TOYOTA RAV4 2006 Service Repair Manual

Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 541 of 2000

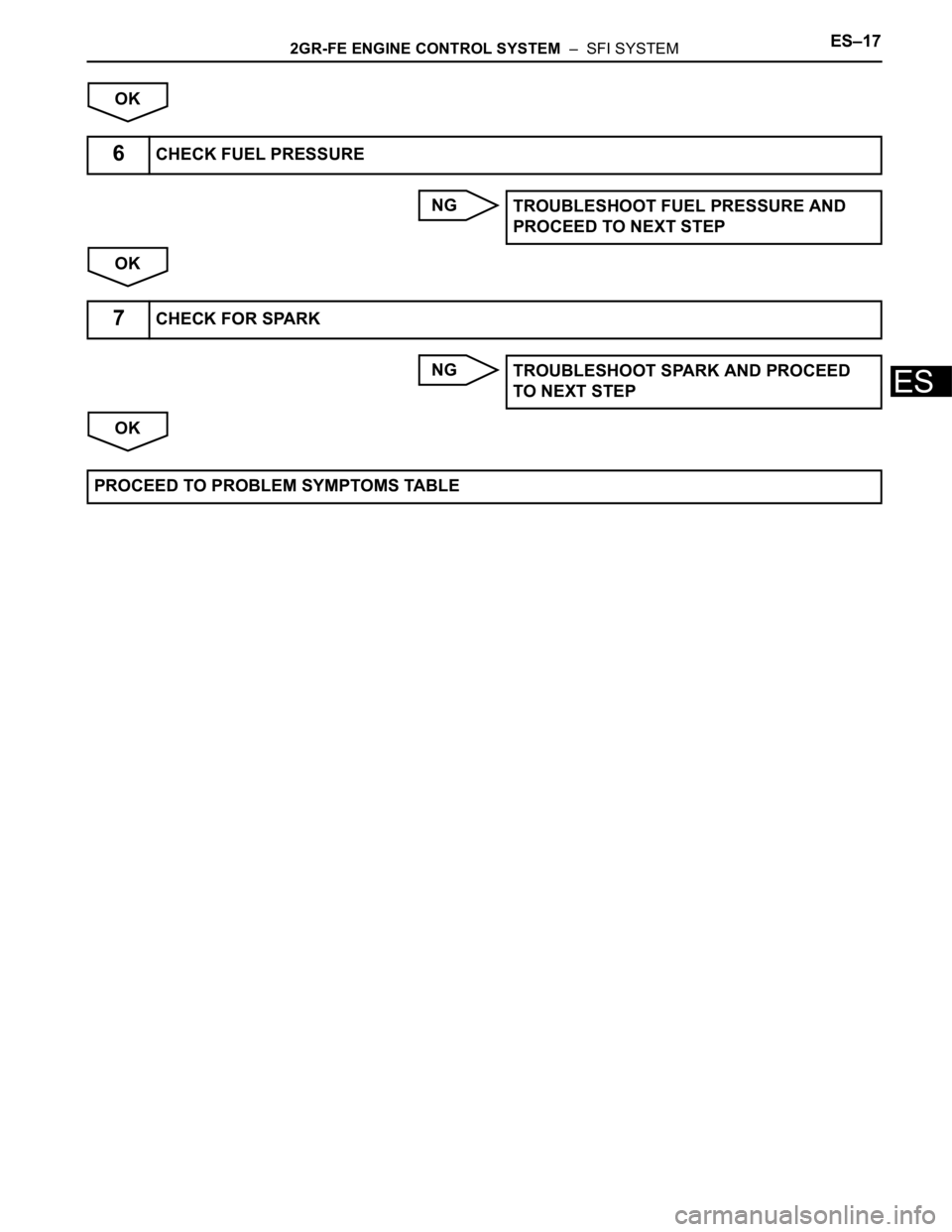

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–17

ES

OK

NG

OK

NG

OK

6CHECK FUEL PRESSURE

TROUBLESHOOT FUEL PRESSURE AND

PROCEED TO NEXT STEP

7CHECK FOR SPARK

TROUBLESHOOT SPARK AND PROCEED

TO NEXT STEP

PROCEED TO PROBLEM SYMPTOMS TABLE

Page 542 of 2000

ES–182GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

REGISTRATION

NOTICE:

The Vehicle Identification Number (VIN) must be input

into the replacement ECM.

HINT:

The VIN is a 17-digit alphanumeric number. The intelligent

tester is required to register the VIN.

