ACURA NSX 1991 Service Repair Manual

Manufacturer: ACURA, Model Year: 1991, Model line: NSX, Model: ACURA NSX 1991Pages: 1640, PDF Size: 60.48 MB

Page 471 of 1640

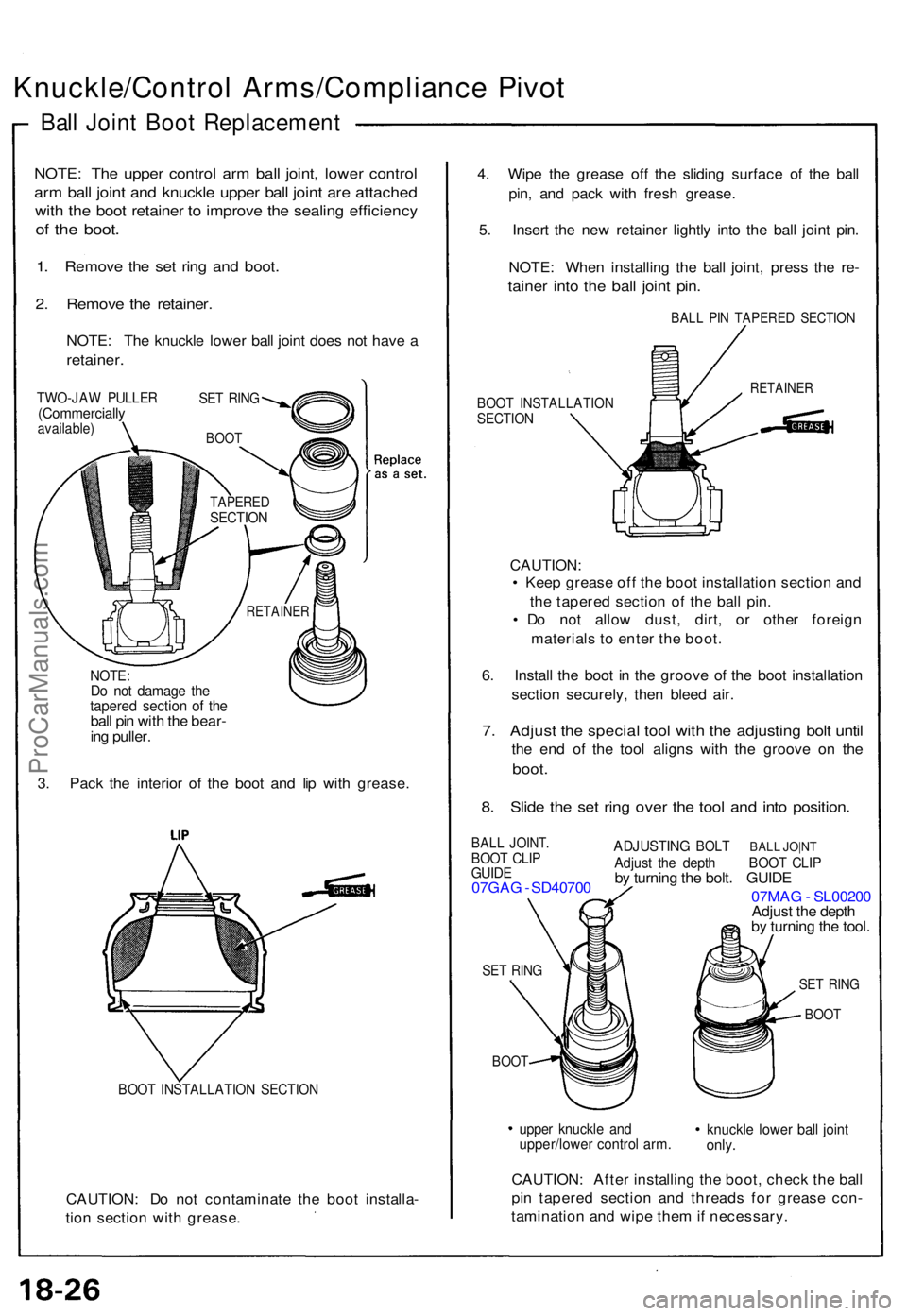

Knuckle/Control Arms/Complianc e Pivo t

Ball Join t Boo t Replacemen t

NOTE:Do no t damag e th etapere d section of th ebal l pi n wit h th e bear -

in g puller .

3 . Pac k th e interio r of the boo t an d li p wit h grease .

BOOT INSTALLATIO N SECTIO N

CAUTION : D o no t contaminat e th e boo t installa -

tio n sectio n wit h grease . 4

. Wip e th e greas e of f th e slidin g surfac e o f th e bal l

pin , an d pac k wit h fres h grease .

5 . Inser t th e ne w retaine r lightl y int o th e bal l join t pin .

NOTE : Whe n installin g th e bal l joint , pres s th e re -

taine r int o th e bal l join t pin .

BAL L PI N TAPERE D SECTIO N

BOOT INSTALLATIO NSECTION

CAUTION :

• Kee p greas e of f th e boo t installatio n sectio n an d

th e tapere d sectio n o f th e bal l pin .

• D o no t allo w dust , dirt , o r othe r foreig n

material s t o ente r th e boot .

6 . Instal l th e boo t i n th e groov e o f th e boo t installatio n

sectio n securely , the n blee d air .

7. Adjus t th e specia l too l wit h th e adjustin g bol t unti l

the en d o f th e too l align s wit h th e groov e o n th e

boot .

8. Slid e th e se t rin g ove r th e too l an d int o position .

BALL JOINT .BOOT CLI PGUID E07GA G - SD4070 0

SET RIN G

BOO T

ADJUSTIN G BOLT BALL JO|N TAdjus t th e dept h BOO T CLI Pby turnin g th e bolt . GUID E

07MA G - SL0020 0

Adjus t th e dept h

b y turnin g th e tool .

uppe r knuckl e an dupper/lowe r contro l arm .knuckl e lowe r bal l join tonly.

CAUTION : Afte r installin g th e boot , chec k th e bal l

pi n tapere d sectio n an d thread s fo r greas e con -

taminatio n an d wip e the m if necessary .

NOTE: Th e uppe r contro l ar m bal l joint , lowe r contro l

arm bal l join t an d knuckl e uppe r bal l join t ar e attache d

with the boo t retaine r t o improv e th e sealin g efficienc y

of th e boot .

1. Remov e th e se t rin g an d boot .

2. Remov e th e retainer .

NOTE: Th e knuckl e lowe r bal l join t doe s no t hav e a

retainer .

