ACURA NSX 1997 Service Repair Manual

Manufacturer: ACURA, Model Year: 1997, Model line: NSX, Model: ACURA NSX 1997Pages: 1503, PDF Size: 57.08 MB

Page 421 of 1503

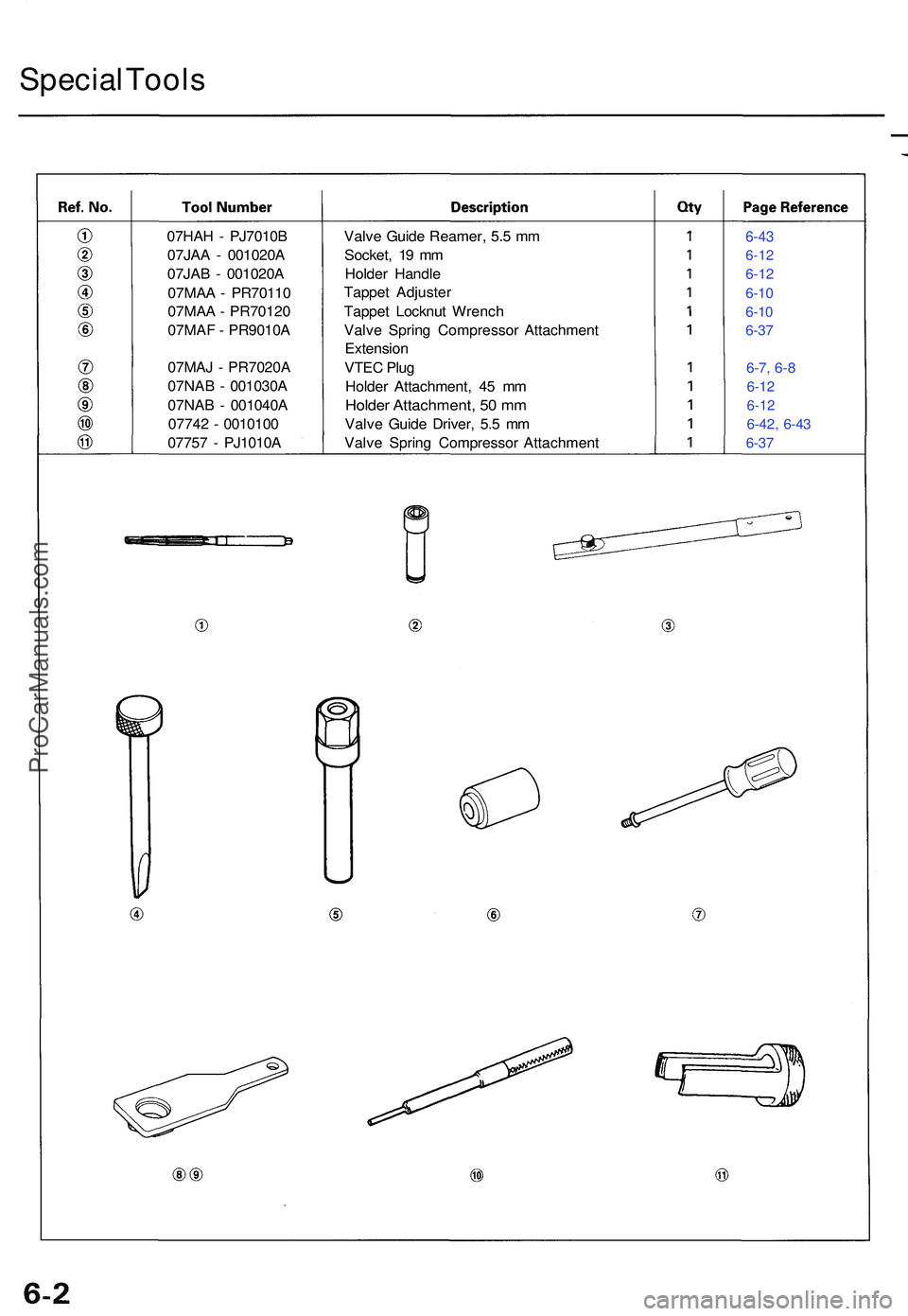

Special Tool s

07HA H - PJ7010 B

07JA A - 001020 A

07JA B - 001020 A

07MA A - PR7011 0

07MA A - PR7012 0

07MA F - PR9010 A

07MA J - PR7020 A

07NA B - 001030 A

07NA B - 001040 A

0774 2 - 001010 0

0775 7 - PJ1010 A Valv

e Guid e Reamer , 5. 5 m m

Socket , 1 9 m m

Holde r Handl e

Tappe t Adjuste r

Tappe t Locknu t Wrenc h

Valv e Sprin g Compresso r Attachmen t

Extensio n

VTE C Plu g

Holde r Attachment , 4 5 m m

Holde r Attachment , 5 0 m m

Valv e Guid e Driver , 5. 5 m m

Valv e Sprin g Compresso r Attachmen t

6-43

6-1 2

6-12

6-1 0

6-1 0

6-3 7

6-7 ,

6-8

6-1 2

6-1 2

6-42 , 6-43

6-37

ProCarManuals.com

Page 422 of 1503

VTEC

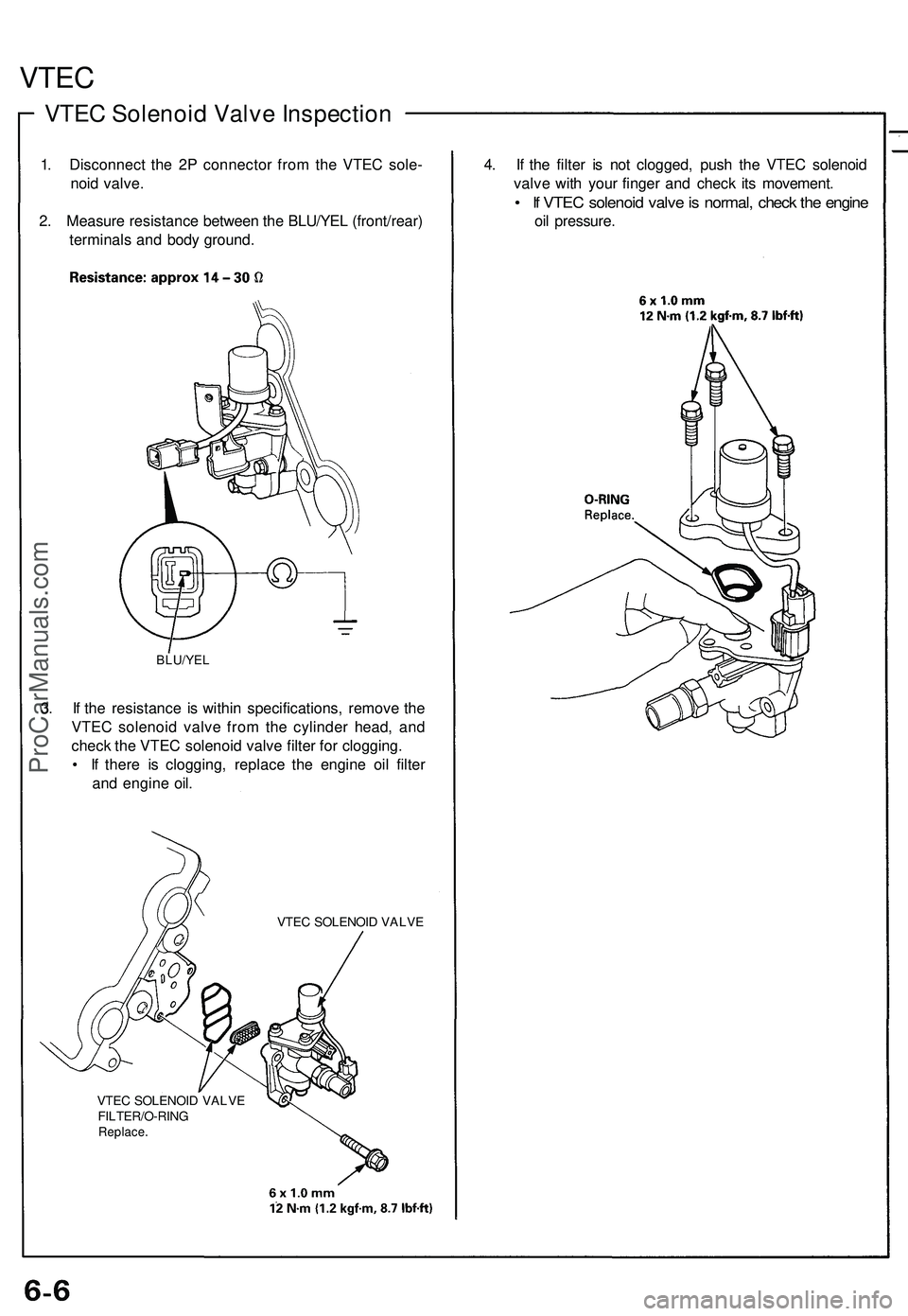

