ACURA NSX 1991 Service Repair Manual

Manufacturer: ACURA, Model Year: 1991, Model line: NSX, Model: ACURA NSX 1991Pages: 1640, PDF Size: 60.48 MB

Page 1551 of 1640

Transmission Assembly

Installation

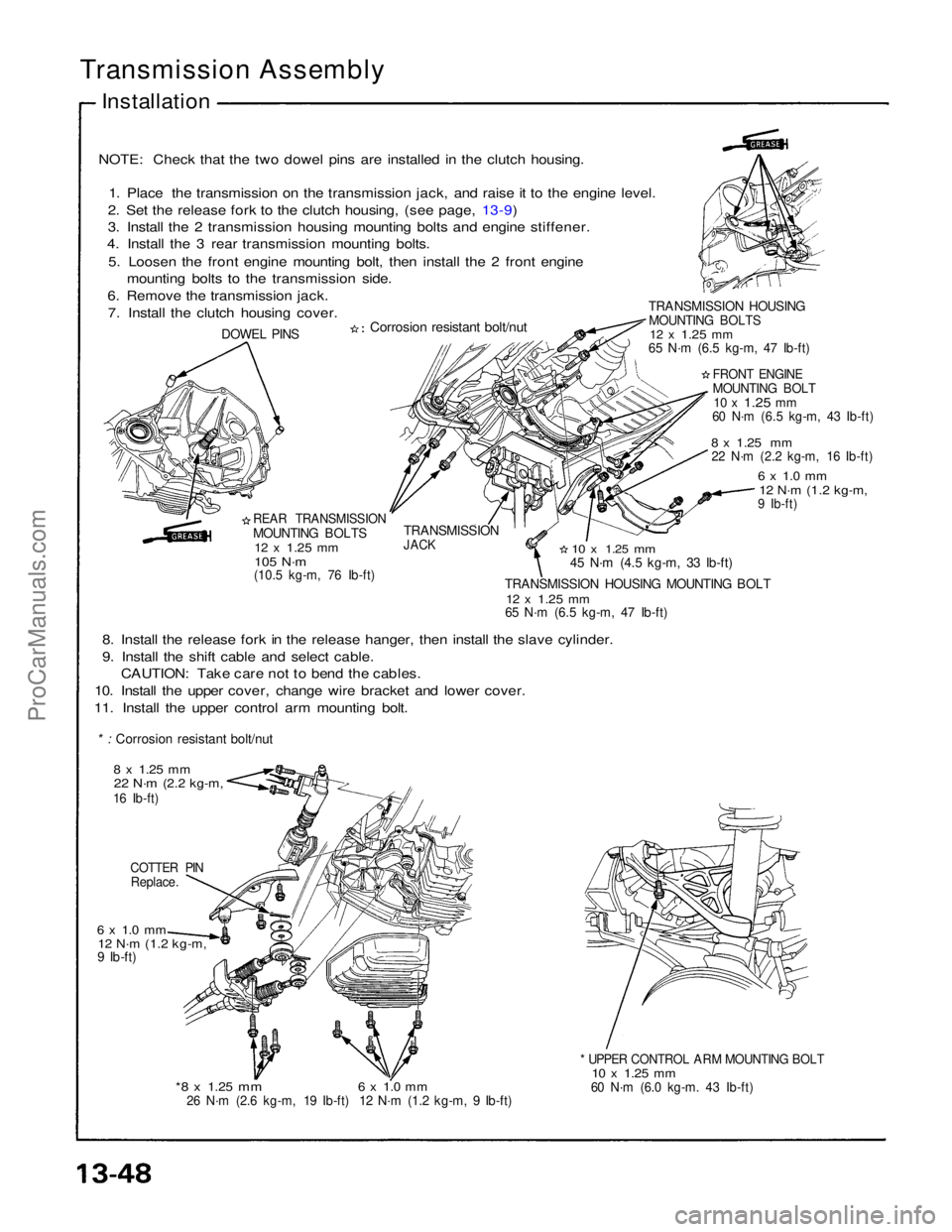

NOTE: Check that the two dowel pins are installed in the clutch housing. 1. Place the transmission on the transmission jack, and raise it to the engine level.

2. Set the release fork to the clutch housing, (see page, 13-9)

3. Install the 2 transmission housing mounting bolts and engine stiffener.

4. Install the 3 rear transmission mounting bolts.

5. Loosen the front engine mounting bolt, then install the 2 front engine mounting bolts to the transmission side.

6. Remove the transmission jack. 7. Install the clutch housing cover.

DOWEL PINS

REAR TRANSMISSION

MOUNTING BOLTS

12 x

1.25

mm

105 N·m

(10.5 kg-m, 76 Ib-ft)

TRANSMISSION

JACK

8. Install the release fork in the release hanger, then install the slave cylinder.

9. Install the shift cable and select cable. CAUTION: Take care not to bend the cables.

10. Install the upper cover, change wire bracket and lower cover.

11. Install the upper control arm mounting bolt.

*: Corrosion resistant bolt/nut

8 x

1.25

mm

22 N·m

(2.2 kg-m,

16 Ib-ft)

COTTER PIN

Replace.

