YAMAHA XSR 900 2022 Workshop Manual

Manufacturer: YAMAHA, Model Year: 2022, Model line: XSR 900, Model: YAMAHA XSR 900 2022Pages: 114, PDF Size: 4.36 MB

Page 51 of 114

Instrument and control functions

4-28

1

2

345

6

7

8

9

10

11

12

13

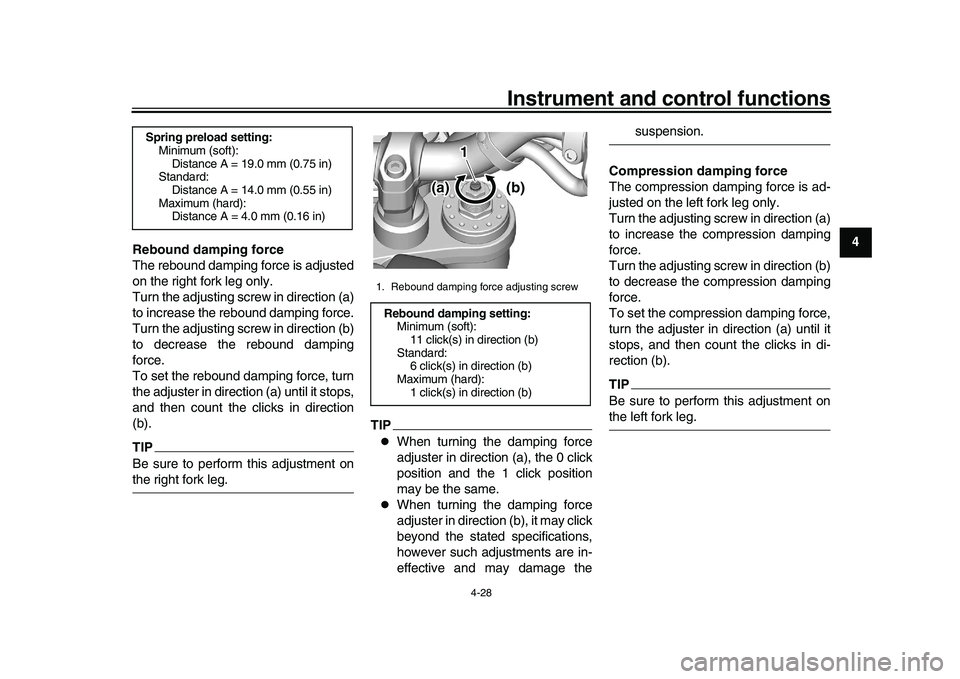

Rebound damping force

The rebound damping force is adjusted

on the right fork leg only.

Turn the adjusting screw in direction (a)

to increase the rebound damping force.

Turn the adjusting screw in direction (b)

to decrease the rebound damping

force.

To set the rebound damping force, turn

the adjuster in direction (a) until it stops,

and then count the clicks in direction

(b).

TIPBe sure to perform this adjustment onthe right fork leg.

TIP

When turning the damping force

adjuster in direction (a), the 0 click

position and the 1 click position

may be the same.

When turning the damping force

adjuster in direction (b), it may click

beyond the stated specifications,

however such adjustments are in-

effective and may damage the

suspension.

