ACURA NSX 1991 Service Repair Manual

Manufacturer: ACURA, Model Year: 1991, Model line: NSX, Model: ACURA NSX 1991Pages: 1640, PDF Size: 60.48 MB

Page 501 of 1640

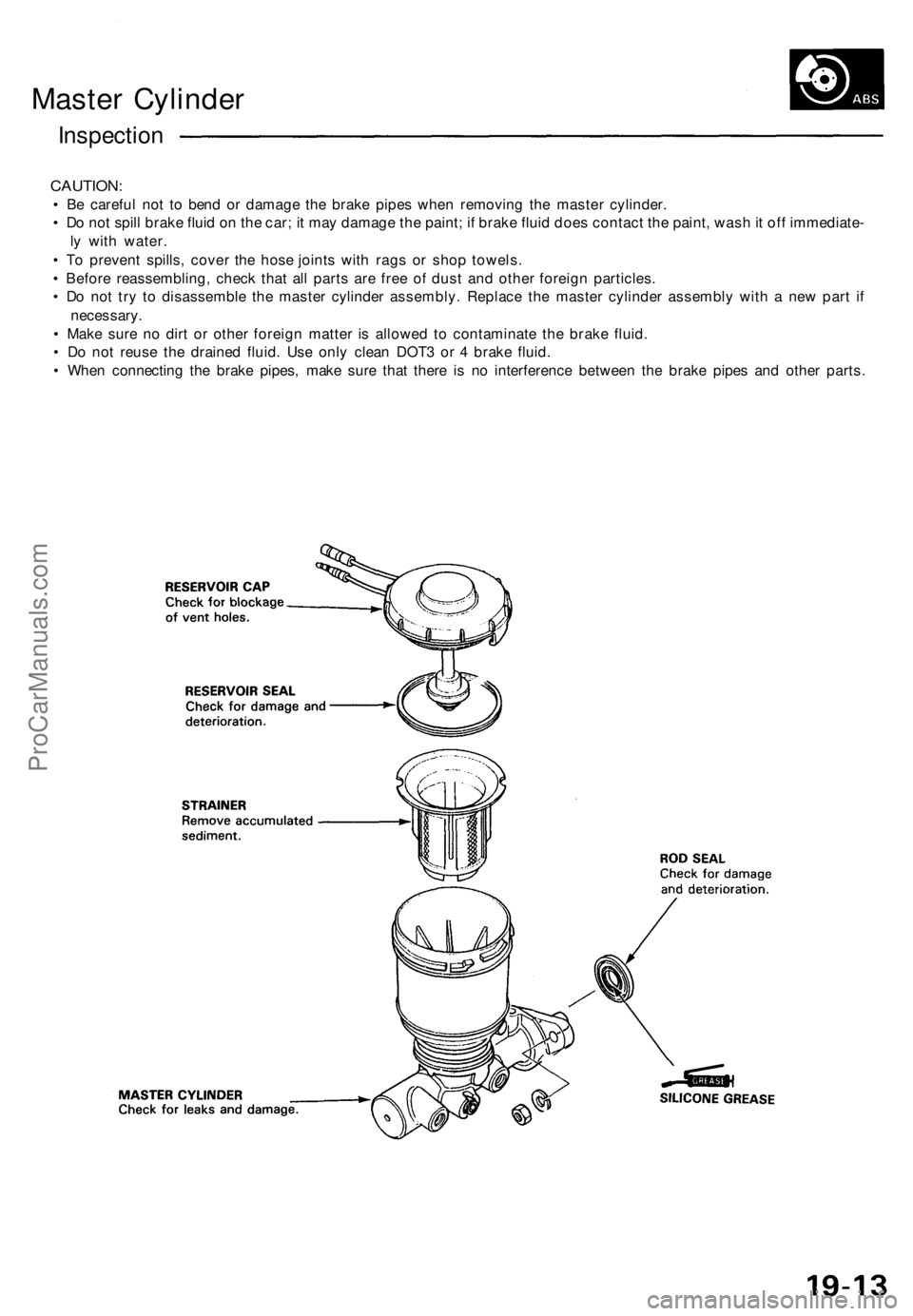

Master Cylinder

Inspection

CAUTION:

• Be careful not to bend or damage the brake pipes when removing the master cylinder.

• Do not spill brake fluid on the car; it may damage the paint; if brake fluid does contact the paint, wash it off immediate-

ly with water.

• To prevent spills, cover the hose joints with rags or shop towels.

• Before reassembling, check that all parts are free of dust and other foreign particles.

• Do not try to disassemble the master cylinder assembly. Replace the master cylinder assembly with a new part if

necessary.

• Make sure no dirt or other foreign matter is allowed to contaminate the brake fluid.

• Do not reuse the drained fluid. Use only clean DOT3 or 4 brake fluid.

• When connecting the brake pipes, make sure that there is no interference between the brake pipes and other parts.ProCarManuals.com

Page 502 of 1640

Brake Booste r

Tests

Functiona l Tes t

1. Wit h th e engin e stopped , depres s th e brak e peda l

severa l time s t o deplet e th e vacuu m reservoir , the n

depres s th e peda l har d an d hol d i t fo r 1 5 seconds .

I f th e peda l sinks , eithe r th e maste r cylinde r i s

bypassin g internally , o r th e brak e syste m (maste r

cylinder , lines , modulator , proportionin g valve , o r

calipers ) ar e leaking .

2 . Star t th e engin e wit h th e peda l depressed . I f th e pe -

da l sink s slightly , th e vacuu m booste r i s operatin g

normally , i f th e peda l heigh t doe s no t vary , th e

booste r o r chec k valv e i s faulty .

3 . Wit h th e engin e running , depres s th e brak e peda l

lightly . Appl y jus t enoug h pressur e t o hol d bac k au -

tomati c transmissio n creep . I f th e brak e peda l sink s

mor e tha n 2 5 m m (1. 0 in. ) i n thre e minutes , th e

maste r cylinde r i s faulty . A sligh t chang e i n peda l

heigh t whe n th e A/ C compresso r cycle s o n an d of f

i f normal . (Th e A/ C compresso r loa d change s th e

vacuu m availabl e t o th e booster. )

Leak Tes t

1. Depres s th e brak e peda l wit h th e engin e running ,

the n sto p th e engine . I f th e peda l heigh t doe s no t

var y whil e depresse d fo r 3 0 seconds , th e vacuu m

booste r i s OK . I f th e peda l rises , th e booste r i s faulty .

