DATSUN PICK-UP 1977 Service Manual

Manufacturer: DATSUN, Model Year: 1977, Model line: PICK-UP, Model: DATSUN PICK-UP 1977Pages: 537, PDF Size: 35.48 MB

Page 251 of 537

Manual

Transmission

CD

t

e

I

2

3

4

5

6

7

8

9

10

11

12

13

14

17

18

19

O

20

o

21

24

25

j

@

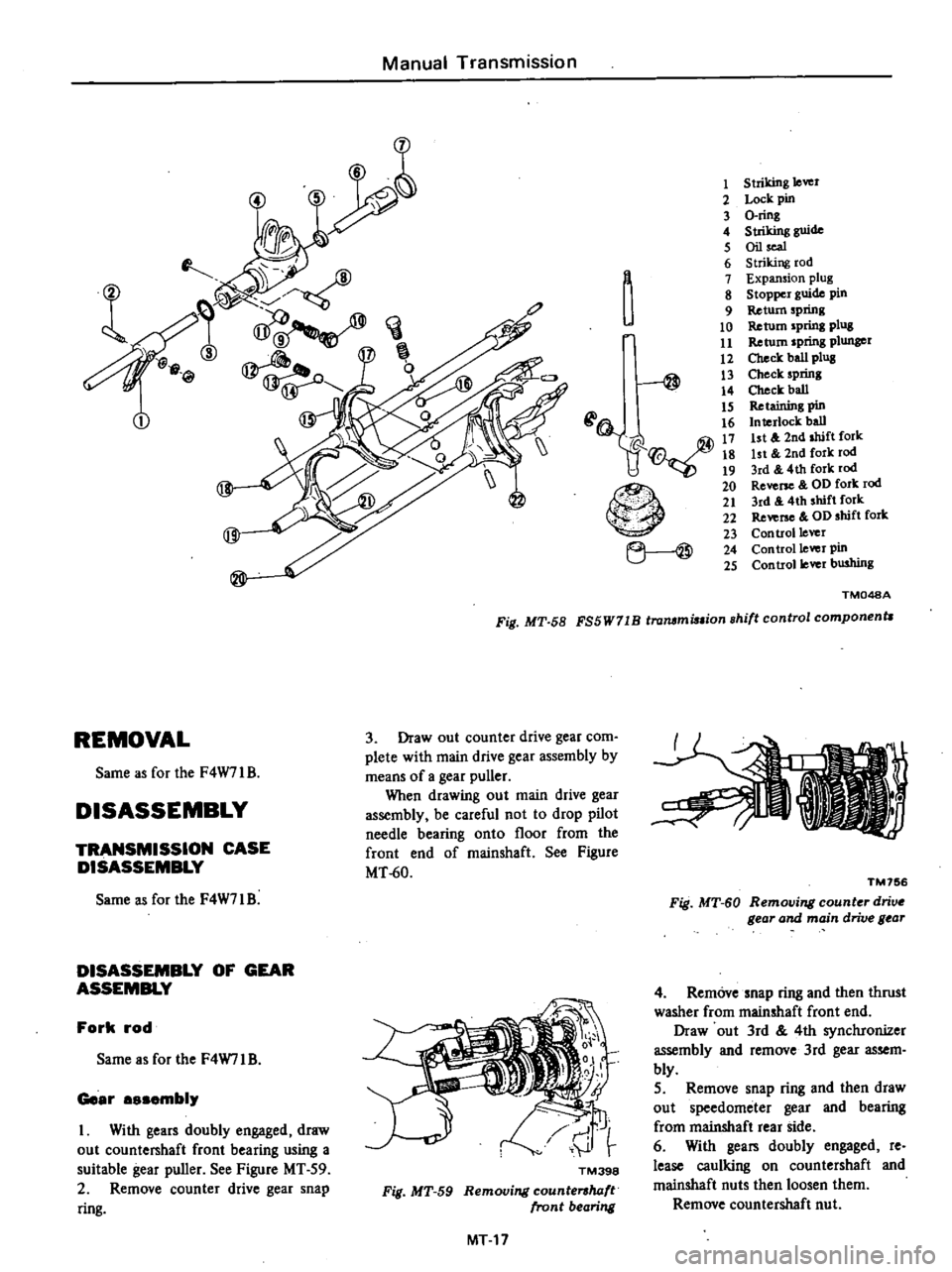

Striking

lever

Lock

pin

Q

ring

Striking

guide

Oil

seal

Striking

rod

Expansion

plug

Stopper

guide

pin

Return

spring

Return

spring

plug

Return

spring

plunger

Check

ball

plUS

Check

spring

Check

ball

Retaining

pin

Interlock

ball

ist

2nd

shift

fork

1st

2nd

fork

rod

3rd

4th

fork

rod

Reverse

OD

fork

rod

3rd

4th

shift

fork

Revene

OD

shift

fork

Con

trol1ever

Con

trol1cver

pin

Con

trollever

bushing

TM048A

Fig

MT

58

FS5W71B

trammi

ion

shift

control

component

3

Draw

out

counter

drive

gear

com

plete

with

main

drive

gear

assembly

by

means

of

a

gear

puller

When

drawing

out

main

drive

gear

assembly

be

careful

not

to

drop

pilot

needle

bearing

onto

floor

from

the

front

end

of

mainshaft

See

Figure

MT

60

REMOVAL

Same

as

for

the

F4W71B

DISASSEMBLY

TRANSMISSION

CASE

DISASSEMBLY

Same

as

for

the

F4W71

B

DISASSEMBLY

OF

GEAR

ASSEMBLY

Fork

rod

Same

as

for

the

F4W71

B

Geer

sembi

I

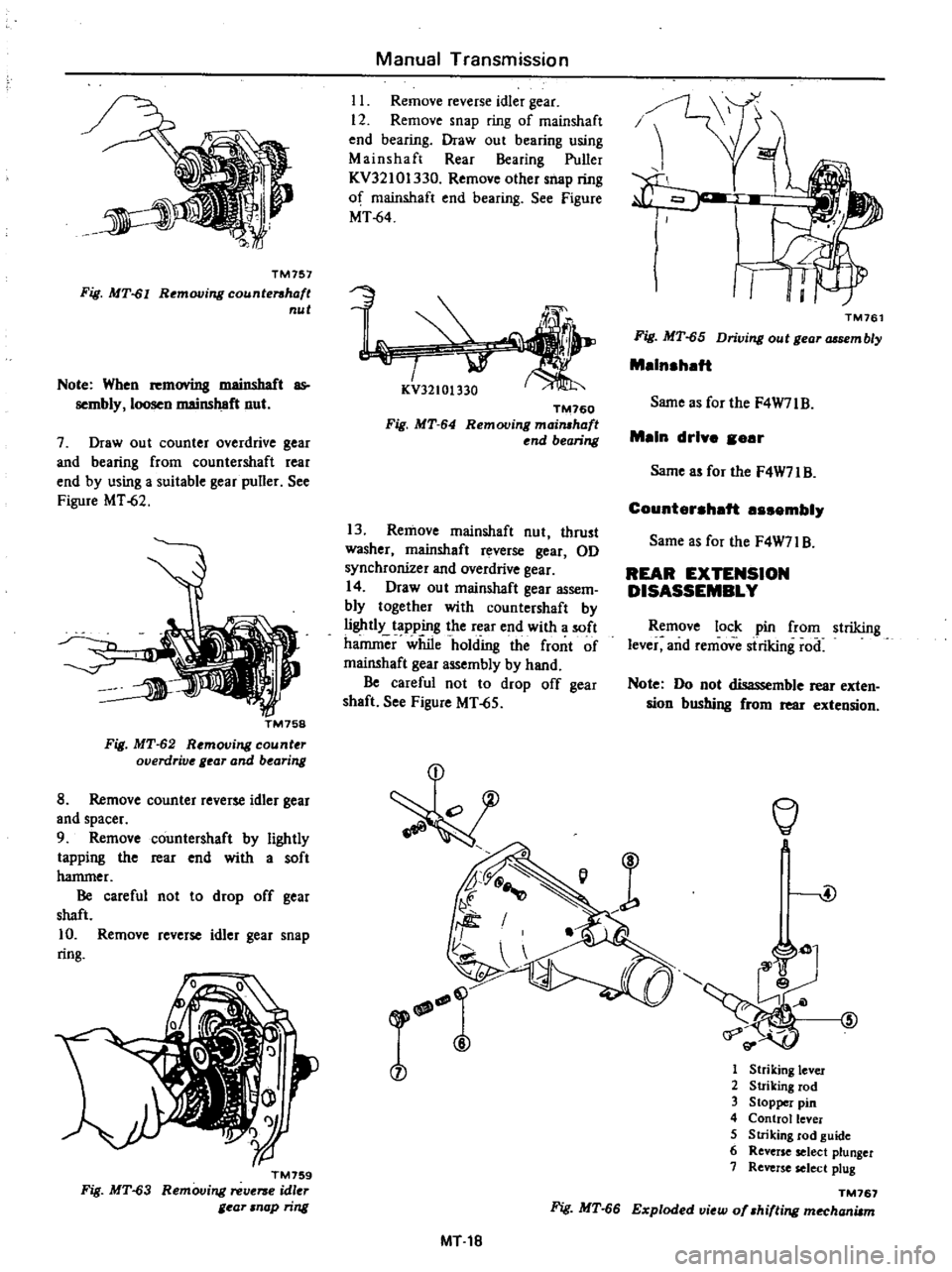

With

gears

doubly

engaged

draw

out

counte

haft

front

bearing

using

a

suitable

gear

puller

See

Figure

MT

59

2

Remove

counter

drive

gear

snap

ring

TM398

Fig

MT

59

Removing

countershaft

front

bearing

MT

17

TM756

Fig

MT

60

Removing

counter

drive

gear

and

main

drive

gear

4

Rem6vesnap

ring

and

then

thrust

washer

from

mainshaft

front

end

Draw

out

3rd

4th

synchronizer

assembly

and

remove

3rd

gear

assem

bly

5

Remove

snap

ring

and

then

draw

out

speedometer

gear

and

bearing

from

