ACURA NSX 1991 Service Repair Manual

Manufacturer: ACURA, Model Year: 1991, Model line: NSX, Model: ACURA NSX 1991Pages: 1640, PDF Size: 60.48 MB

Page 541 of 1640

Bleeding

Air Bleedin g wit h AL B Checke r

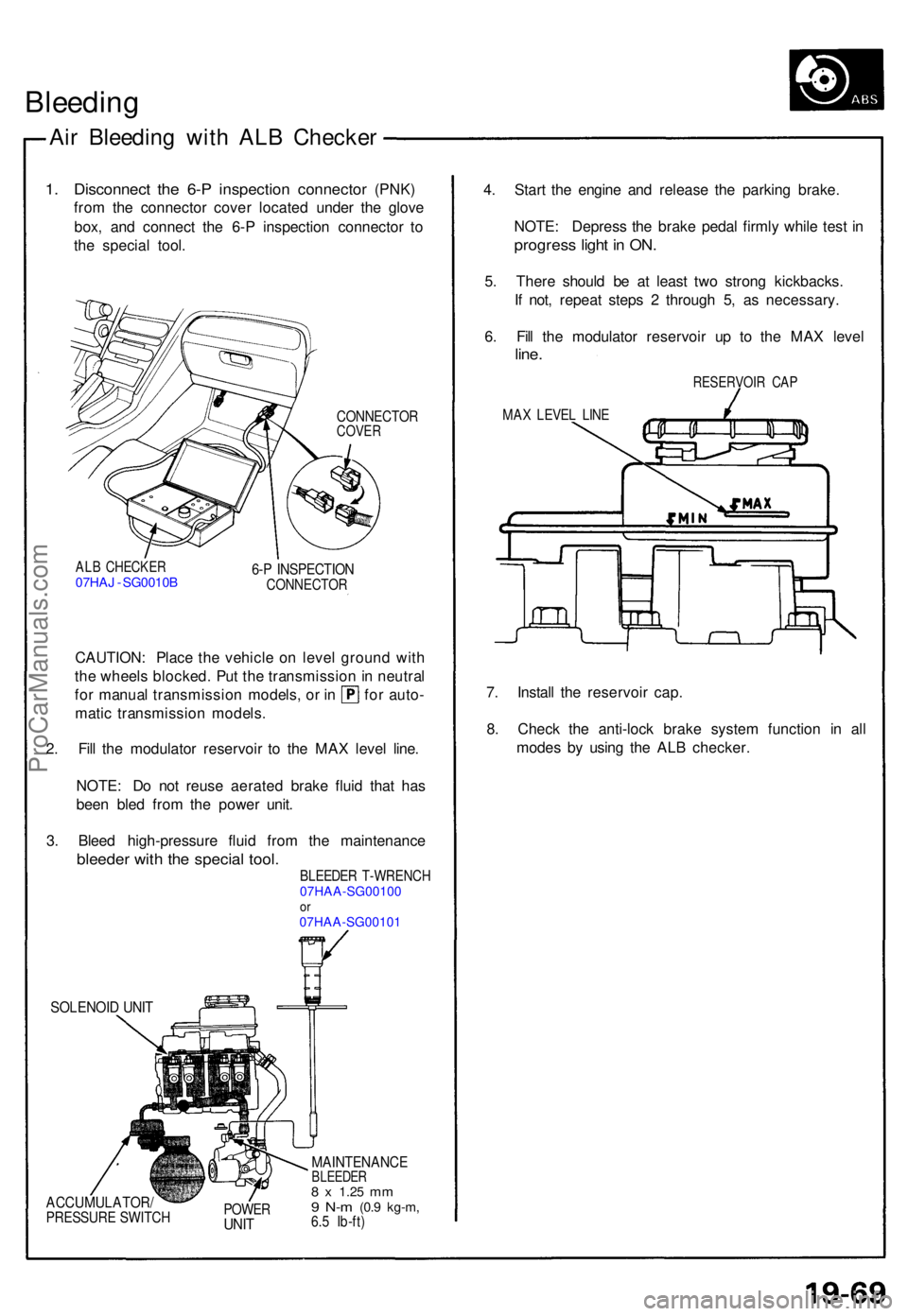

1. Disconnec t the 6- P inspection connector (PNK )

fro m th e connecto r cove r locate d unde r th e glov e

box , an d connec t th e 6- P inspectio n connecto r t o

th e specia l tool .

CONNECTO RCOVER

ALB CHECKE R07HAJ - SG0010 B 6-P INSPECTIO NCONNECTO R

CAUTION: Plac e th e vehicl e o n leve l groun d wit h

th e wheel s blocked . Pu t th e transmissio n in neutra l

for manua l transmissio n models , o r i n fo r auto -

mati c transmissio n models .

2 . Fil l th e modulato r reservoi r t o th e MA X leve l line .

NOTE : D o no t reus e aerate d brak e flui d tha t ha s

bee n ble d fro m th e powe r unit .

3 . Blee d high-pressur e flui d fro m th e maintenanc e

bleeder wit h th e specia l tool.BLEEDE R T-WRENC H07HAA-SG00100or07HAA-SG00101

SOLENOI D UNI T

ACCUMULATOR /PRESSURE SWITC HPOWERUNIT

MAINTENANC EBLEEDER8 x 1.2 5 mm9 N- m (0. 9 kg-m ,6.5 Ib-ft )

4. Star t th e engin e an d releas e th e parkin g brake .

NOTE : Depres s th e brak e peda l firml y whil e tes t i n

progres s ligh t i n ON .

5. Ther e shoul d b e a t leas t tw o stron g kickbacks .

I f not , repea t step s 2 throug h 5 , a s necessary .

6 . Fil l th e modulato r reservoi r u p t o th e MA X leve l

line.

RESERVOI R CA P

MAX LEVE L LIN E

7. Instal l th e reservoi r cap .

8 . Chec k th e anti-loc k brak e syste m functio n i n al l

mode s b y usin g th e AL B checker .

