TOYOTA SIENNA 2007 Service Repair Manual

Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 311 of 3000

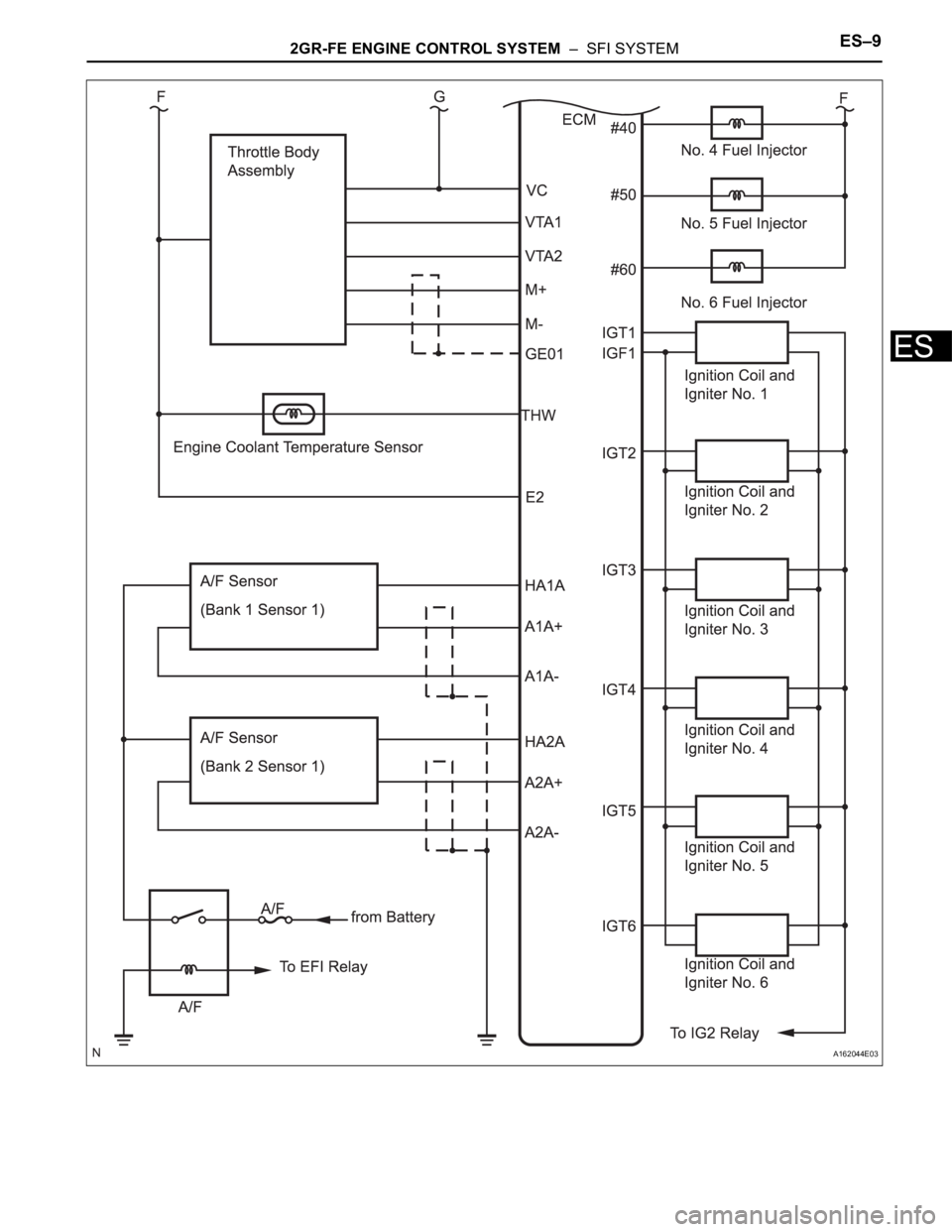

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–9

ES

A162044E03

Page 312 of 3000

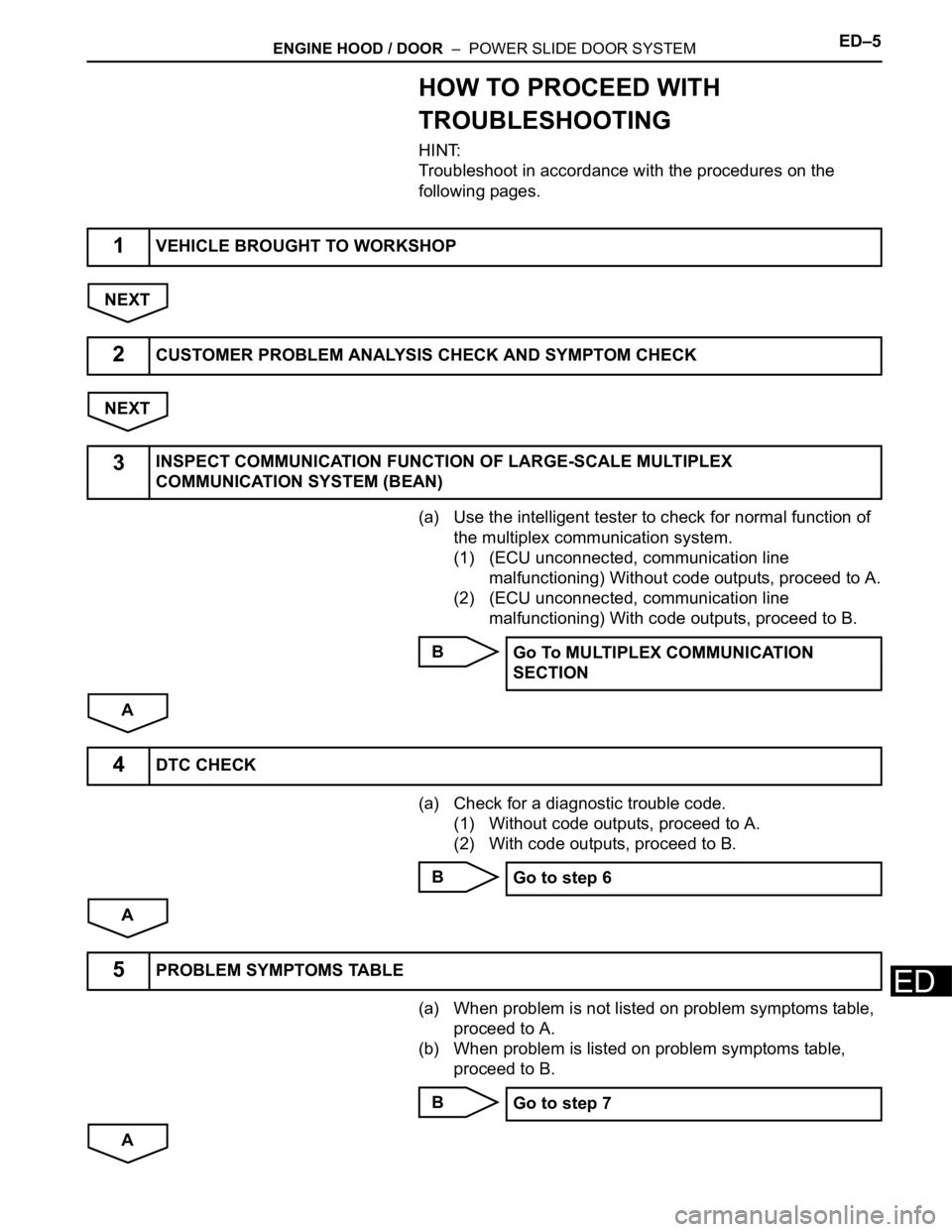

ENGINE HOOD / DOOR – POWER SLIDE DOOR SYSTEMED–5

ED

HOW TO PROCEED WITH

TROUBLESHOOTING

HINT:

Troubleshoot in accordance with the procedures on the

following pages.

NEXT

NEXT

(a) Use the intelligent tester to check for normal function of

the multiplex communication system.

(1) (ECU unconnected, communication line

malfunctioning) Without code outputs, proceed to A.

(2) (ECU unconnected, communication line

malfunctioning) With code outputs, proceed to B.

B

A

(a) Check for a diagnostic trouble code.

(1) Without code outputs, proceed to A.

(2) With code outputs, proceed to B.

B

A

(a) When problem is not listed on problem symptoms table,

proceed to A.

(b) When problem is listed on problem symptoms table,

proceed to B.

B

A

1VEHICLE BROUGHT TO WORKSHOP

2CUSTOMER PROBLEM ANALYSIS CHECK AND SYMPTOM CHECK

3INSPECT COMMUNICATION FUNCTION OF LARGE-SCALE MULTIPLEX

COMMUNICATION SYSTEM (BEAN)