VTEC Solenoid Valve Inspection

1. Disconnect the 2P connector from the VTEC sole-

noid valve.

2. Measure resistance between the BLU/YEL (front/rear)

terminals and body ground.

BLU/YEL

3. If the resistance is within specifications, remove the

VTEC solenoid valve from the cylinder head, and

check the VTEC solenoid valve filter for clogging.

• If there is clogging, replace the engine oil filter

and engine oil.

VTEC SOLENOID VALVE

VTEC SOLENOID VALVE

FILTER/O-RING

Replace.

4. If the filter is not clogged, push the VTEC solenoid

valve with your finger and check its movement.

• If VTEC solenoid valve is normal, check the engine

oil pressure.ProCarManuals.com

Page 423 of 1503

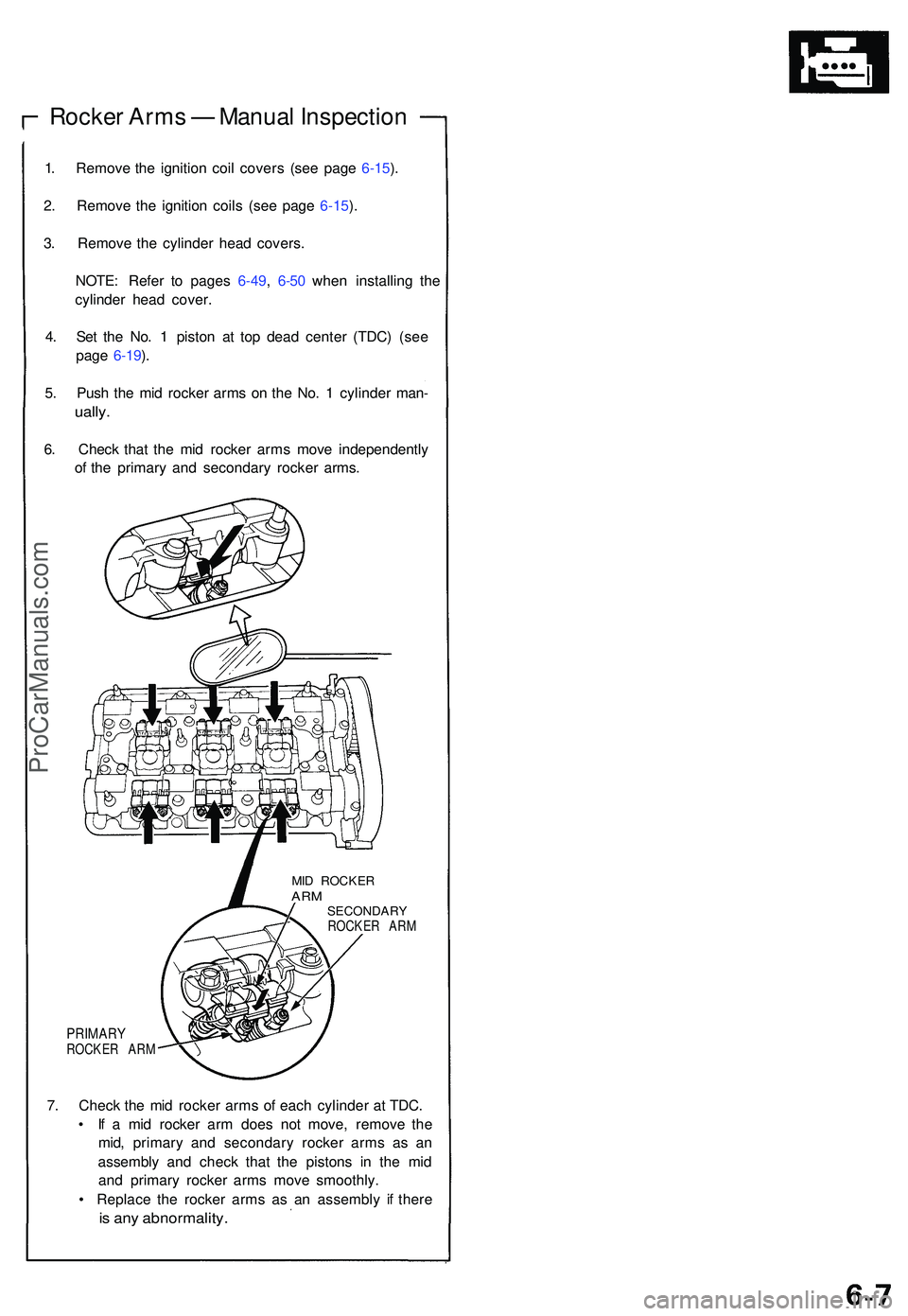

Rocker Arm s — Manua l Inspectio n

1. Remov e th e ignitio n coi l cover s (se e pag e 6-15 ).

2 . Remov e th e ignitio n coil s (se e pag e 6-15 ).

