ACURA NSX 1997 Service Repair Manual

Manufacturer: ACURA, Model Year: 1997, Model line: NSX, Model: ACURA NSX 1997Pages: 1503, PDF Size: 57.08 MB

Page 271 of 1503

Lighting System

HID Lamp System Troubleshooting

1. Check the No. 49 (20 A) or No. 52 (20 A) fuse in the

main under-hood fuse/relay box.

Are the fuses OK?

YES — Go to step 2.

NO — Replace the fuse (s), and recheck.

2. Substitute a known-good HID bulb and recheck.

Does the headlight low beam come on?

YES — Replace the HID bulb.

NO — Go to step 3.

3. Disconnect the 2P connector from the inverter unit.

4. Turn the combination light switch ON.

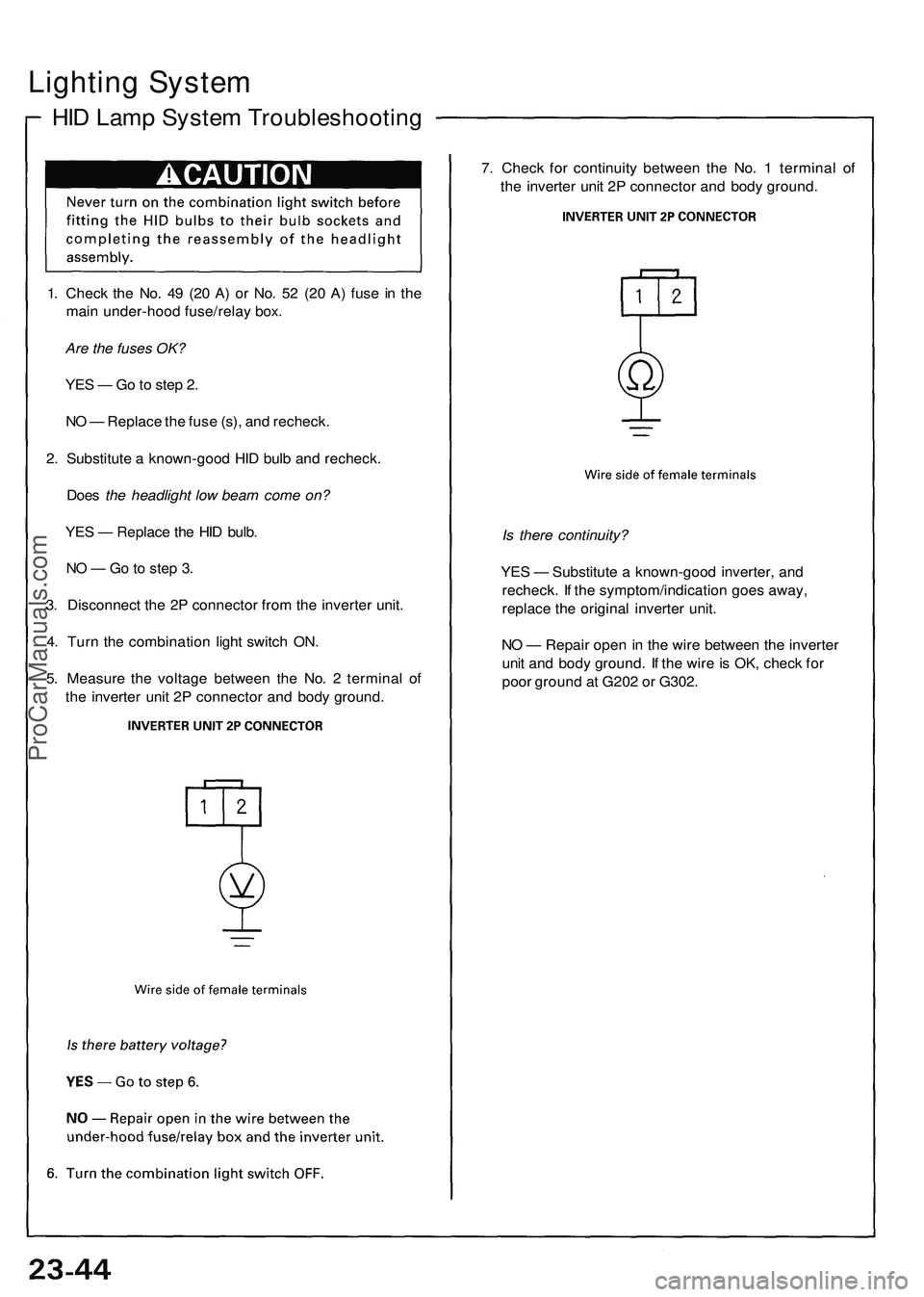

5. Measure the voltage between the No. 2 terminal of

the inverter unit 2P connector and body ground.

7. Check for continuity between the No. 1 terminal of

the inverter unit 2P connector and body ground.

Is there continuity?

YES — Substitute a known-good inverter, and

recheck. If the symptom/indication goes away,

replace the original inverter unit.

