FORD MUSTANG 1969 Volume One Chassis

Manufacturer: FORD, Model Year: 1969, Model line: MUSTANG, Model: FORD MUSTANG 1969Pages: 413, PDF Size: 75.81 MB

Page 101 of 413

03-02-25

Suspension

03-02-25

pivot bolts and nuts to specification

(Part 3-13).

5.

Connect the track bar to the

frame bracket with a new nut and

bolt. Torque the nut to specification

(Part 3-13).

6. Remove the alignment spacers

and jack stands and lower the vehicle.

REAR SUSPENSION-

UPPER ARM

FORD, MERCURY,

METEOR, THUNDERBIRD,

CONTINENTAL MARK HI

Removal

1.

Raise the vehicle and support the

frame side rails with jack stands.

2.

Support the rear axle, then dis

connect the track bar from the frame

bracket.

3.

Lower the axle and support axle

under differential pinion nose, as well

as under axle.

4.

Remove the nut, bolt and two

washers that attach the upper arm to

the axle housing. Disconnect the arm

from the housing.

5.

Remove the nut and bolt that se-

cures the upper arm to the crossmem-

ber and remove the arm.

Installation

1.

Hold the upper arm in place on

the crossmember and install a new at-

taching bolt, a new lockwasher and a

new nut. Do not tighten the nut at this

time.

2.

Secure the upper arm to the axle

housing with a new attaching bolt,

two washers and a new nut. Do not

tighten the nut at this time.

3.

Install alignment spacers be-

tween the rear axle housing and

frame.

4.

Connect the track bar to the

frame bracket with a new nut and

bolt. Torque the nut to specifications.

5.

Torque the upper arm front nut

to specification. Remove the align-

ment spacers and the jack stands.

6. Adjust the pinion angle and tor-

que the rear nut to specification.

7.

Lower the vehicle.

TRACK BAR

FORD, MERCURY,

METEOR, THUNDERBIRD,

CONTINENTAL MARK HI

1.

Raise the vehicle on an axle con-

tact hoist.