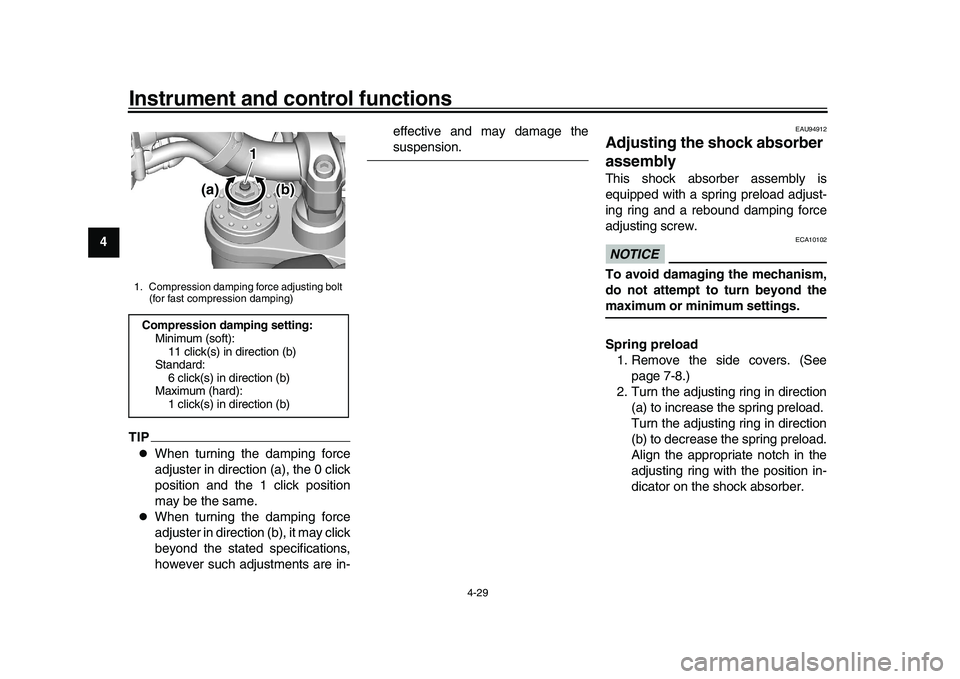

Compression damping force

The compression damping force is ad-

justed on the left fork leg only.

Turn the adjusting screw in direction (a)

to increase the compression damping

force.

Turn the adjusting screw in direction (b)

to decrease the compression damping

force.

To set the compression damping force,

turn the adjuster in direction (a) until it

stops, and then count the clicks in di-

rection (b).

TIPBe sure to perform this adjustment onthe left fork leg.

Spring preload setting: Minimum (soft): Distance A = 19.0 mm (0.75 in)

Standard:

Distance A = 14.0 mm (0.55 in)

Maximum (hard): Distance A = 4.0 mm (0.16 in)

1. Rebound damping force adjusting screwRebound damping setting:Minimum (soft):

11 click(s) in direction (b)

Standard: 6 click(s) in direction (b)

Maximum (hard): 1 click(s) in direction (b)

(b)

(a)

111

BEA-28199-E0.book 28 ページ 2021年12月1日 水曜日 午後7時8分

Page 52 of 114

Instrument and control functions

4-29

1

2

34

5

6

7

8

9

10

11

12

13

TIP

When turning the damping force

adjuster in direction (a), the 0 click

position and the 1 click position

may be the same.

When turning the damping force

adjuster in direction (b), it may click

beyond the stated specifications,

however such adjustments are in- effective and may damage the

suspension.

EAU94912

Adjusting the shock absorber

assemblyThis shock absorber assembly is

equipped with a spring preload adjust-

ing ring and a rebound damping force

adjusting screw.NOTICE

ECA10102

To avoid damaging the mechanism,

do not attempt to turn beyond themaximum or minimum settings.