NO — Repair open in the wire between the inverter

unit and body ground. If the wire is OK, check for

poor ground at G202 or G302.ProCarManuals.com

Page 272 of 1503

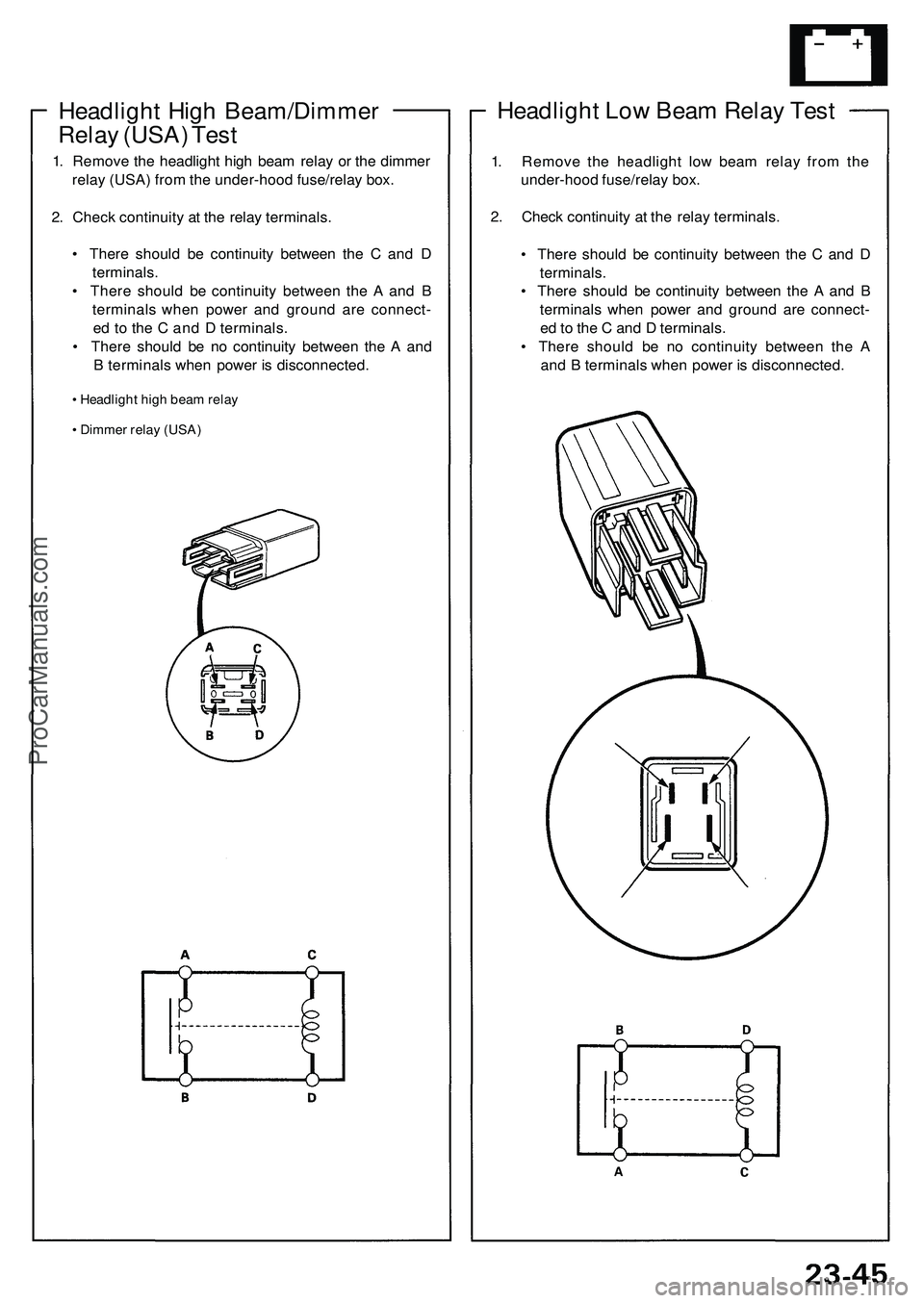

Headlight Low Beam Relay Test

1. Remove the headlight low beam relay from the

under-hood fuse/relay box.

2. Check continuity at the relay terminals.

• There should be continuity between the C and D

terminals.

• There should be continuity between the A and B

terminals when power and ground are connect-

ed to the C and D terminals.

• There should be no continuity between the A

and B terminals when power is disconnected.

Headlight High Beam/Dimmer

Relay (USA) Test

1. Remove the headlight high beam relay or the dimmer

relay (USA) from the under-hood fuse/relay box.

2. Check continuity at the relay terminals.

• There should be continuity between the C and D

terminals.

• There should be continuity between the A and B

terminals when power and ground are connect-

ed to the C and D terminals.

• There should be no continuity between the A and

B terminals when power is disconnected.