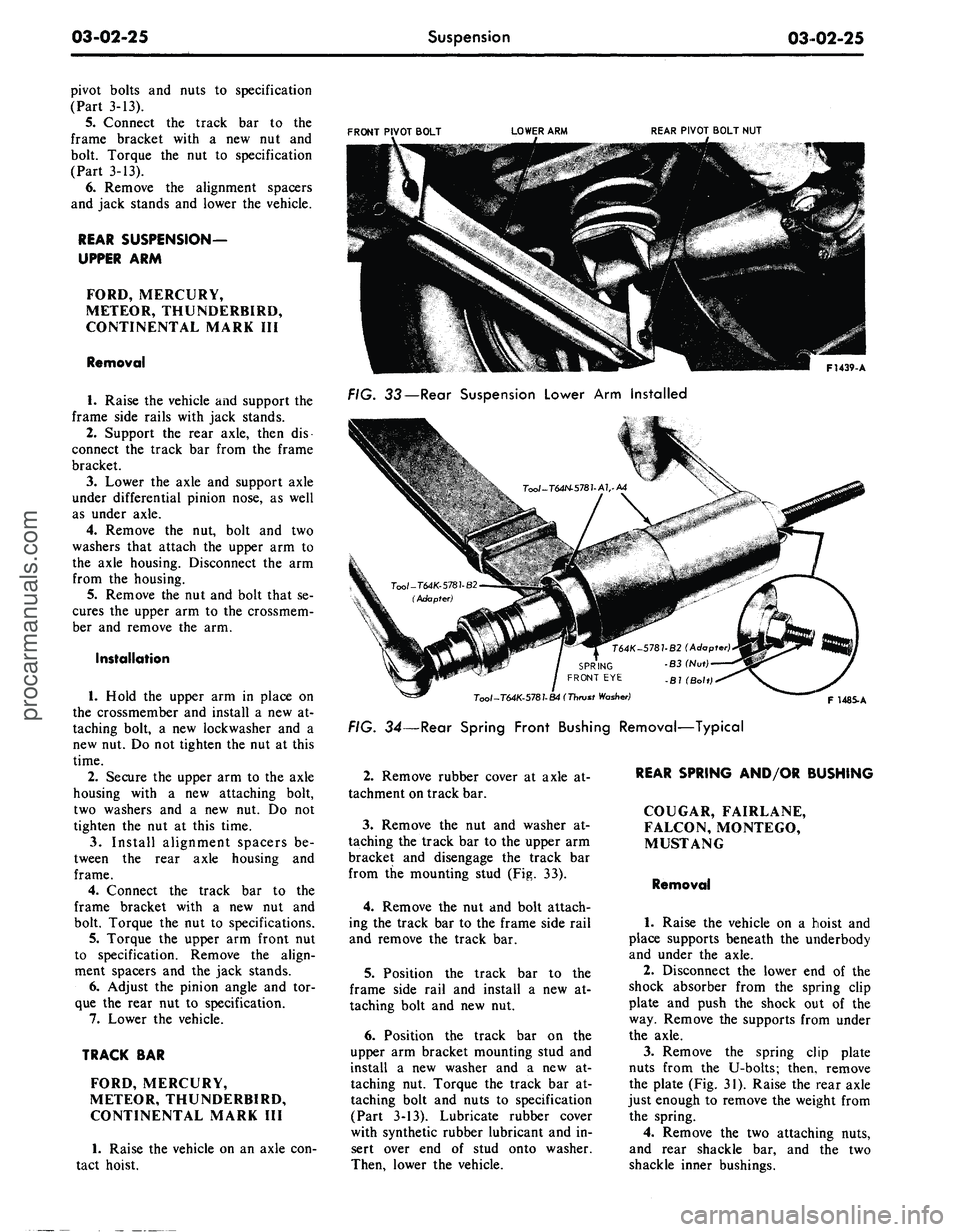

FRONT PIVOT BOLT

LOWER ARM

REAR PIVOT BOLT NUT

F1439-A

FIG. 33—Rear Suspension Lower Arm Installed

Tool-T64K-5781-B4 (Thrust

Washer)

FIG. 34—Rear Spring Front Bushing Removal—Typical

F 1485. A

2.

Remove rubber cover at axle at-

tachment on track bar.

3.

Remove the nut and washer at-

taching the track bar to the upper arm

bracket and disengage the track bar

from the mounting stud (Fig. 33).

4.

Remove the nut and bolt attach-

ing the track bar to the frame side rail

and remove the track bar.

5.

Position the track bar to the

frame side rail and install a new at-

taching bolt and new nut.

6. Position the track bar on the

upper arm bracket mounting stud and

install a new washer and a new at-

taching nut. Torque the track bar at-

taching bolt and nuts to specification

(Part 3-13). Lubricate rubber cover

with synthetic rubber lubricant and in-

sert over end of stud onto washer.

Then, lower the vehicle.

REAR SPRING AND/OR BUSHING

COUGAR, FAIRLANE,

FALCON, MONTEGO,

MUSTANG

Removal

1.

Raise the vehicle on a hoist and

place supports beneath the underbody

and under the axle.

2.

Disconnect the lower end of the

shock absorber from the spring clip

plate and push the shock out of the

way. Remove the supports from under

the axle.

3.

Remove the spring clip plate

nuts from the U-bolts; then, remove

the plate (Fig. 31). Raise the rear axle

just enough to remove the weight from

the spring.

4.

Remove the two attaching nuts,

and rear shackle bar, and the two

shackle inner bushings.procarmanuals.com

Page 102 of 413

03-02-26

Suspension

03-02-26

T64K-578 7-B2 (Adapter)

-83 (Nut)

(Bolt)

SPRING FRONT

EYE

Tool-T64K-5781-B2 (Adapter)

BUSHING

F 1484-A

FIG. 35—Rear Spring Front Bushing Installation—Typical

5.

Remove

the

rear shackle assem-

bly

and the two

outer bushings.

6. Remove

the

front hanger bolt,

nut,

and

washer from

the eye at the

forward

end of the

spring. Lift

out the

spring assembly.

7.

If the

front bushing

is

being

re-

placed, assemble

the

special tool

com-

bination

to the

bushing

in the

spring

front

eye as

shown

in

Fig.

34.

8. While holding

the

tool

nut,

tight-

en

the

tool bolt against

the

tool thrust

washer,

the

adapter,

and

detail

Al.

This operation will force

the

bushing

out

of the

spring

eye

into detail

A4 of

the tool

as

shown.

Installation

During rear suspension leaf spring

assembly replacement

in

service,

all

used attaching components must

be

discarded

and

replaced with

new com-

ponents.

1.

Assemble

the

bushing

and the

special tool combination

to the

spring

front

eye as

shown

in Fig. 35.

2.

While holding

the

tool

nut,

tight-

en

the

tool bolt against

the

tool thrust

washer, adapter,

and

detail

A4 to

force

the

bushing into

the

spring

eye

as shown.

3.

Position

the

spring under

the

rear axle

and

insert

the

shackle

as-

sembly into

the

rear hanger bracket

and

the

rear

eye of the

spring.

4.

Install

the

shackle inner bush-

ings,

the

shackle plate,

and the

lock-

nuts.

Tighten

the

locknuts finger-tight.

5.

Position

the

spring front

eye in

the front hanger, slip

the

washer

on

the front hanger bolt,

and

(from

the

inboard side) insert

the

bolt through

the hanger

and

eye. Install

the

locknut

on

the

hanger bolt

and

tighten finger-

tight.

6. Lower

the

rear axle until

it

rests

on

the

spring. Position

the

spring clip

plate

on the

clips (U-bolts). Install

the

U-bolt nuts

and

torque

to

specifica-

tion.

7.

Connect

the

lower

end of the

shock absorber

to the

spring clip plate

using

a new nut if

working

on a sta-

tion wagon

or

Ranchero.

8. Place safety stands under

the

rear axle, lower

the

vehicle until

the

spring

is in the

approximate curb load

position,

and

then torque

the

front

hanger stud locknut

to

specification.

9. Torque

the

rear shackle locknuts

to specification.

10.

