ACURA NSX 1991 Service Repair Manual

Manufacturer: ACURA, Model Year: 1991, Model line: NSX, Model: ACURA NSX 1991Pages: 1640, PDF Size: 60.48 MB

Page 491 of 1640

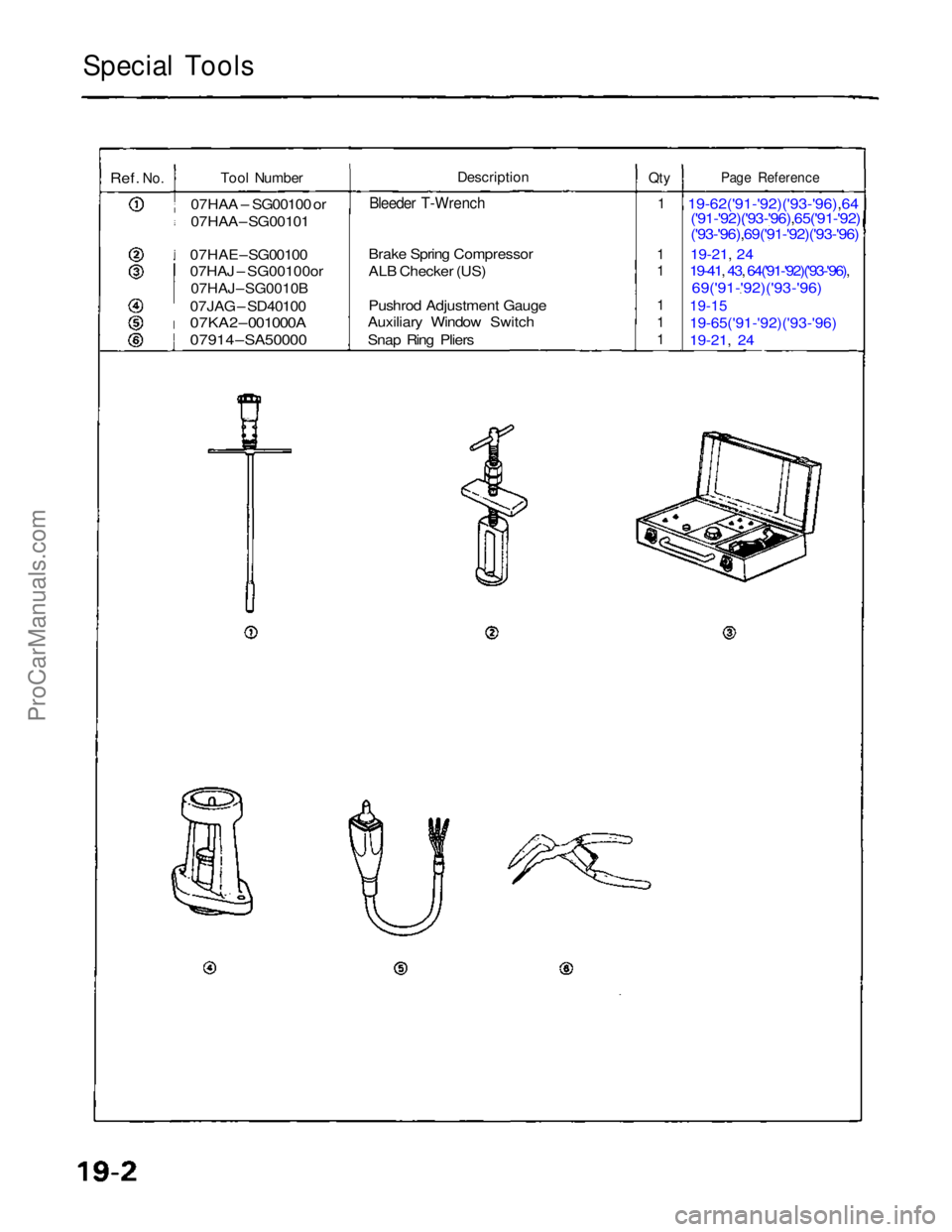

Special Tools

Ref.

No.

Tool Number

07HAA – SG00100 or

07HAA – SG00101

07HAE – SG00100

07HAJ – SG00100or

07HAJ – SG0010B

07JAG – SD40100

07KA2 – 001000A

07914 – SA50000

Description

Bleeder T-Wrench

Brake Spring Compressor

ALB Checker (US)

Pushrod Adjustment Gauge

Auxiliary Window Switch

Snap Ring Pliers

Qty

1

1

1

1

1

1

Page Reference

19-62('91-'92)('93-'96),64('91-'92)('93-'96),65('91-'92)

('93-'96),69('91-'92)('93-'96)

19-21, 24

19-41, 43, 64('91-'92)('93-'96),

69('91-'92)('93-'96)

19-15

19-65('91-'92)('93-'96)