mainshaft

rear

side

6

With

gea

doubly

engaged

re

lease

caulking

on

countershaft

and

mainshaft

nuts

then

loosen

them

Remove

countershaft

nut

Page 252 of 537

TM757

Fig

MT

61

Removing

counterahaft

nut

Note

When

removing

mainshaft

as

sembly

loosen

mainshaft

nut

7

Draw

out

counter

overdrive

gear

and

bearing

from

countershaft

rear

end

by

using

a

suitable

gear

puller

See

Figure

MT

62

TM758

Fig

MT

62

Removing

count

r

overdriv

gear

and

bearing

8

Remove

counter

reverse

idler

gear

and

spacer

9

Remove

countershaft

by

lightly

tapping

the

rear

end

with

a

soft

hammer

Be

careful

not

to

drop

off

gear

shaft

10

Remove

reverse

idler

gear

snap

ring

TM759

Fig

MT

63

Removing

reverse

idler

gear

nap

ring

Manual

Transmission

II

Remove

reverse

idler

gear

12

Remove

snap

ring

of

mainshaft

end

bearing

Draw

out

bearing

using

Mainshaft

Rear

Bearing

Puller

KV32101330

Remove

other

snap

ring

of

mainshafl

end

bearing

See

Figure

MT

64

tw

KV32101330

TM160

Fig

MT

64

Removing

mai

haft

nd

bearing

13

Remove

mainshaft

nut

thrust

washer

mainshaft

reverse

gear

OD

synchronizer

and

overdrive

gear

14

Draw

out

mainshaft

gear

assem

bly

together

with

countershaft

by

lightly

tapping

the

rear

end

with

a

soft

hainmer

Me

holding

the

front

of

mainshaft

gear

assembly

by

hand

Be

careful

not

to

drop

off

gear

shaft

See

Figure

MT

65

k

r

IT

TM761

Fig

MT

65

Driving

out

gear

sembly

Malnahaft

Same

as

for

the

F4W7IB

Main

drive

ear

Same

as

for

the

F4W71

B

Counterahaft

aaaembly

Same

as

for

the

F4W7l

B

REAR

EXTENSION

DISASSEMBLY

Remove

lock

pin

from

striking

lever

and

remove

siriking

rod

Note

Do

not

disassemble

rear

exten

sion

bushing

from

rear

extension

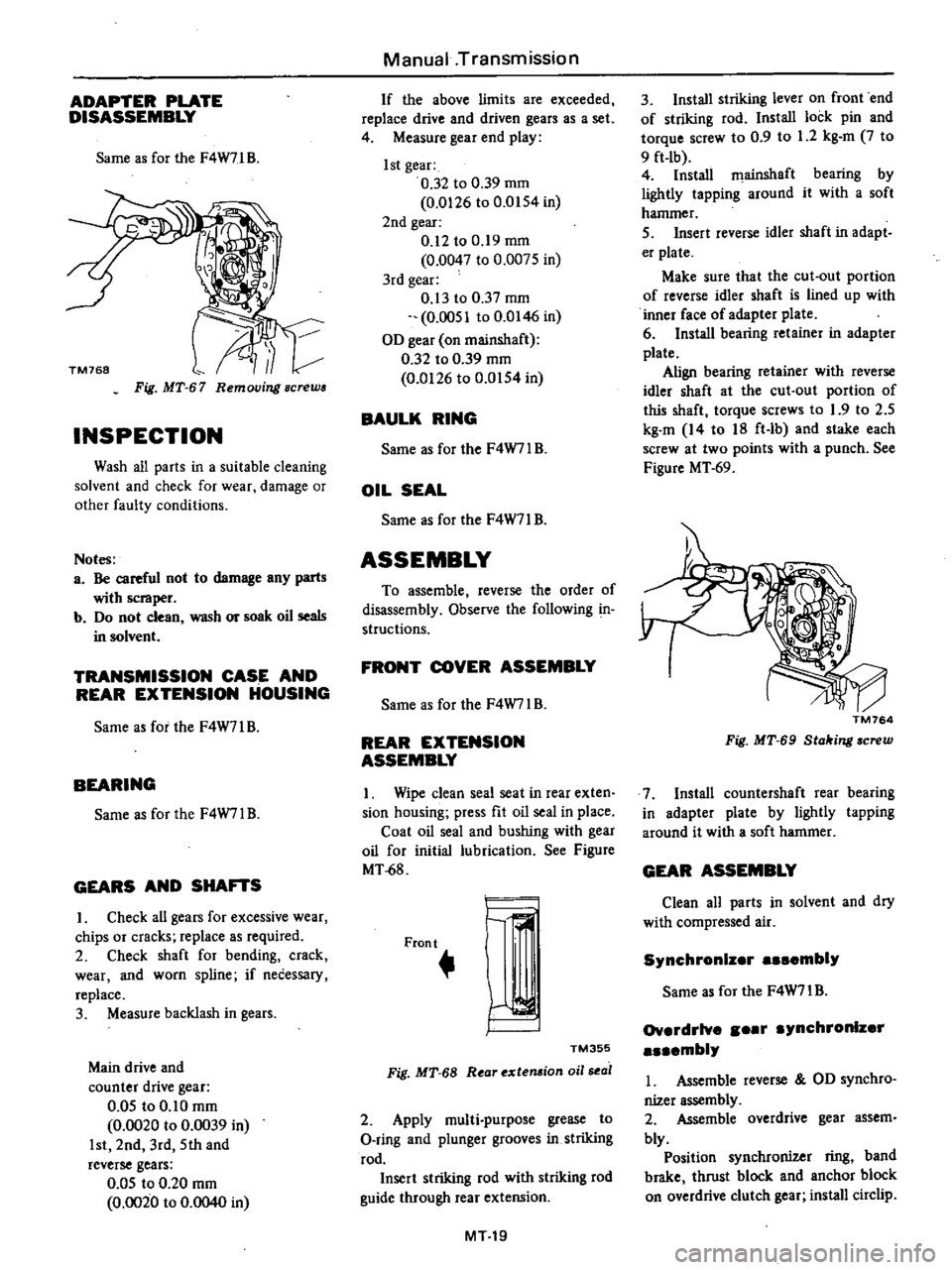

J

l

J

@

1

Striking