2 . Wit h th e engin e stopped , depres s th e brak e peda l

severa l time s usin g norma l pressure . Whe n th e pe -

da l i s firs t depressed , i t shoul d b e low . O n consecu -

tiv e applications , th e peda l heigh t shoul d graduall y

rise . I f th e peda l positio n doe s no t vary , chec k th e

booste r chec k valve .

Booste r Chec k Valv e Tes t

1. Disconnec t th e brak e booste r vacuu m hos e a t th e

booste r o r a t th e booste r sid e o f th e valve .

2 . Star t th e engin e an d le t i t idle . Ther e shoul d b e vacu -

um . I f n o vacuu m is available , th e chec k valv e is no t

workin g properly . Replac e th e chec k valv e an d

retest .

ProCarManuals.com

Page 503 of 1640

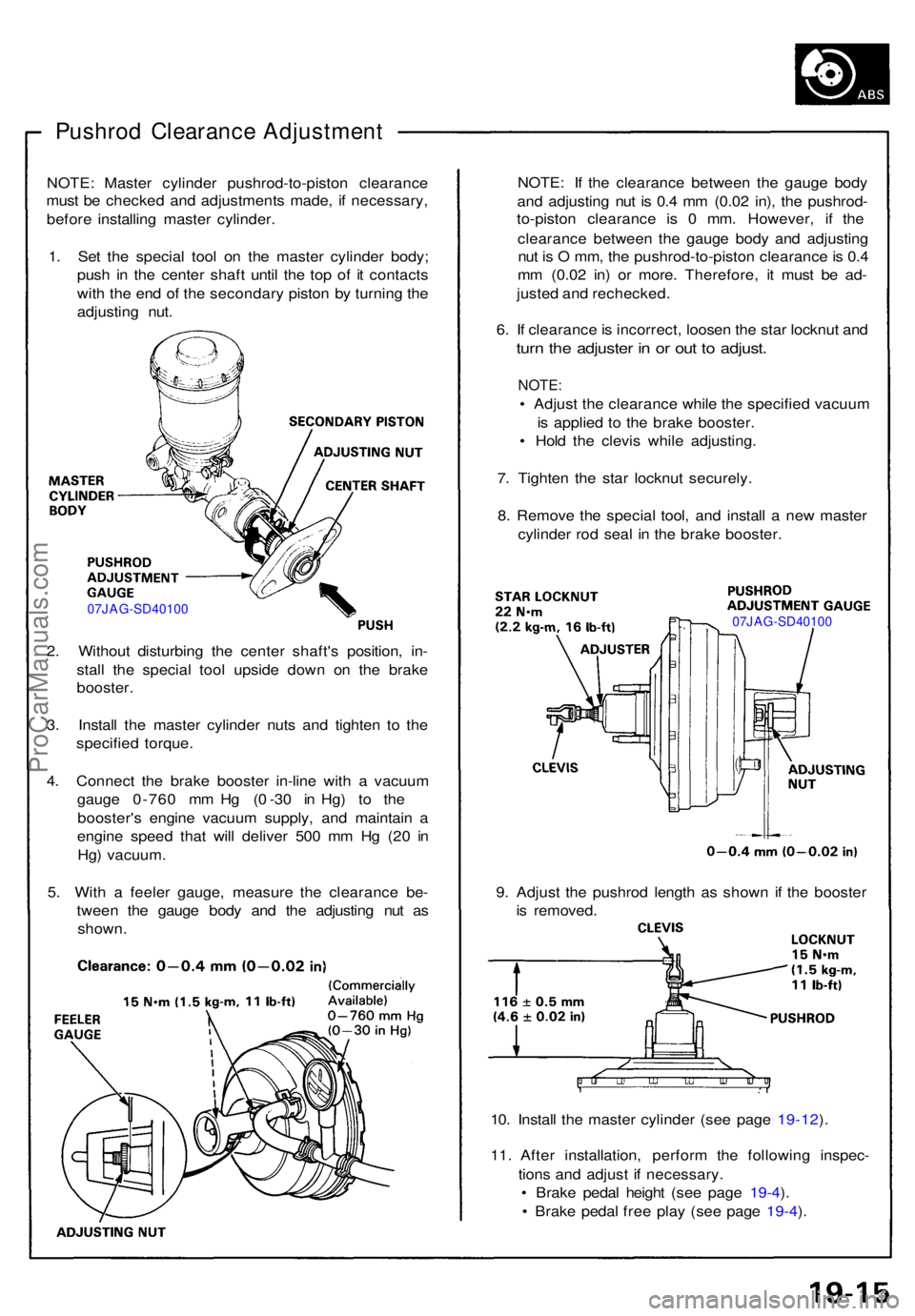

Pushrod Clearanc e Adjustmen t

NOTE: Maste r cylinde r pushrod-to-pisto n clearanc e

mus t b e checke d an d adjustment s made , i f necessary ,

befor e installin g maste r cylinder .

1 . Se t th e specia l too l o n th e maste r cylinde r body ;

pus h i n th e cente r shaf t unti l th e to p o f i t contact s

wit h th e en d o f th e secondar y pisto n b y turnin g th e

adjustin g nut .

07JAG-SD4010 0

2. Withou t disturbin g th e cente r shaft' s position , in -

stal l th e specia l too l upsid e dow n o n th e brak e

booster .

3 . Instal l th e maste r cylinde r nut s an d tighte n t o th e

specifie d torque .

4 . Connec t th e brak e booste r in-lin e wit h a vacuu m

gaug e 0-76 0 m m H g ( 0 -3 0 i n Hg ) t o th e

booster' s engin e vacuu m supply , an d maintai n a

engin e spee d tha t wil l delive r 50 0 m m H g (2 0 i n

Hg ) vacuum .