Go To MULTIPLEX COMMUNICATION

SECTION

4DTC CHECK

Go to step 6

5PROBLEM SYMPTOMS TABLE

Go to step 7

Page 313 of 3000

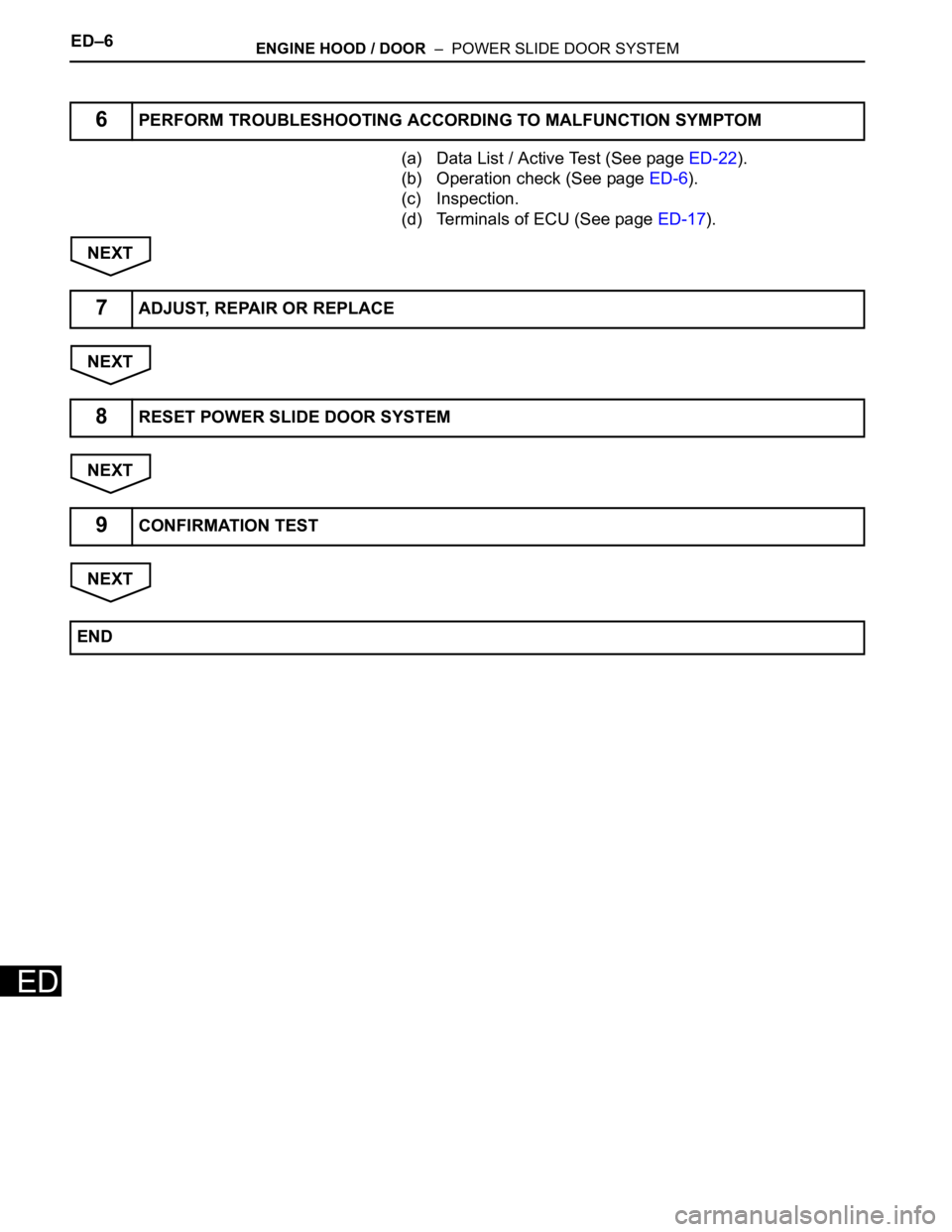

ED–6ENGINE HOOD / DOOR – POWER SLIDE DOOR SYSTEM

ED

(a) Data List / Active Test (See page ED-22).

(b) Operation check (See page ED-6).

(c) Inspection.

(d) Terminals of ECU (See page ED-17).

NEXT

NEXT

NEXT

NEXT

6PERFORM TROUBLESHOOTING ACCORDING TO MALFUNCTION SYMPTOM

7ADJUST, REPAIR OR REPLACE

8RESET POWER SLIDE DOOR SYSTEM

9CONFIRMATION TEST

END

Page 314 of 3000

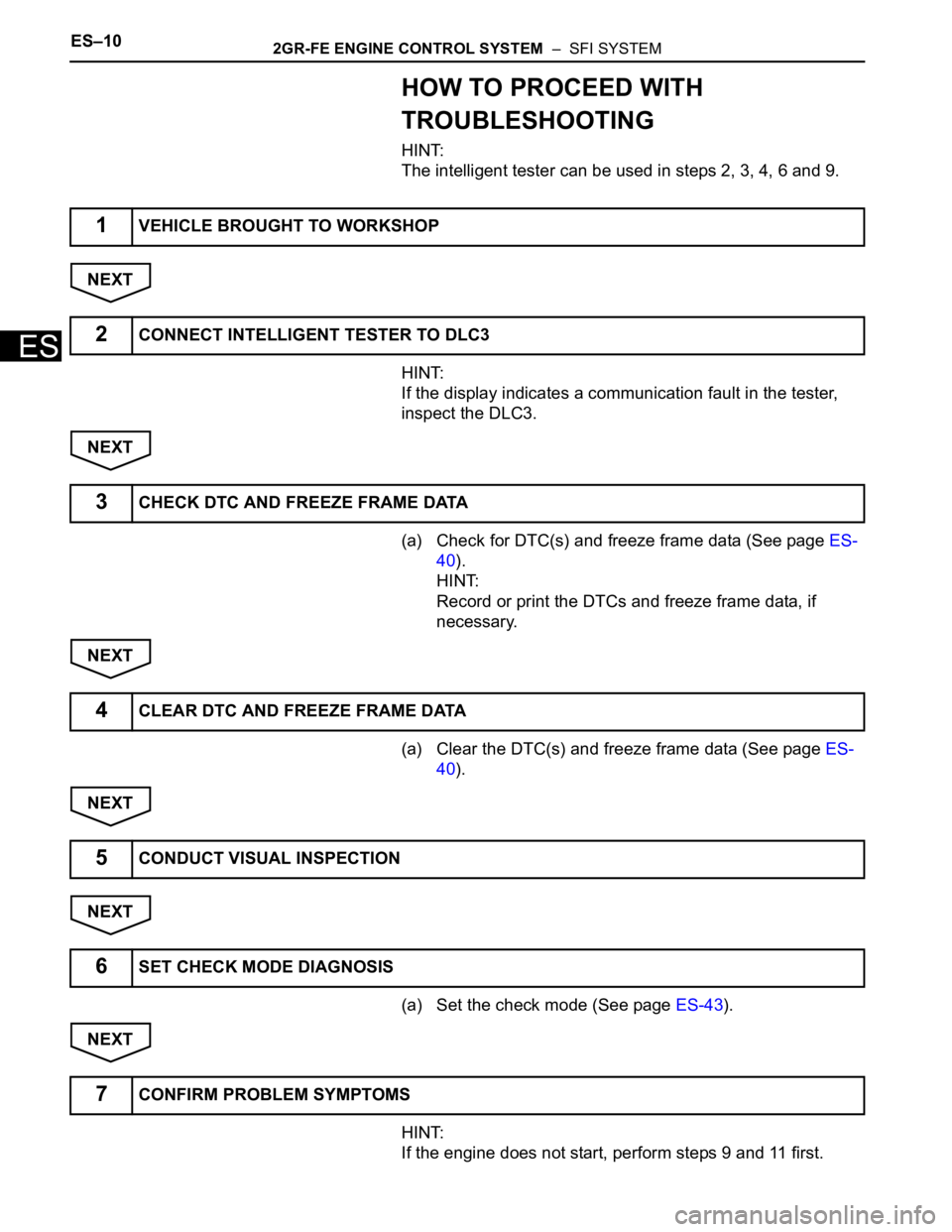

ES–102GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

HOW TO PROCEED WITH

TROUBLESHOOTING

HINT:

The intelligent tester can be used in steps 2, 3, 4, 6 and 9.