lever

2

Striking

rod

3

Stopper

pin

4

Control

lever

5

Striking

rod

guide

6

Reverse

select

plunger

7

Reverse

select

plug

TM767

Fig

MT

66

Exploded

view

of

shifting

mechanilm

MT1B

Page 253 of 537

ADAPTER

PLATE

DISASSEMBLY

Same

as

for

the

F4W71

B

Fig

MT

67

Removing

screws

INSPECTION

Wash

all

parts

in

a

suitable

cleaning

solvent

and

check

for

wear

damage

or

other

faulty

conditions

Notes

a

Be

careful

not

to

damage

any

parts

with

scraper

b

Do

not

clean

wash

or

soak

oil

seals

in

solvent

TRANSMISSION

CASE

AND

REAR

EXTENSION

HOUSING

Same

as

for

the

F4W71

B

BEARING

Same

as

for

the

F4W7l

B

GEARS

AND

SHA

S

I

Check

all

gears

for

excessive

wear

chips

or

cracks

replace

as

required

2

Check

shaft

for

bending

crack

wear

and

worn

spline

if

necessary

replace

3

Measure

backlash

in

gears

Main

drive

and

counter

drive

gear

0

05

to

0

10

mm

0

0020

to

0

0039

in

1st

2nd

3rd

5th

and

reverse

gears

0

05

to

0

20

mm

0

0020

to

0

0040

in

Manual

Transmission

If

the

above

limits

are

exceeded

replace

drive

and

driven

gears

as

a

set

4

Measure

gear

end

play

1st

gear

0

32

to

0

39

mm

0

0126

to

0

0154

in

2nd

gear

0

12

to

0

19

mm

0

0047

to

0

0075

in

3rd

gear

0

13

to

0

37

mm

0

0051

to

0

0146

in

OD

gear

on

mainshaft

0

32

to

0

39

mm

0

0126

to

0

0154

in

BAULK

RING

Same

as

for

the

F4W7IB

OIL

SEAL

Same

as

for

the

F4W71

B

ASSEMBLY

To

assemble

reverse

the

order

of

disassembly

Observe

the

following

in

structions

FRONT

COVER

ASSEMBLY

Same

as

for

the

F4W7l

B

REAR

EXTENSION

ASSEMBLY

I

Wipe

clean

seal

seat

in

rear

exten

sion

housing

press

fit

oil

seal

in

place

Coat

oil

seal

and

bushing

with

gear

oil

for

initial

lubrication

See

Figure

MT

68

Front

r

I

