ACURA NSX 1991 Service Repair Manual

Manufacturer: ACURA, Model Year: 1991,

Model line: NSX,

Model: ACURA NSX 1991

Pages: 1640, PDF Size: 60.48 MB

ACURA NSX 1991 Service Repair Manual

NSX 1991

ACURA

ACURA

https://www.carmanualsonline.info/img/32/56988/w960_56988-0.png

ACURA NSX 1991 Service Repair Manual

Trending: battery, service interval, fuel filter, parking brake, wheel torque, refrigerant type, spark plugs

Page 1241 of 1640

Replace.

7 Bolts

5 Bolts

2 Bolts

2 Bolts

Replace.

2 Bolts

5 Bolts

4 Bolts

7 Bolts

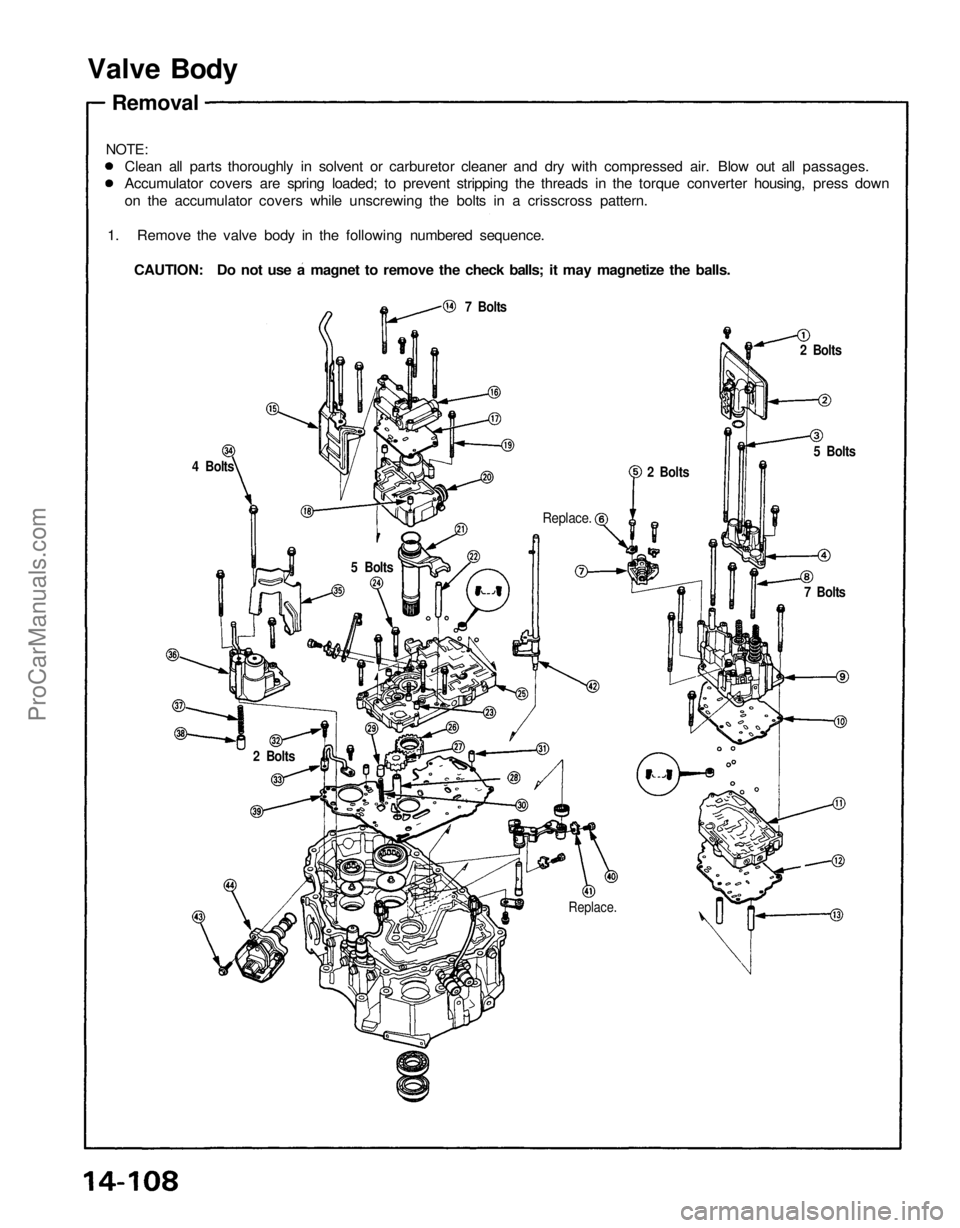

Valve Body

Removal

NOTE:

1. Remove the valve body in the following numbered sequence.

CAUTION: Do not use a magnet to remove the check balls; it may magnetize the balls.

Clean all parts thoroughly in solvent or carburetor cleaner and dry with compressed air. Blow out all passages.

Accumulator covers are spring loaded; to prevent stripping the threads in the torque converter housing, press down

on the accumulator covers while unscrewing the bolts in a crisscross pattern.ProCarManuals.com