• Headlight high beam relay

• Dimmer relay (USA)ProCarManuals.com

Page 273 of 1503

Lighting Syste m

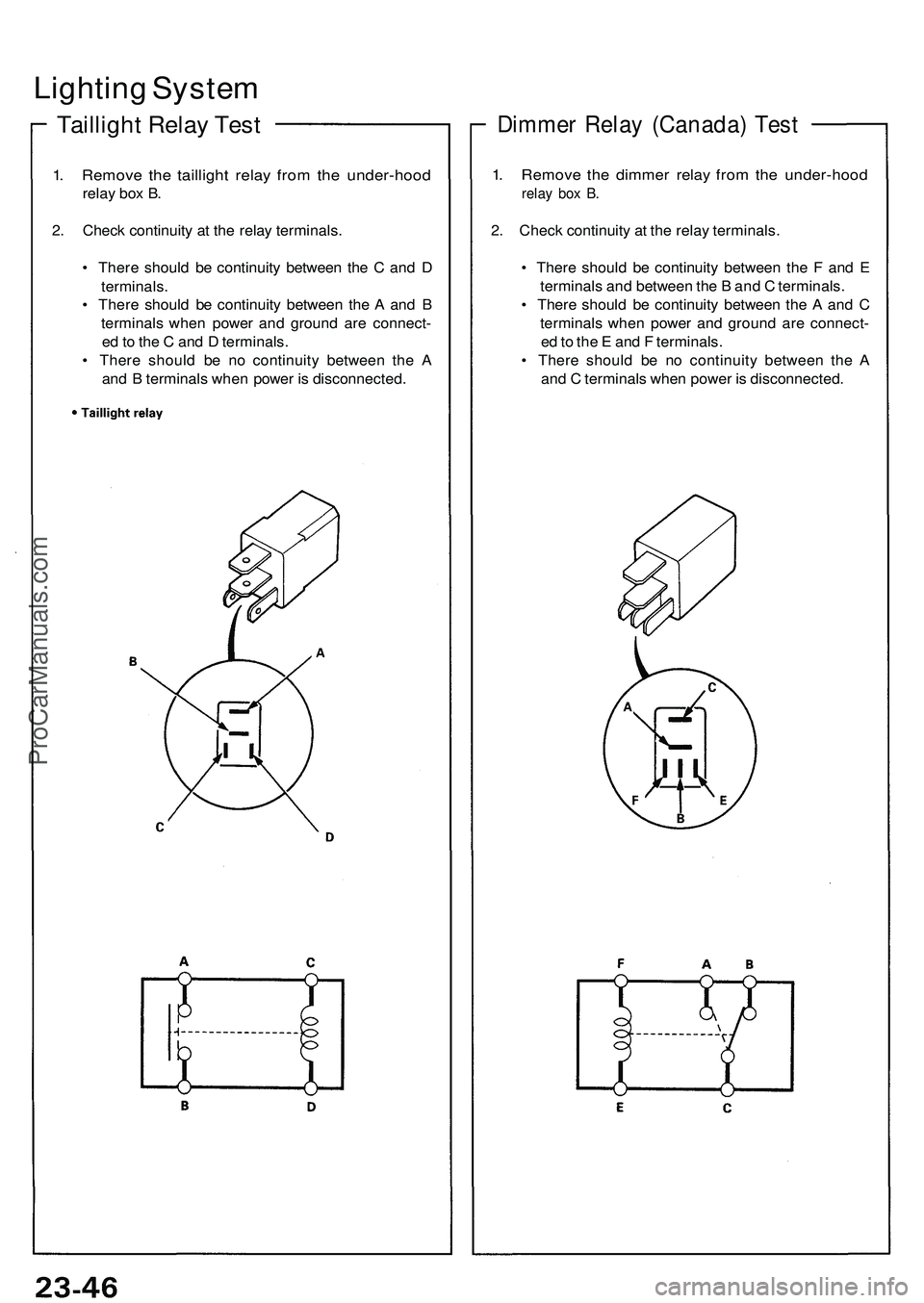

Tailligh t Rela y Tes t

1. Remov e th e tailligh t rela y fro m th e under-hoo d

relay bo x B .

2 . Chec k continuit y a t th e rela y terminals .

• Ther e shoul d b e continuit y betwee n th e C an d D

terminals .

• Ther e shoul d b e continuit y betwee n th e A an d B

terminal s whe n powe r an d groun d ar e connect -

e d to th e C an d D terminals .

• Ther e shoul d b e n o continuit y betwee n th e A

an d B terminal s whe n powe r i s disconnected .

Dimmer Rela y (Canada ) Tes t

1. Remov e th e dimme r rela y fro m th e under-hoo d

relay bo x B .

2. Chec k continuit y a t th e rela y terminals .

• Ther e shoul d b e continuit y betwee n th e F an d E

terminal s an d betwee n th e B an d C terminals .

• Ther e shoul d b e continuit y betwee n th e A an d C

terminal s whe n powe r an d groun d ar e connect -

e d to th e E an d F terminals .

• Ther e shoul d b e n o continuit y betwee n th e A

an d C terminal s whe n powe r i s disconnected .

