TOYOTA RAV4 2006 Service Repair Manual

Manufacturer: TOYOTA, Model Year: 2006,

Model line: RAV4,

Model: TOYOTA RAV4 2006

Pages: 2000, PDF Size: 45.84 MB

TOYOTA RAV4 2006 Service Repair Manual

RAV4 2006

TOYOTA

TOYOTA

https://www.carmanualsonline.info/img/14/57463/w960_57463-0.png

TOYOTA RAV4 2006 Service Repair Manual

Trending: transmission oil, steering, engine, 2GR FE, Transmission fluid type t4, headlight bulb, oil filter

Page 411 of 2000

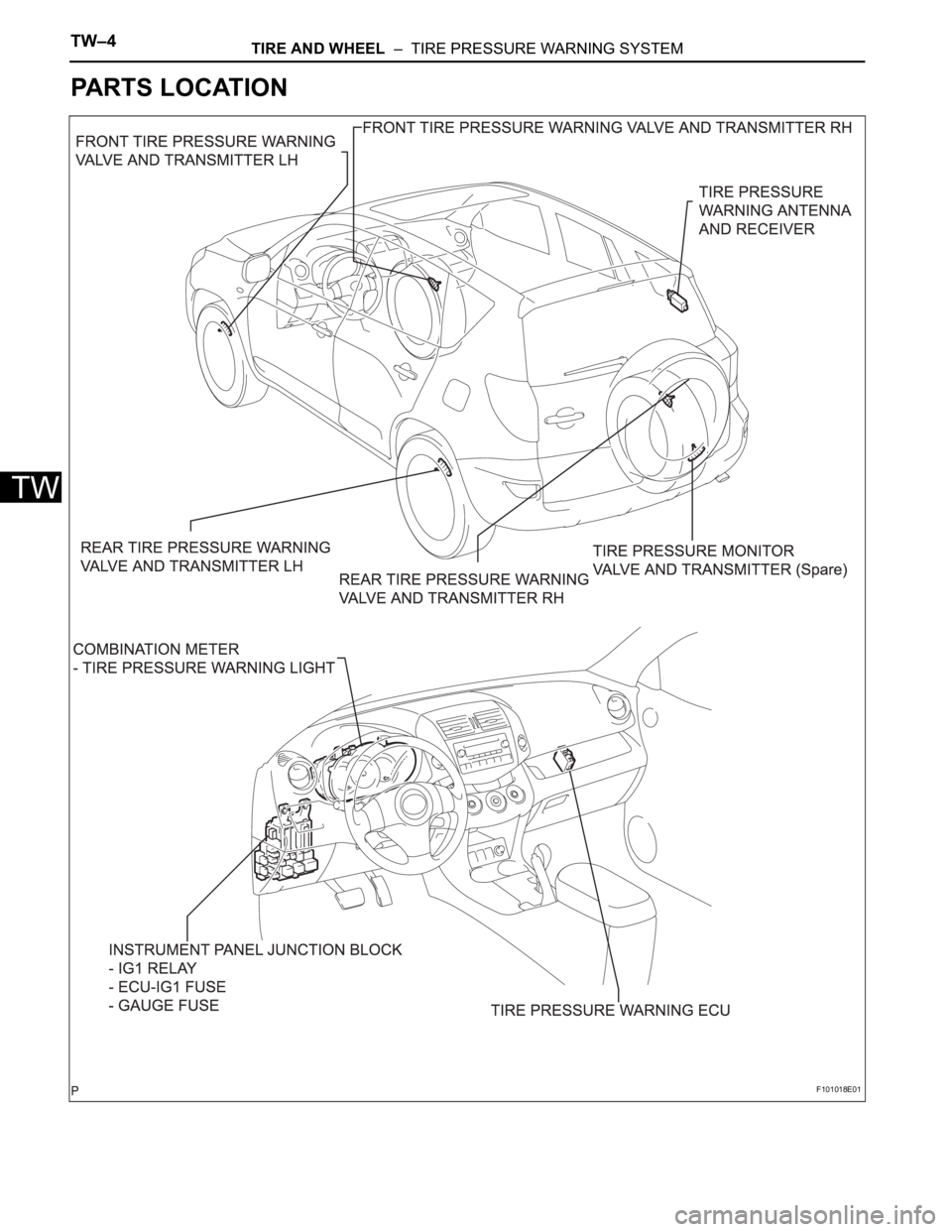

TW–4TIRE AND WHEEL – TIRE PRESSURE WARNING SYSTEM

TW

PARTS LOCATION

F101018E01

Page 412 of 2000

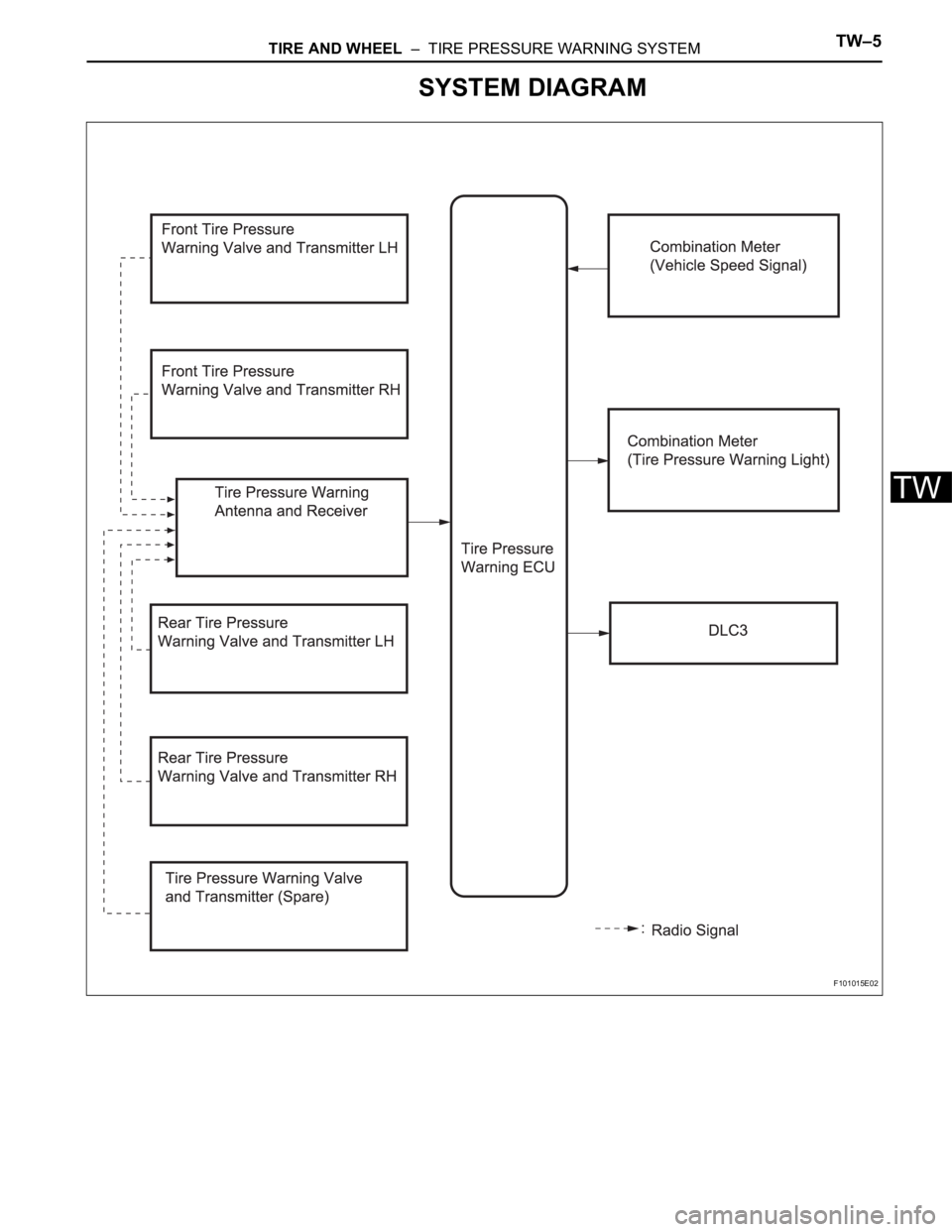

TIRE AND WHEEL – TIRE PRESSURE WARNING SYSTEMTW–5

TW

SYSTEM DIAGRAM

F101015E02