5 . Wit h a feele r gauge , measur e th e clearanc e be -

twee n th e gaug e bod y an d th e adjustin g nu t a s

shown . NOTE

: I f th e clearanc e betwee n th e gaug e bod y

an d adjustin g nu t i s 0. 4 m m (0.0 2 in) , th e pushrod -

to-pisto n clearanc e i s 0 mm . However , i f th e

clearanc e betwee n th e gaug e bod y an d adjustin g

nu t i s O mm , th e pushrod-to-pisto n clearanc e is 0. 4

m m (0.0 2 in ) o r more . Therefore , i t mus t b e ad -

juste d an d rechecked .

6 . I f clearanc e is incorrect , loose n th e sta r locknu t an d

turn th e adjuste r i n o r ou t t o adjust .

NOTE:

• Adjus t th e clearanc e whil e th e specifie d vacuu m

i s applie d t o th e brak e booster .

• Hol d th e clevi s whil e adjusting .

7 . Tighte n th e sta r locknu t securely .

8 . Remov e th e specia l tool , an d instal l a ne w maste r

cylinde r ro d sea l i n th e brak e booster .

07JAG-SD40100

9. Adjus t th e pushro d lengt h a s show n i f th e booste r

i s removed .

10 . Instal l th e maste r cylinde r (se e pag e 19-12 ).

11 . Afte r installation , perfor m th e followin g inspec -

tion s an d adjus t i f necessary .

• Brak e peda l heigh t (se e pag e 19-4 ).

• Brak e peda l fre e pla y (se e pag e 19-4 ).

ProCarManuals.com

Page 504 of 1640

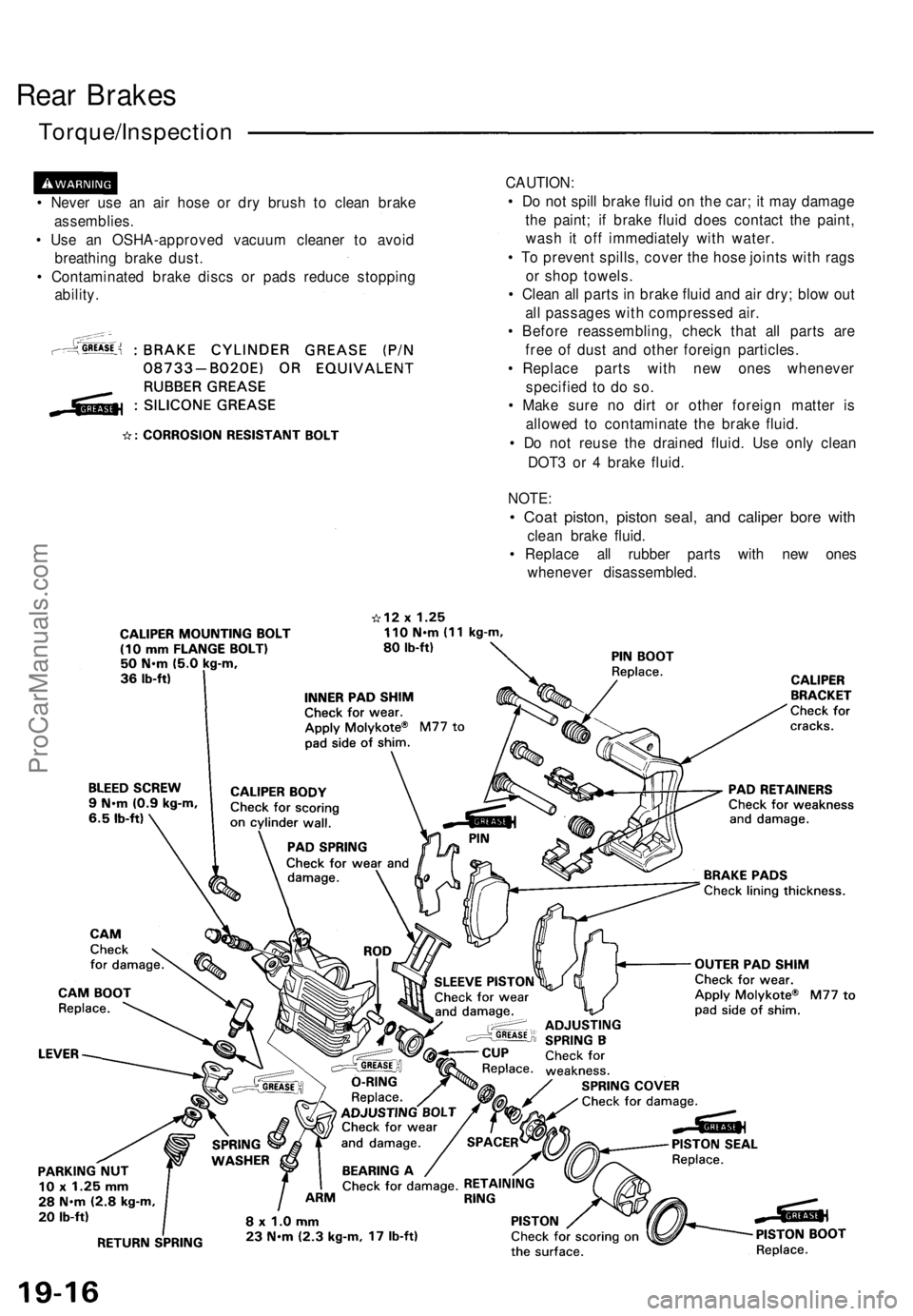

Rear Brakes

Torque/Inspection

• Never use an air hose or dry brush to clean brake

assemblies.

• Use an OSHA-approved vacuum cleaner to avoid

breathing brake dust.

• Contaminated brake discs or pads reduce stopping

ability.

CAUTION:

• Do not spill brake fluid on the car; it may damage

the paint; if brake fluid does contact the paint,

wash it off immediately with water.

• To prevent spills, cover the hose joints with rags

or shop towels.

• Clean all parts in brake fluid and air dry; blow out

all passages with compressed air.

