TOYOTA RAV4 2006 Service Repair Manual

Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 601 of 2000

2AZ-FE ENGINE MECHANICAL – CYLINDER HEADEM–57

EM

REMOVAL

1. DISCHARGE FUEL SYSTEM PRESSURE (See page

FU-9)

2. DISCONNECT CABLE FROM NEGATIVE BATTERY

TERMINAL

CAUTION:

Wait at least 90 seconds after disconnecting the

cable from the negative (-) battery terminal to

prevent airbag and seat belt pretensioner activation.

3. REMOVE RADIATOR SUPPORT OPENING COVER

4. REMOVE FRONT WHEEL RH

5. REMOVE NO. 1 ENGINE UNDER COVER

6. REMOVE FRONT FENDER APRON RH

7. REMOVE NO. 1 ENGINE COVER (See page EM-22)

8. DRAIN ENGINE COOLANT (See page CO-6)

9. DRAIN ENGINE OIL (See page LU-4)

10. REMOVE AIR CLEANER CAP (See page ES-411)

11. REMOVE THROTTLE BODY (See page ES-412)

12. REMOVE FUEL DELIVERY PIPE SUB-ASSEMBLY

(See page FU-10)

13. REMOVE INTAKE MANIFOLD (See page ES-419)

14. REMOVE INTAKE MANIFOLD INSULATOR (See page

ES-420)

15. REMOVE FRONT EXHAUST PIPE (See page EX-3)

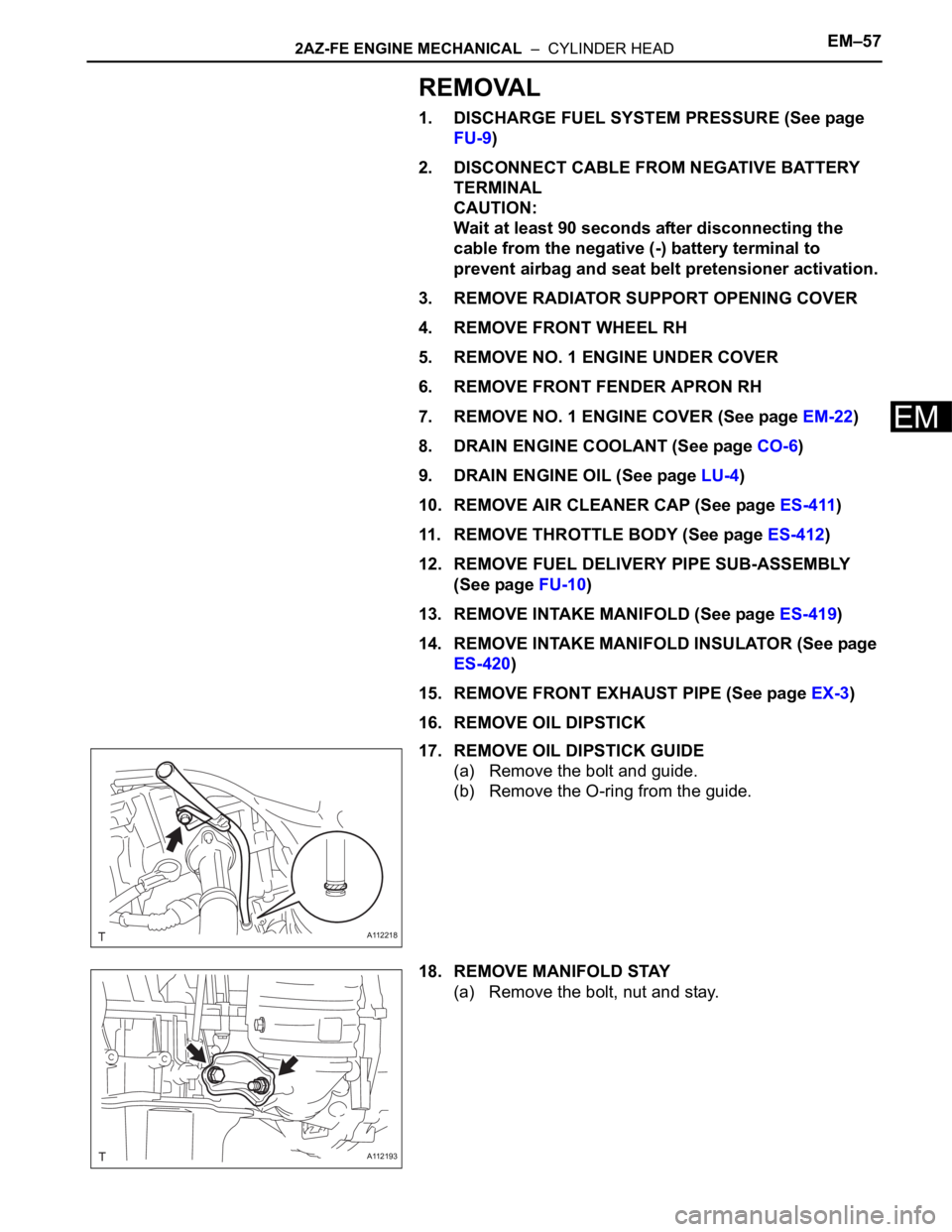

16. REMOVE OIL DIPSTICK

17. REMOVE OIL DIPSTICK GUIDE

(a) Remove the bolt and guide.

(b) Remove the O-ring from the guide.

18. REMOVE MANIFOLD STAY

(a) Remove the bolt, nut and stay.