19-21,

24

ProCarManuals.com

Page 492 of 1640

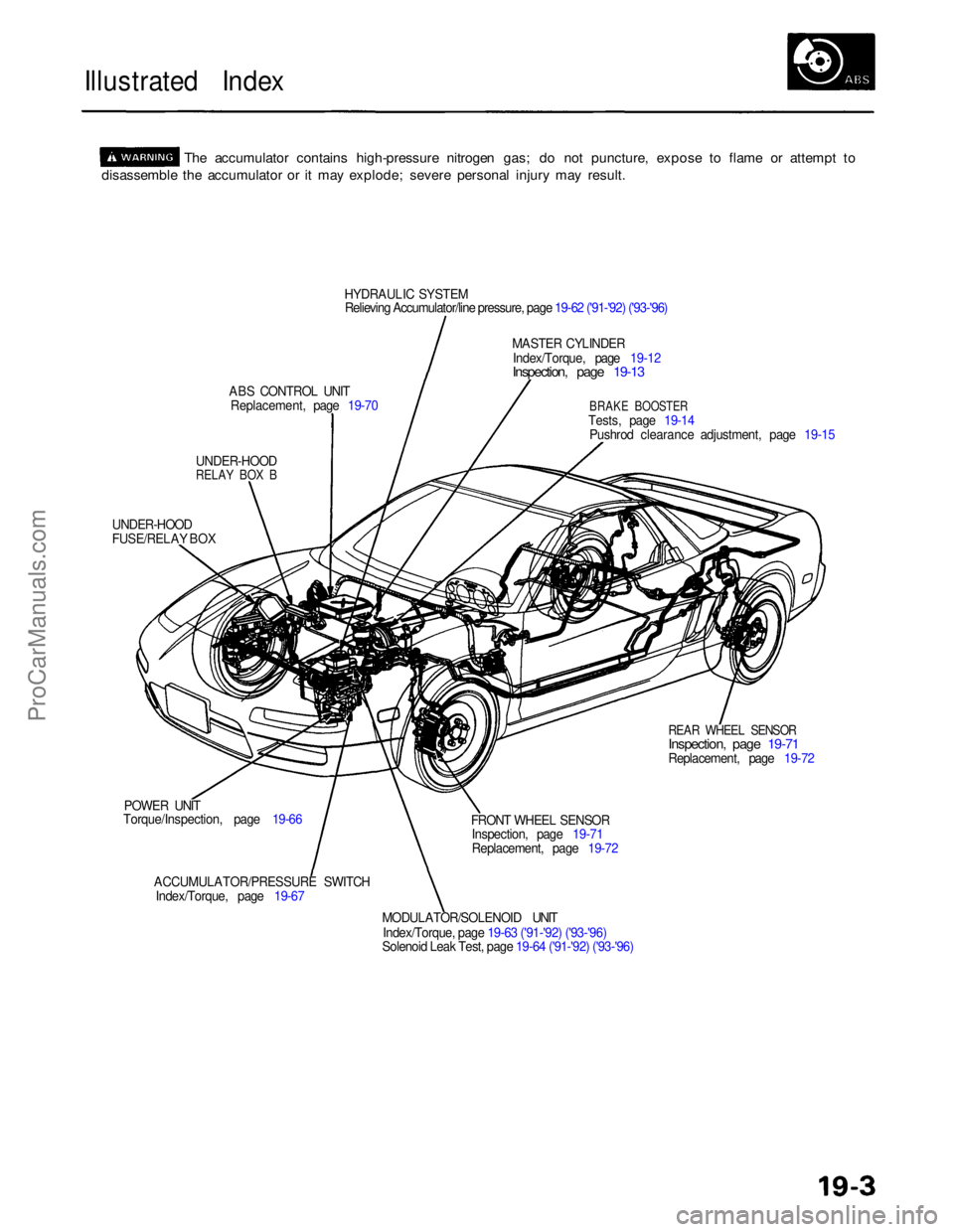

Illustrated Index

The accumulator contains high-pressure nitrogen gas; do not puncture, expose to flame or attempt to

disassemble the accumulator or it may explode; severe personal injury may result.

HYDRAULIC SYSTEM

Relieving Accumulator/line pressure, page 19-62 ('91-'92) ('93-'96)

MASTER CYLINDER

Index/Torque, page 19-12

Inspection, page 19-13

ABS CONTROL UNIT Replacement, page 19-70

BRAKE BOOSTER

Tests, page 19-14 Pushrod clearance adjustment, page 19-15

UNDER-HOOD

RELAY BOX B

UNDER-HOOD

FUSE/RELAY BOX

REAR WHEEL SENSOR

Inspection, page 19-71

Replacement, page 19-72

POWER UNIT

Torque/Inspection, page 19-66

ACCUMULATOR/PRESSURE SWITCHIndex/Torque, page 19-67 FRONT WHEEL SENSOR

Inspection, page 19-71

Replacement, page 19-72

MODULATOR/SOLENOID UNIT

Index/Torque, page 19-63 ('91-'92) ('93-'96)

Solenoid Leak Test, page 19-64 ('91-'92) ('93-'96)

ProCarManuals.com

Page 493 of 1640

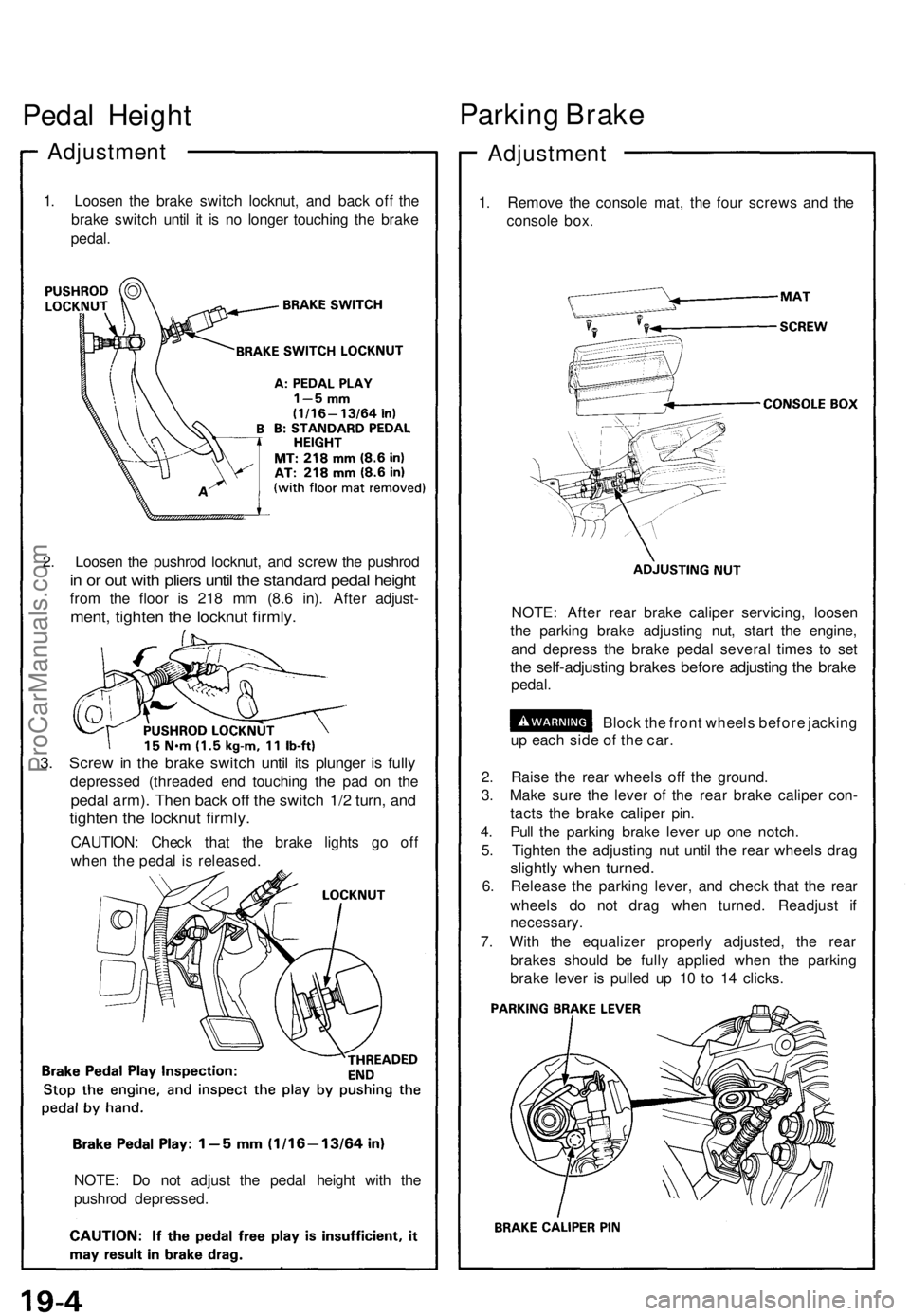

Pedal Heigh t

Adjustmen t

1. Loose n th e brak e switc h locknut , an d bac k of f th e

brak e switc h unti l i t i s n o longe r touchin g th e brak e

pedal .