• Before reassembling, check that all parts are

free of dust and other foreign particles.

• Replace parts with new ones whenever

specified to do so.

• Make sure no dirt or other foreign matter is

allowed to contaminate the brake fluid.

• Do not reuse the drained fluid. Use only clean

DOT3 or 4 brake fluid.

NOTE:

• Coat piston, piston seal, and caliper bore with

clean brake fluid.

• Replace all rubber parts with new ones

whenever disassembled.ProCarManuals.com

Page 505 of 1640

Rear Brak e Pad s

Inspection/Replacemen t

• Neve r us e a n ai r hos e o r dr y brus h t o clea n brak e

assemblies ,

Use a n OSHA-approve d vacuu m cleane r t o avoi d

breathin g brak e dust .

1 . Loose n th e rea r whee l nut s slightly , the n rais e eac h

sid e o f th e ca r an d suppor t i t o n safet y stand s (se e

pag e 1-9 throug h 1-11 ).

Remov e th e rea r wheels .

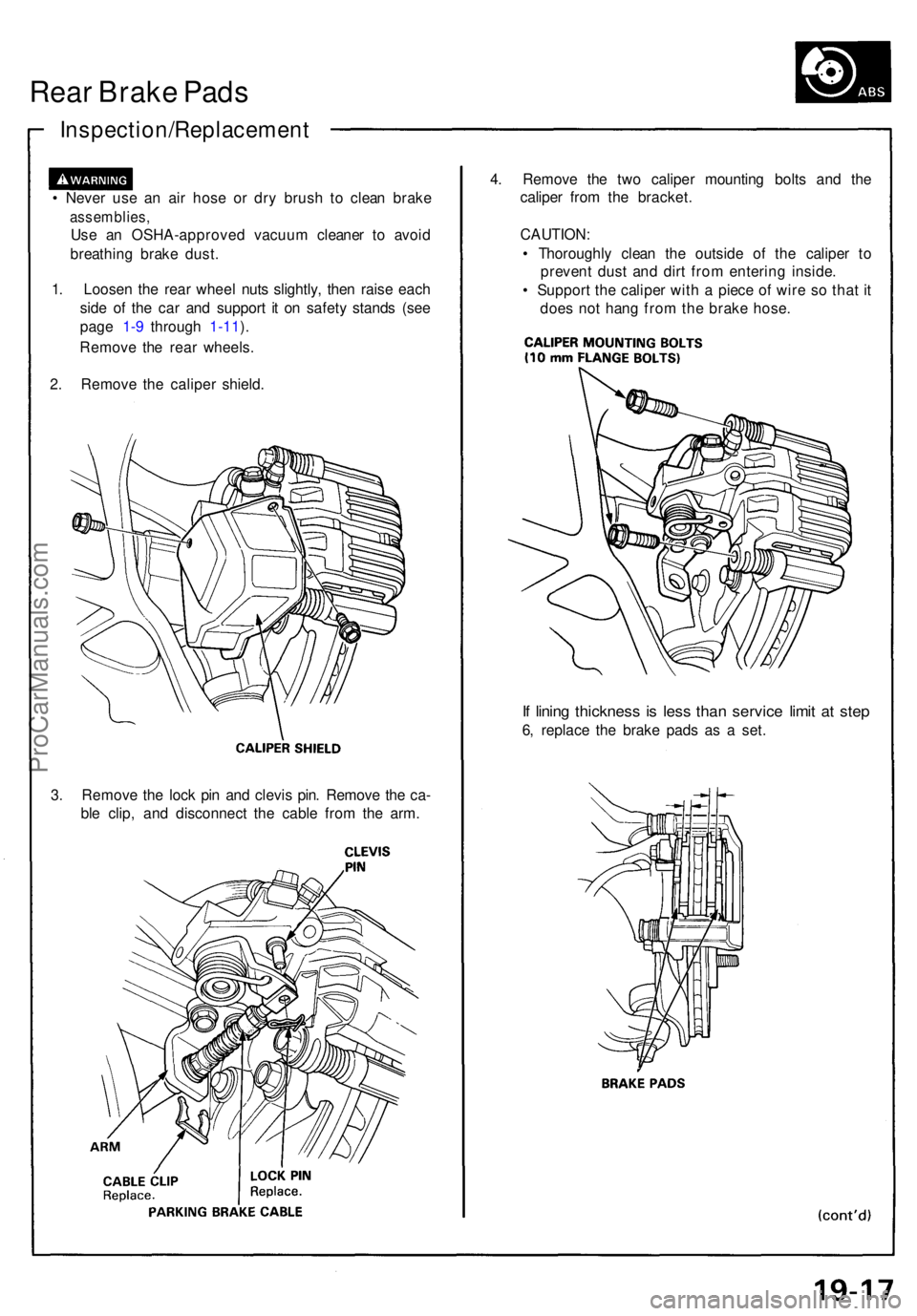

2 . Remov e th e calipe r shield .

3 . Remov e th e loc k pi n an d clevi s pin . Remov e th e ca -

bl e clip , an d disconnec t th e cabl e fro m th e arm . 4

. Remov e th e tw o calipe r mountin g bolt s an d th e

calipe r fro m th e bracket .

CAUTION :

• Thoroughl y clea n th e outsid e o f th e calipe r t o

preven t dus t an d dir t fro m enterin g inside .

• Suppor t th e calipe r wit h a piec e o f wir e s o tha t i t

doe s no t han g fro m th e brak e hose .

If linin g thicknes s i s les s tha n servic e limi t a t ste p

6, replac e th e brak e pad s a s a set .