A112218

A112193

Page 602 of 2000

EM–582AZ-FE ENGINE MECHANICAL – CYLINDER HEAD

EM

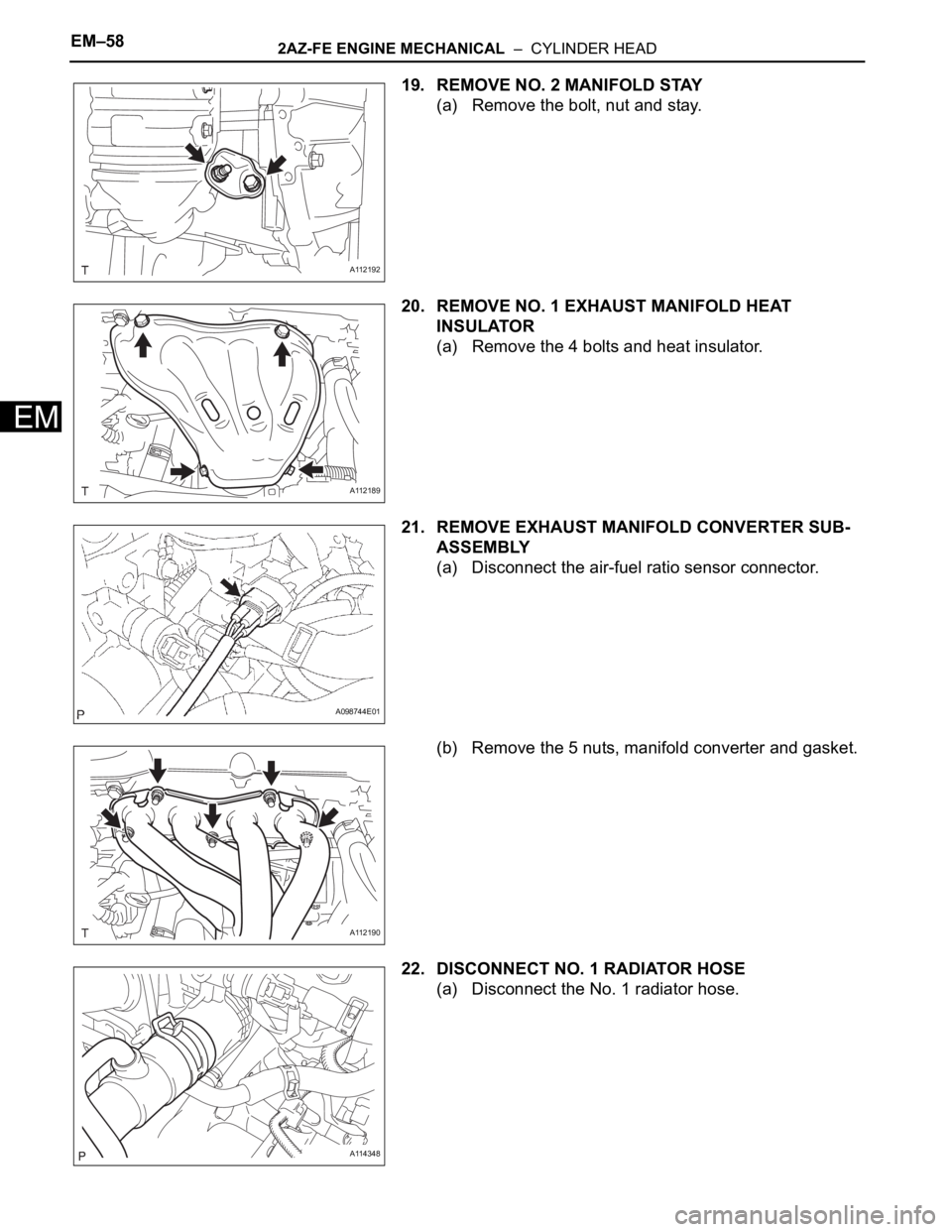

19. REMOVE NO. 2 MANIFOLD STAY

(a) Remove the bolt, nut and stay.

20. REMOVE NO. 1 EXHAUST MANIFOLD HEAT

INSULATOR

(a) Remove the 4 bolts and heat insulator.

21. REMOVE EXHAUST MANIFOLD CONVERTER SUB-

ASSEMBLY

(a) Disconnect the air-fuel ratio sensor connector.

(b) Remove the 5 nuts, manifold converter and gasket.

22. DISCONNECT NO. 1 RADIATOR HOSE

(a) Disconnect the No. 1 radiator hose.

A112192

A112189

A098744E01

A112190

A114348

Page 603 of 2000

2AZ-FE ENGINE MECHANICAL – CYLINDER HEADEM–59

EM

23. DISCONNECT ENGINE WIRE

(a) Disconnect the radio setting condenser connector.

(b) Disconnect the engine oil pressure switch

connector.

(c) Disconnect the engine coolant temperature sensor

connector.

(d) Disconnect the camshaft position sensor connector.

(e) Remove the bolt and ground cable.

24. REMOVE FRONT SUSPENSION MEMBER

REINFORCEMENT RH (See page EM-6)

25. REMOVE FAN AND GENERATOR V BELT (See page

EM-6)

26. REMOVE GENERATOR ASSEMBLY (See page CH-9)

27. REMOVE ENGINE MOUNTING INSULATOR RH (See

page EM-22)

28. REMOVE IDLER PULLEY (See page EM-23)

29. REMOVE IGNITION COIL ASSEMBLY (See page IG-9)

30. REMOVE SPARK PLUG (See page EM-8)

31. REMOVE CYLINDER HEAD COVER SUB-ASSEMBLY

(See page EM-24)

32. REMOVE V-RIBBED BELT TENSIONER ASSEMBLY

(See page EM-26)

33. REMOVE CRANKSHAFT POSITION SENSOR (See

page ES-402)

34. REMOVE OIL PAN SUB-ASSEMBLY (See page EM-

24)