Remove

the

safety stands

and

lower

the

vehicle.

REAR SPRING

LINCOLN CONTINENTAL

Removal

1.

Raise

the

vehicle

and

place

sup-

port stands under

the

sidemembers

on

the rear

of

each rear spring hanger.

2.

Lower

the

rear axle slightly

to

reduce some

of the

spring load; then,

remove

the

spring U-bolts.

3.

Remove

the

nuts, lock washers

and front mounting stud. Refer

to

Fig.

6.

4.

Remove

the

rear shackle nuts

and mounting plate. Remove

the

lower inner insulator. Remove

the

spring.

If the

rear shackle insulators

are

to be

replaced,

it

will

be

necessary

to remove

the

rear hanger assembly.

(Hanger attaching bolts must

be tor-

qued

to

specification when rein-

stalled.)

5.

Remove

the

insulators from

the

spring.

6. Examine

all

parts

for

wear

or

damage. Note

the

condition

of the

spring center bolt.

7.

The

spring center bolt

can be re-

placed

by

clamping

the

spring

in a

vise,

thus keeping

the

spring

com-

pressed during bolt removal

and in-

stallation.

Installation

1.

Attach

the

spring

and

bushing

to

the front hanger. Torque

the

outboard

nut

to

specifications.

Do not

tighten

the inboard

nut at

this time.

2.

Install

the

spring

to the

rear

shackle assembly with

the

insulators

in position.

Do not

tighten

the

nuts

at

this time. Refer

to Fig. 6.

3.

Place

the

insulator

and

retainers

in position

on the

spring.

4.

Lower

the

axle housing onto

the

insulator

and

retainer assembly.

If

a

wedge

was

located between

the

upper retainer

and

mounting

pad,

reinstall

the

same thickness wedge

with

the

taper

in the

original direc-

tion. Raise

the

axle until

the

spring

is

approximately horizontal with

the

floor.

5.

Install

the

lower insulator retain-

er

and

U-bolts.

Do not

tighten

the U-

bolt nuts

at

this time. Torque

the

rear

shackle nuts

to

specifications.

6. Torque

the

inboard

nut at the

front

eye to

specification.

7.

Tighten

the

U-bolt nuts evenly

to

the specified torque.

8. Make sure

the

lower insulator

retainer contacts

the

upper retainer.procarmanuals.com

Page 103 of 413

03-02-27

Suspension

03-02-27

MAJOR

REPAIR OPERATIONS

FRONT

SUSPENSION UPPER

ARM

BUSHINGS—ARM

REMOVED

FORD, MERCURY,

METEOR, THUNDERBIRD,

CONTINENTAL MARK III

1.

Remove the nuts and washers

from both ends of the upper arm inner

shaft.

2.

Install Tool T65P-3044-A1 on

the inner shaft and place Tool T65P-

3044-A3 inside the upper arm around

the inner shaft (Fig. 36).

F1440-A

FIG.

36—Removing Upper Arm

Bushings

3.

Position the upper arm in an

arbor press on Tool T65P-3044-A4

(Fig. 36), and press the lower bushing

out of the upper arm.

4.

Remove the bushing from the

inner shaft; turn the assembly over

and remove the bushing from the

other side of the arm. It may be nec-

essary to remove Tool T65P-3044-A1

from the inner shaft and remove the

shaft from the arm to remove the

bushing from the shaft. Then, install

the tool on the shaft and remove the

other bushing.

5. Position the shaft and bushings

to the upper arm and install the bush-

ings and inner shaft in the upper arm

as shown in Fig. 37.

6. Install a washer and new nut on

each end of the inner shaft.

PRESS

RAM

Tool—3069-AA

Tool

- T65P

3044

- A3

Tool

- T65P

3044

- A2

F1441-A

FIG.

37—Installing Upper Arm

Shaft

Bushings

LOWER

ARM OVERHAUL-

ARM

REMOVED

LINCOLN CONTINENTAL

Inspect the lower arm, bushings and

pivot bolt for cracks, bends, wear or

other damage. Replace the arm if nec-

essary.

1. If the ball joint requires replace-

ment, remove the rivet heads with a

chisel. Punch the remaining portion of

the rivets from the holes.

Do not wash the ball joint with sol-

vent. The solvent may attack parts

within the joint.

2.

If the bushing requires replace-

ment, press it out of the arm with

Tool 3069—details H, AA, and AA2

(Fig. 38).

3.

Apply silicone or liquid soap to

the shell of the new bushing. Place the

bushing in the arm with the flange end

(large end) of the bushing at the front

of the arm.

4.

Press the bushing into the arm

until the shoulder on the bushing shell

seats against the arm. Use tool

3069—details H, AA2, and M5 (Fig.

39).

F

1483-A

FIG.

38—Removing Lower Arm

Bushing

PRESS

RAM

1482-A

FIG.

39—Installing Lower Arm

Bushing

5.

If the ball joint was removed, in-

stall the new joint using the parts sup-

plied in the ball joint kit. Torque the

nuts to specification. Make sure the

joint is completely filled with the spec-

ified lubricant.