Page 413 of 2000

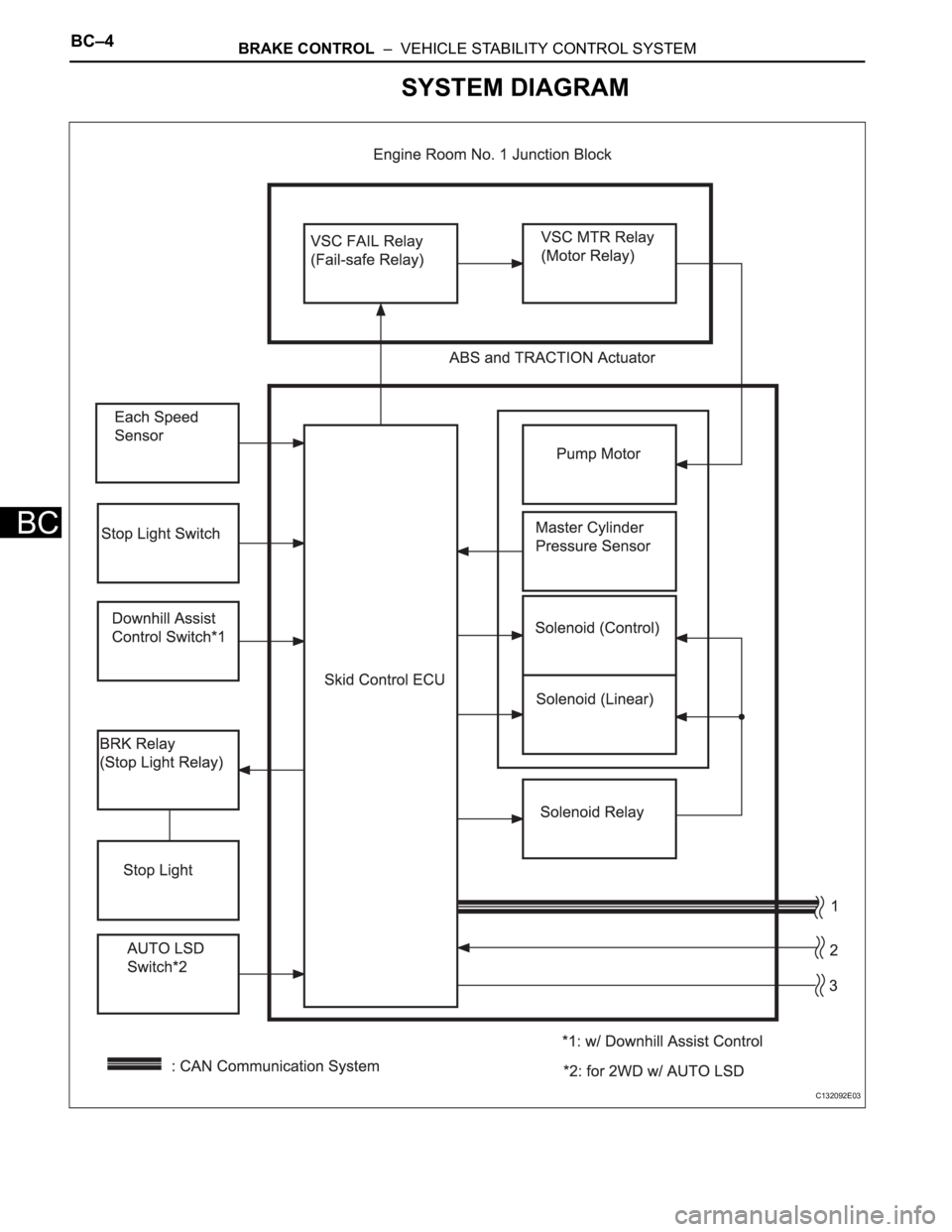

BC–4BRAKE CONTROL – VEHICLE STABILITY CONTROL SYSTEM

BC

SYSTEM DIAGRAM

C132092E03

Page 414 of 2000

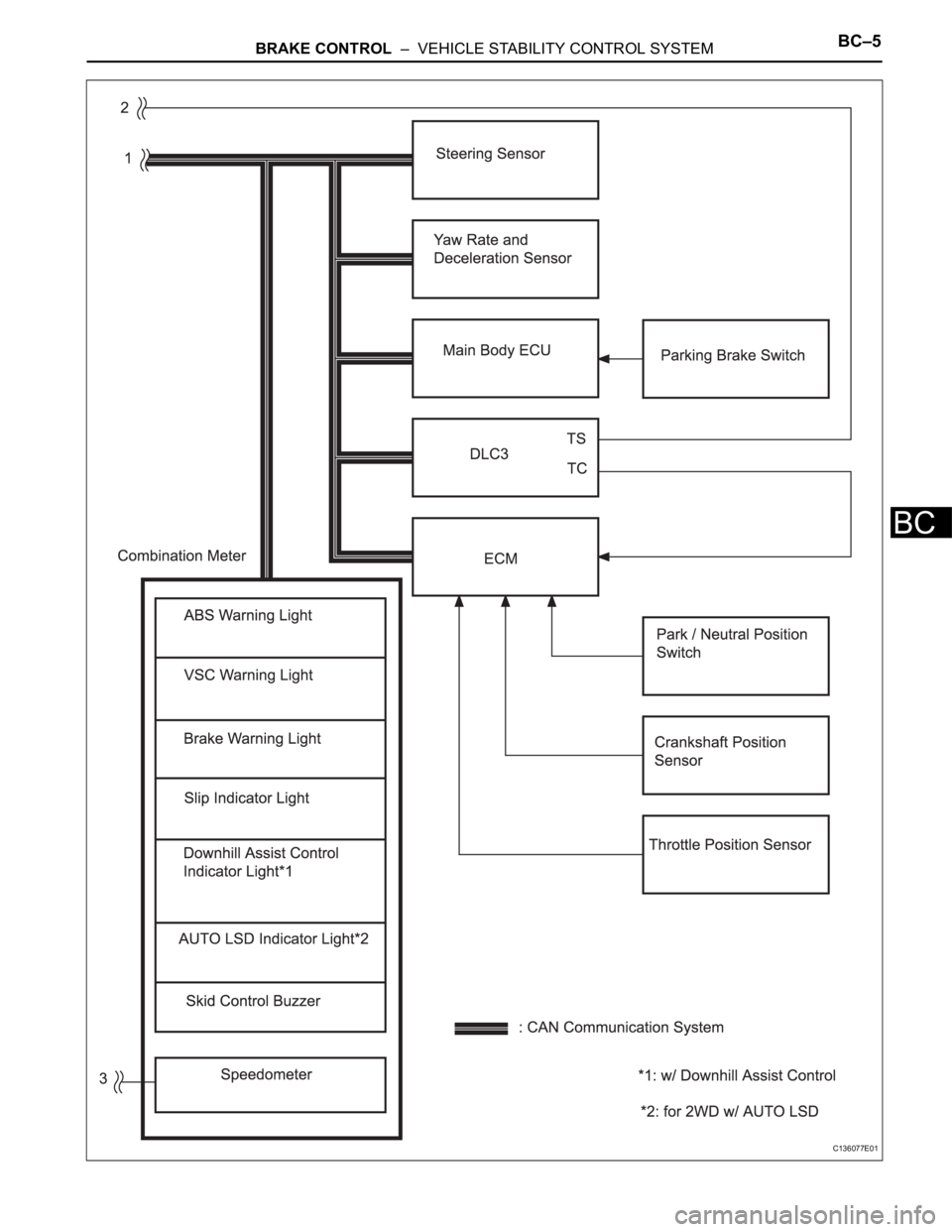

BRAKE CONTROL – VEHICLE STABILITY CONTROL SYSTEMBC–5

BC

C136077E01

Page 415 of 2000

BRAKE – BRAKE SYSTEMBR–3

BR

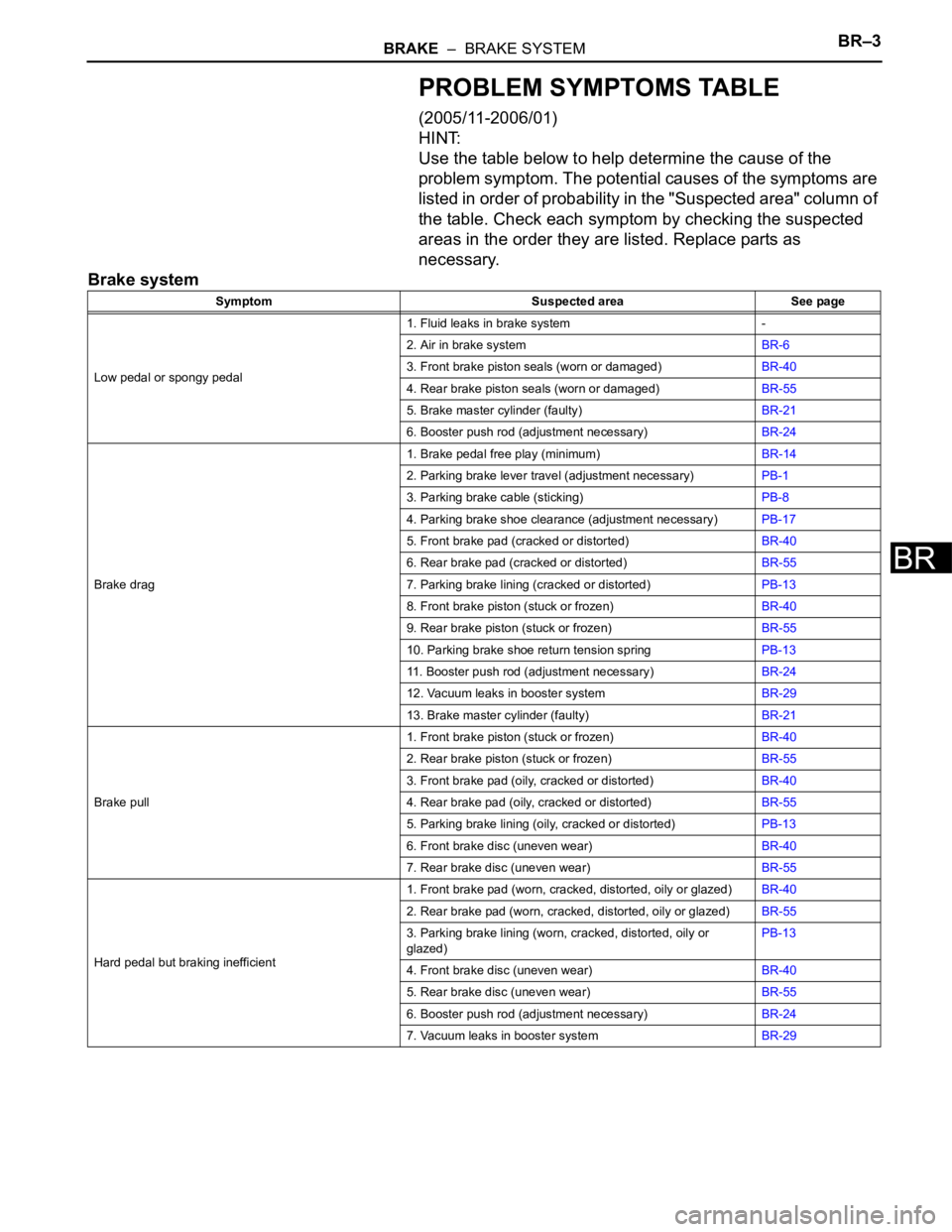

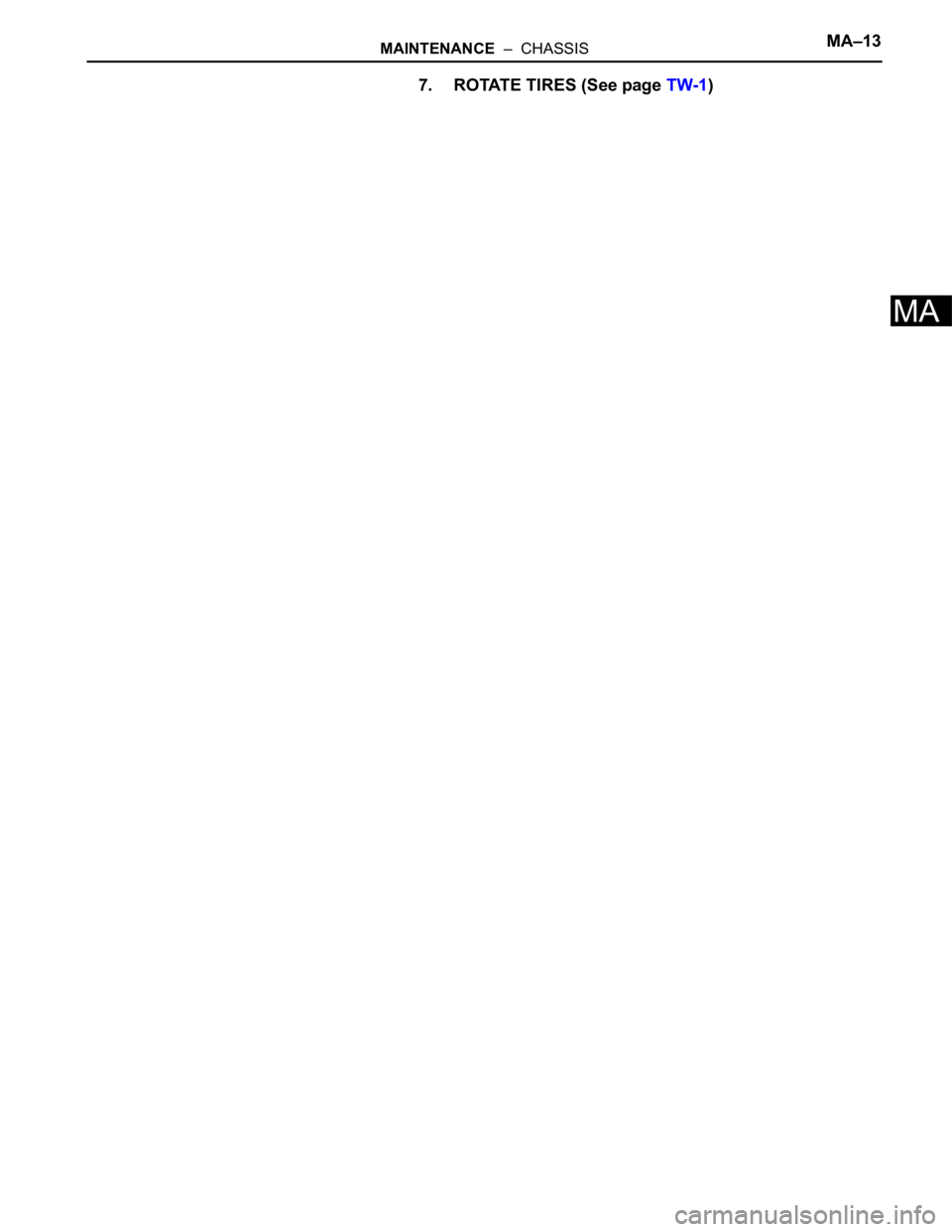

PROBLEM SYMPTOMS TABLE

(2005/11-2006/01)

HINT:

Use the table below to help determine the cause of the

problem symptom. The potential causes of the symptoms are

listed in order of probability in the "Suspected area" column of

the table. Check each symptom by checking the suspected

