TOYOTA RAV4 2006 Service Repair Manual

Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 581 of 2000

EM–242AZ-FE ENGINE MECHANICAL – TIMING CHAIN

EM

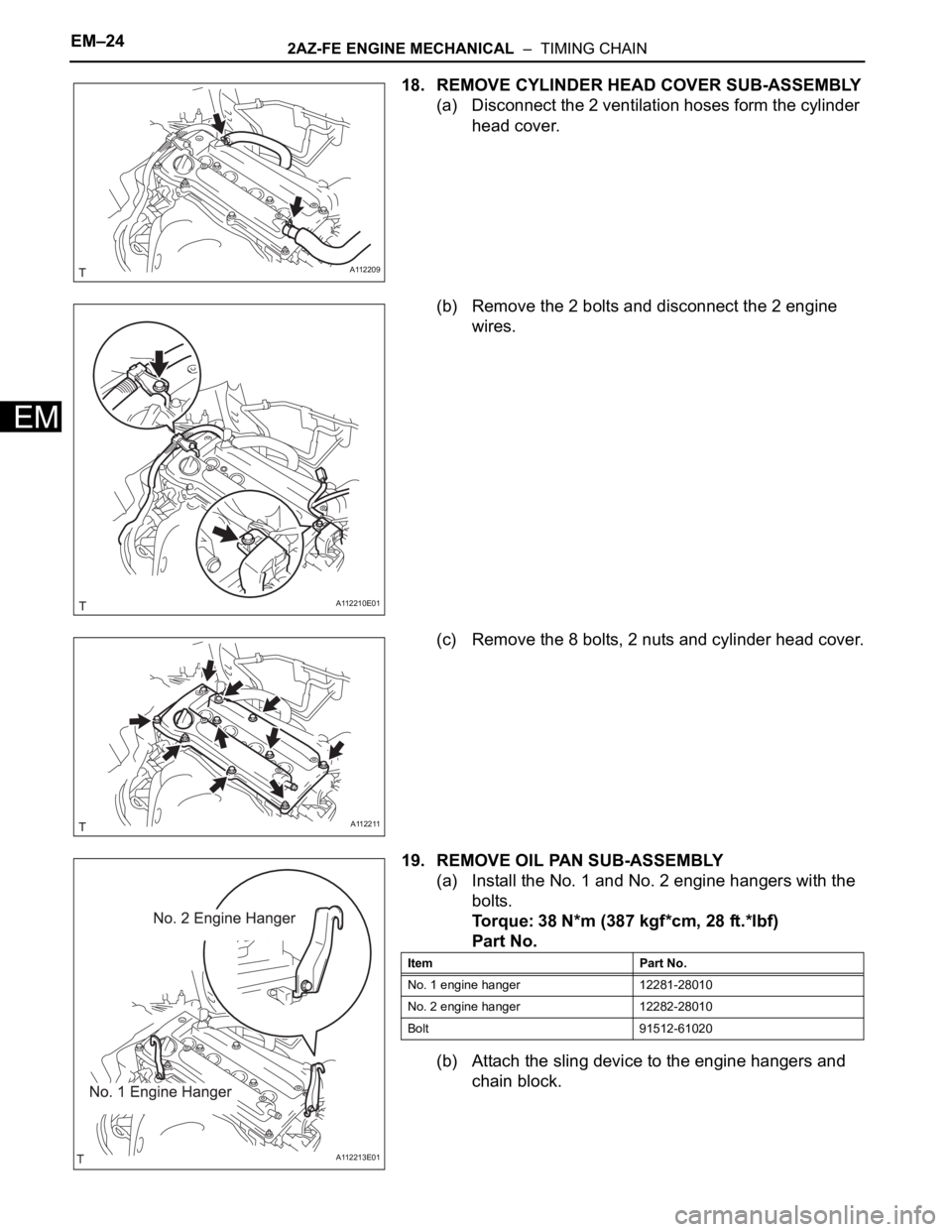

18. REMOVE CYLINDER HEAD COVER SUB-ASSEMBLY

(a) Disconnect the 2 ventilation hoses form the cylinder

head cover.

(b) Remove the 2 bolts and disconnect the 2 engine

wires.

(c) Remove the 8 bolts, 2 nuts and cylinder head cover.

19. REMOVE OIL PAN SUB-ASSEMBLY

(a) Install the No. 1 and No. 2 engine hangers with the

bolts.

Torque: 38 N*m (387 kgf*cm, 28 ft.*lbf)

Part No.

(b) Attach the sling device to the engine hangers and

chain block.

A112209

A112210E01

A112211

A112213E01

Item Part No.