2 . Loose n th e pushro d locknut , an d scre w th e pushro d

in o r ou t wit h plier s unti l th e standar d peda l heigh t

from th e floo r i s 21 8 m m (8. 6 in) . Afte r adjust -

ment, tighte n th e locknu t firmly .

3. Scre w in th e brak e switc h unti l it s plunge r i s full y

depresse d (threade d en d touchin g th e pa d o n th e

peda l arm) . The n bac k of f th e switc h 1/ 2 turn , an d

tighte n th e locknu t firmly .

CAUTION : Chec k tha t th e brak e light s g o of f

whe n th e peda l i s released .

NOTE : D o no t adjus t th e peda l heigh t wit h th e

pushro d depressed .

Parking Brak e

Adjustmen t

1. Remov e th e consol e mat , th e fou r screw s an d th e

consol e box .

NOTE : Afte r rea r brak e calipe r servicing , loose n

th e parkin g brak e adjustin g nut , star t th e engine ,

an d depres s th e brak e peda l severa l time s t o se t

the self-adjustin g brake s befor e adjustin g th e brak e

pedal .

Block th e fron t wheel s befor e jackin g

u p eac h sid e o f th e car .

2 . Rais e th e rea r wheel s of f th e ground .

3 . Mak e sur e th e leve r o f th e rea r brak e calipe r con -

tact s th e brak e calipe r pin .

4 . Pul l th e parkin g brak e leve r u p on e notch .

5 . Tighte n th e adjustin g nu t unti l th e rea r wheel s dra g

slightl y whe n turned .

6. Releas e th e parkin g lever , an d chec k tha t th e rea r

wheel s d o no t dra g whe n turned . Readjus t i f

necessary .

7. Wit h th e equalize r properl y adjusted , th e rea r

brake s shoul d b e full y applie d whe n th e parkin g

brak e leve r i s pulle d u p 1 0 t o 1 4 clicks .

ProCarManuals.com

Page 494 of 1640

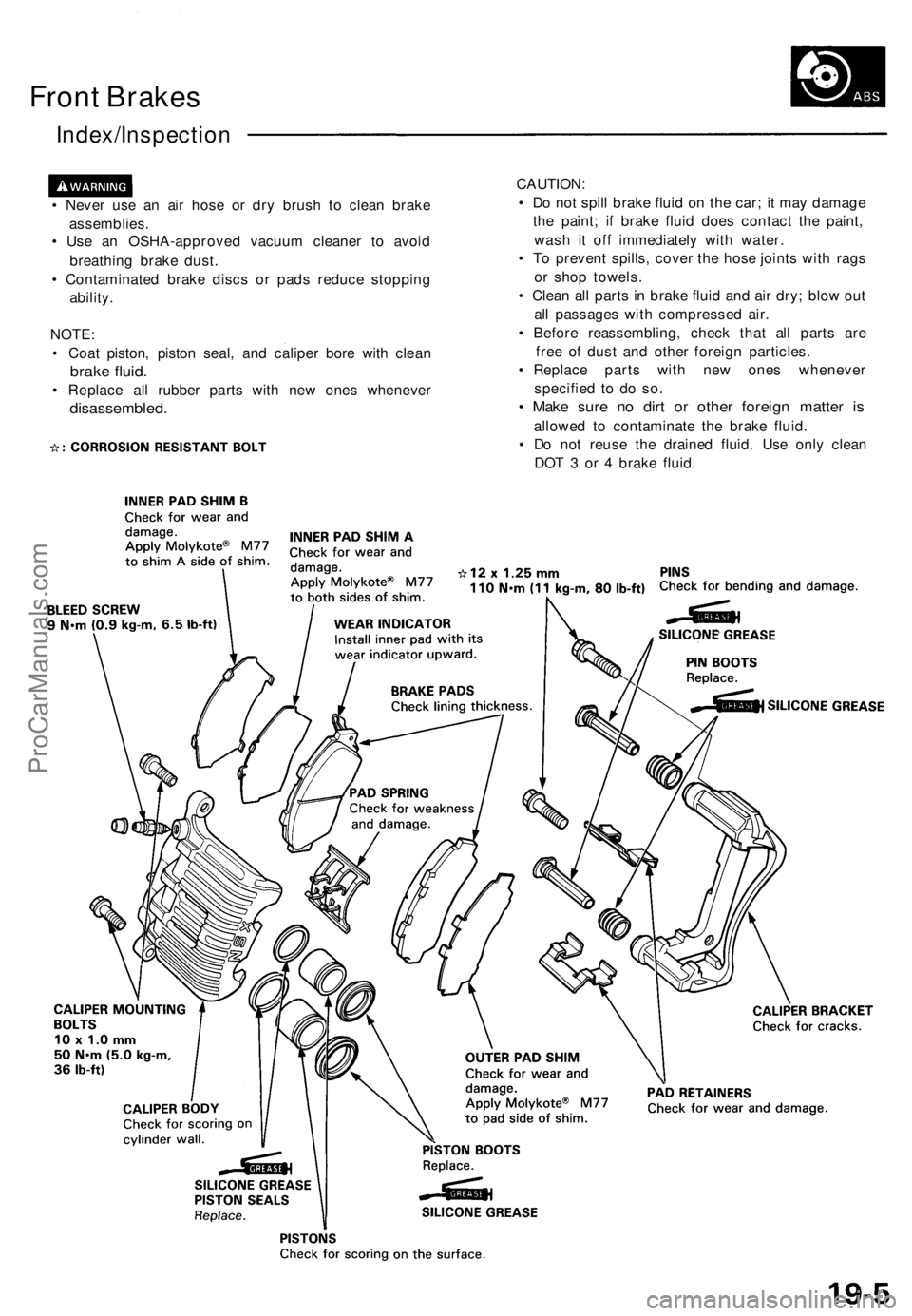

Front Brake s

Index/Inspectio n

• Neve r us e a n ai r hos e o r dr y brus h t o clea n brak e

assemblies .