TWO-JA W PULLE R(Commerciall yavailable)

SET RIN G

BOO T

TAPERE DSECTION

RETAINE R

RETAINER

SET RIN G

BOO T

ProCarManuals.com

Page 472 of 1640

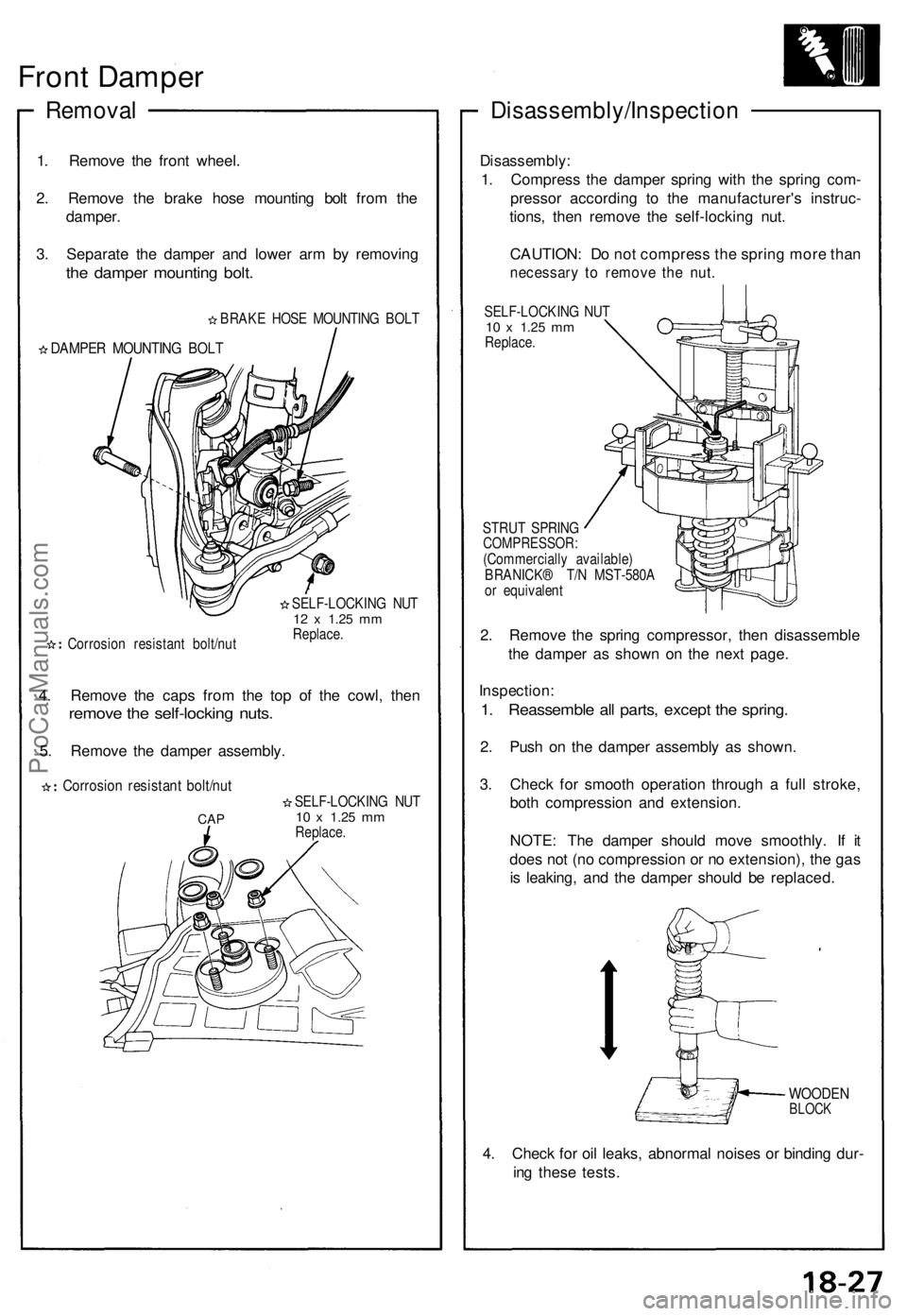

Front Damper

Removal

1. Remove the front wheel.

2. Remove the brake hose mounting bolt from the

damper.

3. Separate the damper and lower arm by removing

the damper mounting bolt.

BRAKE HOSE MOUNTING BOLT

DAMPER MOUNTING BOLT

Corrosion resistant bolt/nut

SELF-LOCKING NUT

12 x

1.25

mm

Replace.

4. Remove the caps from the top of the cowl, then

remove the self-locking nuts.

5. Remove the damper assembly.

Corrosion resistant bolt/nut

CAP

SELF-LOCKING NUT

10 x

1.25

mm

Replace.

Disassembly/Inspection

Disassembly:

1. Compress the damper spring with the spring com-

pressor according to the manufacturer's instruc-

tions, then remove the self-locking nut.

CAUTION: Do not compress the spring more than

necessary to remove the nut.

SELF-LOCKING NUT

10 x

1.25

mm

Replace.

STRUT SPRING

COMPRESSOR:

(Commercially available)

BRANICK® T/N MST-580A

or equivalent

2. Remove the spring compressor, then disassemble

the damper as shown on the next page.

Inspection:

1. Reassemble all parts, except the spring.

2. Push on the damper assembly as shown.

3. Check for smooth operation through a full stroke,

both compression and extension.

NOTE: The damper should move smoothly. If it

does not (no compression or no extension), the gas

is leaking, and the damper should be replaced.