ProCarManuals.com

Page 274 of 1503

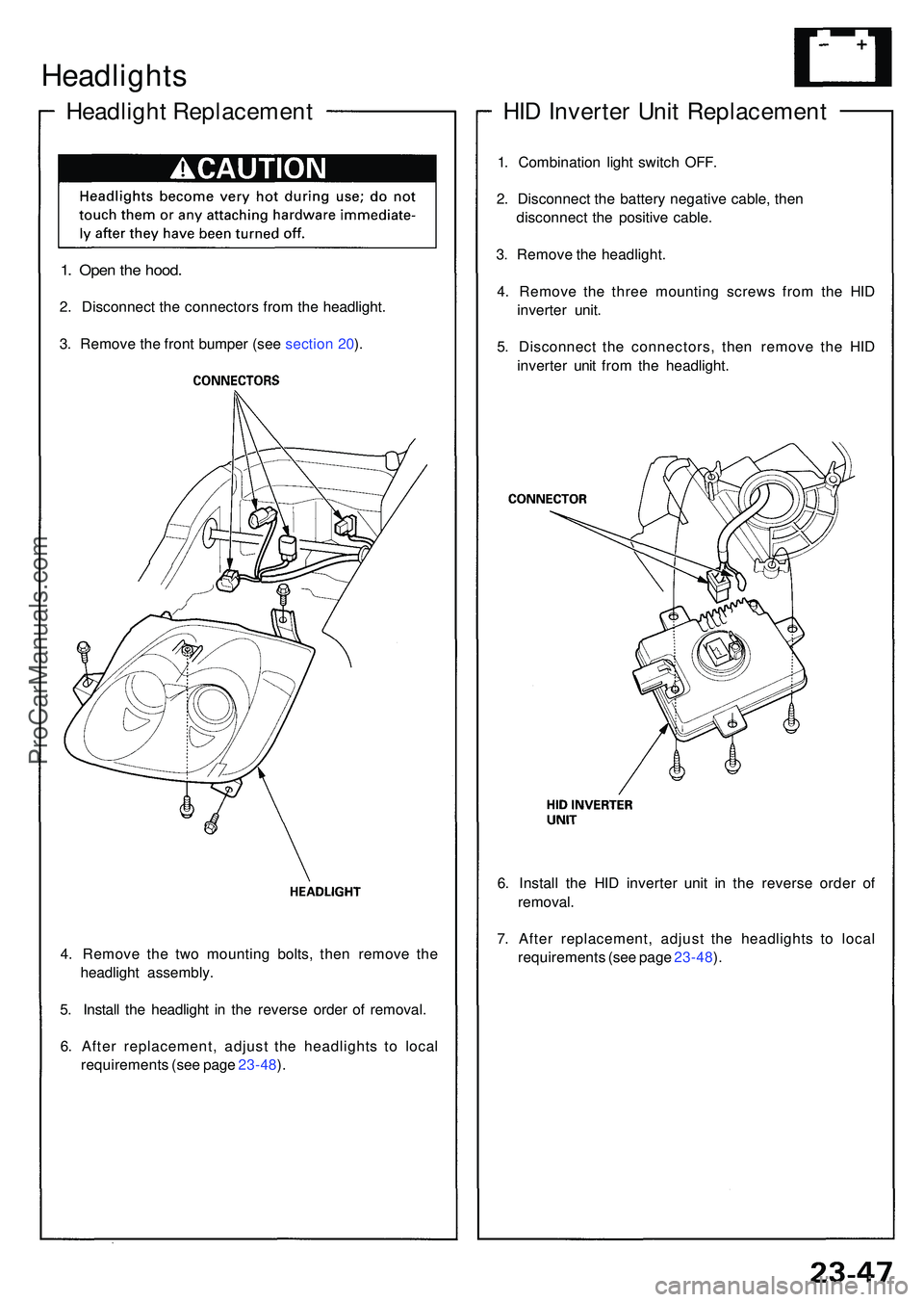

4. Remov e th e tw o mountin g bolts , the n remov e th e

headligh t assembly .

5 . Instal l th e headligh t i n th e revers e orde r o f removal .

6 . Afte r replacement , adjus t th e headlight s t o loca l

requirement s (se e pag e 23-48 ).

Headlight s

Headlight Replacemen t

1. Ope n th e hood .

2. Disconnec t th e connector s fro m th e headlight .

3 . Remov e th e fron t bumpe r (se e sectio n 20 ).

HI D Inverte r Uni t Replacemen t

1. Combinatio n ligh t switc h OFF .

2 . Disconnec t th e batter y negativ e cable , the n

disconnec t th e positiv e cable .

3 . Remov e th e headlight .

4 . Remov e th e thre e mountin g screw s fro m th e HI D

inverte r unit .

5 . Disconnec t th e connectors , the n remov e th e HI D

inverte r uni t fro m th e headlight .

6 . Instal l th e HI D inverte r uni t i n th e revers e orde r o f

removal .

7 . Afte r replacement , adjus t th e headlight s t o loca l

requirement s (se e pag e 23-48 ).

ProCarManuals.com

Page 275 of 1503

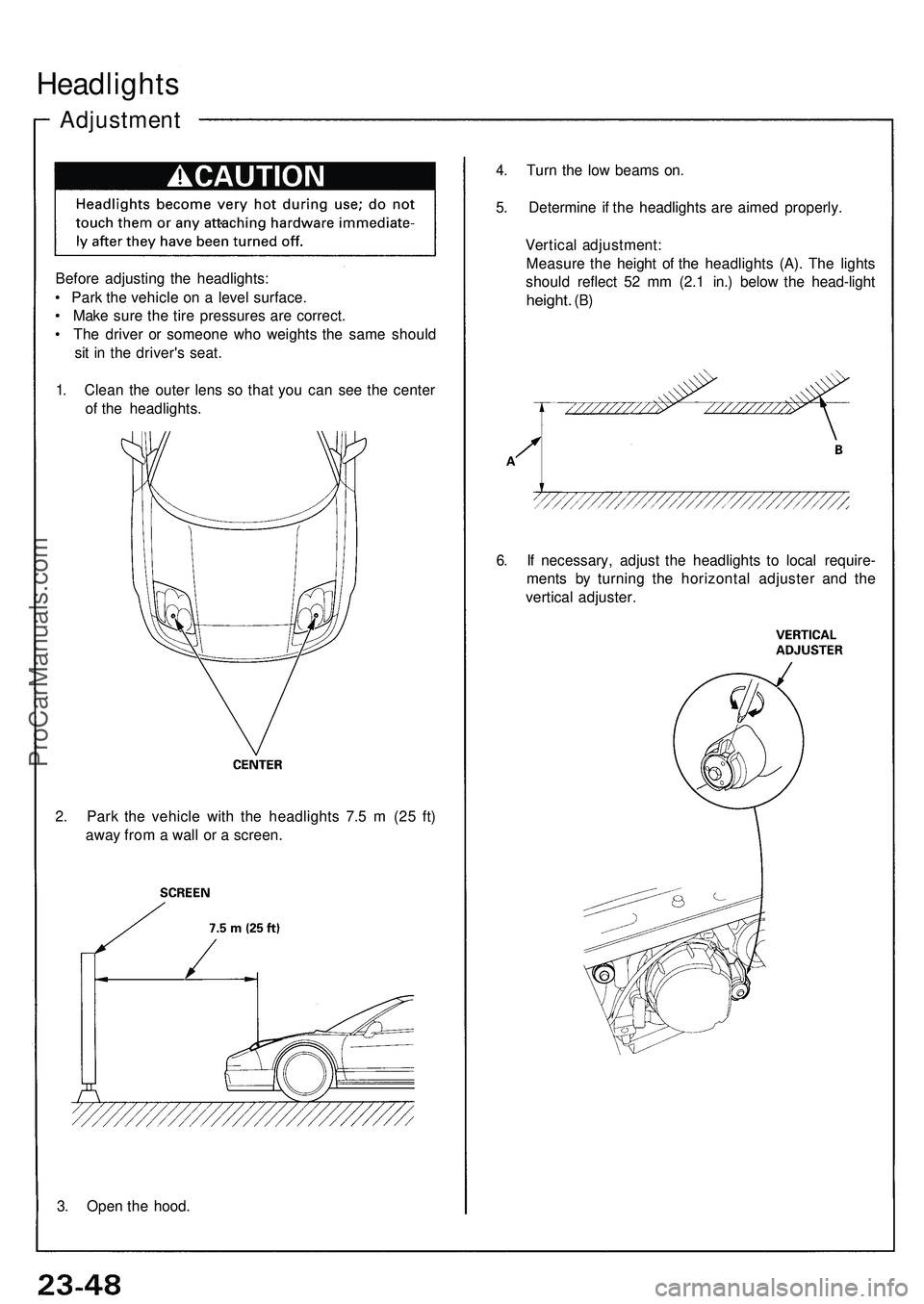

Headlights

Adjustmen t

Before adjustin g th e headlights :

• Par k th e vehicl e o n a leve l surface .