• Us e a n OSHA-approve d vacuu m cleane r t o avoi d

breathin g brak e dust .

• Contaminate d brak e disc s o r pad s reduc e stoppin g

ability .

NOTE :

• Coa t piston , pisto n seal , an d calipe r bor e wit h clea n

brake fluid .

• Replac e al l rubber parts wit h ne w one s wheneve r

disassembled .

CAUTION:

• D o no t spil l brak e flui d o n th e car ; i t ma y damag e

th e paint ; i f brak e flui d doe s contac t th e paint ,

was h i t of f immediatel y wit h water .

• T o preven t spills , cove r th e hos e joint s wit h rag s

o r sho p towels .

• Clea n al l part s in brak e flui d an d ai r dry ; blo w ou t

al l passage s wit h compresse d air .

• Befor e reassembling , chec k tha t al l part s ar e

fre e o f dus t an d othe r foreig n particles .

• Replac e part s wit h ne w one s wheneve r

specifie d t o d o so .

• Mak e sur e n o dir t o r othe r foreig n matte r i s

allowe d t o contaminat e th e brak e fluid .

• D o no t reus e th e draine d fluid . Us e onl y clea n

DO T 3 o r 4 brak e fluid .

ProCarManuals.com

Page 495 of 1640

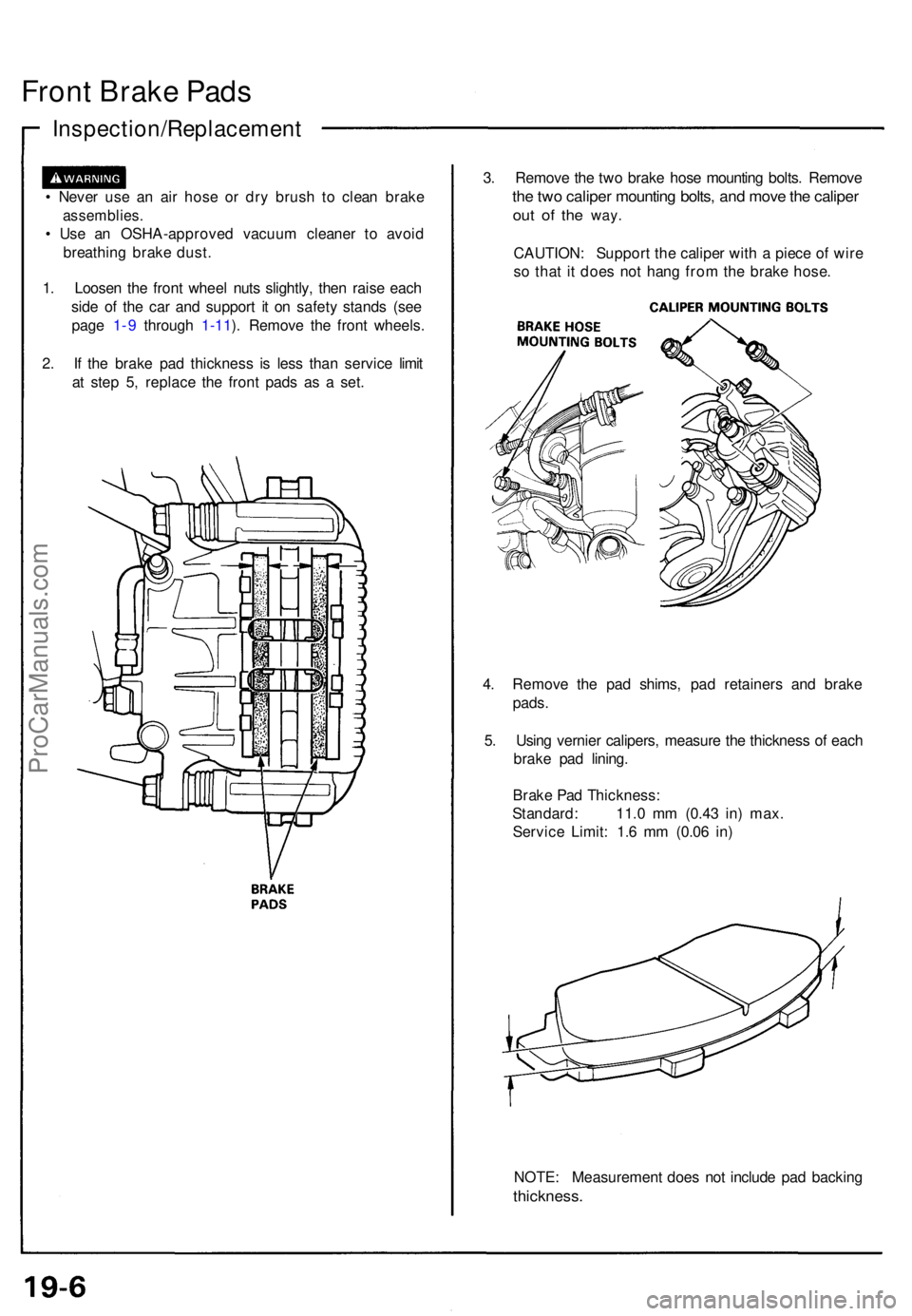

Front Brak e Pad s

Inspection/Replacemen t

• Neve r us e a n ai r hos e o r dr y brus h t o clea n brak e

assemblies .

• Us e a n OSHA-approve d vacuu m cleane r t o avoi d

breathin g brak e dust .

1 . Loose n th e fron t whee l nut s slightly , the n rais e eac h

sid e o f th e ca r an d suppor t i t o n safet y stand s (se e

pag e 1-9 throug h 1-11 ). Remov e th e fron t wheels .

2 . I f th e brak e pa d thicknes s i s les s tha n servic e limi t

a t ste p 5 , replac e th e fron t pad s a s a set . 3

. Remov e th e tw o brak e hos e mountin g bolts . Remov e

the tw o calipe r mountin g bolts , an d mov e th e calipe r

out o f th e way .

CAUTION : Suppor t th e calipe r wit h a piec e o f wir e

s o tha t i t doe s no t han g fro m th e brak e hose .

4 . Remov e th e pa d shims , pa d retainer s an d brak e

pads .

5 . Usin g vernie r calipers , measur e th e thicknes s o f eac h

brak e pa d lining .

Brak e Pa d Thickness :

Standard : 11. 0 m m (0.4 3 in ) max .

Servic e Limit : 1. 6 m m (0.0 6 in )

NOTE : Measuremen t doe s no t includ e pa d backin g

thickness .