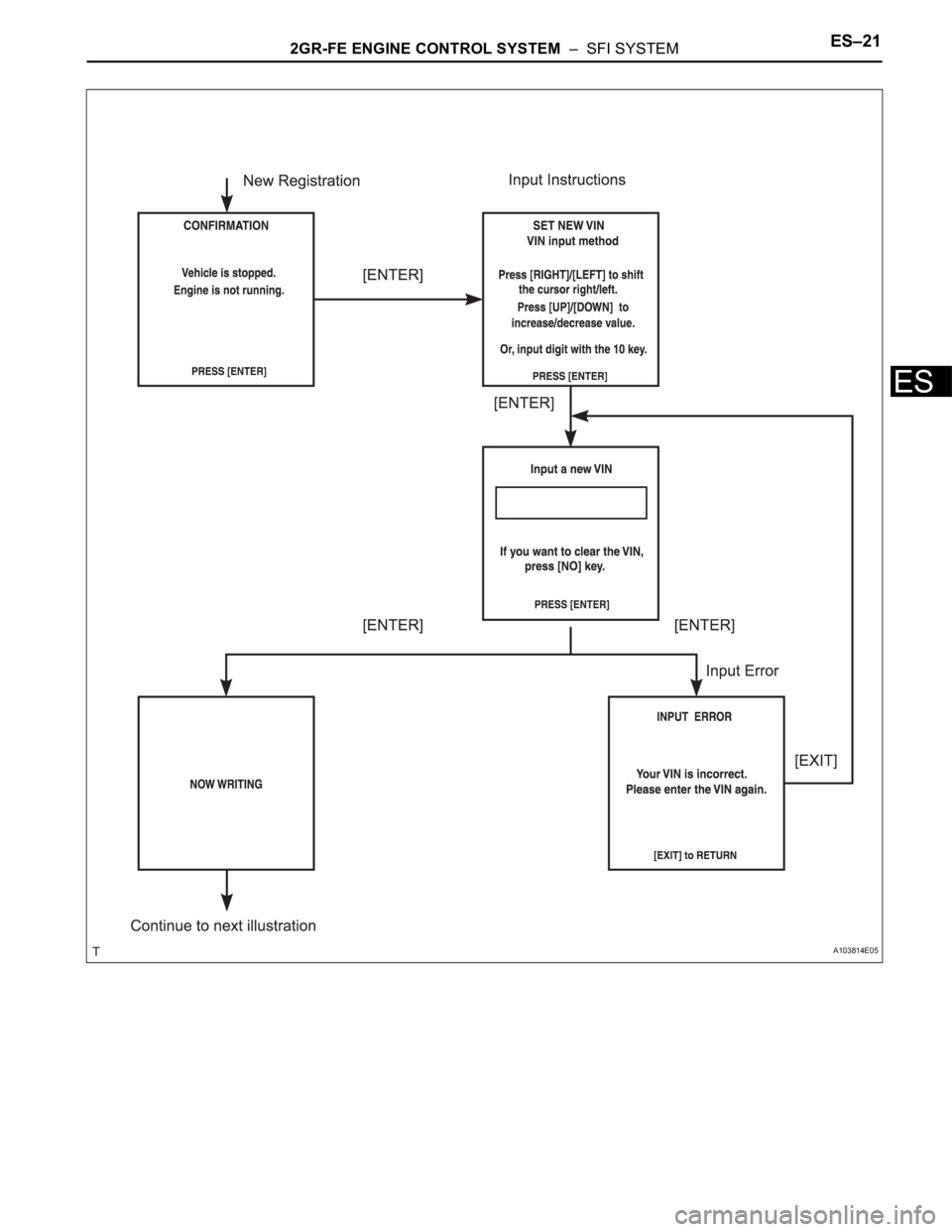

1. DESCRIPTION

This registration section consists of 3 parts: Input

Instructions, Read VIN and Write VIN.

(a) Input Instructions: Explains the general VIN input

instructions when using the intelligent tester.

(b) Read VIN: Explains the VIN reading process in a

flowchart. This process allows the VIN stored in the

ECM to be read in order to confirm that the two

VINs, provided with the vehicle and stored in the

vehicle's ECM, are the same.

(c) Write VIN: Explains the VIN writing process in a

flowchart. This process allows the VIN to be input

into the ECM. If the ECM is changed, or the vehicle

VIN and ECM VIN do not match, the VIN can be

registered or overwritten in the ECM by following

this procedure.

2. INPUT INSTRUCTIONS

(a) Intelligent Tester

The arrow buttons (UP, DOWN, RIGHT and LEFT)

and numerical buttons (0 to 9) are used to input the

VIN.

(b) Cursor Operation

To move the cursor around the tester screen, press

the RIGHT and LEFT buttons.

(c) Alphabetical Character Input

(1) Press the UP and DOWN buttons to select the

desired alphabetical character.

(2) After selection, the cursor should move.

(d) Numeric Character Input

(1) Press the numerical button corresponding to

the number that you want to input.

(2) After input, the cursor should move.

HINT:

Numerical characters can also be selected by

using the UP and DOWN buttons.

(e) Correction

(1) When correcting the input character(s), put the

cursor onto the character using the RIGHT and

LEFT buttons.

(2) Select or input the correct character using the

UP/DOWN buttons, or the numerical buttons.

(f) Finishing Input Operation

(1) Make sure that the input VIN matches the

vehicle VIN after input.

(2) Press the ENTER button on the tester.