ProCarManuals.com

Page 542 of 1640

ABS Contro l Uni t

Replacemen t

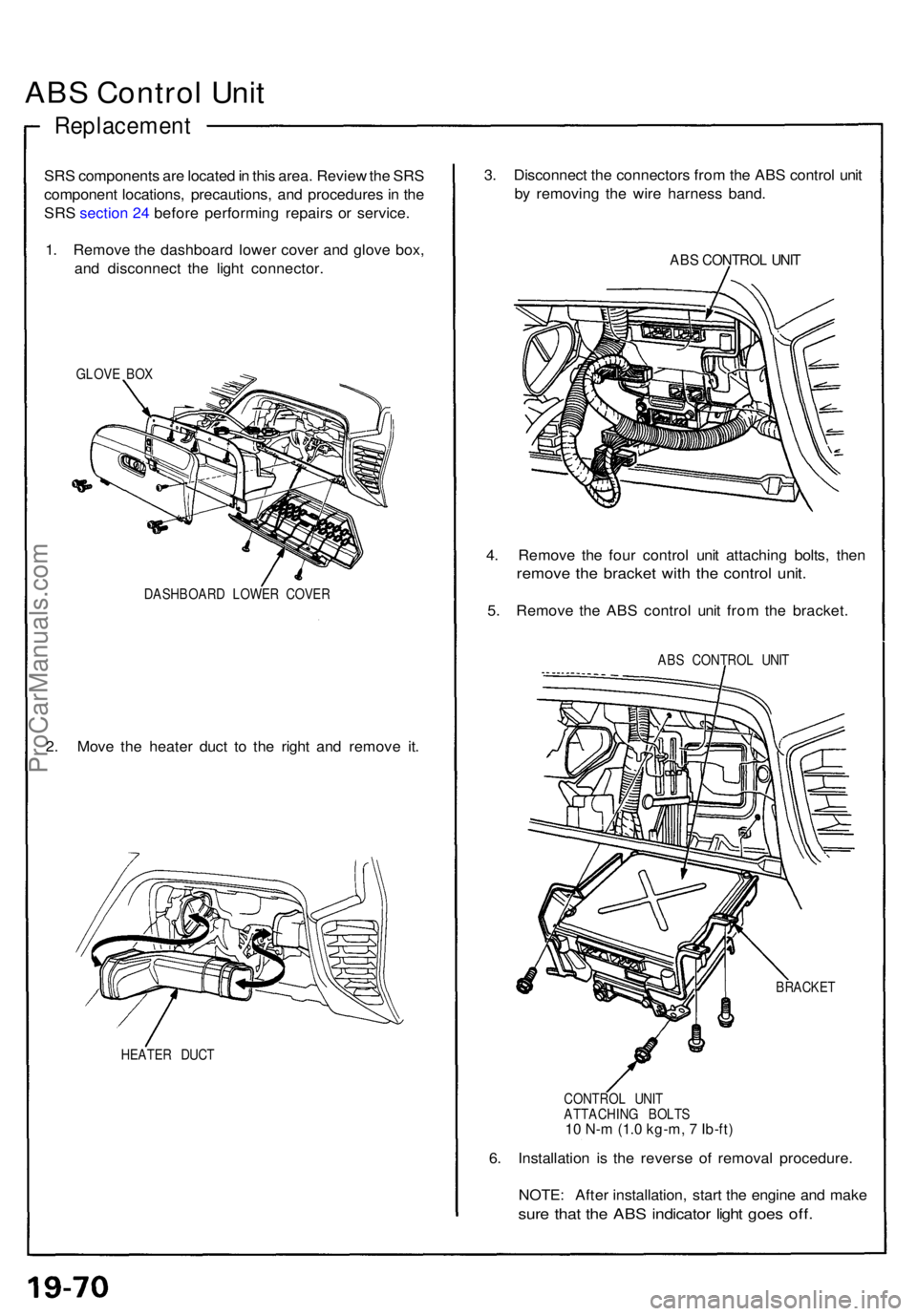

SRS component s ar e locate d in thi s area . Revie w th e SR S

componen t locations , precautions , an d procedure s in th e

SR S

sectio n 2 4 befor e performin g repair s o r service .

1 . Remov e th e dashboar d lowe r cove r an d glov e box ,

an d disconnec t th e ligh t connector .

GLOVE BO X

DASHBOAR D LOWE R COVE R

2. Mov e th e heate r duc t t o th e righ t an d remov e it .

HEATE R DUC T

3. Disconnec t th e connector s fro m th e AB S contro l uni t

b y removin g th e wir e harnes s band .

ABS CONTRO L UNI T

4. Remov e th e fou r contro l uni t attachin g bolts , the n

remov e th e bracke t wit h th e contro l unit .

5. Remov e th e AB S contro l uni t fro m th e bracket .

ABS CONTRO L UNI T

BRACKE T

CONTRO L UNI T

ATTACHIN G BOLT S

10 N-m (1.0 kg-m, 7 Ib-ft)

6. Installatio n i s th e revers e o f remova l procedure .

NOTE : Afte r installation , star t th e engin e an d mak e

sure tha t th e AB S indicato r ligh t goe s off .