Page 1242 of 1640

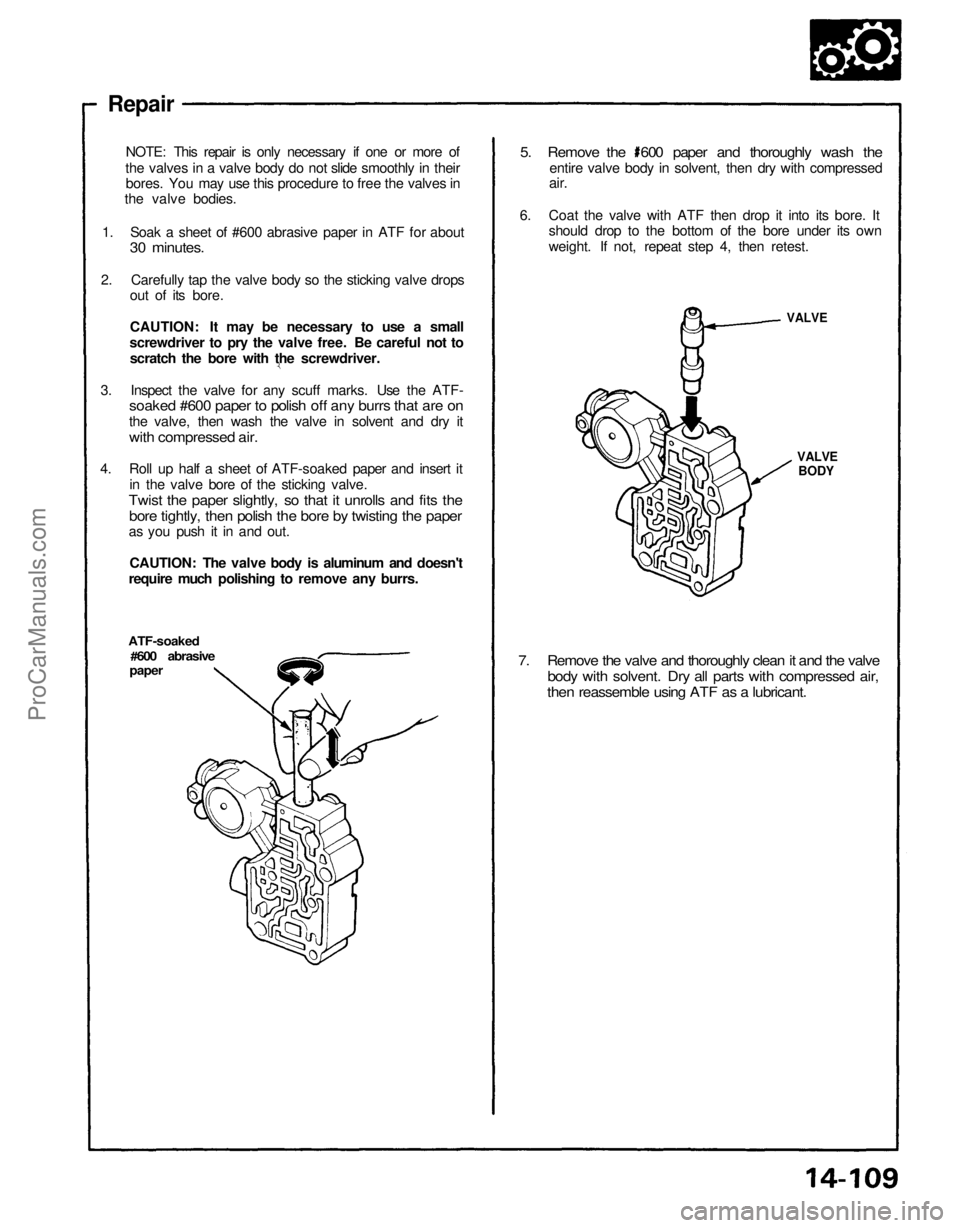

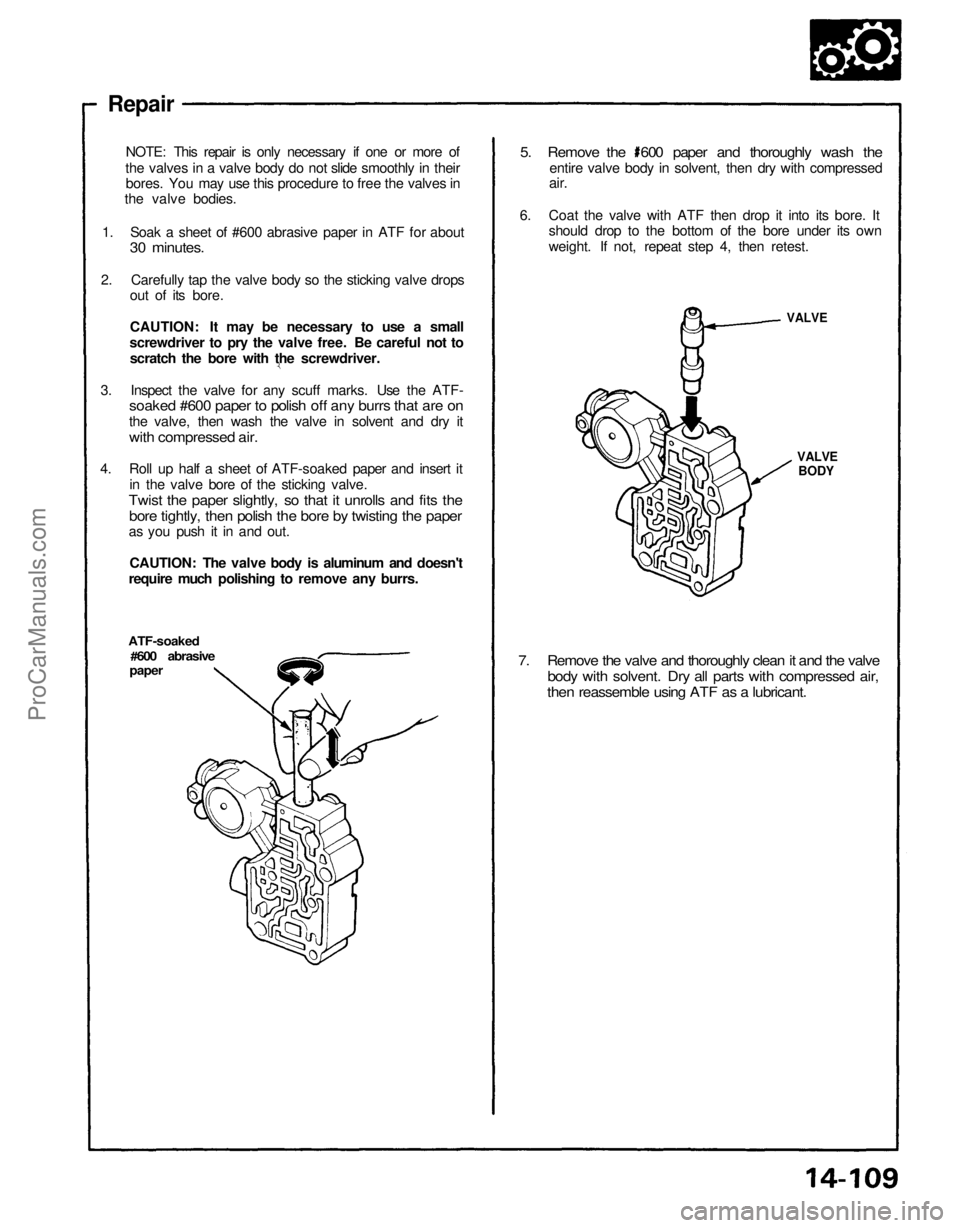

7. Remove the valve and thoroughly clean it and the valve

body with solvent. Dry all parts with compressed air,

then reassemble using ATF as a lubricant.