6 x 1.0 mm 12 N·m

(1.2 kg-m,

9 Ib-ft)

*8 x

1.25

mm

26 N·m (2.6 kg-m, 19 Ib-ft)

* UPPER CONTROL ARM MOUNTING BOLT

10 x

1.25

mm

60 N·m (6.0 kg-m. 43 Ib-ft)

Corrosion resistant bolt/nut

TRANSMISSION HOUSING

MOUNTING BOLTS

12 x

1.25

mm

65 N·m (6.5 kg-m, 47 Ib-ft)

FRONT ENGINE

MOUNTING BOLT

10 x

1.25

mm

60 N·m (6.5 kg-m, 43 Ib-ft)

8 x

1.25

mm

22 N·m (2.2 kg-m, 16 Ib-ft)

6 x 1.0 mm

12 N·m

(1.2 kg-m,

9 Ib-ft)

10 x

1.25

mm

45 N·m (4.5 kg-m, 33 Ib-ft)

TRANSMISSION HOUSING MOUNTING BOLT

12 x

1.25

mm

65 N·m (6.5 kg-m, 47 Ib-ft)

6 x 1.0 mm

12 N·m (1.2 kg-m, 9 Ib-ft)ProCarManuals.com

Page 1552 of 1640

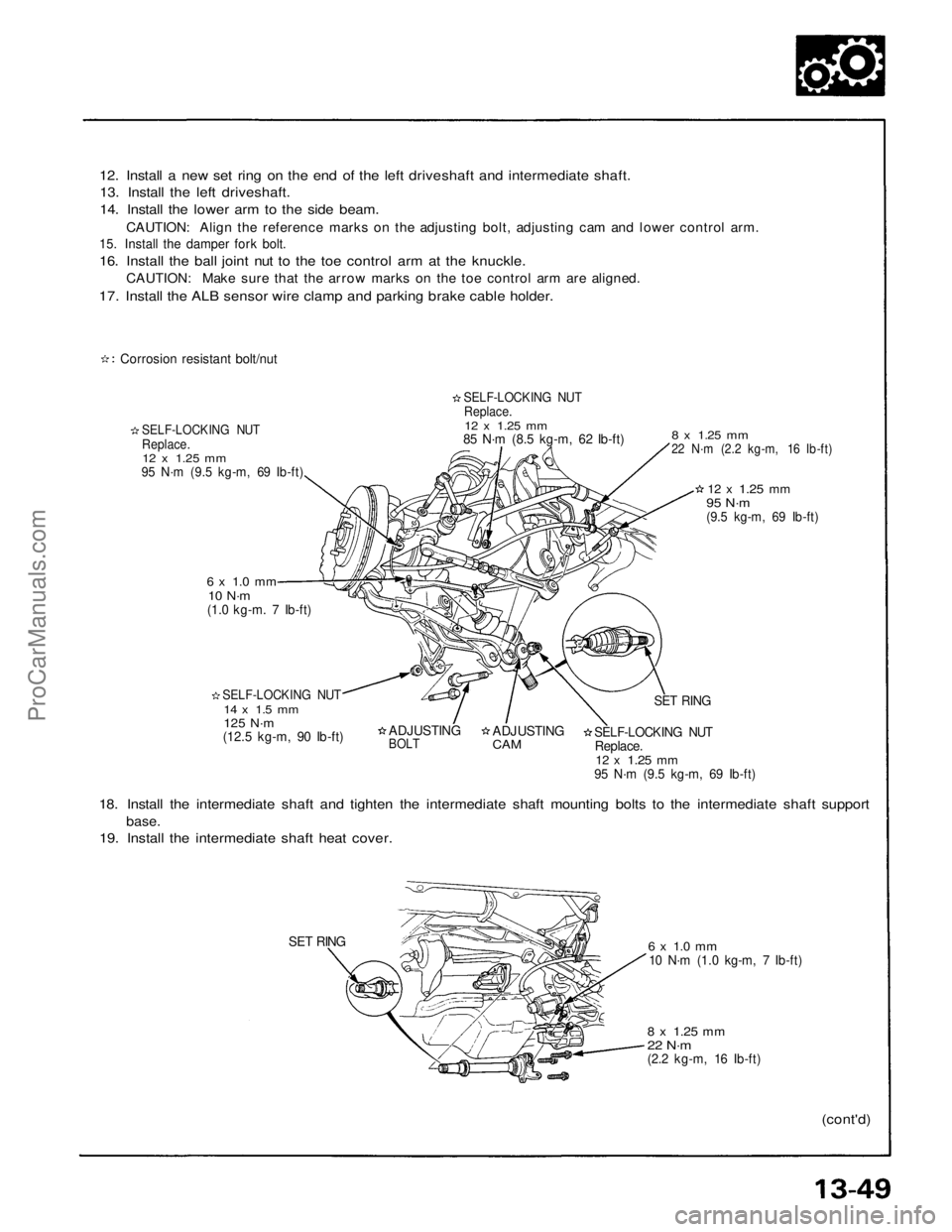

12. Install a new set ring on the end of the left driveshaft and intermediate shaft.

13. Install the left driveshaft.

14. Install the lower arm to the side beam.

CAUTION: Align the reference marks on the adjusting bolt, adjusting cam and lower control arm.

15. Install the damper fork bolt.

16. Install the ball joint nut to the toe control arm at the knuckle.

CAUTION: Make sure that the arrow marks on the toe control arm are aligned.

17. Install the ALB sensor wire clamp and parking brake cable holder.

Corrosion resistant bolt/nut

SELF-LOCKING NUT

Replace.

12 x

1.25

mm

95 N·m (9.5 kg-m, 69 Ib-ft)

SELF-LOCKING NUT

Replace.

12 x

1.25

mm

85 N·m (8.5 kg-m, 62 Ib-ft)

6 x 1.0 mm

10 N·m

(1.0 kg-m. 7 Ib-ft)

SELF-LOCKING NUT

14 x 1.5 mm

125 N·m

(12.5 kg-m, 90 Ib-ft)

8 x

1.25

mm

22 N·m (2.2 kg-m, 16 Ib-ft)

12 x

1.25

mm

95 N·m

(9.5 kg-m, 69 Ib-ft)

ADJUSTING

BOLT

ADJUSTING

CAM

SET RING

SELF-LOCKING NUT

Replace.

12 x

1.25

mm

95 N·m (9.5 kg-m, 69 Ib-ft)

18. Install the intermediate shaft and tighten the intermediate shaft mounting bolts to the intermediate shaft support

base.

19. Install the intermediate shaft heat cover.

SET RING

6 x 1.0 mm

10 N·m (1.0 kg-m, 7 Ib-ft)

8 x

1.25

mm

22 N·m

(2.2 kg-m, 16 Ib-ft)