WOODEN

BLOCK

4. Check for oil leaks, abnormal noises or binding dur-

ing these tests.ProCarManuals.com

Page 473 of 1640

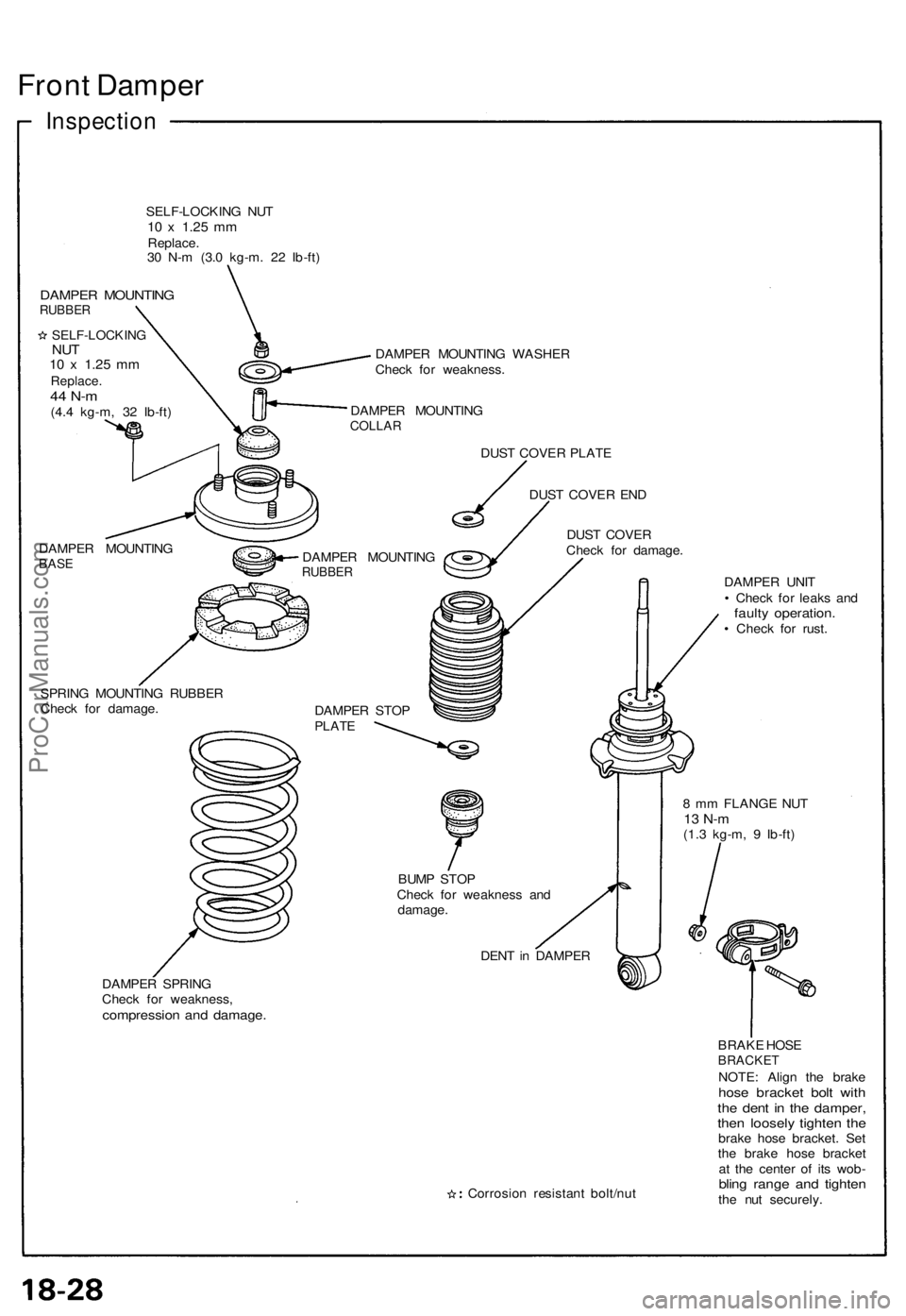

Front Dampe r

Inspectio n

SELF-LOCKIN G NU T10 x 1.2 5 mmReplace .

3 0 N- m (3. 0 kg-m . 2 2 Ib-ft )

DAMPE R MOUNTIN GRUBBER

SELF-LOCKIN GNUT10 x 1.2 5 mmReplace .44 N- m(4.4 kg-m , 3 2 Ib-ft )

DAMPE R MOUNTIN G

BASE

DAMPE R MOUNTIN G WASHE R

Chec k fo r weakness .

DAMPE R MOUNTIN G

COLLAR

DAMPE R MOUNTIN GRUBBER

DUST COVE R PLAT E

DUS T COVE R EN D

DUS T COVE R

Chec k fo r damage .

SPRIN G MOUNTIN G RUBBE R

Chec k fo r damage .

DAMPER STO P

PLAT E

BUMP STO P

Chec k fo r weaknes s an d

damage .

DENT in DAMPE R

DAMPE R SPRIN G

Chec k fo r weakness ,

compression an d damage .

DAMPER UNI T

• Chec k fo r leak s an d

fault y operation .• Chec k fo r rust .

8 m m FLANG E NU T

13 N- m(1.3 kg-m , 9 Ib-ft )

Corrosio n resistan t bolt/nu t BRAK

E HOS E

BRACKE TNOTE: Alig n th e brak ehose bracke t bol t wit hthe den t i n th e damper ,then loosel y tighte n th ebrak e hos e bracket . Se t

th e brak e hos e bracke t

a t th e cente r o f it s wob -

bling rang e an d tighte nthe nu t securely .

ProCarManuals.com

Page 474 of 1640

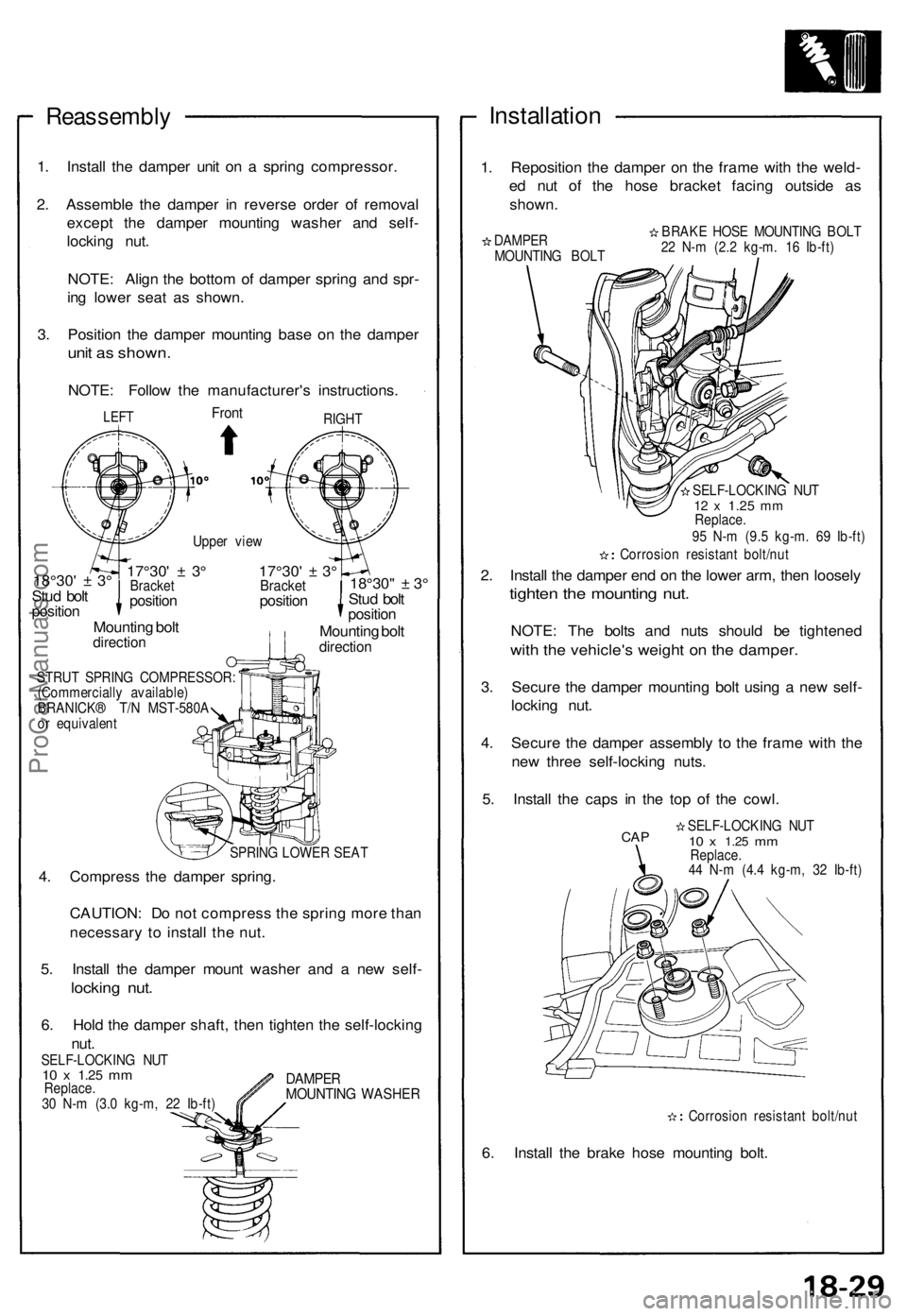

Reassembly

1. Instal l th e dampe r uni t o n a sprin g compressor .

2 . Assembl e th e dampe r i n revers e orde r o f remova l

excep t th e dampe r mountin g washe r an d self -

lockin g nut .

NOTE : Alig n th e botto m o f dampe r sprin g an d spr -

in g lowe r sea t a s shown .