TM355

Fig

MT

68

R

ar

extemion

oil

sea

2

Apply

multi

purpose

grease

to

O

ring

and

plunger

grooves

in

striking

rod

Insert

striking

rod

with

striking

rod

guide

through

rear

extension

MT19

3

Install

striking

lever

on

front

end

of

striking

rod

Install

lock

pin

and

torque

screw

to

0

9

to

1

2

kg

m

7

to

9

ft

lb

4

Install

filainshaft

bearing

by

lightly

tapping

around

it

with

a

soft

hammer

5

Insert

reverse

idler

shaft

in

adapt

er

plate

Make

sure

that

the

cut

out

portion

of

reverse

idler

shaft

is

lined

up

with

inner

face

of

adapter

plate

6

Install

bearing

retainer

in

adapter

plate

Align

bearing

retainer

with

reverse

idler

shaft

at

the

cut

out

portion

of

this

shaft

torque

screws

to

1

9

to

2

5

kg

m

14

to

18

ft

lb

and

stake

each

screw

at

two

points

with

a

punch

See

Figure

MT

69

TM764

Fig

MT

69

Stahing

screw

7

Install

countershaft

rear

bearing

in

adapter

plate

by

lightly

tapping

around

it

with

a

soft

hammer

GEAR

ASSEMBLY

Clean

all

parts

in

solvent

and

dry

with

compressed

air

Synchronlz

r

embly

Same

as

for

the

F4W71

B

Ov

rdrlve

r

ynchronlz

r

mbly

I

Assemble

reverse

OD

synchro

nizer

assembly

2

Assemble

overdrive

gear

assem

bly

Position

synchronizer

ring

band

brake

thrust

block

and

anchor

block

on

overdrive

clutch

gear

install

circlip

Page 254 of 537

Malnshaft

assembly

Same

as

for

the

F4W7IB

Countershaft

assembly

Same

as

for

the

F4W71

B

Main

drive

gear

assembly

Procedures

are

the

same

as

for

the

F4W7IB

trans

i

n

except

as

follows

I

Insert

countershaft

and

mainshaft

into

adapter

plate

and

place

adapter

plate

in

a

vise

with

setting

plate

Manual

Transmission

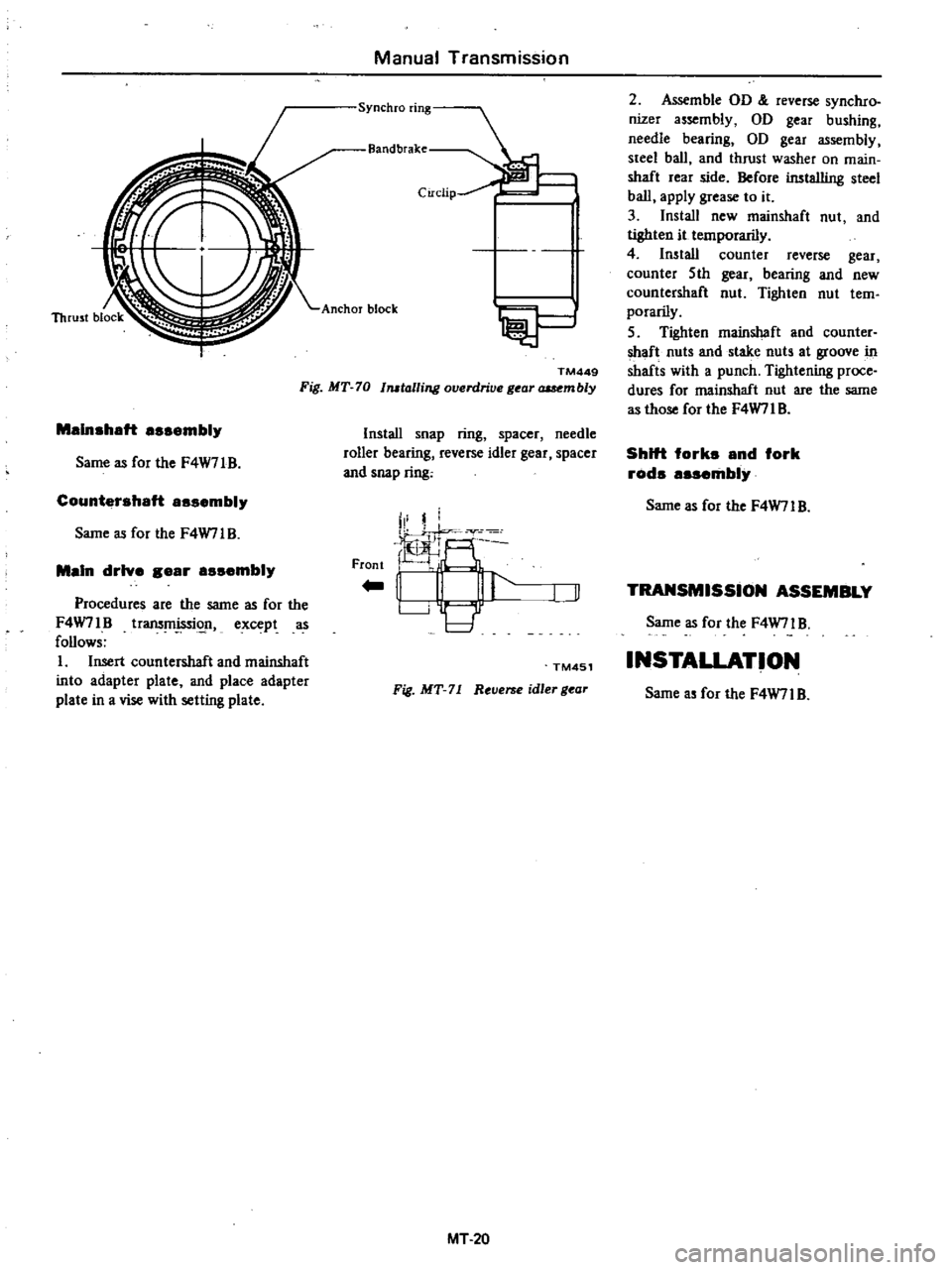

Synchro

ring

8andbrake

Circlip

Anchor

block

TM449

Fig

