ACURA NSX 1991 Service Repair Manual

Manufacturer: ACURA, Model Year: 1991, Model line: NSX, Model: ACURA NSX 1991Pages: 1640, PDF Size: 60.48 MB

Page 521 of 1640

Anti-lock Brake System (ABS) Description

Features/Construction/Operation (cont'd)

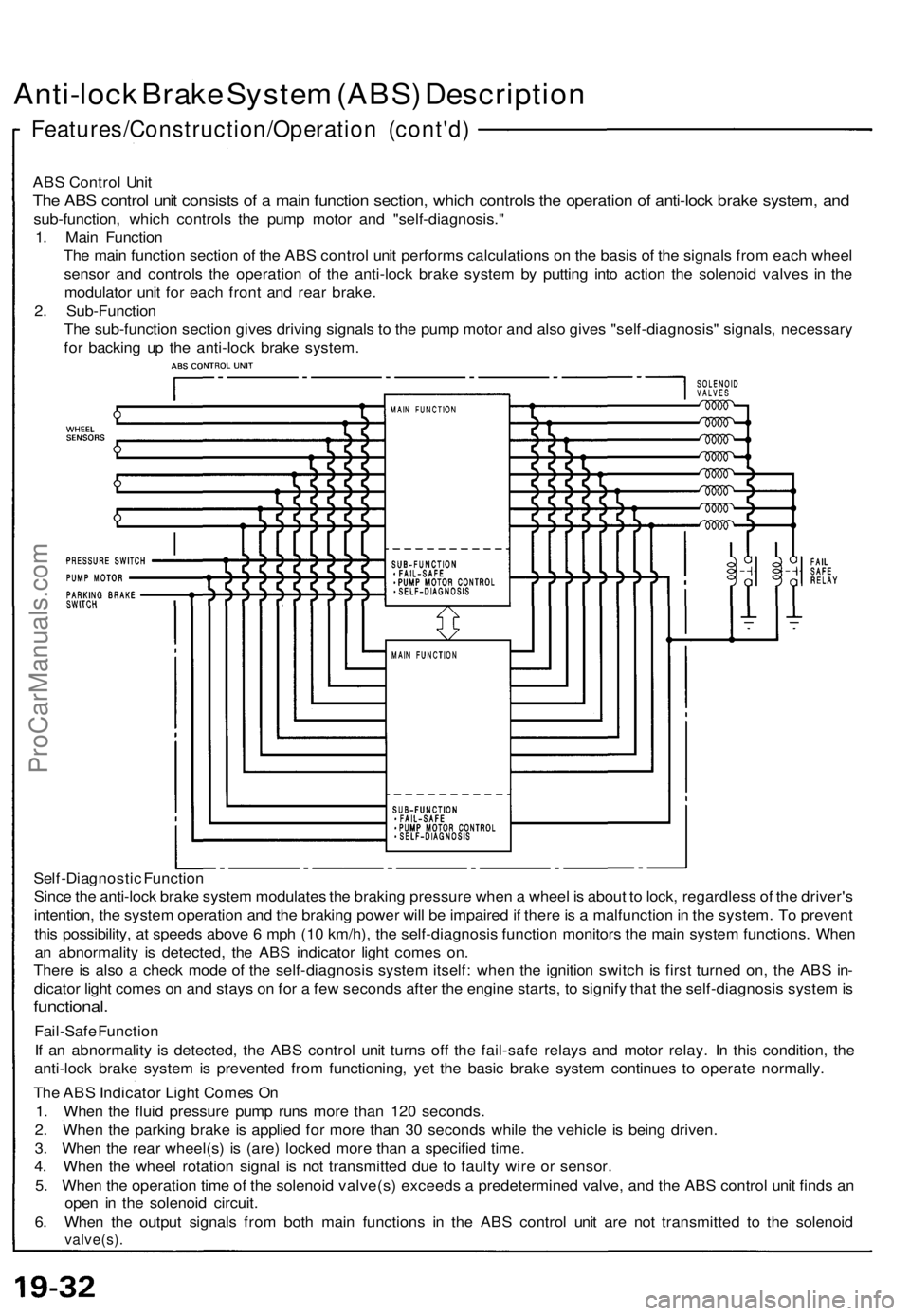

ABS Control Unit

The ABS control unit consists of a main function section, which controls the operation of anti-lock brake system, and

sub-function, which controls the pump motor and "self-diagnosis."

1. Main Function

The main function section of the ABS control unit performs calculations on the basis of the signals from each wheel

sensor and controls the operation of the anti-lock brake system by putting into action the solenoid valves in the

modulator unit for each front and rear brake.

2. Sub-Function

The sub-function section gives driving signals to the pump motor and also gives "self-diagnosis" signals, necessary

for backing up the anti-lock brake system.

Self-Diagnostic Function

Since the anti-lock brake system modulates the braking pressure when a wheel is about to lock, regardless of the driver's

intention, the system operation and the braking power will be impaired if there is a malfunction in the system. To prevent

this possibility, at speeds above 6 mph (10 km/h), the self-diagnosis function monitors the main system functions. When

an abnormality is detected, the ABS indicator light comes on.

There is also a check mode of the self-diagnosis system itself: when the ignition switch is first turned on, the ABS in-

dicator light comes on and stays on for a few seconds after the engine starts, to signify that the self-diagnosis system is

functional.

Fail-Safe Function

If an abnormality is detected, the ABS control unit turns off the fail-safe relays and motor relay. In this condition, the

anti-lock brake system is prevented from functioning, yet the basic brake system continues to operate normally.

The ABS Indicator Light Comes On

1. When the fluid pressure pump runs more than 120 seconds.

2. When the parking brake is applied for more than 30 seconds while the vehicle is being driven.

3. When the rear wheel(s) is (are) locked more than a specified time.

4. When the wheel rotation signal is not transmitted due to faulty wire or sensor.

5. When the operation time of the solenoid valve(s) exceeds a predetermined valve, and the ABS control unit finds an

open in the solenoid circuit.