ProCarManuals.com

Page 543 of 1640

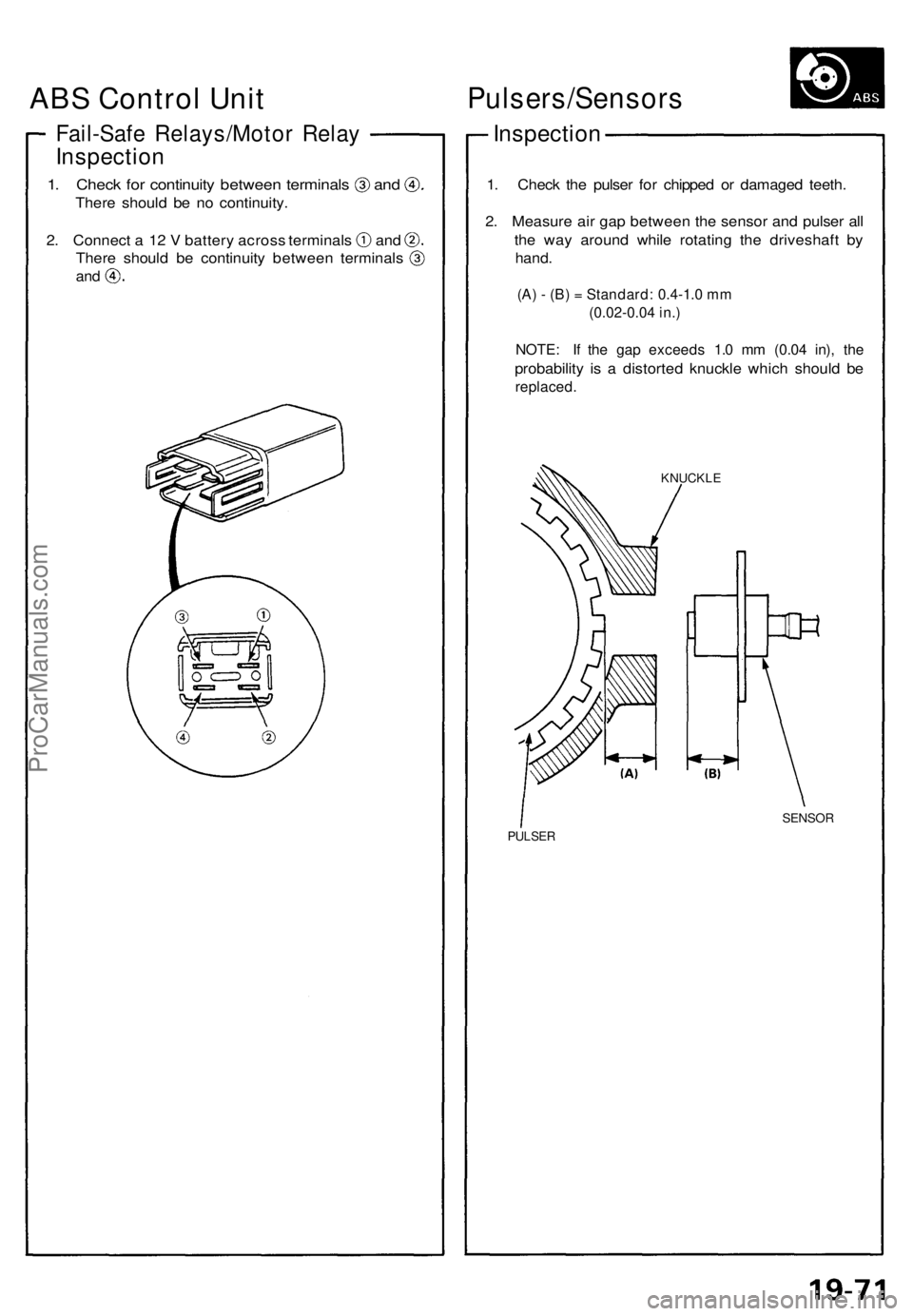

Fail-Safe Relays/Moto r Rela y

Inspectio n

1. Chec k fo r continuit y betwee n terminal s an d

There shoul d b e n o continuity .

2. Connec t a 1 2 V batter y acros s terminal s an d

There shoul d b e continuit y betwee n terminal s

and

Pulsers/Sensor s

Inspection

1. Chec k th e pulse r fo r chippe d o r damage d teeth .

2 . Measur e ai r ga p betwee n th e senso r an d pulse r al l

th e wa y aroun d whil e rotatin g th e driveshaf t b y

hand .

(A) - (B) = Standard: 0.4-1.0 mm

(0.02-0.04 in.)

NOTE: I f th e ga p exceed s 1. 0 m m (0.0 4 in) , th e

probabilit y i s a distorte d knuckl e whic h shoul d b e

replaced .