VALVE

BODY

VALVE

ATF-soaked

#600 abrasive

paper

Repair

NOTE: This repair is only necessary if one or more of

the valves in a valve body do not slide smoothly in their bores. You may use this procedure to free the valves in

the valve bodies.

1. Soak a sheet of #600 abrasive paper in ATF for about

30 minutes.

2. Carefully tap the valve body so the sticking valve drops out of its bore.

CAUTION: It may be necessary to use a small

screwdriver to pry the valve free. Be careful not to scratch the bore with the screwdriver.

3. Inspect the valve for any scuff marks. Use the ATF-

soaked #600 paper to polish off any burrs that are on

the valve, then wash the valve in solvent and dry it

with compressed air.

4. Roll up half a sheet of ATF-soaked paper and insert it in the valve bore of the sticking valve.

Twist the paper slightly, so that it unrolls and fits the

bore tightly, then polish the bore by twisting the paper

as you push it in and out.

CAUTION: The valve body is aluminum and doesn't

require much polishing to remove any burrs.

5. Remove the 600 paper and thoroughly wash the

entire valve body in solvent, then dry with compressed

air.

6. Coat the valve with ATF then drop it into its bore. It should drop to the bottom of the bore under its own

weight. If not, repeat step 4, then retest.ProCarManuals.com

Page 1243 of 1640

CAP

SPRING

VALVE

VALVE BODY

ROLLER

CAP

VALVE BODY

SPRING SEAT

ROLLER

SPRING

VALVE

VALVE BODY

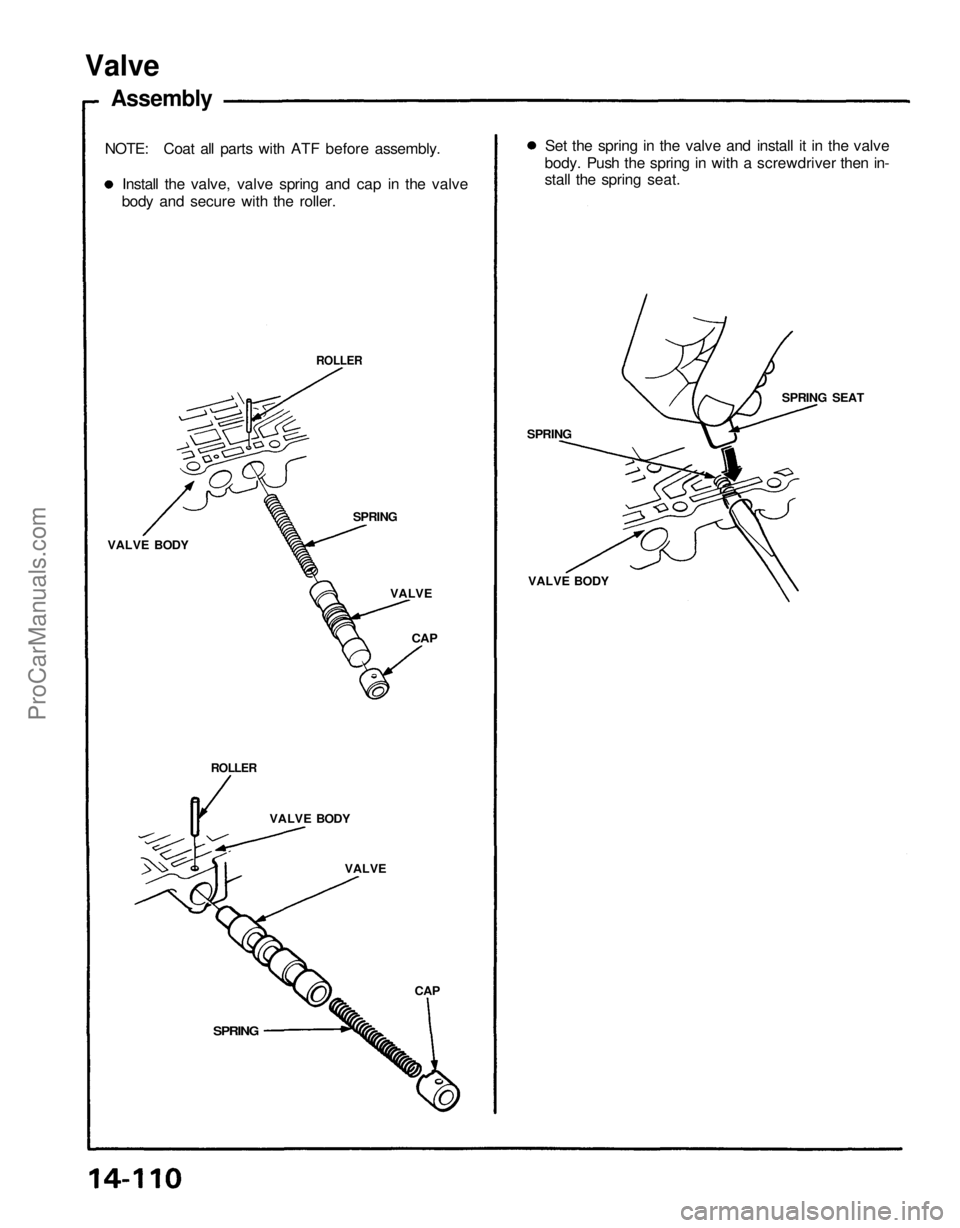

Valve

Assembly

NOTE: Coat all parts with ATF before assembly.

Set the spring in the valve and install it in the valve

body. Push the spring in with a screwdriver then in-

stall the spring seat.