6. When the output signals from both main functions in the ABS control unit are not transmitted to the solenoid

valve(s).ProCarManuals.com

Page 522 of 1640

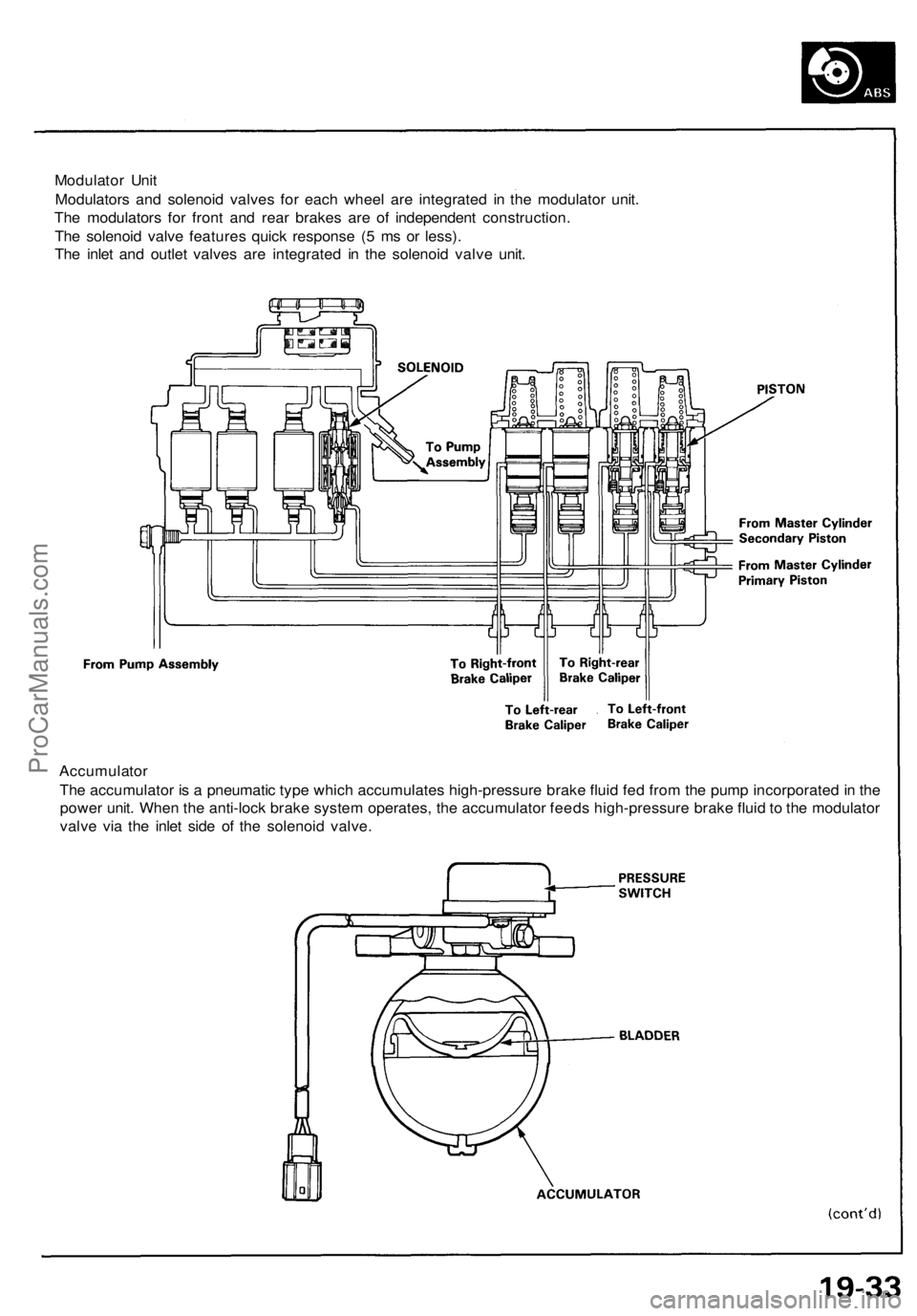

Modulator Unit

Modulators and solenoid valves for each wheel are integrated in the modulator unit.

The modulators for front and rear brakes are of independent construction.

The solenoid valve features quick response (5 ms or less).

The inlet and outlet valves are integrated in the solenoid valve unit.

Accumulator

The accumulator is a pneumatic type which accumulates high-pressure brake fluid fed from the pump incorporated in the

power unit. When the anti-lock brake system operates, the accumulator feeds high-pressure brake fluid to the modulator

valve via the inlet side of the solenoid valve.ProCarManuals.com

Page 523 of 1640

Anti-lock Brak e Syste m (ABS ) Descriptio n

Features/Construction/Operatio n (cont'd )

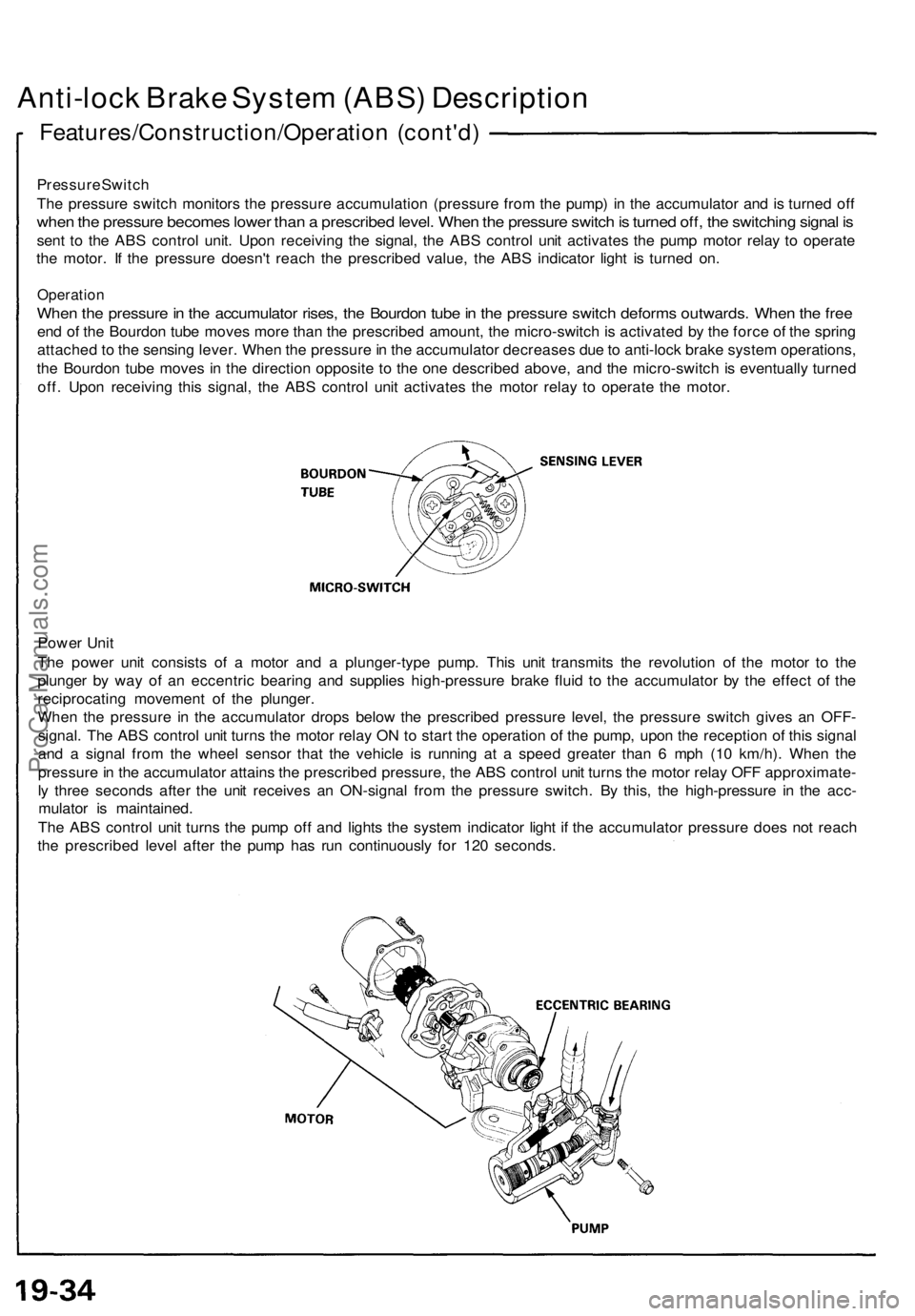

Pressur e Switc h

Th e pressur e switc h monitor s th e pressur e accumulatio n (pressur e fro m th e pump ) i n th e accumulato r an d is turne d of f

whe n th e pressur e become s lowe r tha n a prescribe d level . Whe n th e pressur e switc h is turne d off , th e switchin g signa l i s

sen t t o th e AB S contro l unit . Upo n receivin g th e signal , th e AB S contro l uni t activate s th e pum p moto r rela y t o operat e

th e motor . I f th e pressur e doesn' t reac h th e prescribe d value , th e AB S indicato r ligh t i s turne d on .