NEXT

HINT:

If the display indicates a communication fault in the tester,

inspect the DLC3.

NEXT

(a) Check for DTC(s) and freeze frame data (See page ES-

40).

HINT:

Record or print the DTCs and freeze frame data, if

necessary.

NEXT

(a) Clear the DTC(s) and freeze frame data (See page ES-

40).

NEXT

NEXT

(a) Set the check mode (See page ES-43).

NEXT

HINT:

If the engine does not start, perform steps 9 and 11 first.

1VEHICLE BROUGHT TO WORKSHOP

2CONNECT INTELLIGENT TESTER TO DLC3

3CHECK DTC AND FREEZE FRAME DATA

4CLEAR DTC AND FREEZE FRAME DATA

5CONDUCT VISUAL INSPECTION

6SET CHECK MODE DIAGNOSIS

7CONFIRM PROBLEM SYMPTOMS

Page 315 of 3000

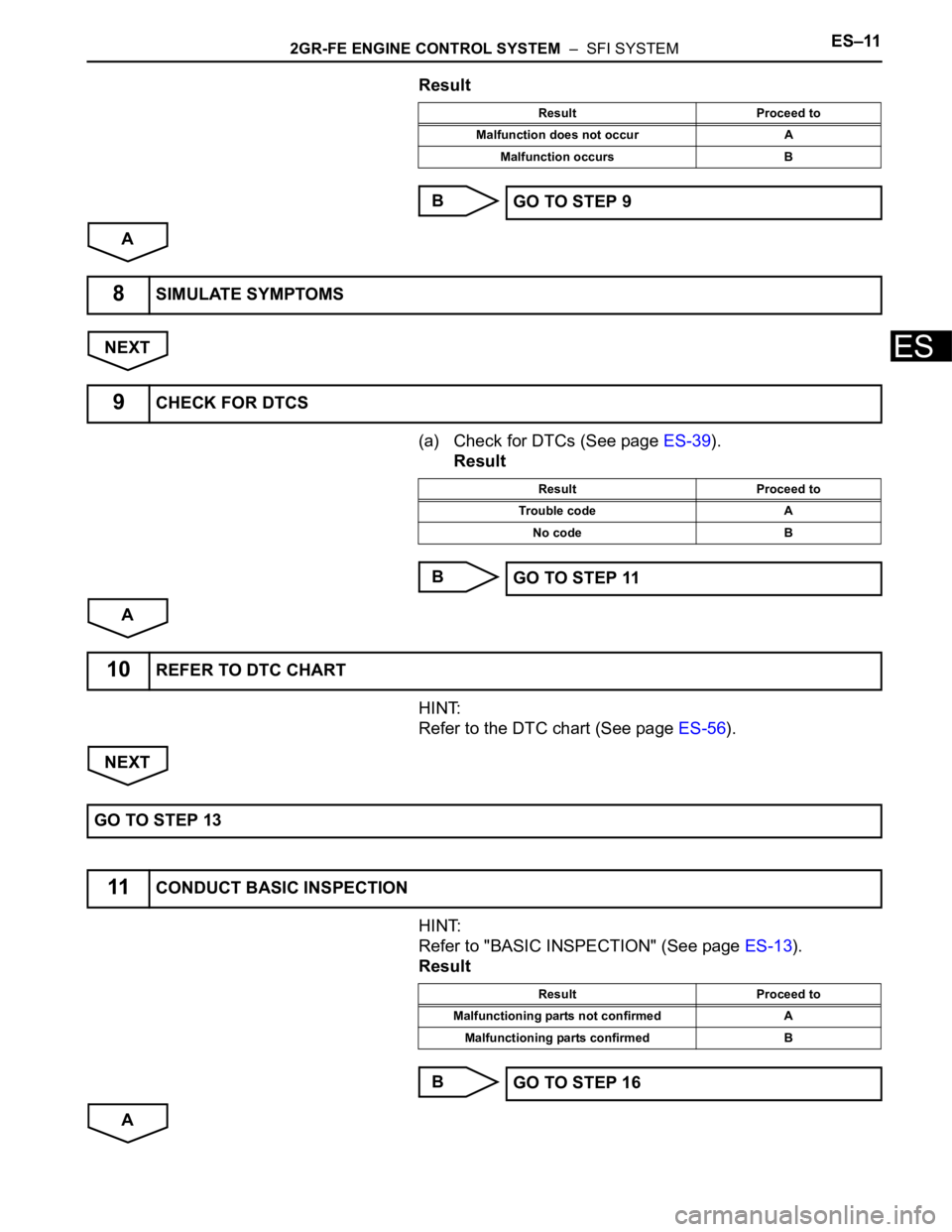

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–11

ES

Result

B

A

NEXT

(a) Check for DTCs (See page ES-39).

Result

B

A

HINT:

Refer to the DTC chart (See page ES-56).

NEXT

HINT:

Refer to "BASIC INSPECTION" (See page ES-13).