Page 543 of 2000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–19

ES

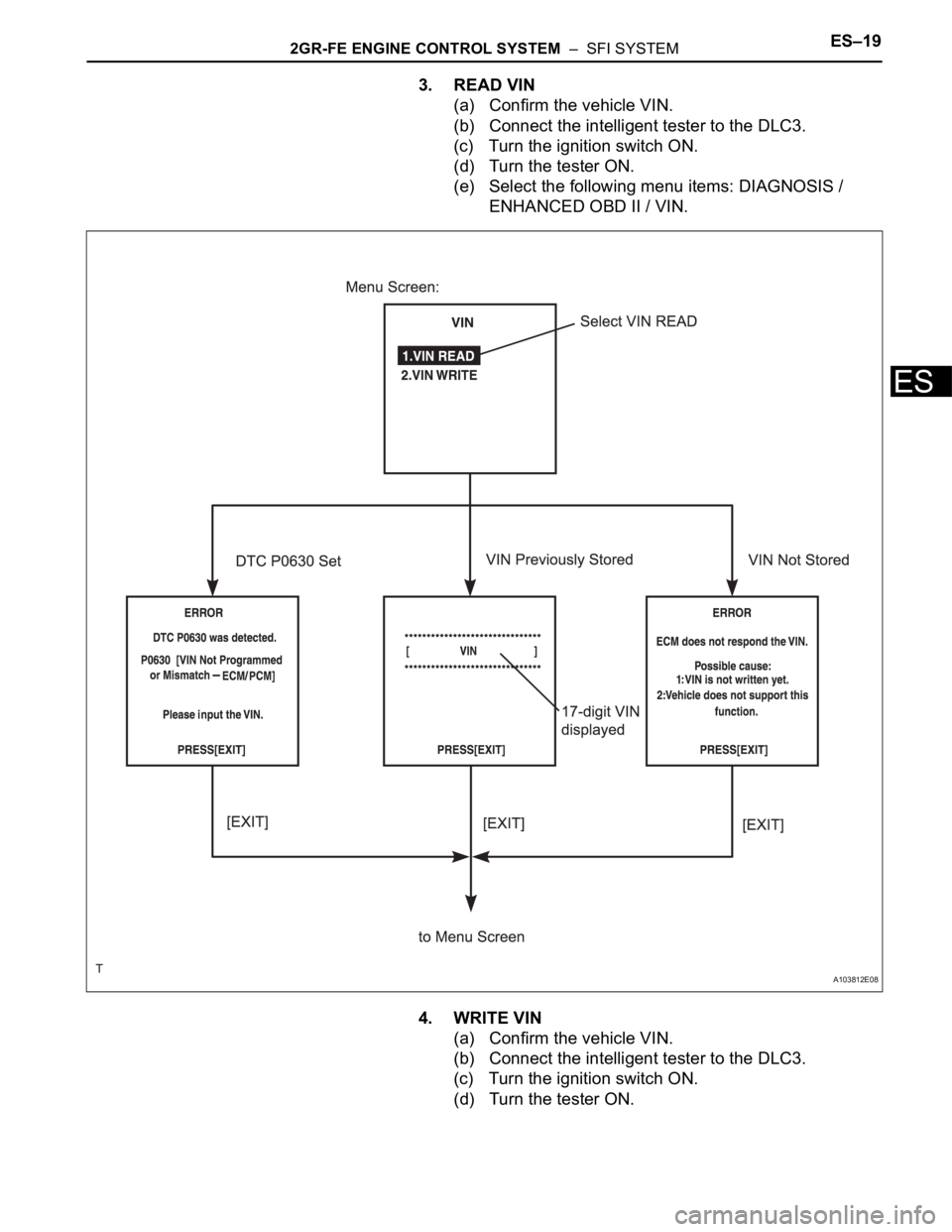

3. READ VIN

(a) Confirm the vehicle VIN.

(b) Connect the intelligent tester to the DLC3.

(c) Turn the ignition switch ON.

(d) Turn the tester ON.

(e) Select the following menu items: DIAGNOSIS /

ENHANCED OBD II / VIN.

