ACURA NSX 1997 Service Owner's Guide

Manufacturer: ACURA, Model Year: 1997, Model line: NSX, Model: ACURA NSX 1997Pages: 1503, PDF Size: 57.08 MB

Page 31 of 1503

Engine Oi l

Replacemen t

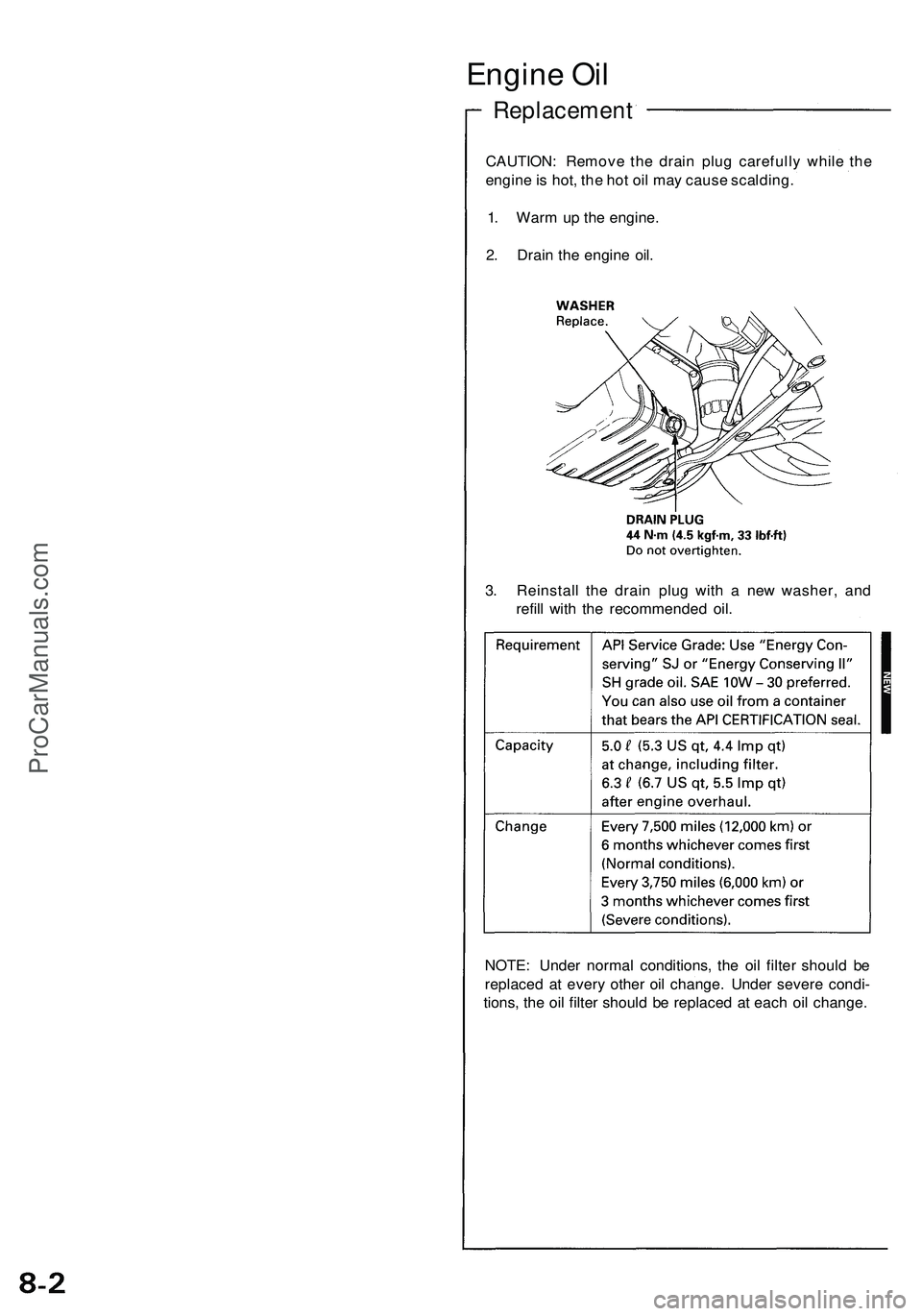

CAUTION: Remov e th e drai n plu g carefull y whil e th e

engin e is hot , th e ho t oi l ma y caus e scalding .

1 . War m u p th e engine .

2 . Drai n th e engin e oil .

3 . Reinstal l th e drai n plu g wit h a ne w washer , an d

refil l wit h th e recommende d oil .

NOTE : Unde r norma l conditions , th e oi l filte r shoul d b e

replace d a t ever y othe r oi l change . Unde r sever e condi -

tions , th e oi l filte r shoul d b e replace d a t eac h oi l change .