3 . Remov e th e cylinde r hea d covers .

NOTE : Refe r t o page s 6-49 , 6-5 0 whe n installin g th e

cylinde r hea d cover .

4 . Se t th e No . 1 pisto n a t to p dea d cente r (TDC ) (se e

pag e 6-19 ).

5 . Pus h th e mi d rocke r arm s o n th e No . 1 cylinde r man -

ually.

6. Chec k tha t th e mi d rocke r arm s mov e independentl y

o f th e primar y an d secondar y rocke r arms .

MID ROCKE RARMSECONDAR YROCKER AR M

PRIMAR YROCKER AR M

7. Chec k th e mi d rocke r arm s o f eac h cylinde r a t TDC .

• I f a mi d rocke r ar m doe s no t move , remov e th e

mid , primar y an d secondar y rocke r arm s a s a n

assembl y an d chec k tha t th e piston s i n th e mi d

an d primar y rocke r arm s mov e smoothly .

• Replac e th e rocke r arm s a s a n assembl y i f ther e

is an y abnormality .

ProCarManuals.com

Page 424 of 1503

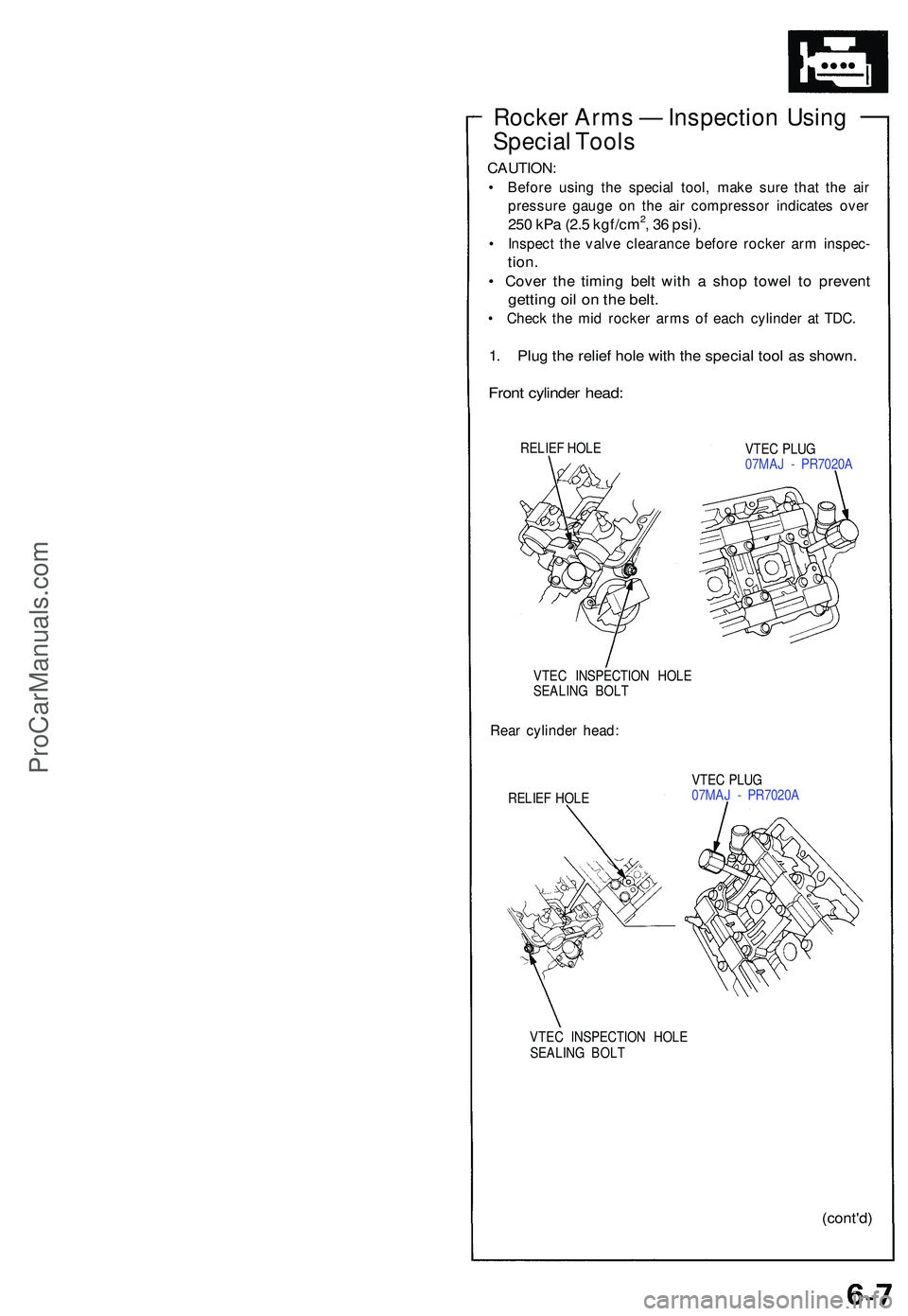

Rocker Arm s — Inspectio n Usin g

Specia l Tool s

CAUTION :

• Befor e usin g th e specia l tool , mak e sur e tha t th e ai r

pressur e gaug e o n th e ai r compresso r indicate s ove r

250 kP a (2. 5 kgf/cm2, 3 6 psi) .

• Inspec t th e valv e clearanc e befor e rocke r ar m inspec -

tion.

• Cove r th e timin g bel t wit h a sho p towe l t o preven t

getting oi l o n th e belt .

• Chec k th e mi d rocke r arm s o f eac h cylinde r a t TDC .