UPPER

ARM OVERHAUL-

ARM

REMOVED

LINCOLN CONTINENTAL

Inspect the upper arm and the inner

shaft for cracks, bends or other dam-

age.

Replace the parts as required.

Replacement arms come with the

bushings, inner shaft, and ball joint

installed. If the original arm is to beprocarmanuals.com

Page 104 of 413

03-02-28

Suspension

03-02-28

used, these components should

be re-

placed

on the

bench.

Do not wash the ball joint with sol-

vent.

The

solvent

may

attack parts

within the joint.

BUSHING AND INNER

SHAFT REPLACEMENT

LINCOLN CONTINENTAL

Always replace both upper

arm

bushings,

if

either bushing

is

worn

or

damaged. Install only

new

bushings

when replacing

the

inner shaft. Refer

to Section

3 for

the upper arm remov-

al procedure.

1.

Remove

the

bolts, lock washers,

and flat washers from the ends

of

the

upper arm shaft.

2.

Assemble

the

remover, tool

3044-LA,

to the

shaft

at the

front

bushing. Press

the

bushing

out of the

arm using

the

support cup, tool 6069-

H,

and the

remover tool 3044-AB3

(Fig. 40).

PRESS RAM

FIG.

40

—Removing Upper

Arm

Front Bushing

3.

Remove

the

shaft.

4.

Remove

the

upper

arm

rear

bushing using

the

support

cup,

tool

3069-H, and

the

remover, tool 3069-L

(Fig. 41).

5.

Both upper

arm

bushings

are

pressed into the arm from the outside

toward the inside

of

the arm. To facil-

itate installation, use silicone

or

liquid

oap

as a

lubricant.

See

Fig.

41 for

PRESS RAM

Tool-3069-H

F 1480-A

FIG. 41—Removing Upper

Arm

Rear Bushing

proper assembly

of the

shaft

and

bushings.

6. Press the upper arm rear bushing

into

the arm

using

the

support cup,

tool 3069-H,

and the

replacer, tool

3068 (Fig. 43). Press

the

bushing

in

until

the

shoulder stop

is

reached.

7.

Insert

the end of the

shaft into

the rear bushing. Press the front bush-

ing onto

the

shaft

and

into

the arm

using the replacer, tool 3068 (Fig. 44).

REAR BUSHING

FRONT BUSHING

F 1479-A

FIG. 42— Upper Arm, Shaft,

and

Bushing Assembly

PRESS RAM

Tool— 3068

JF 1478-A

Bottom the bushing flange against the

flange

in the

arm.

8. Install

the

flat washers, lock-

washers,

and

bolts

at

the ends

of

the

upper

arm

shaft.

Do not

tighten

the

bolts

at

this time. These must

be

tightened after

the

arm assembly

has

been installed, and when the front end

weight

of

the vehicle

is

on the wheels.

These bolts

are

made

of a

special

material. Use only the specified bolt

if

replacement

is

necessary.

PRESS

RAM

FIG. 43—Installing Upper

Arm

Rear Bushing

FIG. 44—Installing Upper

Arm

Front Bushing

REAR SPRING OVERHAUL-

SPRING REMOVED

LINCOLN CONTINENTAL

Front Hanger Assembly

If

the

front hanger

or

bushings

are

to

be

replaced, proceed

as

follows:

1.

Remove

the

nuts and lock wash-

ers from

the

spring front mounting

bolt (Fig.

6).

2.

Tap the

spring mounting stud

out

of the

bushing

and

hanger, then

separate

the

hanger from

the

spring.

3.

Remove

the

front bushing from

the spring with tool T64N-5781-A.

4.

Install

the

bushing

in the

spring

with tool T64N-5781-A.

5.

Assemble the front hanger

to

the

spring

eye and

install

the

spring

mounting stud through

the

hanger,

bushings,

and

spring eye

as

shown

in

Fig.

6.

6. Install the lock washers and nuts

on

the

mounting stud

and

tighten

the

outboard

nut to

specification. Tighten

the inboard

nut to

specification with

the vehicle

at

curb riding height.procarmanuals.com

Page 105 of 413

03-02-29

Suspension

03-02-29

SPRING LEAVES

AND TIE-BOLT

LINCOLN CONTINENTAL

Check for broken spring leaves. In-

spect the anti-squeak inserts between

the leaves, and replace them if they

are worn. The spring leaves must be

dry and free of oil and dirt before new

inserts are installed.

If the spring center tie-bolt requires

replacement, clamp the spring in a

vise to keep the spring compressed

during bolt removal and installation.

REAR SHACKLE AND

HANGER ASSEMBLY

LINCOLN CONTINENTAL

Inspect the rear shackle, bushings,

and studs for wear or damage. Re-

place parts where necessary (Fig. 6).