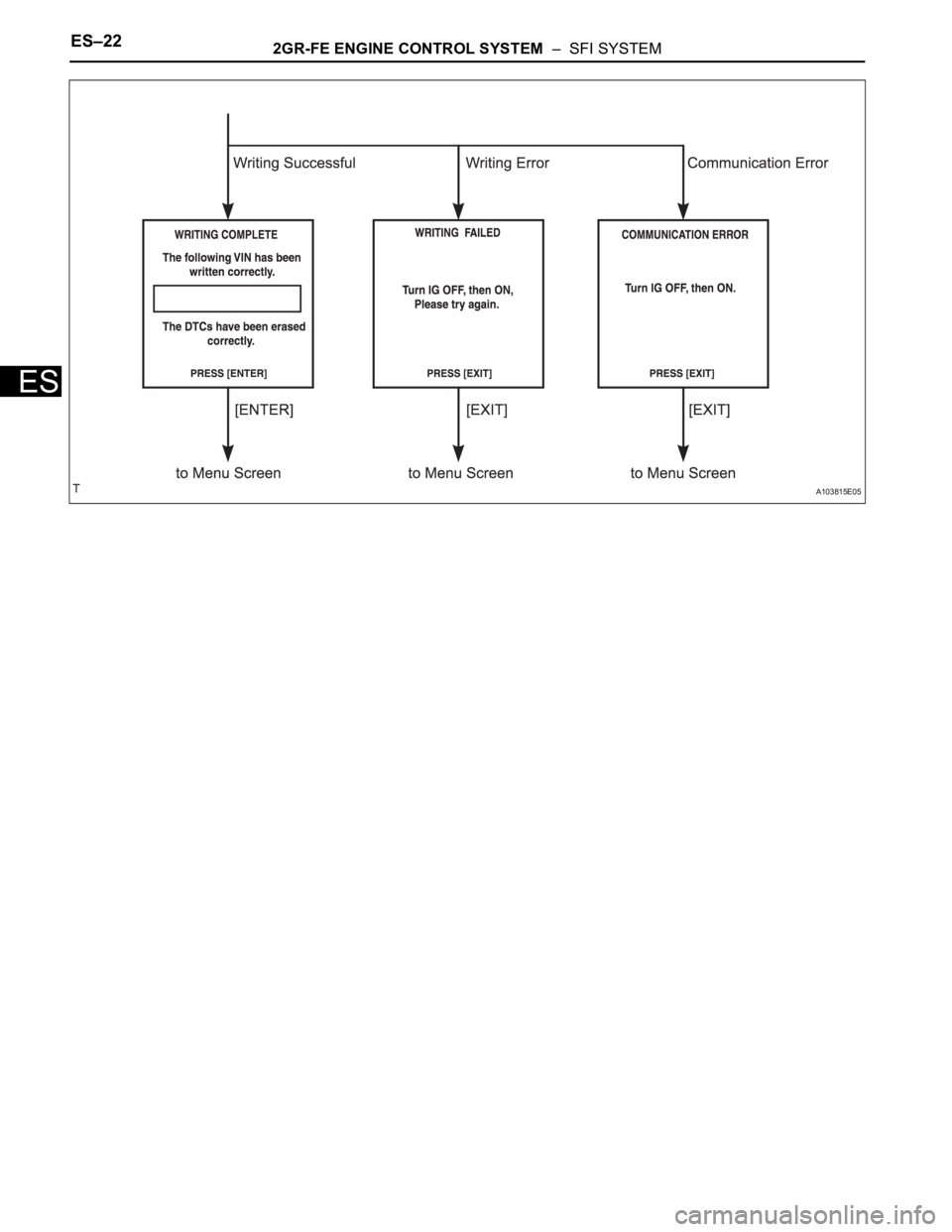

4. WRITE VIN

(a) Confirm the vehicle VIN.

(b) Connect the intelligent tester to the DLC3.

(c) Turn the ignition switch ON.

(d) Turn the tester ON.

A103812E08

Page 544 of 2000

ES–202GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

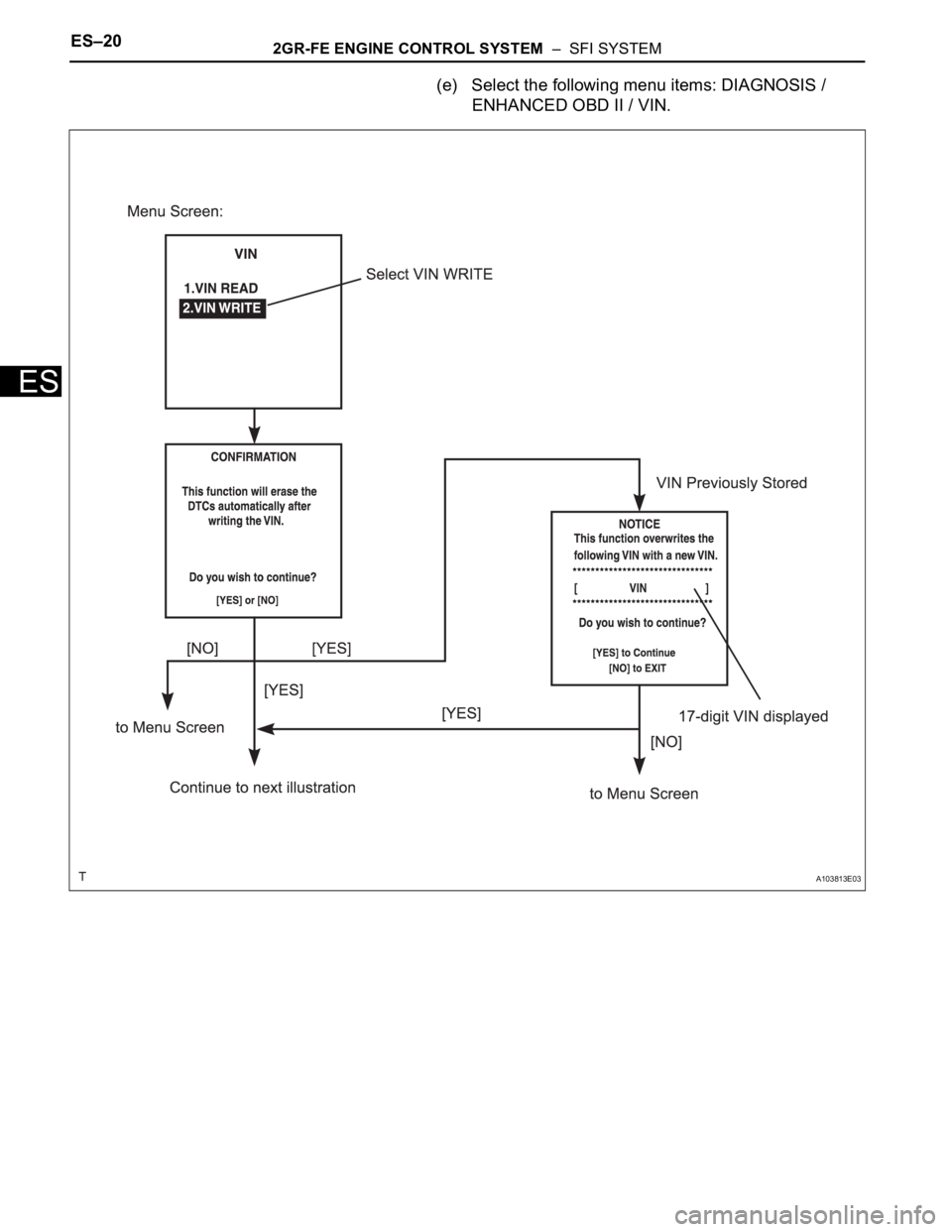

(e) Select the following menu items: DIAGNOSIS /

ENHANCED OBD II / VIN.