KNUCKL E

SENSOR

PULSER

ABS Control Unit

ProCarManuals.com

Page 544 of 1640

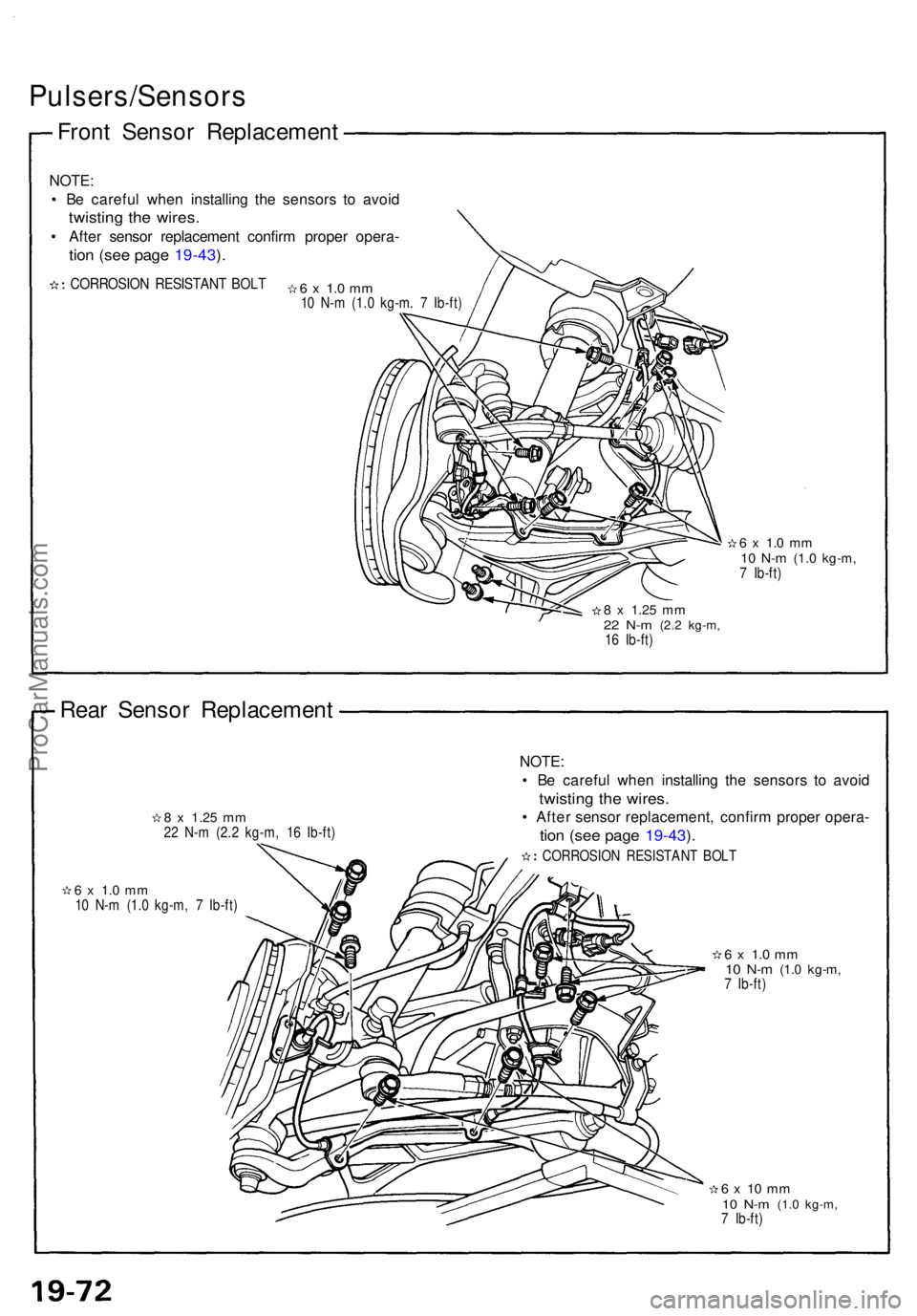

Pulsers/Sensors

Front Senso r Replacemen t

NOTE:

• B e carefu l whe n installin g th e sensor s t o avoi d

twistin g th e wires .

• Afte r senso r replacemen t confir m prope r opera -

tion (se e pag e 19-43 ).

CORROSIO N RESISTAN T BOL T6 x 1. 0 m m10 N- m (1. 0 kg-m . 7 Ib-ft )

6 x 1. 0 m m10 N- m (1. 0 kg-m ,7 Ib-ft )

8 x 1.2 5 mm22 N- m (2. 2 kg-m ,16 Ib-ft )

Rear Senso r Replacemen t

8 x 1.2 5 mm22 N- m (2. 2 kg-m , 1 6 Ib-ft )

NOTE :

• B e carefu l whe n installin g th e sensor s t o avoi d

twistin g th e wires .

• Afte r senso r replacement , confir m prope r opera -

tion (se e pag e 19-43 ).

CORROSIO N RESISTAN T BOL T

6 x 1. 0 m m10 N- m (1. 0 kg-m , 7 Ib-ft )

6 x 1. 0 m m10 N- m (1. 0 kg-m ,7 Ib-ft )

6 x 1 0 m m10 N- m (1. 0 kg-m ,7 Ib-ft )

ProCarManuals.com

Page 545 of 1640

Special Tools

Ref.

No.

Tool Number

07PAZ-0010100

Description

SCS Service Connector

Qty

1

19-84('91-'93)('94-'96)Page ReferenceProCarManuals.com

Page 546 of 1640

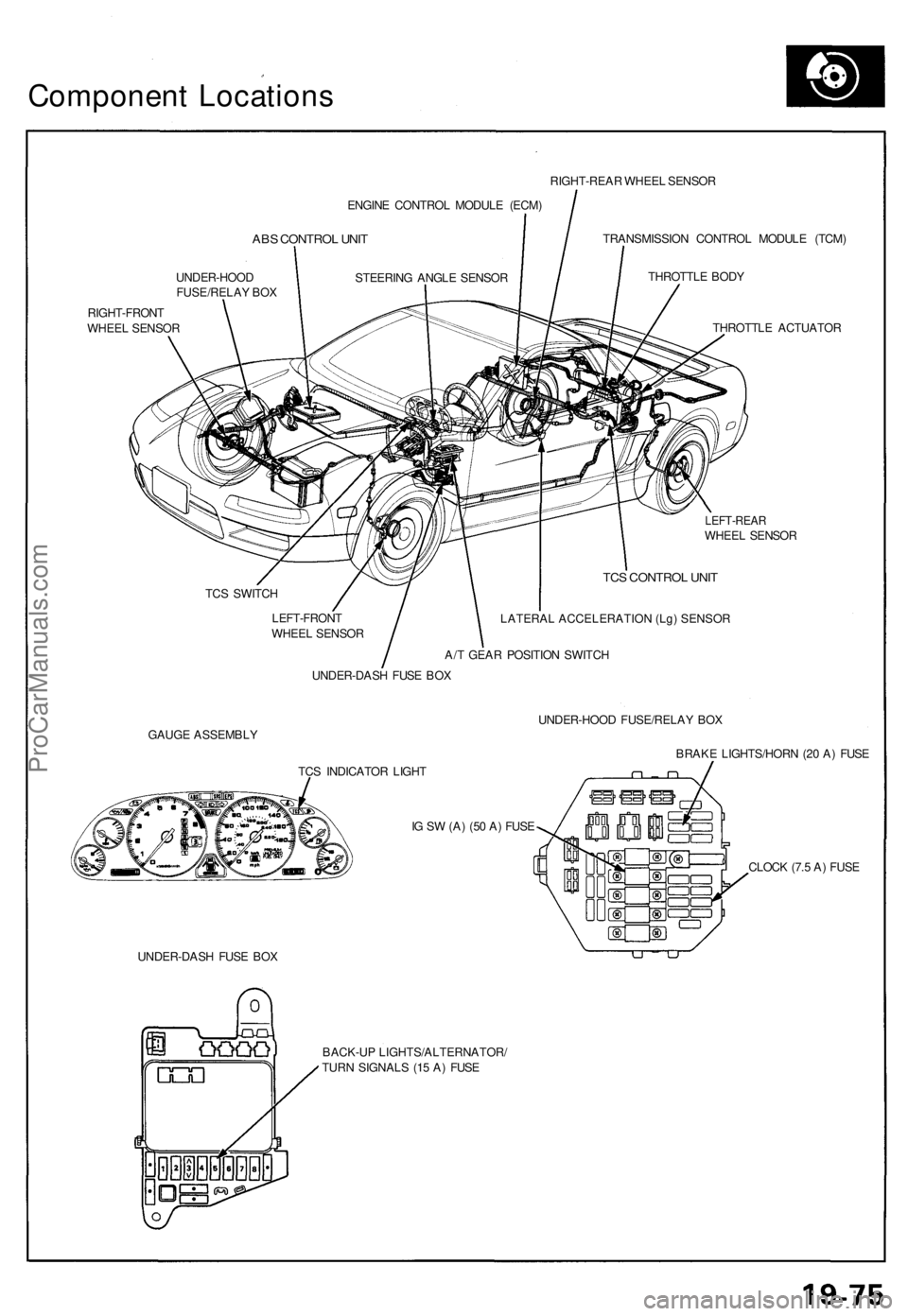

Component Location s

ENGINE CONTRO L MODUL E (ECM )