ProCarManuals.com

Page 506 of 1640

Rear Brak e Pad s

Inspection/Replacemen t (cont'd )

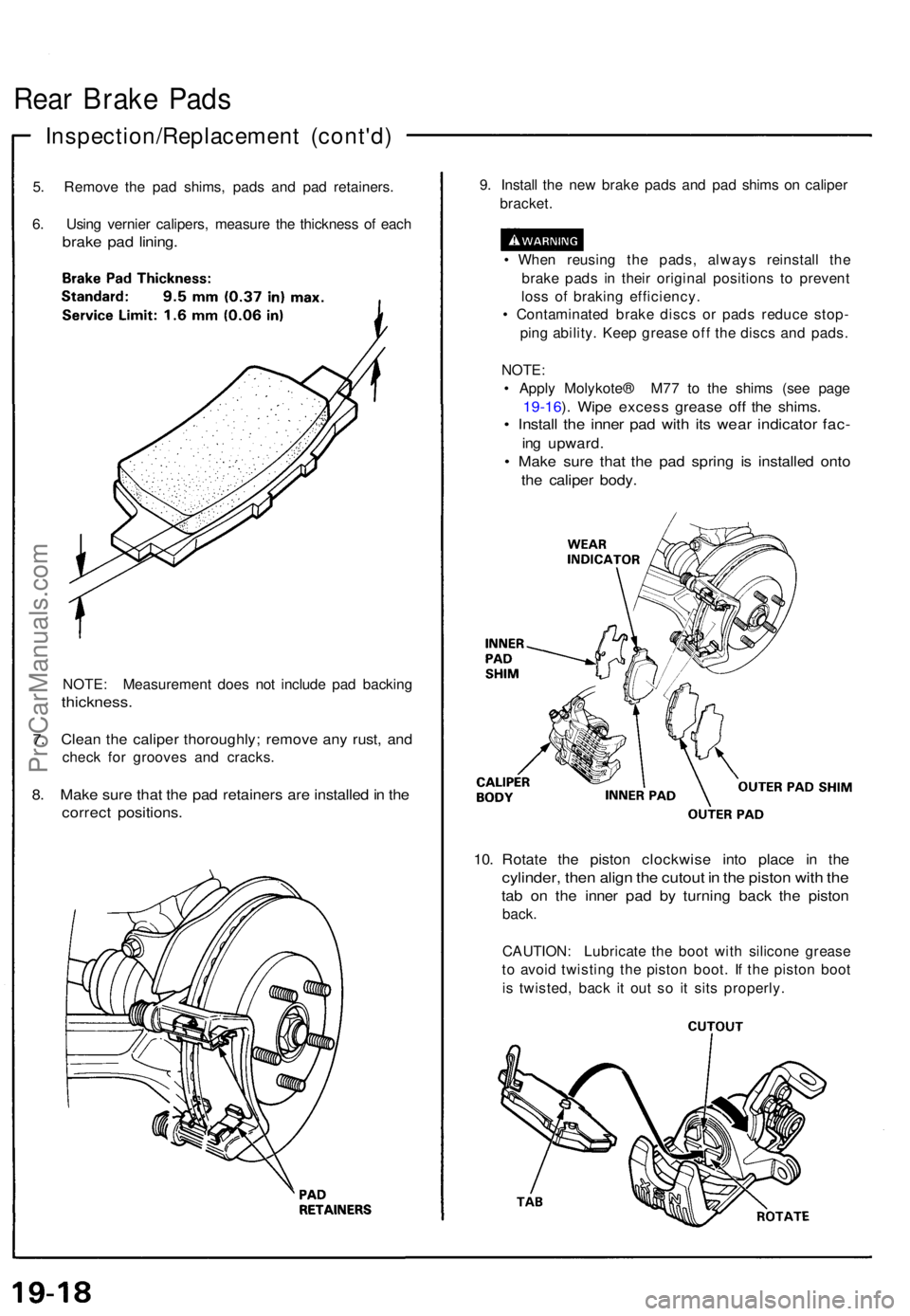

5. Remov e th e pa d shims , pad s an d pa d retainers .

6 . Usin g vernie r calipers , measur e th e thicknes s o f eac h

brak e pa d lining .

NOTE : Measuremen t doe s no t includ e pa d backin g

thickness .

7. Clea n th e calipe r thoroughly ; remov e an y rust , an d

chec k fo r groove s an d cracks .

8. Mak e sur e tha t th e pa d retainer s ar e installe d in th e

correc t positions .

9. Instal l th e ne w brak e pad s an d pa d shim s o n calipe r

bracket .

• Whe n reusin g th e pads , alway s reinstal l th e

brak e pad s i n thei r origina l position s t o preven t

los s o f brakin g efficiency .

• Contaminate d brak e disc s o r pad s reduc e stop -

pin g ability . Kee p greas e of f th e disc s an d pads .

NOTE :

• Appl y Molykote ® M7 7 t o th e shim s (se e pag e

19-16 ). Wip e exces s greas e of f th e shims .

• Instal l th e inne r pa d wit h it s wea r indicato r fac -

ing upward .

• Mak e sur e tha t th e pa d sprin g i s installe d ont o

the calipe r body .

10. Rotat e th e pisto n clockwis e int o plac e i n th e

cylinder , the n alig n th e cutou t i n th e pisto n wit h th e

tab o n th e inne r pa d b y turnin g bac k th e pisto n

back.

CAUTION : Lubricat e th e boo t wit h silicon e greas e

t o avoi d twistin g th e pisto n boot . I f th e pisto n boo t

i s twisted , bac k i t ou t s o i t sit s properly .