A103813E03

Page 545 of 2000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–21

ES

A103814E05

Page 546 of 2000

ES–222GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

A103815E05

Page 547 of 2000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–23

ES

CHECKING MONITOR STATUS

The purpose of the monitor result (mode 06) is to allow

access to the results of on-board diagnostic monitoring tests

of specific components/systems that are not continuously

monitored. Examples are catalysts, evaporative emissions

(EVAP) and thermostats.

The monitor result allows the OBD II scan tool to display the

monitor status, test value, minimum test limit and maximum

test limit. These data are displayed after the vehicle has been

driven to run the monitor.

When the test value is not between the minimum and

maximum test limits, the ECM (PCM) interprets this as a

malfunction. If the test value is on the borderline of the test

limits, the component is likely to malfunction in the near

future.

Perform the following procedures to view the monitor status.

Although these procedures refer to the Lexus/Toyota

diagnostic tester, the monitor status can be checked using a

generic OBD II scan tool. Refer to your scan tool operator's

manual for specific procedural information.

1. PERFORM MONITOR DRIVE PATTERN

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch and the tester ON.

(c) Clear the DTCs (see page ES-39).

(d) Run the vehicle in accordance with the applicable

drive pattern described in READINESS MONITOR

DRIVE PATTERN (see page ES-22). Do not turn the

ignition switch OFF.

NOTE:

The test results will be lost if the ignition

switch is turned OFF.

2. ACCESS MONITOR RESULT

(a) Select the following items from the intelligent tester

menus: DIAGNOSIS, ENHANCED OBD II,

MONITOR INFO and MONITOR RESULT. The

monitor status appears after the component name.

• INCMP: The component has not been monitored

yet.

• PASS: The component is functioning normally.

• FAIL: The component is malfunctioning.

(b) Confirm that the component is either PASS or FAIL.

(c) Select the component and press ENTER. The

accuracy test value appears if the monitor status is

either PASS or FAIL.

3. CHECK COMPONENT STATUS

(a) Compare the test value with the minimum test limit

(MIN LIMIT) and maximum test limit (MAX LIMIT).

Page 548 of 2000

ES–242GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

(b) If the test value is between the minimum and

maximum test limits, the component is functioning

normally. If not, the component is malfunctioning.

The test value is usually not near the test limits. If

the test value is on the borderline of the test limits,

the component is likely to malfunction in the near

future.

HINT:

The monitor result might on rare occasions be

PASS even if the malfunction indicator lamp (MIL) is

illuminated. This indicates the system malfunctioned

on a previous driving cycle. This might be caused by

an intermittent problem.