SPRING

Install the valve, valve spring and cap in the valve

body and secure with the roller.ProCarManuals.com

Page 1244 of 1640

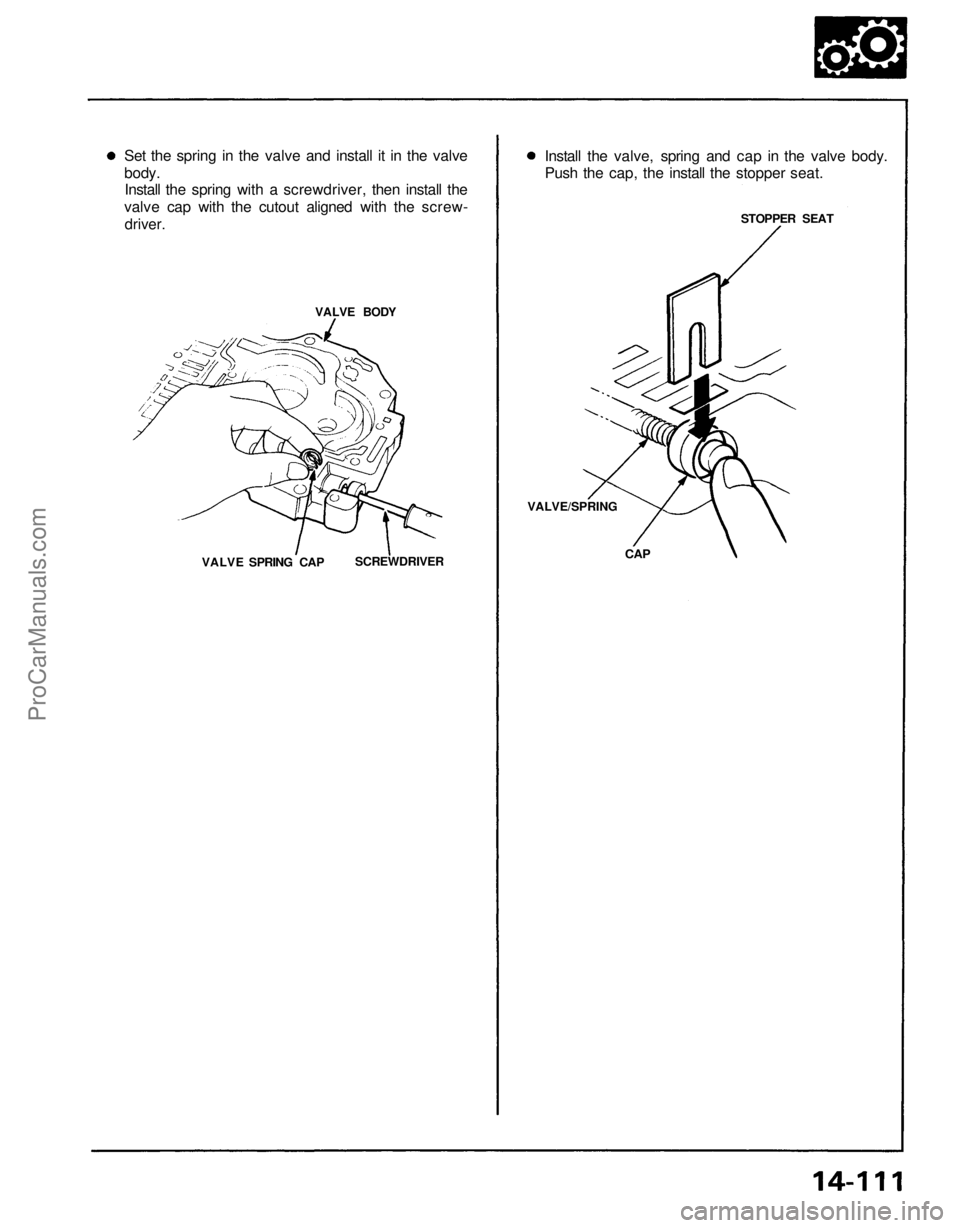

Set the spring in the valve and install it in the valve

body.

Install the spring with a screwdriver, then install the

valve cap with the cutout aligned with the screw-

driver.

Install the valve, spring and cap in the valve body.

Push the cap, the install the stopper seat.