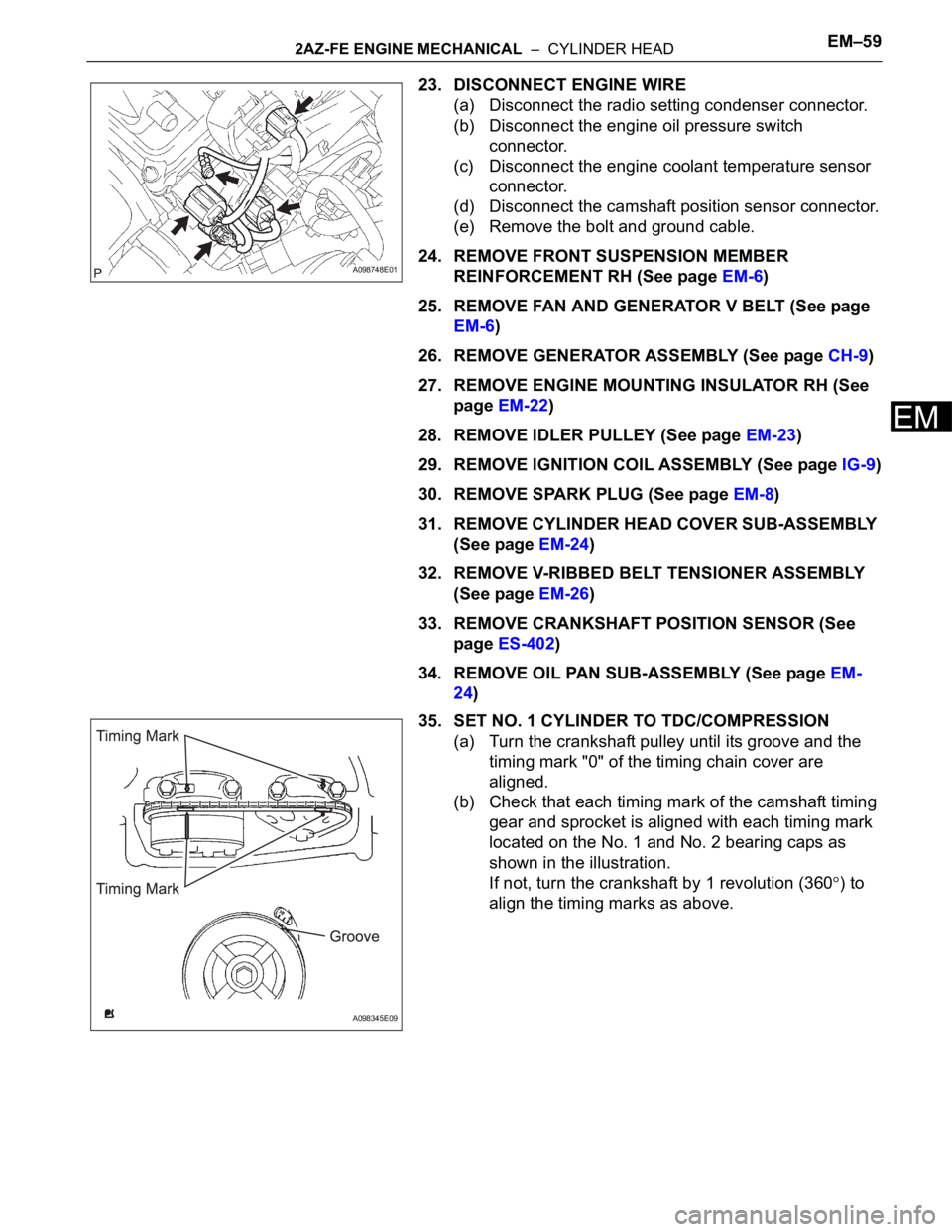

35. SET NO. 1 CYLINDER TO TDC/COMPRESSION

(a) Turn the crankshaft pulley until its groove and the

timing mark "0" of the timing chain cover are

aligned.

(b) Check that each timing mark of the camshaft timing

gear and sprocket is aligned with each timing mark

located on the No. 1 and No. 2 bearing caps as

shown in the illustration.

If not, turn the crankshaft by 1 revolution (360

) to

align the timing marks as above.