(cont'd)ProCarManuals.com

Page 1553 of 1640

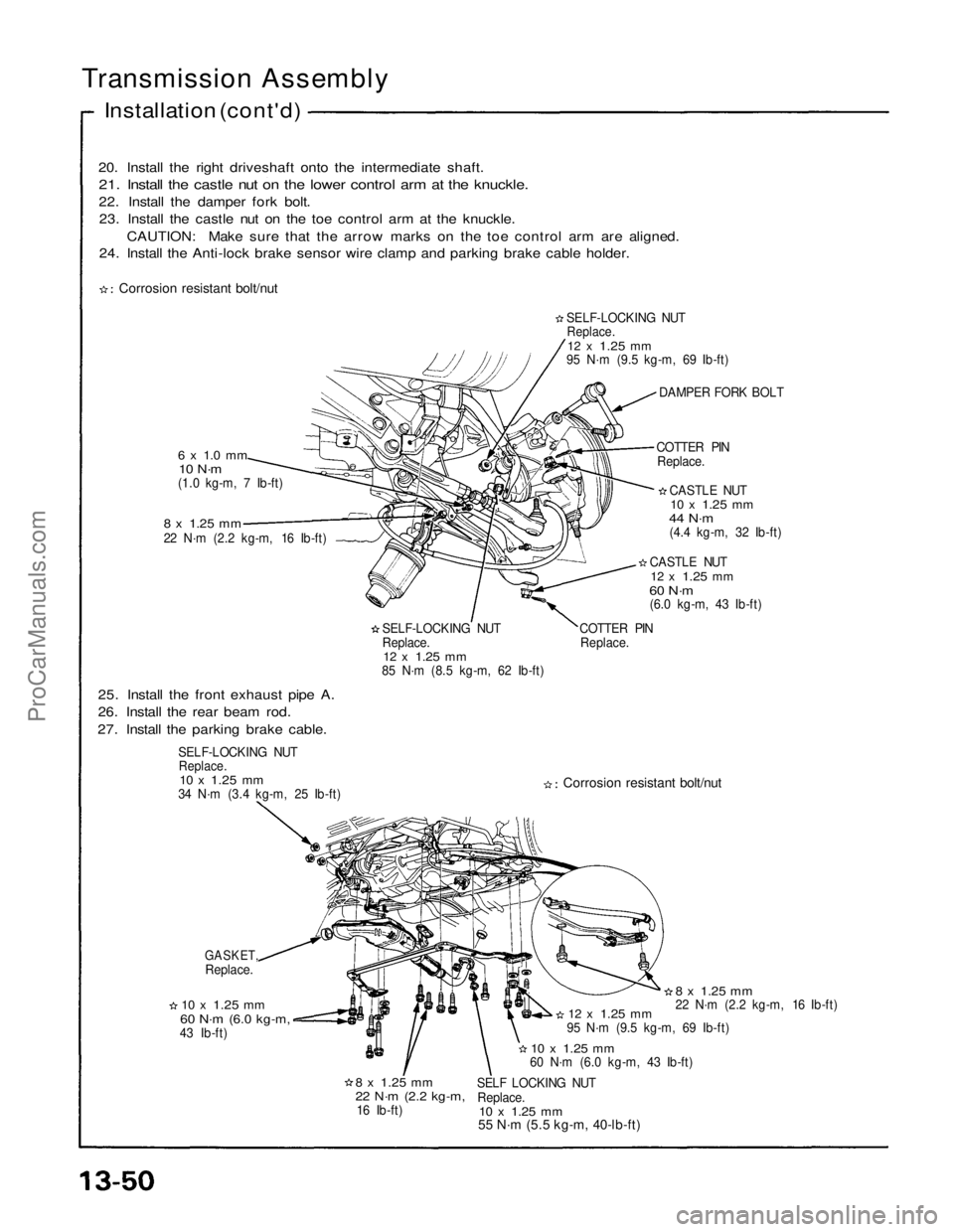

20. Install the right driveshaft onto the intermediate shaft.

21. Install the castle nut on the lower control arm at the knuckle.

22. Install the damper fork bolt.23. Install the castle nut on the toe control arm at the knuckle.

CAUTION: Make sure that the arrow marks on the toe control arm are aligned.

24. Install the Anti-lock brake sensor wire clamp and parking brake cable holder.

Transmission Assembly

Installation (cont'd)

Corrosion resistant bolt/nut

6 x 1.0 mm

10 N·m

(1.0 kg-m, 7 Ib-ft)

8 x

1.25

mm

22 N·m (2.2 kg-m, 16 Ib-ft)

SELF-LOCKING NUT

Replace.

12 x

1.25

mm

85 N·m (8.5 kg-m, 62 Ib-ft) COTTER PIN

Replace. CASTLE NUT

12 x

1.25

mm

60 N·m

(6.0 kg-m, 43 Ib-ft) CASTLE NUT

10 x

1.25

mm

44 N·m

(4.4 kg-m, 32 Ib-ft)

COTTER PIN

Replace. DAMPER FORK BOLT

SELF-LOCKING NUT

Replace.

12 x

1.25

mm

95 N·m (9.5 kg-m, 69 Ib-ft)

25. Install the front exhaust pipe A.

26. Install the rear beam rod.

27. Install the parking brake cable.

SELF-LOCKING NUT

Replace.

10 x

1.25

mm

34 N·m (3.4 kg-m, 25 Ib-ft)

Corrosion resistant bolt/nut

GASKET,

Replace.

10 x

1.25

mm

60 N·m

(6.0 kg-m,

43 Ib-ft)

8 x

1.25

mm

22 N·m

(2.2 kg-m,

16 Ib-ft) SELF LOCKING NUT

Replace.