ABS CONTRO L UNI T

UNDER-HOO D

FUSE/RELA Y BO X

RIGHT-FRON T

WHEE L SENSO R RIGHT-REA

R WHEE L SENSO R

TRANSMISSIO N CONTRO L MODUL E (TCM )

THROTTL E BOD Y

THROTTL E ACTUATO R

LEFT-REARWHEEL SENSO R

TC S SWITC H

LEFT-FRON T

WHEE L SENSO R

TCS CONTRO L UNI T

LATERAL ACCELERATION (Lg) SENSOR

A/T GEA R POSITIO N SWITC H

UNDER-DAS H FUS E BO X

GAUG E ASSEMBL Y UNDER-HOO

D FUSE/RELA Y BO X

BRAK E LIGHTS/HOR N (2 0 A ) FUS E

TC S INDICATO R LIGH T

I G S W (A ) (5 0 A ) FUS E

UNDER-DAS H FUS E BO X CLOC

K (7. 5 A ) FUS E

BACK-U P LIGHTS/ALTERNATOR /

TUR N SIGNAL S (1 5 A ) FUS E

STEERIN

G ANGL E SENSO R

ProCarManuals.com

Page 547 of 1640

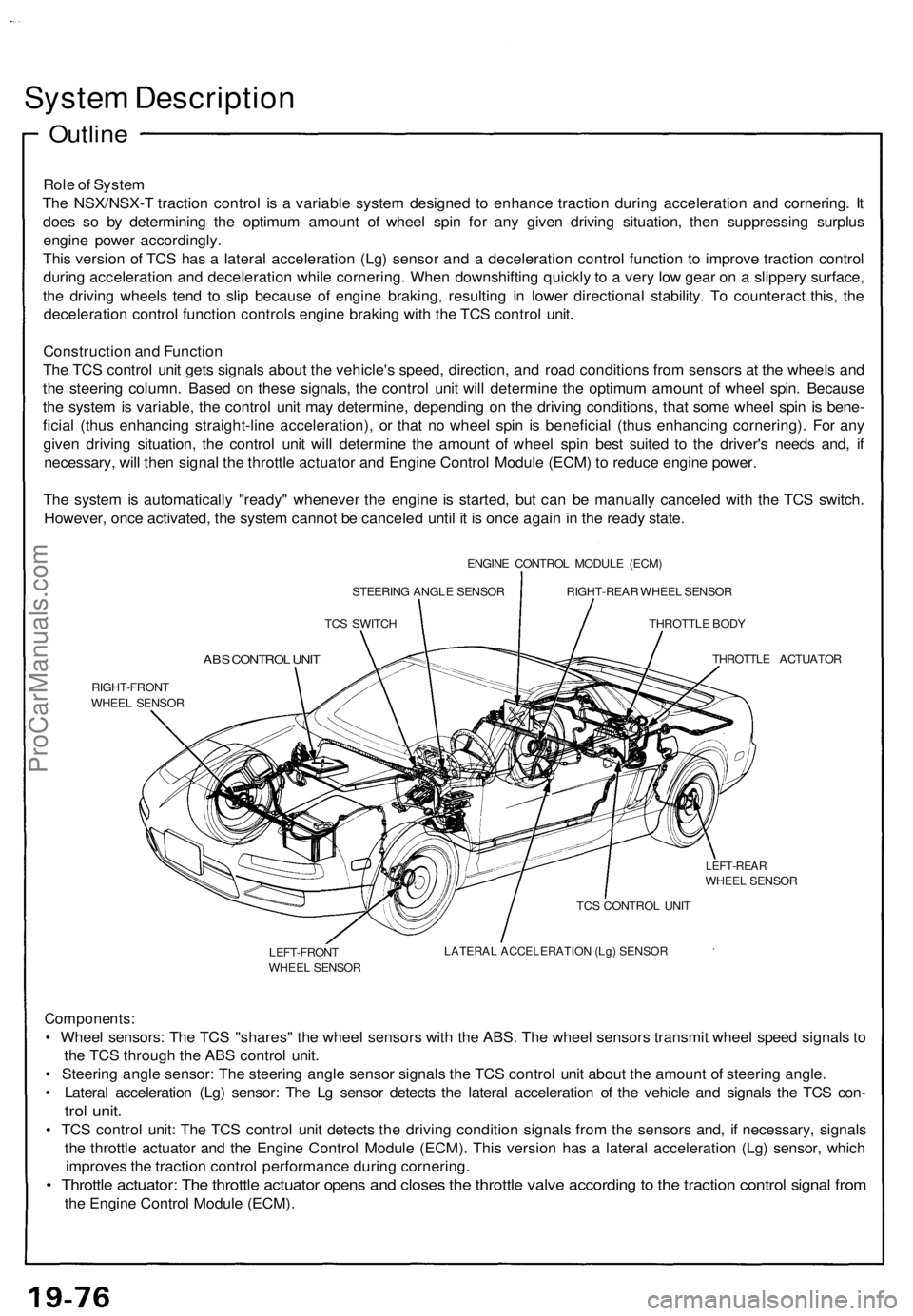

System Descriptio n

Outline

Role o f Syste m

Th e NSX/NSX- T tractio n contro l i s a variabl e syste m designe d t o enhanc e tractio n durin g acceleratio n an d cornering . I t

doe s s o b y determinin g th e optimu m amoun t o f whee l spi n fo r an y give n drivin g situation , the n suppressin g surplu s

engin e powe r accordingly .

Thi s versio n o f TC S ha s a latera l acceleratio n (Lg ) senso r an d a deceleratio n contro l functio n t o improv e tractio n contro l

durin g acceleratio n an d deceleratio n whil e cornering . Whe n downshiftin g quickl y t o a ver y lo w gea r o n a slipper y surface ,

th e drivin g wheel s ten d t o sli p becaus e o f engin e braking , resultin g i n lowe r directiona l stability . T o counterac t this , th e

deceleratio n contro l functio n control s engine braking wit h th e TC S contro l unit .