ProCarManuals.com

Page 32 of 1503

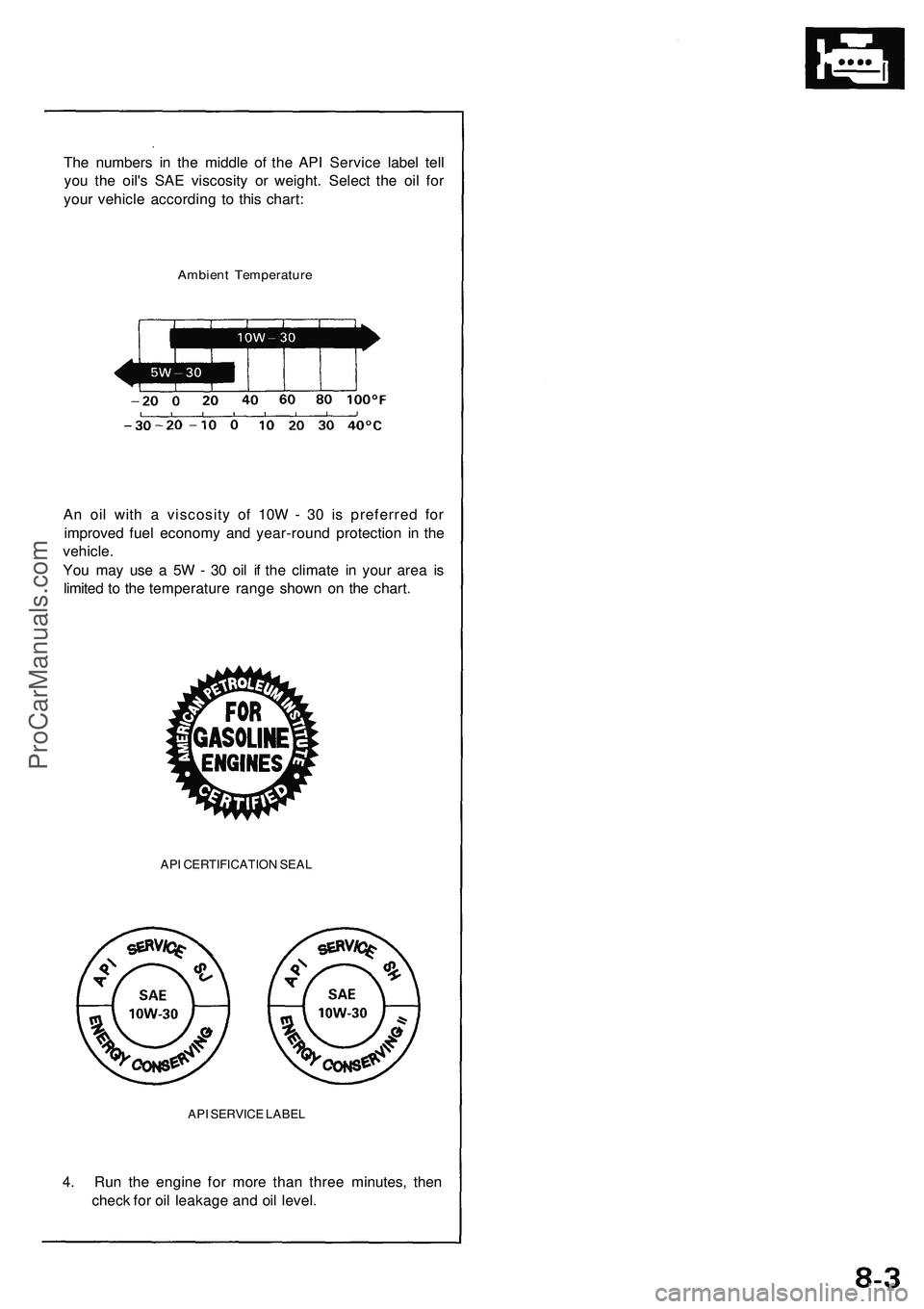

The numbers in the middle of the API Service label tell

you the oil's SAE viscosity or weight. Select the oil for

your vehicle according to this chart:

Ambient Temperature

An oil with a viscosity of 10W - 30 is preferred for

improved fuel economy and year-round protection in the

vehicle.

You may use a 5W - 30 oil if the climate in your area is

limited to the temperature range shown on the chart.

API CERTIFICATION SEAL

API SERVICE LABEL

4. Run the engine for more than three minutes, then

check for oil leakage and oil level.ProCarManuals.com

Page 33 of 1503

Troubleshooting Procedure s

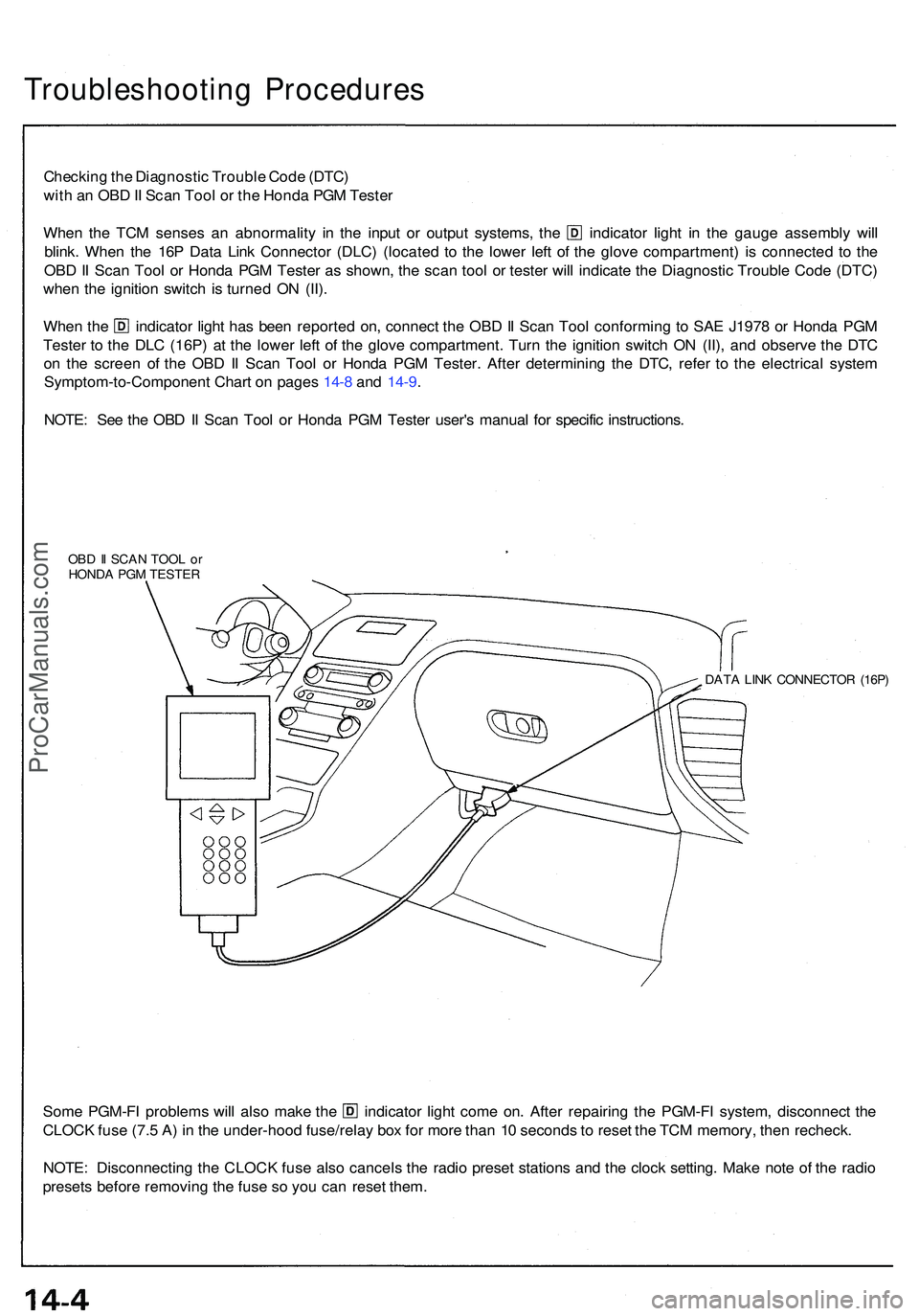

Checking th e Diagnosti c Troubl e Cod e (DTC )

wit h a n OB D II Sca n Too l o r th e Hond a PG M Teste r

When th e TC M sense s a n abnormalit y i n th e inpu t o r outpu t systems , th e indicato r ligh t i n th e gaug e assembl y wil l

blink . Whe n th e 16 P Dat a Lin k Connecto r (DLC ) (locate d t o th e lowe r lef t o f th e glov e compartment ) i s connecte d t o th e

OB D II Sca n Too l o r Hond a PG M Teste r a s shown , th e sca n too l o r teste r wil l indicat e th e Diagnosti c Troubl e Cod e (DTC )

whe n th e ignitio n switc h i s turne d O N (II) .