areas in the order they are listed. Replace parts as

necessary.

Brake system

Symptom Suspected area See page

Low pedal or spongy pedal1. Fluid leaks in brake system -

2. Air in brake systemBR-6

3. Front brake piston seals (worn or damaged)BR-40

4. Rear brake piston seals (worn or damaged)BR-55

5. Brake master cylinder (faulty)BR-21

6. Booster push rod (adjustment necessary)BR-24

Brake drag1. Brake pedal free play (minimum)BR-14

2. Parking brake lever travel (adjustment necessary)PB-1

3. Parking brake cable (sticking)PB-8

4. Parking brake shoe clearance (adjustment necessary)PB-17

5. Front brake pad (cracked or distorted)BR-40

6. Rear brake pad (cracked or distorted)BR-55

7. Parking brake lining (cracked or distorted)PB-13

8. Front brake piston (stuck or frozen)BR-40

9. Rear brake piston (stuck or frozen)BR-55

10. Parking brake shoe return tension springPB-13

11. Booster push rod (adjustment necessary)BR-24

12. Vacuum leaks in booster systemBR-29

13. Brake master cylinder (faulty)BR-21

Brake pull1. Front brake piston (stuck or frozen)BR-40

2. Rear brake piston (stuck or frozen)BR-55

3. Front brake pad (oily, cracked or distorted)BR-40

4. Rear brake pad (oily, cracked or distorted)BR-55

5. Parking brake lining (oily, cracked or distorted)PB-13

6. Front brake disc (uneven wear)BR-40

7. Rear brake disc (uneven wear)BR-55

Hard pedal but braking inefficient1. Front brake pad (worn, cracked, distorted, oily or glazed)BR-40