3 . Positio n th e dampe r mountin g bas e o n th e dampe r

unit a s shown .

NOTE: Follo w th e manufacturer' s instructions .

LEFTFron tRIGH T

Uppe r vie w

17°30 ' ± 3°Bracke tposition

18°30' ± 3°

Stu d bol t

positio n

17°30' ± 3 °Bracke tposition

Mountin g bol tdirectio n

STRUT SPRIN G COMPRESSOR :

(Commerciall y available )

BRANICK ® T/ N MST-580 A

o r equivalen t

18°30" ± 3 °

Stu d bol t

positio n

Mountin g bol tdirectio n

SPRING LOWE R SEA T

4. Compres s th e dampe r spring .

CAUTION : D o no t compres s th e sprin g mor e tha n

necessar y t o instal l th e nut .

5 . Instal l th e dampe r moun t washe r an d a ne w self -

lockin g nut .

6. Hol d th e dampe r shaft , the n tighte n th e self-lockin g

nut.SELF-LOCKIN G NU T10 x 1.2 5 mmReplace .

3 0 N- m (3. 0 kg-m , 2 2 Ib-ft )

Installatio n

1. Repositio n th e dampe r o n th e fram e wit h th e weld -

e d nu t o f th e hos e bracke t facin g outsid e a s

shown .

DAMPE R

MOUNTIN G BOL T BRAK

E HOS E MOUNTIN G BOL T

2 2 N- m (2. 2 kg-m . 1 6 Ib-ft )

SELF-LOCKIN G NU T

12 x 1.2 5 mmReplace .

9 5 N- m (9. 5 kg-m . 6 9 Ib-ft )

Corrosio n resistan t bolt/nu t

2. Instal l th e dampe r en d o n th e lowe r arm , the n loosel y

tighten th e mountin g nut .

NOTE : Th e bolt s an d nut s shoul d b e tightene d

with the vehicle' s weigh t o n th e damper .

3. Secur e th e dampe r mountin g bol t usin g a ne w self -

lockin g nut .

4 . Secur e th e dampe r assembl y t o th e fram e wit h th e

ne w thre e self-lockin g nuts .

5 . Instal l th e cap s i n th e to p o f th e cowl .

CAPSELF-LOCKIN G NU T10 x 1.2 5 mmReplace .44 N- m (4. 4 kg-m , 3 2 Ib-ft )

Corrosio n resistan t bolt/nu t

6. Instal l th e brak e hos e mountin g bolt .

DAMPE RMOUNTIN G WASHE R

ProCarManuals.com

Page 475 of 1640

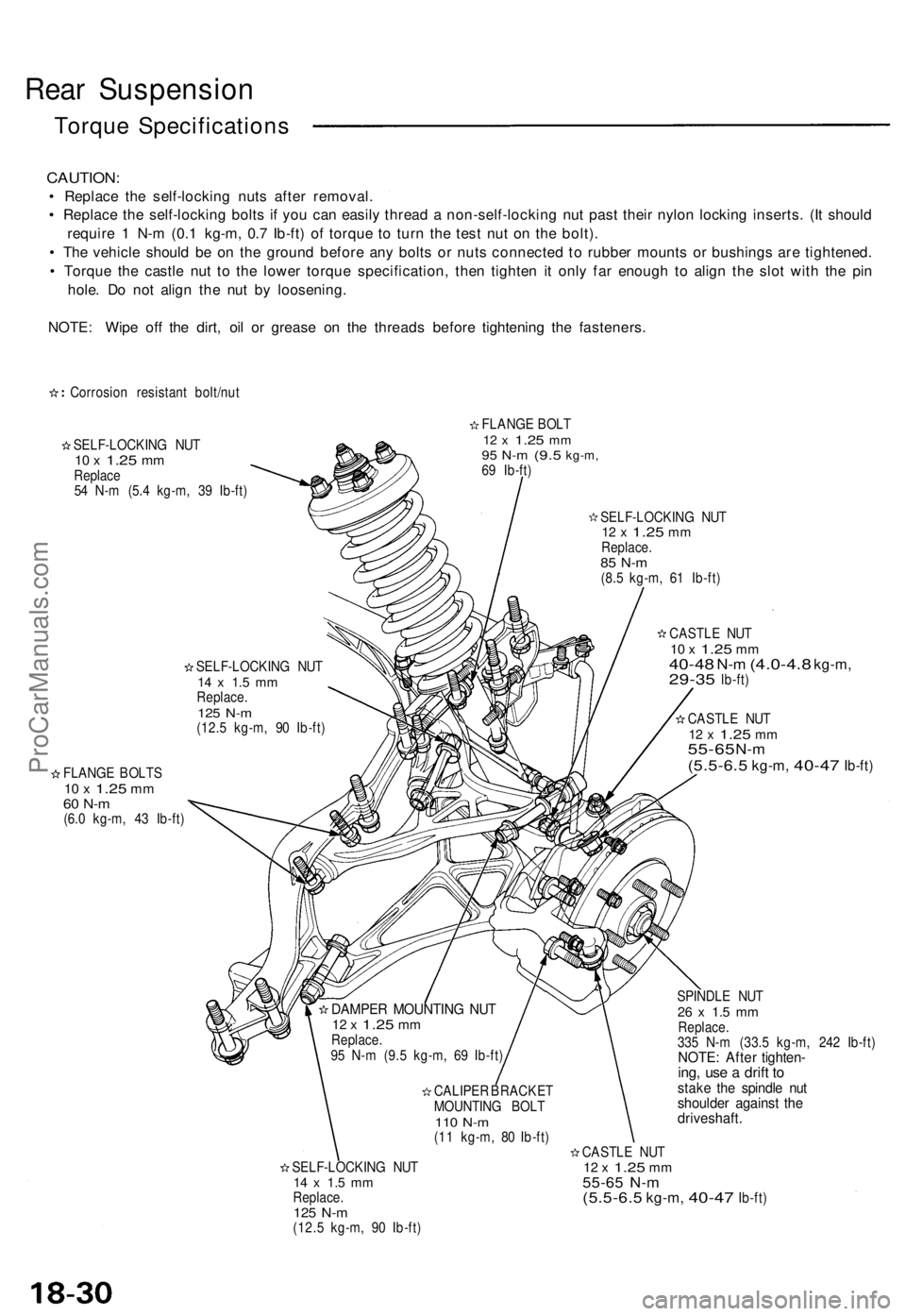

Rear Suspension

Torque Specifications

CAUTION:

• Replace the self-locking nuts after removal.

• Replace the self-locking bolts if you can easily thread a non-self-locking nut past their nylon locking inserts. (It should

require 1 N-m (0.1 kg-m, 0.7 Ib-ft) of torque to turn the test nut on the bolt).

• The vehicle should be on the ground before any bolts or nuts connected to rubber mounts or bushings are tightened.

• Torque the castle nut to the lower torque specification, then tighten it only far enough to align the slot with the pin

hole. Do not align the nut by loosening.

NOTE: Wipe off the dirt, oil or grease on the threads before tightening the fasteners.

Corrosion resistant bolt/nut

SELF-LOCKING NUT

10 x

1.25

mm

Replace

54 N-m (5.4 kg-m, 39 Ib-ft)

FLANGE BOLT

12 x

1.25

mm

95 N-m

(9.5

kg-m,

69 Ib-ft)

SELF-LOCKING NUT

12 x

1.25

mm

Replace.