1. Plu g th e relie f hol e wit h th e specia l too l a s shown .

Front cylinde r head :

RELIE F HOL E

VTEC PLU G

07MA J - PR7020 A

VTE C INSPECTIO N HOL E

SEALIN G BOL T

Rear cylinde r head :

RELIE F HOL E VTE

C PLU G

07MA J - PR7020 A

VTE C INSPECTIO N HOL E

SEALIN G BOL T

(cont'd )

ProCarManuals.com

Page 425 of 1503

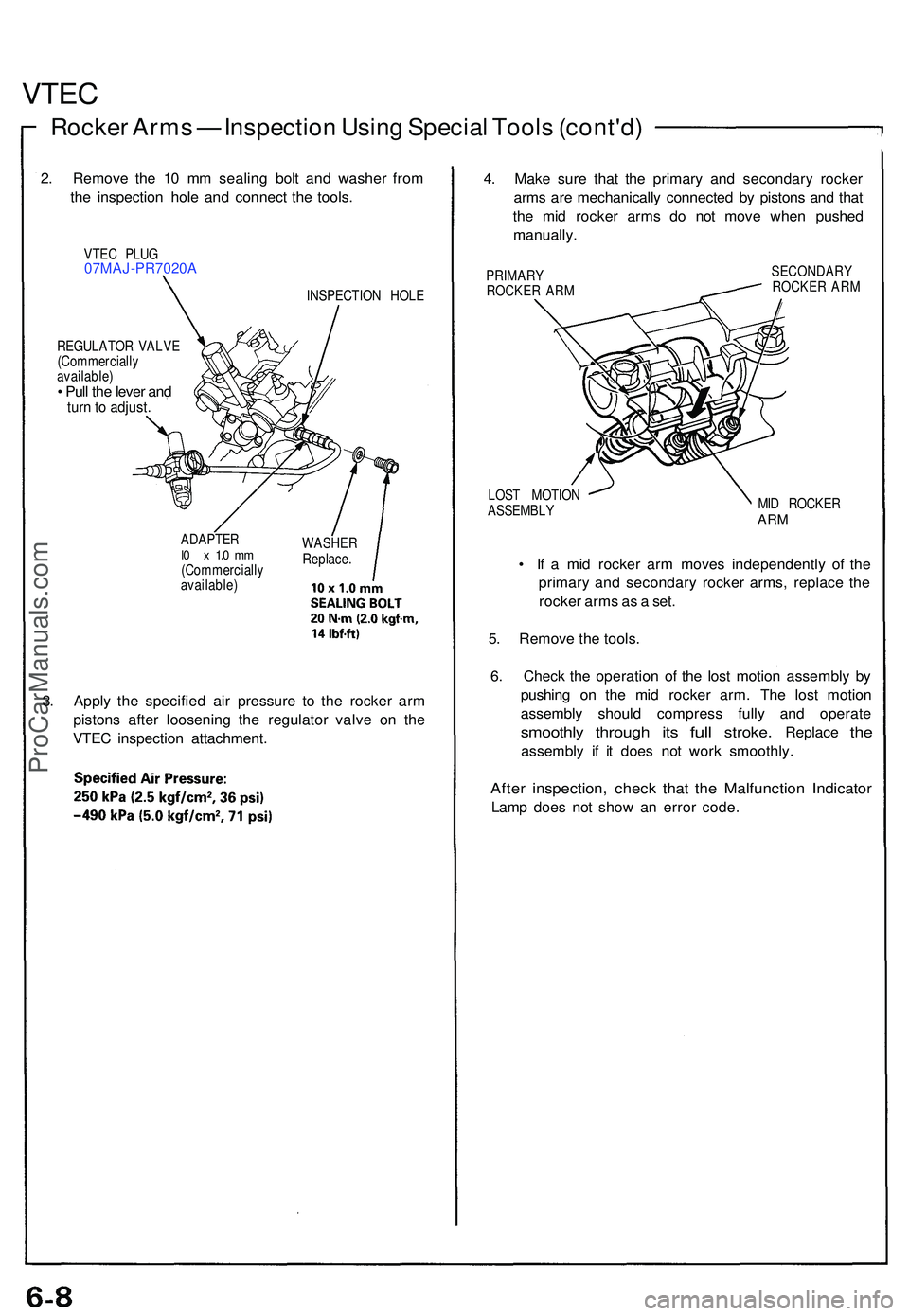

VTEC

Rocke r Arm s — Inspectio n Usin g Specia l Tool s (cont'd )

2. Remov e th e 1 0 m m sealin g bol t an d washe r fro m

th e inspectio n hol e an d connec t th e tools .

VTEC PLU G07MAJ-PR7020 A

REGULATOR VALV E

(Commerciall y

available )

• Pul l th e leve r an dturn to adjust .

INSPECTIO N HOL E

ADAPTE R

l0 x 1.0 m m(Commerciall y

available ) WASHE

R

Replace .

3. Appl y th e specifie d ai r pressur e t o th e rocke r ar m

piston s afte r loosenin g th e regulato r valv e o n th e

VTE C inspectio n attachment . 4

. Mak e sur e tha t th e primar y an d secondar y rocke r

arm s ar e mechanicall y connecte d b y piston s an d tha t

th e mi d rocke r arm s d o no t mov e whe n pushe d

manually .

PRIMARY

ROCKE R ARM

LOS T MOTIO N

ASSEMBL Y SECONDAR

Y

ROCKE R AR M

MI D ROCKE R

ARM

• I f a mi d rocke r ar m move s independentl y o f th e

primar y an d secondar y rocke r arms , replac e th e

rocke r arm s a s a set .

5 . Remov e th e tools .

6 . Chec k th e operatio n of the los t motio n assembl y b y

pushin g o n th e mi d rocke r arm . Th e los t motio n

assembl y shoul d compres s full y an d operat e

smoothly throug h its ful l stroke . Replac e the

assembl y i f i t doe s no t wor k smoothly .

After inspection , chec k tha t th e Malfunctio n Indicato r

Lamp doe s no t sho w a n erro r code .