A098748E01

A098345E09

Page 604 of 2000

EM–602AZ-FE ENGINE MECHANICAL – CYLINDER HEAD

EM

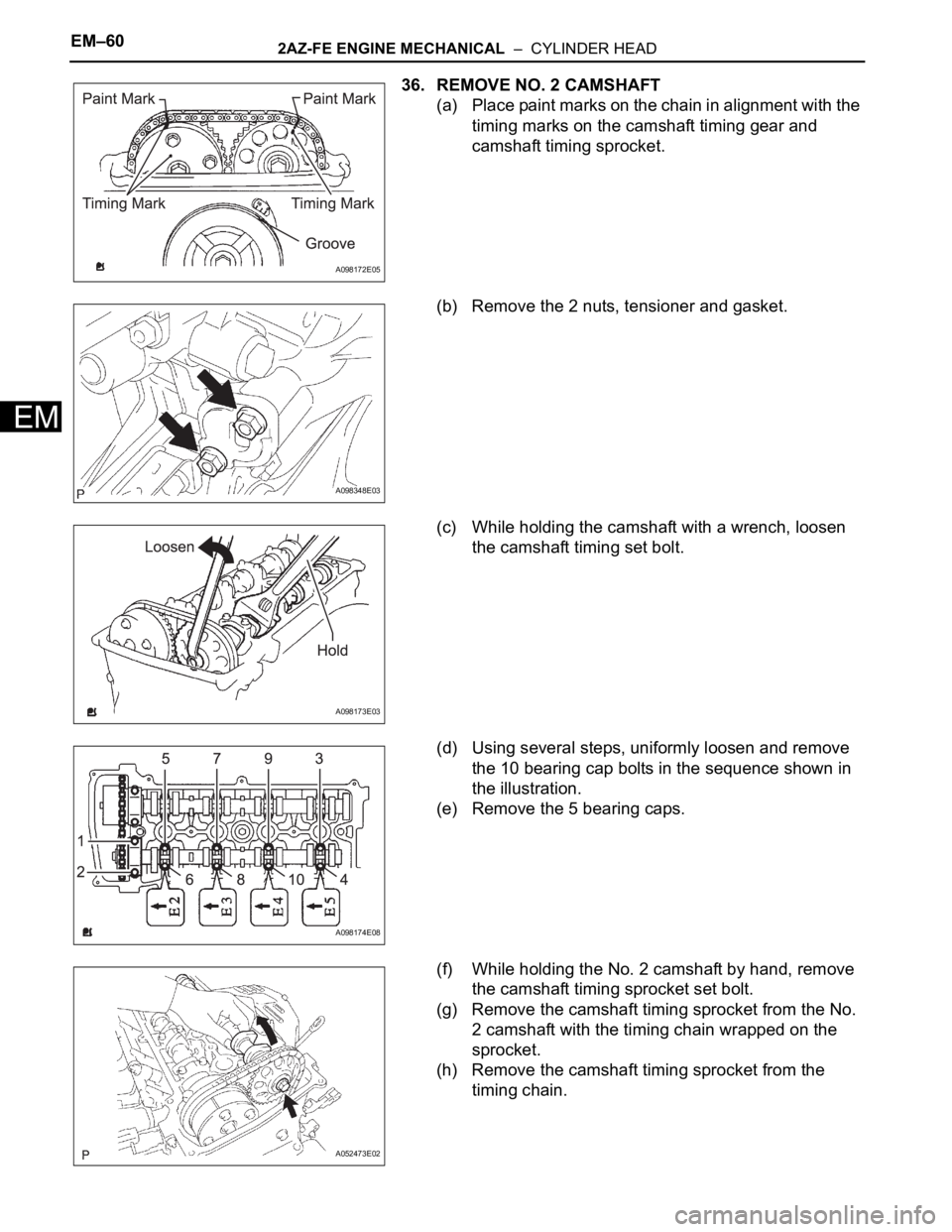

36. REMOVE NO. 2 CAMSHAFT

(a) Place paint marks on the chain in alignment with the

timing marks on the camshaft timing gear and

camshaft timing sprocket.

(b) Remove the 2 nuts, tensioner and gasket.

(c) While holding the camshaft with a wrench, loosen

the camshaft timing set bolt.

(d) Using several steps, uniformly loosen and remove

the 10 bearing cap bolts in the sequence shown in

the illustration.

(e) Remove the 5 bearing caps.

(f) While holding the No. 2 camshaft by hand, remove

the camshaft timing sprocket set bolt.

(g) Remove the camshaft timing sprocket from the No.

2 camshaft with the timing chain wrapped on the

sprocket.

(h) Remove the camshaft timing sprocket from the

timing chain.

A098172E05

A098348E03

A098173E03

A098174E08

A052473E02

Page 605 of 2000

2AZ-FE ENGINE MECHANICAL – CYLINDER HEADEM–61

EM

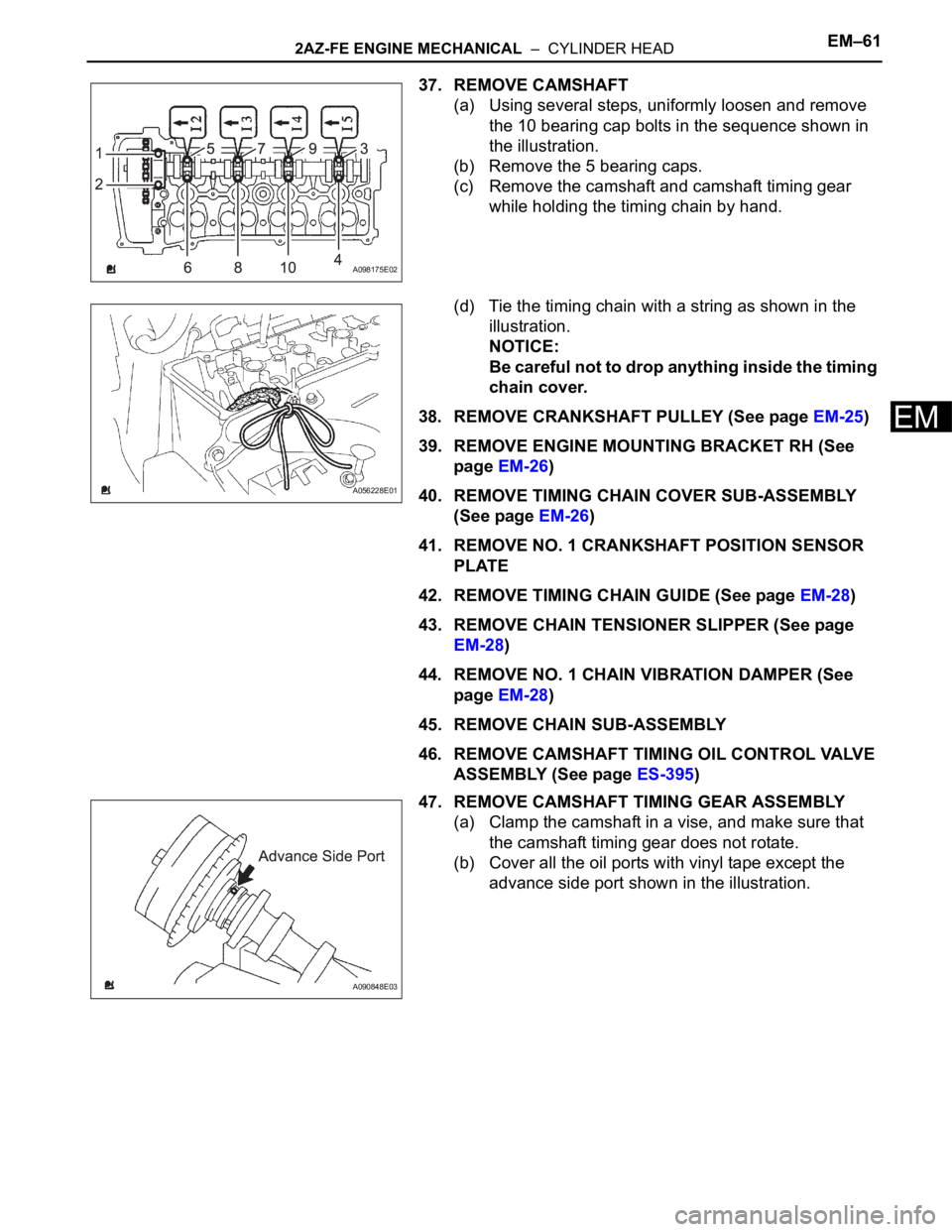

37. REMOVE CAMSHAFT

(a) Using several steps, uniformly loosen and remove

the 10 bearing cap bolts in the sequence shown in

the illustration.

(b) Remove the 5 bearing caps.

(c) Remove the camshaft and camshaft timing gear

while holding the timing chain by hand.