2. Rear brake pad (worn, cracked, distorted, oily or glazed)BR-55

3. Parking brake lining (worn, cracked, distorted, oily or

glazed)PB-13

4. Front brake disc (uneven wear)BR-40

5. Rear brake disc (uneven wear)BR-55

6. Booster push rod (adjustment necessary)BR-24

7. Vacuum leaks in booster systemBR-29

Page 416 of 2000

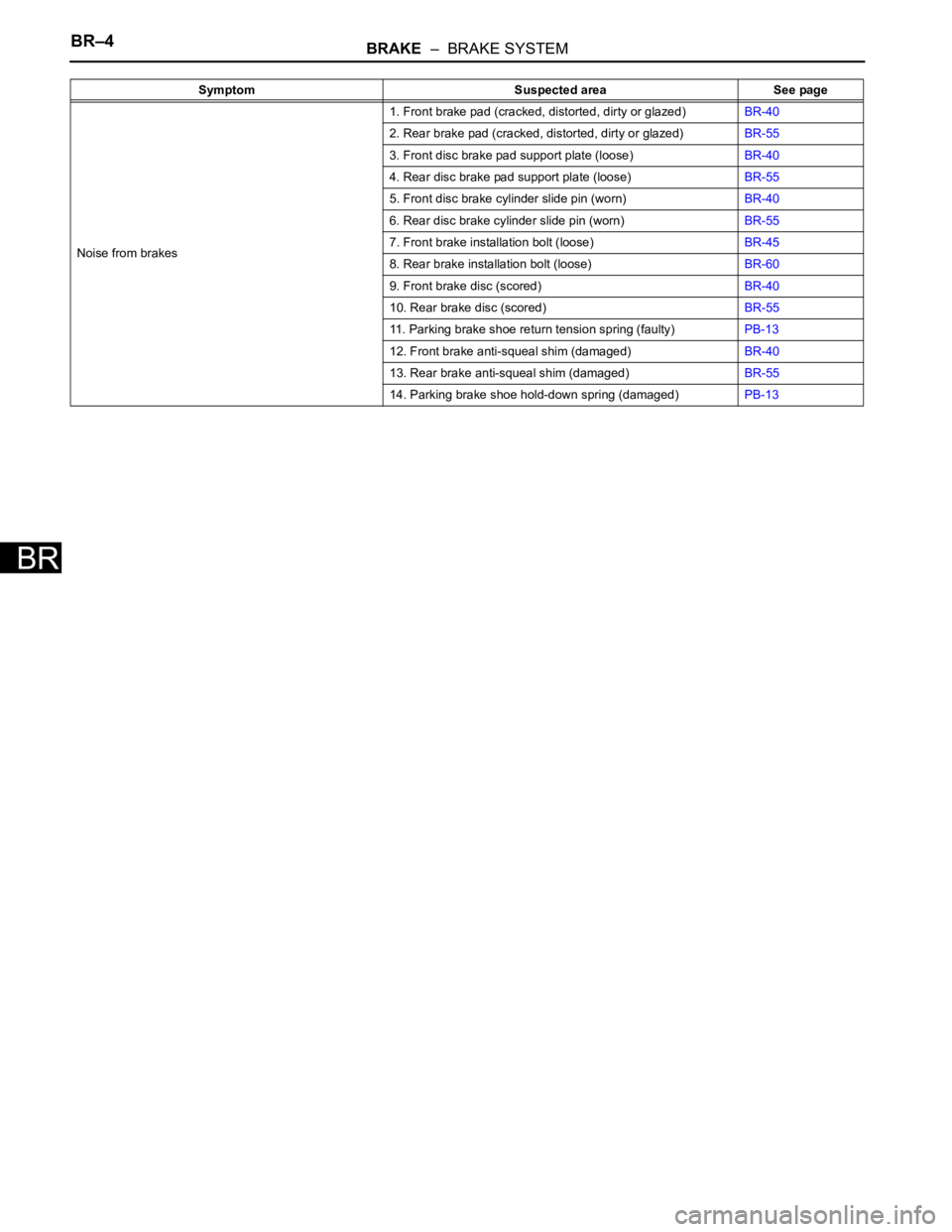

BR–4BRAKE – BRAKE SYSTEM

BR

Noise from brakes1. Front brake pad (cracked, distorted, dirty or glazed)BR-40

2. Rear brake pad (cracked, distorted, dirty or glazed)BR-55

3. Front disc brake pad support plate (loose)BR-40

4. Rear disc brake pad support plate (loose)BR-55

5. Front disc brake cylinder slide pin (worn)BR-40

6. Rear disc brake cylinder slide pin (worn)BR-55

