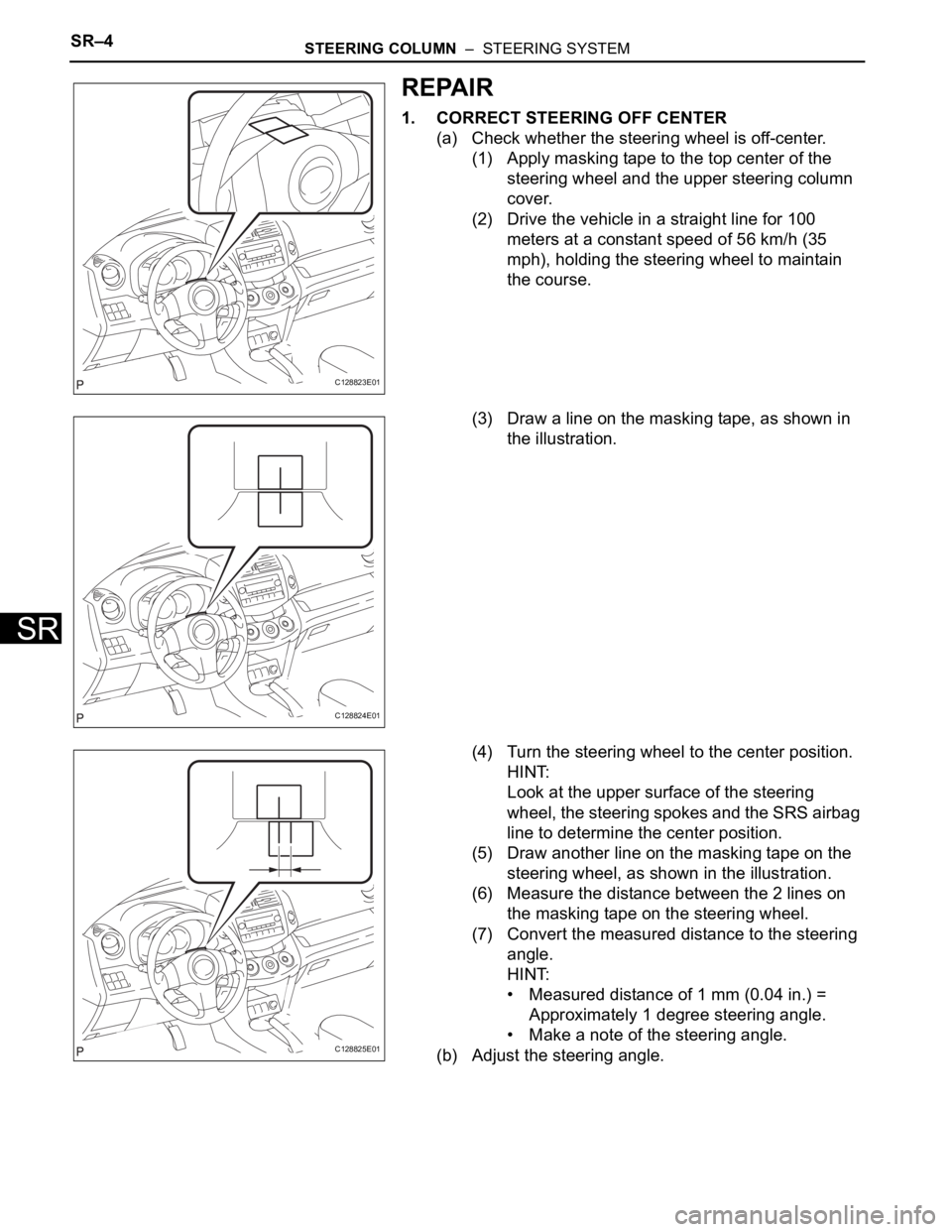

REPAIR

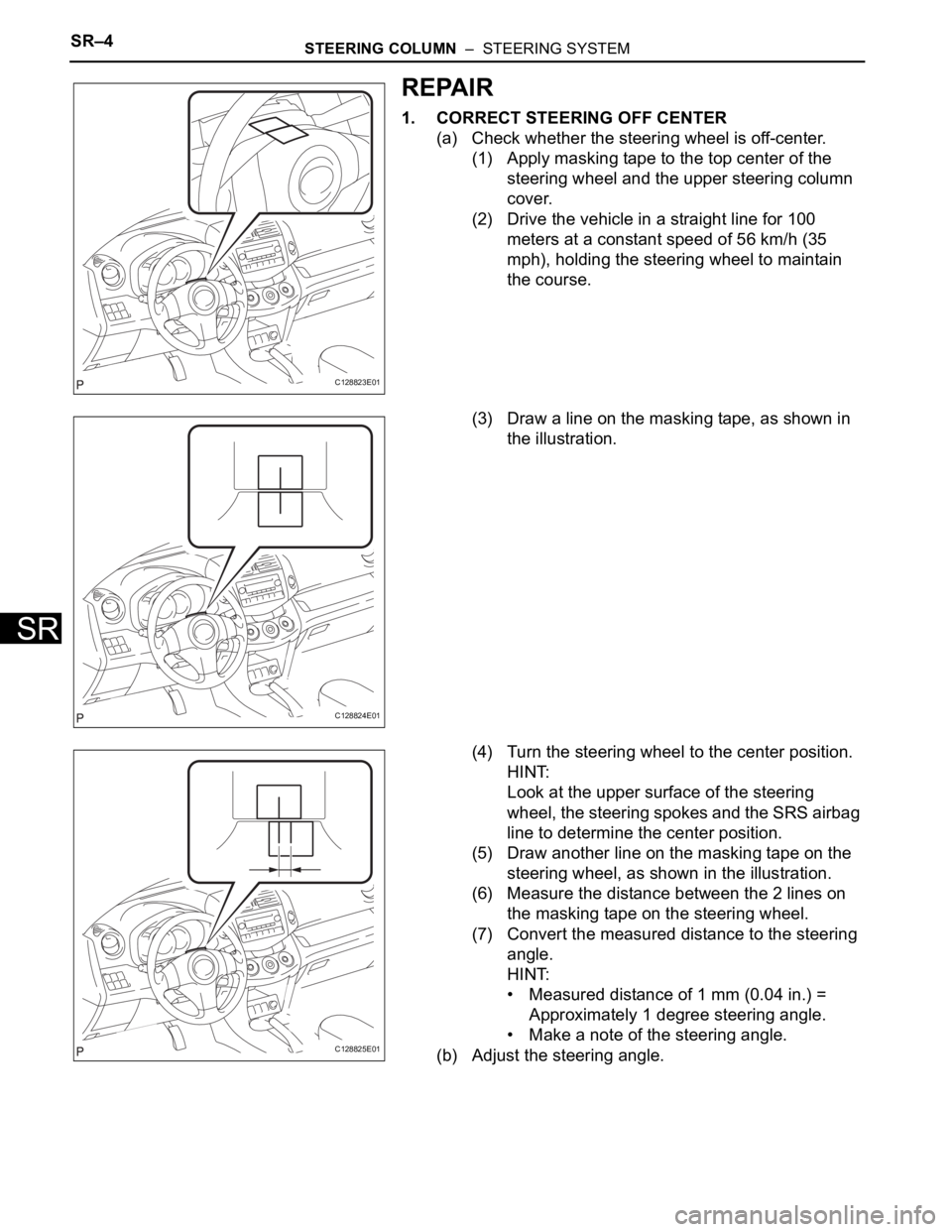

1. CORRECT STEERING OFF CENTER

(a) Check whether the steering wheel is off-center.

(1) Apply masking tape to the top center of the

steering wheel and the upper steering column

cover.

(2) Drive the vehicle in a straight line for 100

meters at a constant speed of 56 km/h (35

mph), holding the steering wheel to maintain

the course.

(3) Draw a line on the masking tape, as shown in

the illustration.

(4) Turn the steering wheel to the center position.

HINT:

Look at the upper surface of the steering

wheel, the steering spokes and the SRS airbag

line to determine the center position.