No. 1 engine hanger 12281-28010

No. 2 engine hanger 12282-28010

Bolt 91512-61020

Page 582 of 2000

2AZ-FE ENGINE MECHANICAL – TIMING CHAINEM–25

EM

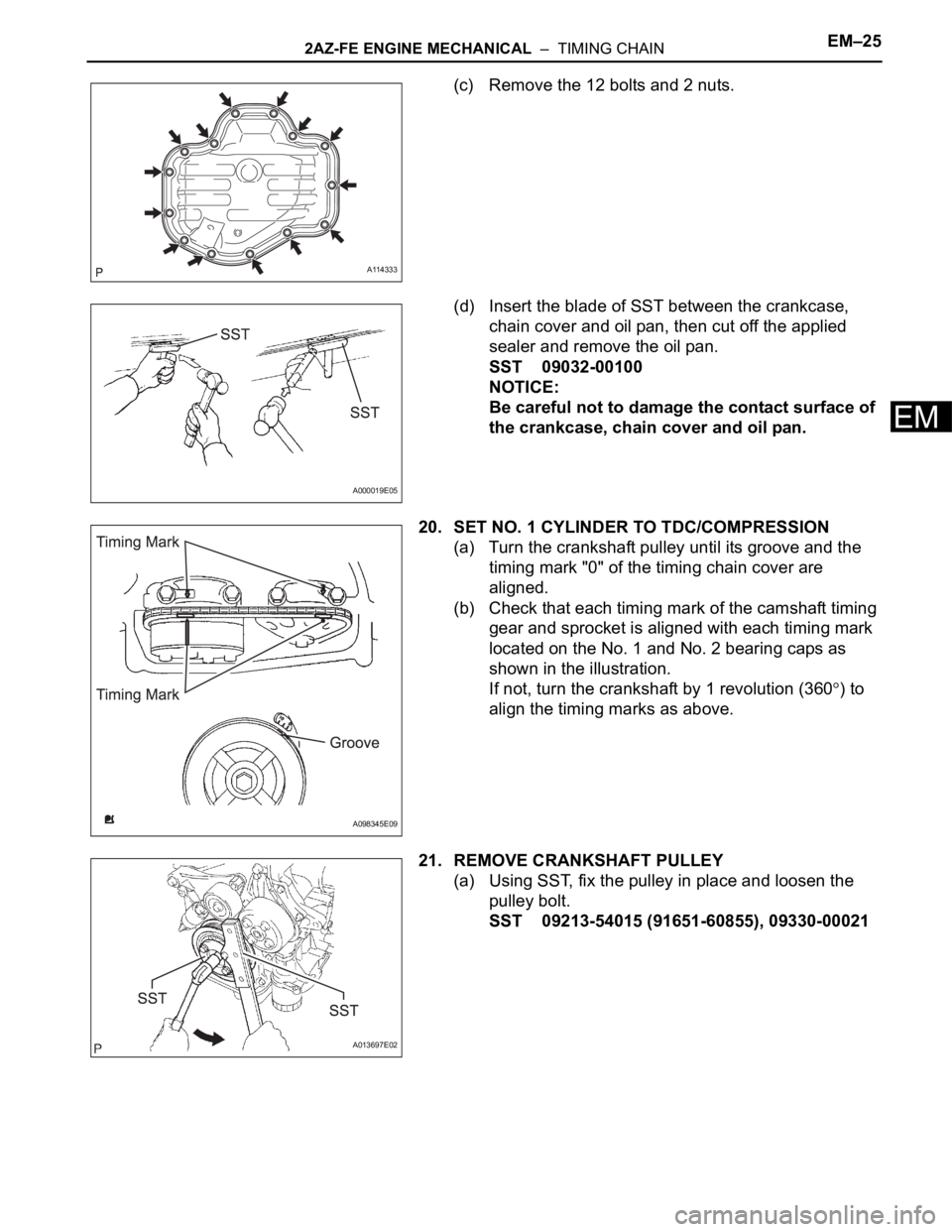

(c) Remove the 12 bolts and 2 nuts.

(d) Insert the blade of SST between the crankcase,

chain cover and oil pan, then cut off the applied

sealer and remove the oil pan.

SST 09032-00100

NOTICE:

Be careful not to damage the contact surface of

the crankcase, chain cover and oil pan.

20. SET NO. 1 CYLINDER TO TDC/COMPRESSION

(a) Turn the crankshaft pulley until its groove and the

timing mark "0" of the timing chain cover are

aligned.

(b) Check that each timing mark of the camshaft timing

gear and sprocket is aligned with each timing mark

located on the No. 1 and No. 2 bearing caps as

shown in the illustration.

If not, turn the crankshaft by 1 revolution (360

) to

align the timing marks as above.

21. REMOVE CRANKSHAFT PULLEY

(a) Using SST, fix the pulley in place and loosen the

pulley bolt.