10 x

1.25

mm

55 N·m (5.5 kg-m, 40-lb-ft)

10 x

1.25

mm

60 N·m (6.0 kg-m, 43 Ib-ft)

12 x

1.25

mm

95 N·m (9.5 kg-m, 69 Ib-ft)

8 x

1.25

mm

22 N·m (2.2 kg-m, 16 Ib-ft)ProCarManuals.com

Page 1554 of 1640

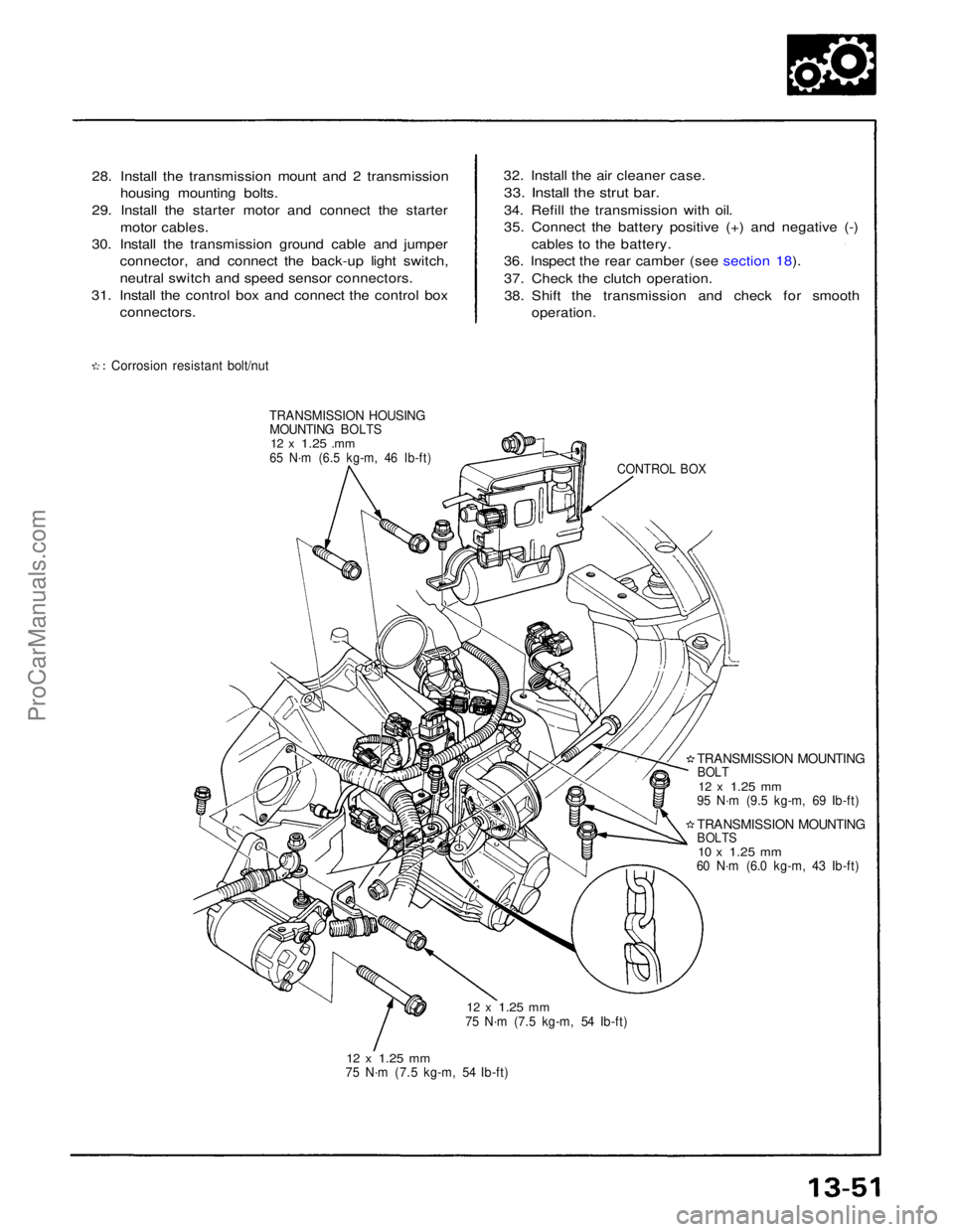

28. Install the transmission mount and 2 transmission

housing mounting bolts.

29. Install the starter motor and connect the starter motor cables.

30. Install the transmission ground cable and jumper connector, and connect the back-up light switch,

neutral switch and speed sensor connectors.

31. Install the control box and connect the control box

connectors.

Corrosion resistant bolt/nut

TRANSMISSION HOUSING

MOUNTING BOLTS

12 x

1.25

.mm

65 N·m (6.5 kg-m, 46 Ib-ft)

12 x

1.25

mm

75 N·m (7.5 kg-m, 54 Ib-ft)

12 x

1.25

mm

75 N·m (7.5 kg-m, 54 Ib-ft)

TRANSMISSION MOUNTING

BOLTS

10 x

1.25

mm

60 N·m (6.0 kg-m, 43 Ib-ft)

TRANSMISSION MOUNTING

BOLT

12 x

1.25

mm

95 N·m (9.5 kg-m, 69 Ib-ft)

CONTROL BOX

32. Install the air cleaner case.

33. Install the strut bar.

34. Refill the transmission with oil.

35. Connect the battery positive (+) and negative (-) cables to the battery.

36. Inspect the rear camber (see section 18).

37. Check the clutch operation.

38. Shift the transmission and check for smooth

operation.ProCarManuals.com

Page 1555 of 1640

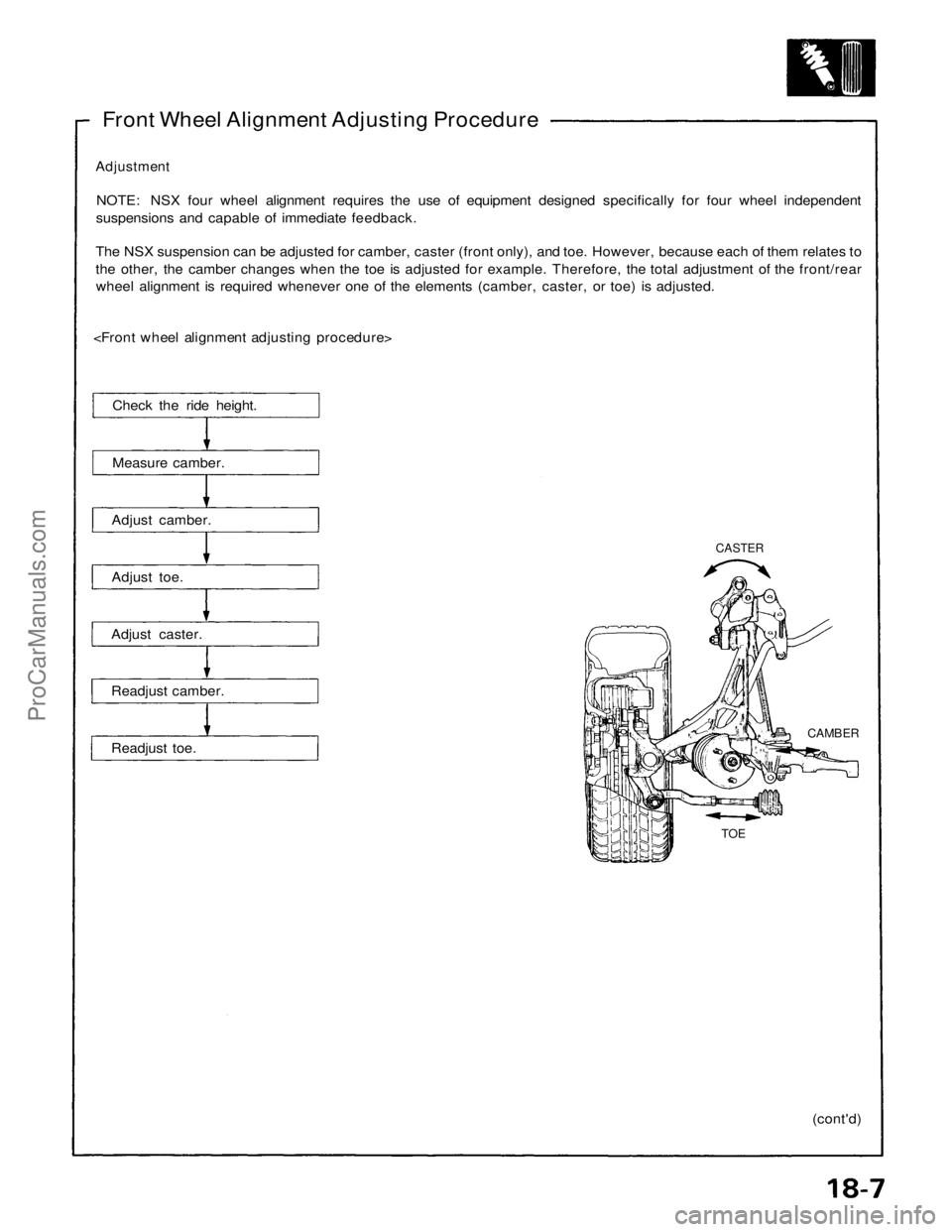

Front Wheel Alignment Adjusting Procedure

Adjustment

NOTE: NSX four wheel alignment requires the use of equipment designed specifically for four wheel independent

suspensions and capable of immediate feedback.