85 N-m

(8.5 kg-m, 61 Ib-ft)

SELF-LOCKING NUT

14 x 1.5 mm

Replace.

125 N-m

(12.5 kg-m, 90 Ib-ft)

FLANGE BOLTS

10 x

1.25

mm

60 N-m

(6.0 kg-m, 43 Ib-ft)

CASTLE NUT

10 x

1.25

mm

40-48

N-m

(4.0-4.8

kg-m,

29-35

lb-ft)

CASTLE NUT

12 x

1.25

mm

55-65

N-m

(5.5-6.5

kg-m,

40-47

Ib-ft)

SPINDLE NUT

26 x 1.5 mm

Replace.

335 N-m (33.5 kg-m, 242 Ib-ft)

NOTE: After tighten-

ing, use a drift to

stake the spindle nut

shoulder against the

driveshaft.

SELF-LOCKING NUT

14 x 1.5 mm

Replace.

125 N-m

(12.5 kg-m, 90 Ib-ft)

CASTLE NUT

12 x

1.25

mm

55-65 N-m

(5.5-6.5

kg-m,

40-47

Ib-ft)

DAMPER MOUNTING NUT

12 x

1.25

mm

Replace.

95 N-m (9.5 kg-m, 69 Ib-ft)

CALIPER BRACKET

MOUNTING BOLT

110 N-m

(11 kg-m, 80 Ib-ft)ProCarManuals.com

Page 476 of 1640

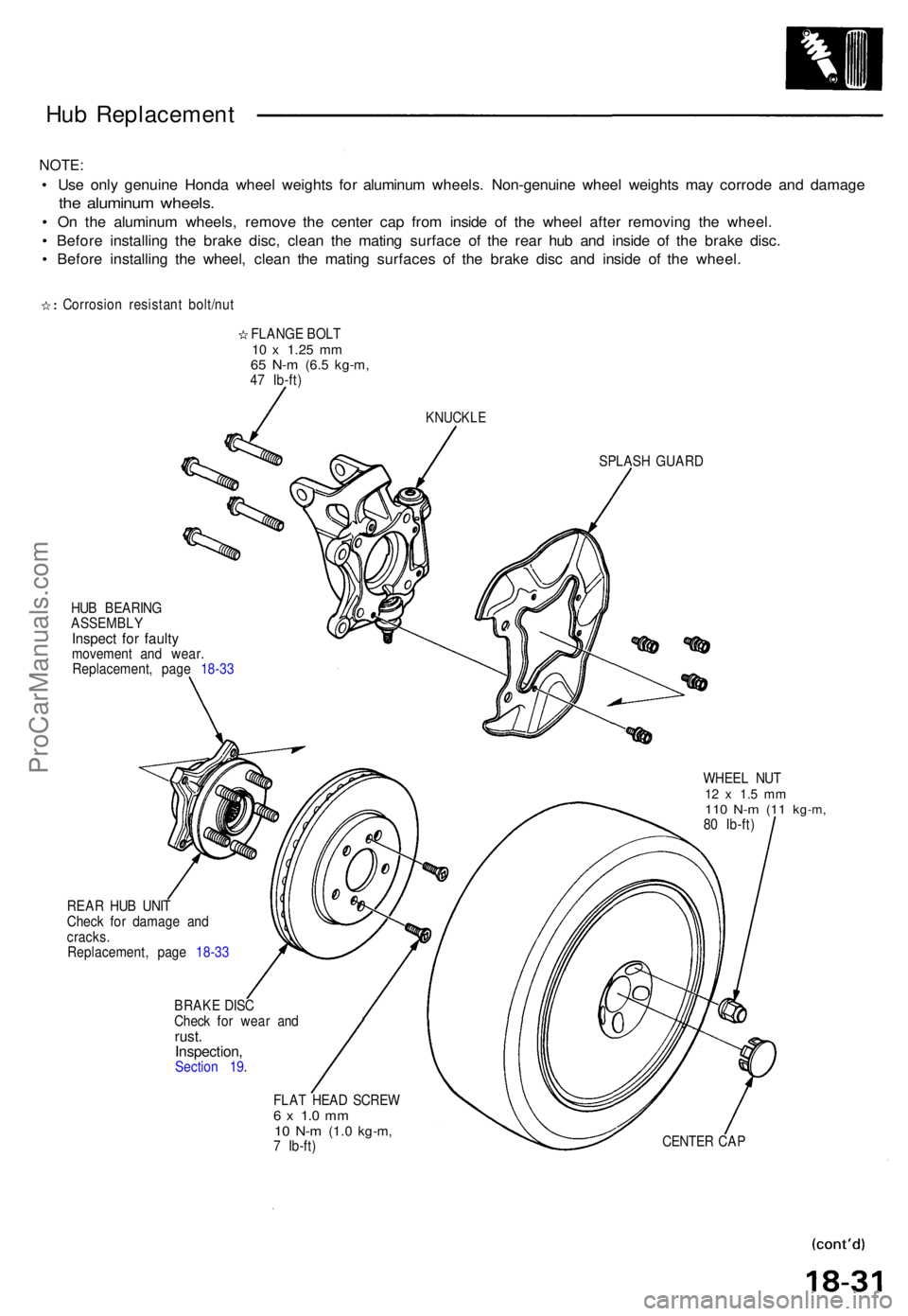

Hub Replacemen t

NOTE:

• Us e onl y genuin e Hond a whee l weight s fo r aluminu m wheels . Non-genuin e whee l weight s ma y corrod e an d damag e

the aluminu m wheels .

• O n th e aluminu m wheels , remov e th e cente r cap from insid e o f th e whee l afte r removin g th e wheel .

• Befor e installin g th e brak e disc , clea n th e matin g surfac e o f th e rea r hu b an d insid e o f th e brak e disc .

• Befor e installin g th e wheel , clea n th e matin g surface s o f th e brak e dis c an d insid e o f th e wheel .

Corrosio n resistan t bolt/nu t

FLANG E BOL T

10 x 1.2 5 mm65 N- m (6. 5 kg-m ,47 Ib-ft )

KNUCKL E

SPLASH GUAR D

HU B BEARIN G

ASSEMBL YInspect fo r fault ymovemen t an d wear .

Replacement , pag e 18-3 3

WHEEL NU T

12 x 1. 5 m m110 N- m (1 1 kg-m ,80 Ib-ft )

REA R HU B UNI T

Chec k fo r damag e an d

cracks .

Replacement , pag e 18-3 3

BRAK E DIS C

Chec k fo r wea r an d

rust .Inspection ,Section 19 .