Whe n th e indicato r ligh t ha s bee n reporte d on , connec t th e OB D II Sca n Too l conformin g t o SA E J197 8 o r Hond a PG M

Teste r t o th e DL C (16P ) a t th e lowe r lef t o f th e glov e compartment . Tur n th e ignitio n switc h O N (II) , an d observ e th e DT C

o n th e scree n o f th e OB D II Sca n Too l o r Hond a PG M Tester . Afte r determinin g th e DTC , refe r t o th e electrica l syste m

Symptom-to-Componen t Char t o n page s 14- 8 an d 14-9 .

NOTE : Se e th e OB D II Sca n Too l o r Hond a PG M Teste r user' s manua l fo r specifi c instructions .

OBD II SCA N TOO L o r

HOND A PG M TESTE R

DATA LIN K CONNECTO R (16P )

Some PGM-F I problem s wil l als o mak e th e indicato r ligh t com e on . Afte r repairin g th e PGM-F I system , disconnec t th e

CLOC K fus e (7. 5 A ) i n th e under-hoo d fuse/rela y bo x fo r mor e tha n 1 0 second s t o rese t th e TC M memory , the n recheck .

NOTE : Disconnectin g th e CLOC K fus e als o cancel s th e radi o prese t station s an d th e cloc k setting . Mak e not e o f th e radi o

preset s befor e removin g th e fus e s o yo u ca n rese t them .

ProCarManuals.com

Page 34 of 1503

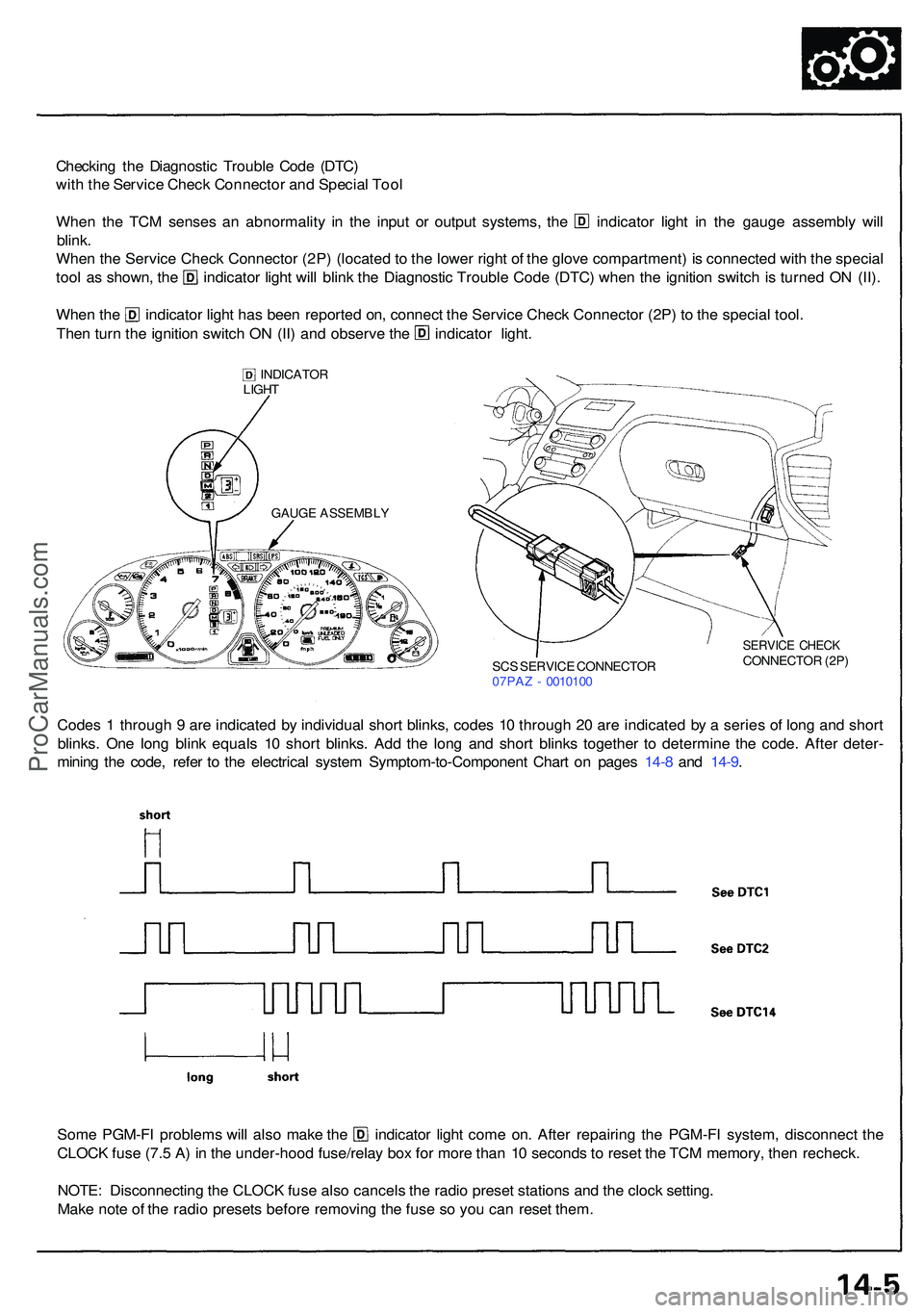

Checking th e Diagnosti c Troubl e Cod e (DTC )

wit h th e Servic e Chec k Connecto r an d Specia l Too l

Whe n th e TC M sense s a n abnormalit y i n th e inpu t o r outpu t systems , th e indicato r ligh t i n th e gaug e assembl y wil l

blink .

Whe n th e Servic e Chec k Connecto r (2P ) (locate d to th e lowe r righ t o f th e glov e compartment ) i s connecte d wit h th e specia l

tool a s shown , th e indicato r ligh t wil l blin k th e Diagnosti c Troubl e Cod e (DTC ) whe n th e ignitio n switc h i s turne d O N (II) .

Whe n th e indicato r ligh t ha s bee n reporte d on , connec t th e Servic e Chec k Connecto r (2P ) t o th e specia l tool .

Then tur n th e ignitio n switc h O N (II ) an d observ e th e indicato r light .