Operatio n

When th e pressur e in th e accumulato r rises , th e Bourdo n tub e in th e pressur e switc h deform s outwards . Whe n th e fre e

end o f th e Bourdo n tub e move s mor e tha n th e prescribe d amount , th e micro-switc h is activate d b y th e forc e o f th e sprin g

attache d t o th e sensin g lever . Whe n th e pressur e in th e accumulato r decrease s du e to anti-loc k brak e syste m operations ,

th e Bourdo n tub e move s i n th e directio n opposit e t o th e on e describe d above , an d th e micro-switc h is eventuall y turne d

off . Upo n receivin g thi s signal , th e AB S contro l uni t activate s th e moto r rela y t o operat e th e motor .

Powe r Uni t

Th e powe r uni t consist s o f a moto r an d a plunger-typ e pump . Thi s uni t transmit s th e revolutio n o f th e moto r t o th e

plunge r b y wa y o f a n eccentri c bearin g an d supplie s high-pressur e brak e flui d t o th e accumulato r b y th e effec t o f th e

reciprocatin g movemen t o f th e plunger .

Whe n th e pressur e i n th e accumulato r drop s belo w th e prescribe d pressur e level , th e pressur e switc h give s a n OFF -

signal . Th e AB S contro l uni t turn s th e moto r rela y O N to star t th e operatio n o f th e pump , upo n th e receptio n o f thi s signa l

an d a signa l fro m th e whee l senso r tha t th e vehicl e i s runnin g a t a spee d greate r tha n 6 mp h (1 0 km/h) . Whe n th e

pressur e in th e accumulato r attain s th e prescribe d pressure , th e AB S contro l uni t turn s th e moto r rela y OF F approximate -

l y thre e second s afte r th e uni t receive s a n ON-signa l fro m th e pressur e switch . B y this , th e high-pressur e i n th e acc -

mulato r i s maintained .

Th e AB S contro l uni t turn s th e pum p of f an d light s th e syste m indicato r ligh t i f th e accumulato r pressur e doe s no t reac h

th e prescribe d leve l afte r th e pum p ha s ru n continuousl y fo r 12 0 seconds .

ProCarManuals.com

Page 524 of 1640

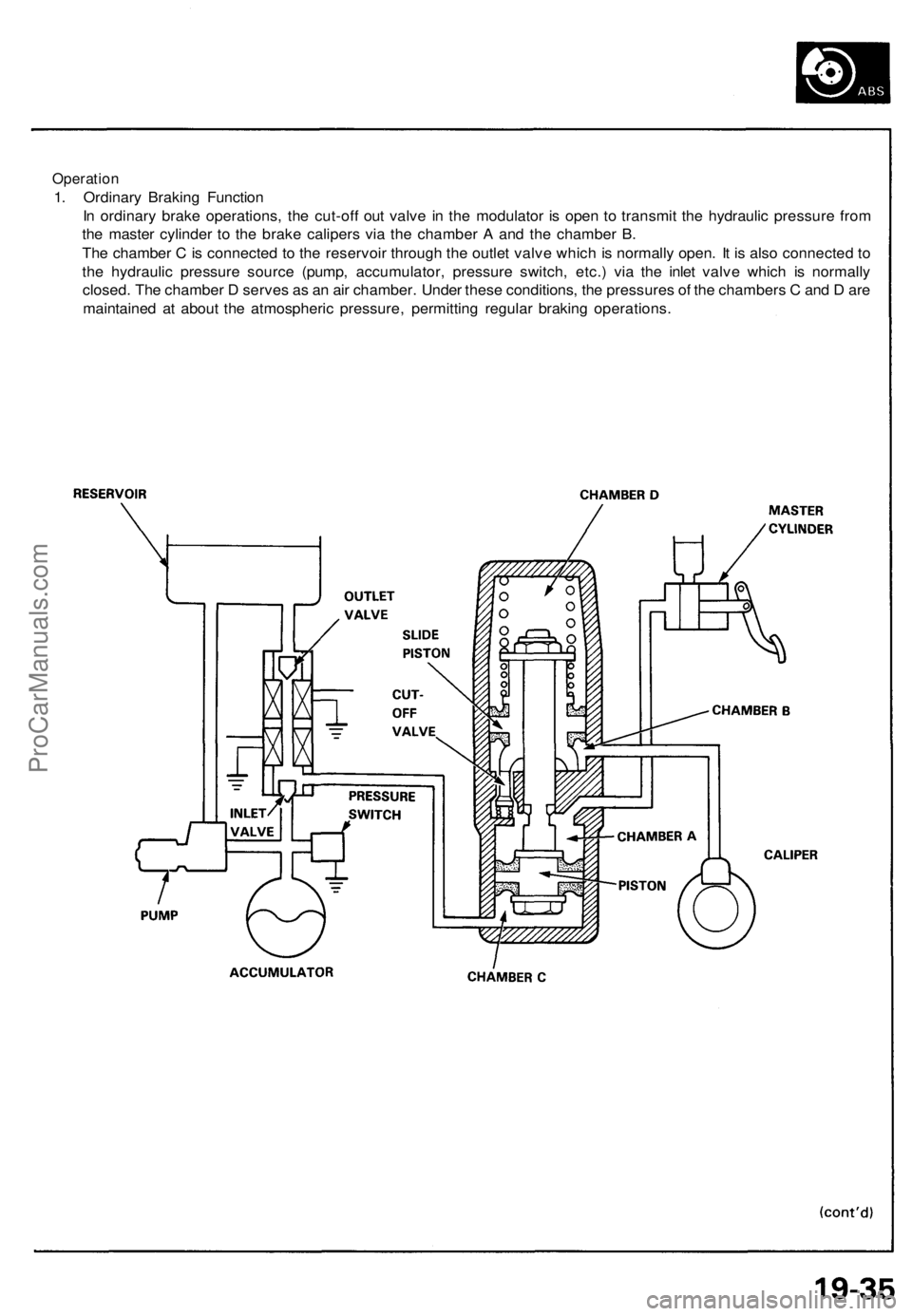

Operation

1. Ordinary Braking Function

In ordinary brake operations, the cut-off out valve in the modulator is open to transmit the hydraulic pressure from

the master cylinder to the brake calipers via the chamber A and the chamber B.