SST 09213-54015 (91651-60855), 09330-00021

A114333

A000019E05

A098345E09

A013697E02

Page 583 of 2000

EM–262AZ-FE ENGINE MECHANICAL – TIMING CHAIN

EM

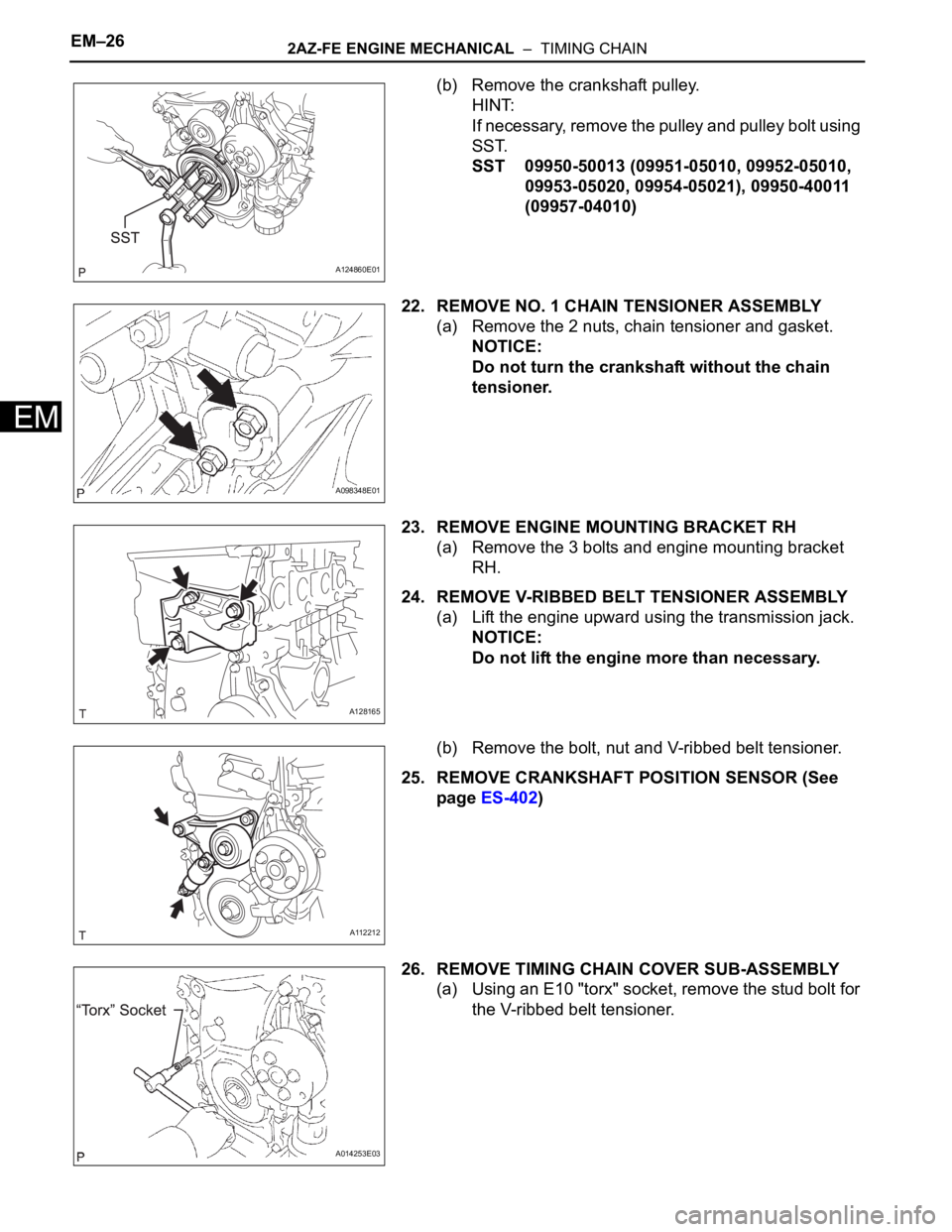

(b) Remove the crankshaft pulley.

HINT:

If necessary, remove the pulley and pulley bolt using

SST.

SST 09950-50013 (09951-05010, 09952-05010,

09953-05020, 09954-05021), 09950-40011

(09957-04010)

22. REMOVE NO. 1 CHAIN TENSIONER ASSEMBLY

(a) Remove the 2 nuts, chain tensioner and gasket.

NOTICE:

Do not turn the crankshaft without the chain

tensioner.

23. REMOVE ENGINE MOUNTING BRACKET RH

(a) Remove the 3 bolts and engine mounting bracket

RH.

24. REMOVE V-RIBBED BELT TENSIONER ASSEMBLY

(a) Lift the engine upward using the transmission jack.

NOTICE:

Do not lift the engine more than necessary.

(b) Remove the bolt, nut and V-ribbed belt tensioner.

25. REMOVE CRANKSHAFT POSITION SENSOR (See

page ES-402)

26. REMOVE TIMING CHAIN COVER SUB-ASSEMBLY

(a) Using an E10 "torx" socket, remove the stud bolt for

the V-ribbed belt tensioner.

A124860E01

A098348E01

A128165

A112212

A014253E03

Page 584 of 2000

2AZ-FE ENGINE MECHANICAL – TIMING CHAINEM–27

EM

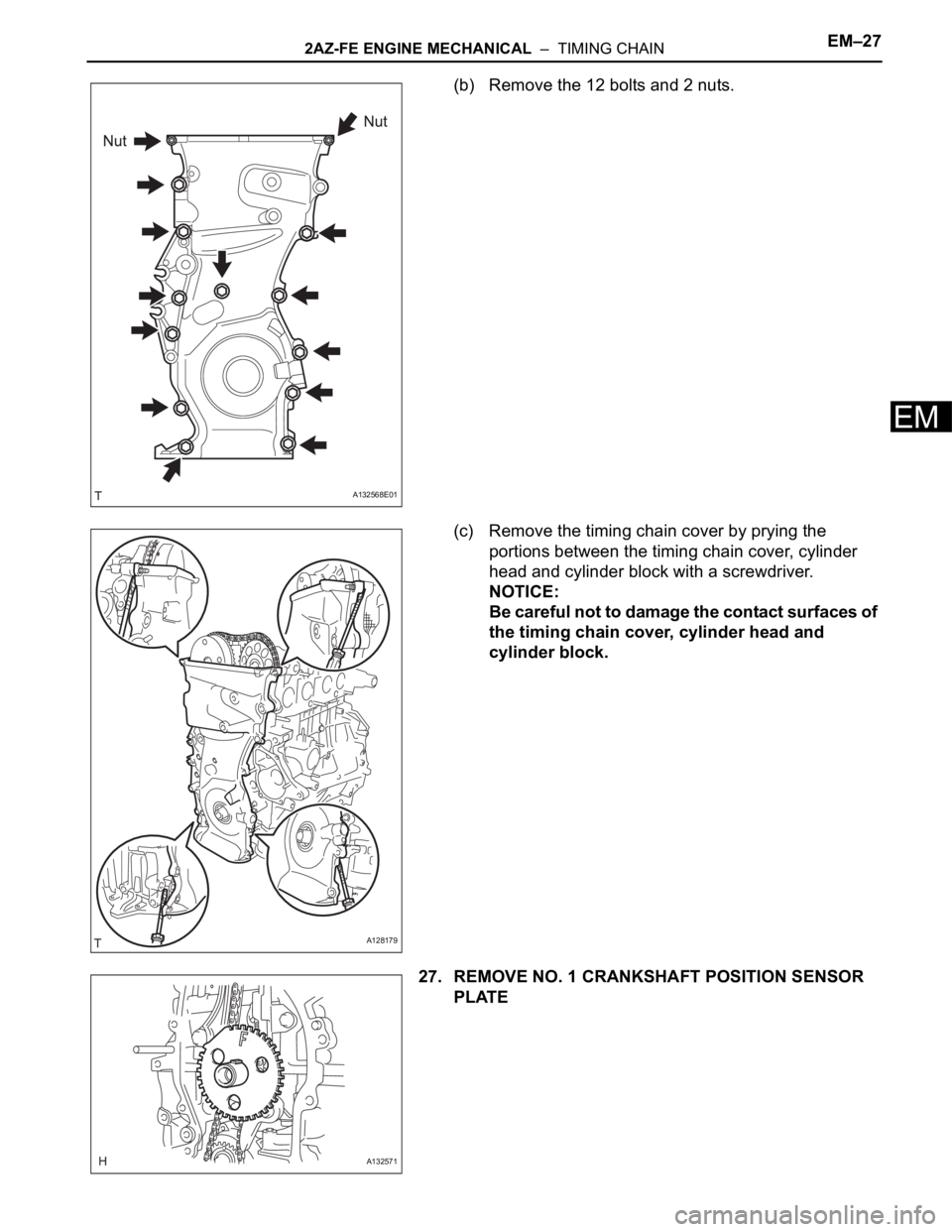

(b) Remove the 12 bolts and 2 nuts.