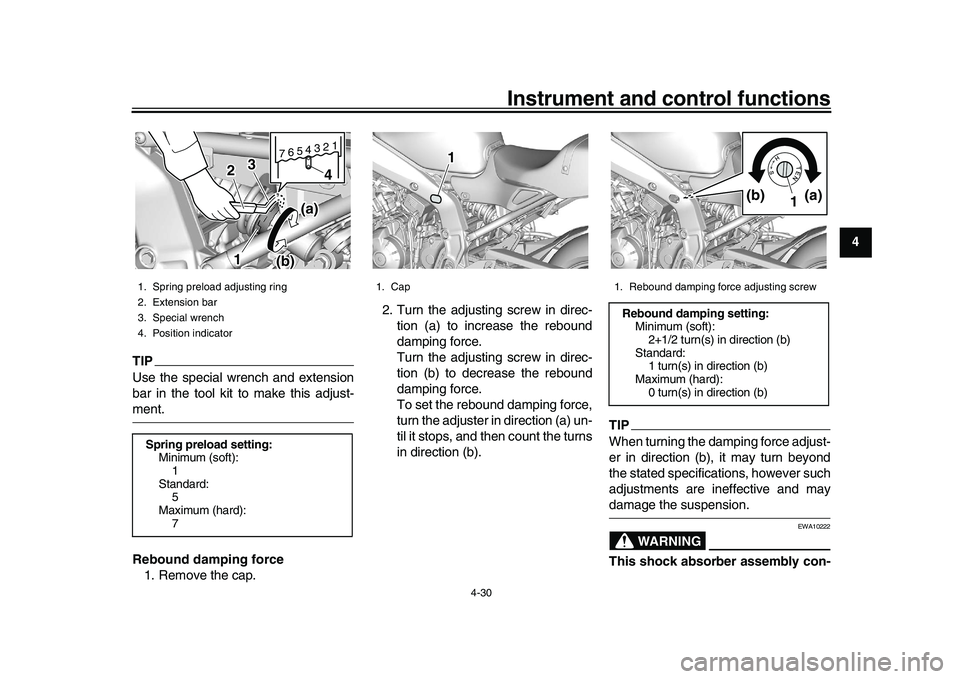

Spring preload

1. Remove the side covers. (See page 7-8.)

2. Turn the adjusting ring in direction (a) to increase the spring preload.

Turn the adjusting ring in direction

(b) to decrease the spring preload.

Align the appropriate notch in the

adjusting ring with the position in-

dicator on the shock absorber.

1. Compression damping force adjusting bolt (for fast compression damping)Compression damping setting:Minimum (soft):

11 click(s) in direction (b)

Standard: 6 click(s) in direction (b)

Maximum (hard): 1 click(s) in direction (b)

(b)

(a)

111

BEA-28199-E0.book 29 ページ 2021年12月1日 水曜日 午後7時8分

Page 53 of 114

Instrument and control functions

4-30

1

2

345

6

7

8

9

10

11

12

13

TIPUse the special wrench and extension

bar in the tool kit to make this adjust-ment.

Rebound damping force 1. Remove the cap. 2. Turn the adjusting screw in direc-

tion (a) to increase the rebound

damping force.

Turn the adjusting screw in direc-

tion (b) to decrease the rebound

damping force.

To set the rebound damping force,

turn the adjuster in direction (a) un-

til it stops, and then count the turns

in direction (b).

TIPWhen turning the damping force adjust-

er in direction (b), it may turn beyond

the stated specifications, however such

adjustments are ineffective and maydamage the suspension.

WARNING

EWA10222

This shock absorber assembly con-

1. Spring preload adjusting ring

2. Extension bar

3. Special wrench

4. Position indicatorSpring preload setting:Minimum (soft):

1

Standard: 5

Maximum (hard): 7

7654321

4

1 1 1

2 2

3 3

(a) (a) (a)

(b) (b) (b)

1. Cap

111

1. Rebound damping force adjusting screwRebound damping setting: Minimum (soft):

2+1/2 turn(s) in direction (b)

Standard: 1 turn(s) in direction (b)

Maximum (hard): 0 turn(s) in direction (b)

1(a)

(b)

BEA-28199-E0.book 30 ページ 2021年12月1日 水曜日 午後7時8分

Page 54 of 114

Instrument and control functions

4-31

1

2

34

5

6

7

8

9

10

11

12

13 tains highly pressurized nitrogen

gas. Read and understand the fol-

lowing information before handling

the shock absorber assembly.

Do not tamper with or attempt to

open the cylinder assembly.

Do not subject the shock ab-

sorber assembly to an open

flame or other high heat source.

This may cause the unit to ex-

plode due to excessive gas

pressure.

Do not deform or damage the

cylinder in any way. Cylinder

damage will result in poor

damping performance.

Do not dispose of a damaged or

worn-out shock absorber as-

sembly yourself. Take the shock

absorber assembly to a Yamahadealer for any service.

EAU77390

Auxiliary DC connectorsThis vehicle is equipped with an auxilia-

ry DC connector and a grip warmer DC

connector. Consult your Yamaha deal-

er before installing any accessories.

EAU15306

SidestandThe sidestand is located on the left side

of the frame. Raise the sidestand or

lower it with your foot while holding the

vehicle upright.TIPThe built-in sidestand switch is part of

the ignition circuit cu

t-off system, which

cuts the ignition in certain situations.

(See the following section for an expla-

nation of the ignition circuit cut-off sys-tem.)

WARNING

EWA10242

The vehicle must not be ridden with

the sidestand down, or if the sides-

tand cannot be properly moved up

(or does not stay up), otherwise the

sidestand could contact the ground

and distract the operator, resulting

in a possible loss of control.