ProCarManuals.com

Page 507 of 1640

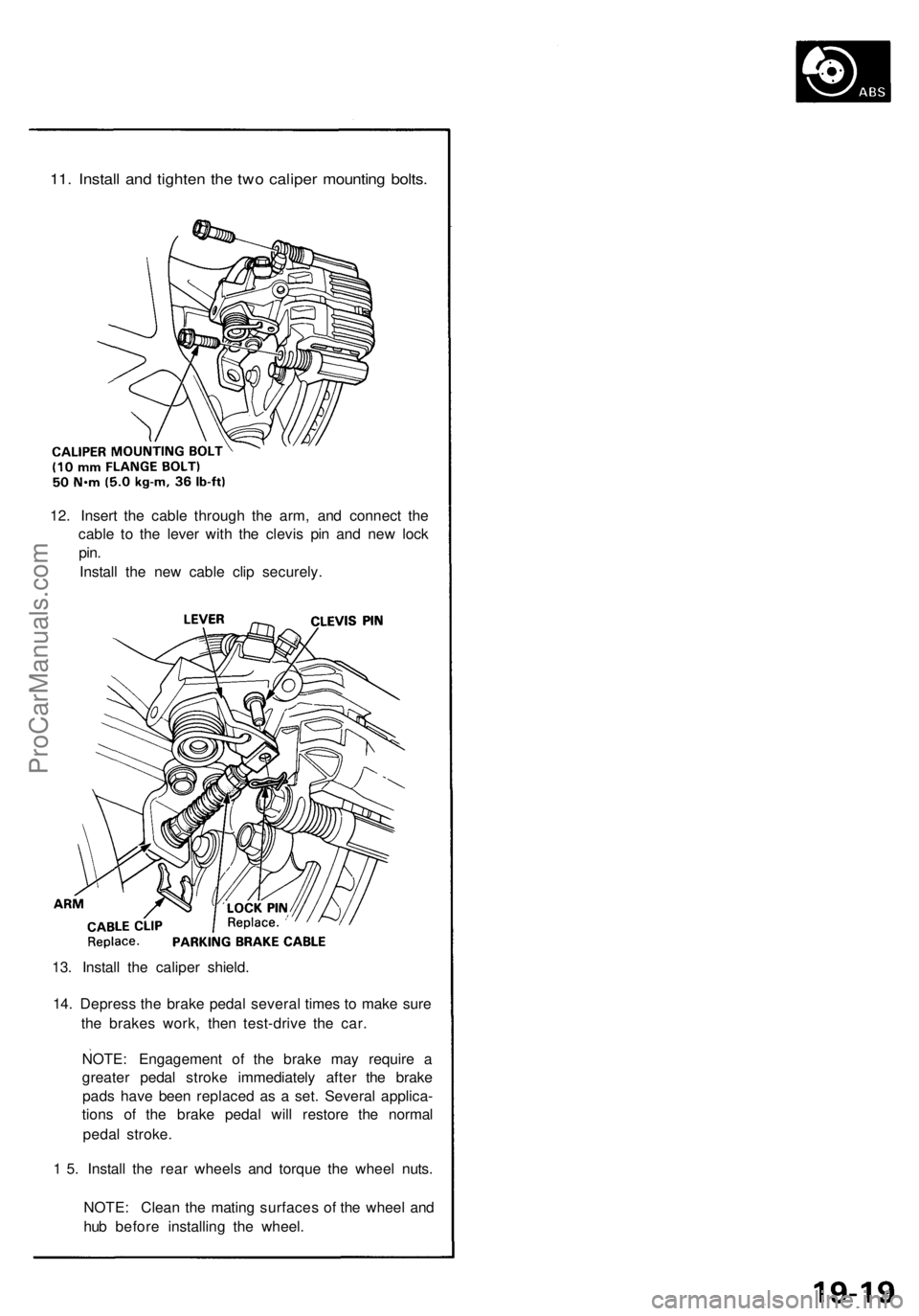

11. Install and tighten the two caliper mounting bolts.

12. Insert the cable through the arm, and connect the

cable to the lever with the clevis pin and new lock

pin.

Install the new cable clip securely.

13. Install the caliper shield.

14. Depress the brake pedal several times to make sure

the brakes work, then test-drive the car.

NOTE: Engagement of the brake may require a

greater pedal stroke immediately after the brake

pads have been replaced as a set. Several applica-

tions of the brake pedal will restore the normal

pedal stroke.

1 5. Install the rear wheels and torque the wheel nuts.