(c) Remove the timing chain cover by prying the

portions between the timing chain cover, cylinder

head and cylinder block with a screwdriver.

NOTICE:

Be careful not to damage the contact surfaces of

the timing chain cover, cylinder head and

cylinder block.

27. REMOVE NO. 1 CRANKSHAFT POSITION SENSOR

PLATE

A132568E01

A128179

A132571

Page 585 of 2000

EM–282AZ-FE ENGINE MECHANICAL – TIMING CHAIN

EM

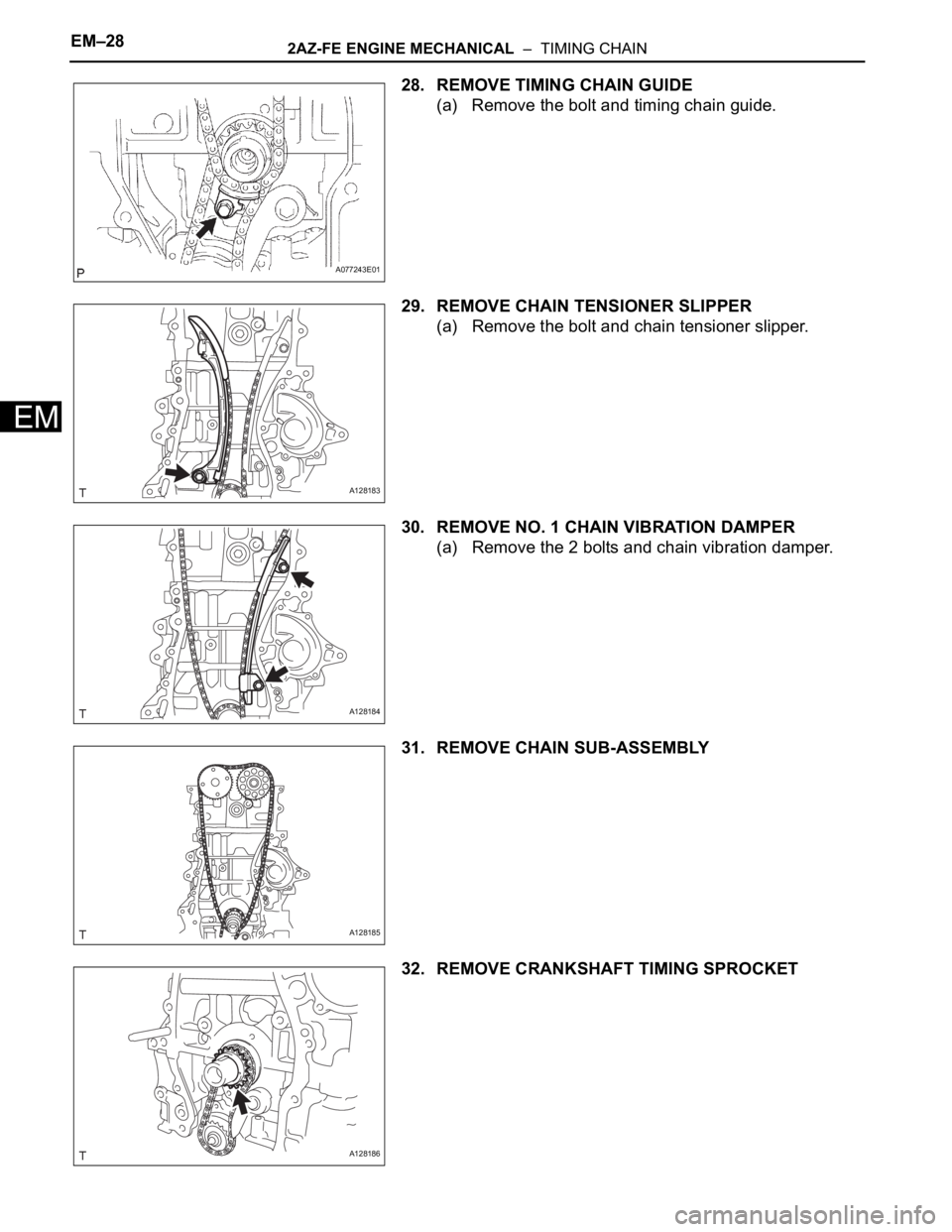

28. REMOVE TIMING CHAIN GUIDE

(a) Remove the bolt and timing chain guide.

29. REMOVE CHAIN TENSIONER SLIPPER

(a) Remove the bolt and chain tensioner slipper.

30. REMOVE NO. 1 CHAIN VIBRATION DAMPER

(a) Remove the 2 bolts and chain vibration damper.