ProCarManuals.com

Page 496 of 1640

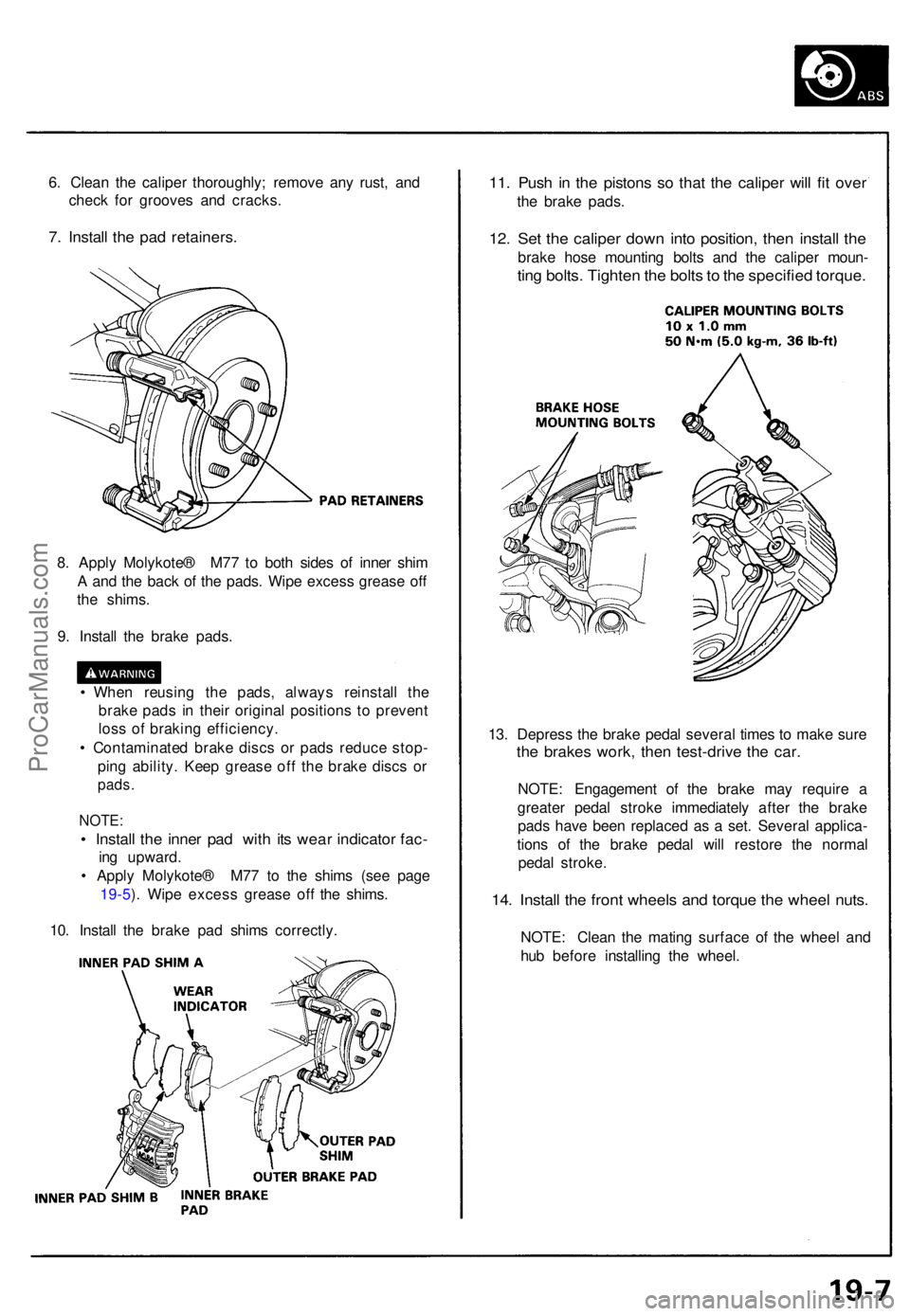

6. Clea n th e calipe r thoroughly ; remov e an y rust , an d

chec k fo r groove s an d cracks .

7. Instal l th e pa d retainers .

11. Pus h i n th e piston s s o tha t th e calipe r wil l fi t ove r

the brak e pads .

12. Se t th e calipe r dow n int o position , the n instal l th e

brak e hos e mountin g bolt s an d th e calipe r moun -

ting bolts . Tighte n th e bolt s to th e specifie d torque .

8. Appl y Molykote ® M7 7 t o bot h side s o f inne r shi m

A an d th e bac k o f th e pads . Wip e exces s greas e of f

th e shims .

9 . Instal l th e brak e pads .

• Whe n reusin g th e pads , alway s reinstal l th e

brak e pad s i n thei r origina l position s t o preven t

los s o f brakin g efficiency .

• Contaminate d brak e disc s o r pad s reduc e stop -

pin g ability . Kee p greas e of f th e brak e disc s o r

pads .

NOTE :

• Instal l th e inne r pa d wit h it s wea r indicato r fac -

ing upward .

• Appl y Molykote ® M7 7 t o th e shim s (se e pag e

19-5 ). Wip e exces s greas e of f th e shims .

10 . Instal l th e brak e pa d shim s correctly . 13

. Depres s th e brak e peda l severa l time s t o mak e sur e

the brake s work , the n test-driv e th e car .

NOTE : Engagemen t of the brak e ma y requir e a

greate r peda l strok e immediatel y afte r th e brak e

pad s hav e bee n replace d a s a set . Severa l applica -

tion s of the brak e peda l wil l restor e th e norma l

peda l stroke .

14. Instal l th e fron t wheel s an d torqu e th e whee l nuts .

NOTE : Clea n th e matin g surfac e o f th e whee l an d

hu b befor e installin g th e wheel .