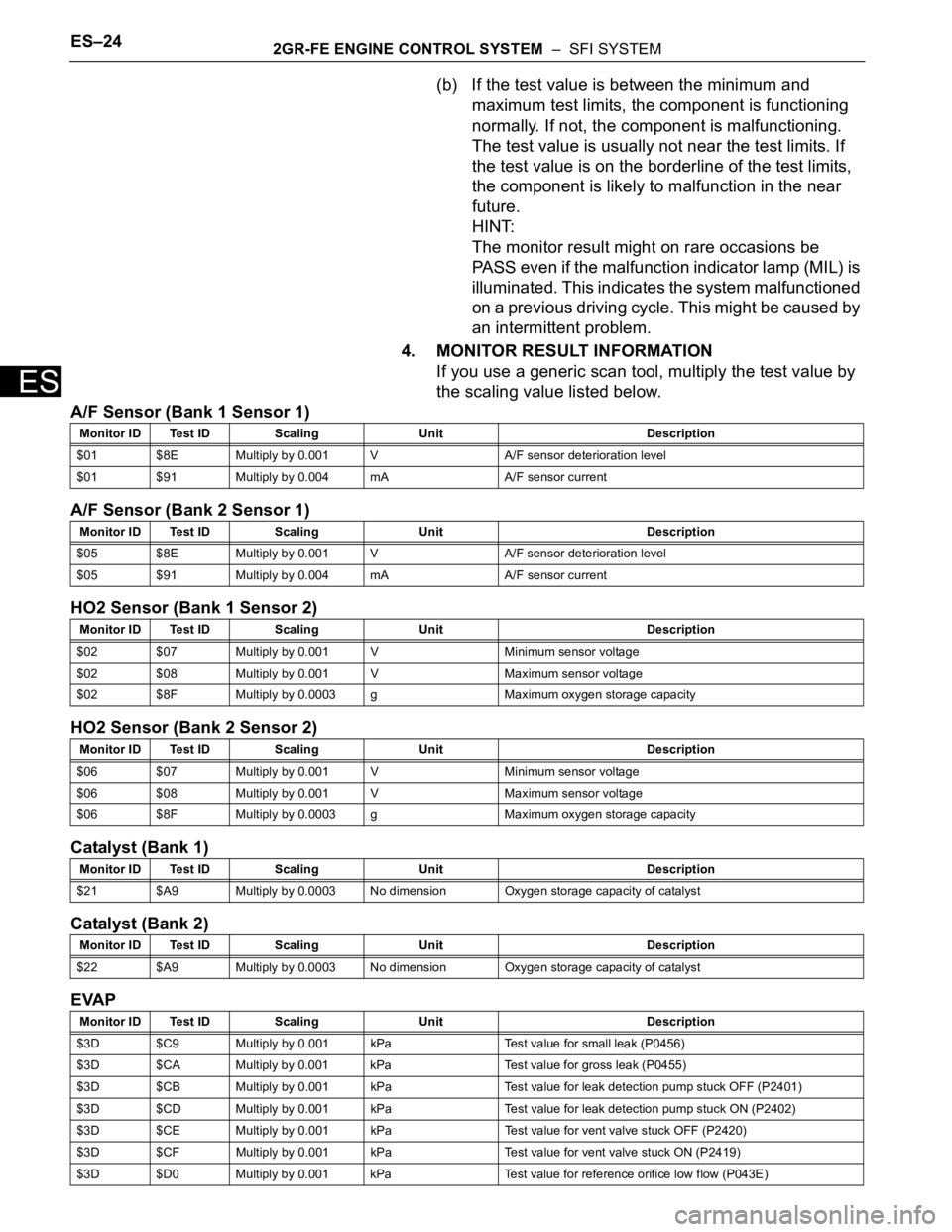

4. MONITOR RESULT INFORMATION

If you use a generic scan tool, multiply the test value by

the scaling value listed below.

A/F Sensor (Bank 1 Sensor 1)

A/F Sensor (Bank 2 Sensor 1)

HO2 Sensor (Bank 1 Sensor 2)

HO2 Sensor (Bank 2 Sensor 2)

Catalyst (Bank 1)

Catalyst (Bank 2)

EVAP

Monitor ID Test ID Scaling Unit Description

$01 $8E Multiply by 0.001 V A/F sensor deterioration level

$01 $91 Multiply by 0.004 mA A/F sensor current

Monitor ID Test ID Scaling Unit Description

$05 $8E Multiply by 0.001 V A/F sensor deterioration level

$05 $91 Multiply by 0.004 mA A/F sensor current

Monitor ID Test ID Scaling Unit Description

$02 $07 Multiply by 0.001 V Minimum sensor voltage

$02 $08 Multiply by 0.001 V Maximum sensor voltage

$02 $8F Multiply by 0.0003 g Maximum oxygen storage capacity

Monitor ID Test ID Scaling Unit Description

$06 $07 Multiply by 0.001 V Minimum sensor voltage

$06 $08 Multiply by 0.001 V Maximum sensor voltage

$06 $8F Multiply by 0.0003 g Maximum oxygen storage capacity

Monitor ID Test ID Scaling Unit Description

$21 $A9 Multiply by 0.0003 No dimension Oxygen storage capacity of catalyst

Monitor ID Test ID Scaling Unit Description

$22 $A9 Multiply by 0.0003 No dimension Oxygen storage capacity of catalyst

Monitor ID Test ID Scaling Unit Description

$3D $C9 Multiply by 0.001 kPa Test value for small leak (P0456)

$3D $CA Multiply by 0.001 kPa Test value for gross leak (P0455)

$3D $CB Multiply by 0.001 kPa Test value for leak detection pump stuck OFF (P2401)

$3D $CD Multiply by 0.001 kPa Test value for leak detection pump stuck ON (P2402)

$3D $CE Multiply by 0.001 kPa Test value for vent valve stuck OFF (P2420)

$3D $CF Multiply by 0.001 kPa Test value for vent valve stuck ON (P2419)

$3D $D0 Multiply by 0.001 kPa Test value for reference orifice low flow (P043E)