31. REMOVE CHAIN SUB-ASSEMBLY

32. REMOVE CRANKSHAFT TIMING SPROCKET

A077243E01

A128183

A128184

A128185

A128186

Page 586 of 2000

2AZ-FE ENGINE MECHANICAL – TIMING CHAINEM–29

EM

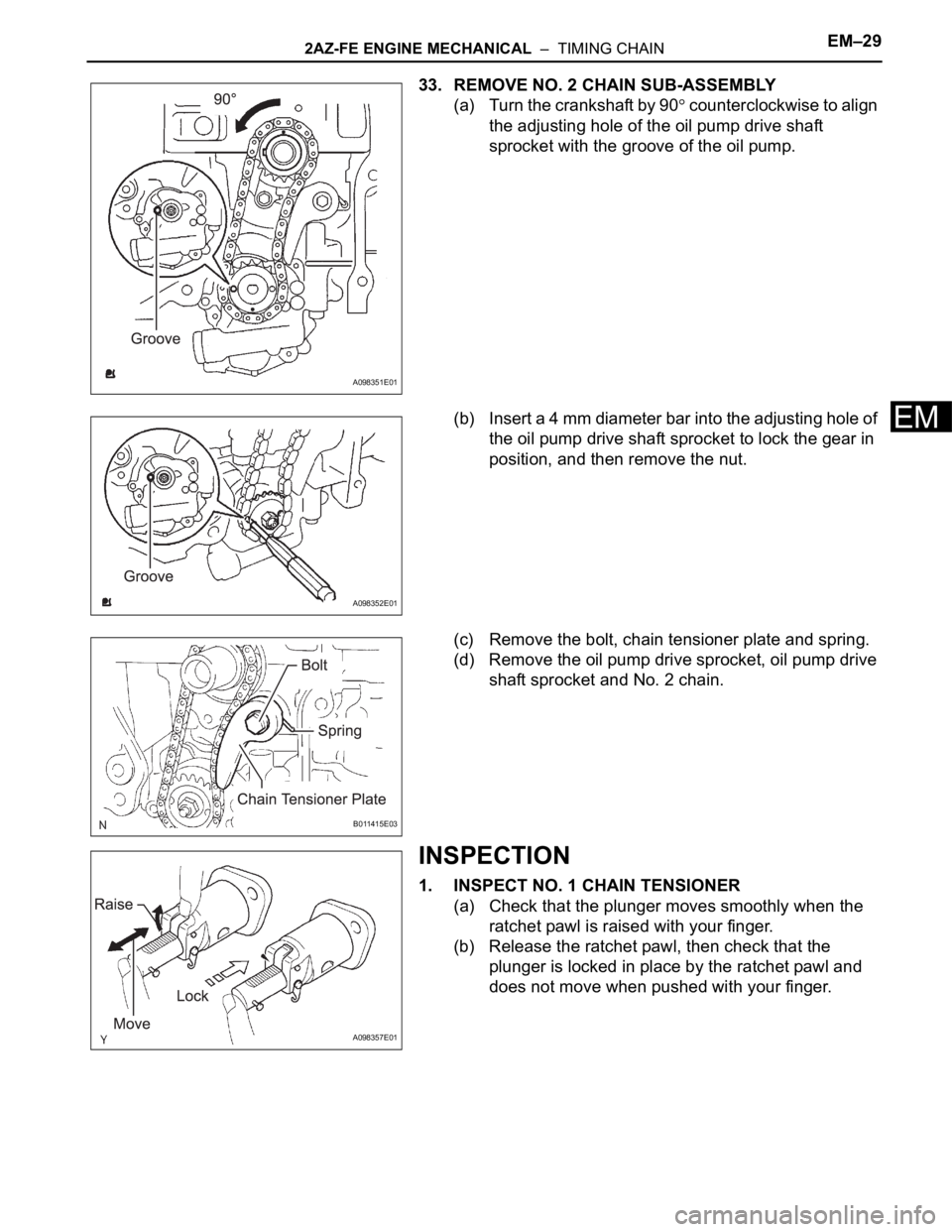

33. REMOVE NO. 2 CHAIN SUB-ASSEMBLY

(a) Turn the crankshaft by 90

counterclockwise to align

the adjusting hole of the oil pump drive shaft

sprocket with the groove of the oil pump.

(b) Insert a 4 mm diameter bar into the adjusting hole of

the oil pump drive shaft sprocket to lock the gear in

position, and then remove the nut.

(c) Remove the bolt, chain tensioner plate and spring.

(d) Remove the oil pump drive sprocket, oil pump drive

shaft sprocket and No. 2 chain.

INSPECTION

1. INSPECT NO. 1 CHAIN TENSIONER

(a) Check that the plunger moves smoothly when the

ratchet pawl is raised with your finger.

(b) Release the ratchet pawl, then check that the

plunger is locked in place by the ratchet pawl and

does not move when pushed with your finger.