The chamber C is connected to the reservoir through the outlet valve which is normally open. It is also connected to

the hydraulic pressure source (pump, accumulator, pressure switch, etc.) via the inlet valve which is normally

closed. The chamber D serves as an air chamber. Under these conditions, the pressures of the chambers C and D are

maintained at about the atmospheric pressure, permitting regular braking operations.ProCarManuals.com

Page 525 of 1640

Anti-lock Brak e Syste m (ABS ) Descriptio n

Features/Construction/Operation (cont'd)

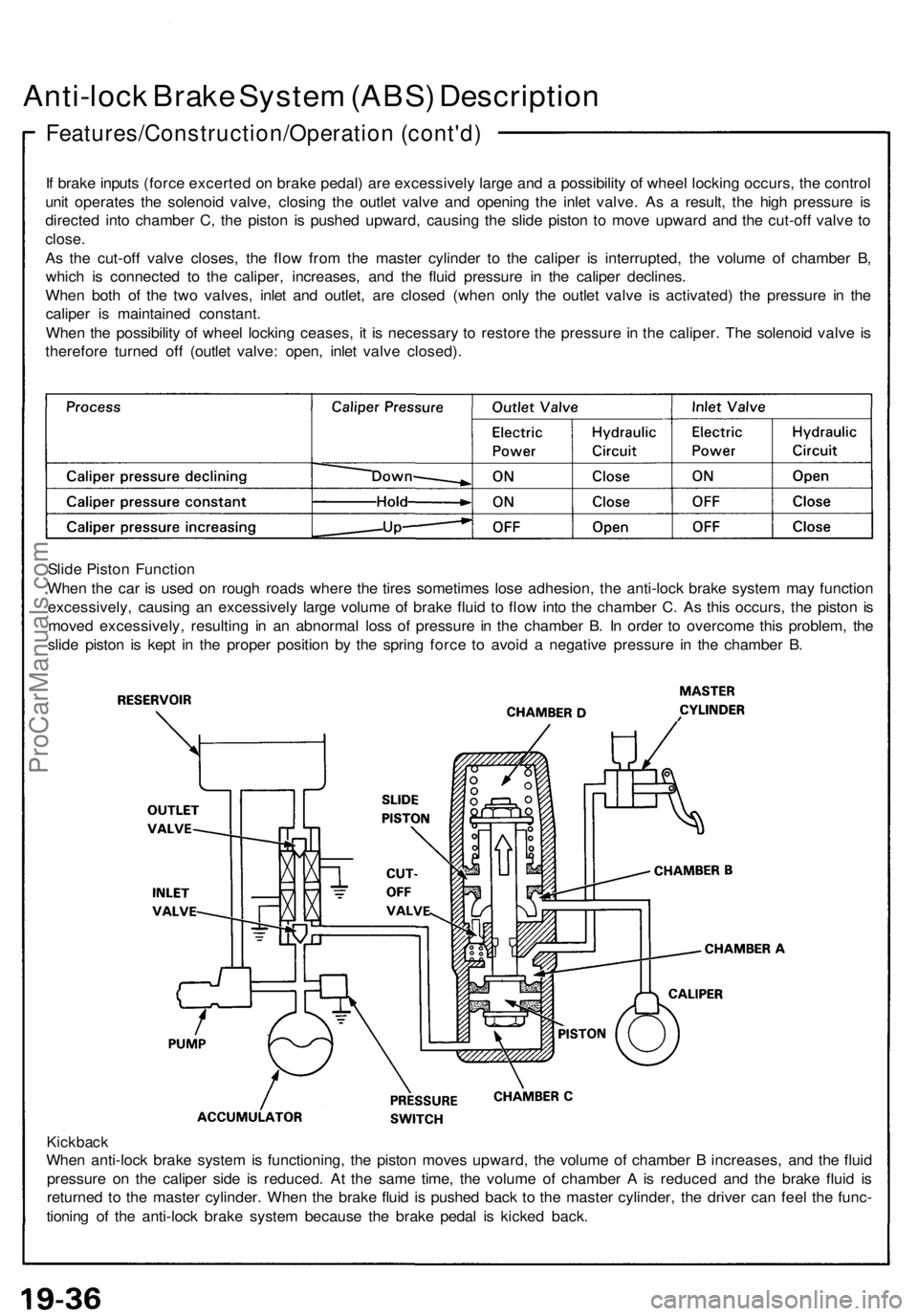

If brak e input s (forc e excerte d o n brak e pedal ) ar e excessivel y larg e an d a possibilit y o f whee l lockin g occurs , th e contro l

uni t operate s th e solenoi d valve , closin g th e outle t valv e an d openin g th e inle t valve . A s a result , th e hig h pressur e i s

directe d int o chambe r C , th e pisto n i s pushe d upward , causin g th e slid e pisto n t o mov e upwar d an d th e cut-of f valv e t o

close .

A s th e cut-of f valv e closes , th e flo w fro m th e maste r cylinde r t o th e calipe r i s interrupted , th e volum e o f chambe r B ,

whic h i s connecte d t o th e caliper , increases , an d th e flui d pressur e i n th e calipe r declines .

Whe n bot h o f th e tw o valves , inle t an d outlet , ar e close d (whe n onl y th e outle t valv e i s activated ) th e pressur e i n th e

calipe r i s maintaine d constant .

Whe n th e possibilit y o f whee l lockin g ceases , i t i s necessar y t o restor e th e pressur e in th e caliper . Th e solenoi d valv e i s

therefor e turne d of f (outle t valve : open , inle t valv e closed) .

Slid e Pisto n Functio n

Whe n th e ca r i s use d o n roug h road s wher e th e tire s sometime s los e adhesion , th e anti-loc k brak e syste m ma y functio n

excessively , causin g a n excessivel y larg e volum e o f brak e flui d t o flo w int o th e chambe r C . A s thi s occurs , th e pisto n i s

move d excessively , resultin g i n a n abnorma l los s o f pressur e in th e chambe r B . I n orde r t o overcom e thi s problem , th e

slid e pisto n i s kep t i n th e prope r positio n b y th e sprin g forc e t o avoi d a negativ e pressur e i n th e chambe r B .

Kickbac k

When anti-loc k brak e syste m is functioning , th e pisto n move s upward , th e volum e o f chambe r B increases , an d th e flui d

pressur e o n th e calipe r sid e i s reduced . A t th e sam e time , th e volum e o f chambe r A is reduce d an d th e brak e flui d i s

returne d t o th e maste r cylinder . Whe n th e brak e flui d i s pushe d bac k t o th e maste r cylinder , th e drive r ca n fee l th e func -

tionin g o f th e anti-loc k brak e syste m becaus e th e brak e peda l i s kicke d back .