Yamaha’s ignition circuit cut-off

system has been designed to assist

the operator in fulfilling the respon-

sibility of raising the sidestand be-

fore starting off. Therefore, check

this system regularly and have a

BEA-28199-E0.book 31 ページ 2021年12月1日 水曜日 午後7時8分

Page 55 of 114

Instrument and control functions

4-32

1

2

345

6

7

8

9

10

11

12

13

Yamaha dealer repair it if it does not

function properly.

EAU57952

Ignition circuit cut-off systemThis system prevents in-gear engine

starts unless the clutch lever is pulled

and the sidestand is up. Also, it will stop

the running engine should the sides-

tand be lowered while the transmission

is in gear.

Periodically check this system via the

following procedure.TIP

This check is most reliable if per-

formed with a warmed-up engine.

See pages 4-2 and 4-3 for switchoperation information.

BEA-28199-E0.book 32 ページ 2021年12月1日 水曜日 午後7時8分

Page 56 of 114

Instrument and control functions

4-33

1

2

34

5

6

7

8

9

10

11

12

13

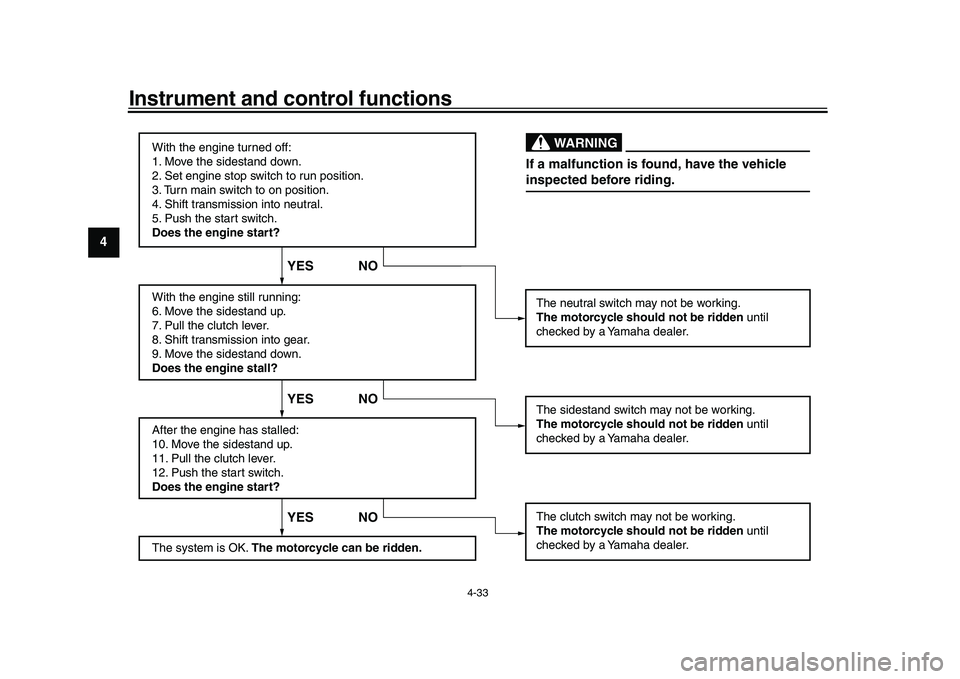

With the engine turned off:

1. Move the sidestand down.

2. Set engine stop s witch to run position.

3. T urn m ain switch to on position.

4. Shift tr ansmission into neutr al.

5. Push the start switch.

Does the engine start?

With the engine still r unning:

6. Move the sidestand up.

7. Pull the clutch lever.

8. Shift tr ansmission into gear.

9. Move the sidestand down.

Does the engine stall?

After the engine has stalled:

10. Move the sidestand up.

11. P

ull the clutch lever.

12. Push the start switch.

Does the engine start?

The system is OK. The motorcycle can be ridden.

YES NO YES NO YES NO

The neutr al switch ma y not be working.

The motorcycle should not be ridden until

checked b y a Yamaha dealer.

The clutch s witch may not be working.

The motorcycle should not be ridden until

checked b y a Yamaha dealer.The sidestand s witch may not be working.

The motorcycle should not be ridden until

checked b y a Yamaha dealer.If a malfunction is found, have the vehicle

inspected before riding.