Page 549 of 2000

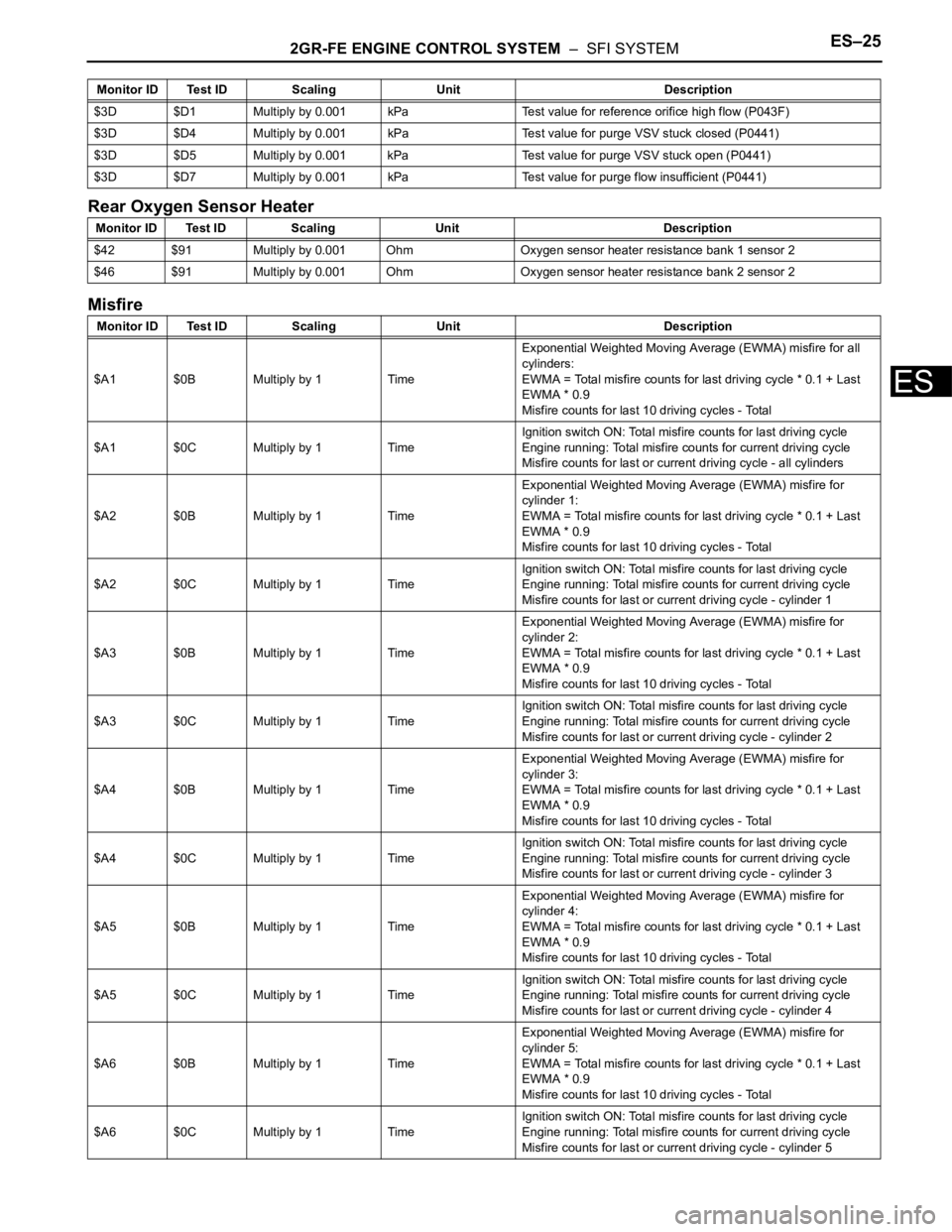

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–25

ES

Rear Oxygen Sensor Heater

Misfire

$3D $D1 Multiply by 0.001 kPa Test value for reference orifice high flow (P043F)

$3D $D4 Multiply by 0.001 kPa Test value for purge VSV stuck closed (P0441)

$3D $D5 Multiply by 0.001 kPa Test value for purge VSV stuck open (P0441)

$3D $D7 Multiply by 0.001 kPa Test value for purge flow insufficient (P0441)

Monitor ID Test ID Scaling Unit Description

$42 $91 Multiply by 0.001 Ohm Oxygen sensor heater resistance bank 1 sensor 2

$46 $91 Multiply by 0.001 Ohm Oxygen sensor heater resistance bank 2 sensor 2

Monitor ID Test ID Scaling Unit Description

$A1 $0B Multiply by 1 TimeExponential Weighted Moving Average (EWMA) misfire for all

cylinders:

EWMA = Total misfire counts for last driving cycle * 0.1 + Last

EWMA * 0.9

Misfire counts for last 10 driving cycles - Total

$A1 $0C Multiply by 1 TimeIgnition switch ON: Total misfire counts for last driving cycle

Engine running: Total misfire counts for current driving cycle

Misfire counts for last or current driving cycle - all cylinders

$A2 $0B Multiply by 1 TimeExponential Weighted Moving Average (EWMA) misfire for

cylinder 1:

EWMA = Total misfire counts for last driving cycle * 0.1 + Last

EWMA * 0.9

Misfire counts for last 10 driving cycles - Total

$A2 $0C Multiply by 1 TimeIgnition switch ON: Total misfire counts for last driving cycle

Engine running: Total misfire counts for current driving cycle

Misfire counts for last or current driving cycle - cylinder 1

$A3 $0B Multiply by 1 TimeExponential Weighted Moving Average (EWMA) misfire for

cylinder 2:

EWMA = Total misfire counts for last driving cycle * 0.1 + Last

EWMA * 0.9

Misfire counts for last 10 driving cycles - Total

$A3 $0C Multiply by 1 TimeIgnition switch ON: Total misfire counts for last driving cycle

Engine running: Total misfire counts for current driving cycle

Misfire counts for last or current driving cycle - cylinder 2

$A4 $0B Multiply by 1 TimeExponential Weighted Moving Average (EWMA) misfire for

cylinder 3:

EWMA = Total misfire counts for last driving cycle * 0.1 + Last

EWMA * 0.9

Misfire counts for last 10 driving cycles - Total

$A4 $0C Multiply by 1 TimeIgnition switch ON: Total misfire counts for last driving cycle

Engine running: Total misfire counts for current driving cycle

Misfire counts for last or current driving cycle - cylinder 3

$A5 $0B Multiply by 1 TimeExponential Weighted Moving Average (EWMA) misfire for

cylinder 4:

EWMA = Total misfire counts for last driving cycle * 0.1 + Last

EWMA * 0.9

Misfire counts for last 10 driving cycles - Total

$A5 $0C Multiply by 1 TimeIgnition switch ON: Total misfire counts for last driving cycle

Engine running: Total misfire counts for current driving cycle

Misfire counts for last or current driving cycle - cylinder 4

$A6 $0B Multiply by 1 TimeExponential Weighted Moving Average (EWMA) misfire for

cylinder 5:

EWMA = Total misfire counts for last driving cycle * 0.1 + Last

EWMA * 0.9

Misfire counts for last 10 driving cycles - Total

$A6 $0C Multiply by 1 TimeIgnition switch ON: Total misfire counts for last driving cycle

Engine running: Total misfire counts for current driving cycle

Misfire counts for last or current driving cycle - cylinder 5 Monitor ID Test ID Scaling Unit Description

Page 550 of 2000

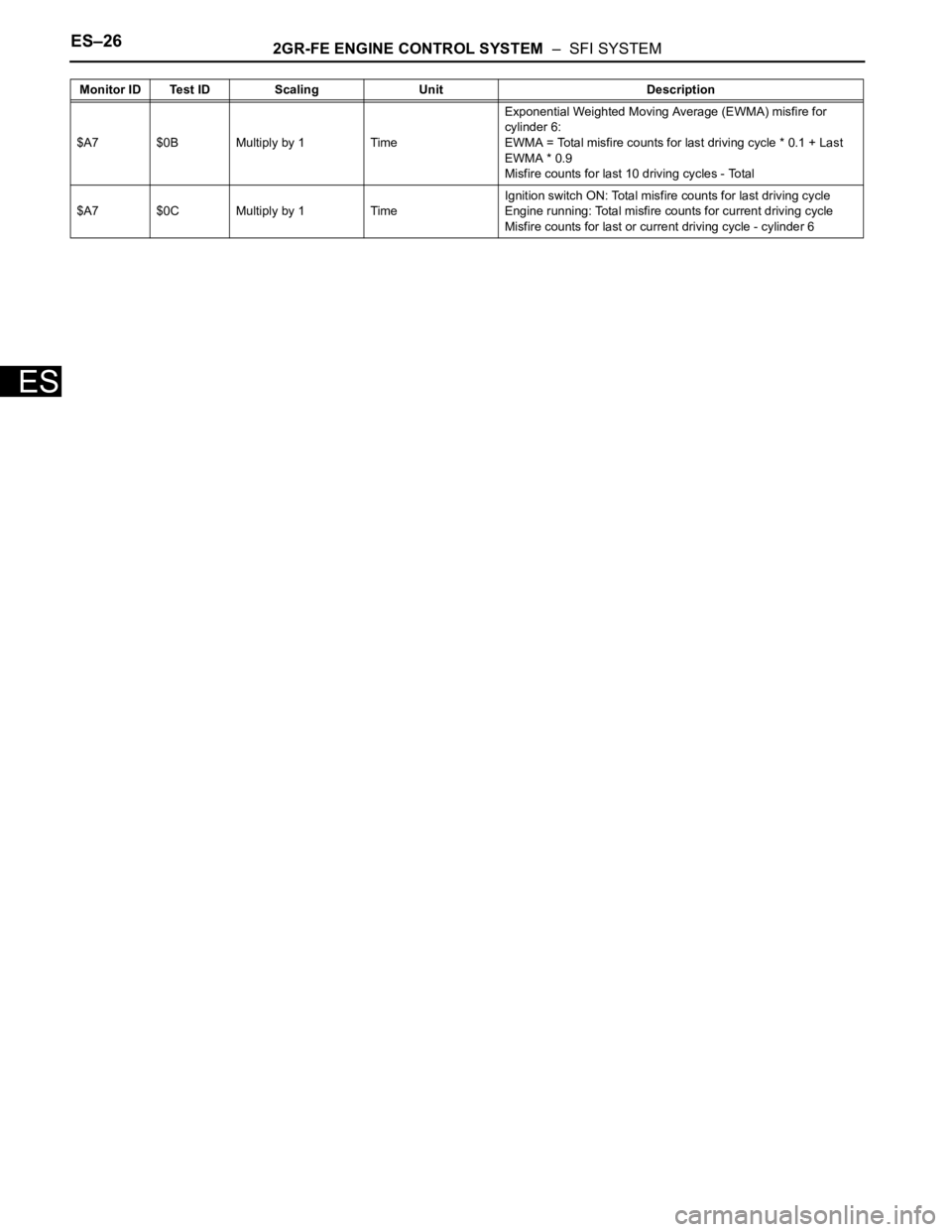

ES–262GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

$A7 $0B Multiply by 1 TimeExponential Weighted Moving Average (EWMA) misfire for

cylinder 6:

EWMA = Total misfire counts for last driving cycle * 0.1 + Last

EWMA * 0.9

Misfire counts for last 10 driving cycles - Total

$A7 $0C Multiply by 1 TimeIgnition switch ON: Total misfire counts for last driving cycle

Engine running: Total misfire counts for current driving cycle

Misfire counts for last or current driving cycle - cylinder 6 Monitor ID Test ID Scaling Unit Description