(5) Draw another line on the masking tape on the

steering wheel, as shown in the illustration.

(6) Measure the distance between the 2 lines on

the masking tape on the steering wheel.

(7) Convert the measured distance to the steering

angle.

HINT:

• Measured distance of 1 mm (0.04 in.) =

Approximately 1 degree steering angle.

• Make a note of the steering angle.

(b) Adjust the steering angle.

C128823E01

C128824E01

C128825E01

Page 423 of 2000

STEERING COLUMN – STEERING SYSTEMSR–5

SR

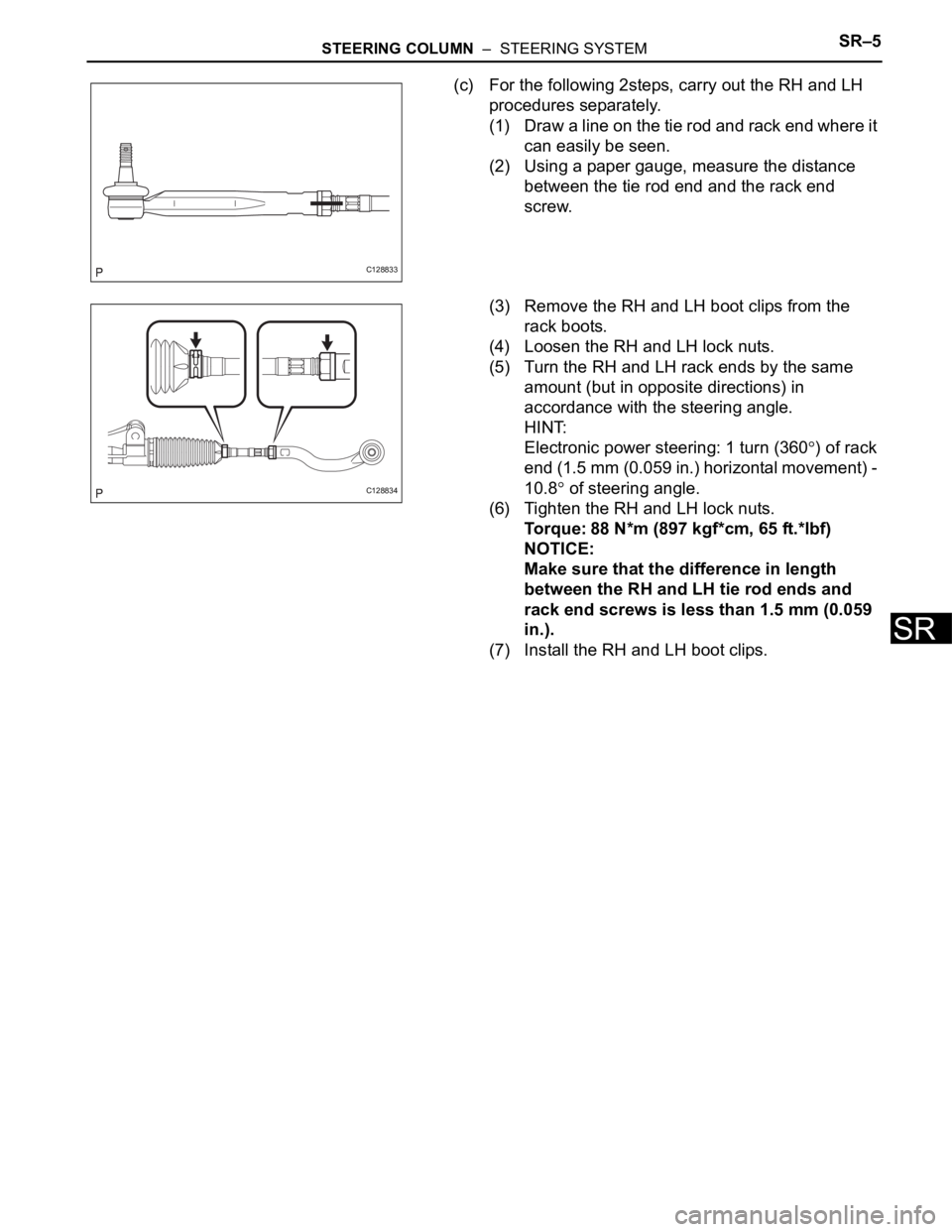

(c) For the following 2steps, carry out the RH and LH

procedures separately.