A098351E01

A098352E01

B011415E03

A098357E01

Page 587 of 2000

EM–302AZ-FE ENGINE MECHANICAL – TIMING CHAIN

EM

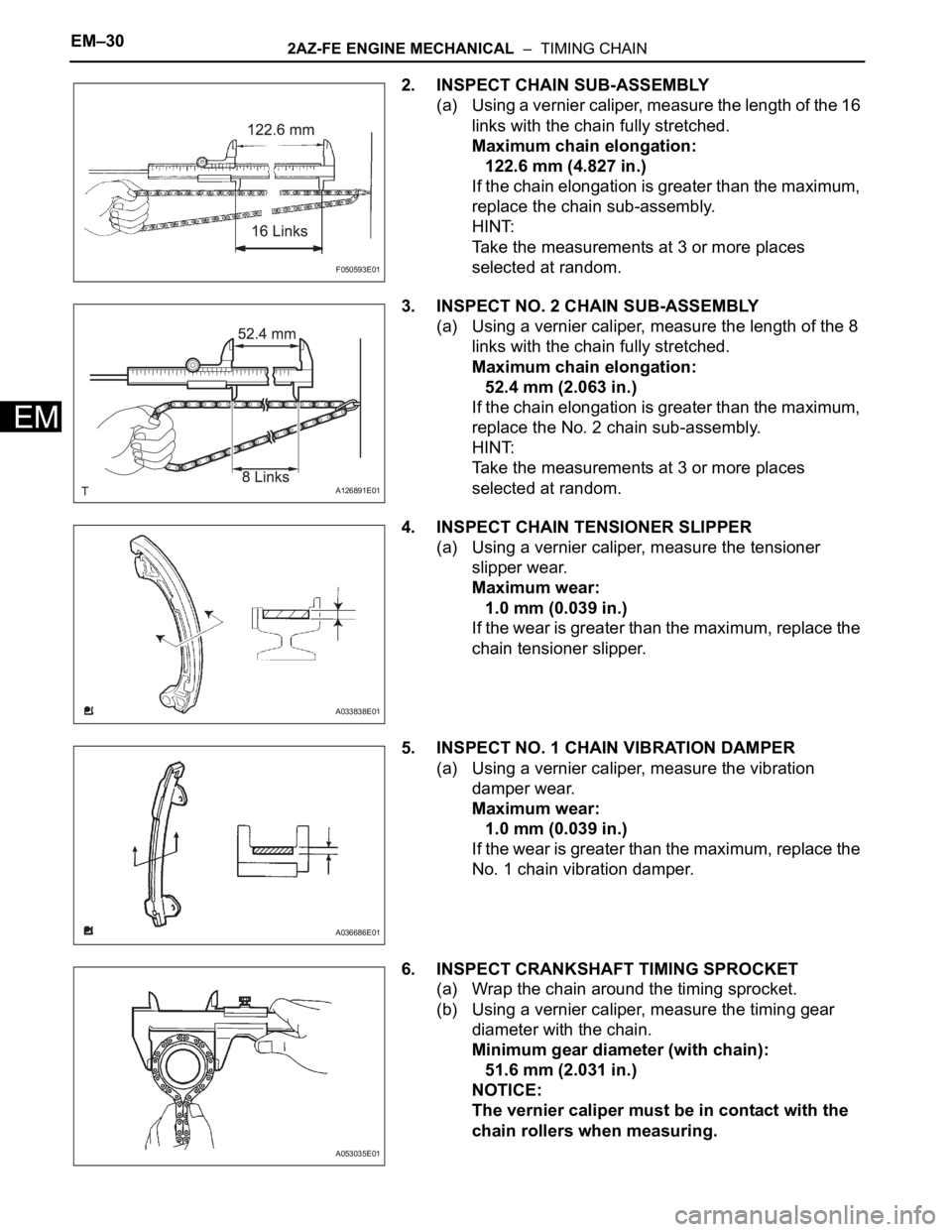

2. INSPECT CHAIN SUB-ASSEMBLY

(a) Using a vernier caliper, measure the length of the 16

links with the chain fully stretched.

Maximum chain elongation:

122.6 mm (4.827 in.)

If the chain elongation is greater than the maximum,

replace the chain sub-assembly.

HINT:

Take the measurements at 3 or more places

selected at random.

3. INSPECT NO. 2 CHAIN SUB-ASSEMBLY

(a) Using a vernier caliper, measure the length of the 8

links with the chain fully stretched.

Maximum chain elongation:

52.4 mm (2.063 in.)

If the chain elongation is greater than the maximum,

replace the No. 2 chain sub-assembly.

HINT:

Take the measurements at 3 or more places

selected at random.

4. INSPECT CHAIN TENSIONER SLIPPER

(a) Using a vernier caliper, measure the tensioner

slipper wear.

Maximum wear:

1.0 mm (0.039 in.)

If the wear is greater than the maximum, replace the

chain tensioner slipper.

5. INSPECT NO. 1 CHAIN VIBRATION DAMPER

(a) Using a vernier caliper, measure the vibration

damper wear.

Maximum wear:

1.0 mm (0.039 in.)

If the wear is greater than the maximum, replace the

No. 1 chain vibration damper.

6. INSPECT CRANKSHAFT TIMING SPROCKET

(a) Wrap the chain around the timing sprocket.

(b) Using a vernier caliper, measure the timing gear

diameter with the chain.

Minimum gear diameter (with chain):

51.6 mm (2.031 in.)

NOTICE:

The vernier caliper must be in contact with the

chain rollers when measuring.