If the rear shackle bushings are to

be replaced, it will be necessary to re-

move the rear hanger assembly. Tor-

que the hanger attaching bolts to

specification when installed.procarmanuals.com

Page 106 of 413

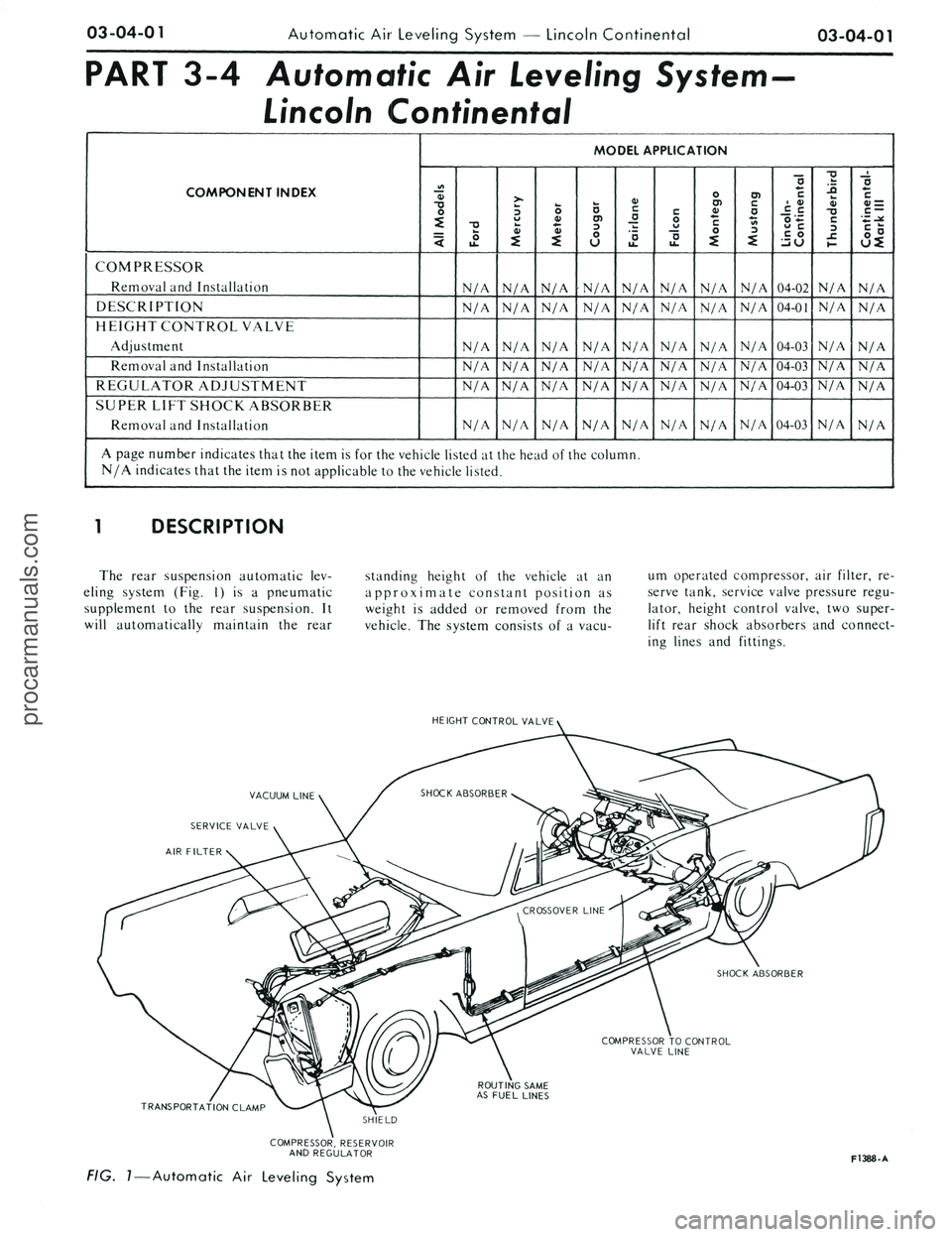

03-03-01

Automatic

Air

Leveling System

03-03-01

PART

3-3

Automatic

Air

Leveling System

COMPONENT INDEX

AIR COMPRESSOR

Disassembly

and

Overhaul

Removal

and

Installation

AIR CYLINDER

Removal

and

Installation

DESCRIPTION

HEIGHT CONTROL VALVE

Disassembly

and

Overhaul

Removal

and

Installation

MODEL APPLICATION

All

Models

Ford

03-03

03-02

03-02

03-01

03-03

03-02

Mercury

03-03

03-02

03-02

03-01

03-03

03-02

Meteor

03-03

03-02

03-02

03-01

03-03

03-02

Cougar

N/A

N/A

N/A

N/A

N/A

N/A

Fairlane

N/A

N/A

N/A

N/A

N/A

N/A

A page number indicates that the item

is for the

vehicle listed

at

the head

of

the column.

N/A indicates that

the

item

is not

applicable

to the

vehicle listed.