(1) Draw a line on the tie rod and rack end where it

can easily be seen.

(2) Using a paper gauge, measure the distance

between the tie rod end and the rack end

screw.

(3) Remove the RH and LH boot clips from the

rack boots.

(4) Loosen the RH and LH lock nuts.

(5) Turn the RH and LH rack ends by the same

amount (but in opposite directions) in

accordance with the steering angle.

HINT:

Electronic power steering: 1 turn (360

) of rack

end (1.5 mm (0.059 in.) horizontal movement) -

10.8

of steering angle.

(6) Tighten the RH and LH lock nuts.

Torque: 88 N*m (897 kgf*cm, 65 ft.*lbf)

NOTICE:

Make sure that the difference in length

between the RH and LH tie rod ends and

rack end screws is less than 1.5 mm (0.059

in.).

(7) Install the RH and LH boot clips.

C128833

C128834

Page 424 of 2000

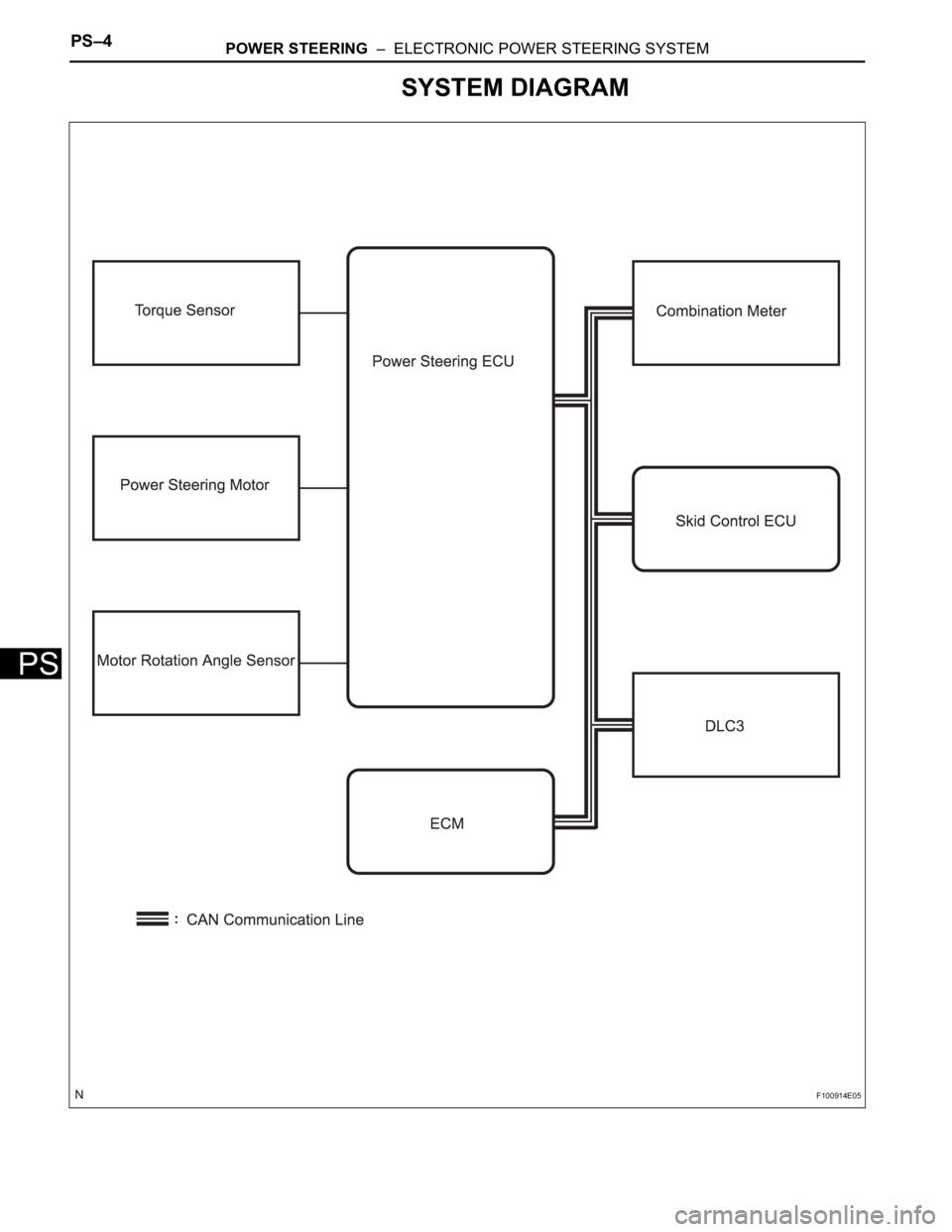

PS–4POWER STEERING – ELECTRONIC POWER STEERING SYSTEM

PS

SYSTEM DIAGRAM

F100914E05

Page 425 of 2000

POWER STEERING – ELECTRONIC POWER STEERING SYSTEMPS–5

PS

SYSTEM DESCRIPTION

1. DESCRIPTION

The EPS (Electronic Power Steering) system generates

torque through the operation of the motor and the

reduction gear installed on the column shaft in order to

assist steering effort.

The power steering ECU determines directions and the

amount of assisting power in accordance with vehicle

speed signals and signals from the torque sensor built

into the steering column assembly. As a result, the power

steering adjusts the steering effort so that it is lighter

during low speed driving and heavier during high speed

driving.

(a) Power steering ECU:

The power steering ECU calculates assisting power

based on steering torque signals from the torque

sensor and vehicle speed signals from the skid

control ECU.

(b) Torque sensor:

The torque sensor detects the steering effort

generated when the steering wheel is turned and

converts it to an electrical signal.

(c) EPS motor:

The EPS motor is activated by the current from the

power steering ECU and generates torque to assist

the steering effort.

(d) Motor rotation angle sensor:

The motor rotation angle sensor consists of the

resolver sensor, which excels in reliability and

durability. The rotation angle sensor detects the

rotation angle of the motor and outputs it to the

power steering ECU. As a result, it ensures efficient

EPS control.