MT

70

Imtalling

overdrive

gear

assembly

Install

snap

ring

spacer

needle

roller

bearing

reverse

idler

gear

spacer

and

snap

ring

h

I

L

TM4S1

Fig

MT

71

R

lJerse

idler

gear

MT

20

2

Assemble

OD

reverse

synchro

nizer

assembly

OD

gear

bushing

needle

bearing

OD

gear

assembly

sreel

ball

and

thrust

washer

on

main

shaft

rear

side

Before

installing

steel

ball

apply

grease

to

it

3

Install

new

mainshaft

nut

and

tighten

it

temporarily

4

Install

counter

reverse

gear

counter

5

th

gear

bearing

and

new

countershaft

nut

Tighten

nut

tem

porarily

5

Tighten

mainshafl

and

counter

shaft

nuts

and

stake

nuts

at

groove

in

shafts

with

a

punch

Tightening

proce

dures

for

mainshaft

nut

are

the

same

as

those

for

the

F4W7IB

Shift

forks

and

fork

rods

assembly

Same

as

for

the

F4W71

B

u

TRANSMISSION

ASSEMBLY

Same

as

for

the

F4W71

B

INSTALLATION

Same

as

for

the

F4W71

B

Page 255 of 537

Manual

Transmission

SERVICE

DATA

AND

SPECIFICATIONS

GENERAL

SPECIFICATIONS

Transmission

type

F4W71B

FS5W71B

Synchromesh

type

Warner

1st

to

4th

Warner

5th

Servo

Shift

type

1

3

T

i

i

2

4

R

1

3

5

II

1

2

4

R

Gear

ratio

1st

2nd

3rd

4th

5th

Reverse

3

592

2

246

1

415

1

000

3

657

3

321

2

077

1

308

1

000

0

864

3

382

Final

gear

ratio

4

375

4

375

Speedometer

gear

ratio

20

6

I

7

3

3

20

6

2

0

4X

3

f

Oil

capacity

US

pt

Imp

pt

MT

21

Page 256 of 537

Manual

iTransmission

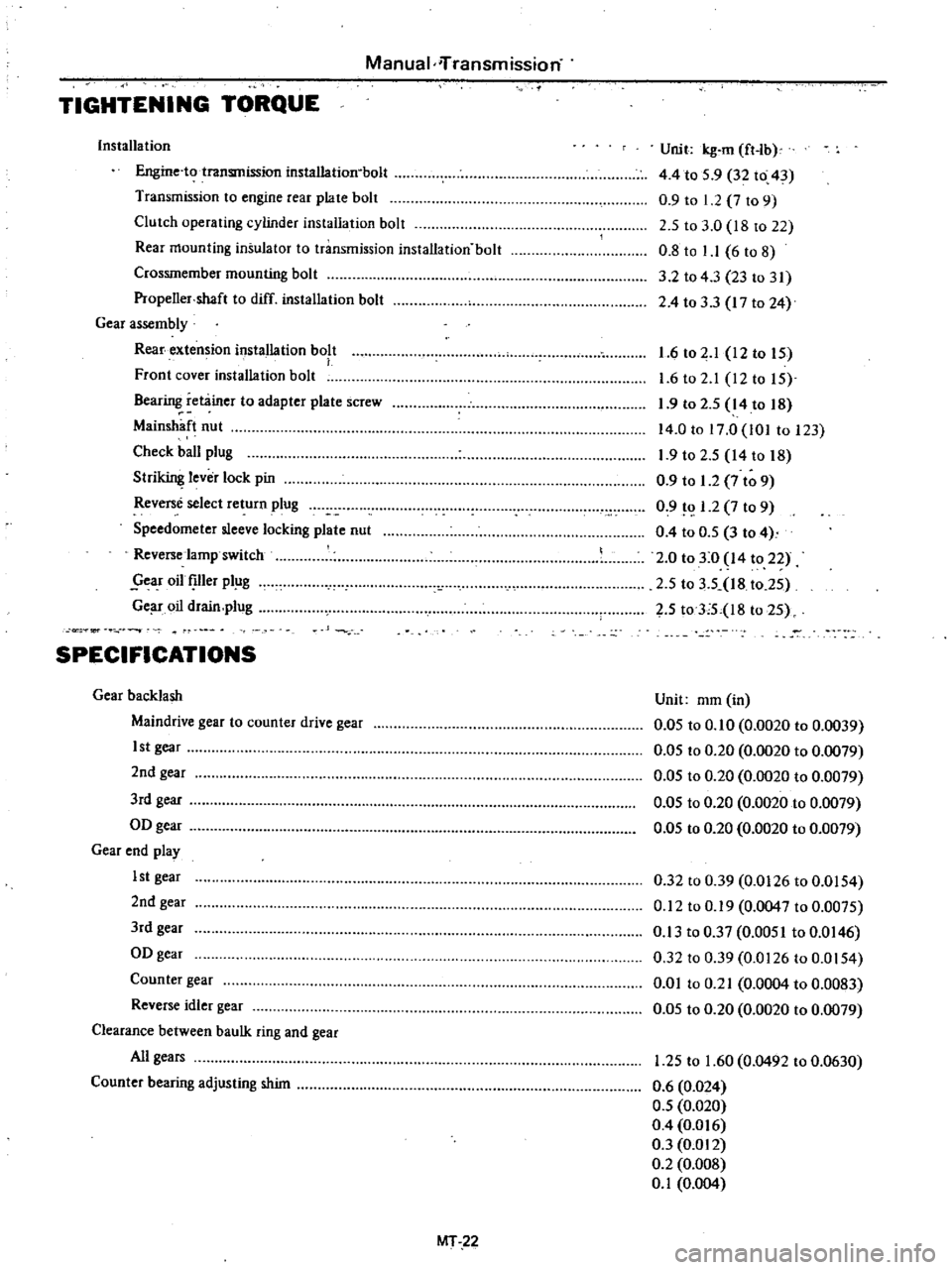

TIGHTENING

TORQUE

Installa

tion

Engine

to

transmission

installation

bolt

Transmission

to

engine

rear

plate

bolt

Clutch

operating

cylinder

installation

bolt

Rear

mounting

insulator

to

transmission

installation

bolt

Crossmember

mounting

bolt

Propeller

shaft

to

diff

installation

bolt

Gear

assembly