Falcon

N/A

N/A

N/A

N/A

N/A

N/A

Montego

N/A

N/A

N/A

N/A

N/A

N/A

Mustang

N/A

N/A

N/A

N/A

N/A

N/A

Lincoln-

Continental

N/A

N/A

N/A

N/A

N/A

N/A

Thunderbird

N/A

N/A

N/A

N/A

N/A

N/A

Continental-

Mark III

N/A

N/A

N/A

N/A

N/A

N/A

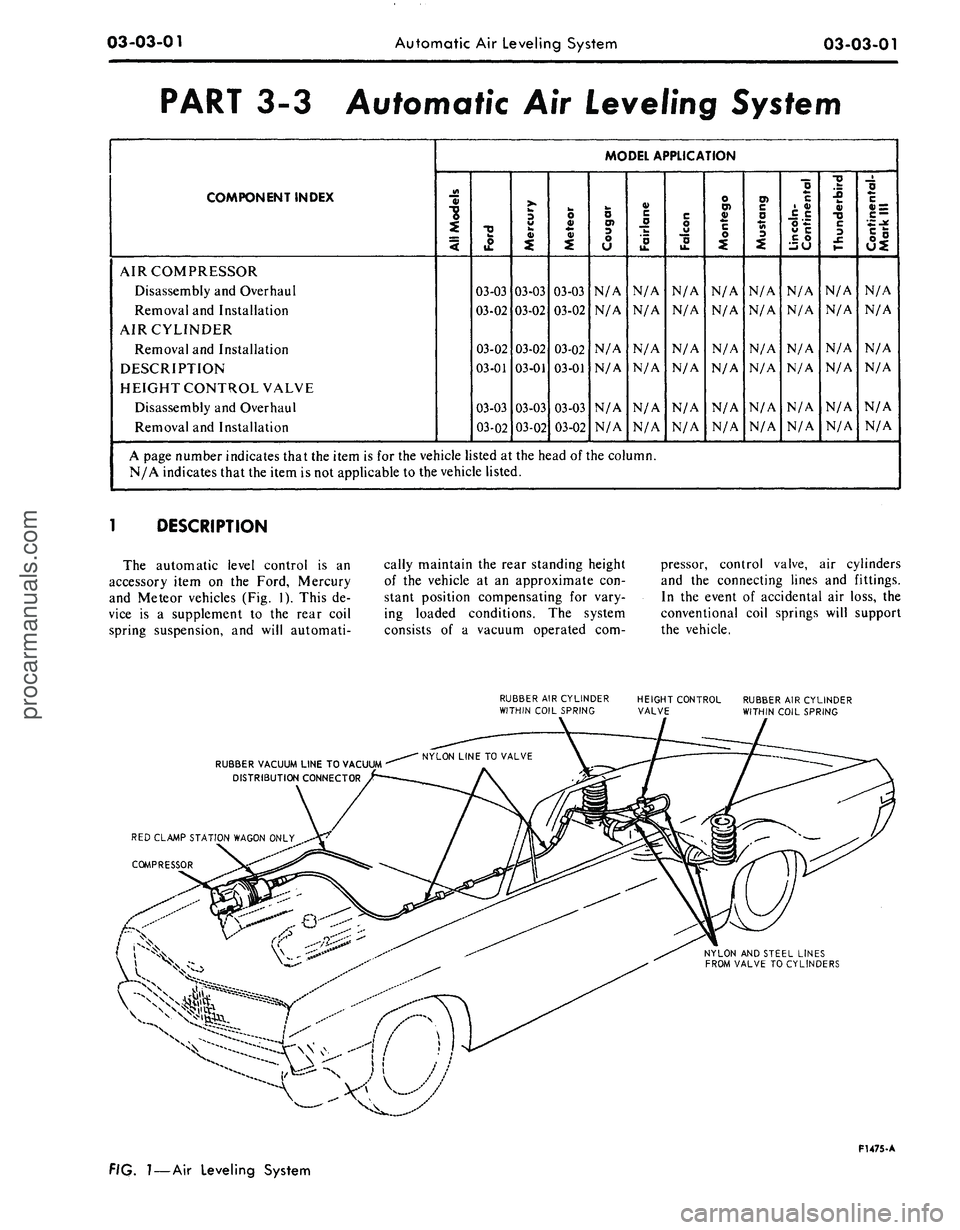

DESCRIPTION

The automatic level control

is an

accessory item

on the

Ford, Mercury

and Meteor vehicles

(Fig. 1).

This

de-

vice

is a

supplement

to the

rear coil

spring suspension,

and

will automati-

cally maintain

the

rear standing height

of

the

vehicle

at an

approximate

con-

stant position compensating

for

vary-

ing loaded conditions.

The

system

consists

of a

vacuum operated

com-

pressor, control valve,

air

cylinders

and

the

connecting lines

and

fittings.

In

the

event

of

accidental

air

loss,

the

conventional coil springs will support

the vehicle.

RUBBER

AIR

CYLINDER

WITHIN COIL SPRING

HEIGHT CONTROL

VALVE

RUBBER

AIR

CYLINDER

WITHIN COIL SPRING

RUBBER VACUUM LINE

TO

VACUUM

DISTRIBUTION CONNECTOR

RED CLAMP STATION WAGON ONLY

COMPRESSOR

NYLON

AND

STEEL LINES

FROM VALVE

TO

CYLINDERS

FIG.