WARNING

BEA-28199-E0.book 33 ページ 2021年12月1日 水曜日 午後7時8分

Page 57 of 114

5-1

1

2

3

456

7

8

9

10

11

12

13

For your safety – pre-operation checks

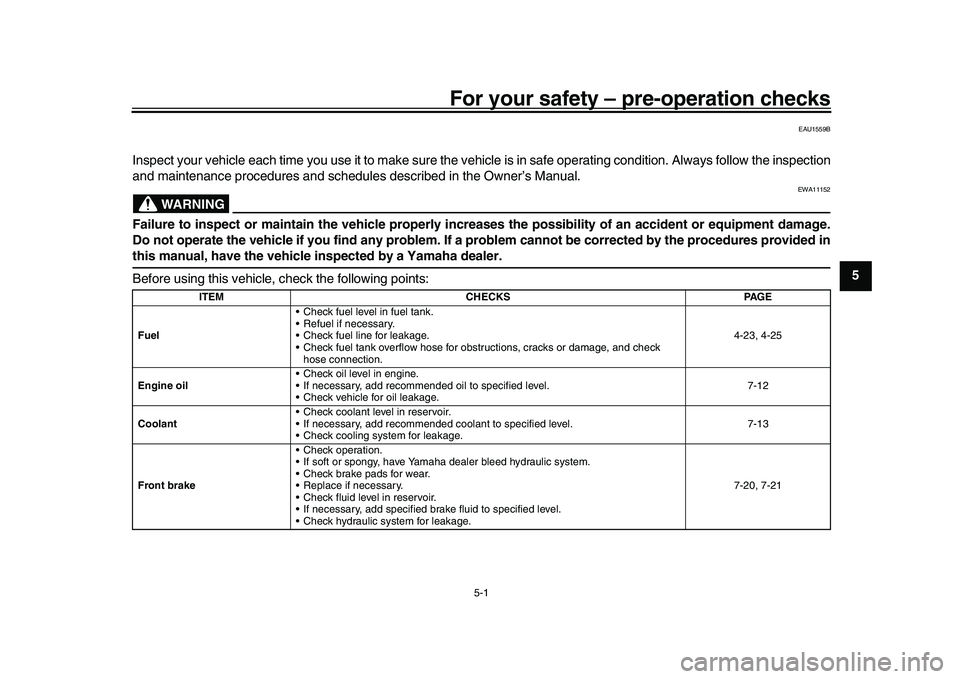

EAU1559B

Inspect your vehicle each time you use it to make sure the vehicle is in safe operating condition. Always follow the inspection

and maintenance procedures and schedules described in the Owner’s Manual.

WARNING

EWA11152

Failure to inspect or maintain the vehicle properly increases the possibility of an accident or equipment damage.

Do not operate the vehicle if you find any problem. If a problem cannot be corrected by the procedures provided inthis manual, have the vehicle inspected by a Yamaha dealer.

Before using this vehicle, check the following points:

ITEM CHECKS PAGE

Fuel Check fuel level in fuel tank.

Refuel if necessary.

Check fuel line for leakage.

Check fuel tank overflow hose for obstr

uctions, cracks or damage, and check

hose connection. 4-23, 4-25

Engine oil Check oil level in engine.

If necessary, add recommended oil to specified level.

Check vehicle for oil leakage. 7-12

Coolant Check coolant level in reservoir.

If necessary, add recommended coolant to specified level.

Check cooling system for leakage. 7-13

Front brake Check operation.

If soft or spongy, have Yamaha dealer bleed hydraulic system.

Check brake pads for wear.

Replace if necessary.

Check fluid level in reservoir.

If necessary, add specified brake fluid to specified level.