7. Front brake installation bolt (loose)BR-45

8. Rear brake installation bolt (loose)BR-60

9. Front brake disc (scored)BR-40

10. Rear brake disc (scored)BR-55

11. Parking brake shoe return tension spring (faulty)PB-13

12. Front brake anti-squeal shim (damaged)BR-40

13. Rear brake anti-squeal shim (damaged)BR-55

14. Parking brake shoe hold-down spring (damaged)PB-13 Symptom Suspected area See page

Page 417 of 2000

PARKING BRAKE – PARKING BRAKE LEVERPB–5

PB

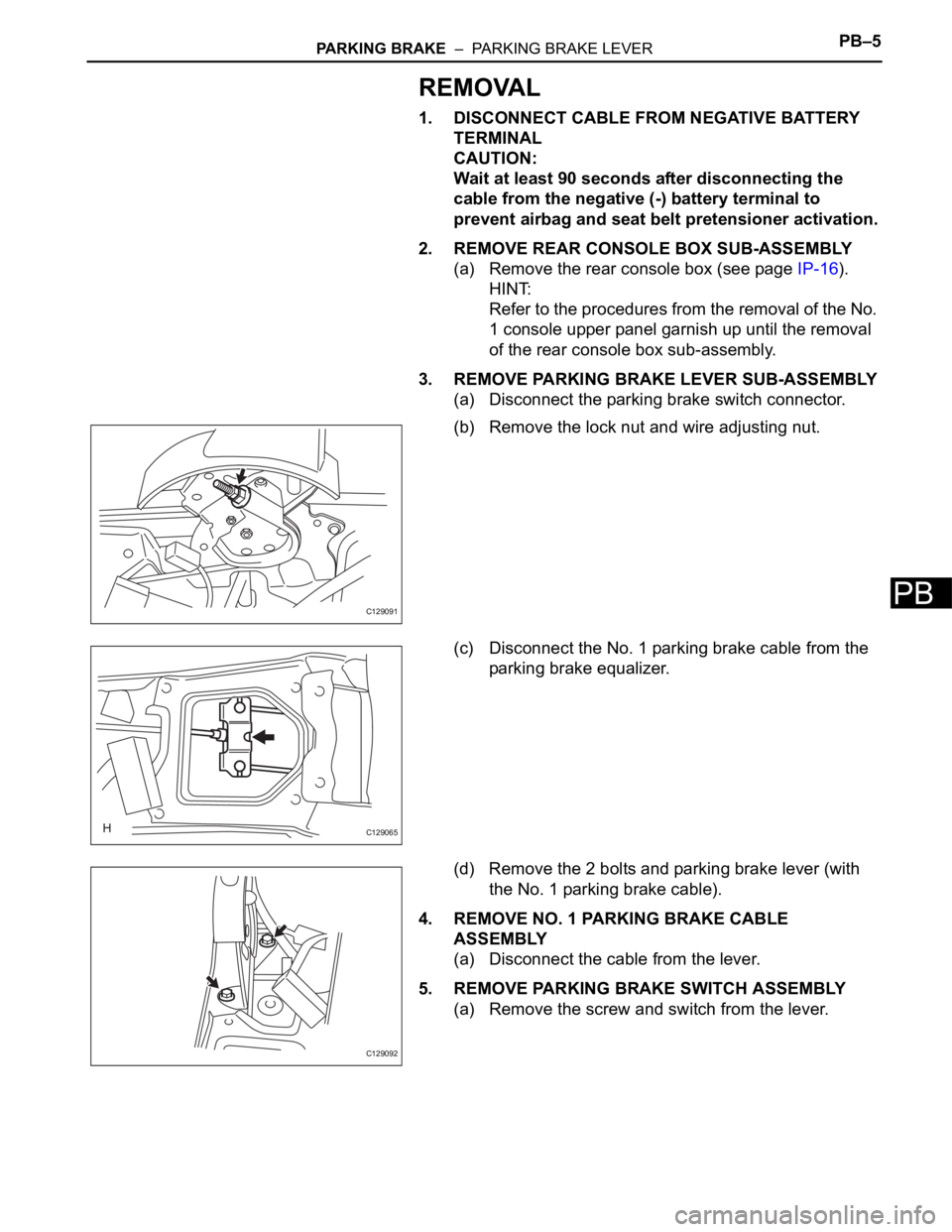

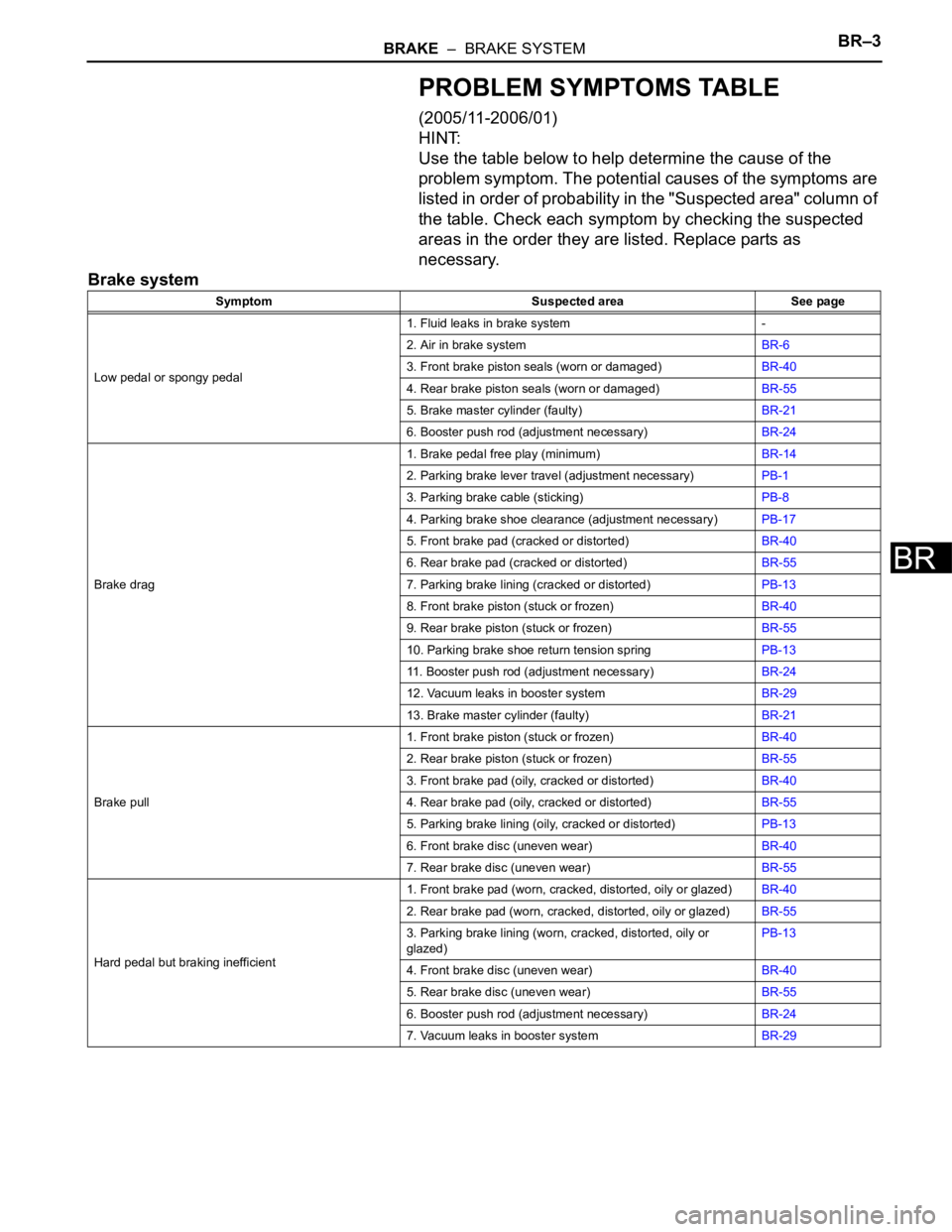

REMOVAL

1. DISCONNECT CABLE FROM NEGATIVE BATTERY

TERMINAL

CAUTION:

Wait at least 90 seconds after disconnecting the

cable from the negative (-) battery terminal to

prevent airbag and seat belt pretensioner activation.