Result

B

A

Result Proceed to

Malfunction does not occur A

Malfunction occurs B

GO TO STEP 9

8SIMULATE SYMPTOMS

9CHECK FOR DTCS

Result Proceed to

Trouble code A

No code B

GO TO STEP 11

10REFER TO DTC CHART

GO TO STEP 13

11CONDUCT BASIC INSPECTION

Result Proceed to

Malfunctioning parts not confirmed A

Malfunctioning parts confirmed B

GO TO STEP 16

Page 316 of 3000

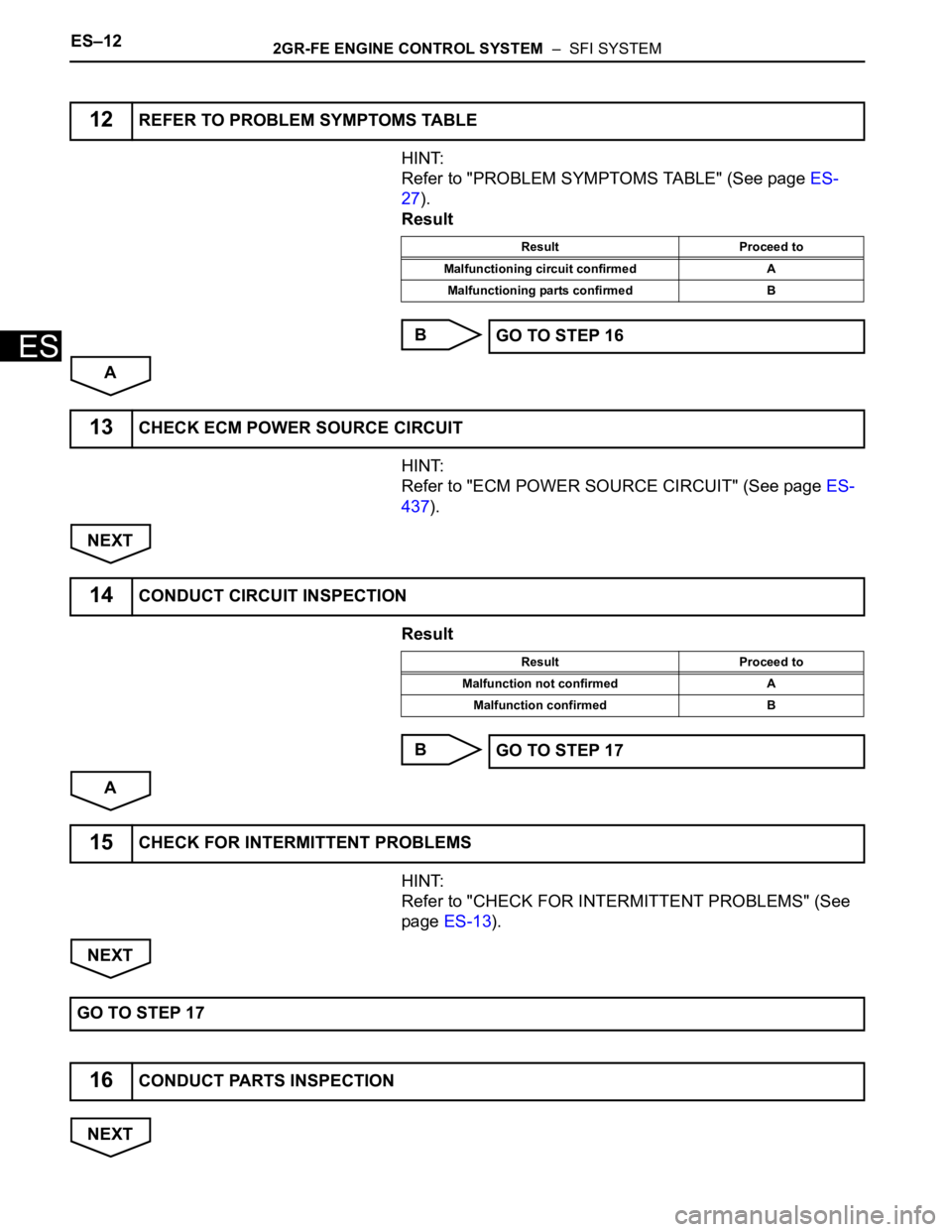

ES–122GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

HINT:

Refer to "PROBLEM SYMPTOMS TABLE" (See page ES-

27).

Result

B

A

HINT:

Refer to "ECM POWER SOURCE CIRCUIT" (See page ES-

437).

NEXT

Result

B

A

HINT:

Refer to "CHECK FOR INTERMITTENT PROBLEMS" (See

page ES-13).