INDICATO R

LIGH T

SCS SERVIC E CONNECTO R

07PA Z - 001010 0

SERVIC E CHEC KCONNECTO R (2P )

Code s 1 throug h 9 ar e indicate d b y individua l shor t blinks , code s 1 0 throug h 2 0 ar e indicate d b y a serie s o f lon g an d shor t

blinks . On e lon g blin k equal s 1 0 shor t blinks . Ad d th e lon g an d shor t blink s togethe r t o determin e th e code . Afte r deter -

minin g th e code , refe r t o th e electrica l syste m Symptom-to-Componen t Char t o n page s 14-8 an d 14-9 .

Som e PGM-F I problem s wil l als o mak e th e indicato r ligh t com e on . Afte r repairin g th e PGM-F I system , disconnec t th e

CLOC K fus e (7. 5 A ) i n th e under-hoo d fuse/rela y bo x fo r mor e tha n 1 0 second s t o rese t th e TC M memory , the n recheck .

NOTE : Disconnectin g th e CLOC K fus e als o cancel s th e radi o prese t station s an d th e cloc k setting .

Mak e not e o f th e radi o preset s befor e removin g th e fus e s o yo u ca n rese t them .

GAUG E ASSEMBL Y

ProCarManuals.com

Page 35 of 1503

Troubleshooting Procedure s

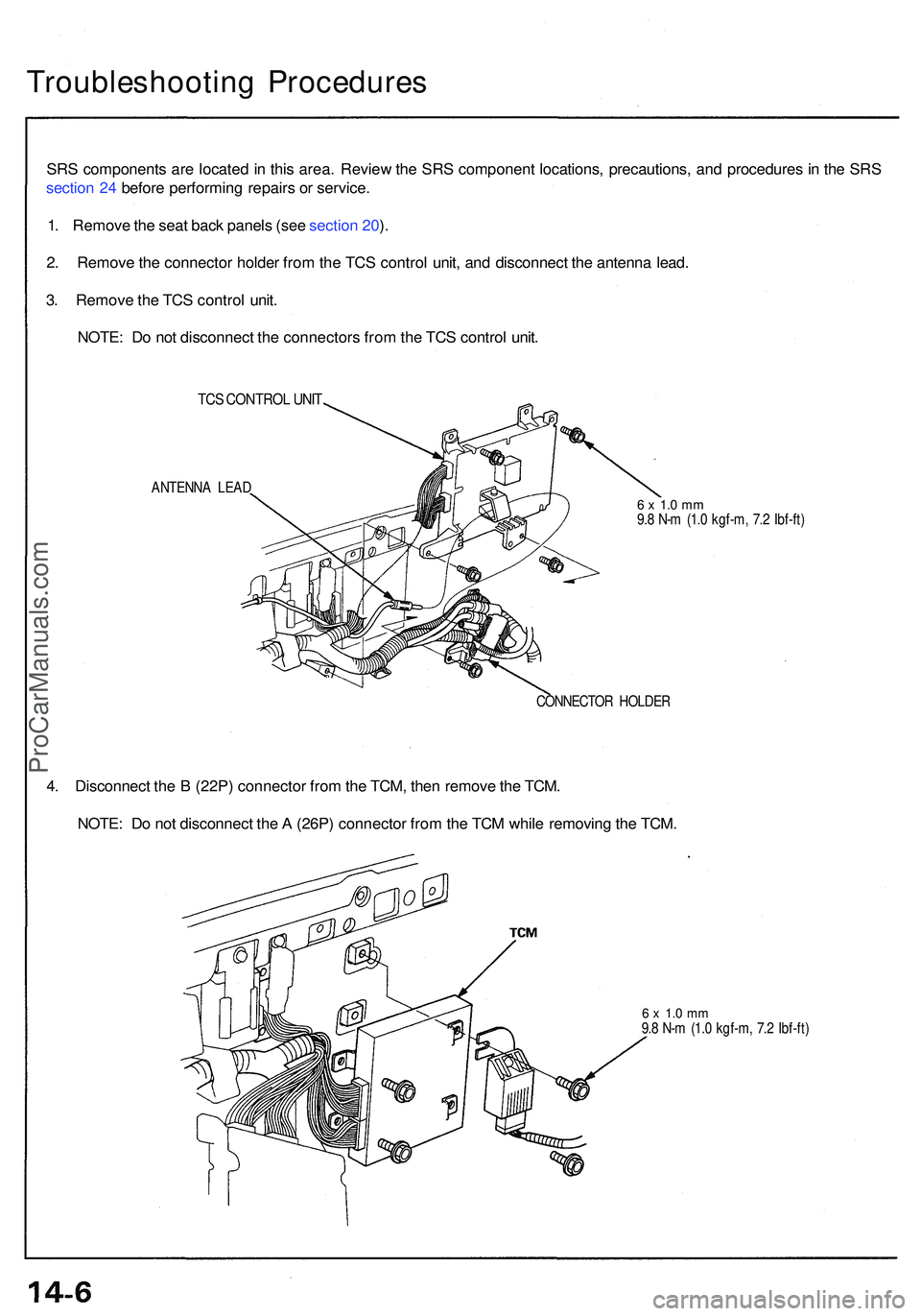

SRS component s ar e locate d in thi s area . Revie w th e SR S componen t locations , precautions , an d procedure s in th e SR S

sectio n 24 befor e performin g repair s o r service .

1 . Remov e th e sea t bac k panel s (se e sectio n 20 ).

2 . Remov e th e connecto r holde r fro m th e TC S contro l unit , an d disconnec t th e antenn a lead .

3 . Remov e th e TC S contro l unit .

NOTE : D o no t disconnec t th e connector s fro m th e TC S contro l unit .

TCS CONTRO L UNI T

ANTENN A LEA D6 x 1. 0 m m9.8 N- m (1. 0 kgf-m , 7. 2 Ibf-ft )

CONNECTO R HOLDE R

4. Disconnec t th e B (22P ) connecto r fro m th e TCM , the n remov e th e TCM .

NOTE : D o no t disconnec t th e A (26P ) connecto r fro m th e TC M whil e removin g th e TCM .