STOPPER SEAT

VALVE/SPRING

CAP

SCREWDRIVER

VALVE BODY

VALVE SPRING CAPProCarManuals.com

Page 1245 of 1640

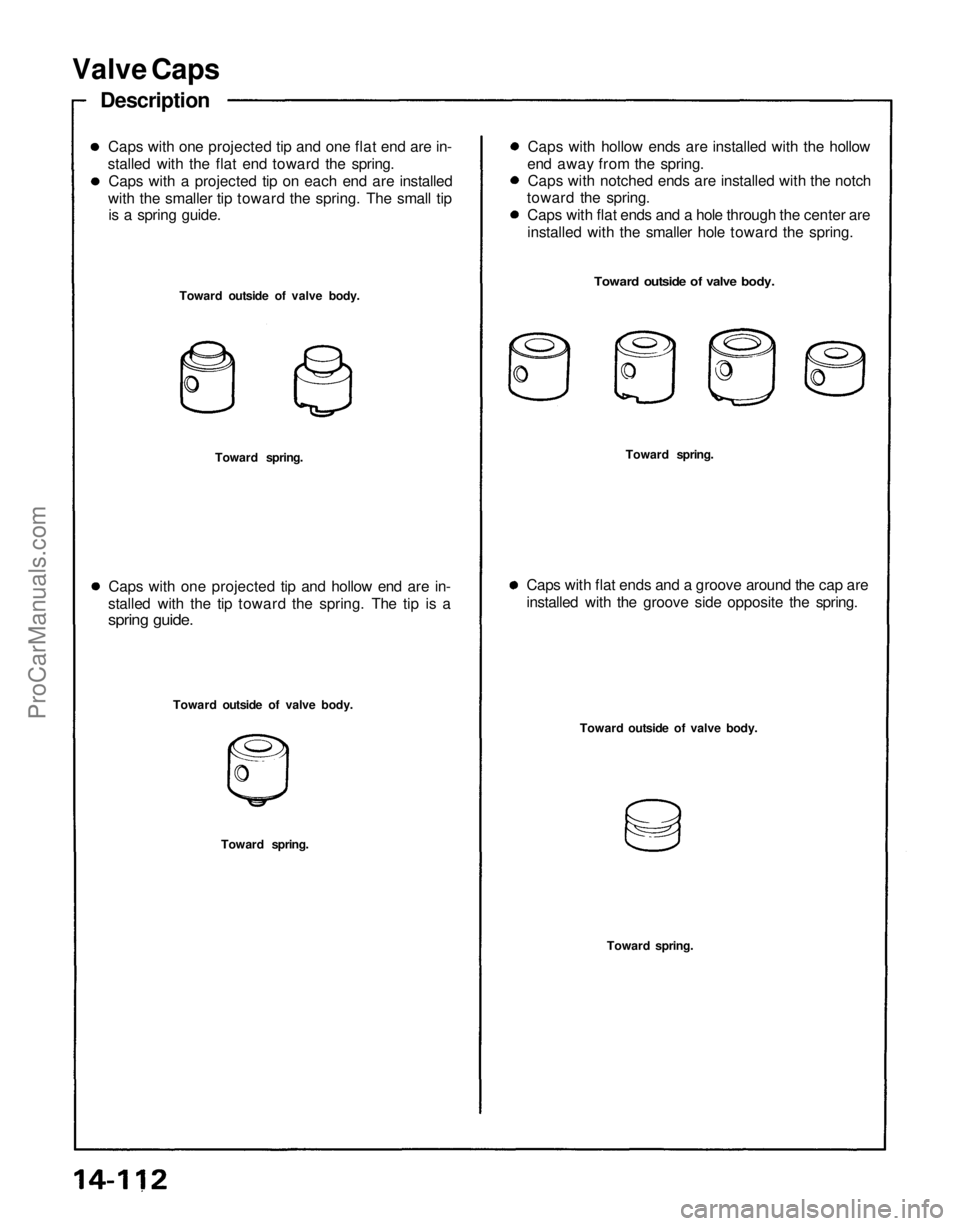

Toward spring.

Toward outside of valve body.

Toward spring.

Toward outside of valve body.

Toward spring.

Caps with flat ends and a groove around the cap are

installed with the groove side opposite the spring.

Toward spring.

Caps with one projected tip and hollow end are in-

stalled with the tip toward the spring. The tip is a

spring guide.

Toward outside of valve body.

Toward outside of valve body.

Caps with hollow ends are installed with the hollow

end away from the spring.

Caps with notched ends are installed with the notch

toward the spring.

Caps with flat ends and a hole through the center are

installed with the smaller hole toward the spring.

Caps with one projected tip and one flat end are in-

stalled with the flat end toward the spring.

Caps with a projected tip on each end are installed

with the smaller tip toward the spring. The small tip

is a spring guide.

Valve Caps

DescriptionProCarManuals.com

Page 1246 of 1640

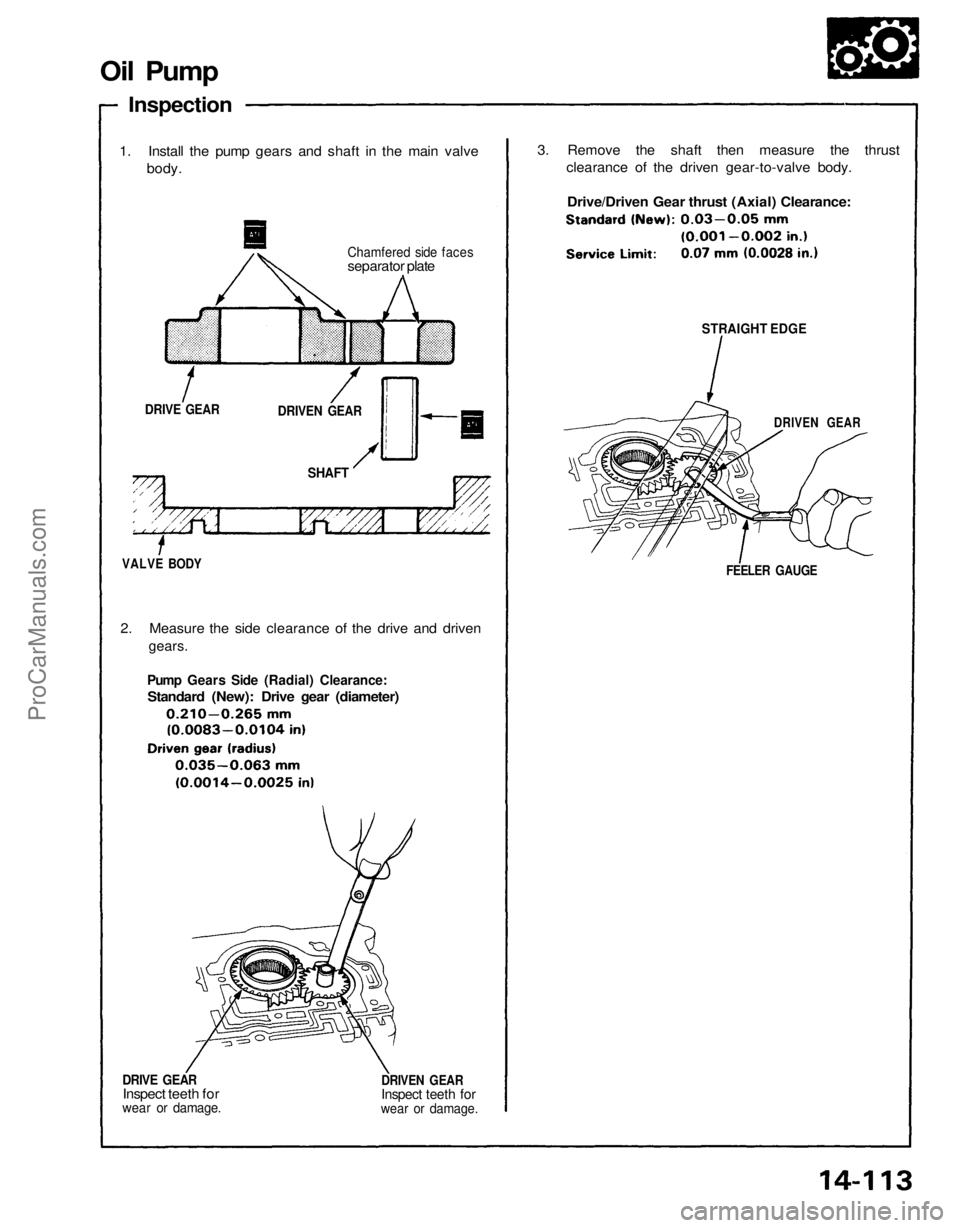

DRIVEN GEAR

Inspect teeth for

wear or damage.

DRIVE GEAR

Inspect teeth for

wear or damage.

FEELER GAUGE

DRIVEN GEAR

STRAIGHT EDGE

VALVE BODY

2. Measure the side clearance of the drive and driven

gears.

Pump Gears Side (Radial) Clearance:

Standard (New): Drive gear (diameter) 3. Remove the shaft then measure the thrust

clearance of the driven gear-to-valve body.

Drive/Driven Gear thrust (Axial) Clearance:

DRIVE GEAR

DRIVEN GEAR

SHAFT

Chamfered side faces

separator plate

1. Install the pump gears and shaft in the main valve

body.