Rear

extension

installation

bolt

Front

cover

installation

bolt

Bearing

retainer

to

adapter

plate

screw

Main

haft

nut

Check

ball

plug

Stri

lever

lock

pin

Reverse

select

return

plug

Speedometer

sleeve

locking

plate

nut

Reverse

lamp

switch

year

oil

Ier

pl

g

Ge

r

oil

drain

plug

Unit

kg

m

ft

lb

4

4

to

5

9

32

to

43

0

9

to

1

2

7

to

9

2

5

to

3

0

18

to

22

0

8

to

1

1

6

to

8

3

2

to

43

23

to

31

2

4

to

33

17

to

24

1

6

to

2

1

12

to

IS

1

6

to

2

1

12to

IS

1

9

to

2

S

14

to

18

14

0

to

17

0

101

to

123

1

9

to

2

S

14

to

18

0

9

to

1

2

7

to

9

0

9

1

2

7

to

9

0

4

to

O

S

3

to

4

2

0

to

3

0

14

to

22

2

S

to

3

5

18

t02S

2

S

toTS

l8

to

2S

or

SPECIFICATIONS

Gear

backlash

Maindrive

gear

to

counter

drive

gear

1st

gear

2nd

gear

3rd

gear

OD

gear

Gear

end

play

1st

gear

2nd

gear

3rd

gear

OD

gear

Counter

gear

Reverse

idler

gear

Clearance

between

baulk

ring

and

gear

All

gears

Counter

bearing

adjusting

shim

Unit

mm

in

0

05

to

0

10

0

0020

to

0

0039

0

05

to

0

20

0

0020

to

0

0079

O

OS

to

0

20

0

0020

to

0

0079

0

05

to

0

20

0

0020

to

0

0079

0

05

to

0

20

0

0020

to

0

0079

0

32

to

0

39

0

0126

to

0

0154

0

12

to

0

19

0

0047

to

0

0075

0

13

to

0

37

0

0051

to

0

0146

0

32

to

0

39

0

0126

to

0

0154

0

01

to

0

21

0

0004

to

0

0083

0

05

to

0

20

0

0020

to

0

0079

1

25

to

1

60

0

0492

to

0

0630

0

6

0

024

0

5

0

020

0

4

0

016

0

3

0

012

0

2

0

008

0

1

0

004

MT

22

Page 257 of 537

Manual

Transmission

I

TROUBLE

DIAGNOSES

AND

CORREGTIONS

Condition

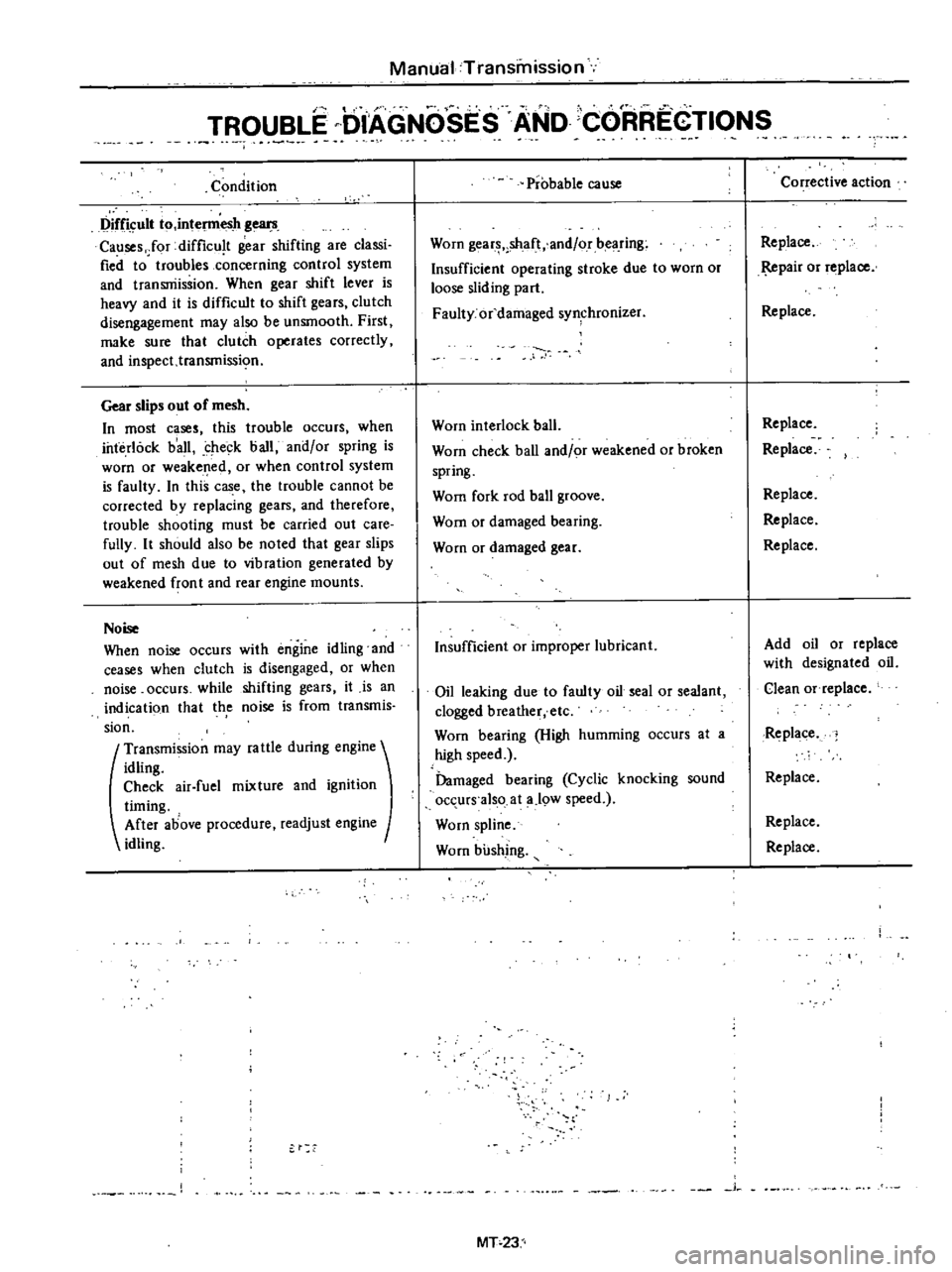

Difficult

to

intel11lesh

gears

Causes

Jor

difficu

t

gear

shifting

are

classi

fied

to

troubles

concerning

control