ProCarManuals.com

Page 497 of 1640

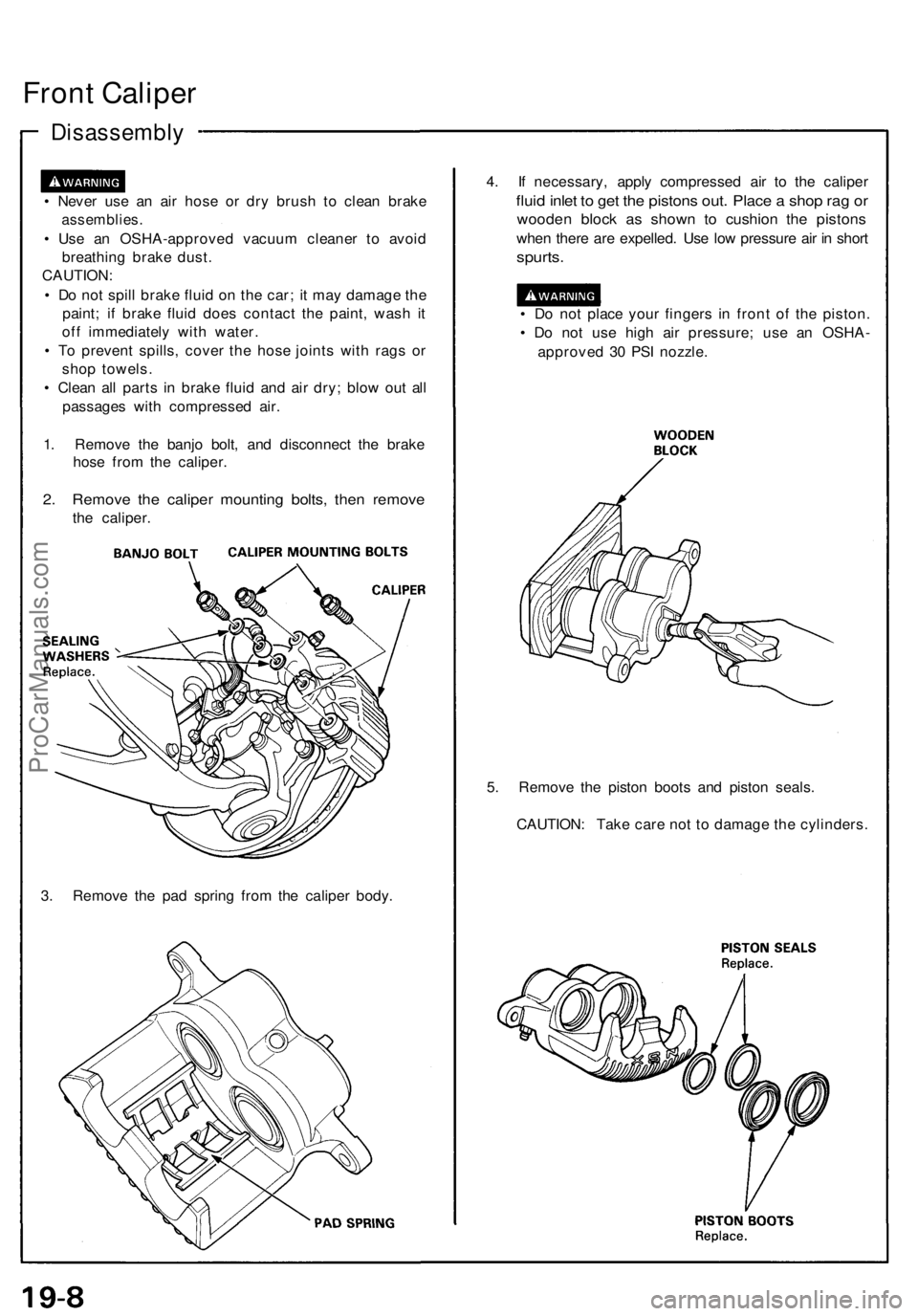

Front Calipe r

Disassembl y

• Neve r us e a n ai r hos e o r dr y brus h t o clea n brak e

assemblies .

• Us e a n OSHA-approve d vacuu m cleane r t o avoi d

breathin g brak e dust .

CAUTION :

• D o no t spil l brak e flui d o n th e car ; i t ma y damag e th e

paint ; i f brak e flui d doe s contac t th e paint , was h i t

of f immediatel y wit h water .

• T o preven t spills , cove r th e hos e joint s wit h rag s o r

sho p towels .

• Clea n al l part s i n brak e flui d an d ai r dry ; blo w ou t al l

passage s wit h compresse d air .

1 . Remov e th e banj o bolt , an d disconnec t th e brak e

hos e fro m th e caliper .

2. Remov e th e calipe r mountin g bolts , the n remov e

the caliper .

3 . Remov e th e pa d sprin g fro m th e calipe r body . 4

. I f necessary , appl y compresse d ai r t o th e calipe r

fluid inle t t o ge t th e piston s out . Plac e a sho p ra g o r

woode n bloc k a s show n t o cushio n th e piston s

when ther e ar e expelled . Us e lo w pressur e ai r i n shor t

spurts .

• D o no t plac e you r finger s i n fron t o f th e piston .

• D o no t us e hig h ai r pressure ; us e a n OSHA -

approve d 3 0 PS I nozzle .

5 . Remov e th e pisto n boot s an d pisto n seals .

CAUTION : Tak e car e no t t o damag e th e cylinders .