ProCarManuals.com

Page 526 of 1640

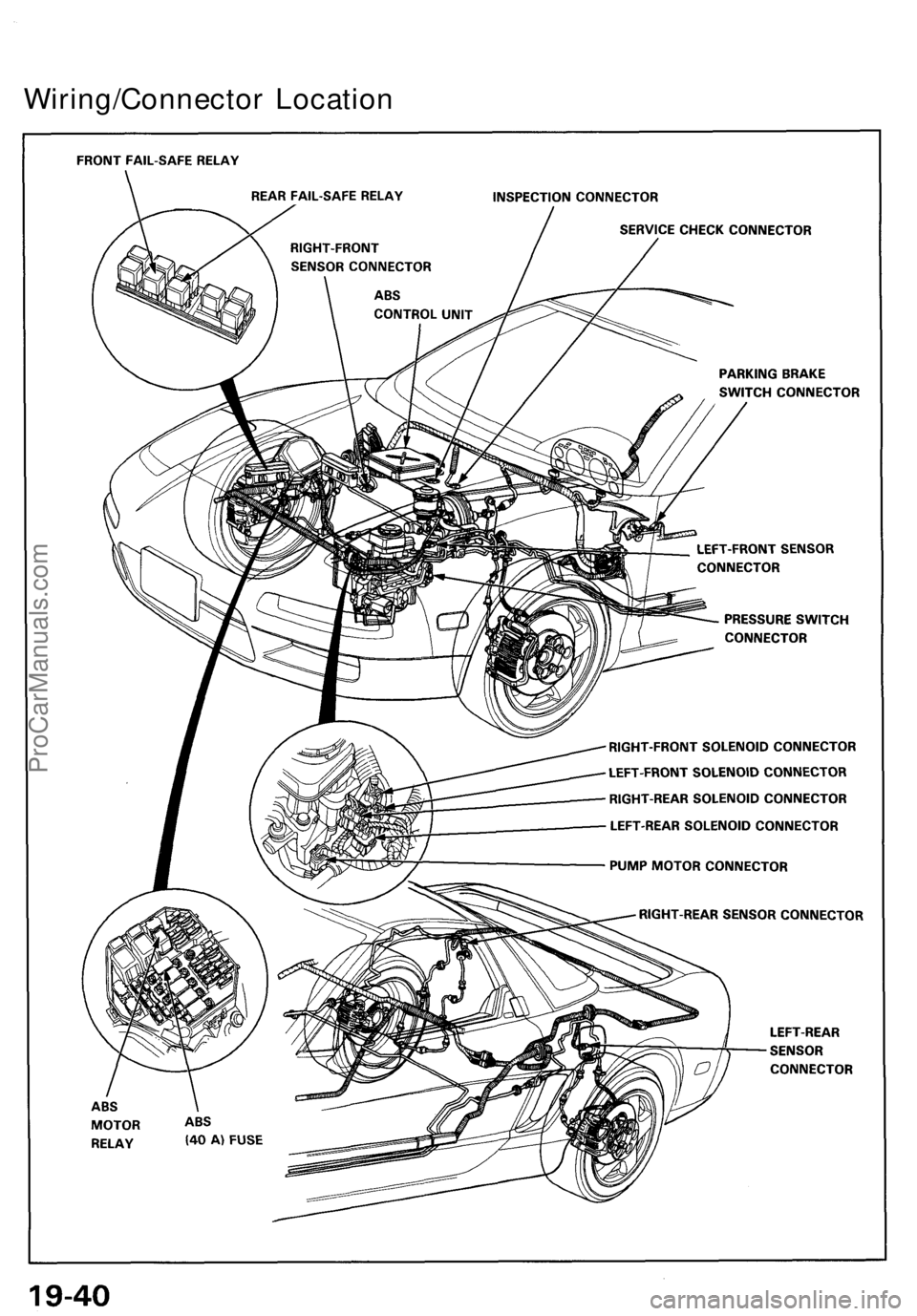

Wiring/Connector Locatio n

ProCarManuals.com

Page 527 of 1640

ALB Checke r

Function Tes t

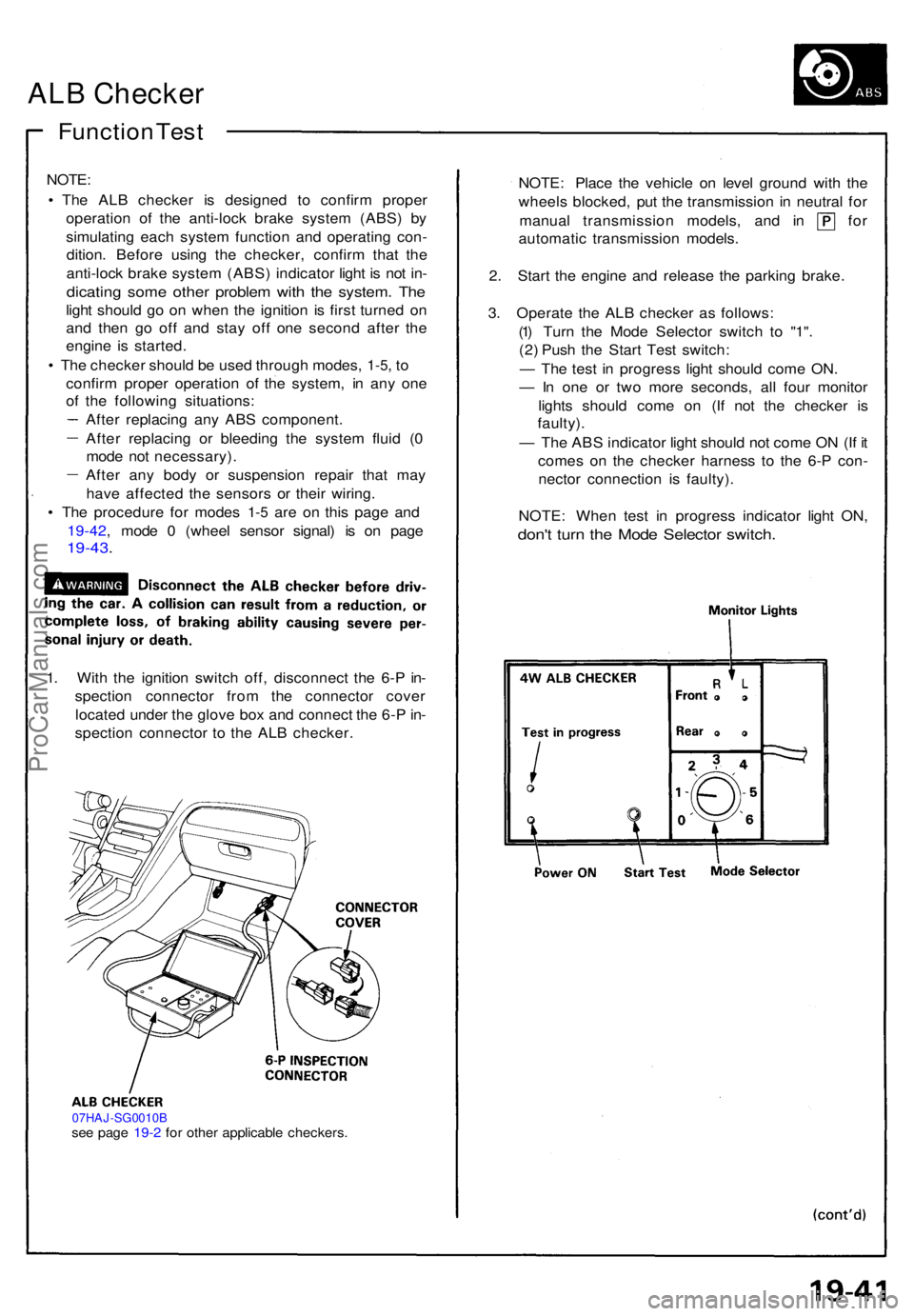

NOTE :

• Th e AL B checke r i s designe d t o confir m prope r

operatio n of the anti-loc k brak e syste m (ABS ) b y

simulatin g eac h syste m functio n an d operatin g con -

dition . Befor e usin g th e checker , confir m tha t th e

anti-loc k brak e syste m (ABS ) indicato r ligh t i s no t in -

dicatin g som e othe r proble m wit h th e system . Th e

light shoul d g o o n whe n th e ignitio n i s firs t turne d o n

an d the n g o of f an d sta y of f on e secon d afte r th e

engin e i s started .