6 x 1. 0 m m9.8 N- m (1. 0 kgf-m , 7. 2 Ibf-ft )

ProCarManuals.com

Page 36 of 1503

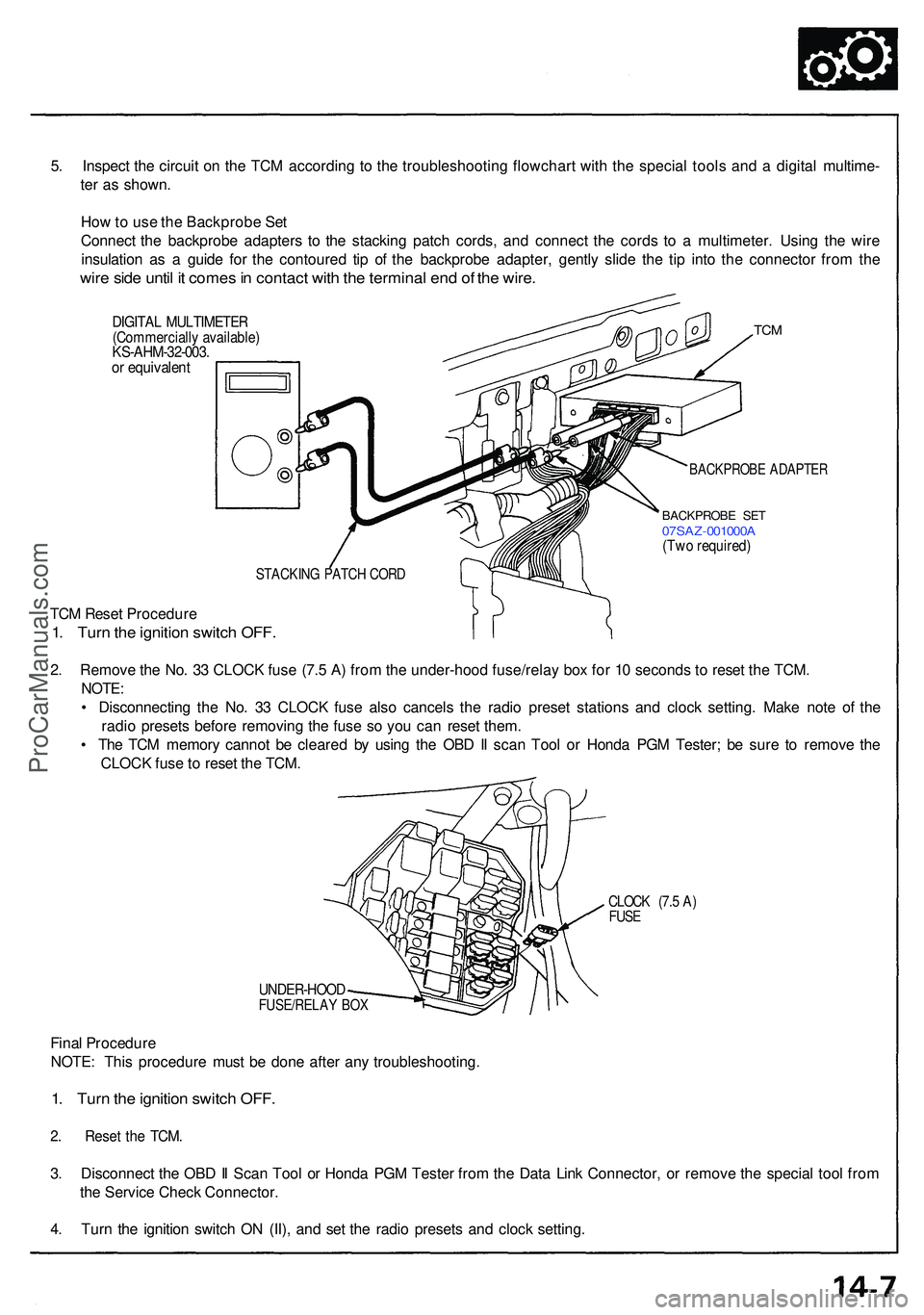

5. Inspec t th e circui t o n th e TC M accordin g t o th e troubleshootin g flowchar t wit h th e specia l tool s an d a digita l multime -

te r a s shown .

Ho w to us e th e Backprob e Se t

Connec t th e backprob e adapter s t o th e stackin g patc h cords , an d connec t th e cord s t o a multimeter . Usin g th e wir e

insulatio n a s a guid e fo r th e contoure d ti p o f th e backprob e adapter , gentl y slid e th e ti p int o th e connecto r fro m th e

wire sid e unti l i t come s in contac t wit h th e termina l en d o f th e wire .

DIGITA L MULTIMETE R(Commerciall y available )KS-AHM-32-003 .or equivalen t

TCM

BACKPROB E ADAPTE R

BACKPROB E SE T07SA Z-001000 A(Two required )

STACKIN G PATC H COR D

TCM Rese t Procedur e

1. Tur n th e ignitio n switc h OFF .

2. Remov e th e No . 3 3 CLOC K fus e (7. 5 A ) fro m th e under-hoo d fuse/rela y bo x fo r 1 0 second s t o rese t th e TCM .

NOTE :

• Disconnectin g th e No . 3 3 CLOC K fus e als o cancel s th e radi o prese t station s an d cloc k setting . Mak e not e o f th e

radi o preset s befor e removin g th e fus e s o yo u ca n rese t them .

• Th e TC M memor y canno t b e cleare d b y usin g th e OB D II sca n Too l o r Hond a PG M Tester ; b e sur e t o remov e th e

CLOC K fus e to rese t th e TCM .

CLOC K (7. 5 A )FUS E

UNDER-HOO DFUSE/RELAY BO X

Fina l Procedur e

NOTE : Thi s procedur e mus t b e don e afte r an y troubleshooting .

1. Tur n th e ignitio n switc h OFF .

2. Rese t th e TCM .

3. Disconnec t th e OB D II Sca n Too l o r Hond a PG M Teste r fro m th e Dat a Lin k Connector , o r remov e th e specia l too l fro m

th e Servic e Chec k Connector .

4 . Tur n th e ignitio n switc h O N (II) , an d se t th e radi o preset s an d cloc k setting .