Page 426 of 2000

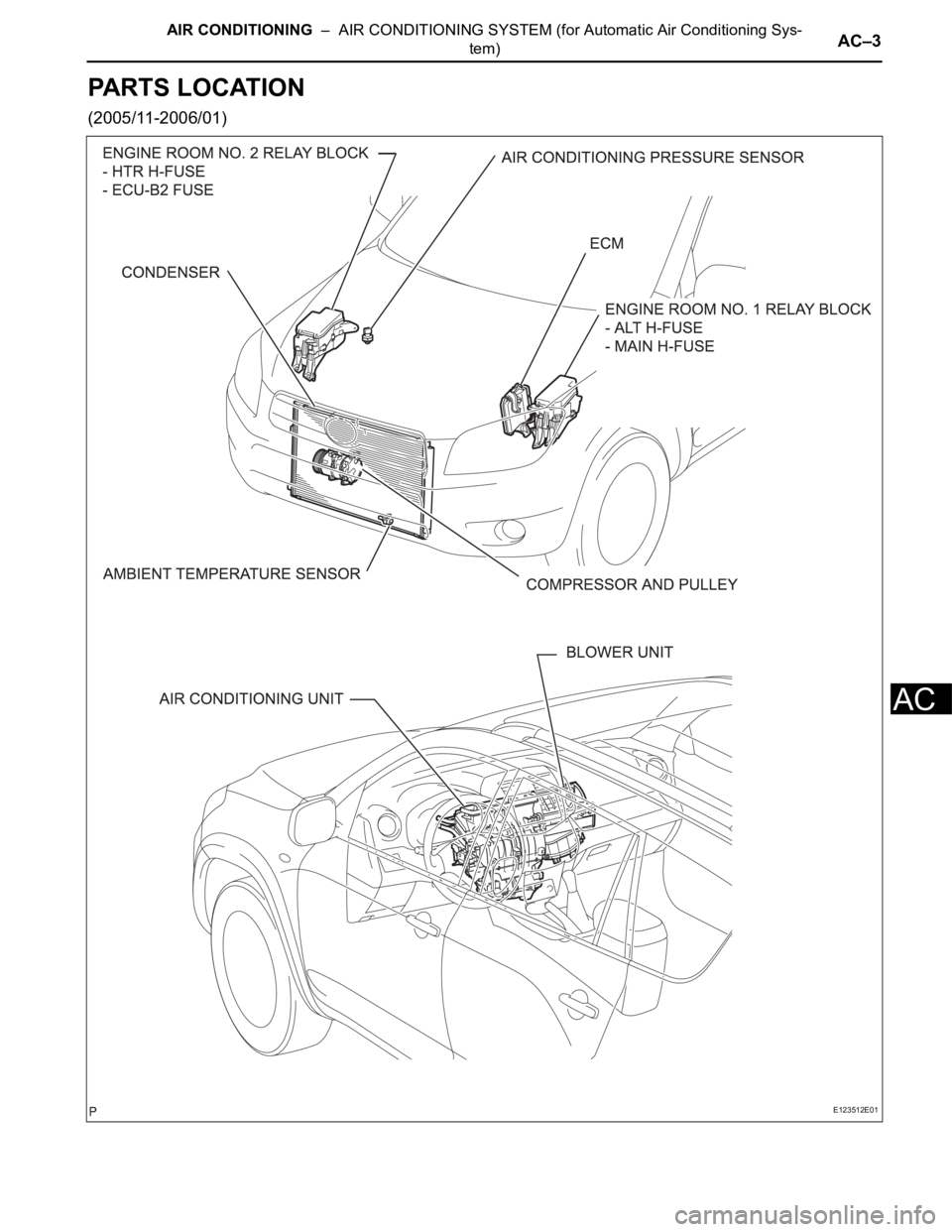

AIR CONDITIONING – AIR CONDITIONING SYSTEM (for Automatic Air Conditioning Sys-

tem)AC–3

AC

PARTS LOCATION

(2005/11-2006/01)