system

and

transniissioo

When

gear

shift

lever

is

heavy

and

it

is

difficult

to

shift

gears

clutch

disengagement

may

also

be

unsmooth

First

make

sure

that

clutch

operates

correctly

and

inspect

transmissi

o

Gear

slips

out

of

mesh

In

most

cases

this

trouble

occurs

when

interlock

b

all

check

ball

and

or

spring

is

worn

or

weakened

or

when

control

system

is

faulty

In

this

case

the

trouble

cannot

be

corrected

by

replacing

gears

and

therefore

trouble

shooting

must

be

carried

out

care

fully

It

should

also

be

noted

that

gear

slips

out

of

mesh

due

to

vibration

generated

by

weakened

fron

t

and

rear

engine

mounts

Noise

When

noise

occurs

with

engine

idling

and

ceases

when

clutch

is

disengaged

or

when

noise

occurs

while

shifting

gears

it

is

an

indicati90

that

th

e

noise

is

from

transmis

sion

t

Transmission

may

fa

ule

during

engine

idling

Check

air

fuel

mixture

and

ignition

timing

After

above

procedure

readjust

engine

idling

Probable

cause

Worn

gear

shaft

and

or

bearing

Insufficient

operating

stroke

due

to

worn

or

loose

sliding

part

Faulty

or

damaged

synchronizer

Worn

interlock

ball

Worn

check

ball

and

or

weakened

or

broken

spring

Wom

fork

rod

ball

groove

Wom

or

damaged

bearing

Worn

or

damaged

gear

Insufficient

or

improper

lubricant

Oil

leaking

due

to

faulty

oil

seal

or

sealant

clogged

breather

etc

Worn

bearing

High

humming

occurs

at

a

high

speed

Damaged

bearing

Cyclic

knocking

sound

occurs

also

at

a

19W

speed

Worn

spline

Worn

bushing

j

MT

23

Corrective

action

Replace

pair

or

replace

Replace

Replace

Replace

Replace

Replace

Replace

Add

oil

or

replace

with

designated

oil

Clean

Of

replace

Replace

Replace

Replace

Replace

Page 258 of 537

No

Tool

number

tool

name