• Mak e sur e th e tir e pressure s ar e correct .

• Th e drive r o r someon e wh o weight s th e sam e shoul d

si t i n th e driver' s seat .

1 . Clea n th e oute r len s s o tha t yo u ca n se e th e cente r

o f th e headlights . 4

. Tur n th e lo w beam s on .

5 . Determin e i f th e headlight s ar e aime d properly .

Vertica l adjustment :

Measur e th e heigh t o f th e headlight s (A) . Th e light s

shoul d reflec t 5 2 m m (2. 1 in. ) belo w th e head-ligh t

height. (B)

6. I f necessary , adjus t th e headlight s t o loca l require -

ment s b y turnin g th e horizonta l adjuste r an d th e

vertica l adjuster .

2 . Par k th e vehicl e wit h th e headlight s 7. 5 m (2 5 ft )

awa y fro m a wal l o r a screen .

3 . Ope n th e hood .

ProCarManuals.com

Page 276 of 1503

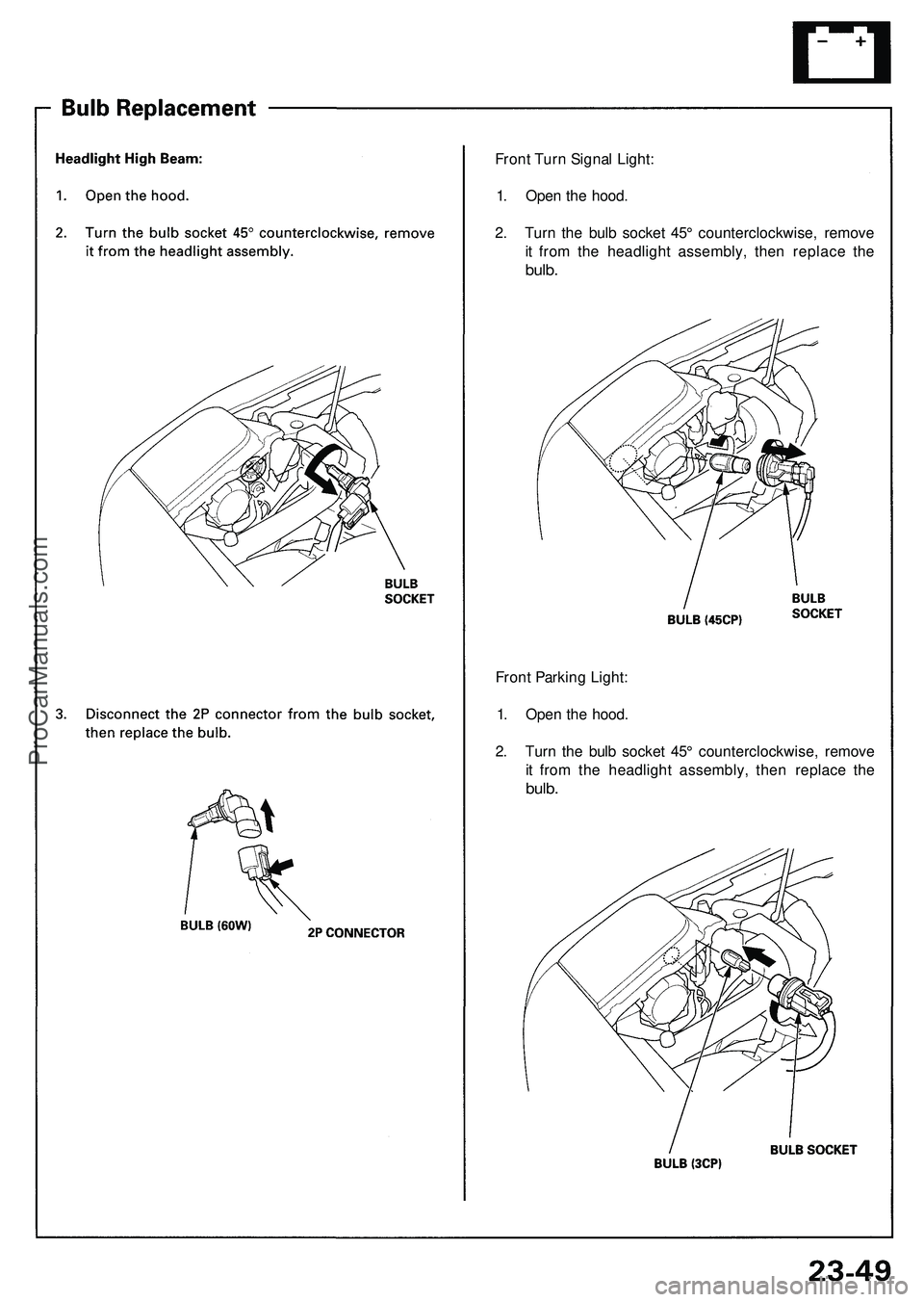

Front Turn Signal Light:

1. Open the hood.

2. Turn the bulb socket 45° counterclockwise, remove

it from the headlight assembly, then replace the

bulb.

Front Parking Light:

1. Open the hood.

2. Turn the bulb socket 45° counterclockwise, remove

it from the headlight assembly, then replace the

bulb.ProCarManuals.com

Page 277 of 1503

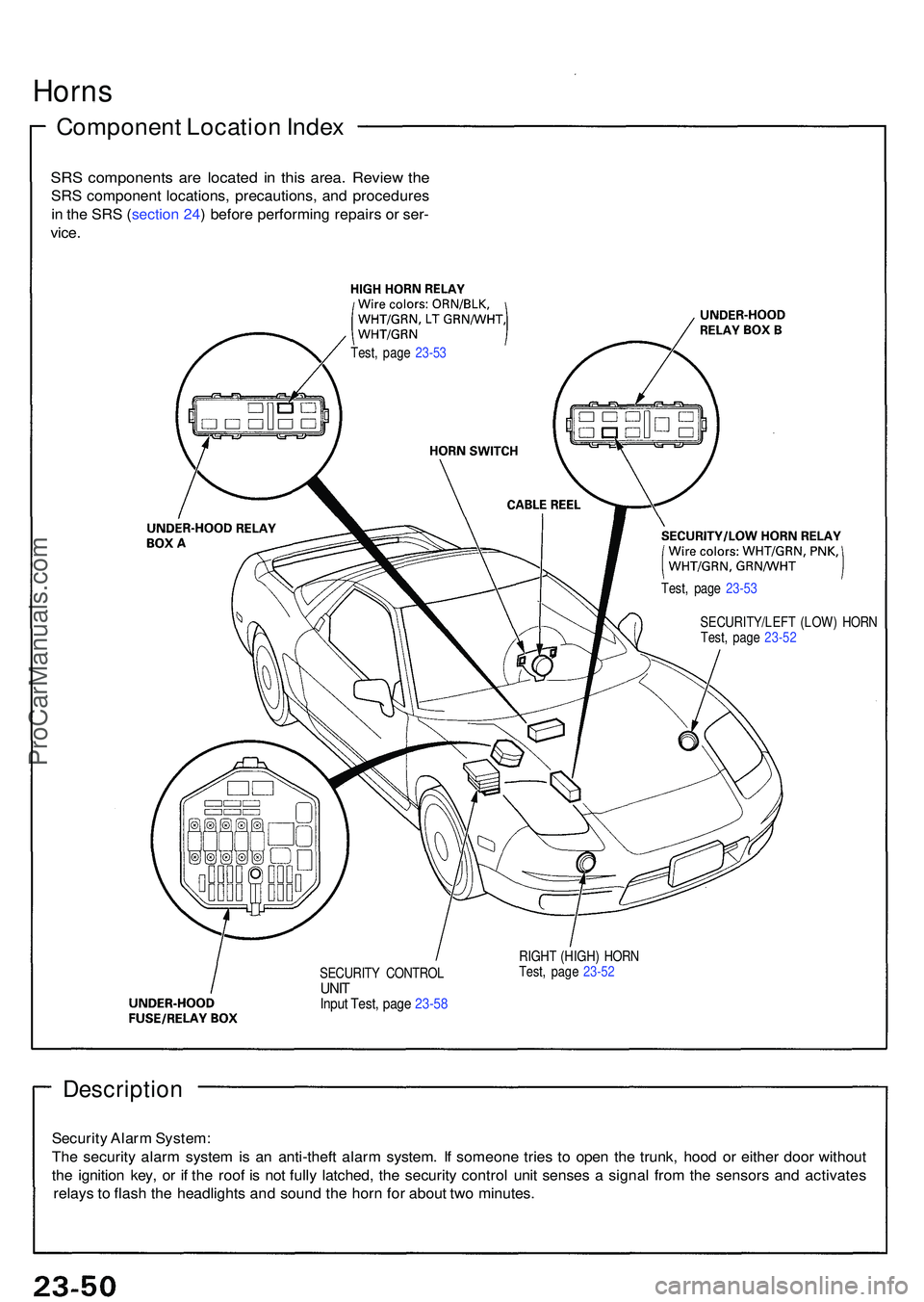

Description

Security Alar m System :

Th e securit y alar m syste m is a n anti-thef t alar m system . I f someon e trie s t o ope n th e trunk , hoo d o r eithe r doo r withou t

th e ignitio n key , o r i f th e roo f i s no t full y latched , th e securit y contro l uni t sense s a signa l fro m th e sensor s an d activate s

relay s t o flas h th e headlight s an d soun d th e hor n fo r abou t tw o minutes .

SECURIT Y CONTRO LUNITInpu t Test , pag e 23-5 8

RIGH T (HIGH ) HOR N

Test , pag e 23-5 2

Horn s

Componen t Locatio n Inde x

SRS component s ar e locate d i n thi s area . Revie w th e

SR S componen t locations , precautions , an d procedure s

i n th e SR S (sectio n 24 ) befor e performin g repair s o r ser -

vice .