FLAT HEA D SCRE W

6 x 1. 0 m m10 N- m (1. 0 kg-m ,7 Ib-ft ) CENTE

R CA P

ProCarManuals.com

Page 477 of 1640

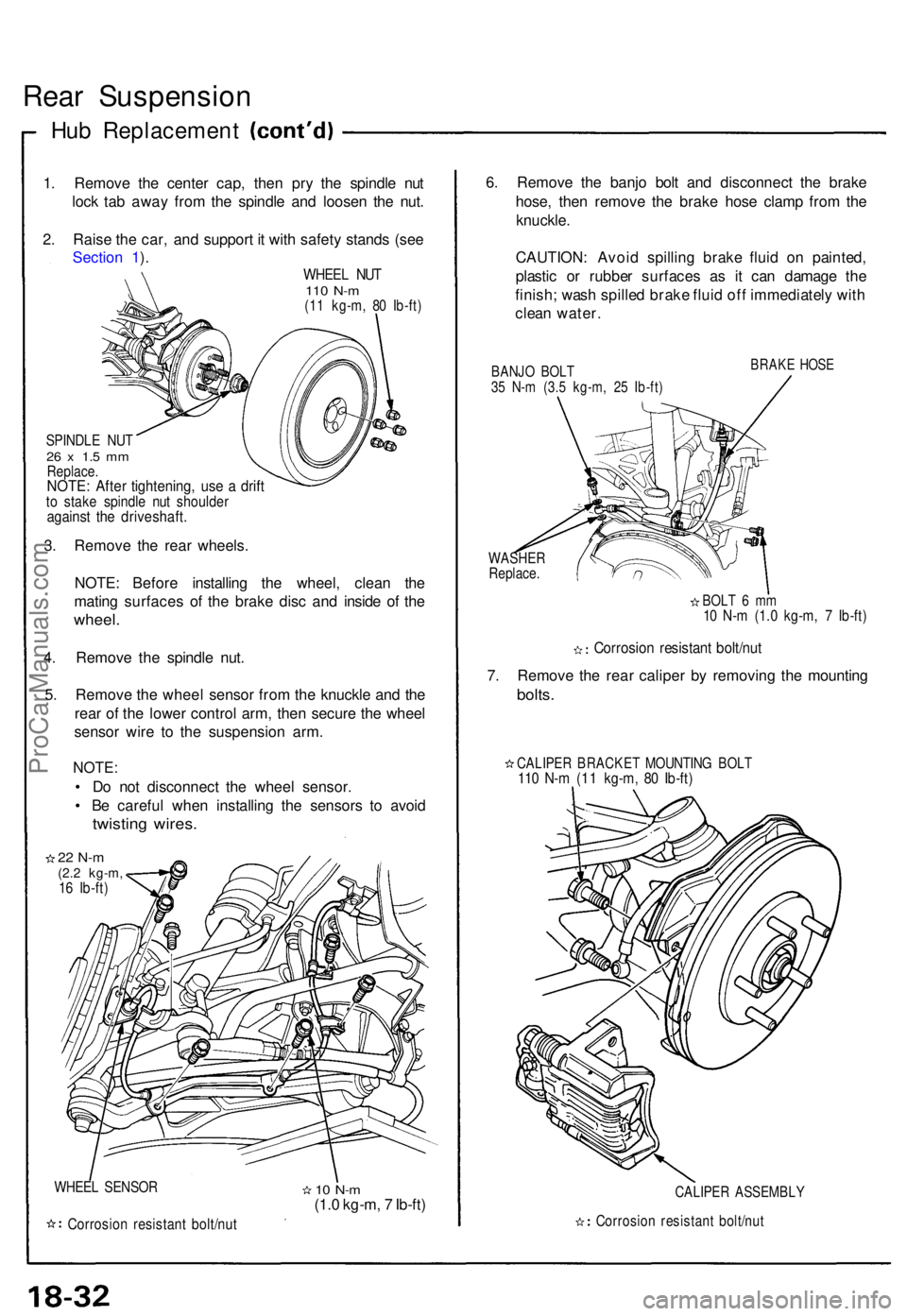

Rear Suspensio n

Hub Replacemen t

1. Remov e th e cente r cap , the n pr y th e spindl e nu t

loc k ta b awa y fro m th e spindl e an d loose n th e nut .

2 . Rais e th e car , an d suppor t i t wit h safet y stand s (se e

Sectio n 1 ).

WHEE L NU T110 N- m(11 kg-m , 8 0 Ib-ft )

SPINDL E NU T26 x 1. 5 m mReplace .NOTE: Afte r tightening , us e a drif tto stak e spindl e nu t shoulde ragainst th e driveshaft .

3. Remov e th e rea r wheels .

NOTE : Befor e installin g th e wheel, clean th e

matin g surface s o f th e brak e dis c an d insid e o f th e

wheel .

4. Remov e th e spindl e nut .

5 . Remov e th e whee l senso r fro m th e knuckl e an d th e

rea r o f th e lowe r contro l arm , the n secur e th e whee l

senso r wir e t o th e suspensio n arm .

NOTE :

• D o no t disconnec t th e whee l sensor .

• B e carefu l whe n installin g th e sensor s t o avoi d

twistin g wires .

22 N- m(2.2 kg-m ,16 Ib-ft )

WHEE L SENSO R

Corrosio n resistan t bolt/nu t

10 N- m(1.0 kg-m , 7 Ib-ft ) 6

. Remov e th e banj o bol t an d disconnec t th e brak e

hose , the n remov e th e brak e hos e clam p fro m th e

knuckle .

CAUTION : Avoi d spillin g brak e flui d o n painted ,

plasti c o r rubbe r surface s a s i t ca n damag e th e

finish ; was h spille d brak e flui d of f immediatel y wit h

clea n water .

BANJO BOL T35 N- m (3. 5 kg-m , 2 5 Ib-ft )

BRAK E HOS E

WASHE RReplace.

BOLT 6 m m10 N- m (1. 0 kg-m , 7 Ib-ft )

Corrosio n resistan t bolt/nu t

7. Remov e th e rea r calipe r b y removin g th e mountin g

bolts.

CALIPE R BRACKE T MOUNTIN G BOL T110 N- m (1 1 kg-m , 8 0 Ib-ft )