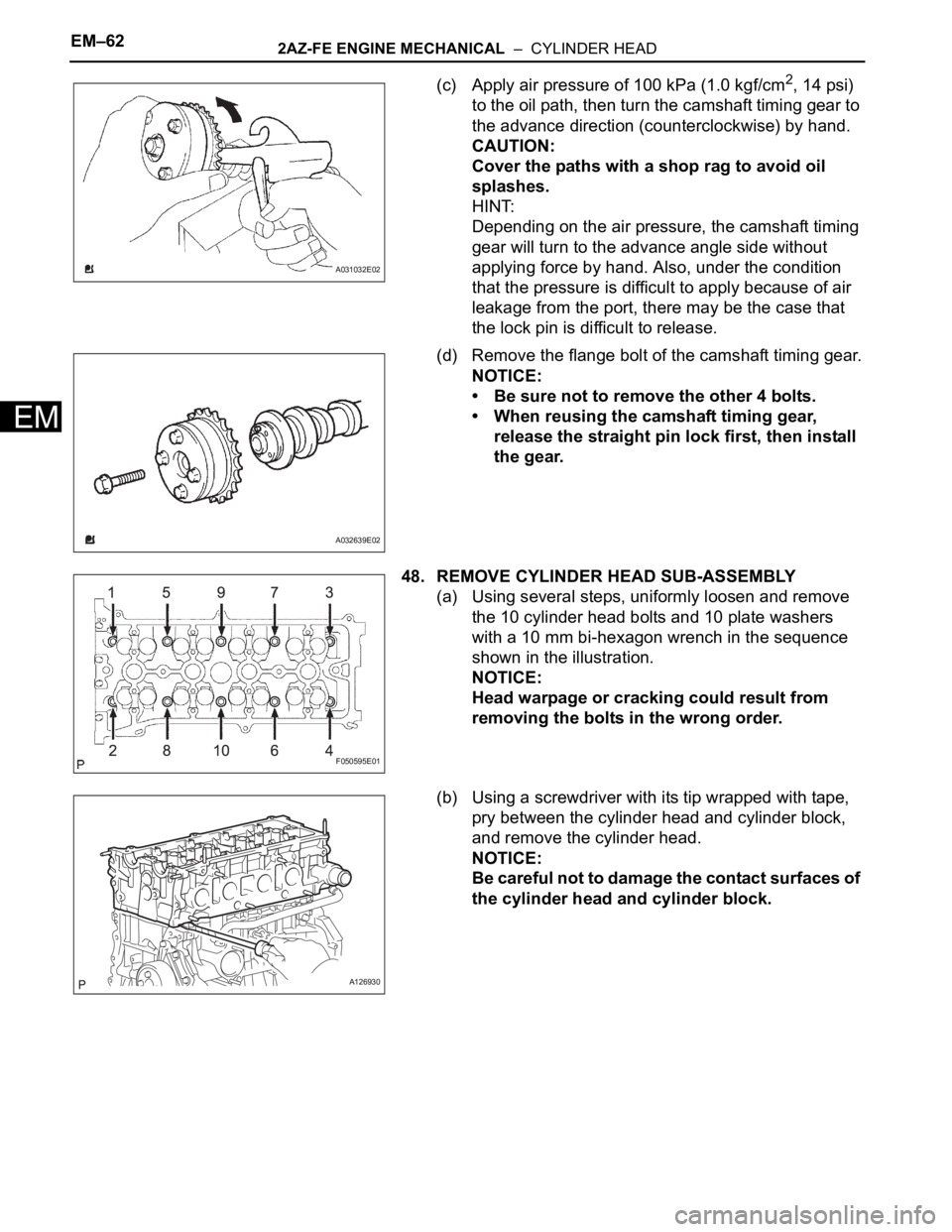

(d) Tie the timing chain with a string as shown in the

illustration.

NOTICE:

Be careful not to drop anything inside the timing

chain cover.

38. REMOVE CRANKSHAFT PULLEY (See page EM-25)

39. REMOVE ENGINE MOUNTING BRACKET RH (See

page EM-26)

40. REMOVE TIMING CHAIN COVER SUB-ASSEMBLY

(See page EM-26)

41. REMOVE NO. 1 CRANKSHAFT POSITION SENSOR

PLATE

42. REMOVE TIMING CHAIN GUIDE (See page EM-28)

43. REMOVE CHAIN TENSIONER SLIPPER (See page

EM-28)

44. REMOVE NO. 1 CHAIN VIBRATION DAMPER (See

page EM-28)

45. REMOVE CHAIN SUB-ASSEMBLY

46. REMOVE CAMSHAFT TIMING OIL CONTROL VALVE

ASSEMBLY (See page ES-395)