E123512E01

Page 427 of 2000

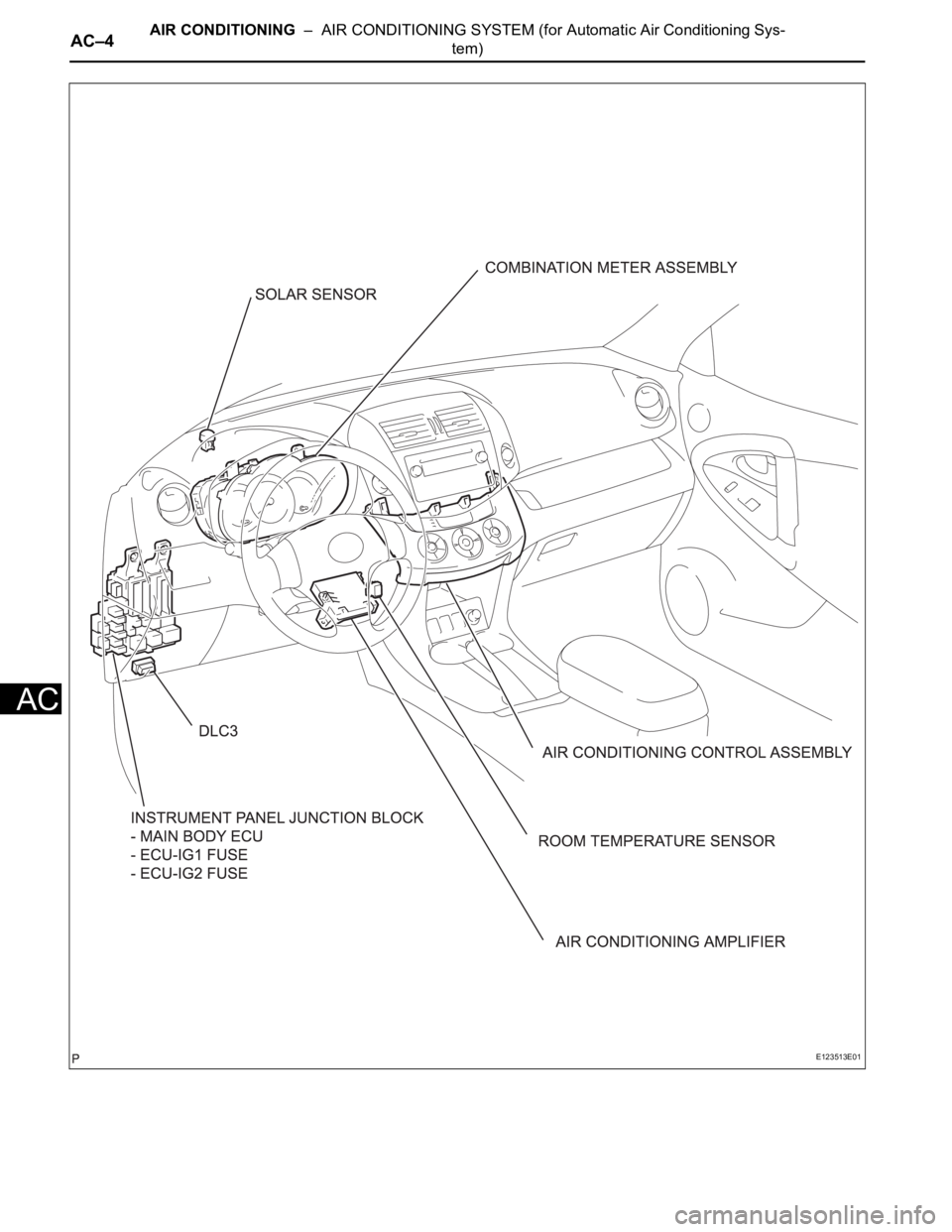

AC–4AIR CONDITIONING – AIR CONDITIONING SYSTEM (for Automatic Air Conditioning Sys-

tem)