CALIPE R ASSEMBL Y

Corrosion resistan t bolt/nu t

ProCarManuals.com

Page 478 of 1640

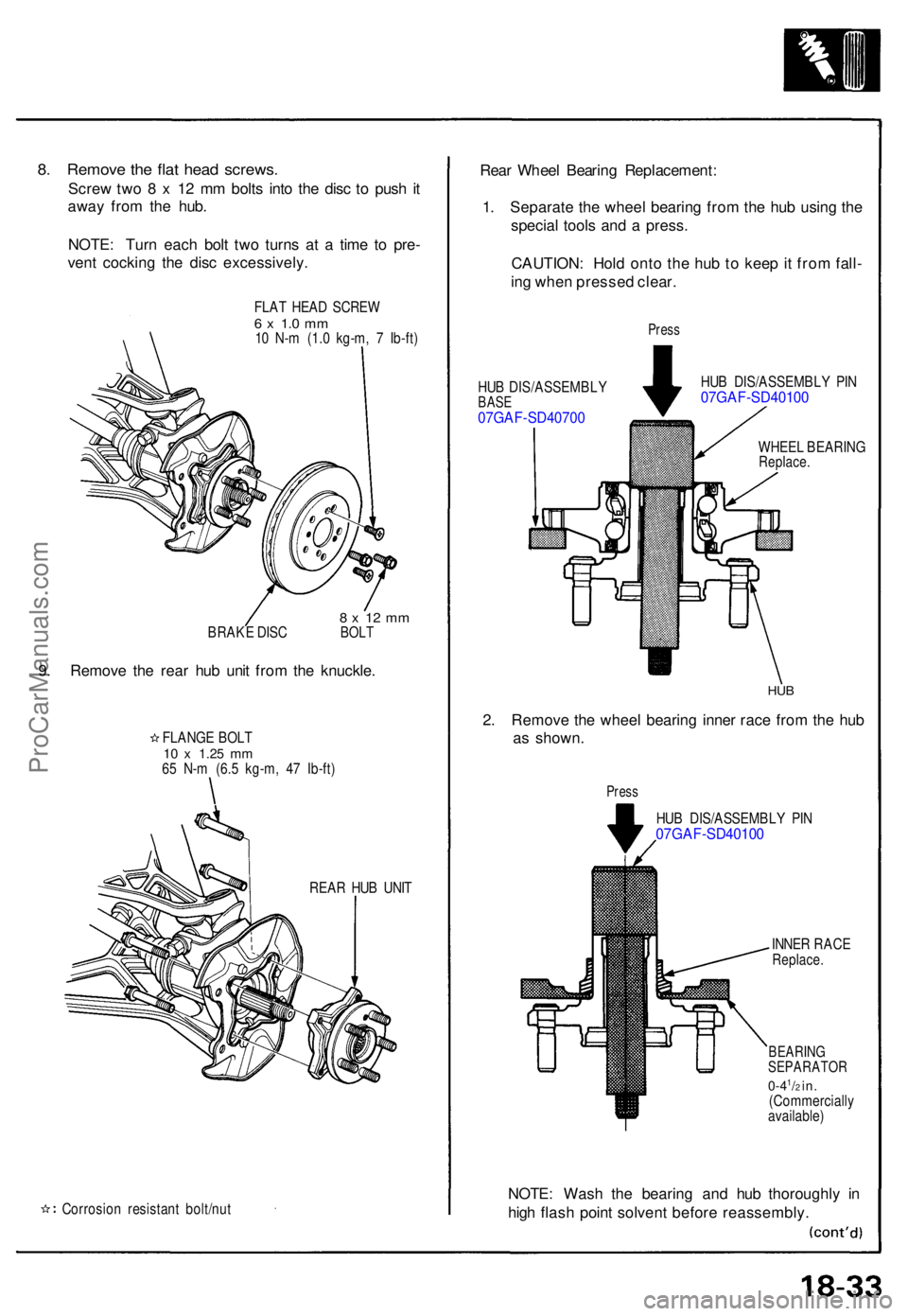

8. Remov e th e fla t hea d screws .

Screw tw o 8 x 12 m m bolt s int o th e dis c t o pus h i t

awa y fro m th e hub .

NOTE : Tur n eac h bol t tw o turn s a t a tim e t o pre -

ven t cockin g th e dis c excessively .

FLAT HEA D SCRE W6 x 1. 0 m m10 N- m (1. 0 kg-m , 7 Ib-ft )

BRAK E DIS C

9. Remov e th e rea r hu b uni t fro m th e knuckle .

FLANGE BOL T10 x 1.2 5 mm65 N- m (6. 5 kg-m , 4 7 Ib-ft )

8 x 1 2 m mBOL T

REA R HU B UNI T

Corrosio n resistan t bolt/nu t

Rear Whee l Bearin g Replacement :

1 . Separat e th e whee l bearin g fro m th e hu b usin g th e

specia l tool s an d a press .

CAUTION : Hol d ont o th e hu b t o kee p it fro m fall -

in g whe n presse d clear .

Press

HUB DIS/ASSEMBL YBASE07GA F-SD4070 0

HUB DIS/ASSEMBL Y PI N07GA F-SD4010 0

WHEEL BEARIN GReplace.

HUB

2. Remov e th e whee l bearin g inne r rac e fro m th e hu b

a s shown .

Press

HUB DIS/ASSEMBL Y PI N07GA F-SD4010 0

INNER RAC EReplace .

BEARINGSEPARATO R

0-41/2 in.(Commerciall y

available )

NOTE: Was h th e bearin g an d hu b thoroughl y i n

hig h flas h poin t solven t befor e reassembly .

ProCarManuals.com

Page 479 of 1640

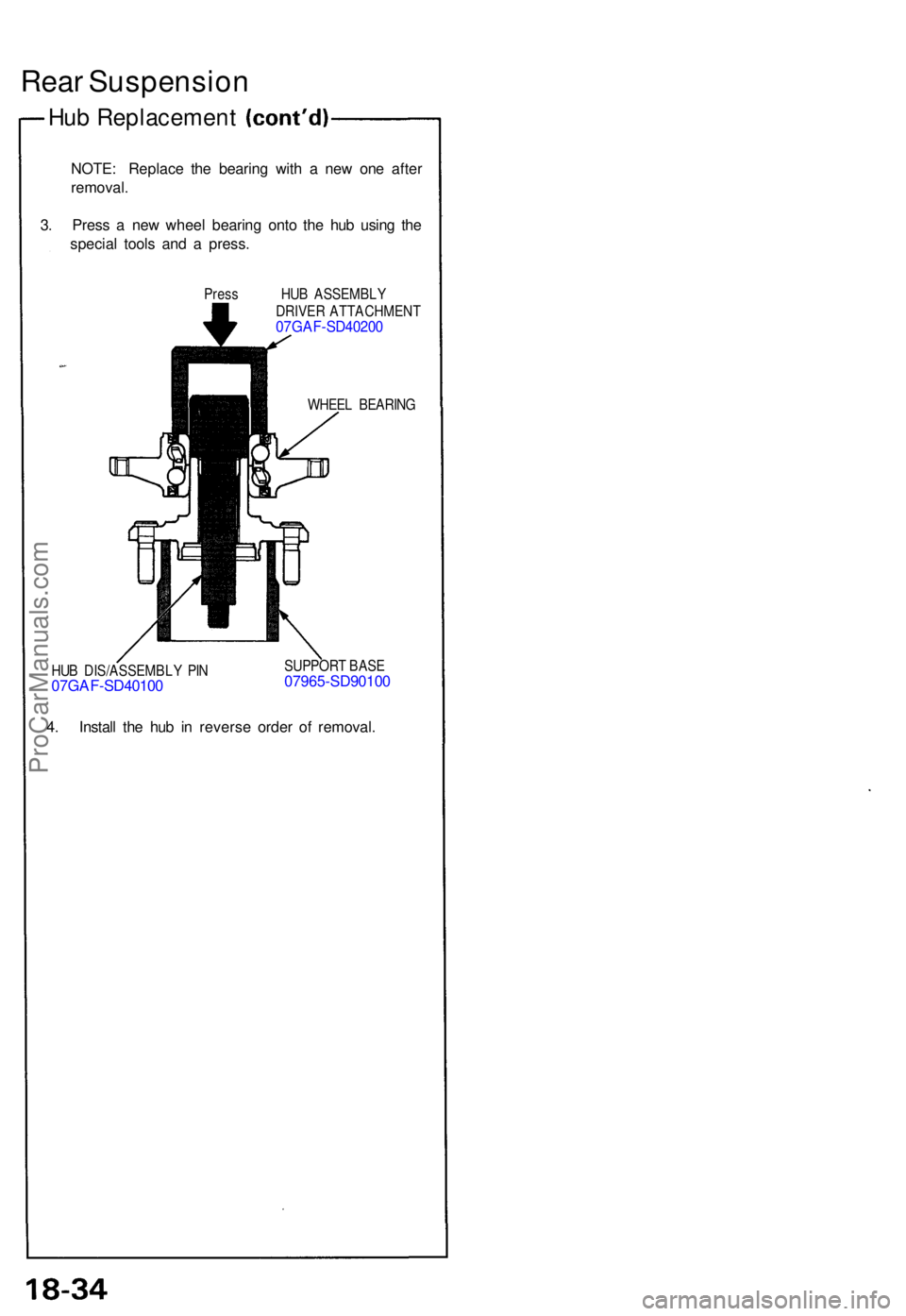

Rear Suspensio n

Hub Replacemen t

NOTE: Replac e th e bearin g wit h a ne w on e afte r

removal .