Check hydraulic system for leakage. 7-20, 7-21

BEA-28199-E0.book 1 ページ 2021年12月1日 水曜日 午後7時8分

Page 58 of 114

For your safety – pre-operation checks

5-2

1

2

3

45

6

7

8

9

10

11

12

13

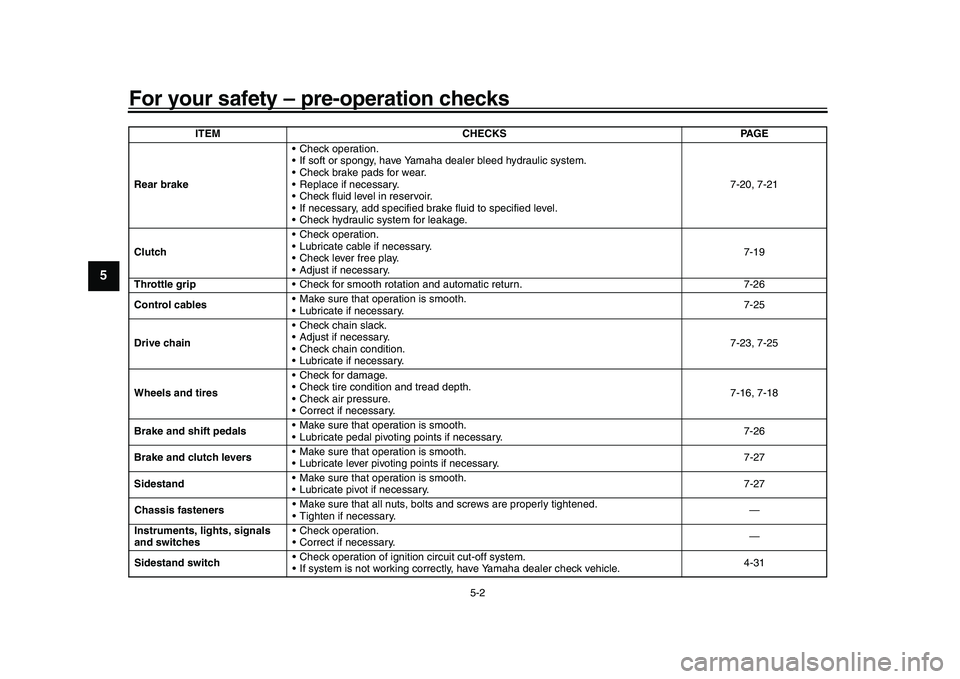

Rear brake Check operation.

If soft or spongy, have Yamaha dealer bleed hydraulic system.

Check brake pads for wear.

Replace if necessary.

Check fluid level in reservoir.

If necessary, add specified brake fluid to specified level.

Check hydraulic system for leakage. 7-20, 7-21

Clutch Check operation.

Lubricate cable if necessary.

Check lever free play.

Adjust if necessary. 7-19

Throttle grip Check for smooth rotation and automatic return. 7-26

Control cables Make sure that operation is smooth.

Lubricate if necessary. 7-25

Drive chain Check chain slack.

Adjust if necessary.

Check chain condition.

Lubricate if necessary. 7-23, 7-25

Wheels and tires Check for damage.

Check tire condition and tread depth.

Check air pressure.

Correct if necessary. 7-16, 7-18

Brake and shift pedals Make sure that operation is smooth.

Lubricate pedal pivoting points if necessary. 7-26

Brake and clutch levers Make sure that operation is smooth.

Lubricate lever pivoting points if necessary. 7-27

Sidestand Make sure that operation is smooth.

Lubricate pivot if necessary. 7-27

Chassis fasteners Make sure that all nuts, bolts

and screws are properly tightened.

Tighten if necessary. —

Instruments, lights, signals

and switches Check operation.

Correct if necessary.

—

Sidestand switch Check operation of ignition circuit cut-off system.

If system is not working correctly, have Yamaha dealer check vehicle. 4-31

ITEM CHECKS PAGE

BEA-28199-E0.book 2 ページ 2021年12月1日 水曜日 午後7時8分

Page 59 of 114

6-1

1

2

3

4

567

8

9

10

11

12

13

Operation and important riding points

EAU15952

Read the Owner’s Manual carefully to

become familiar with all controls. If

there is a control or function you do not

understand, ask your Yamaha dealer.

WARNING

EWA10272

Failure to familiarize yourself with

the controls can lead to loss of con-

trol, which could cause an accidentor injury.

EAU16842

Engine break-inThere is never a more important period

in the life of your engine than the period

between 0 and 1600 km (1000 mi). For

this reason, you should read the follow-

ing material carefully.

Since the engine is brand new, do not

put an excessive load on it for the first

1600 km (1000 mi). The various parts in

the engine wear and polish themselves

to the correct operating clearances.

During this period, prolonged full-throt-

tle operation or any condition that might

result in engine overheating must be

avoided.

EAU17094

0–1000 km (0–600 mi)

Avoid prolonged operation above 5300

r/min. NOTICE: After 1000 km (600

mi) of operation, the engine oil must

be changed and the oil filter car-

tridge or element replaced.