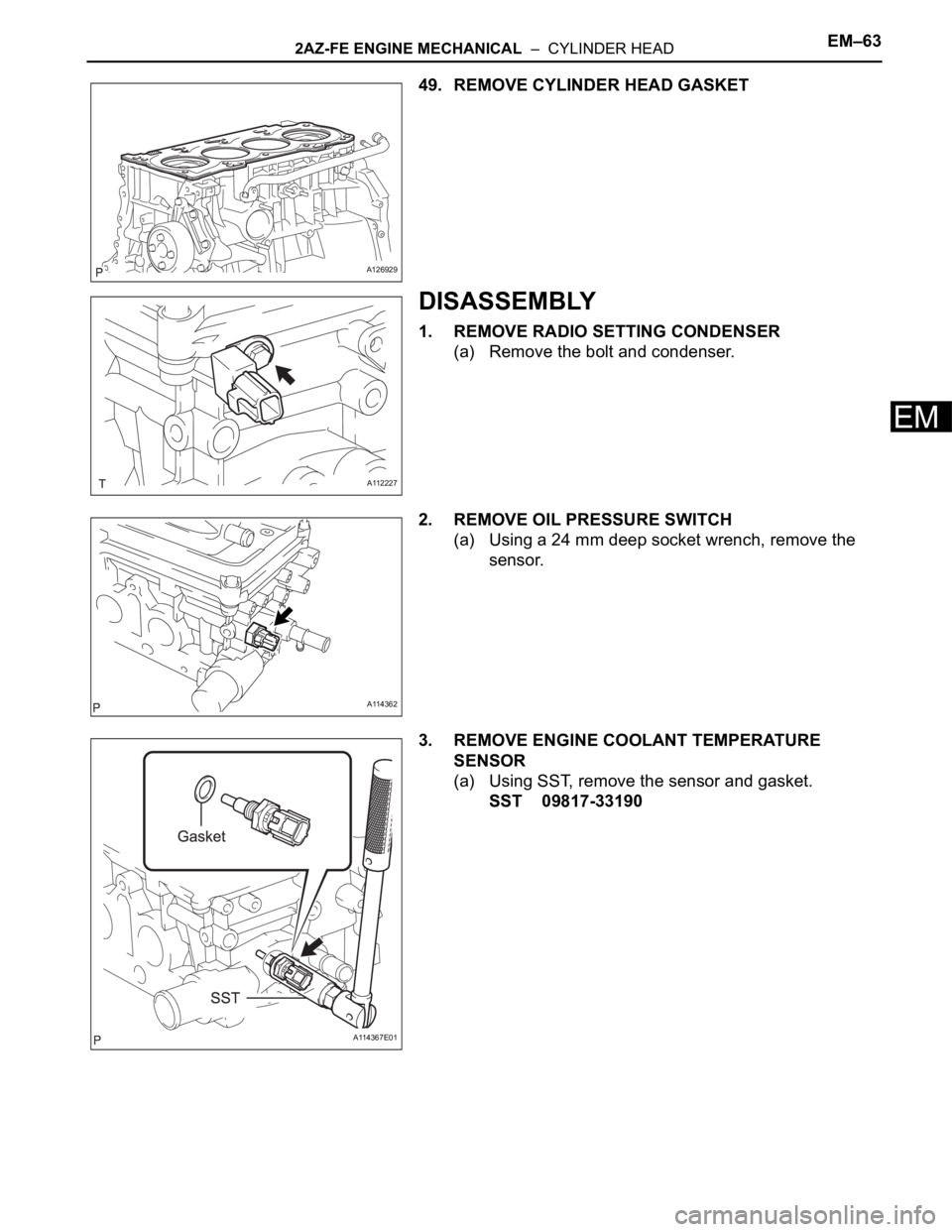

47. REMOVE CAMSHAFT TIMING GEAR ASSEMBLY

(a) Clamp the camshaft in a vise, and make sure that

the camshaft timing gear does not rotate.

(b) Cover all the oil ports with vinyl tape except the

advance side port shown in the illustration.

A098175E02

A056228E01

A090848E03

Page 606 of 2000

EM–622AZ-FE ENGINE MECHANICAL – CYLINDER HEAD

EM

(c) Apply air pressure of 100 kPa (1.0 kgf/cm2, 14 psi)

to the oil path, then turn the camshaft timing gear to

the advance direction (counterclockwise) by hand.

CAUTION:

Cover the paths with a shop rag to avoid oil

splashes.

HINT:

Depending on the air pressure, the camshaft timing

gear will turn to the advance angle side without

applying force by hand. Also, under the condition

that the pressure is difficult to apply because of air

leakage from the port, there may be the case that

the lock pin is difficult to release.

(d) Remove the flange bolt of the camshaft timing gear.

NOTICE:

• Be sure not to remove the other 4 bolts.

• When reusing the camshaft timing gear,

release the straight pin lock first, then install

the gear.

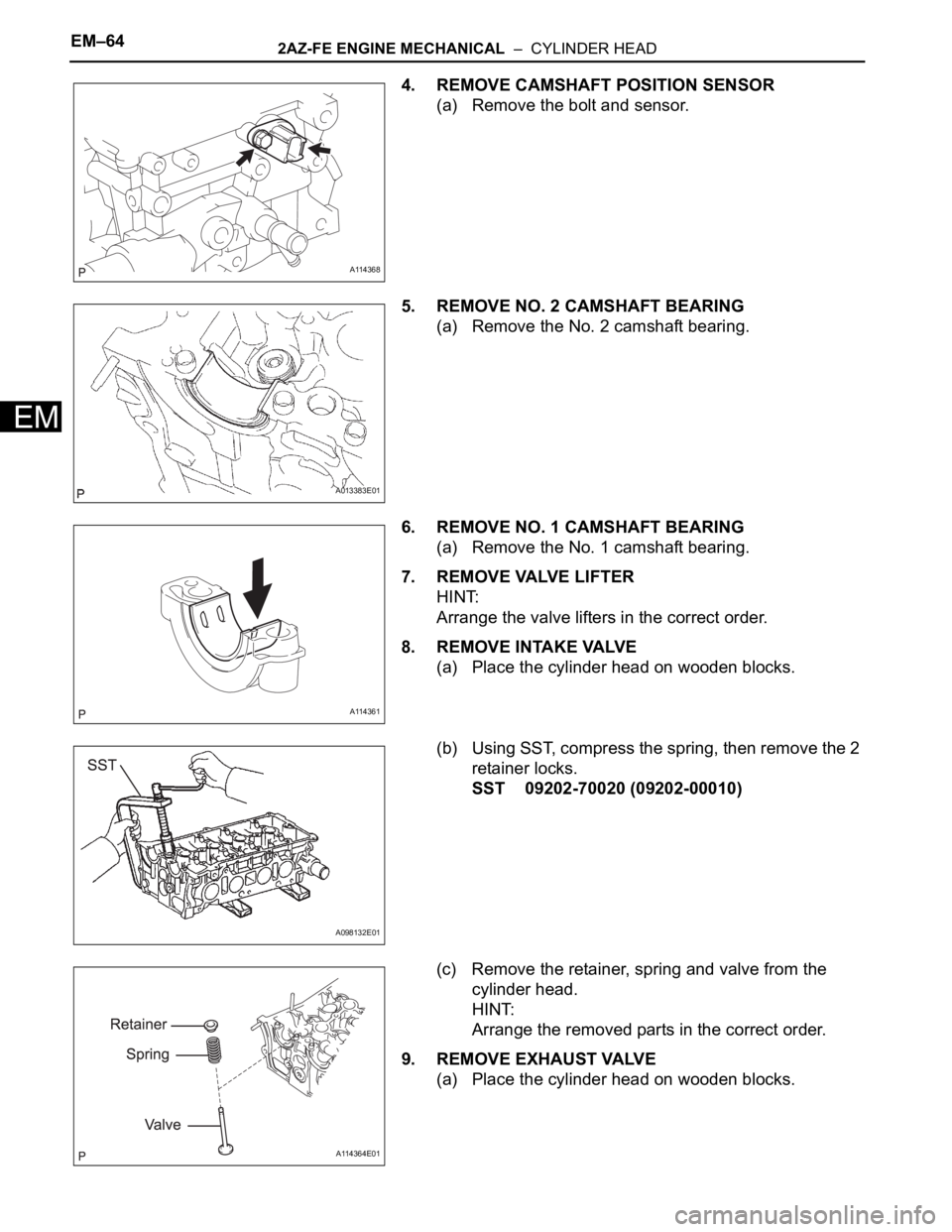

48. REMOVE CYLINDER HEAD SUB-ASSEMBLY

(a) Using several steps, uniformly loosen and remove

the 10 cylinder head bolts and 10 plate washers

with a 10 mm bi-hexagon wrench in the sequence

shown in the illustration.