1

—

Air Leveling System

FT475-A

procarmanuals.com

Page 107 of 413

03-03-02

Automatic Air Leveling System

03-03-02

REMOVAL AND INSTALLATION

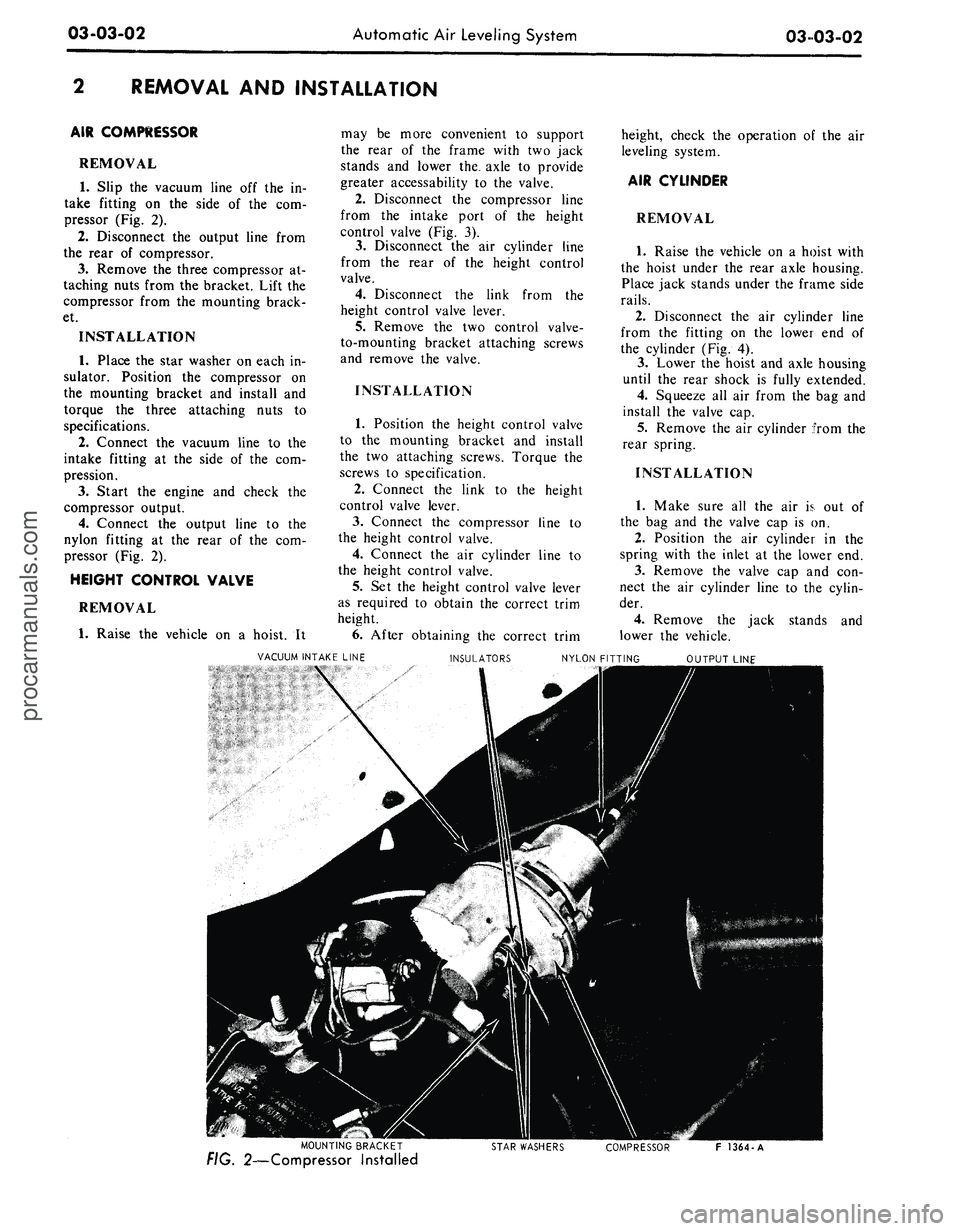

AIR COMPRESSOR

REMOVAL

1.

Slip the vacuum line off the in-

take fitting on the side of the com-

pressor (Fig. 2).

2.

Disconnect the output line from

the rear of compressor.

3.

Remove the three compressor at-

taching nuts from the bracket. Lift the

compressor from the mounting brack-

et.

INSTALLATION

1.

Place the star washer on each in-

sulator. Position the compressor on

the mounting bracket and install and

torque the three attaching nuts to

specifications.

2.

Connect the vacuum line to the

intake fitting at the side of the com-

pression.

3.

Start the engine and check the

compressor output.

4.

Connect the output line to the

nylon fitting at the rear of the com-

pressor (Fig. 2).