ProCarManuals.com

Page 498 of 1640

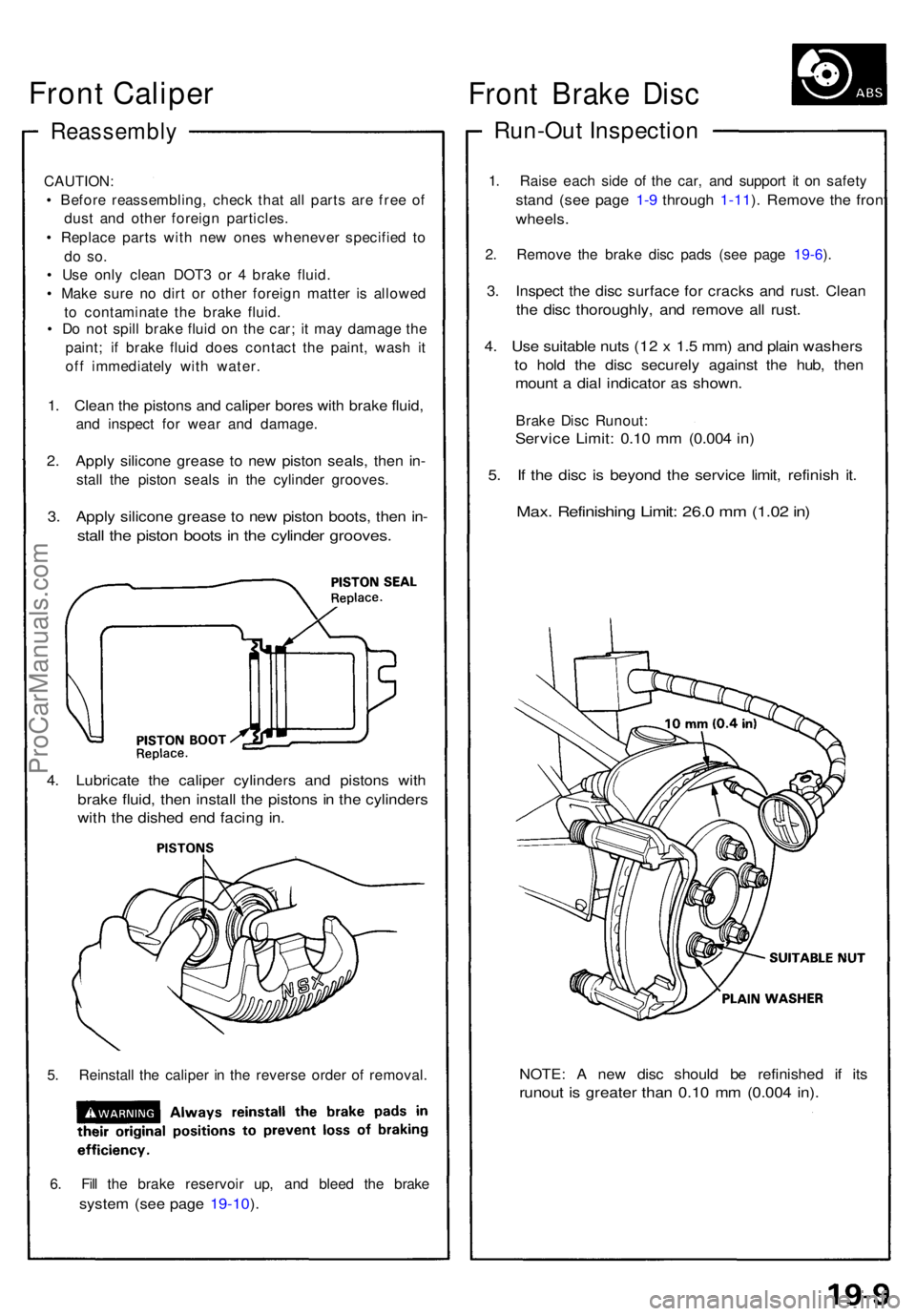

Reassembly

CAUTION:

• Befor e reassembling , chec k tha t al l part s ar e fre e o f

dus t an d othe r foreig n particles .

• Replac e part s wit h ne w one s wheneve r specifie d t o

do so .

• Us e onl y clea n DOT 3 o r 4 brak e fluid .

• Mak e sur e n o dir t o r othe r foreig n matte r i s allowe d

t o contaminat e th e brak e fluid .

• D o no t spil l brak e flui d o n th e car ; i t ma y damag e th e

paint ; i f brak e flui d doe s contac t th e paint , was h i t

of f immediatel y wit h water .

1. Clea n th e piston s an d calipe r bore s wit h brak e fluid ,

and inspec t fo r wea r an d damage .

2. Appl y silicon e greas e t o ne w pisto n seals , the n in -

stal l th e pisto n seal s i n th e cylinde r grooves .

3. Appl y silicon e greas e t o ne w pisto n boots , the n in -

stal l th e pisto n boot s in th e cylinde r grooves .

4. Lubricat e th e calipe r cylinder s an d piston s wit h

brak e fluid , the n instal l th e piston s i n th e cylinder s

with th e dishe d en d facin g in .

5. Reinstal l th e calipe r i n th e revers e orde r o f removal .

6 . Fil l th e brak e reservoi r up , an d blee d th e brak e

system (se e pag e 19-10 ).

NOTE : A ne w dis c shoul d b e refinishe d i f it s

runou t i s greate r tha n 0.1 0 m m (0.00 4 in) .

Fron t Brak e Dis c

Run-Ou t Inspectio n

1. Rais e eac h sid e o f th e car , an d suppor t i t o n safet y

stand (se e pag e 1-9 throug h 1-11 ). Remov e th e fron t

wheels .

2. Remov e th e brak e dis c pad s (se e pag e 19-6 ).

3 . Inspec t th e dis c surfac e fo r crack s an d rust . Clea n

the dis c thoroughly , an d remov e al l rust .

4. Us e suitabl e nut s (1 2 x 1. 5 mm ) an d plai n washer s

to hol d th e dis c securel y agains t th e hub , the n

moun t a dia l indicato r a s shown .

Brake Dis c Runout :

Service Limit : 0.1 0 m m (0.00 4 in )

5. I f th e dis c i s beyon d th e servic e limit , refinis h it .

Max . Refinishin g Limit : 26. 0 m m (1.0 2 in )