AC

E123513E01

Page 428 of 2000

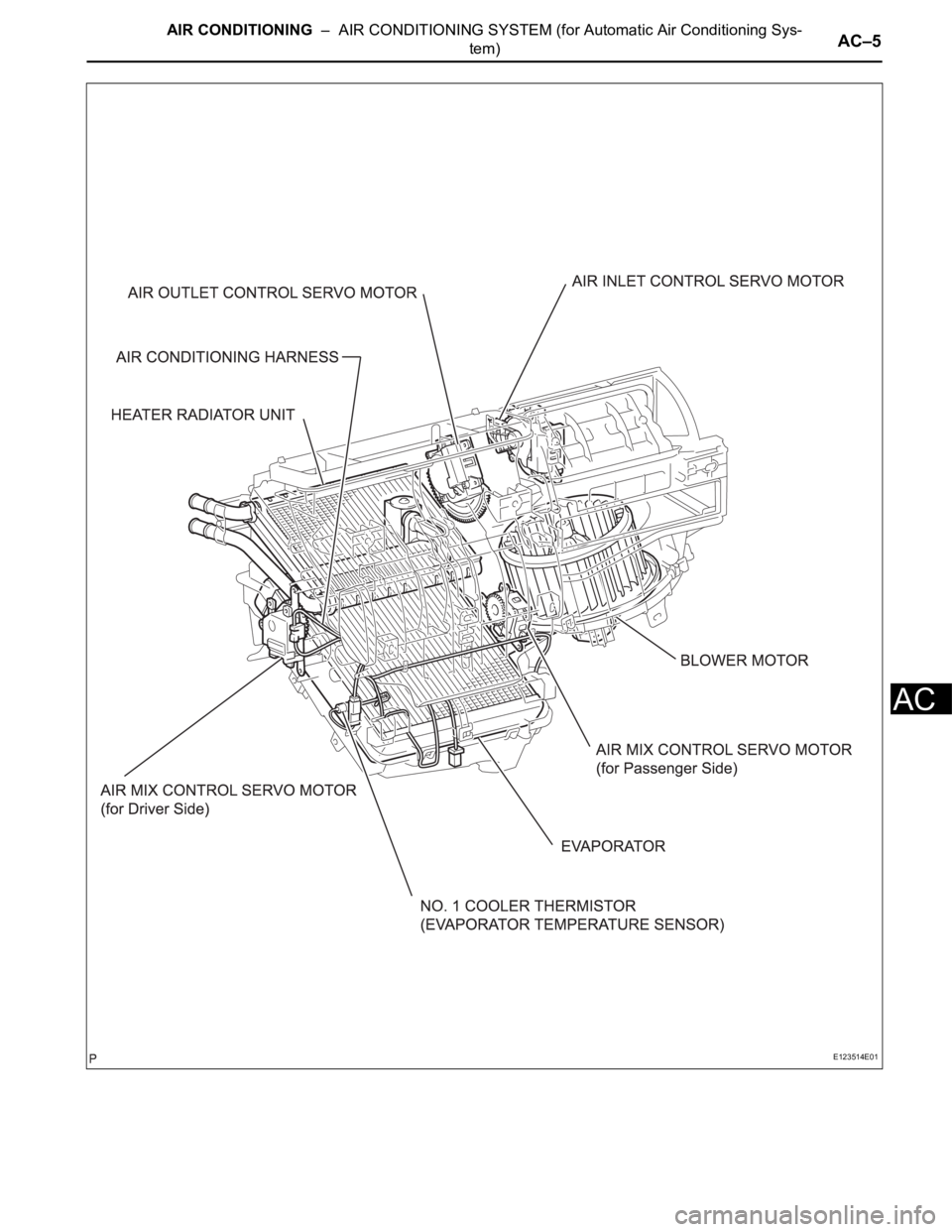

AIR CONDITIONING – AIR CONDITIONING SYSTEM (for Automatic Air Conditioning Sys-

tem)AC–5

AC

E123514E01

Page 429 of 2000

AIR CONDITIONING – AIR OUTLET CONTROL SERVO MOTOR (for Automatic Air Condi-

tioning System)AC–213

AC

INSTALLATION

1. INSTALL AIR OUTLET CONTROL SERVO MOTOR

(See page AC-196)

2. INSTALL AIR CONDITIONING UNIT

(a) Install the air conditioning radiator (see page AC-

197).

Page 430 of 2000

AIR CONDITIONING – AIR CONDITIONING CONTROL ASSEMBLY (for Manual Air Condi-

tioning System)AC–245

AC

INSTALLATION

1. INSTALL AIR VENT MODE CONTROL SWITCH

(a) Attach the 2 claws to install the mode control switch.

2. INSTALL BLOWER CONTROL SWITCH

(a) Attach the 2 claws to install the blower control

switch.

3. INSTALL AIR MIX CONTROL SWITCH

(a) Attach the 2 claws to install the air mix control

switch.

4. INSTALL AIR CONDITIONING CONTROL ASSEMBLY

(a) Connect the connectors.

(b) Attach the 3 clips to install the air conditioning

control.

(c) Install the 2 screws.

5. INSTALL RADIO RECEIVER ASSEMBLY (w/ Radio

Receiver) (See page IP-10)

6. INSTALL NO. 1 INSTRUMENT CLUSTER FINISH

PANEL CENTER (See page IP-10)

7. INSTALL NO. 2 INSTRUMENT CLUSTER FINISH

PANEL CENTER (See page IP-10)

8. CONNECT CABLE TO NEGATIVE BATTERY

TERMINAL

9. CHECK SRS WARNING LIGHT

(a) Check the SRS warning light (see page RS-37).

E118688

Trending: maintenance, octane, head gasket, steering column, width, fuel, park assist