NEXT

NEXT

12REFER TO PROBLEM SYMPTOMS TABLE

Result Proceed to

Malfunctioning circuit confirmed A

Malfunctioning parts confirmed B

GO TO STEP 16

13CHECK ECM POWER SOURCE CIRCUIT

14CONDUCT CIRCUIT INSPECTION

Result Proceed to

Malfunction not confirmed A

Malfunction confirmed B

GO TO STEP 17

15CHECK FOR INTERMITTENT PROBLEMS

GO TO STEP 17

16CONDUCT PARTS INSPECTION

Page 317 of 3000

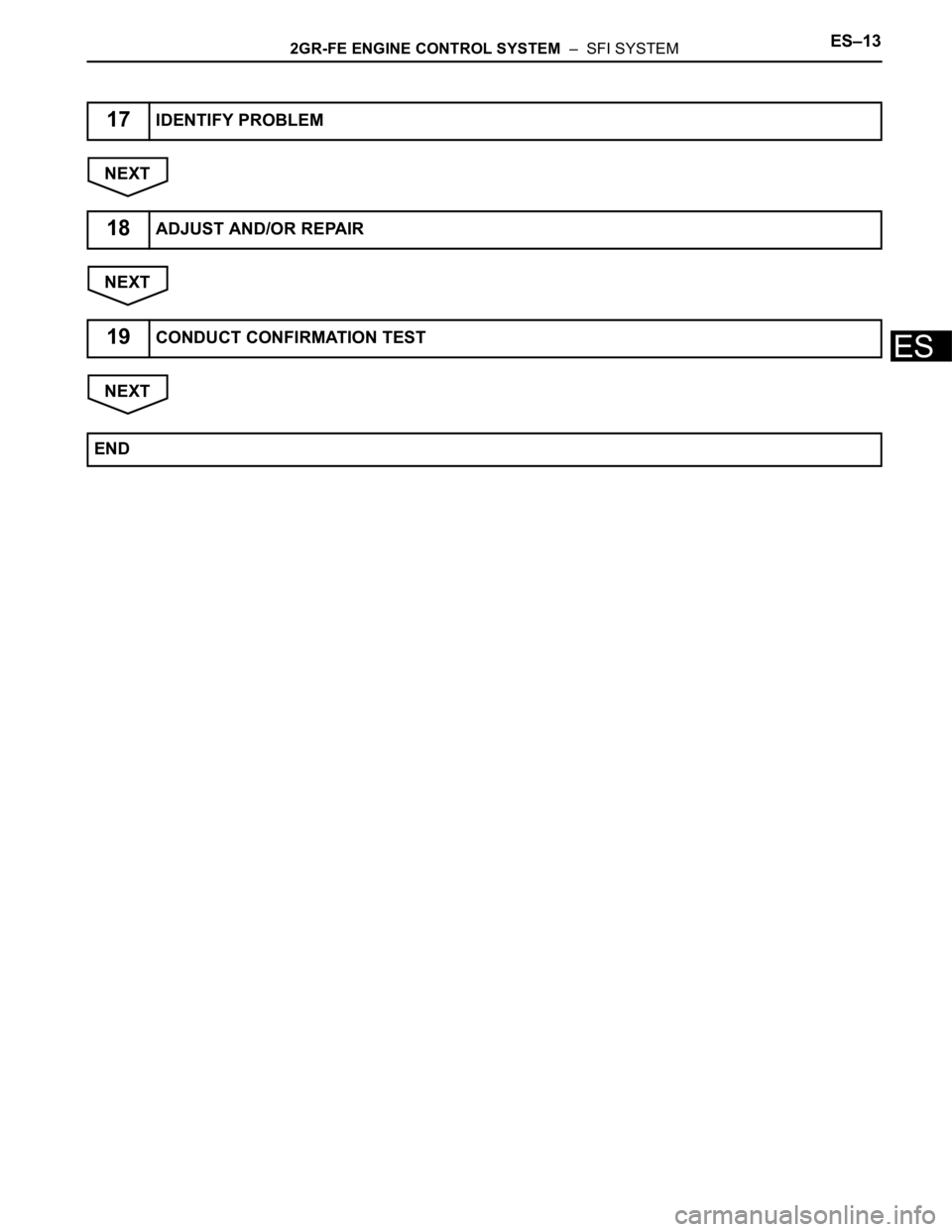

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–13

ES

NEXT

NEXT

NEXT

17IDENTIFY PROBLEM

18ADJUST AND/OR REPAIR

19CONDUCT CONFIRMATION TEST

END

Page 318 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–1

ES

SFI SYSTEM

PRECAUTION

1. INITIALIZATION

NOTICE:

• Perform RESET MEMORY (AT initialization) when

replacing the automatic transaxle assembly, engine

assembly or ECM (See page AX-16).

• Perform REGISTRATION (VIN registration) when

replacing the ECM (See page ES-15).

HINT:

Initialization cannot be completed by only removing the

battery.

2. FOR USING INTELLIGENT TESTER

CAUTION:

Observe the following items for safety reasons:

• Before using the tester, read the instruction

manual.

• Prevent the tester cable from being caught on the

pedals, shift lever and steering wheel when

driving with the tester connected to the vehicle.

• When driving the vehicle for testing purposes

using the tester, two persons are required. One is

for driving the vehicle, and the other operates the

tester.

3. FOR USING BATTERY DURING INSPECTION

(a) While using the battery during inspection, do not

bring the positive and negative tester probes too

close to each other as a short circuit may occur.

4. COOLING FAN SYSTEM

NOTICE:

• When the ignition switch is turned off and the engine

temperature is high, the cooling fans may operate for

approximately 3 minutes.

• After turning the ignition switch off, keep hands and

objects away from the fans when they are operating.

HINT:

If all of the following are met for a certain period of time during

a few minute period immediately before the engine is

stopped, the electric fans will continue to operate for 3

minutes after the engine is stopped. This is performed to

ensure restartability and stabilize idle speed.

– The intelligent tester indicates a very high coolant

temperature.

– The intelligent tester indicates a high outside air

temperature.

– The vehicle has been driven under high load (driving on an

uphill or equivalent).