The NSX suspension can be adjusted for camber, caster (front only), and toe. However, because each of them relates to

the other, the camber changes when the toe is adjusted for example. Therefore, the total adjustment of the front/rear

wheel alignment is required whenever one of the elements (camber, caster, or toe) is adjusted.

Check the ride height.

Measure camber.

Adjust camber.

Adjust toe.

Adjust caster.

Readjust camber.

Readjust toe.

(cont'd)

TOE

CAMBER

CASTERProCarManuals.com

Page 1556 of 1640

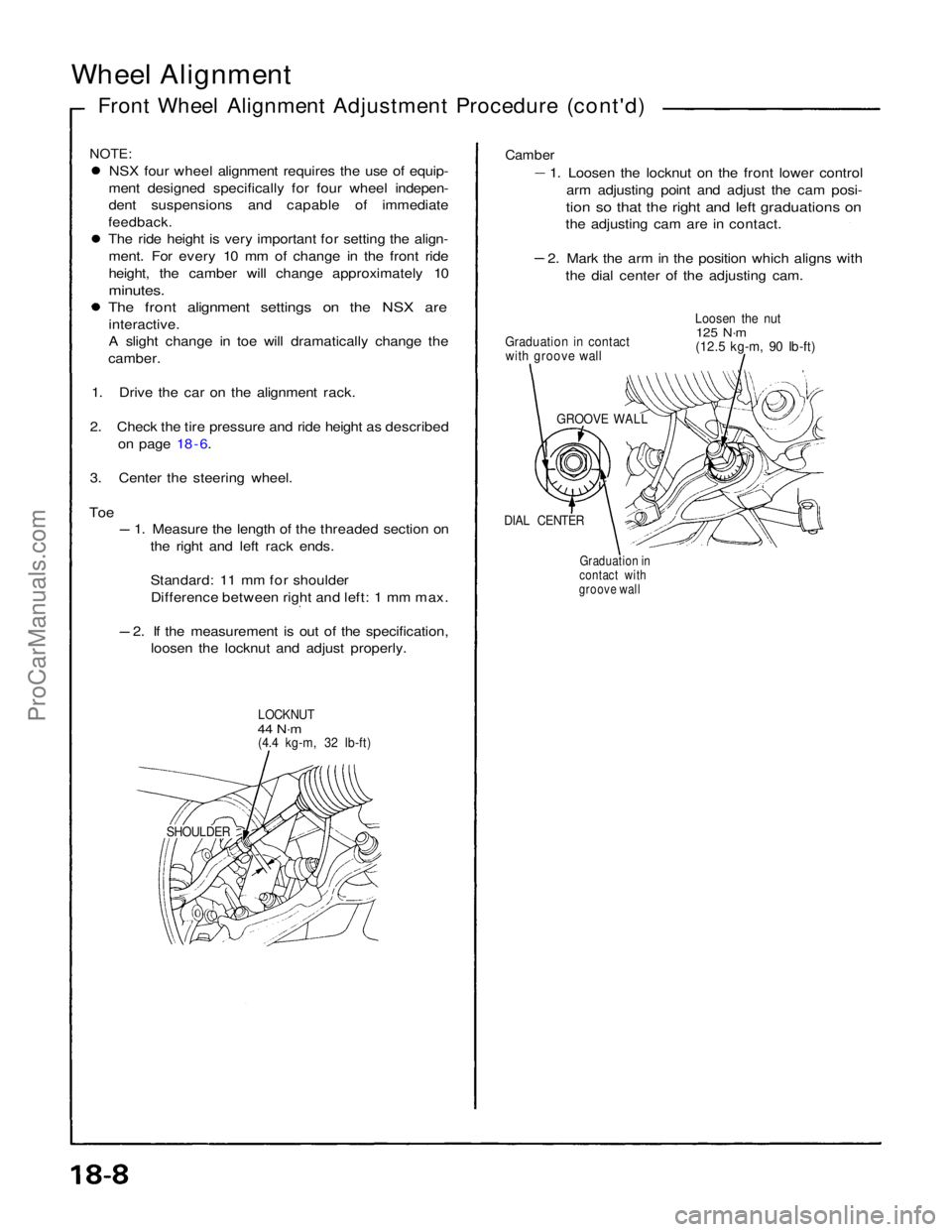

Wheel Alignment

Front Wheel Alignment Adjustment Procedure (cont'd)

NOTE:

NSX four wheel alignment requires the use of equip-

ment designed specifically for four wheel indepen-

dent suspensions and capable of immediate

feedback.

The ride height is very important for setting the align-

ment. For every 10 mm of change in the front ride

height, the camber will change approximately 10

minutes.

The front alignment settings on the NSX are

interactive.

A slight change in toe will dramatically change the

camber.

1. Drive the car on the alignment rack.

2. Check the tire pressure and ride height as described on page 18 - 6.

3. Center the steering wheel.

Toe

1. Measure the length of the threaded section on

the right and left rack ends.

Standard: 11 mm for shoulderDifference between right and left: 1 mm max. 2. If the measurement is out of the specification,

loosen the locknut and adjust properly.