ProCarManuals.com

Page 426 of 1503

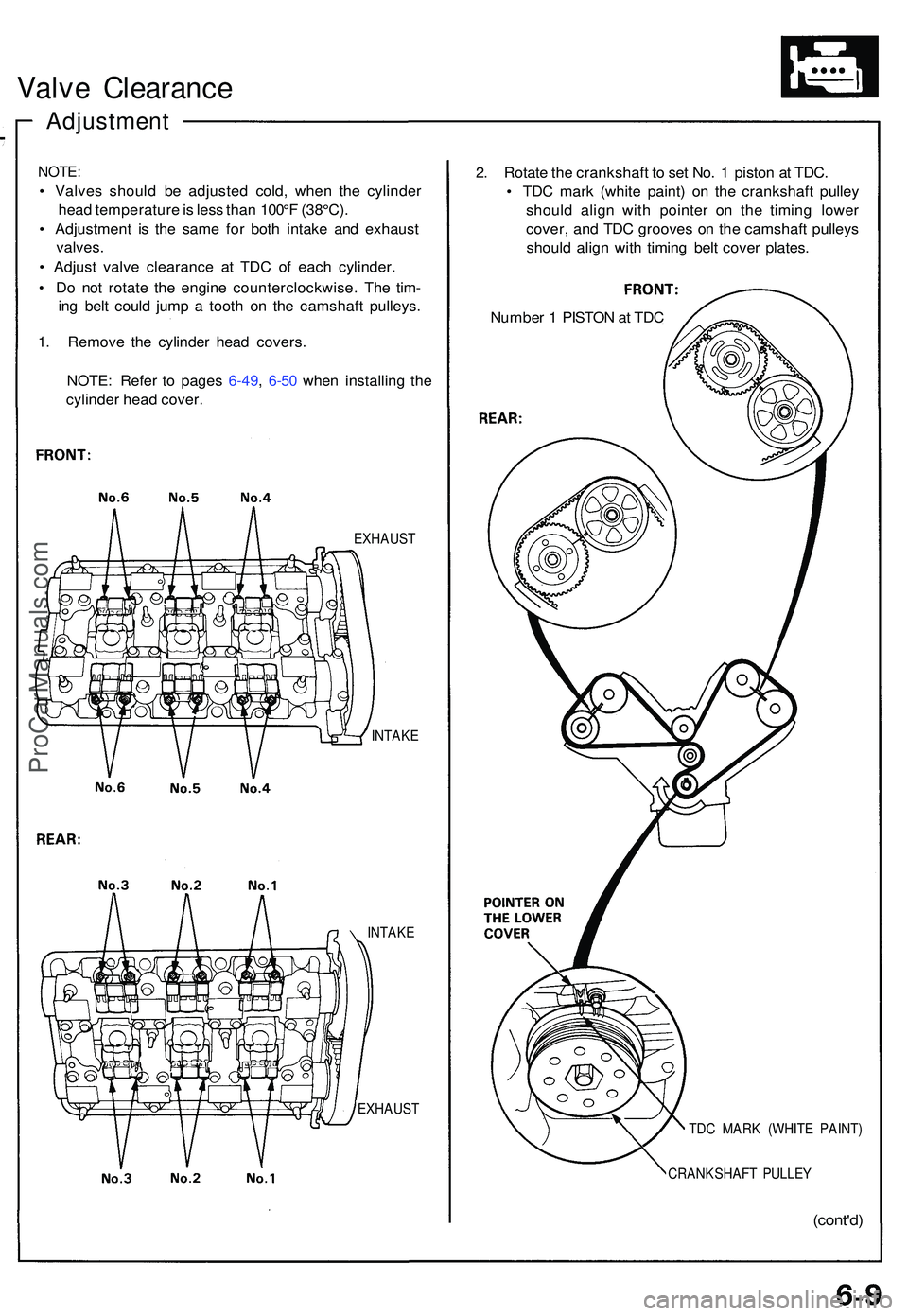

Valve Clearanc e

Adjustmen t

NOTE:

• Valve s shoul d b e adjuste d cold , whe n th e cylinde r

hea d temperatur e is les s tha n 100° F (38°C) .

• Adjustmen t i s th e sam e fo r bot h intak e an d exhaus t

valves .

• Adjus t valv e clearanc e a t TD C o f eac h cylinder .

• D o no t rotat e th e engin e counterclockwise . Th e tim -

in g bel t coul d jum p a toot h o n th e camshaf t pulleys .

1 . Remov e th e cylinde r hea d covers .

NOTE : Refe r t o page s 6-49 , 6-5 0 whe n installin g th e

cylinde r hea d cover .

EXHAUS T

INTAK E

INTAK E

EXHAUS T

2. Rotat e th e crankshaf t t o se t No . 1 pisto n a t TDC .

• TD C mar k (whit e paint ) o n th e crankshaf t pulle y

shoul d alig n wit h pointe r o n th e timin g lowe r

cover , an d TD C groove s o n th e camshaf t pulley s

shoul d alig n wit h timin g bel t cove r plates .

Numbe r 1 PISTO N a t TD C

TDC MAR K (WHIT E PAINT )

CRANKSHAF T PULLE Y

(cont'd)