The following sensors are used for this control:

– Coolant temperature sensor

– Outside air temperature sensor

–MAF sensor

– Vehicle speed sensors

Page 319 of 3000

ES–22GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

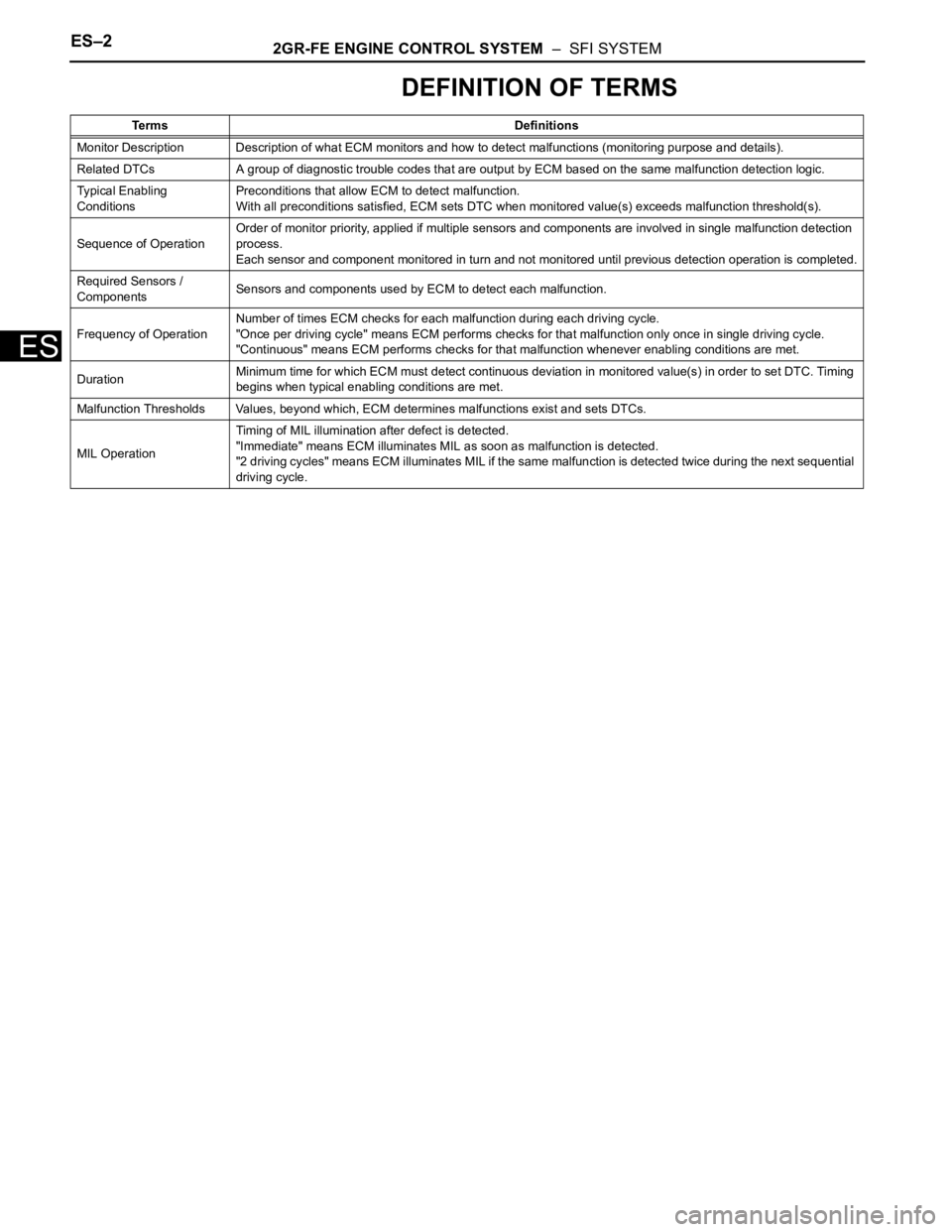

DEFINITION OF TERMS

Terms Definitions

Monitor Description Description of what ECM monitors and how to detect malfunctions (monitoring purpose and details).

Related DTCs A group of diagnostic trouble codes that are output by ECM based on the same malfunction detection logic.

Typical Enabling

ConditionsPreconditions that allow ECM to detect malfunction.

With all preconditions satisfied, ECM sets DTC when monitored value(s) exceeds malfunction threshold(s).

Sequence of OperationOrder of monitor priority, applied if multiple sensors and components are involved in single malfunction detection

process.

Each sensor and component monitored in turn and not monitored until previous detection operation is completed.

Required Sensors /

ComponentsSensors and components used by ECM to detect each malfunction.

Frequency of OperationNumber of times ECM checks for each malfunction during each driving cycle.

"Once per driving cycle" means ECM performs checks for that malfunction only once in single driving cycle.

"Continuous" means ECM performs checks for that malfunction whenever enabling conditions are met.

DurationMinimum time for which ECM must detect continuous deviation in monitored value(s) in order to set DTC. Timing

begins when typical enabling conditions are met.

Malfunction Thresholds Values, beyond which, ECM determines malfunctions exist and sets DTCs.

MIL OperationTiming of MIL illumination after defect is detected.

"Immediate" means ECM illuminates MIL as soon as malfunction is detected.

"2 driving cycles" means ECM illuminates MIL if the same malfunction is detected twice during the next sequential

driving cycle.