ProCarManuals.com

Page 37 of 1503

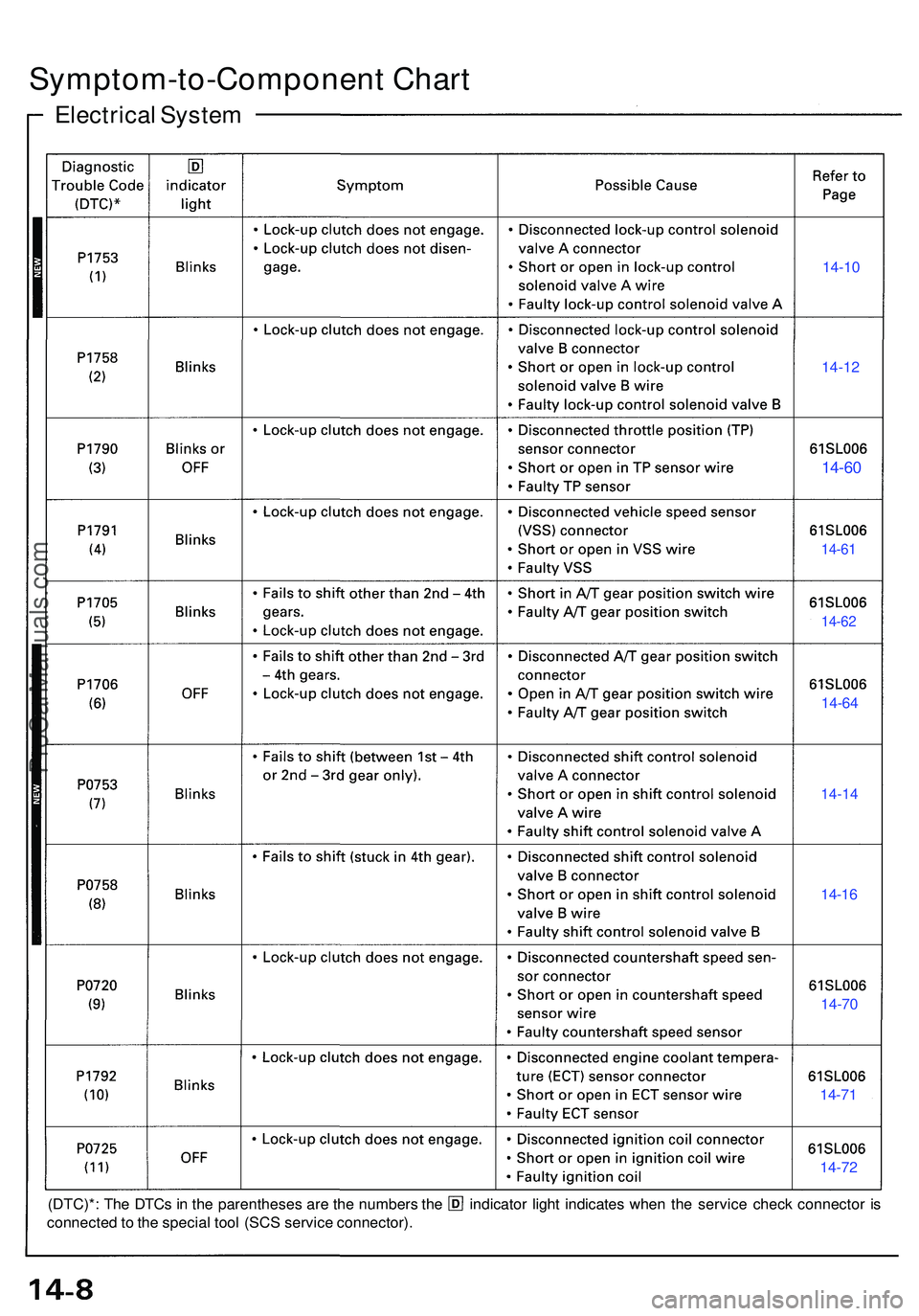

Symptom-to-Component Char t

Electrica l Syste m

14-10

14-1 2

14-60

14-6 1

14-62

14-6 4

14-1 4

14-16

14-7 0

14-71

14-7 2

(DTC)* : Th e DTC s i n th e parenthese s ar e th e number s th e indicato r ligh t indicate s whe n th e servic e chec k connecto r i s

connecte d to th e specia l too l (SC S servic e connector) .

ProCarManuals.com

Page 38 of 1503

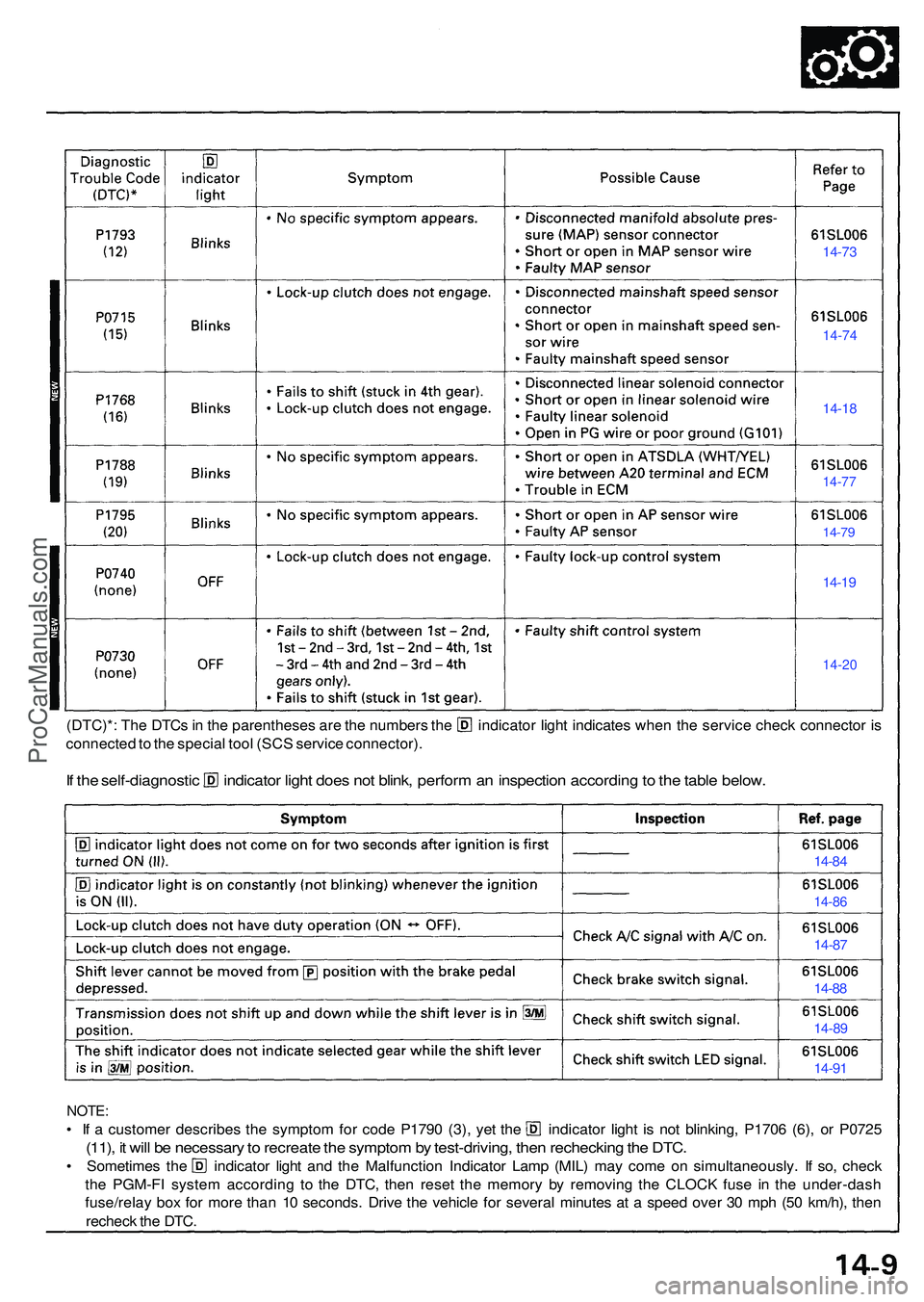

(DTC)*: The DTC s in th e parenthese s ar e th e number s th e indicato r ligh t indicate s whe n th e servic e chec k connecto r i s

connecte d to th e specia l too l (SC S servic e connector) .