LOCKNUT

44 N·m

(4.4 kg-m, 32 Ib-ft)

SHOULDERGraduation in

contact with

groove wall

DIAL CENTER

GROOVE WALL

Graduation in contact

with groove wall Loosen the nut

125 N·m

(12.5 kg-m, 90 Ib-ft)

Camber

1. Loosen the locknut on the front lower control

arm adjusting point and adjust the cam posi-

tion so that the right and left graduations on

the adjusting cam are in contact. 2. Mark the arm in the position which aligns with

the dial center of the adjusting cam.ProCarManuals.com

Page 1557 of 1640

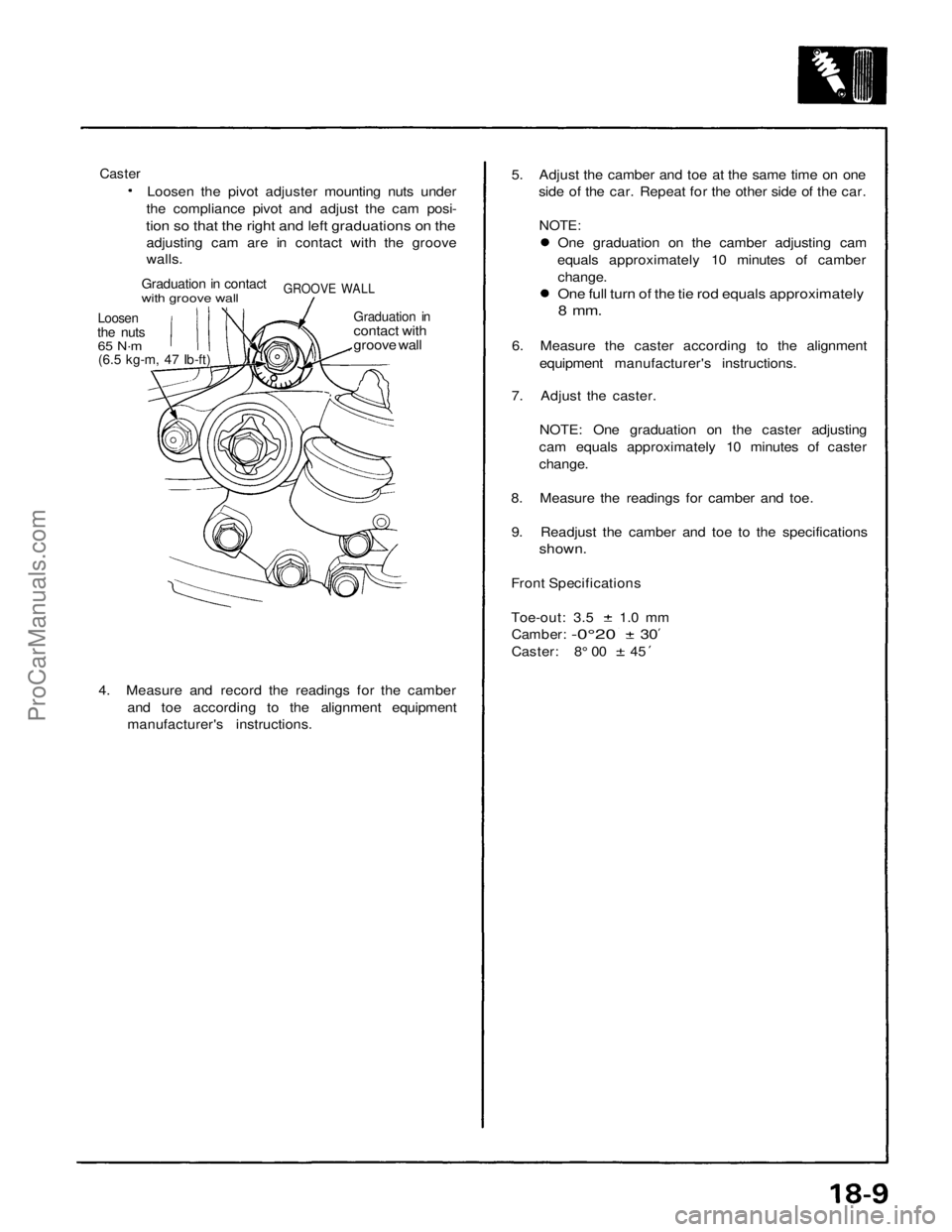

Caster

Loosen the pivot adjuster mounting nuts under

the compliance pivot and adjust the cam posi-

tion so that the right and left graduations on the

adjusting cam are in contact with the groove

walls.

Graduation in contact

with groove wall

GROOVE WALL

Loosen

the nuts

65 N·m

(6.5 kg-m, 47 Ib-ft)

Graduation in

contact with

groove wall

4. Measure and record the readings for the camber

and toe according to the alignment equipment

manufacturer's instructions.

5. Adjust the camber and toe at the same time on one

side of the car. Repeat for the other side of the car.

NOTE:

One graduation on the camber adjusting cam

equals approximately 10 minutes of camber

change.

One full turn of the tie rod equals approximately

8 mm.

6. Measure the caster according to the alignment

equipment manufacturer's instructions.

7. Adjust the caster.

NOTE: One graduation on the caster adjusting

cam equals approximately 10 minutes of caster

change.

8. Measure the readings for camber and toe.

9. Readjust the camber and toe to the specifications

shown.

Front Specifications

Toe-out: 3.5 1.0 mm

Camber:

-0°20

30

Caster: 8° 00 45ProCarManuals.com

Page 1558 of 1640

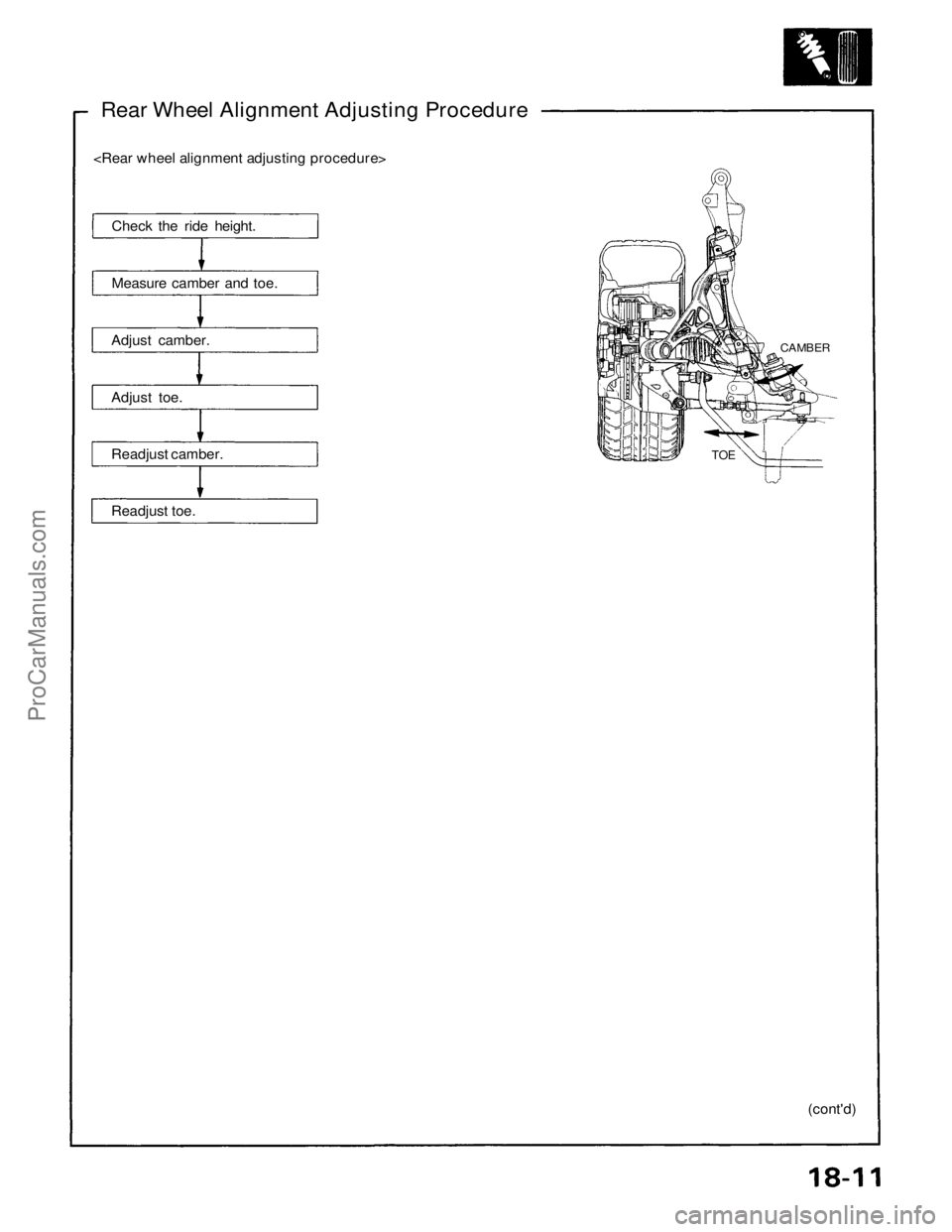

Rear Wheel Alignment Adjusting Procedure

Check the ride height.

Measure camber and toe.

Adjust camber.

Adjust toe.

Readjust camber.

Readjust toe.

CAMBER

TOE

(cont'd)ProCarManuals.com

Page 1559 of 1640

Wheel Alignment

Rear Wheel Alignment Adjusting Procedure (cont'd)

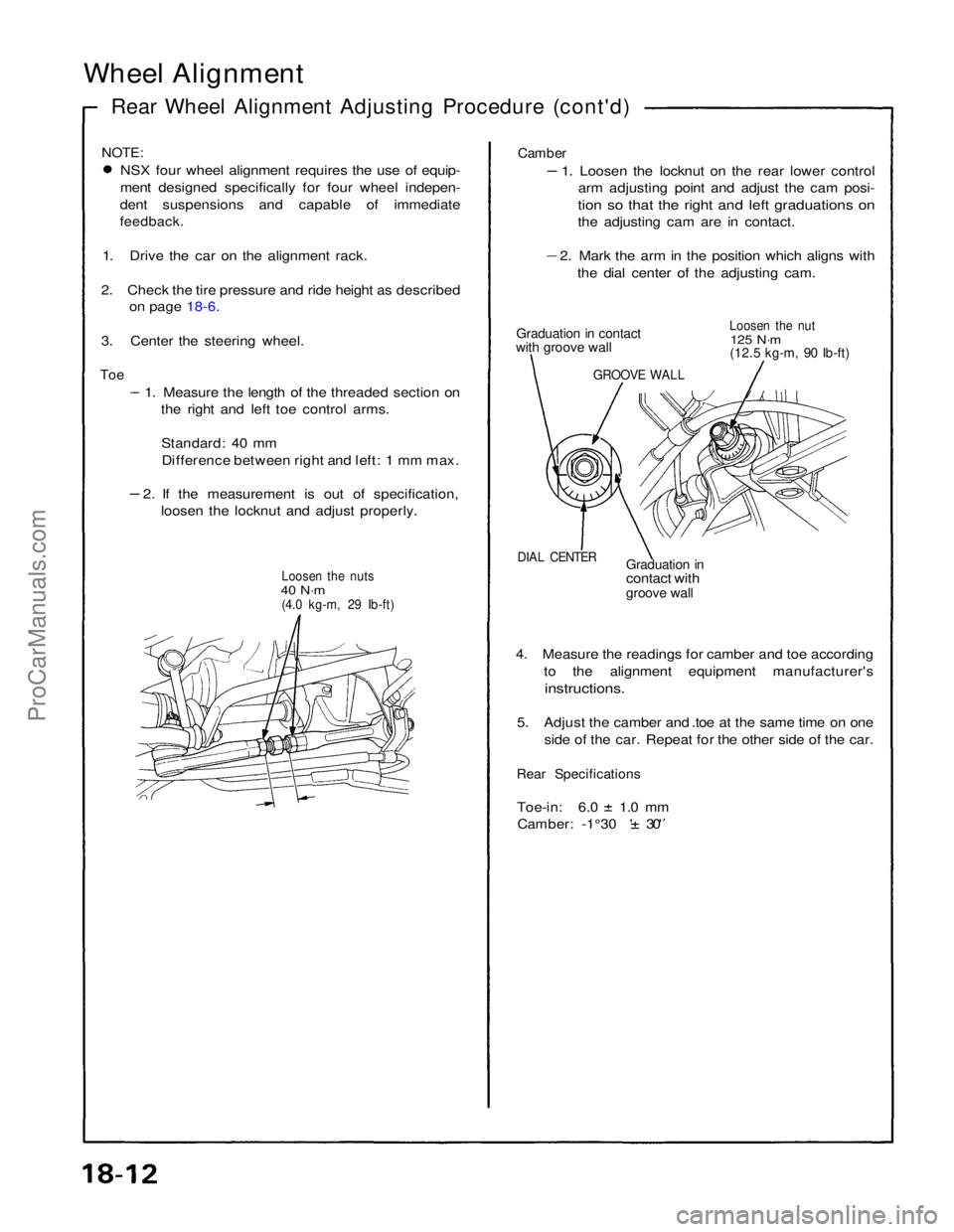

NOTE:

NSX four wheel alignment requires the use of equip-

ment designed specifically for four wheel indepen-

dent suspensions and capable of immediate

feedback.