Page 320 of 3000

ES–2522GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

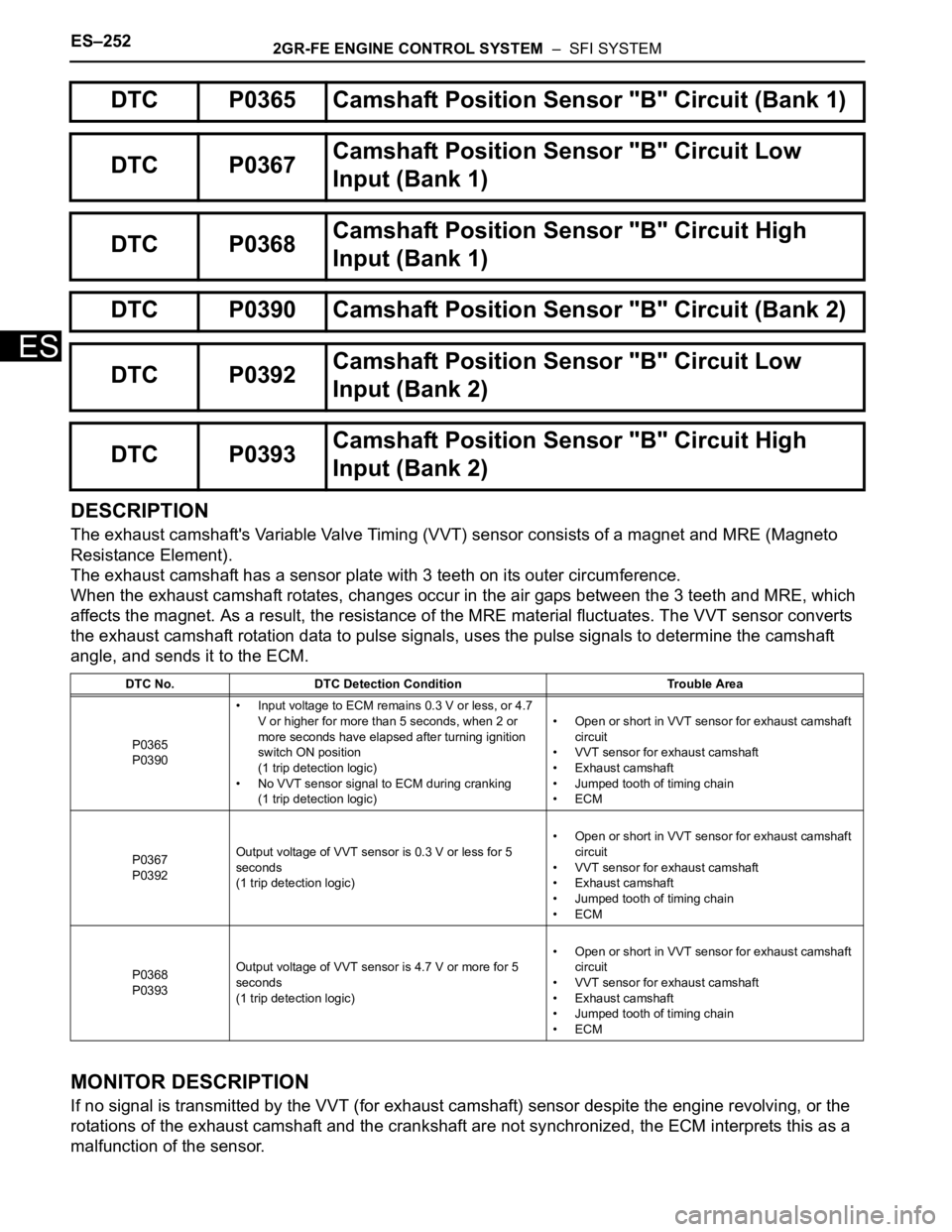

DESCRIPTION

The exhaust camshaft's Variable Valve Timing (VVT) sensor consists of a magnet and MRE (Magneto

Resistance Element).

The exhaust camshaft has a sensor plate with 3 teeth on its outer circumference.

When the exhaust camshaft rotates, changes occur in the air gaps between the 3 teeth and MRE, which

affects the magnet. As a result, the resistance of the MRE material fluctuates. The VVT sensor converts

the exhaust camshaft rotation data to pulse signals, uses the pulse signals to determine the camshaft

angle, and sends it to the ECM.

MONITOR DESCRIPTION

If no signal is transmitted by the VVT (for exhaust camshaft) sensor despite the engine revolving, or the

rotations of the exhaust camshaft and the crankshaft are not synchronized, the ECM interprets this as a

malfunction of the sensor.

DTC P0365 Camshaft Position Sensor "B" Circuit (Bank 1)

DTC P0367Camshaft Position Sensor "B" Circuit Low

Input (Bank 1)

DTC P0368Camshaft Position Sensor "B" Circuit High

Input (Bank 1)

DTC P0390 Camshaft Position Sensor "B" Circuit (Bank 2)

DTC P0392Camshaft Position Sensor "B" Circuit Low

Input (Bank 2)

DTC P0393Camshaft Position Sensor "B" Circuit High

Input (Bank 2)

DTC No. DTC Detection Condition Trouble Area

P0365

P0390• Input voltage to ECM remains 0.3 V or less, or 4.7

V or higher for more than 5 seconds, when 2 or

more seconds have elapsed after turning ignition

switch ON position

(1 trip detection logic)

• No VVT sensor signal to ECM during cranking

(1 trip detection logic)• Open or short in VVT sensor for exhaust camshaft

circuit

• VVT sensor for exhaust camshaft

• Exhaust camshaft

• Jumped tooth of timing chain

•ECM

P0367

P0392Output voltage of VVT sensor is 0.3 V or less for 5

seconds

(1 trip detection logic)• Open or short in VVT sensor for exhaust camshaft

circuit

• VVT sensor for exhaust camshaft

• Exhaust camshaft

• Jumped tooth of timing chain

•ECM

P0368

P0393Output voltage of VVT sensor is 4.7 V or more for 5

seconds

(1 trip detection logic)• Open or short in VVT sensor for exhaust camshaft

circuit

• VVT sensor for exhaust camshaft

• Exhaust camshaft

• Jumped tooth of timing chain

•ECM