Oil Pump

InspectionProCarManuals.com

Page 1247 of 1640

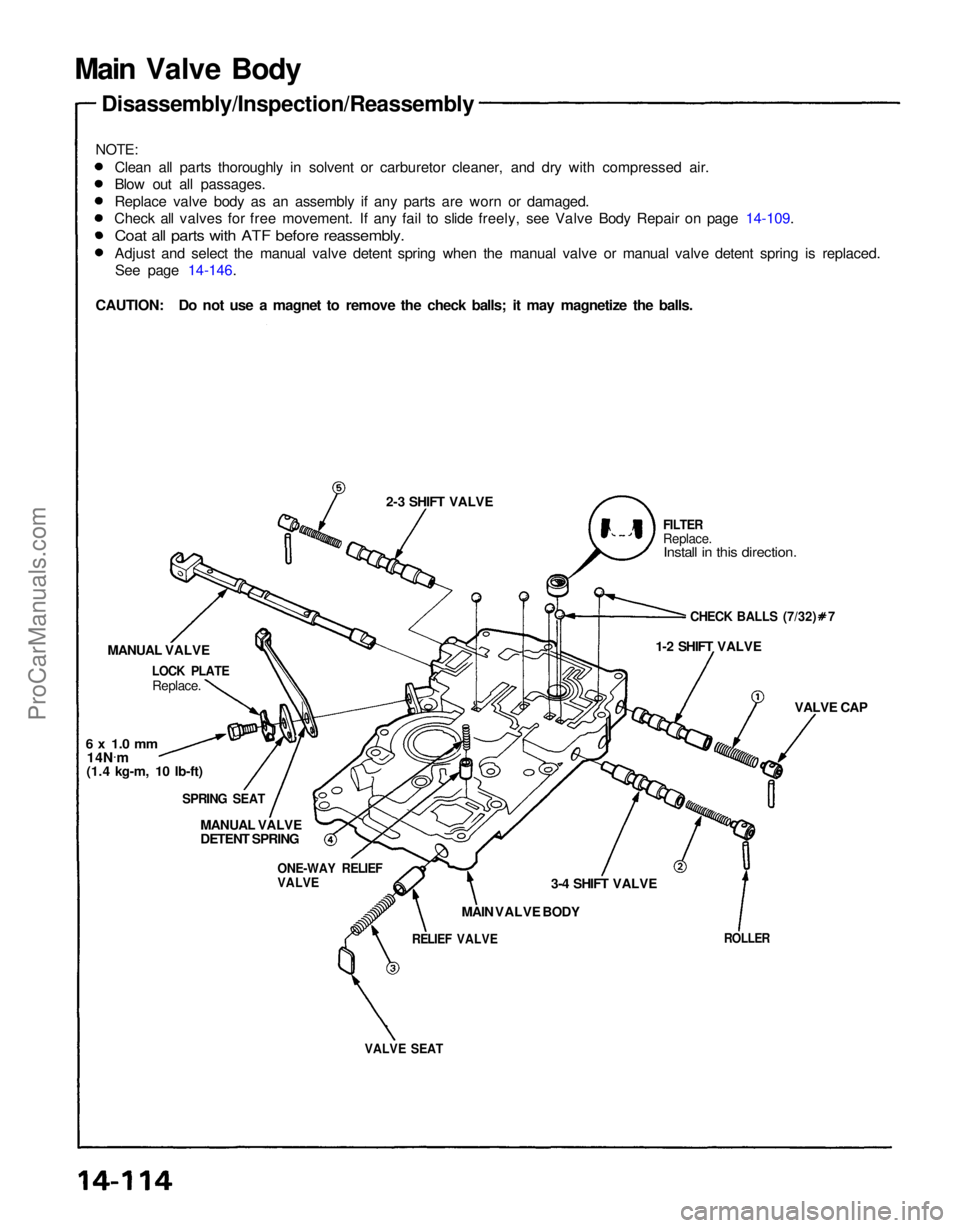

VALVE SEAT

ROLLER

RELIEF VALVE

MAIN VALVE BODY 3-4 SHIFT VALVE VALVE CAP

1-2 SHIFT VALVE

CHECK BALLS (7/32) 7

FILTER

Replace.

Install in this direction.

2-3 SHIFT VALVE

ONE-WAY RELIEF

VALVE

MANUAL VALVE

DETENT SPRING

SPRING SEAT

6 x 1.0 mm

MANUAL VALVE

Replace.

Main Valve Body

Disassembly/Inspection/Reassembly

Clean all parts thoroughly in solvent or carburetor cleaner, and dry with compressed air.

Blow out all passages.

Replace valve body as an assembly if any parts are worn or damaged.

Check all valves for free movement. If any fail to slide freely, see Valve Body Repair on page 14-109.

Coat all parts with ATF before reassembly.

Adjust and select the manual valve detent spring when the manual valve or manual valve detent spring is replaced.See page 14-146.

LOCK PLATE

14N .

m

(1.4 kg-m, 10 Ib-ft)

NOTE:

CAUTION: Do not use a magnet to remove the check balls; it may magnetize the balls.ProCarManuals.com