ST23540000

Fork

rod

pin

punch

2

ST22360002

Drift

C

3

ST23800000

Transmission

adapter

4

ST238

10001

Setting

plate

adapter

Manual

Transmission

SPECIAL

SERVICE

TOOLS

Description

Unit

mm

in

For

removal

of

fork

rod

retaining

pin

L

i

150

5

91

10

0

39

dia

For

assembly

of

counter

drive

bearing

oOler

dia

32

1

26

inner

dia

23

0

91

SE034

For

assembly

of

main

bearing

480

18

90

outer

dia

44

1

73

inner

dia

31

1

22

SE037

For

setting

adapter

plate

in

a

vise

SE132

74

2

91

MT

24

For

use

on

Reference

page

or

Figure

No

All

Fig

MT

15

models

llBT

M

Fig

MT

44

FS5W

63A

All

Page

MT

1O

models

71BT

M

Fig

MT

14

Fig

MT

15

Fig

MT

45

Page 259 of 537

Manual

Transmission

No

Tool

number

tool

name

Description

Unit

mm

in

For

use

on

Reference

page

or

Figure

No

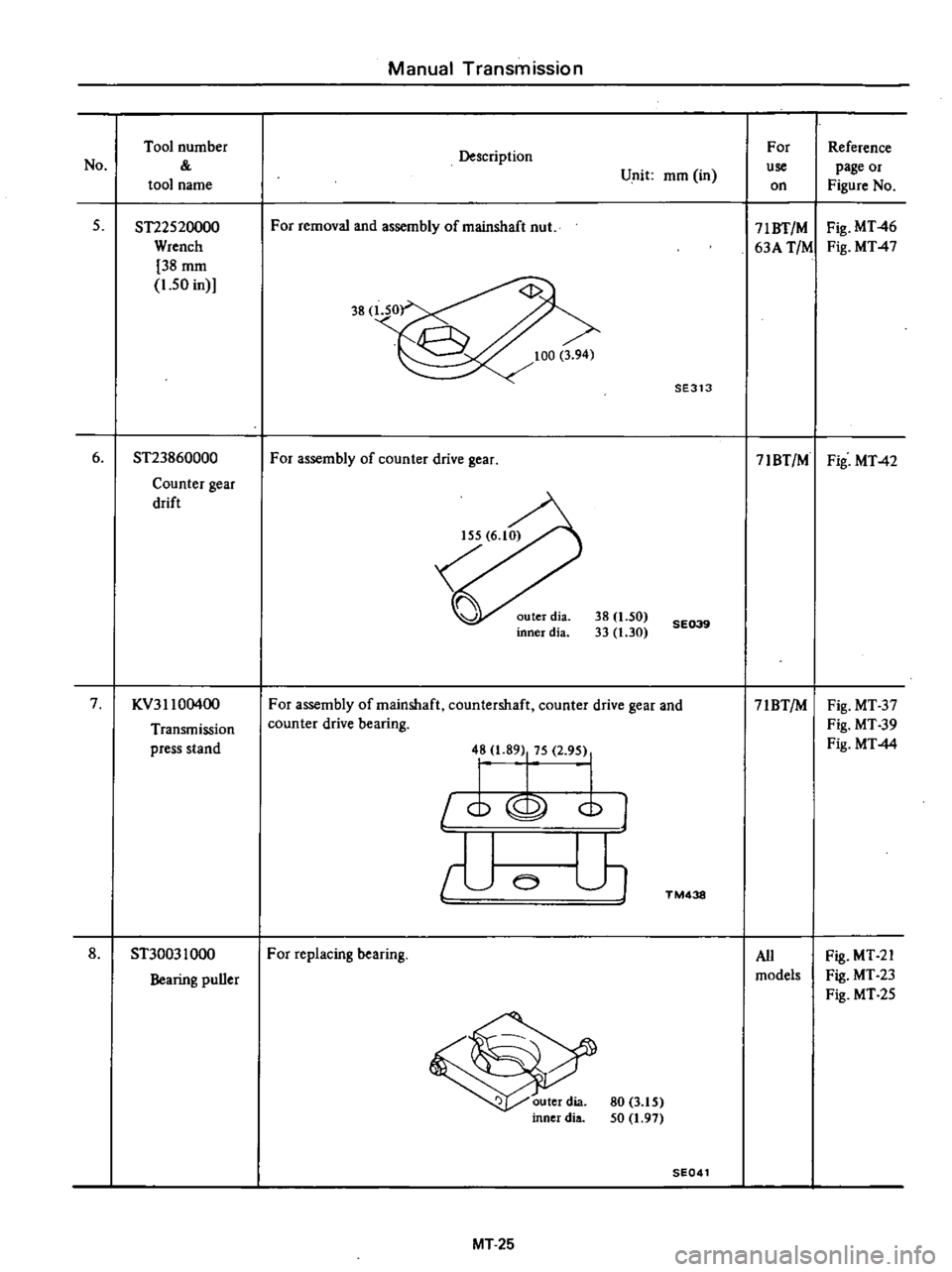

5

ST22520000

Wrench

38mm

1

50

in

For

removal

and

assembly

of

mainshaft

nut

71BT

M

Fig

MT46

63A

TIM

Fig

MT47

SE313

6

ST23860000

For

assembly

of

counter

drive

gear

7IBT

M

Fig

MT42

Counter

gear

drift

outer

dia

38

50

inner

dia

33

1

30

SE039

7

KV31100400

For

assembly

of

rnainshaft

countershaft

counte

drive

gear

and

7IBT

M

Fig

MT

37

Transmission

counter

drive

bearing

Fig

MT

39

press

stand

4

8

1

89

75

2

95

Fig

MT44

0

Q

0

J

I

0

TM438

8

STJ0031000

For

replacing

bearing

All

Fig

MT

21

Bearing

puller

models

Fig

MT

23

Fig

MT

25

80

3

15

50

1

97

SE041

MT

25

Page 260 of 537

Manual

Transmission

No

Tool

number

tool

name

Unit

mm

in

Description

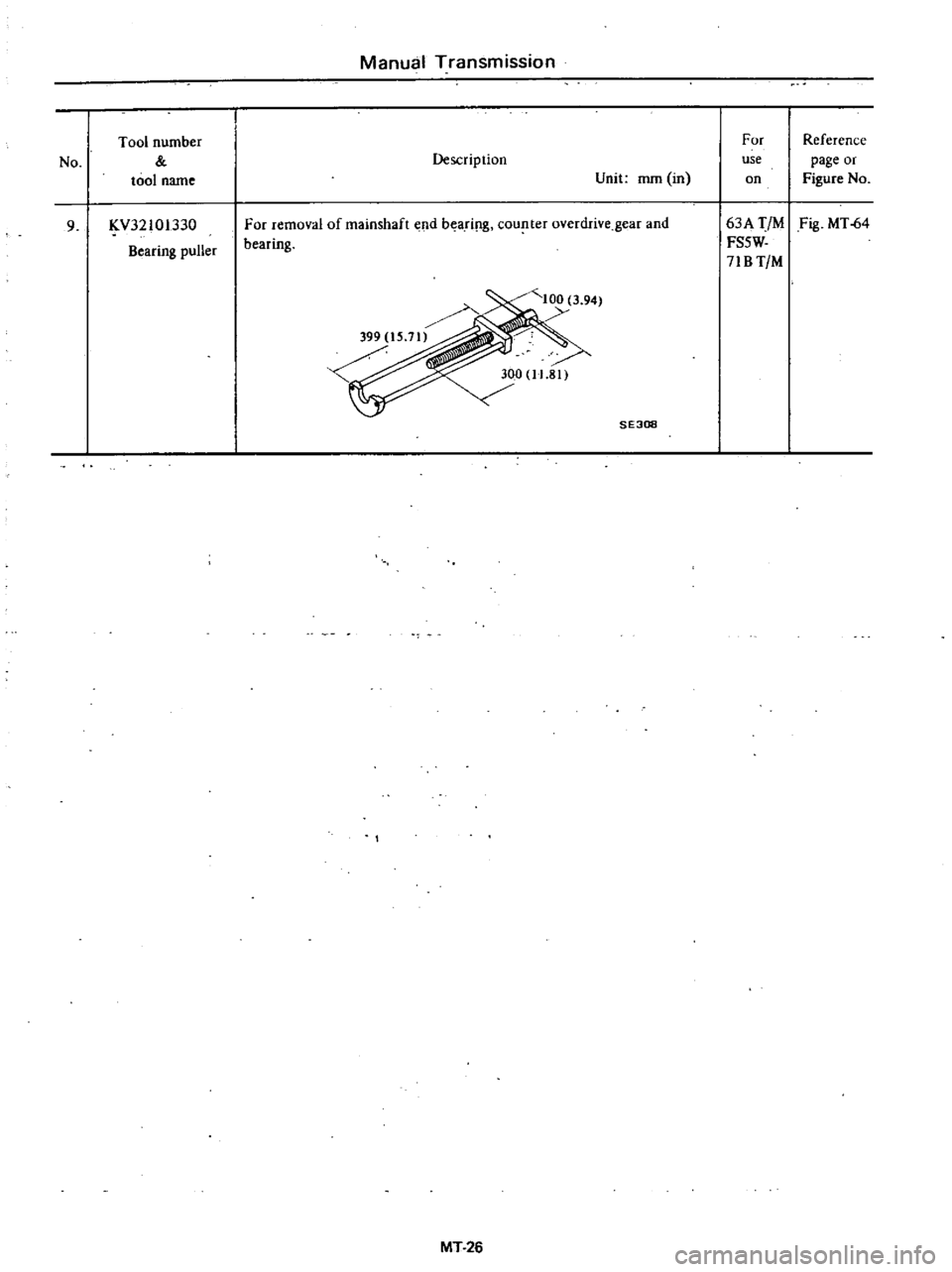

9

KV32101330

For

removal

of

mainshaft

end

b

ari

lg

counter

overdrive

gear

and

Bearing

puller

bearing

300

11

81

SE308

MT

26

For

use

on

Reference

page

or

Figure

No

63A

l

fM

Fig

MT

64

FS5W

7IBT

M