2. REMOVE REAR CONSOLE BOX SUB-ASSEMBLY

(a) Remove the rear console box (see page IP-16).

HINT:

Refer to the procedures from the removal of the No.

1 console upper panel garnish up until the removal

of the rear console box sub-assembly.

3. REMOVE PARKING BRAKE LEVER SUB-ASSEMBLY

(a) Disconnect the parking brake switch connector.

(b) Remove the lock nut and wire adjusting nut.

(c) Disconnect the No. 1 parking brake cable from the

parking brake equalizer.

(d) Remove the 2 bolts and parking brake lever (with

the No. 1 parking brake cable).

4. REMOVE NO. 1 PARKING BRAKE CABLE

ASSEMBLY

(a) Disconnect the cable from the lever.

5. REMOVE PARKING BRAKE SWITCH ASSEMBLY

(a) Remove the screw and switch from the lever.

C129091

C129065

C129092

Page 418 of 2000

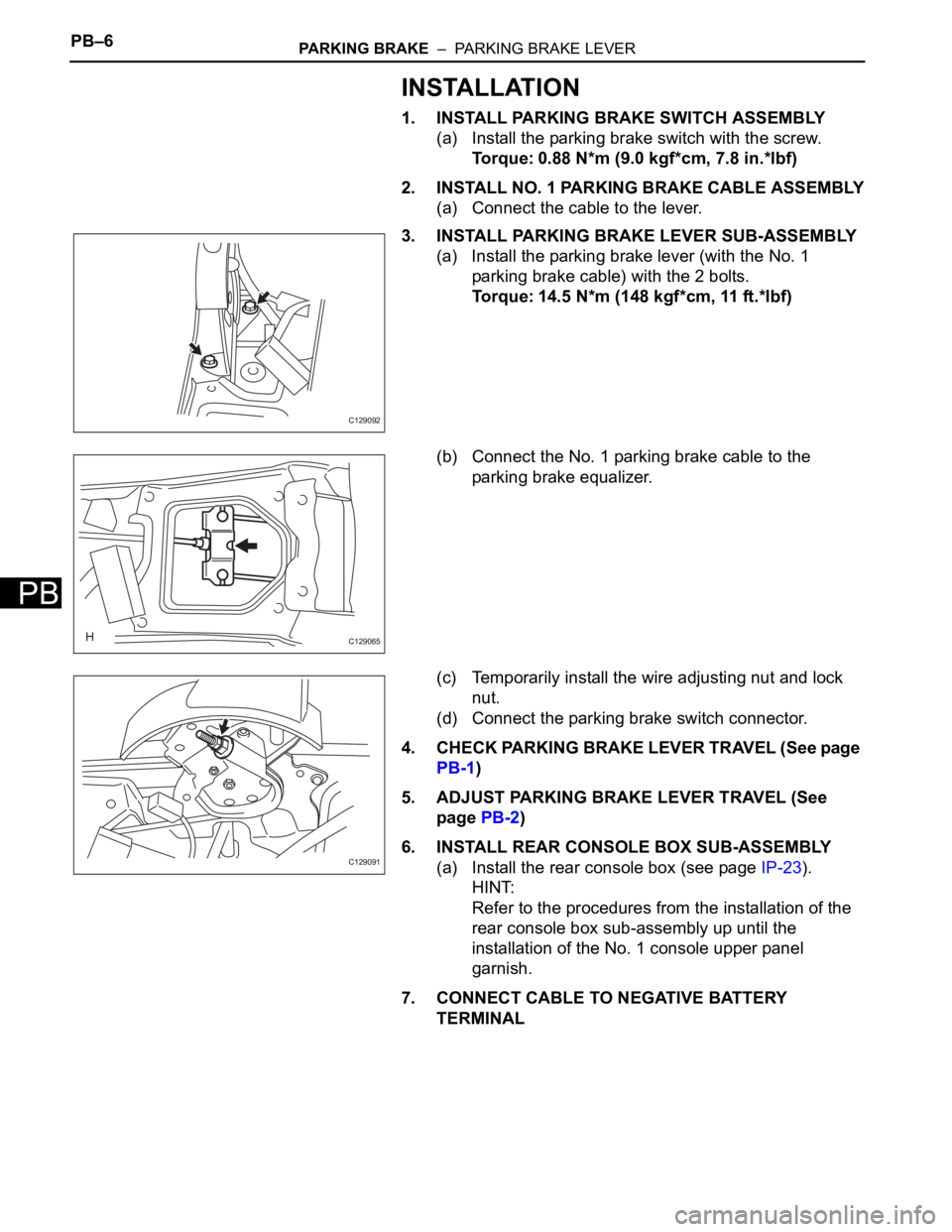

PB–6PARKING BRAKE – PARKING BRAKE LEVER

PB

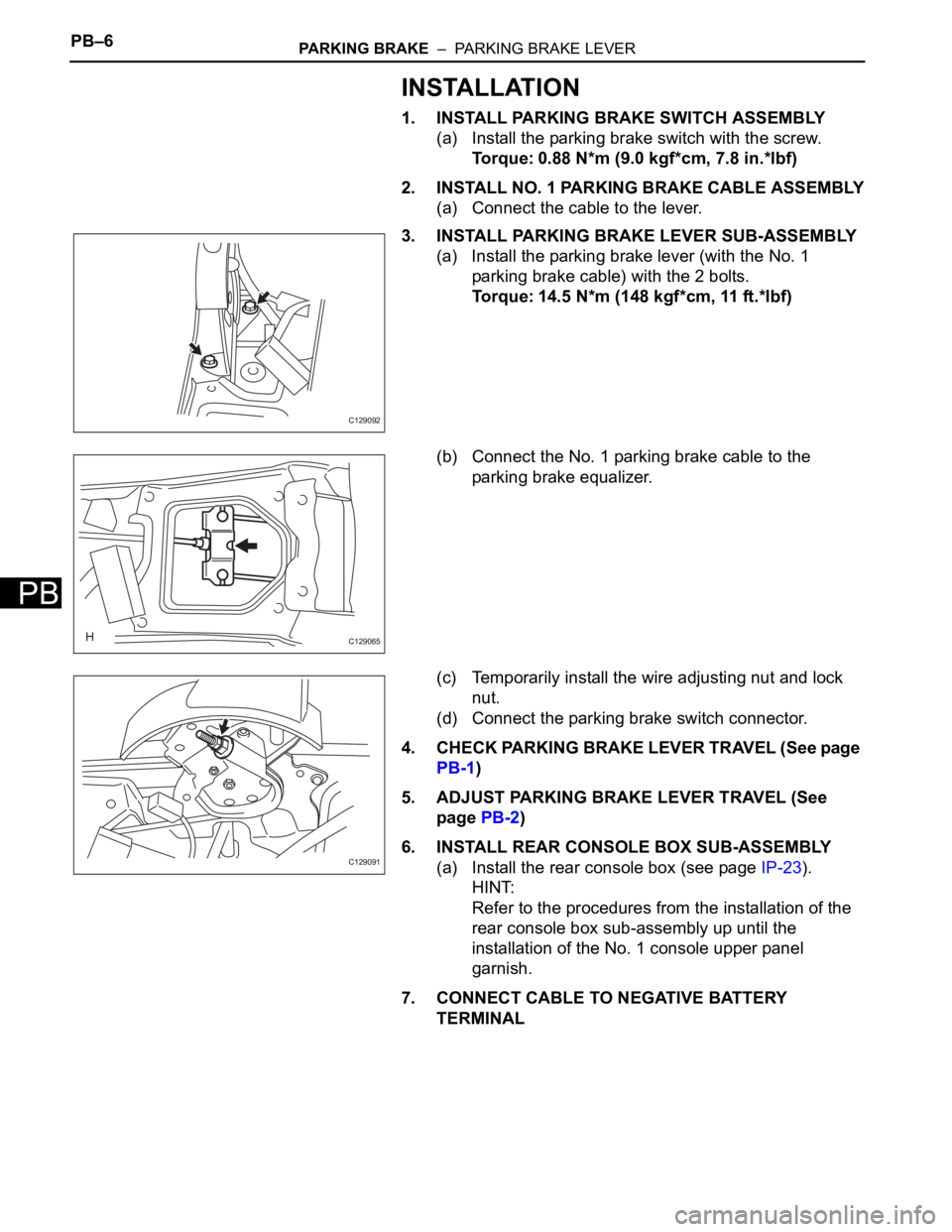

INSTALLATION

1. INSTALL PARKING BRAKE SWITCH ASSEMBLY

(a) Install the parking brake switch with the screw.

Torque: 0.88 N*m (9.0 kgf*cm, 7.8 in.*lbf)

2. INSTALL NO. 1 PARKING BRAKE CABLE ASSEMBLY

(a) Connect the cable to the lever.

3. INSTALL PARKING BRAKE LEVER SUB-ASSEMBLY

(a) Install the parking brake lever (with the No. 1

parking brake cable) with the 2 bolts.

Torque: 14.5 N*m (148 kgf*cm, 11 ft.*lbf)

(b) Connect the No. 1 parking brake cable to the

parking brake equalizer.

(c) Temporarily install the wire adjusting nut and lock

nut.

(d) Connect the parking brake switch connector.

4. CHECK PARKING BRAKE LEVER TRAVEL (See page

PB-1)

5. ADJUST PARKING BRAKE LEVER TRAVEL (See

page PB-2)

6. INSTALL REAR CONSOLE BOX SUB-ASSEMBLY

(a) Install the rear console box (see page IP-23).

HINT:

Refer to the procedures from the installation of the

rear console box sub-assembly up until the

installation of the No. 1 console upper panel

garnish.

7. CONNECT CABLE TO NEGATIVE BATTERY

TERMINAL

C129092

C129065

C129091

Page 419 of 2000

MA–12MAINTENANCE – CHASSIS

MA

GENERAL MAINTENANCE