Constructio n an d Functio n

Th e TC S contro l uni t get s signal s abou t th e vehicle' s speed , direction , an d roa d condition s fro m sensor s a t th e wheel s an d

th e steerin g column . Base d o n thes e signals , th e contro l uni t wil l determin e th e optimu m amoun t o f whee l spin . Becaus e

th e syste m is variable , th e contro l uni t ma y determine , dependin g o n th e drivin g conditions , tha t som e whee l spi n i s bene -

ficia l (thu s enhancin g straight-lin e acceleration) , o r tha t n o whee l spi n i s beneficia l (thu s enhancin g cornering) . Fo r an y

give n drivin g situation , th e contro l uni t wil l determin e th e amoun t o f whee l spi n bes t suite d t o th e driver' s need s and , i f

necessary , wil l the n signa l th e throttl e actuato r an d Engin e Contro l Modul e (ECM ) t o reduc e engin e power .

Th e syste m is automaticall y "ready " wheneve r th e engin e i s started , bu t ca n b e manuall y cancele d wit h th e TC S switch .

However , onc e activated , th e syste m canno t b e cancele d unti l i t i s onc e agai n in th e read y state .

ENGIN E CONTRO L MODUL E (ECM )

STEERIN G ANGL E SENSO R

TC S SWITC H RIGHT-REA

R WHEE L SENSO R

THROTTL E BOD Y

ABS CONTRO L UNI T

RIGHT-FRON T

WHEE L SENSO R THROTTL

E ACTUATO R

LEFT-REARWHEEL SENSO R

LEFT-FRON T

WHEE L SENSO R TC

S CONTRO L UNI T

LATERAL ACCELERATION (Lg) SENSOR

Components :

• Whee l sensors : Th e TC S "shares " th e whee l sensor s wit h th e ABS . Th e whee l sensor s transmi t whee l spee d signal s t o

th e TC S throug h th e AB S contro l unit .

• Steerin g angl e sensor : Th e steerin g angl e senso r signal s th e TC S contro l uni t abou t th e amoun t o f steerin g angle .

• Latera l acceleratio n (Lg ) sensor : Th e L g senso r detect s th e latera l acceleratio n o f th e vehicl e an d signal s th e TC S con -

trol unit .

• TC S contro l unit : Th e TC S contro l uni t detect s th e drivin g conditio n signal s fro m th e sensor s and , i f necessary , signal s

th e throttl e actuato r an d th e Engin e Contro l Modul e (ECM) . Thi s versio n ha s a latera l acceleratio n (Lg ) sensor , whic h

improve s th e tractio n contro l performanc e durin g cornering .

• Throttl e actuator : Th e throttl e actuato r open s an d close s th e throttl e valv e accordin g to th e tractio n contro l signa l fro m

the Engin e Contro l Modul e (ECM) .

ProCarManuals.com

Page 548 of 1640

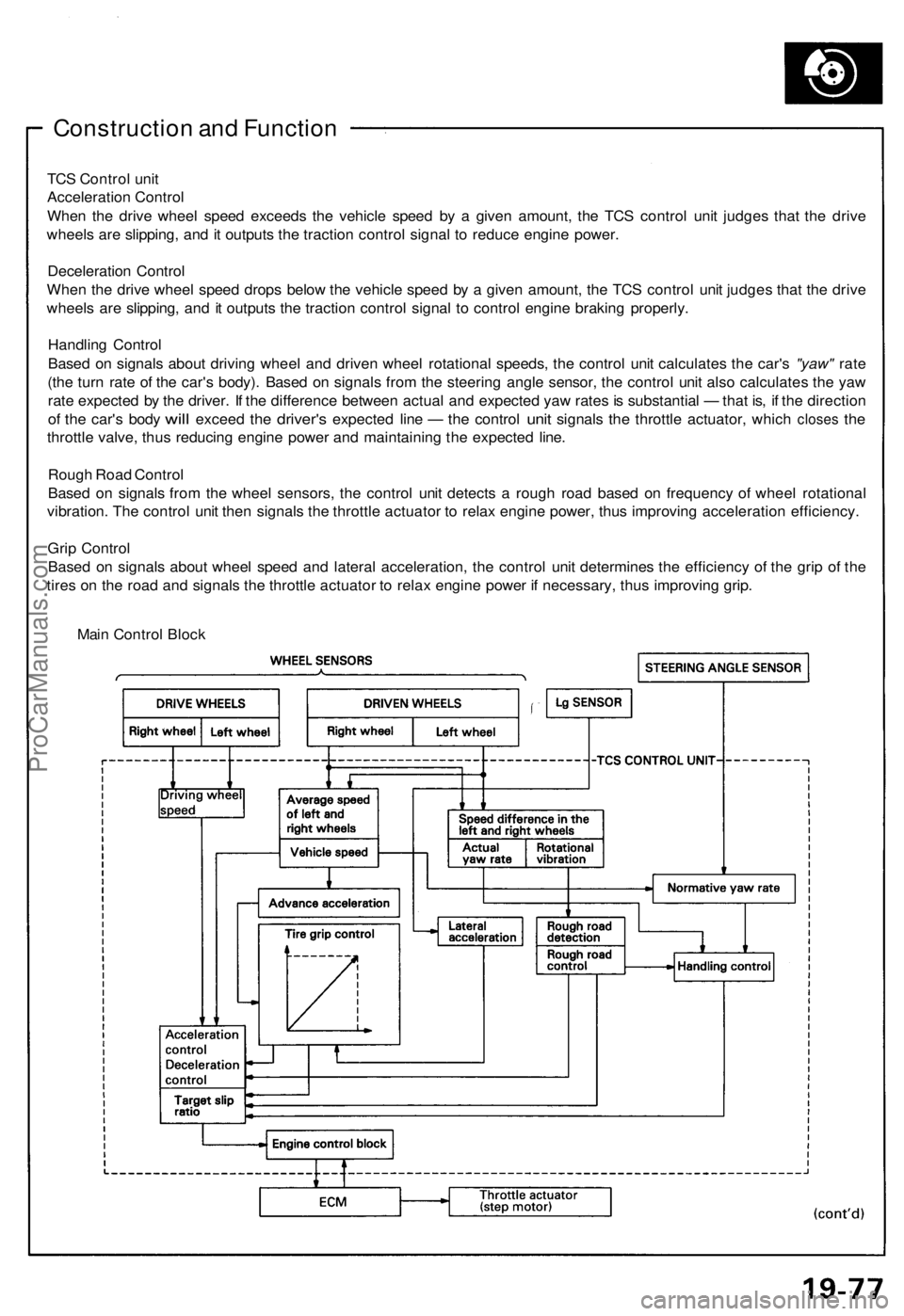

Construction an d Functio n

TCS Contro l uni t

Acceleratio n Contro l

Whe n th e driv e whee l spee d exceed s th e vehicl e spee d b y a give n amount , th e TC S contro l uni t judge s tha t th e driv e

wheel s ar e slipping , an d it output s th e tractio n contro l signa l t o reduc e engin e power .