Test , pag e 23-5 3

Test, pag e 23-5 3

SECURITY/LEF T (LOW ) HOR N

Test , pag e 23-5 2

ProCarManuals.com

Page 278 of 1503

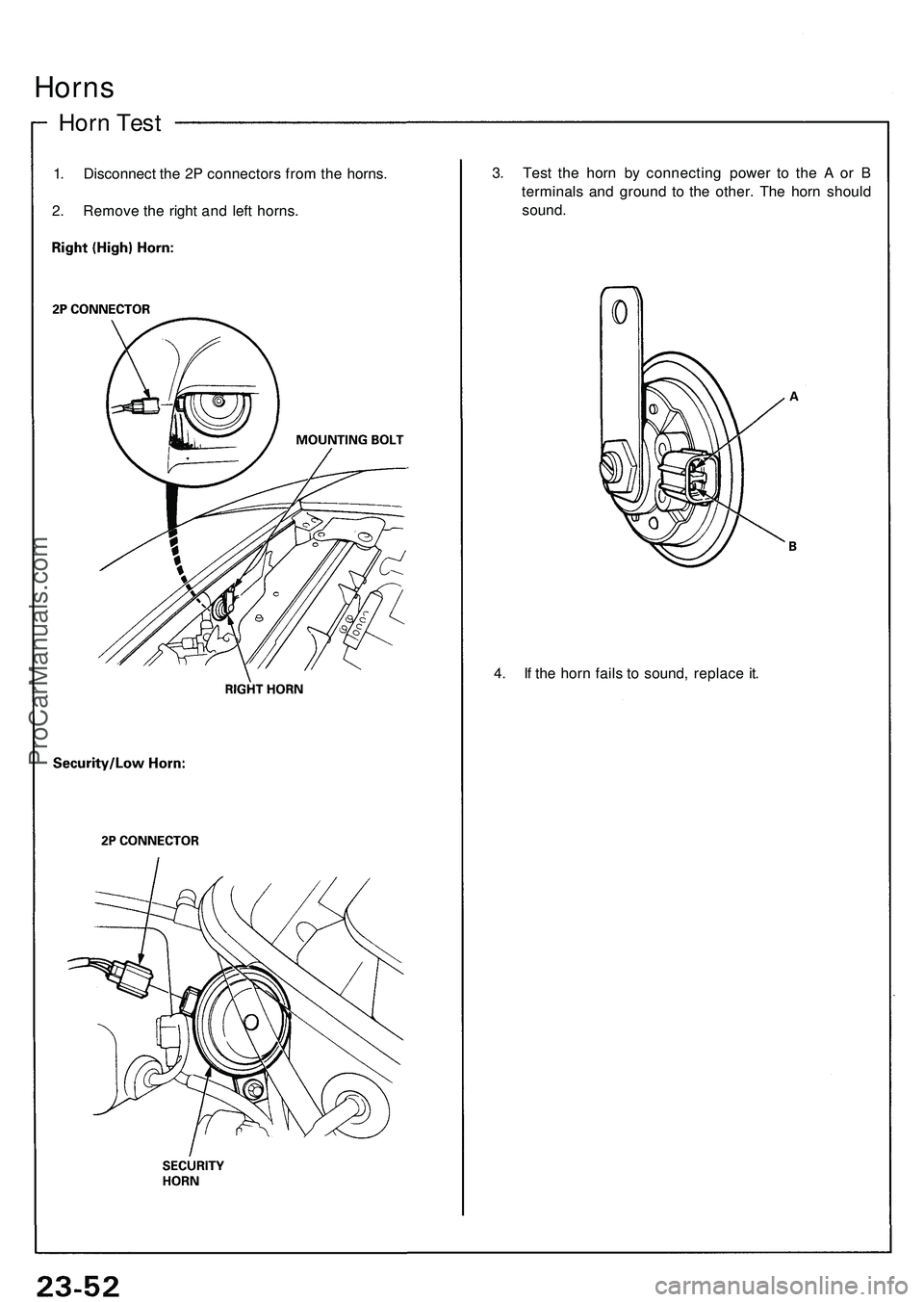

Horns

Horn Tes t

1. Disconnec t th e 2 P connector s fro m th e horns .

2 . Remov e th e righ t an d lef t horns . 3

. Tes t th e hor n b y connectin g powe r t o th e A or B

terminal s an d groun d t o th e other . Th e hor n shoul d

sound .

4 . I f th e hor n fail s t o sound , replac e it .

ProCarManuals.com

Page 279 of 1503

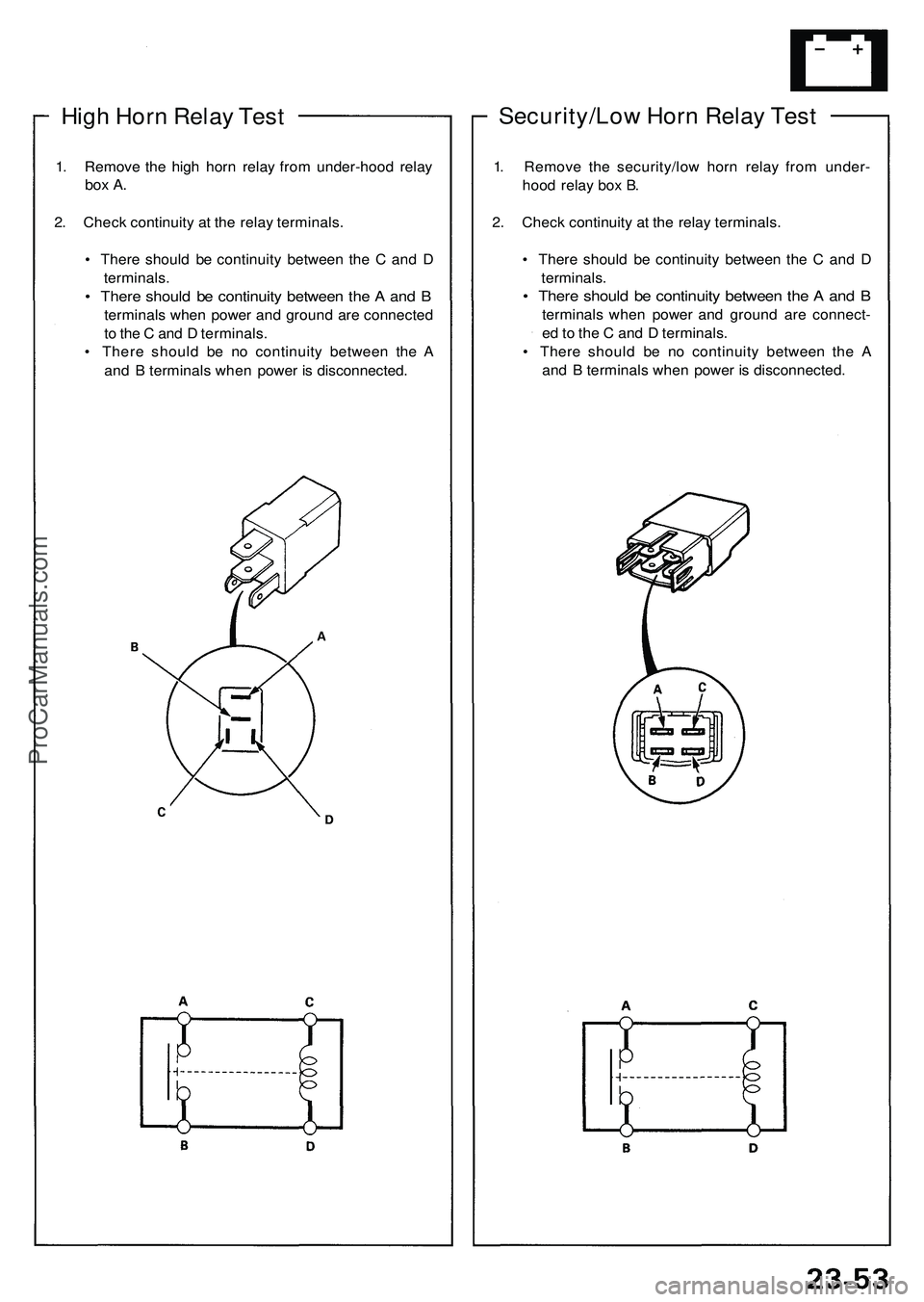

High Hor n Rela y Tes t

1. Remov e th e hig h hor n rela y fro m under-hoo d rela y

box A .