3 . Pres s a ne w whee l bearin g ont o th e hu b usin g th e

specia l tool s an d a press .

Press HUB ASSEMBL Y

DRIVE R ATTACHMEN T

07GAF-SD4020 0

WHEEL BEARIN G

HU B DIS/ASSEMBL Y PI N

07GA F-SD4010 0

SUPPOR T BAS E07965-SD9010 0

4 . Instal l th e hu b i n revers e orde r of removal .

ProCarManuals.com

Page 480 of 1640

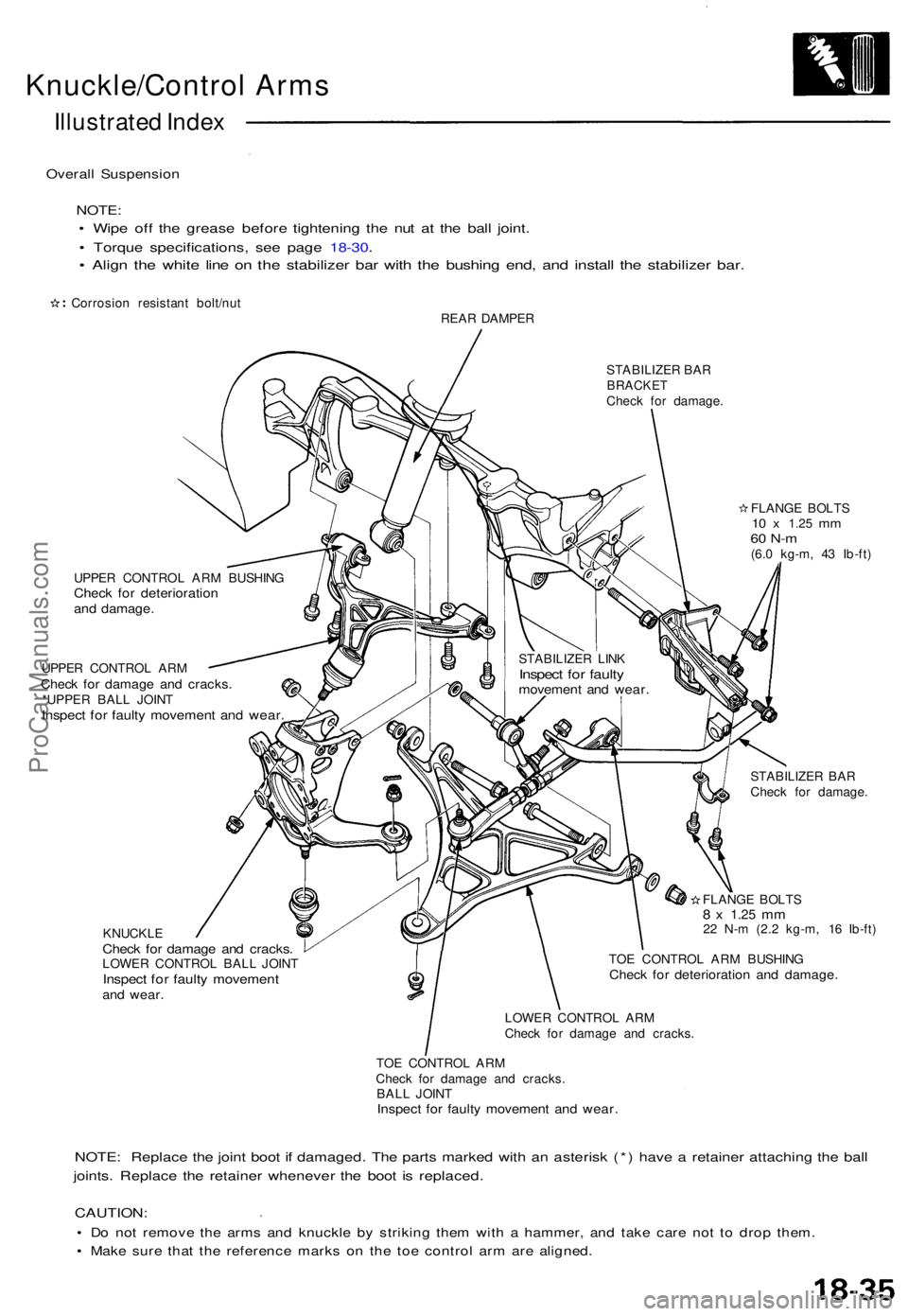

Knuckle/Control Arm s

Illustrate d Inde x

Overal l Suspensio n

NOTE:

• Wip e of f th e greas e befor e tightenin g th e nu t a t th e bal l joint .

• Torqu e specifications , se e pag e 18-30 .

• Alig n th e whit e lin e o n th e stabilize r ba r wit h th e bushin g end , an d instal l th e stabilize r bar .

Corrosio n resistan t bolt/nu t

REAR DAMPE R

STABILIZER BA R

BRACKE TCheck fo r damage .

UPPE R CONTRO L AR M BUSHIN G

Check fo r deterioratio nand damage .

UPPER CONTRO L AR MChec k fo r damag e an d cracks .*UPPE R BAL L JOIN TInspec t fo r fault y movemen t an d wear .

KNUCKL ECheck for damag e an d cracks .LOWER CONTRO L BAL L JOIN TInspec t fo r faulty movemen tand wear .

FLANG E BOLT S10 x 1.2 5 mm60 N- m(6.0 kg-m , 4 3 Ib-ft )

STABILIZE R BA R

Chec k fo r damage .

FLANG E BOLT S

8 x 1.2 5 mm22 N- m (2. 2 kg-m , 1 6 Ib-ft )

TO E CONTRO L AR M BUSHIN G

Check fo r deterioratio n an d damage .

LOWER CONTRO L AR M

Chec k fo r damag e an d cracks .

TO E CONTRO L AR M

Chec k fo r damag e an d cracks .

BAL L JOIN T

Inspec t fo r fault y movemen t an d wear .

NOTE : Replac e th e join t boo t i f damaged . Th e part s marke d wit h a n asteris k (* ) hav e a retaine r attachin g th e bal l

joints . Replac e th e retaine r wheneve r th e boo t i s replaced .

CAUTION :

• D o no t remov e th e arm s an d knuckl e b y strikin g the m wit h a hammer , an d tak e car e no t t o dro p them .

• Mak e sur e tha t th e referenc e mark s o n th e to e contro l ar m ar e aligned .

STABILIZE R LIN KInspec t fo r fault ymovemen t an d wear .

ProCarManuals.com