Deceleratio n Contro l

Whe n th e driv e whee l spee d drop s belo w th e vehicl e spee d b y a give n amount , th e TC S contro l uni t judge s tha t th e driv e

wheel s ar e slipping , an d it output s th e tractio n contro l signa l t o contro l engin e brakin g properly .

Handlin g Contro l

Base d o n signal s abou t drivin g whee l an d drive n whee l rotationa l speeds , th e contro l uni t calculate s th e car' s "yaw" rate

(th e tur n rat e o f th e car' s body) . Base d o n signal s fro m th e steerin g angl e sensor , th e contro l uni t als o calculate s th e ya w

rat e expecte d b y th e driver . I f th e differenc e betwee n actua l an d expecte d ya w rate s is substantia l — tha t is , i f th e directio n

of th e car' s bod y will excee d the driver' s expecte d lin e — the contro l unit signal s the throttl e actuator , whic h close s the

throttl e valve , thu s reducin g engin e powe r an d maintainin g th e expecte d line .

Roug h Roa d Contro l

Base d o n signal s fro m th e whee l sensors , th e contro l uni t detect s a roug h roa d base d o n frequenc y o f whee l rotationa l

vibration . Th e contro l uni t the n signal s th e throttl e actuato r t o rela x engine power, thu s improvin g acceleratio n efficiency .

Gri p Contro l

Base d o n signal s abou t whee l spee d an d latera l acceleration , th e contro l uni t determine s th e efficienc y o f th e gri p o f th e

tire s o n th e roa d an d signal s th e throttl e actuato r t o rela x engine power i f necessary , thu s improvin g grip .

Mai n Contro l Bloc k

ProCarManuals.com

Page 549 of 1640

System Descriptio n

Constructio n an d Functio n

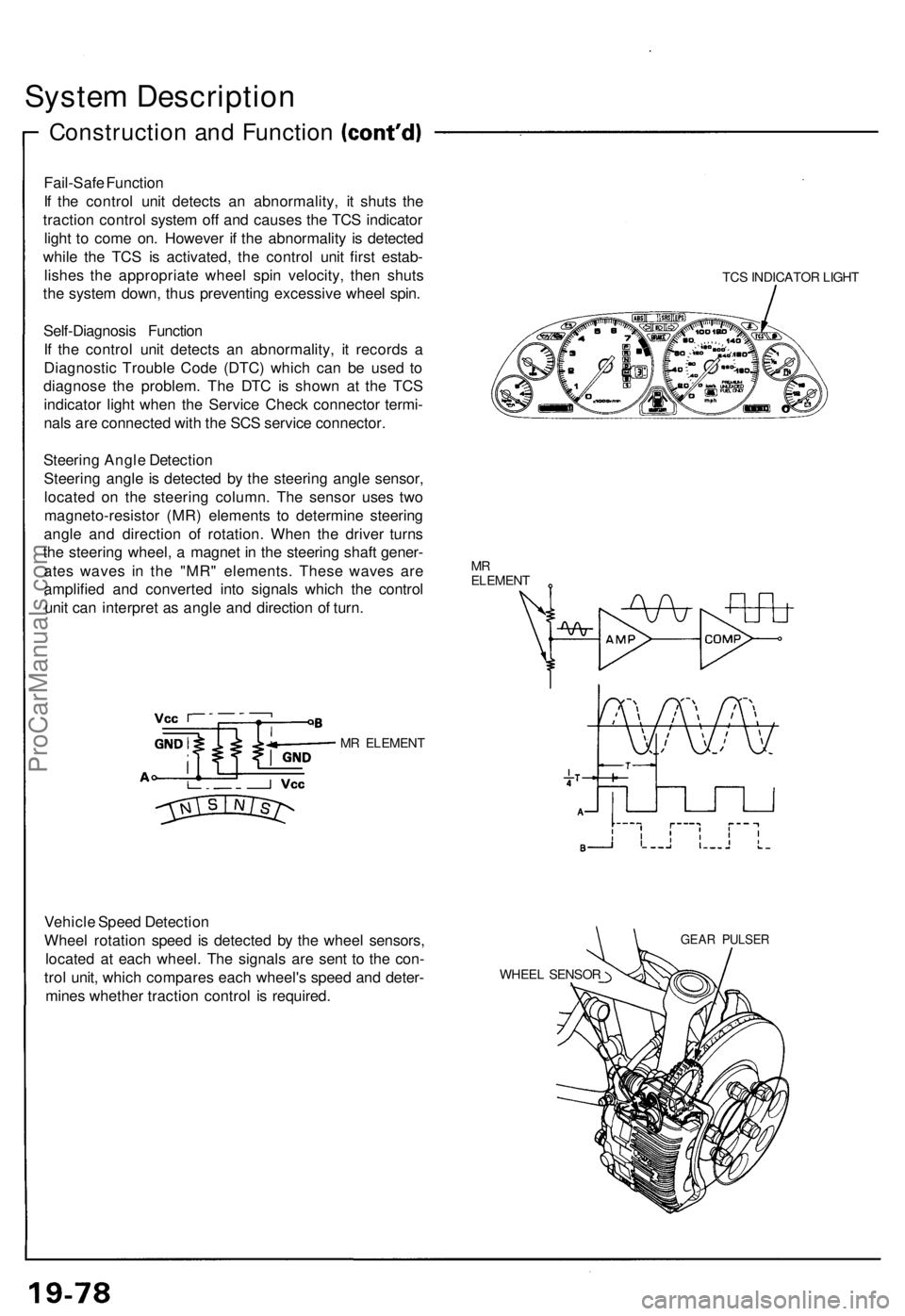

Fail-Safe Functio n

I f th e contro l uni t detect s a n abnormality , i t shut s th e

tractio n contro l syste m of f an d cause s th e TC S indicato r

ligh t t o com e on . Howeve r i f th e abnormalit y i s detecte d

whil e th e TC S i s activated , th e contro l uni t firs t estab -

lishe s th e appropriat e whee l spi n velocity , the n shut s

th e syste m down , thu s preventin g excessiv e whee l spin .