Front Caliper

ProCarManuals.com

Page 499 of 1640

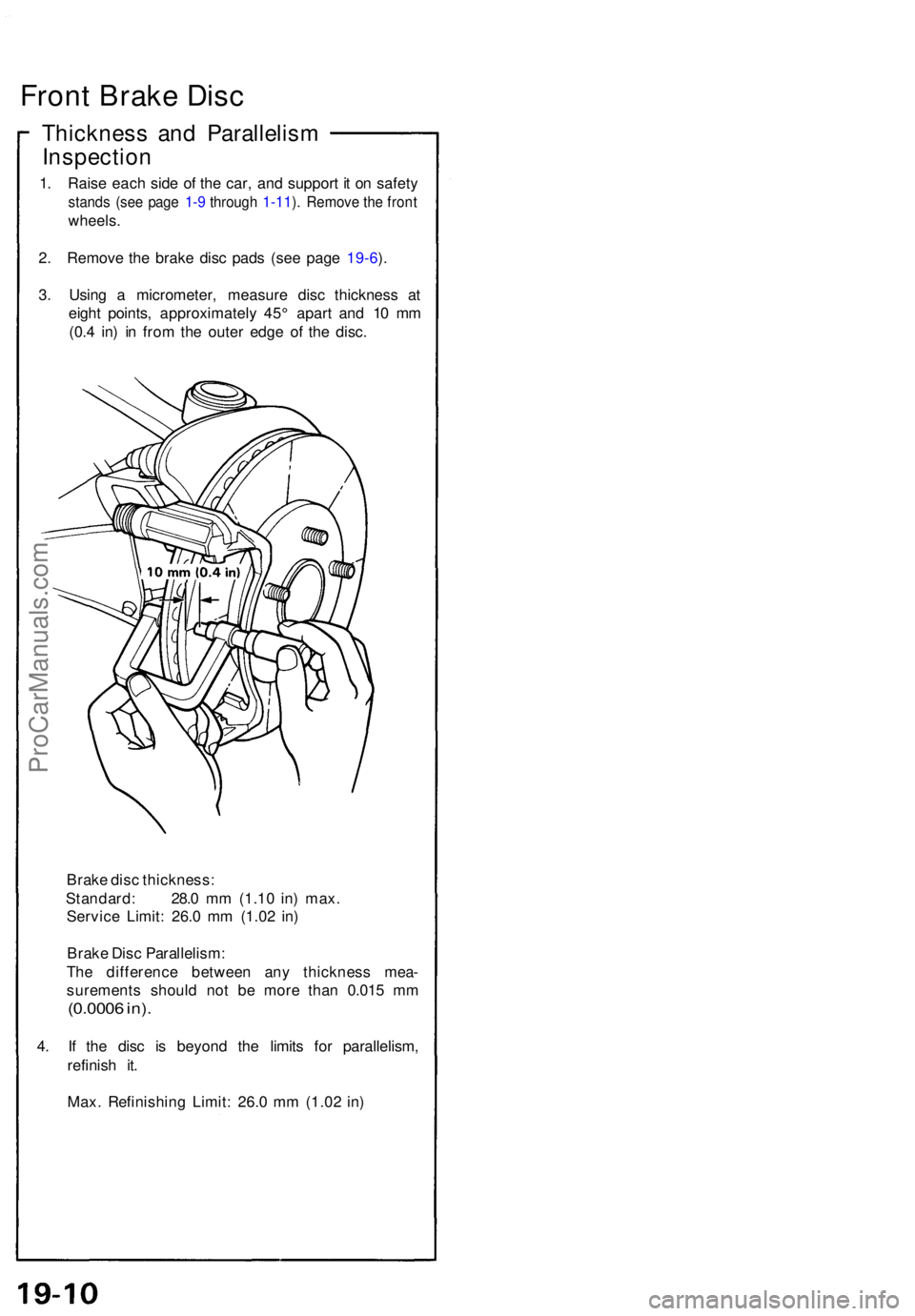

Front Brak e Dis c

Thicknes s an d Parallelis m

Inspectio n

1. Rais e eac h sid e o f th e car , an d suppor t i t o n safet y

stands (se e pag e 1-9 throug h 1-11 ). Remov e th e fron t

wheels .

2 . Remov e th e brak e dis c pad s (se e pag e 19-6 ).

3 . Usin g a micrometer , measur e dis c thicknes s a t

eigh t points , approximatel y 45 ° apar t an d 1 0 m m

(0. 4 in ) i n fro m th e oute r edg e o f th e disc .

Brak e dis c thickness :

Standard : 28. 0 m m (1.1 0 in ) max .

Servic e Limit : 26. 0 m m (1.0 2 in )

Brak e Dis c Parallelism :

Th e differenc e betwee n an y thicknes s mea -

surement s shoul d no t b e mor e tha n 0.01 5 m m

(0.000 6 in) .

4. I f th e dis c i s beyon d th e limit s fo r parallelism ,

refinis h it .

Max . Refinishin g Limit : 26.0 mm (1.0 2 in )

ProCarManuals.com

Page 500 of 1640

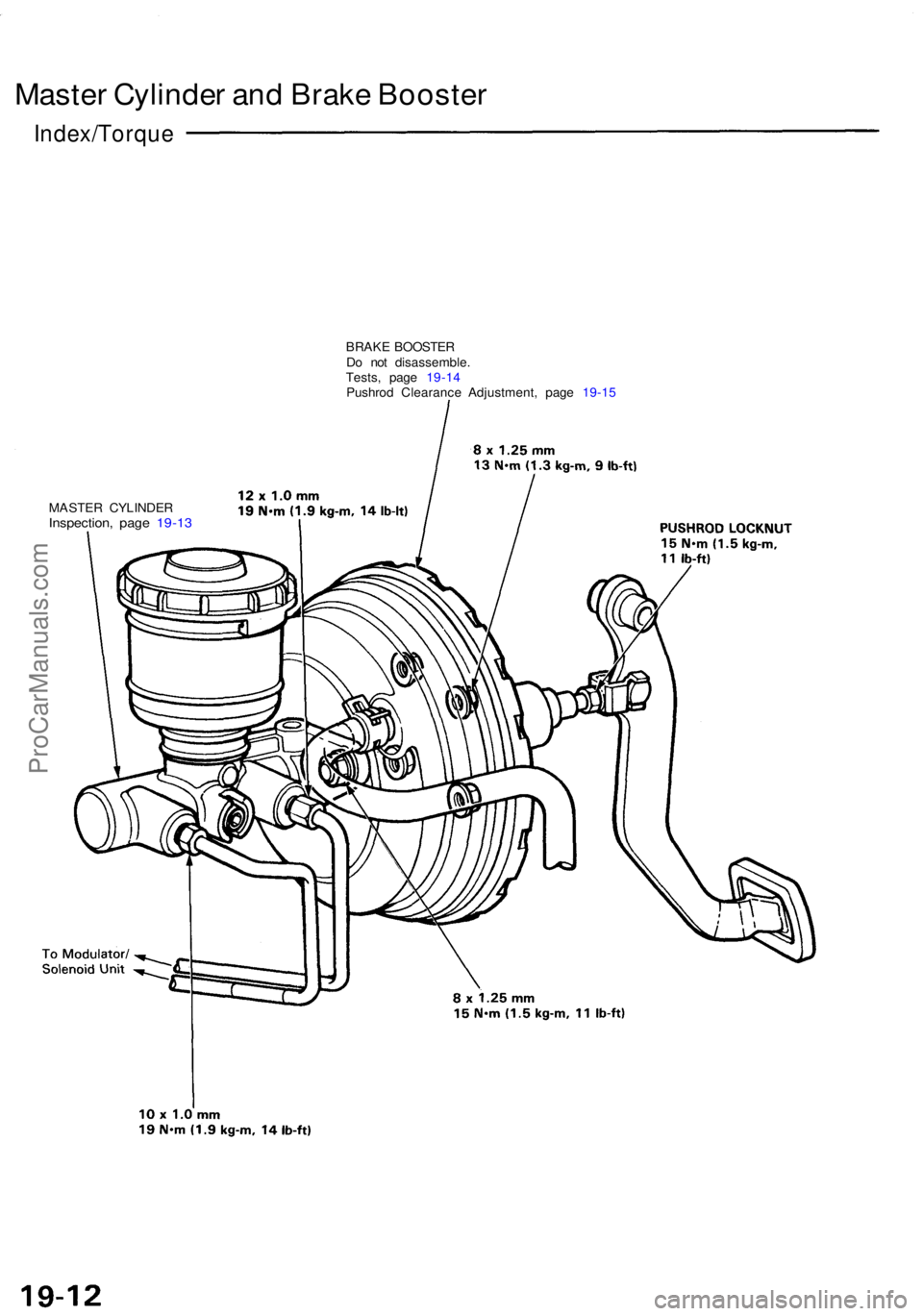

Master Cylinde r an d Brak e Booste r

Index/Torqu e

BRAKE BOOSTE R

D o no t disassemble .

Tests , pag e 19-1 4

Pushro d Clearanc e Adjustment , pag e 19-1 5

MASTE R CYLINDE R

Inspection, pag e 19-1 3

ProCarManuals.com