1. Drive the car on the alignment rack.

2. Check the tire pressure and ride height as described on page 18-6.

3. Center the steering wheel.

Toe

1. Measure the length of the threaded section onthe right and left toe control arms.

Standard: 40 mmDifference between right and left: 1 mm max. 2. If the measurement is out of specification,

loosen the locknut and adjust properly.

Loosen the nuts

40 N·m

(4.0 kg-m, 29 Ib-ft)

Camber

1. Loosen the locknut on the rear lower controlarm adjusting point and adjust the cam posi-

tion so that the right and left graduations on

the adjusting cam are in contact. 2. Mark the arm in the position which aligns with

the dial center of the adjusting cam.

Graduation in contact

with groove wall

Loosen the nut

125 N·m

(12.5 kg-m, 90 Ib-ft)

DIAL CENTER

Graduation in

contact with

groove wall

4. Measure the readings for camber and toe according to the alignment equipment manufacturer's

instructions.

5. Adjust the camber and .toe at the same time on one side of the car. Repeat for the other side of the car.

Rear Specifications

Toe-in: 6.0 1.0 mm

Camber: -1°30 ' 30'

GROOVE WALLProCarManuals.com

Page 1560 of 1640

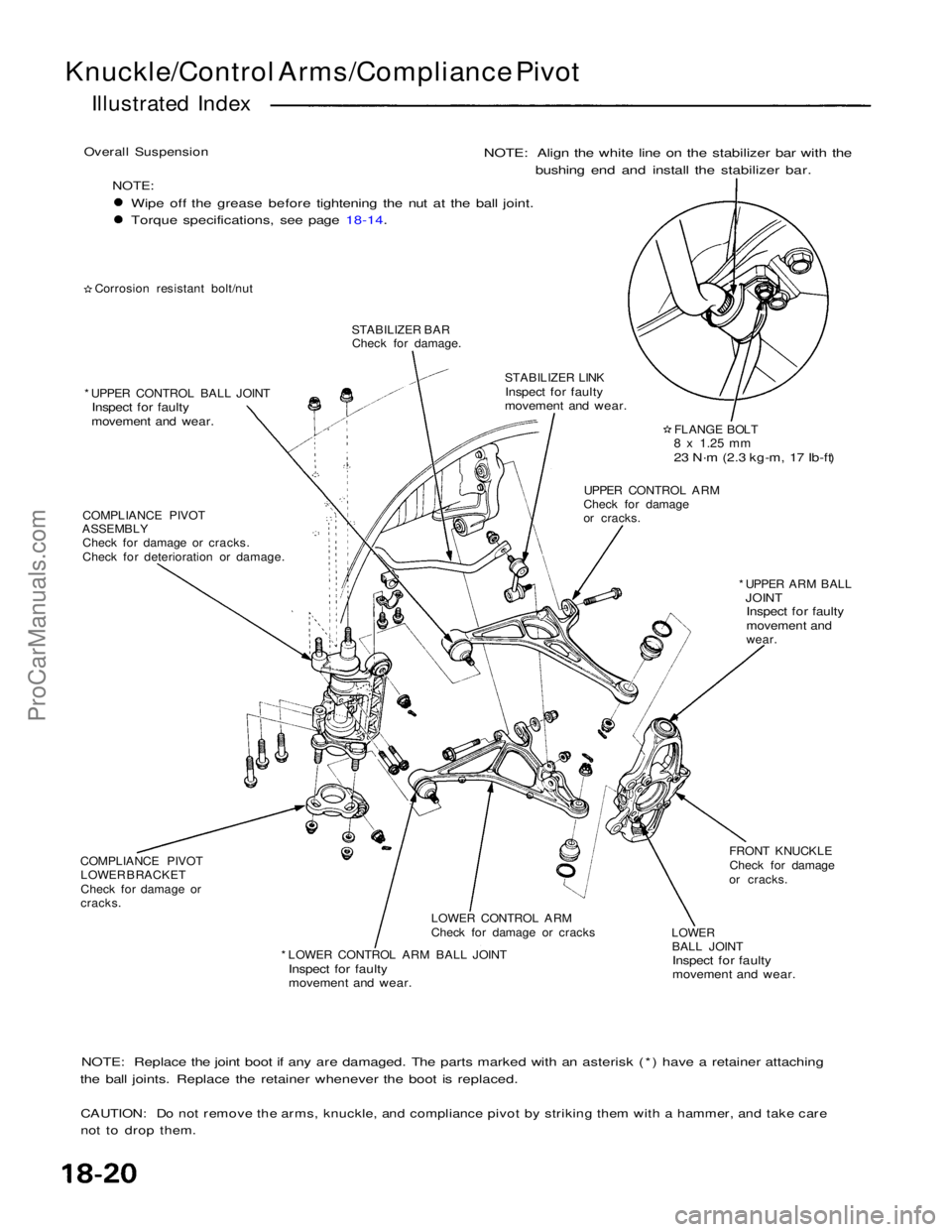

Knuckle/Control Arms/Compliance Pivot

Illustrated Index

Overall Suspension

NOTE:

Wipe off the grease before tightening the nut at the ball joint.

Torque specifications, see page 18-14.

Corrosion resistant bolt/nut

NOTE: Align the white line on the stabilizer bar with the

bushing end and install the stabilizer bar.

* UPPER CONTROL BALL JOINT

Inspect for faulty

movement and wear.

STABILIZER BAR

Check for damage.

STABILIZER LINK

Inspect for faulty

movement and wear.

COMPLIANCE PIVOT

ASSEMBLY

Check for damage or cracks.

Check for deterioration or damage.

COMPLIANCE PIVOT LOWER BRACKET

Check for damage or

cracks.

* LOWER CONTROL ARM BALL JOINT

Inspect for faulty

movement and wear.

LOWER CONTROL ARM

Check for damage or cracks

NOTE: Replace the joint boot if any are damaged. The parts marked with an asterisk (*) have a retainer attaching

the ball joints. Replace the retainer whenever the boot is replaced.

CAUTION: Do not remove the arms, knuckle, and compliance pivot by striking them with a hammer, and take care

not to drop them.

LOWER

BALL JOINT

Inspect for faulty

movement and wear.

FRONT KNUCKLE

Check for damage

or cracks. * UPPER ARM BALL

JOINT

Inspect for faulty

movement and

wear.

UPPER CONTROL ARM

Check for damage

or cracks. FLANGE BOLT

8 x

1.25

mm

23 N·m (2.3 kg-m, 17 Ib-ft )ProCarManuals.com