ProCarManuals.com

Page 427 of 1503

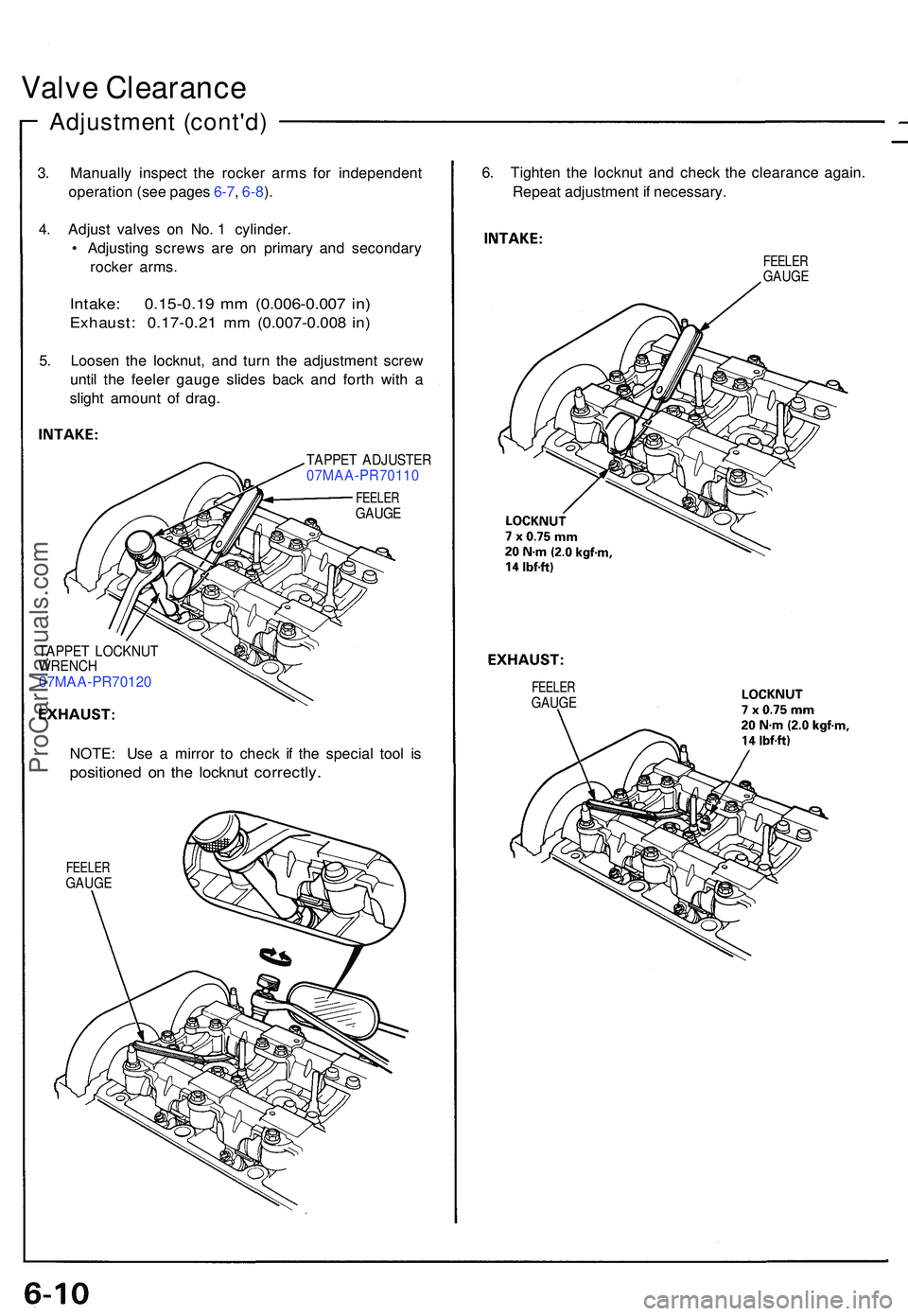

Valve Clearanc e

Adjustmen t (cont'd )

3. Manuall y inspec t th e rocke r arm s fo r independen t

operatio n (se e page s 6-7 , 6-8 ).

4 . Adjus t valve s o n No . 1 cylinder .

• Adjustin g screw s ar e o n primar y an d secondar y

rocke r arms .

Intake : 0.15-0.1 9 m m (0.006-0.00 7 in )

Exhaust : 0.17-0.2 1 m m (0.007-0.00 8 in )

5. Loose n th e locknut , an d tur n th e adjustmen t scre w

unti l th e feele r gaug e slide s bac k an d fort h wit h a

sligh t amoun t o f drag .

TAPPE T ADJUSTE R07MAA-PR7011 0

FEELERGAUGE

TAPPE T LOCKNU T

WRENC H

07MAA-PR7012 0

NOTE: Us e a mirro r t o chec k i f th e specia l too l i s

positione d o n th e locknu t correctly .

FEELERGAUGE

6. Tighte n th e locknu t an d chec k th e clearanc e again .

Repea t adjustmen t i f necessary .

FEELERGAUGE

FEELE RGAUGE

ProCarManuals.com

Page 428 of 1503

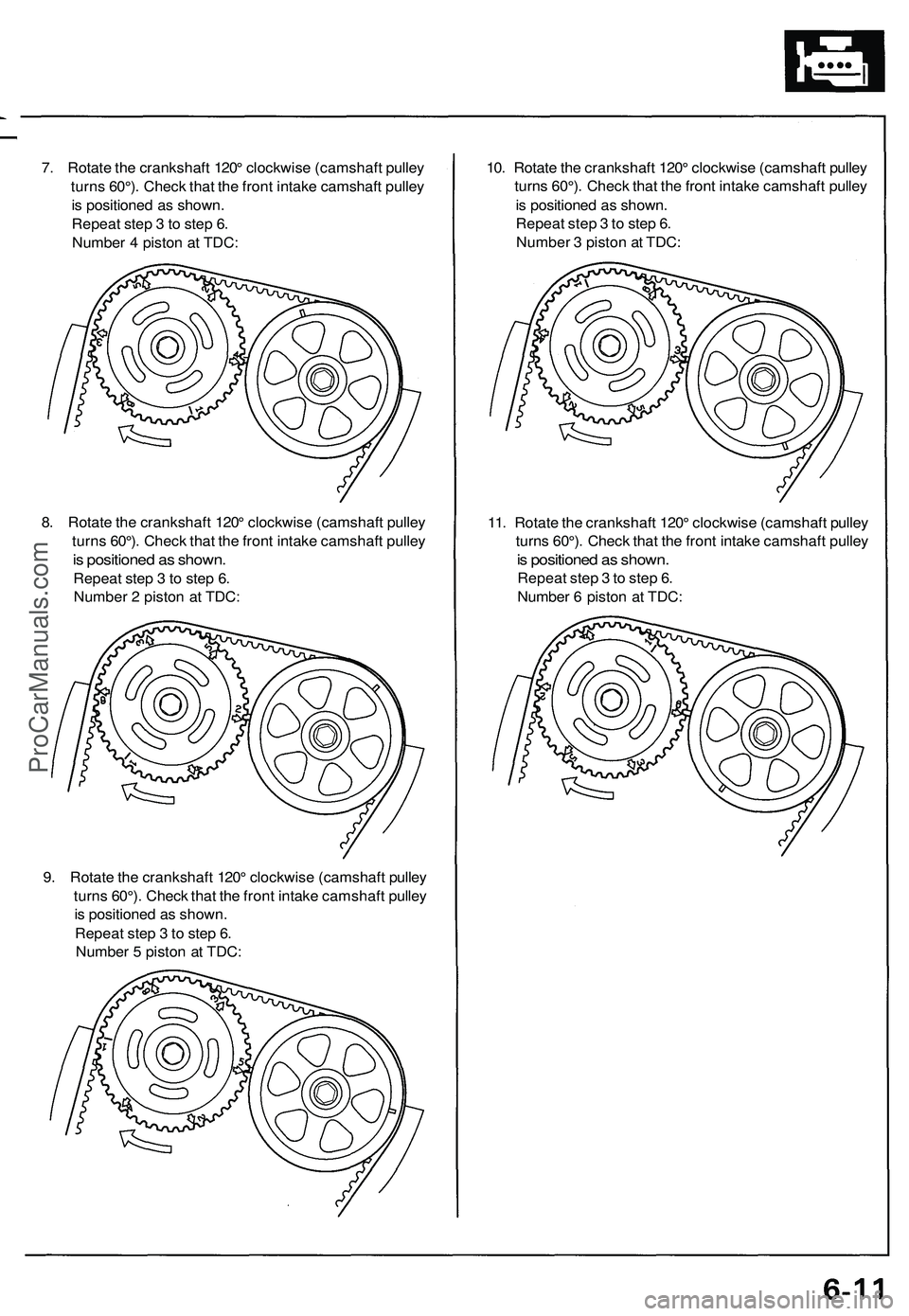

7. Rotat e th e crankshaf t 120 ° clockwis e (camshaf t pulle y

turn s 60°) . Chec k tha t th e fron t intak e camshaf t pulle y

i s positione d a s shown .