• Th e checke r shoul d b e use d throug h modes ,

1-5, t o

confir m prope r operatio n of the system , i n an y on e

of th e followin g situations :

Afte r replacin g an y AB S component .

Afte r replacin g o r bleedin g th e syste m flui d ( 0

mod e no t necessary) .

Afte r an y bod y o r suspensio n repai r tha t ma y

hav e affecte d th e sensor s o r thei r wiring .

• Th e procedur e fo r mode s

1-5 ar e o n thi s pag e an d

19-42 , mod e 0 (whee l senso r signal ) i s o n pag e

19-43 .

1. Wit h th e ignitio n switc h off , disconnec t th e 6- P in -

spectio n connecto r fro m th e connecto r cove r

locate d unde r th e glov e bo x an d connec t th e 6- P in -

spectio n connecto r t o th e AL B checker .

07HAJ-SG0010Bsee pag e 19- 2 fo r othe r applicabl e checkers .

NOTE: Plac e th e vehicl e o n leve l ground with th e

wheel s blocked , pu t th e transmissio n i n neutra l fo r

manua l transmissio n models , an d i n fo r

automati c transmissio n models .

2 . Star t th e engin e an d releas e th e parkin g brake .

3 . Operat e th e AL B checke r a s follows :

(1 ) Tur n th e Mod e Selecto r switc h t o "1" .

(2 ) Pus h th e Star t Tes t switch :

— Th e tes t i n progres s ligh t shoul d com e ON .

— In on e o r tw o mor e seconds , al l fou r monito r

light s shoul d com e o n (I f no t th e checke r i s

faulty) .

— Th e AB S indicato r ligh t shoul d no t com e O N (I f i t

come s o n th e checke r harnes s t o th e 6- P con -

necto r connectio n i s faulty) .

NOTE : Whe n tes t i n progres s indicato r ligh t ON ,

don't tur n th e Mod e Selecto r switch .

ProCarManuals.com

Page 528 of 1640

ALB Checker

Function Test (cont'd)

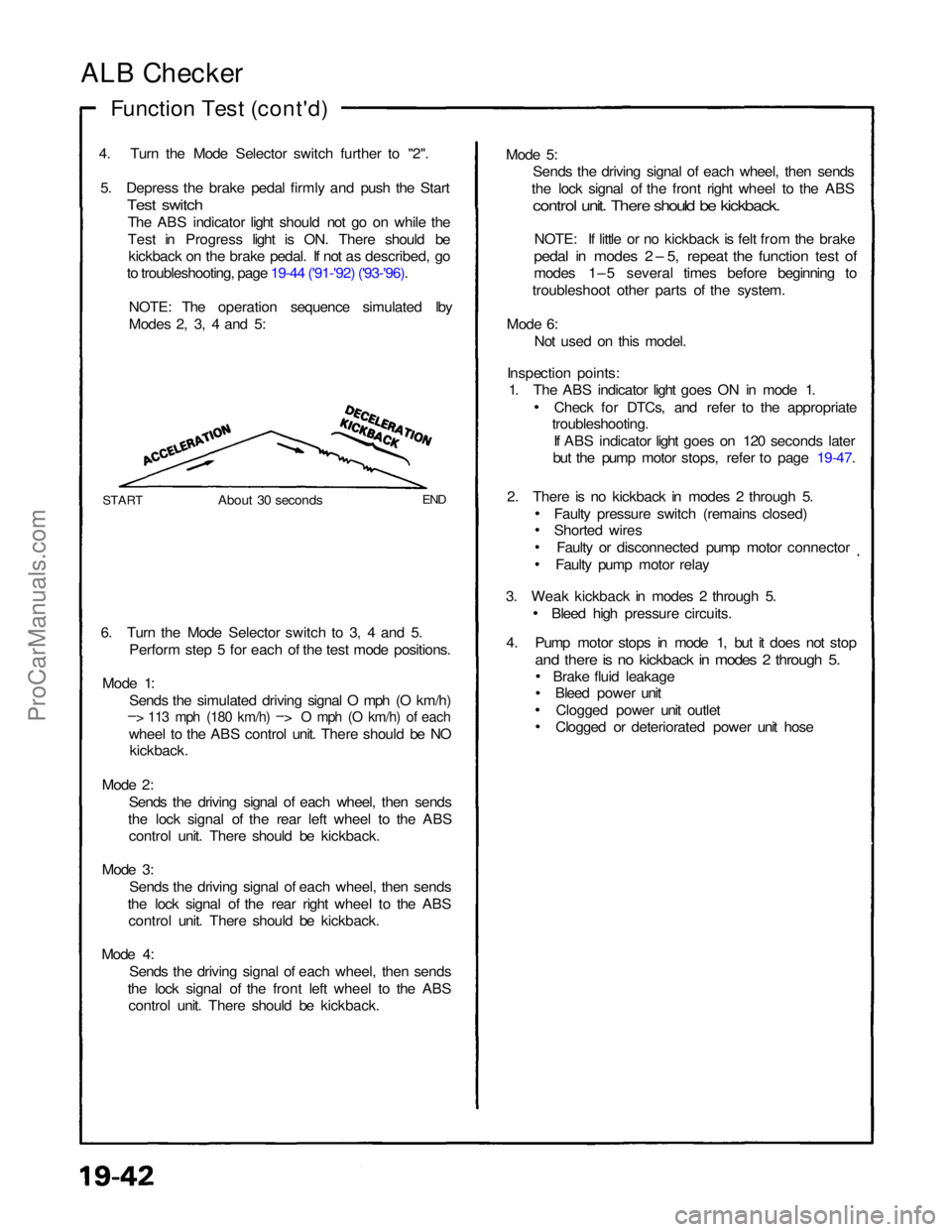

4. Turn the Mode Selector switch further to "2". 5. Depress the brake pedal firmly and push the Start

Test switch

The ABS indicator light should not go on while the

Test in Progress light is ON. There should bekickback on the brake pedal. If not as described, go

to troubleshooting, page 19-44 ('91-'92) ('93-'96).

NOTE: The operation sequence simulated lby

Modes 2, 3, 4 and 5:

START

About 30 seconds

END

6. Turn the Mode Selector switch to 3, 4 and 5. Perform step 5 for each of the test mode positions.

Mode 1: Sends the simulated driving signal O mph (O km/h)

– > 113 mph (180 km/h) –

>

O mph (O km/h) of each

wheel to the ABS control unit. There should be NO

kickback.

Mode 2: Sends the driving signal of each wheel, then sends

the lock signal of the rear left wheel to the ABS control unit. There should be kickback.

Mode 3: Sends the driving signal of each wheel, then sends

the lock signal of the rear right wheel to the ABS control unit. There should be kickback.

Mode 4: Sends the driving signal of each wheel, then sends

the lock signal of the front left wheel to the ABS control unit. There should be kickback. Mode 5:

Sends the driving signal of each wheel, then sends

the lock signal of the front right wheel to the ABS

control unit. There should be kickback.

NOTE: If little or no kickback is felt from the brake

pedal in modes 2 – 5, repeat the function test of

modes 1–5 several times before beginning to

troubleshoot other parts of the system.