If th e self-diagnosti c indicato r ligh t doe s no t blink , perfor m an inspectio n accordin g to th e tabl e below .

NOTE:

• I f a custome r describe s th e sympto m fo r cod e P179 0 (3) , ye t th e indicato r ligh t i s no t blinking , P170 6 (6) , o r P072 5

(11), i t wil l b e necessar y to recreat e th e sympto m by test-driving , the n recheckin g th e DTC .

• Sometime s th e indicato r ligh t an d th e Malfunctio n Indicato r Lam p (MIL ) ma y com e o n simultaneously . I f so , chec k

th e PGM-F I syste m accordin g t o th e DTC , the n rese t th e memor y b y removin g th e CLOC K fus e i n th e under-das h

fuse/rela y bo x fo r mor e tha n 1 0 seconds . Driv e th e vehicl e fo r severa l minute s a t a spee d ove r 3 0 mp h (5 0 km/h) , the n

rechec k th e DTC .

14-73

14-7 4

14-18

14-7 7

14-79

14-19

14-2 0

14-84

14-8 6

14-87

14-8 8

14-8 9

14-91

ProCarManuals.com

Page 39 of 1503

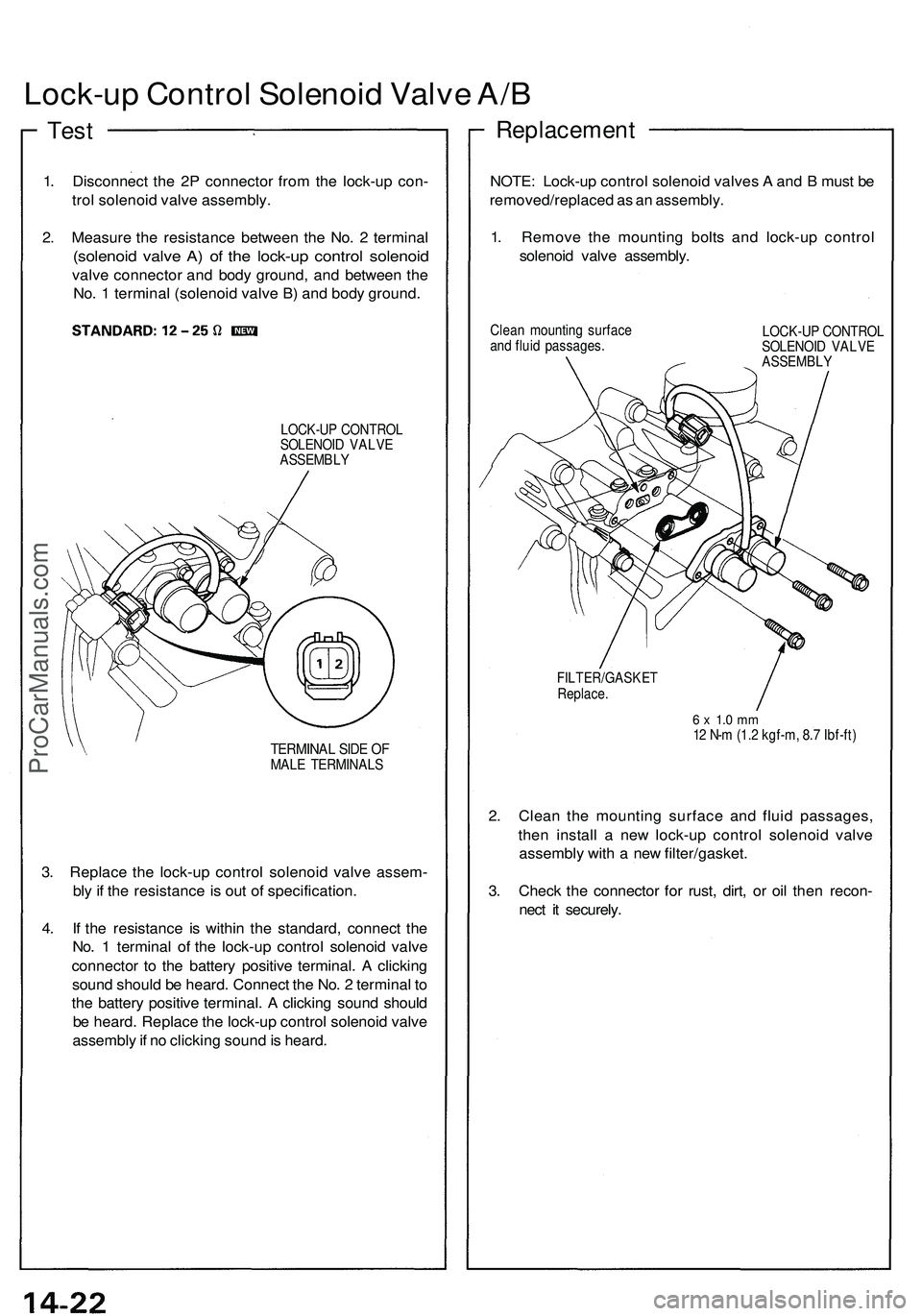

Lock-up Contro l Solenoi d Valv e A/ B

Replacemen t

1. Disconnec t th e 2 P connecto r fro m th e lock-u p con -

tro l solenoi d valv e assembly .

2 . Measur e th e resistanc e betwee n th e No . 2 termina l

(solenoid valv e A ) o f th e lock-u p contro l solenoi d

valve connecto r an d bod y ground , an d betwee n th e

No . 1 termina l (solenoi d valv e B ) an d bod y ground .

LOCK-U P CONTRO L

SOLENOI D VALV E

ASSEMBL Y

TERMINAL SID E O FMAL E TERMINAL S

3. Replac e th e lock-u p contro l solenoi d valv e assem -

bl y if th e resistanc e is ou t o f specification .

4 . I f th e resistanc e i s withi n th e standard , connec t th e

No . 1 termina l o f th e lock-u p contro l solenoi d valv e

connecto r t o th e batter y positiv e terminal . A clickin g

soun d shoul d b e heard . Connec t th e No . 2 termina l t o

th e batter y positiv e terminal . A clickin g soun d shoul d

b e heard . Replac e th e lock-u p contro l solenoi d valv e

assembl y if n o clickin g soun d is heard . NOTE

: Lock-u p contro l solenoi d valve s A an d B mus t b e

removed/replace d a s a n assembly .