Page 1248 of 1640

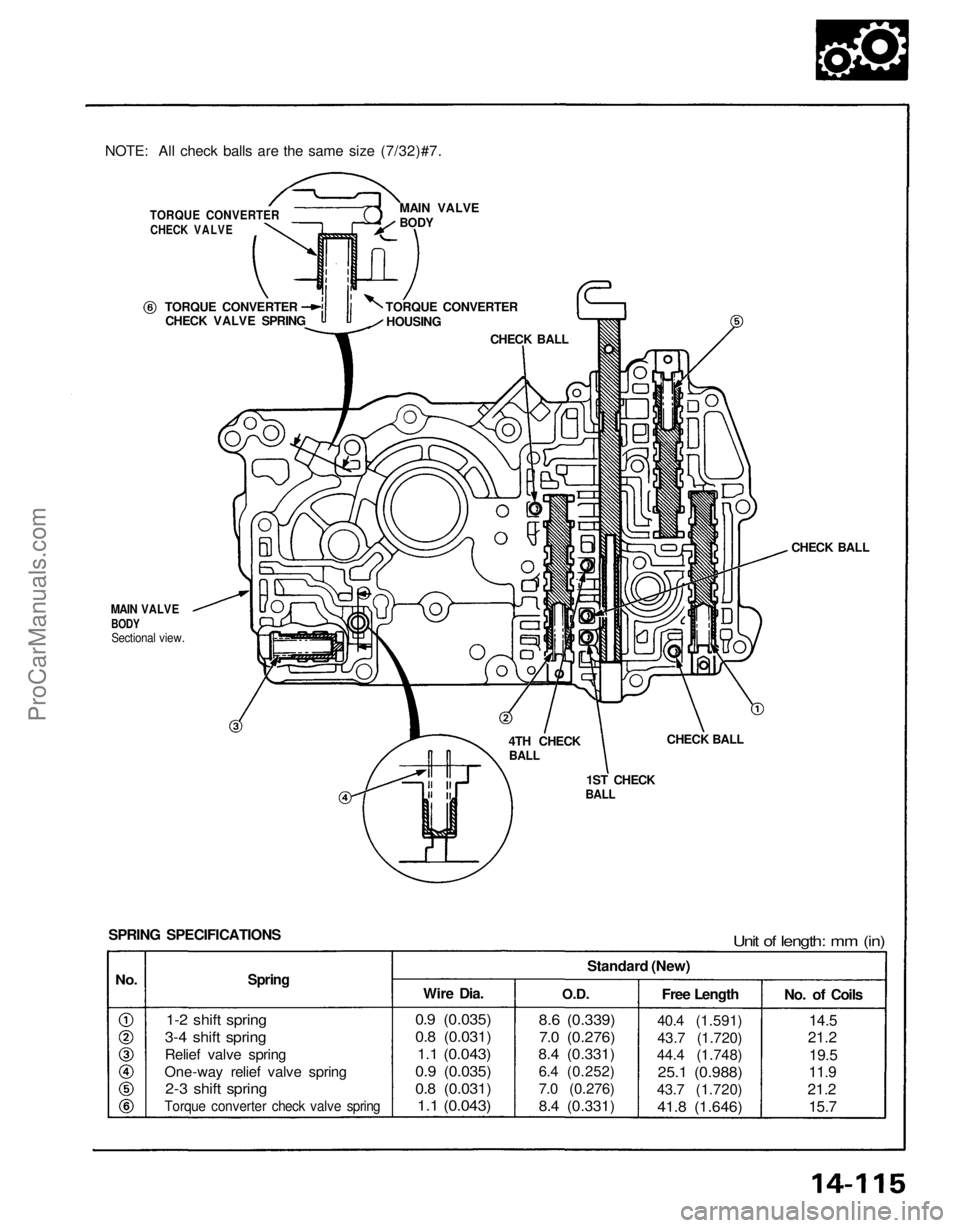

NOTE: All check balls are the same size (7/32)#7.

TORQUE CONVERTER

CHECK VALVE

TORQUE CONVERTER

CHECK VALVE SPRING TORQUE CONVERTER

HOUSING

CHECK BALL

MAIN VALVE

BODY

CHECK BALL

CHECK BALL

1ST CHECK

BALL

4TH CHECK

BALL

Unit of length: mm (in)

SPRING SPECIFICATIONS

Spring

No.

1-2 shift spring

3-4 shift spring

Relief valve spring

One-way relief valve spring

2-3 shift spring

Torque converter check valve spring

Wire Dia.

O.D.Standard (New)

Free Length

0.9 (0.035)

0.8 (0.031)

1.1 (0.043)

0.9 (0.035)

0.8 (0.031)

1.1 (0.043)

8.6 (0.339)

7.0 (0.276)

8.4 (0.331)

6.4 (0.252)

7.0 (0.276)

8.4 (0.331)

40.4 (1.591)

43.7 (1.720)

44.4 (1.748)

25.1 (0.988)

43.7 (1.720)

41.8 (1.646)

No. of Coils

14.5

21.2

19.5

11.9

21.2 15.7

MAIN VALVE

BODY

Sectional view.