NOTE: Clean the mating surfaces of the wheel and

hub before installing the wheel.ProCarManuals.com

Page 508 of 1640

Rear Brak e Dis c

Run-Ou t Inspectio n

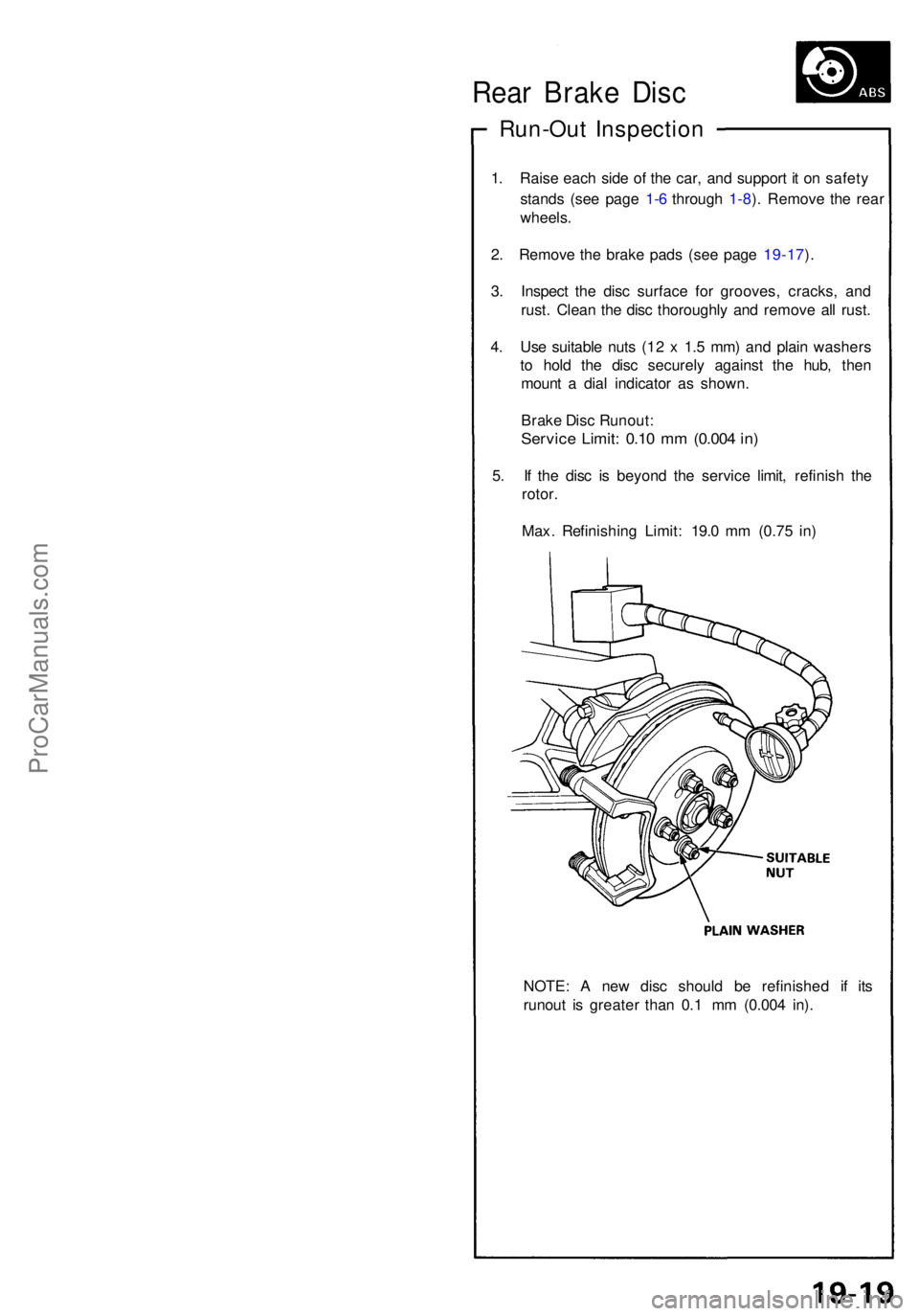

1. Rais e eac h sid e o f th e car , an d suppor t i t o n safet y

stand s (se e pag e 1- 6 throug h 1-8 ). Remov e th e rea r

wheels .

2 . Remov e th e brak e pad s (se e pag e 19-17 ).

3 . Inspec t th e dis c surfac e fo r grooves , cracks , an d

rust . Clea n th e dis c thoroughl y an d remov e al l rust .

4 . Us e suitabl e nut s (1 2 x 1. 5 mm ) an d plai n washer s

t o hol d th e dis c securel y agains t th e hub , the n

moun t a dia l indicato r a s shown .

Brak e Dis c Runout :

Service Limit : 0.1 0 m m (0.00 4 in )

5. I f th e dis c i s beyon d th e servic e limit , refinis h th e

rotor .

Max . Refinishin g Limit : 19. 0 m m (0.7 5 in )

NOTE : A ne w dis c shoul d b e refinishe d i f it s

runou t i s greate r tha n 0. 1 m m (0.00 4 in) .

ProCarManuals.com

Page 509 of 1640

Rear Calipe r

Disassembl y

• Neve r us e a n ai r hos e o r dr y brus h t o clea n brak e

assemblies .

• Us e a n OSHA-approve d vacuu m cleane r t o avoi d

breathin g brak e dust .

CAUTION :

• D o no t spil l brak e flui d o n th e car ; i t ma y damag e th e

paint ; i f brak e flui d doe s contac t th e paint , was h i t

of f immediatel y wit h water .

• T o preven t spills , cove r th e hos e joint s wit h rag s o r

sho p towels .

• Clea n al l part s i n brak e flui d an d ai r dry ; blo w ou t al l

passage s wit h compresse d air .

1 . Remov e th e calipe r shiel d (se e pag e 19-17 ).

2 . Disconnec t th e parkin g cabl e (se e pag e 19-17 ).