Mode 6: Not used on this model.

Inspection points: 1. The ABS indicator light goes ON in mode 1.

Check for DTCs, and refer to the appropriate

troubleshooting.

If ABS indicator light goes on 120 seconds later

but the pump motor stops, refer to page 19-47.

2. There is no kickback in modes 2 through 5. Faulty pressure switch (remains closed)

Shorted wiresFaulty or disconnected pump motor connector

Faulty pump motor relay

3. Weak kickback in modes 2 through 5. Bleed high pressure circuits.

4. Pump motor stops in mode 1, but it does not stop

and there is no kickback in modes 2 through 5.

Brake fluid leakageBleed power unit

Clogged power unit outlet

Clogged or deteriorated power unit hoseProCarManuals.com

Page 529 of 1640

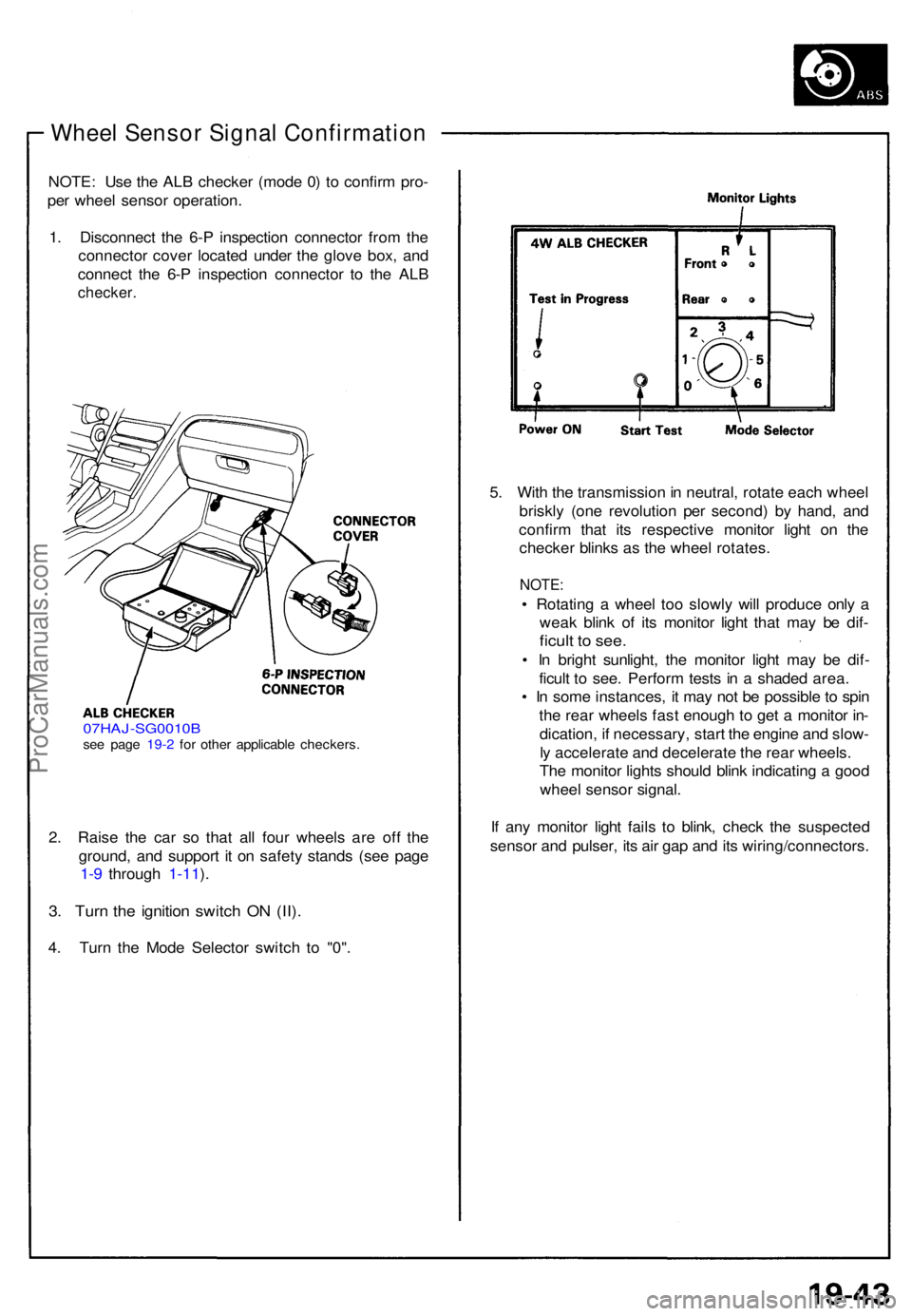

Wheel Sensor Signal Confirmation

NOTE: Us e th e AL B checke r (mod e 0 ) t o confir m pro -

pe r whee l senso r operation .

1 . Disconnec t th e 6- P inspectio n connecto r fro m th e

connecto r cove r locate d unde r th e glov e box , an d

connec t th e 6- P inspectio n connecto r t o th e AL B

checker .

07HAJ-SG0010 Bsee pag e 19- 2 fo r othe r applicabl e checkers .

2. Rais e th e ca r s o tha t al l fou r wheel s ar e of f th e

ground , an d suppor t i t o n safet y stand s (se e pag e

1-9 throug h 1-11 ).

3 . Tur n th e ignitio n switc h O N (II) .

4. Tur n th e Mod e Selecto r switc h t o "0" . 5

. Wit h th e transmissio n in neutral , rotat e eac h whee l

briskl y (on e revolutio n pe r second ) b y hand , an d

confir m tha t it s respectiv e monito r ligh t o n th e

checke r blink s a s th e whee l rotates .

NOTE:

• Rotatin g a whee l to o slowl y wil l produc e onl y a

wea k blin k o f it s monito r ligh t tha t ma y b e dif -

ficul t t o see .

• I n brigh t sunlight , th e monito r ligh t ma y b e dif -

ficul t t o see . Perfor m test s i n a shade d area .

• I n som e instances , i t ma y no t b e possibl e to spi n

th e rea r wheel s fas t enoug h t o ge t a monito r in -

dication , i f necessary , star t th e engin e an d slow -

l y accelerat e an d decelerat e th e rea r wheels .

Th e monito r light s shoul d blin k indicatin g a goo d

whee l senso r signal .

I f an y monito r ligh t fail s t o blink , chec k th e suspecte d

senso r an d pulser , it s ai r ga p an d it s wiring/connectors .