F050593E01

A126891E01

A033838E01

A036686E01

A053035E01

Page 588 of 2000

2AZ-FE ENGINE MECHANICAL – TIMING CHAINEM–31

EM

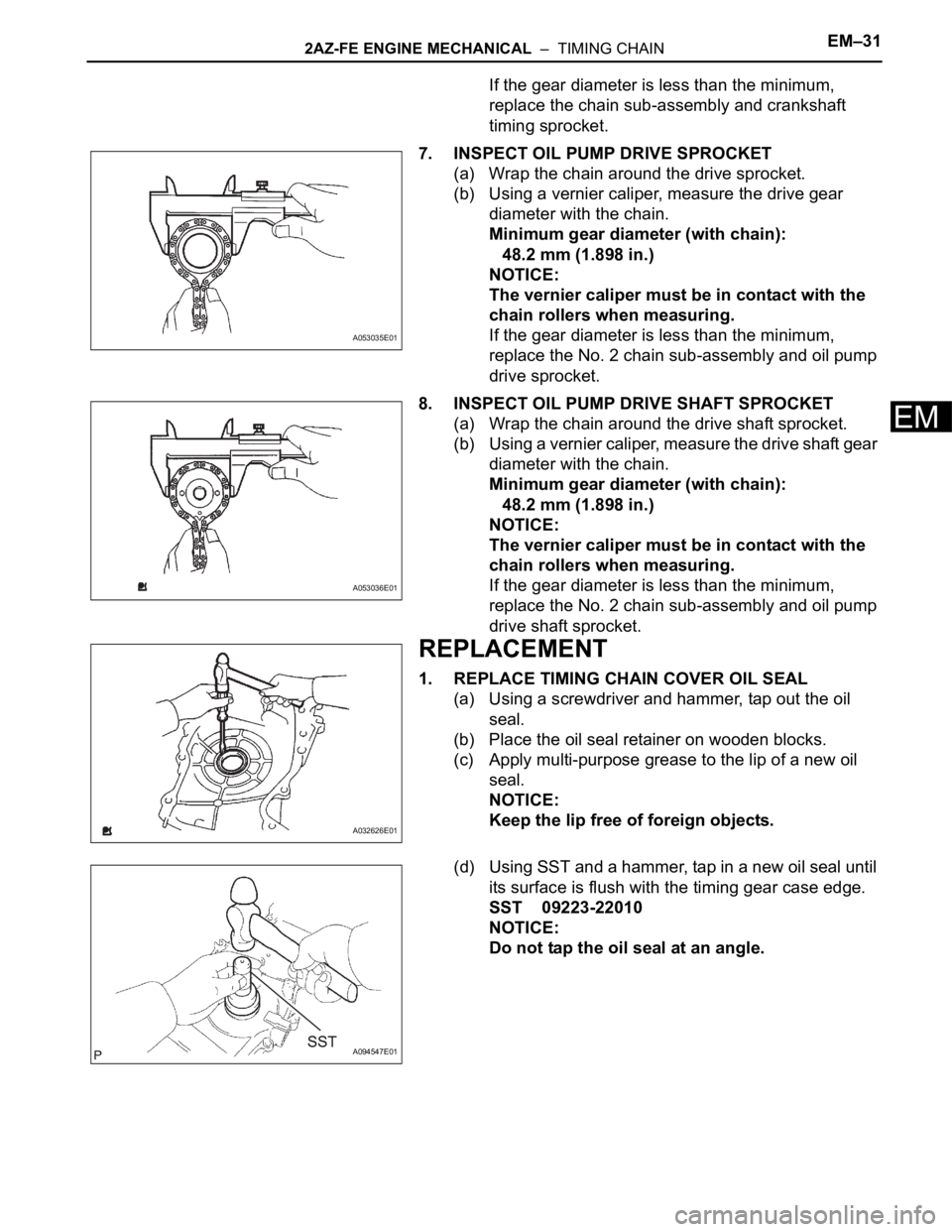

If the gear diameter is less than the minimum,

replace the chain sub-assembly and crankshaft

timing sprocket.

7. INSPECT OIL PUMP DRIVE SPROCKET

(a) Wrap the chain around the drive sprocket.

(b) Using a vernier caliper, measure the drive gear

diameter with the chain.

Minimum gear diameter (with chain):

48.2 mm (1.898 in.)

NOTICE:

The vernier caliper must be in contact with the

chain rollers when measuring.

If the gear diameter is less than the minimum,

replace the No. 2 chain sub-assembly and oil pump

drive sprocket.

8. INSPECT OIL PUMP DRIVE SHAFT SPROCKET

(a) Wrap the chain around the drive shaft sprocket.

(b) Using a vernier caliper, measure the drive shaft gear

diameter with the chain.

Minimum gear diameter (with chain):

48.2 mm (1.898 in.)

NOTICE:

The vernier caliper must be in contact with the

chain rollers when measuring.

If the gear diameter is less than the minimum,

replace the No. 2 chain sub-assembly and oil pump

drive shaft sprocket.

REPLACEMENT

1. REPLACE TIMING CHAIN COVER OIL SEAL

(a) Using a screwdriver and hammer, tap out the oil

seal.

(b) Place the oil seal retainer on wooden blocks.

(c) Apply multi-purpose grease to the lip of a new oil

seal.

NOTICE:

Keep the lip free of foreign objects.

(d) Using SST and a hammer, tap in a new oil seal until

its surface is flush with the timing gear case edge.

SST 09223-22010

NOTICE:

Do not tap the oil seal at an angle.

A053035E01

A053036E01

A032626E01

A094547E01

Page 589 of 2000

EM–322AZ-FE ENGINE MECHANICAL – TIMING CHAIN

EM

INSTALLATION

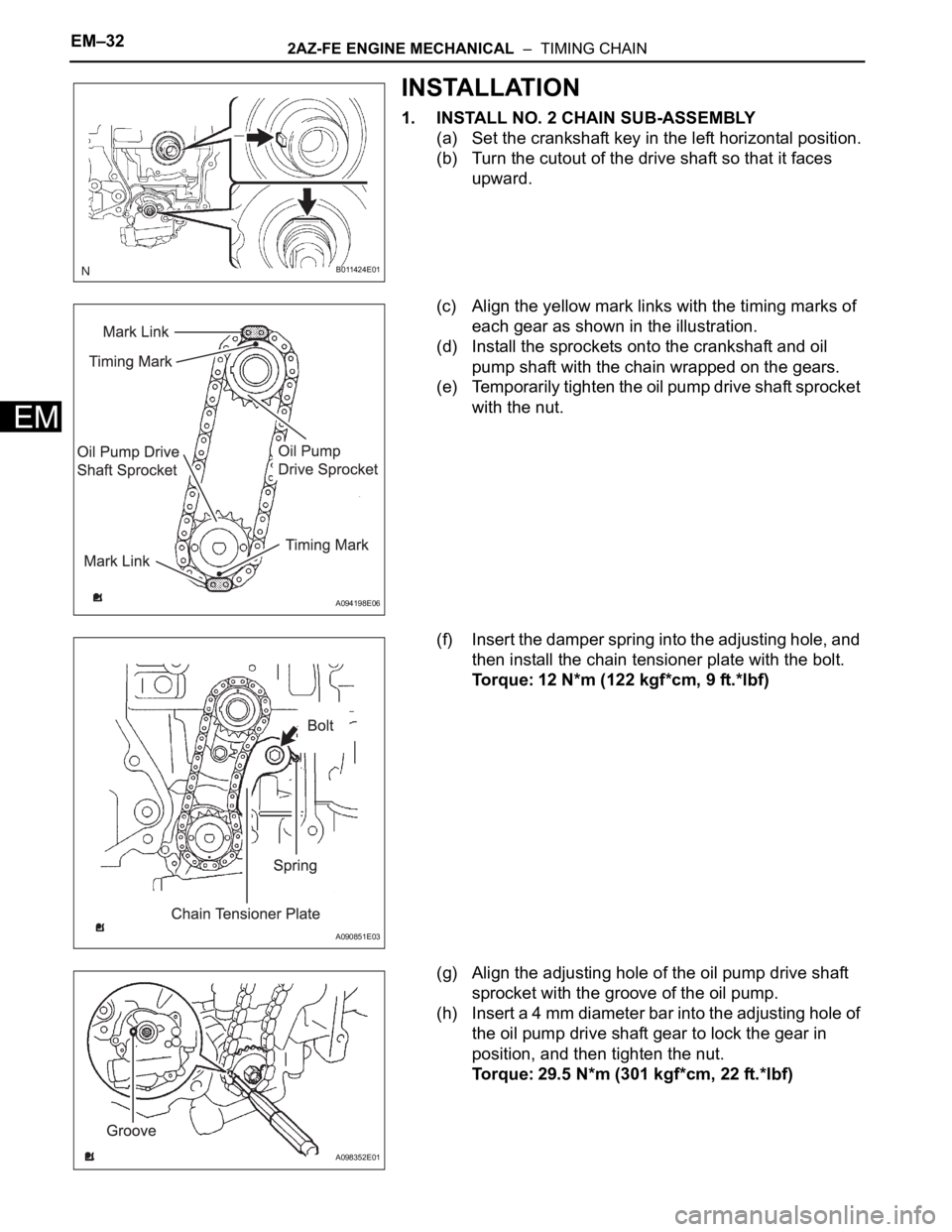

1. INSTALL NO. 2 CHAIN SUB-ASSEMBLY

(a) Set the crankshaft key in the left horizontal position.