NOTICE:

Head warpage or cracking could result from

removing the bolts in the wrong order.

(b) Using a screwdriver with its tip wrapped with tape,

pry between the cylinder head and cylinder block,

and remove the cylinder head.

NOTICE:

Be careful not to damage the contact surfaces of

the cylinder head and cylinder block.

A031032E02

A032639E02

F050595E01

A126930

Page 607 of 2000

2AZ-FE ENGINE MECHANICAL – CYLINDER HEADEM–63

EM

49. REMOVE CYLINDER HEAD GASKET

DISASSEMBLY

1. REMOVE RADIO SETTING CONDENSER

(a) Remove the bolt and condenser.

2. REMOVE OIL PRESSURE SWITCH

(a) Using a 24 mm deep socket wrench, remove the

sensor.

3. REMOVE ENGINE COOLANT TEMPERATURE

SENSOR

(a) Using SST, remove the sensor and gasket.

SST 09817-33190

A126929

A112227

A114362

A114367E01

Page 608 of 2000

EM–642AZ-FE ENGINE MECHANICAL – CYLINDER HEAD

EM

4. REMOVE CAMSHAFT POSITION SENSOR

(a) Remove the bolt and sensor.

5. REMOVE NO. 2 CAMSHAFT BEARING

(a) Remove the No. 2 camshaft bearing.

6. REMOVE NO. 1 CAMSHAFT BEARING

(a) Remove the No. 1 camshaft bearing.

7. REMOVE VALVE LIFTER

HINT:

Arrange the valve lifters in the correct order.

8. REMOVE INTAKE VALVE

(a) Place the cylinder head on wooden blocks.

(b) Using SST, compress the spring, then remove the 2

retainer locks.

SST 09202-70020 (09202-00010)

(c) Remove the retainer, spring and valve from the

cylinder head.

HINT:

Arrange the removed parts in the correct order.

9. REMOVE EXHAUST VALVE

(a) Place the cylinder head on wooden blocks.

A114368

A013383E01

A114361

A098132E01

A114364E01

Page 609 of 2000

2AZ-FE ENGINE MECHANICAL – CYLINDER HEADEM–65

EM

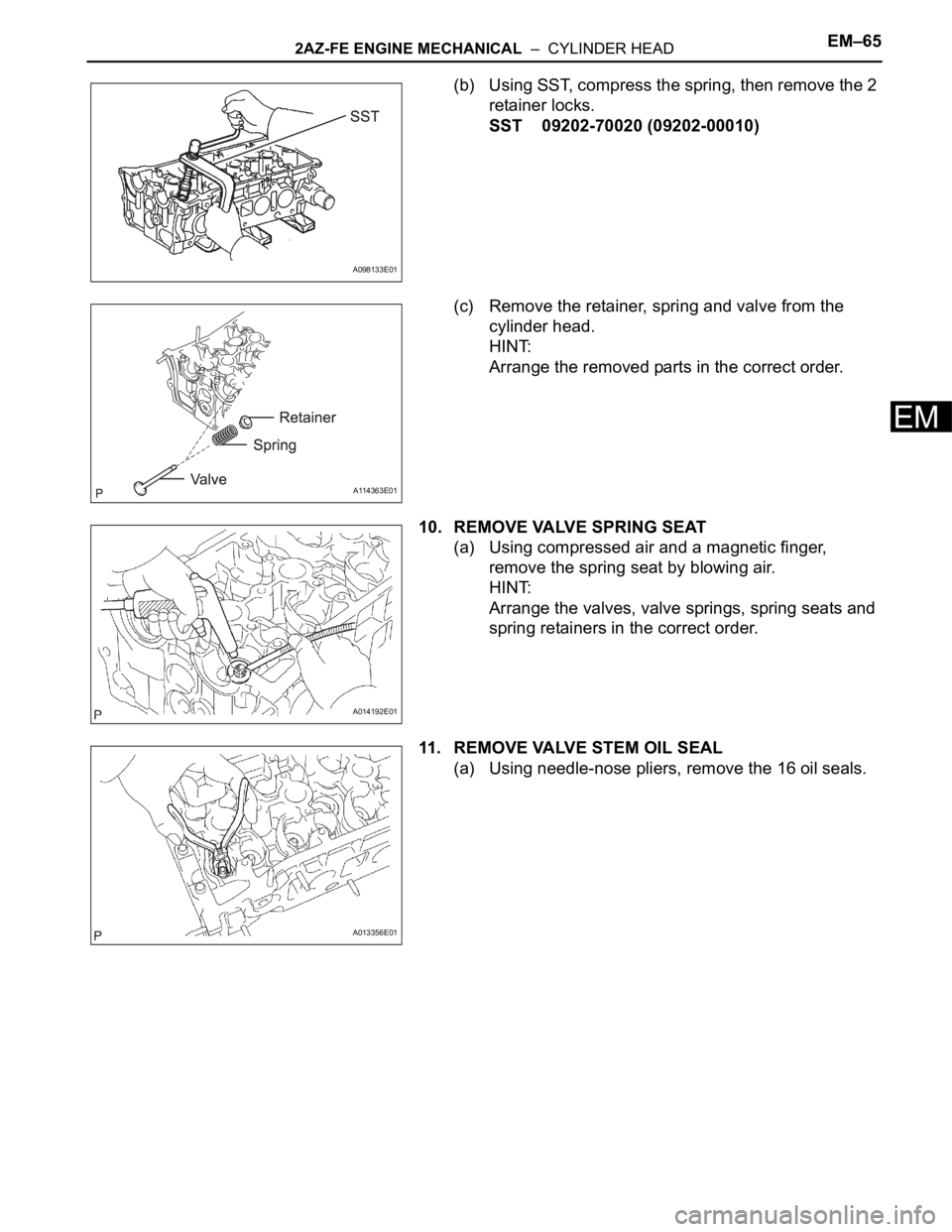

(b) Using SST, compress the spring, then remove the 2

retainer locks.