(2006/01- )

1. INSPECT STEERING LINKAGE AND GEAR HOUSING

(a) Check the steering wheel free play.

(b) Check the steering linkage for looseness or

damage.

(1) Check that the tie rod ends do not have

excessive play.

(2) Check that the dust seals and boots are not

damaged.

(3) Check that the boot clamps are not loose.

(4) Check that the steering gear housing is not

damaged.

(5) Check that the connectors are properly

connected to the steering gear housing.

2. INSPECT BALL JOINTS AND DUST COVERS

(a) Inspect the ball joints for excessive looseness.

(1) Jack up the front of the vehicle and place

wooden blocks with a height of 180 to 200 mm

(7.09 to 7.87 in.) under the front tires.

(2) Lower the vehicle until the front coil spring has

about half its ordinary load. Place stands under

the vehicle for safety.

(3) Check that the front wheels are pointing

straight ahead. Use wheel chocks on all 4

wheels.

(4) Using a lever, pry up the end of the lower arm.

Check the amount of play.

Maximum ball joint vertical play:

0 mm (0 in.)

If there is any play, replace the ball joint.

(b) Check the dust cover for damage.

3. INSPECT DRIVE SHAFT BOOTS

(a) Check the drive shaft boots for loose clamps,

grease leakage, kinks or damage.

4. INSPECT AUTOMATIC TRANSAXLE FLUID LEVEL

(a) Visually check the transmission for fluid leakage. If

oil is leaking, find the cause and repair it.

5. INSPECT TRANSFER OIL (for 4WD)

(a) Visually check the transfer for oil leakage. If oil is

leaking, find the cause and repair it.

6. INSPECT REAR DIFFERENTIAL OIL (for 4WD)

(a) For the rear differential oil inspection, refer to the

following procedures (see page DF-3).

Type See procedures

U151E See page AX-126

U151F See page AX-126

Type See procedures

Front Oil See page TF-45

Rear Oil See page TF-45

Page 420 of 2000

MAINTENANCE – CHASSISMA–13

MA

7. ROTATE TIRES (See page TW-1)

Trending: bolt pattern, page ac-172, cruise control, low oil pressure, adding oil, AC-172, drive train