Repea t ste p 3 to ste p 6 .

Numbe r 4 pisto n a t TDC :

8 . Rotat e th e crankshaf t 120 ° clockwis e (camshaf t pulle y

turn s 60°) . Chec k tha t th e fron t intak e camshaf t pulle y

is positione d a s shown .

Repea t ste p 3 to ste p 6 .

Numbe r 2 pisto n a t TDC :

9 . Rotat e th e crankshaf t 120 ° clockwis e (camshaf t pulle y

turn s 60°) . Chec k tha t th e fron t intak e camshaf t pulle y

i s positione d a s shown .

Repea t ste p 3 to ste p 6 .

Numbe r 5 pisto n a t TDC : 10

. Rotat e th e crankshaf t 120 ° clockwis e (camshaf t pulle y

turn s 60°) . Chec k tha t th e fron t intak e camshaf t pulle y

i s positione d a s shown .

Repea t ste p 3 to ste p 6 .

Numbe r 3 pisto n a t TDC :

11 . Rotat e th e crankshaf t 120 ° clockwis e (camshaf t pulle y

turn s 60°) . Chec k tha t th e fron t intak e camshaf t pulle y

is positione d a s shown .

Repea t ste p 3 to ste p 6 .

Numbe r 6 pisto n a t TDC :

ProCarManuals.com

Page 429 of 1503

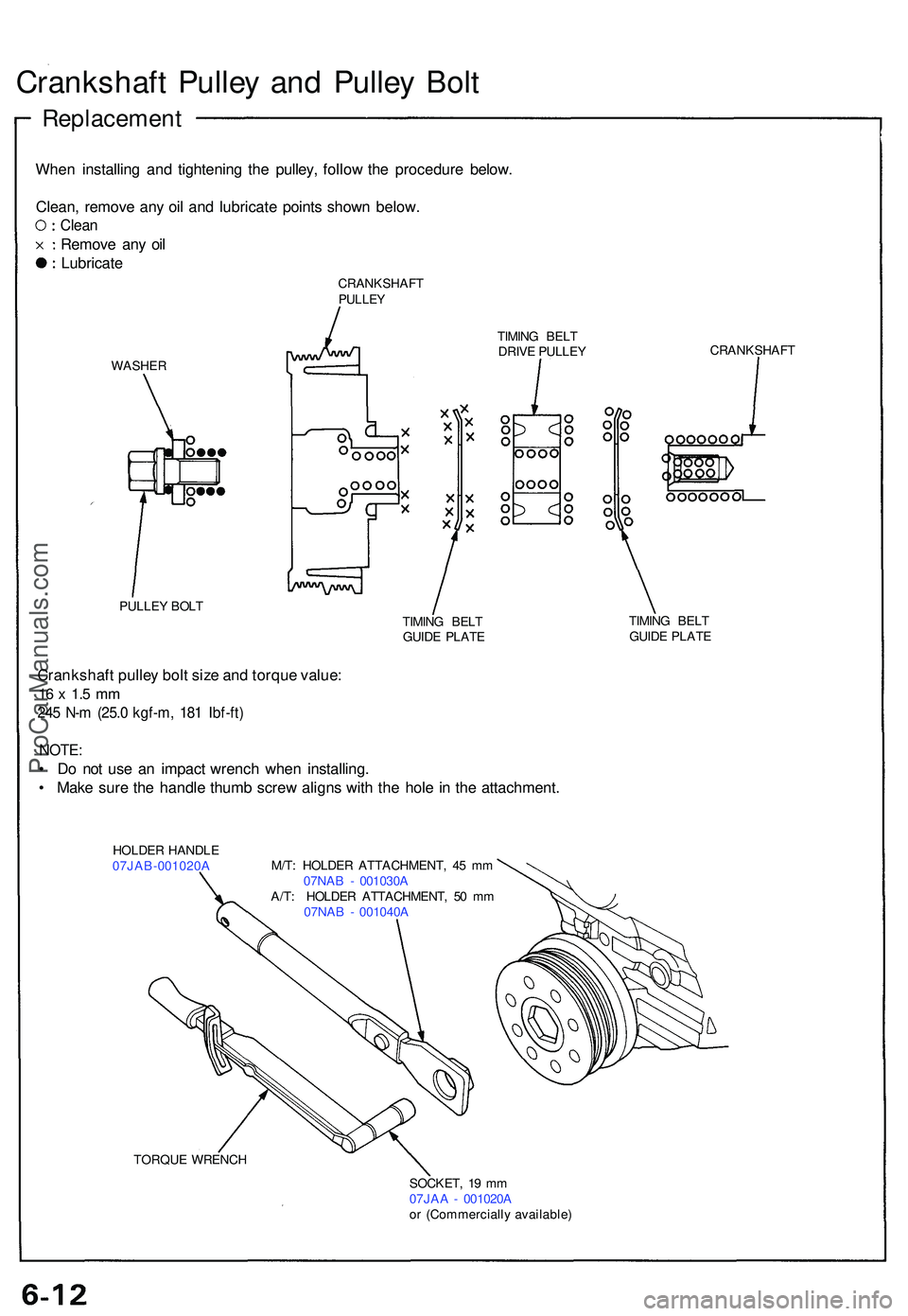

Crankshaft Pulle y an d Pulle y Bol t

Replacemen t

When installin g an d tightenin g th e pulley , follo w th e procedur e below .

Clean , remov e an y oi l an d lubricat e point s show n below .

Clean

Remov e an y oi l

Lubricat e

CRANKSHAF TPULLEY

WASHE R

PULLEY BOL T TIMIN

G BEL T

DRIV E PULLE Y CRANKSHAF

T

TIMIN G BEL T

GUID E PLAT E TIMIN

G BEL T

GUID E PLAT E

Crankshaf t pulle y bol t siz e an d torqu e value :

16 x 1. 5 m m

245 N- m (25. 0 kgf-m , 18 1 Ibf-ft )

NOTE :

• D o no t us e a n impac t wrenc h whe n installing .