(b) Turn the cutout of the drive shaft so that it faces

upward.

(c) Align the yellow mark links with the timing marks of

each gear as shown in the illustration.

(d) Install the sprockets onto the crankshaft and oil

pump shaft with the chain wrapped on the gears.

(e) Temporarily tighten the oil pump drive shaft sprocket

with the nut.

(f) Insert the damper spring into the adjusting hole, and

then install the chain tensioner plate with the bolt.

Torque: 12 N*m (122 kgf*cm, 9 ft.*lbf)

(g) Align the adjusting hole of the oil pump drive shaft

sprocket with the groove of the oil pump.

(h) Insert a 4 mm diameter bar into the adjusting hole of

the oil pump drive shaft gear to lock the gear in

position, and then tighten the nut.

Torque: 29.5 N*m (301 kgf*cm, 22 ft.*lbf)

B011424E01

A094198E06

A090851E03

A098352E01

Page 590 of 2000

2AZ-FE ENGINE MECHANICAL – TIMING CHAINEM–33

EM

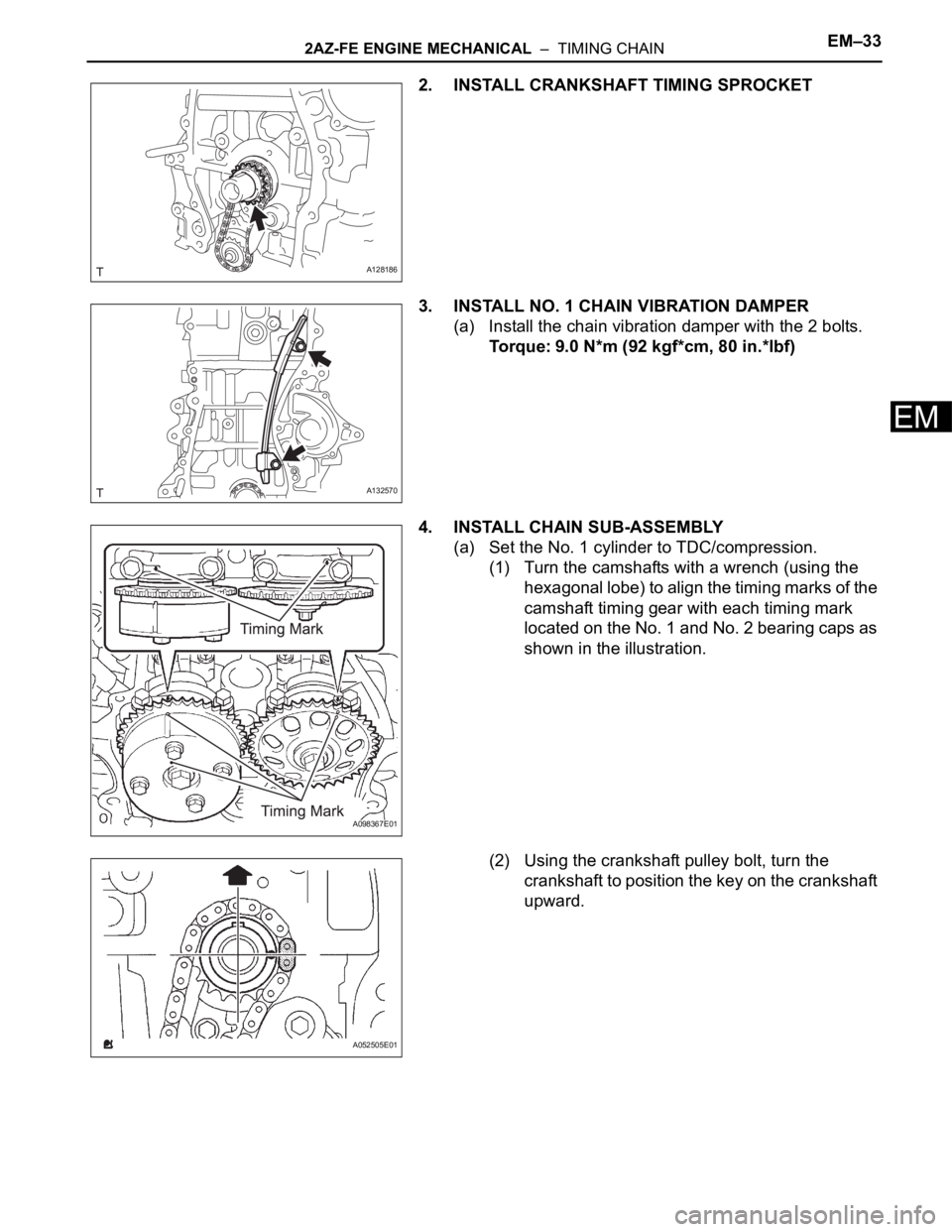

2. INSTALL CRANKSHAFT TIMING SPROCKET

3. INSTALL NO. 1 CHAIN VIBRATION DAMPER

(a) Install the chain vibration damper with the 2 bolts.

Torque: 9.0 N*m (92 kgf*cm, 80 in.*lbf)

4. INSTALL CHAIN SUB-ASSEMBLY

(a) Set the No. 1 cylinder to TDC/compression.

(1) Turn the camshafts with a wrench (using the

hexagonal lobe) to align the timing marks of the

camshaft timing gear with each timing mark

located on the No. 1 and No. 2 bearing caps as

shown in the illustration.

(2) Using the crankshaft pulley bolt, turn the

crankshaft to position the key on the crankshaft

upward.

A128186

A132570

A098367E01

A052505E01