ProCarManuals.com

Page 530 of 1640

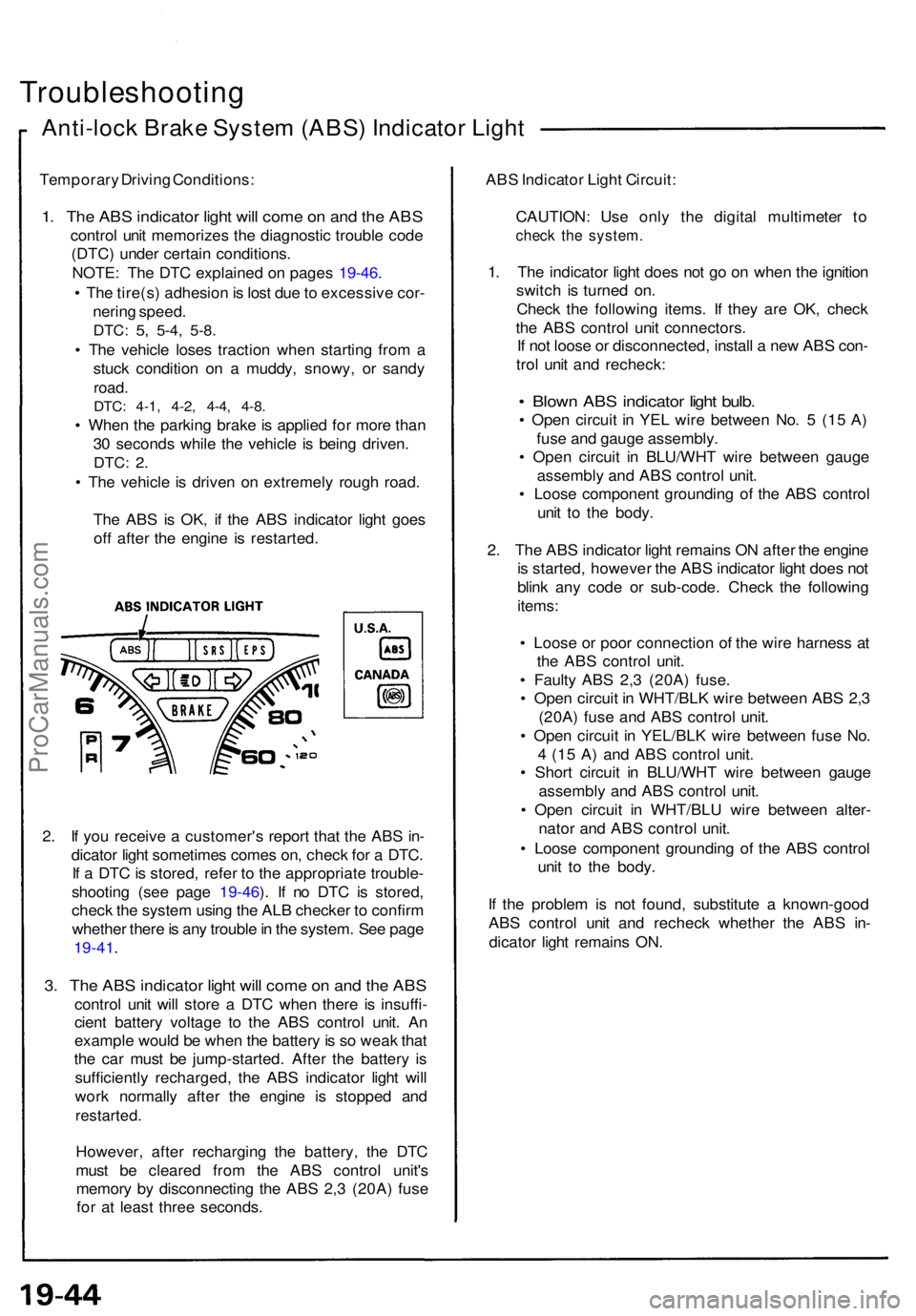

Troubleshooting

Anti-lock Brak e Syste m (ABS ) Indicato r Ligh t

Temporar y Drivin g Conditions :

1. Th e AB S indicato r ligh t wil l com e o n an d th e AB S

contro l uni t memorize s th e diagnosti c troubl e cod e

(DTC ) unde r certai n conditions .

NOTE : Th e DT C explaine d o n page s 19-46 .

• Th e tire(s ) adhesio n is los t du e to excessiv e cor -

nerin g speed .

DTC: 5, 5-4 , 5-8 .

• Th e vehicl e lose s tractio n whe n startin g fro m a

stuc k conditio n o n a muddy , snowy , o r sand y

road.

DTC: 4-1 , 4-2 , 4-4 , 4-8 .

• Whe n th e parkin g brak e is applie d fo r mor e tha n

3 0 second s whil e th e vehicl e i s bein g driven .

DTC: 2.

• Th e vehicl e is drive n o n extremel y roug h road .

Th e AB S is OK , i f th e AB S indicato r ligh t goe s

of f afte r th e engin e i s restarted .

2 . I f yo u receiv e a customer' s repor t tha t th e AB S in -

dicato r ligh t sometime s come s on , chec k fo r a DTC .

I f a DT C is stored , refe r t o th e appropriat e trouble -

shootin g (se e pag e 19-46 ). I f n o DT C is stored ,

chec k th e syste m usin g th e AL B checke r t o confir m

whethe r ther e is an y troubl e in th e system . Se e pag e

19-41 .

3. Th e AB S indicato r ligh t wil l com e o n an d th e AB S

contro l uni t wil l stor e a DT C whe n ther e i s insuffi -

cien t batter y voltag e t o th e AB S contro l unit . A n

exampl e woul d b e whe n th e batter y is s o wea k tha t

th e ca r mus t b e jump-started . Afte r th e batter y i s

sufficientl y recharged , th e AB S indicato r ligh t wil l

wor k normall y afte r th e engin e i s stoppe d an d

restarted .

However , afte r rechargin g th e battery , th e DT C

mus t b e cleare d fro m th e AB S contro l unit' s

memor y b y disconnectin g th e AB S 2, 3 (20A ) fus e

fo r a t leas t thre e seconds . AB

S Indicato r Ligh t Circuit :

CAUTION : Us e onl y th e digita l multimete r t o

chec k th e system .

1. Th e indicato r ligh t doe s no t g o o n whe n th e ignitio n

switc h i s turne d on .

Chec k th e followin g items . I f the y ar e OK , chec k

th e AB S contro l uni t connectors .

I f no t loos e o r disconnected , instal l a ne w AB S con -

tro l uni t an d recheck :

• Blow n AB S indicato r ligh t bulb .

• Ope n circui t i n YE L wir e betwee n No . 5 (1 5 A )

fus e an d gaug e assembly .

• Ope n circui t i n BLU/WH T wir e betwee n gaug e

assembl y an d AB S contro l unit .

• Loos e componen t groundin g of the AB S contro l

uni t t o th e body .

2 . Th e AB S indicato r ligh t remain s O N afte r th e engin e

i s started , howeve r th e AB S indicato r ligh t doe s no t

blin k an y cod e o r sub-code . Chec k th e followin g

items :

• Loos e o r poo r connectio n of the wir e harnes s a t

th e AB S contro l unit .

• Fault y AB S 2, 3 (20A ) fuse .

• Ope n circui t i n WHT/BL K wir e betwee n AB S 2, 3

(20A ) fus e an d AB S contro l unit .

• Ope n circui t i n YEL/BL K wir e betwee n fus e No .

4 (1 5 A ) an d AB S contro l unit .

• Shor t circui t i n BLU/WH T wir e betwee n gaug e

assembl y an d AB S contro l unit .

• Ope n circui t i n WHT/BL U wir e betwee n alter -

nato r an d AB S contro l unit .

• Loos e componen t groundin g o f th e AB S contro l

uni t t o th e body .

I f th e proble m is no t found , substitut e a known-goo d

AB S contro l uni t an d rechec k whethe r th e AB S in -

dicato r ligh t remain s ON .

ProCarManuals.com