1 . Remov e th e mountin g bolt s an d lock-u p contro l

solenoi d valv e assembly .

Clean mountin g surfac e

an d flui d passages . LOCK-U

P CONTRO L

SOLENOI D VALV E

ASSEMBL Y

FILTER/GASKE TReplace.

6 x 1. 0 m m12 N- m (1. 2 kgf-m , 8. 7 Ibf-ft )

2. Clea n th e mountin g surfac e an d flui d passages ,

the n instal l a ne w lock-u p contro l solenoi d valv e

assembl y wit h a ne w filter/gasket .

3 . Chec k th e connecto r fo r rust , dirt , o r oi l the n recon -

nec t i t securely .

Test

ProCarManuals.com

Page 40 of 1503

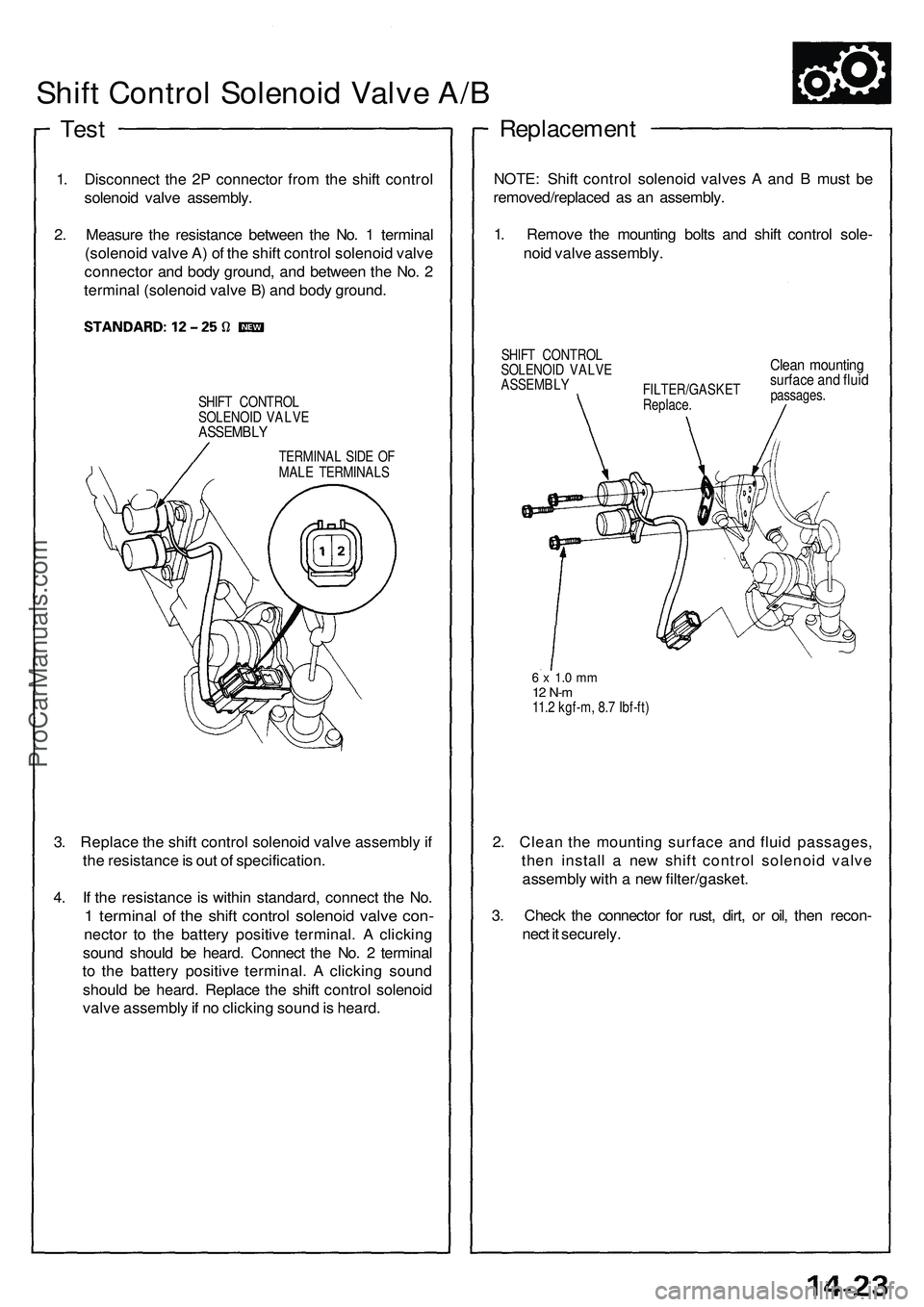

Shift Contro l Solenoi d Valv e A/ B

Tes t

1. Disconnec t th e 2 P connecto r fro m th e shif t contro l

solenoi d valv e assembly .

2 . Measur e th e resistanc e betwee n th e No . 1 termina l

(solenoi d valv e A ) o f th e shif t contro l solenoi d valv e

connecto r an d bod y ground , an d betwee n th e No . 2

termina l (solenoi d valv e B ) an d bod y ground .

SHIFT CONTRO L

SOLENOI D VALV E

ASSEMBL Y

TERMINAL SID E O F

MAL E TERMINAL S

3. Replac e th e shif t contro l solenoi d valv e assembl y if

th e resistanc e is ou t o f specification .

4 . I f th e resistanc e is withi n standard , connec t th e No .

1 termina l o f th e shif t contro l solenoi d valv e con -

necto r t o th e batter y positiv e terminal . A clickin g

soun d shoul d b e heard . Connec t th e No . 2 termina l

t o th e batter y positiv e terminal . A clickin g soun d

shoul d b e heard . Replac e th e shif t contro l solenoi d

valv e assembl y if n o clickin g soun d is heard .

Replacemen t

NOTE: Shif t contro l solenoi d valve s A an d B mus t b e

removed/replace d a s a n assembly .

1 . Remov e th e mountin g bolt s an d shif t contro l sole -

noi d valv e assembly .

SHIFT CONTRO L

SOLENOI D VALV E

ASSEMBL Y

FILTER/GASKE T

Replace .Clean mountin gsurface an d flui dpassages .

6 x 1. 0 m m12 N- m11. 2 kgf-m , 8. 7 Ibf-ft )

2. Clea n th e mountin g surfac e an d flui d passages ,

the n instal l a ne w shif t contro l solenoi d valv e

assembl y wit h a ne w filter/gasket .

3 . Chec k th e connecto r fo r rust , dirt , o r oil , the n recon -

nec t i t securely .

ProCarManuals.com