• Mak e sur e th e handl e thum b scre w align s wit h th e hol e in th e attachment .

HOLDER HANDL E

07JAB-001020 A M/T

: HOLDE R ATTACHMENT , 4 5 m m

07NA B - 001030 A

A/T : HOLDE R ATTACHMENT , 5 0 m m

07NA B - 001040 A

TORQU E WRENC H

SOCKET, 1 9 m m

07JA A - 001020 A

o r (Commerciall y available )

ProCarManuals.com

Page 430 of 1503

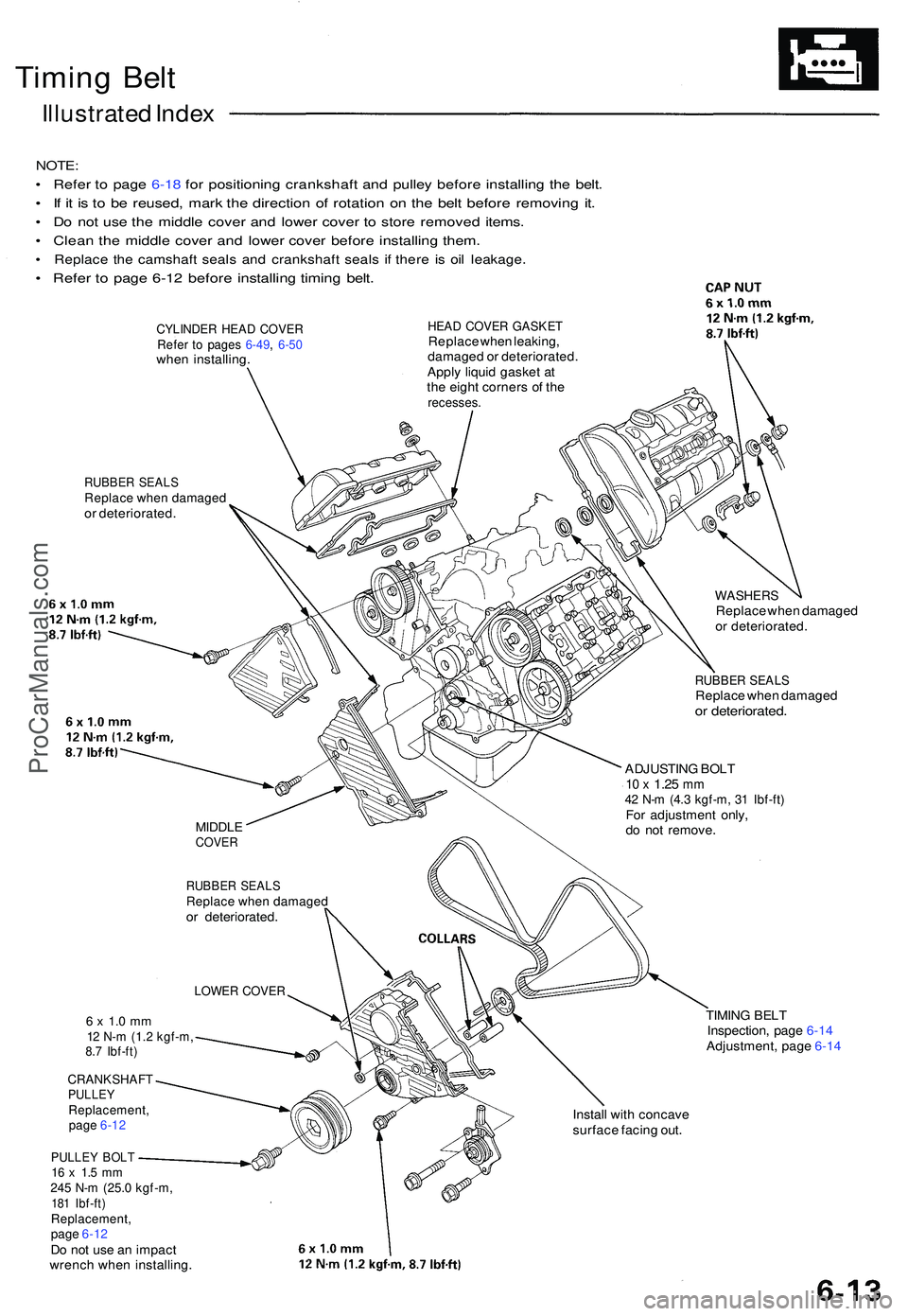

Timing Bel t

Illustrate d Inde x

NOTE :

• Refe r t o pag e 6-1 8 fo r positionin g crankshaf t an d pulle y befor e installin g th e belt .

• I f i t i s t o b e reused , mar k th e directio n o f rotatio n o n th e bel t befor e removin g it .

• D o no t us e th e middl e cove r an d lowe r cove r t o stor e remove d items .

• Clea n th e middl e cove r an d lowe r cove r befor e installin g them .

• Replac e th e camshaf t seal s an d crankshaf t seal s i f ther e i s oi l leakage .

• Refe r t o pag e 6-1 2 befor e installin g timin g belt .

CYLINDE R HEA D COVE RRefer t o page s 6-49 , 6-5 0whe n installing .

HEAD COVE R GASKE TReplace whe n leaking ,

damage d o r deteriorated .

Appl y liqui d gaske t a t

th e eigh t corner s o f th e

recesses .

RUBBER SEAL SReplac e whe n damage dor deteriorated .

WASHERSReplace whe n damage d

o r deteriorated .

RUBBER SEAL SReplac e whe n damage dor deteriorated .

MIDDLECOVER

RUBBE R SEAL SReplac e whe n damage dor deteriorated . ADJUSTIN

G BOL T

10 x 1.2 5 mm42 N- m (4. 3 kgf-m , 3 1 Ibf-ft )For adjustmen t only ,

d o no t remove .

LOWER COVE R

6 x 1. 0 m m12 N- m (1. 2 kgf-m ,8.7 Ibf-ft )

CRANKSHAF TPULLEYReplacement ,page 6-1 2

PULLE Y BOL T16 x 1. 5 m m245 N- m (25. 0 kgf-m ,181 Ibf-ft )Replacement ,page 6-1 2Do no t us e a n impac t

wrenc h whe n installing . TIMIN

G BEL T

Inspection , pag e 6-1 4

Adjustment , pag e 6-1 4

Instal l wit h concav e

surfac e facin g out .

ProCarManuals.com