2. Chec k continuit y a t th e rela y terminals .

• Ther e shoul d b e continuit y betwee n th e C an d D

terminals .

• Ther e shoul d b e continuit y betwee n th e A an d B

terminal s whe n powe r an d groun d ar e connecte d

t o th e C an d D terminals .

• Ther e shoul d b e n o continuit y betwee n th e A

an d B terminal s whe n powe r i s disconnected .

Security/Low Hor n Rela y Tes t

1. Remov e th e security/lo w hor n rela y fro m under -

hoo d rela y bo x B .

2 . Chec k continuit y a t th e rela y terminals .

• Ther e shoul d b e continuit y betwee n th e C an d D

terminals .

• Ther e shoul d b e continuit y betwee n th e A an d B

terminal s whe n powe r an d groun d ar e connect -

e d to th e C an d D terminals .

• Ther e shoul d b e n o continuit y betwee n th e A

an d B terminal s whe n powe r i s disconnected .

ProCarManuals.com

Page 280 of 1503

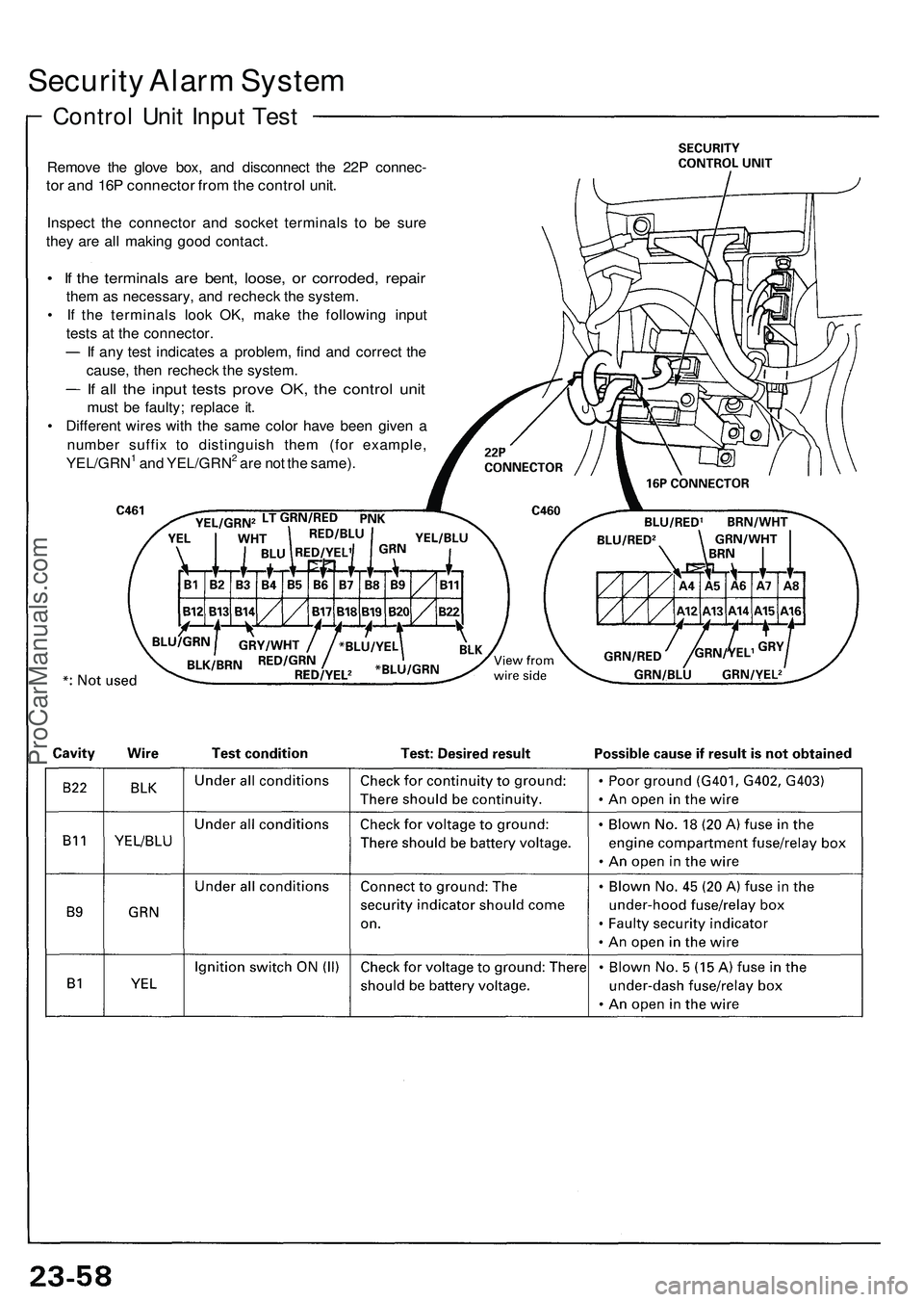

Security Alarm System

Control Unit Input Test

Remove the glove box, and disconnect the 22P connec-

tor and 16P connector from the control unit.

Inspect the connector and socket terminals to be sure

they are all making good contact.

• If the terminals are bent, loose, or corroded, repair

them as necessary, and recheck the system.

• If the terminals look OK, make the following input

tests at the connector.

If any test indicates a problem, find and correct the

cause, then recheck the system.

If all the input tests prove OK, the control unit

must be faulty; replace it.

• Different wires with the same color have been given a

number suffix to distinguish them (for example,

YEL/GRN1 and YEL/GRN2 are not the same).ProCarManuals.com