ProCarManuals.com

Page 1249 of 1640

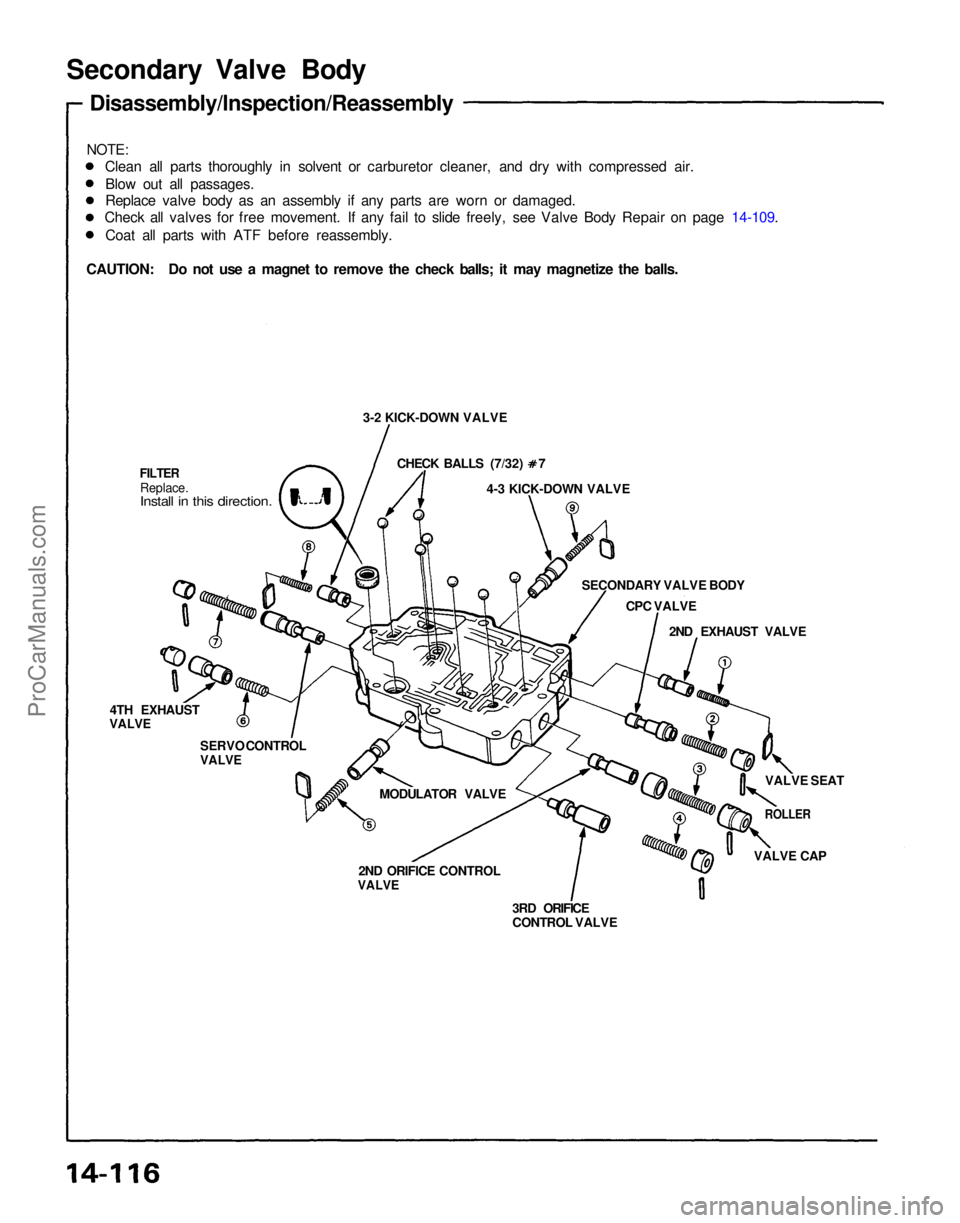

3RD ORIFICE

CONTROL VALVE

VALVE CAP

ROLLER

VALVE SEAT

2ND EXHAUST VALVE

CPC VALVE

SECONDARY VALVE BODY

4-3 KICK-DOWN VALVE CHECK BALLS (7/32) 7

3-2 KICK-DOWN VALVE

FILTER

Replace.

Install in this direction.

4TH EXHAUST

VALVE

SERVO CONTROL

VALVE

MODULATOR VALVE

2ND ORIFICE CONTROL

VALVE

Secondary Valve Body

Disassembly/lnspection/Reassembly

Clean all parts thoroughly in solvent or carburetor cleaner, and dry with compressed air.Blow out all passages.

Replace valve body as an assembly if any parts are worn or damaged.

Check all valves for free movement. If any fail to slide freely, see Valve Body Repair on page 14-109.

Coat all parts with ATF before reassembly.

CAUTION: Do not use a magnet to remove the check balls; it may magnetize the balls.

NOTE:ProCarManuals.com

Page 1250 of 1640

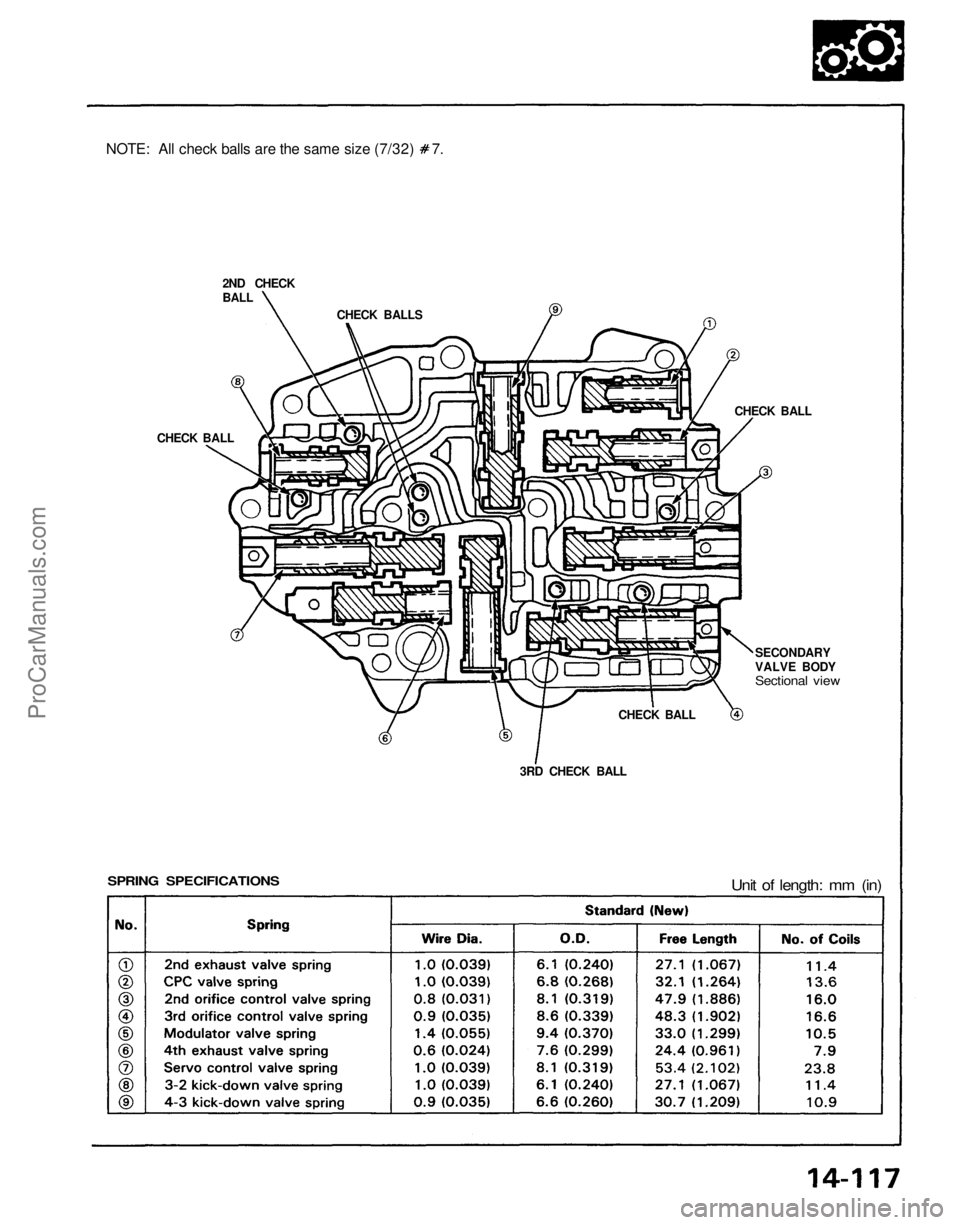

NOTE: All check balls are the same size (7/32) 7.

2ND CHECK

CHECK BALLS

CHECK BALL

SECONDARY

VALVE BODY

Sectional view

CHECK BALL

3RD CHECK BALL

CHECK BALL

Unit of length: mm (in)

SPRING SPECIFICATIONS

BALLProCarManuals.com

Trending: bolt pattern, park assist, brakes, fuel pressure, AUX, tire size, tire type