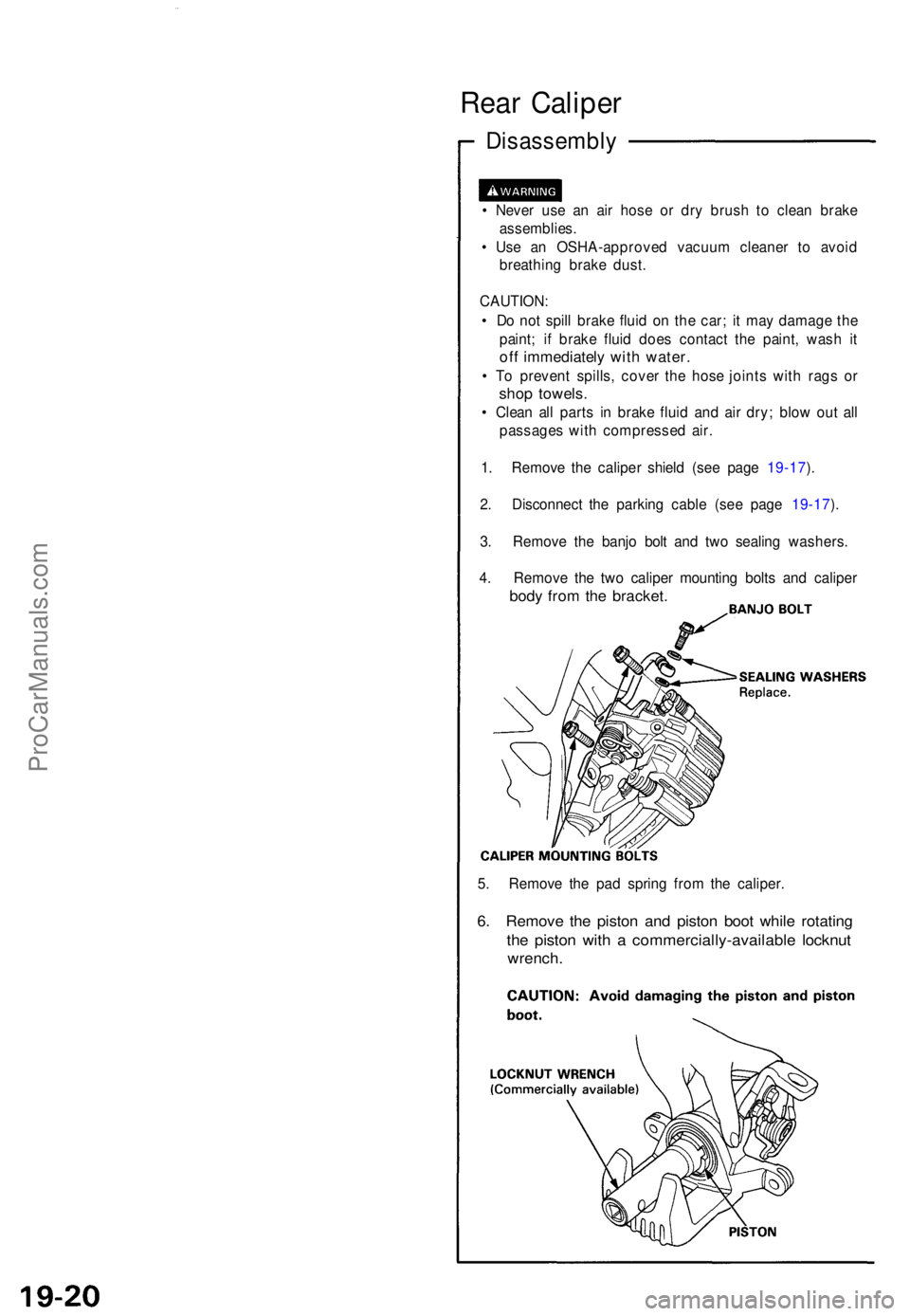

3 . Remov e th e banj o bol t an d tw o sealin g washers .

4 . Remov e th e tw o calipe r mountin g bolt s an d calipe r

body fro m th e bracket .

5. Remov e th e pa d sprin g fro m th e caliper .

6. Remov e th e pisto n an d pisto n boo t whil e rotatin g

the pisto n wit h a commercially-availabl e locknu t

wrench .

ProCarManuals.com

Page 510 of 1640

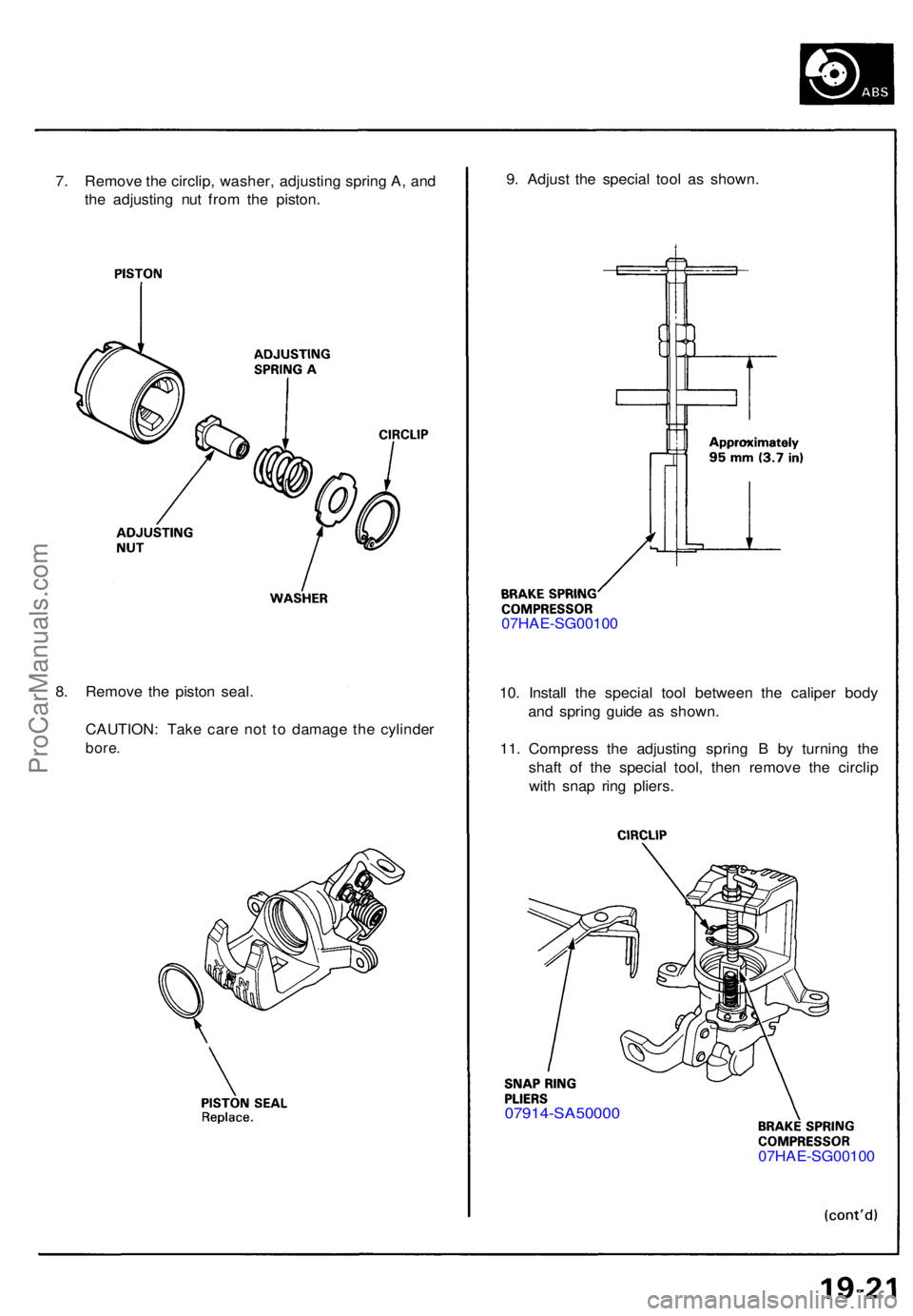

7. Remov e th e circlip , washer , adjustin g sprin g A , an d

th e adjustin g nu t fro m th e piston . 9

. Adjus t th e specia l too l a s shown .

07HAE-SG0010 0

10 . Instal l th e specia l too l betwee n th e calipe r bod y

an d sprin g guid e a s shown .

11 . Compres s th e adjustin g sprin g B by turnin g th e

shaf t o f th e specia l tool , the n remov e th e circli p

wit h sna p rin g pliers .

07914-SA5000 0

07HAE-SG0010 0

8

. Remov e th e pisto n seal .

CAUTION : Tak e car e no t t o damag e th e cylinde r

bore.

ProCarManuals.com