[ECA10303]

1000–1600 km (600–1000 mi)

Avoid prolonged operation above 6300 r/min.

1600 km (1000 mi) and beyond

The vehicle can now be operated nor-

mally.

NOTICE

ECA10311

Keep the engine speed out of

the tachometer red zone.

If any engine trouble should oc-

cur during the engine break-in

period, immediately have a

Yamaha dealer check the vehi-cle.

BEA-28199-E0.book 1 ページ 2021年12月1日 水曜日 午後7時8分

Page 60 of 114

Operation and important riding points

6-2

1

2

3

4

56

7

8

9

10

11

12

13

EAU91411

Starting the engineThe ignition circuit cut-off system will

enable starting when:

the transmission is in the neutral

position or

the transmission is in gear, the sid-

estand is up, and the clutch lever is

pulled.

To start the engine

1. Turn the main switch on and set the engine stop switch to the run

position.

2. Confirm the indicator and warning light(s) come on for a few seconds,

and then go off. (See page 4-5.)TIP

Do not start the engine if the mal-

function indicator light remains on.

The oil pressure and coolant tem-

perature warning light should

come on and stay on until the en-

gine is started.

The ABS warning light should

come on and stay on until the vehi-

cle reaches a speed of 5 km/h (3mi/h).

NOTICE

ECA24110

If a warning or indicator light does

not work as described above, have aYamaha dealer check the vehicle.

3. Shift the transmission into the neu- tral position.

4. Start the engine by pushing the start switch.

5. Release the start switch when the engine starts, or after 5 seconds.

Wait 10 seconds before pressing

the switch again to allow battery

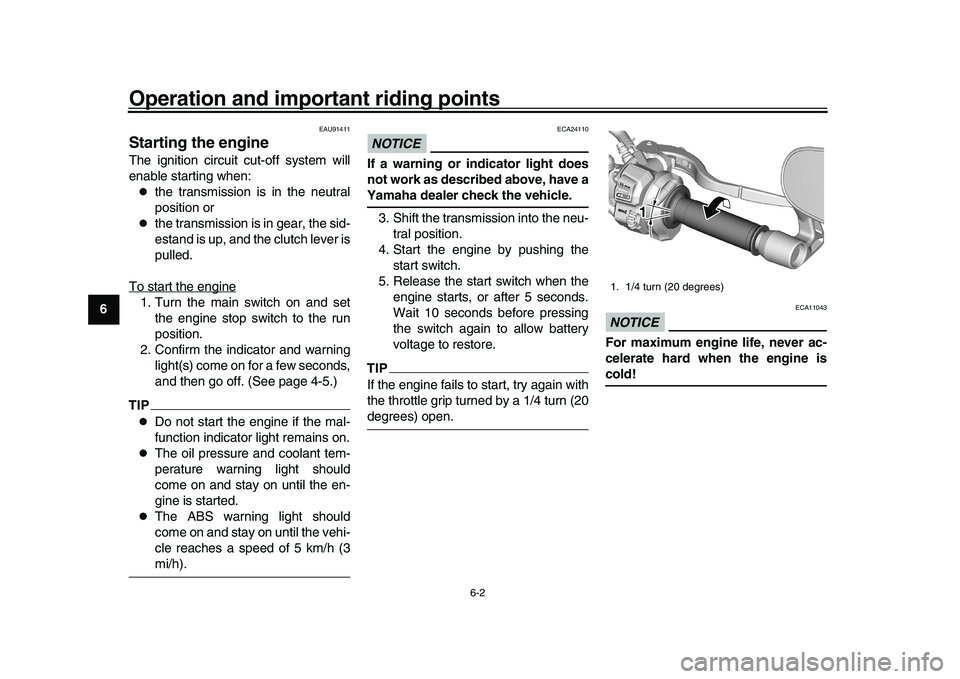

voltage to restore.TIPIf the engine fails to start, try again with

the throttle grip turned by a 1/4 turn (20degrees) open.

NOTICE

ECA11043

For maximum engine life, never ac-

celerate hard when the engine iscold!1. 1/4 turn (20 degrees)

111

BEA-28199-E0.book 2 ページ 2021年12月1日 水曜日 午後7時8分