SST 09202-70020 (09202-00010)

(c) Remove the retainer, spring and valve from the

cylinder head.

HINT:

Arrange the removed parts in the correct order.

10. REMOVE VALVE SPRING SEAT

(a) Using compressed air and a magnetic finger,

remove the spring seat by blowing air.

HINT:

Arrange the valves, valve springs, spring seats and

spring retainers in the correct order.

11. REMOVE VALVE STEM OIL SEAL

(a) Using needle-nose pliers, remove the 16 oil seals.

A098133E01

A114363E01

A014192E01

A013356E01

Page 610 of 2000

EM–662AZ-FE ENGINE MECHANICAL – CYLINDER HEAD

EM

INSPECTION

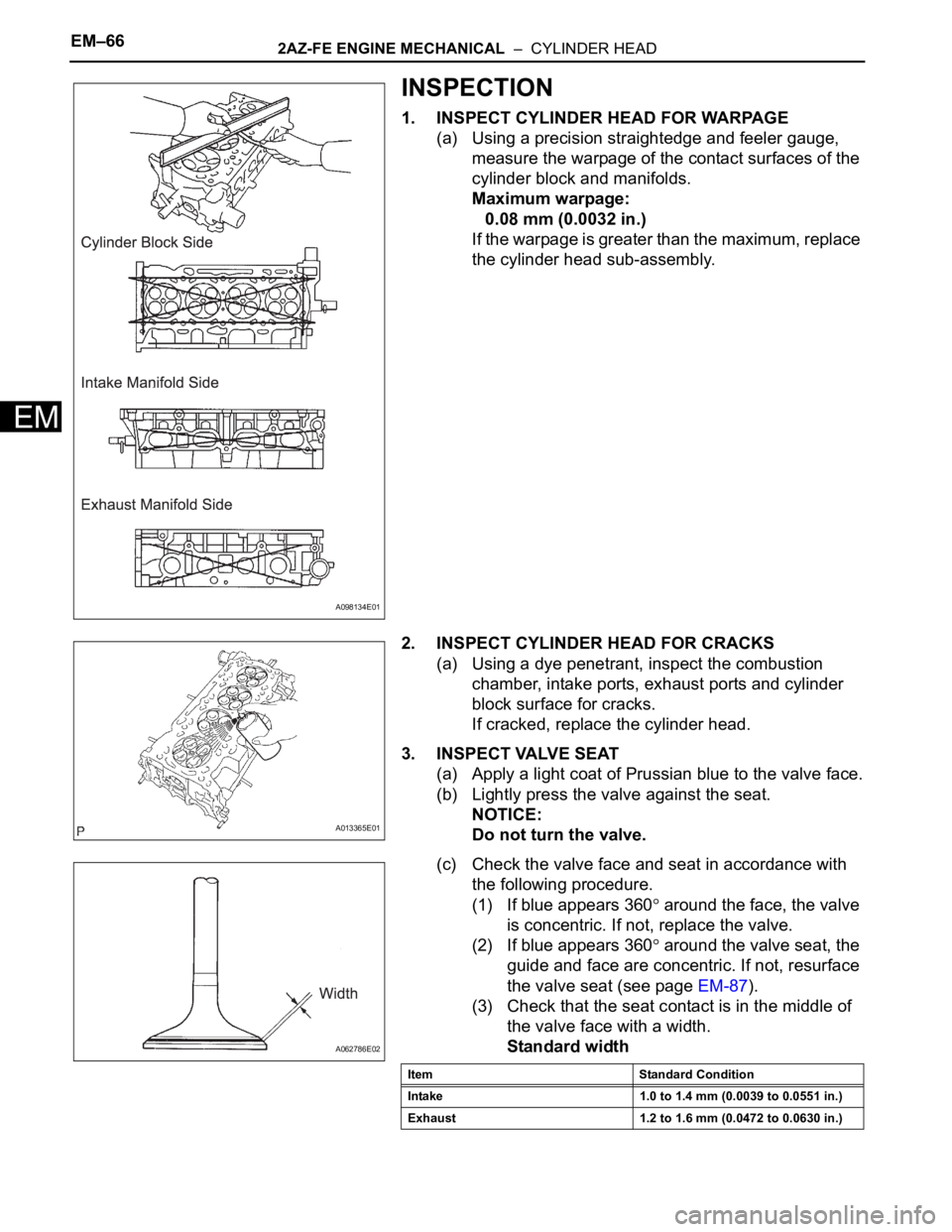

1. INSPECT CYLINDER HEAD FOR WARPAGE

(a) Using a precision straightedge and feeler gauge,

measure the warpage of the contact surfaces of the

cylinder block and manifolds.

Maximum warpage:

0.08 mm (0.0032 in.)

If the warpage is greater than the maximum, replace

the cylinder head sub-assembly.

2. INSPECT CYLINDER HEAD FOR CRACKS

(a) Using a dye penetrant, inspect the combustion

chamber, intake ports, exhaust ports and cylinder

block surface for cracks.

If cracked, replace the cylinder head.

3. INSPECT VALVE SEAT

(a) Apply a light coat of Prussian blue to the valve face.

(b) Lightly press the valve against the seat.

NOTICE:

Do not turn the valve.

(c) Check the valve face and seat in accordance with

the following procedure.

(1) If blue appears 360

around the face, the valve

is concentric. If not, replace the valve.

(2) If blue appears 360

around the valve seat, the

guide and face are concentric. If not, resurface

the valve seat (see page EM-87).

(3) Check that the seat contact is in the middle of

the valve face with a width.

Standard width

A098134E01

A013365E01

A062786E02

Item Standard Condition

Intake 1.0 to 1.4 mm (0.0039 to 0.0551 in.)

Exhaust 1.2 to 1.6 mm (0.0472 to 0.0630 in.)