Self-Diagnosi s Functio n

I f th e contro l uni t detect s a n abnormality , i t record s a

Diagnosti c Troubl e Cod e (DTC ) whic h ca n b e use d t o

diagnos e th e problem . Th e DT C is show n a t th e TC S

indicato r ligh t whe n th e Servic e Chec k connecto r termi -

nal s ar e connecte d wit h th e SC S servic e connector .

Steerin g Angl e Detectio n

Steerin g angl e is detecte d b y th e steerin g angl e sensor ,

locate d o n th e steerin g column . Th e senso r use s tw o

magneto-resisto r (MR ) element s t o determin e steerin g

angl e an d directio n o f rotation . Whe n th e drive r turn s

th e steerin g wheel , a magne t i n th e steerin g shaf t gener -

ate s wave s i n th e "MR " elements . Thes e wave s ar e

amplifie d an d converte d int o signal s whic h th e contro l

uni t ca n interpre t a s angl e an d directio n o f turn .

MR ELEMEN T

TCS INDICATO R LIGH T

MRELEMEN T

Vehicle Spee d Detectio n

Whee l rotatio n spee d i s detecte d b y th e whee l sensors ,

locate d a t eac h wheel . Th e signal s ar e sen t t o th e con -

tro l unit , whic h compare s eac h wheel' s spee d an d deter -

mine s whethe r tractio n contro l i s required .

GEAR PULSE R

WHEEL SENSO R

ProCarManuals.com

Page 550 of 1640

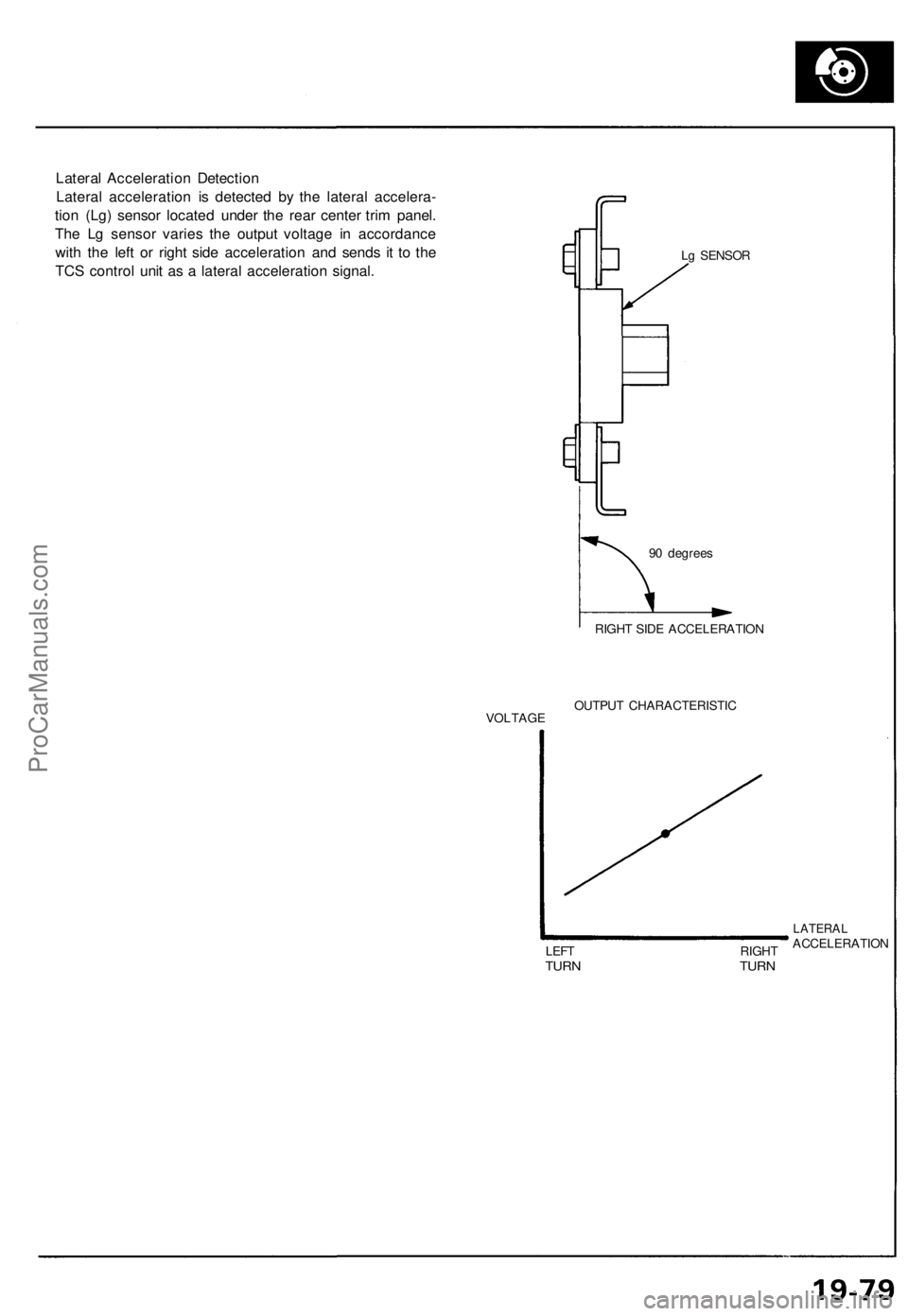

Lateral Acceleration Detection

Lateral acceleration is detected by the lateral accelera-

tion (Lg) sensor located under the rear center trim panel.

The Lg sensor varies the output voltage in accordance

with the left or right side acceleration and sends it to the

TCS control unit as a lateral acceleration signal.

Lg SENSOR

90 degrees

VOLTAGE

RIGHT SIDE ACCELERATION

OUTPUT CHARACTERISTIC

LEFT

TURN

RIGHT

TURN

LATERAL

ACCELERATIONProCarManuals.com