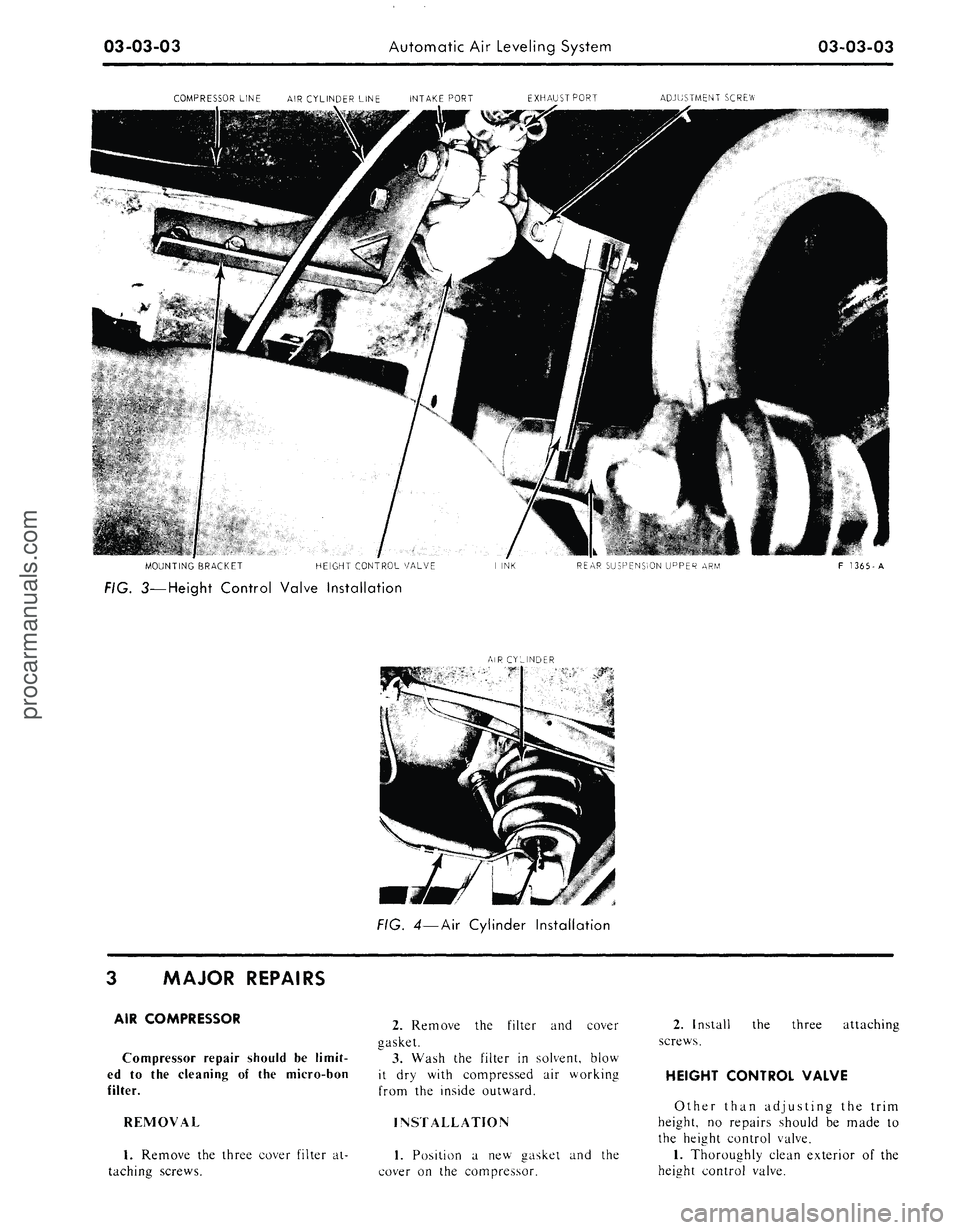

HEIGHT CONTROL VALVE

REMOVAL

1.

Raise the vehicle on a hoist. It

may be more convenient to support

the rear of the frame with two jack

stands and lower the, axle to provide

greater accessability to the valve.

2.

Disconnect the compressor line

from the intake port of the height

control valve (Fig. 3).

3.

Disconnect the air cylinder line

from the rear of the height control

valve.

4.

Disconnect the link from the

height control valve lever.

5.

Remove the two control valve-

to-mounting bracket attaching screws

and remove the valve.

INSTALLATION

1.

Position the height control valve

to the mounting bracket and install

the two attaching screws. Torque the

screws to specification.

2.

Connect the link to the height

control valve lever.

3.

Connect the compressor line to

the height control valve.

4.

Connect the air cylinder line to

the height control valve.

5.

Set the height control valve lever

as required to obtain the correct trim

height.

6. After obtaining the correct trim

height, check the operation of the air

leveling system.

AIR CYLINDER

REMOVAL

1.

Raise the vehicle on a hoist with

the hoist under the rear axle housing.

Place jack stands under the frame side

rails.

2.

Disconnect the air cylinder line

from the fitting on the lower end of

the cylinder (Fig. 4).

3.

Lower the hoist and axle housing

until the rear shock is fully extended.

4.

Squeeze all air from the bag and

install the valve cap.

5.

Remove the air cylinder from the

rear spring.

INSTALLATION

1.

Make sure all the air is out of

the bag and the valve cap is on.

2.

Position the air cylinder in the

spring with the inlet at the lower end.

3.

Remove the valve cap and con-

nect the air cylinder line to the cylin-

der.

4.

Remove the jack stands and

lower the vehicle.

VACUUM INTAKE LINE

INSULATORS

NYLON FITTING

MOUNTING BRACKET

FIG. 2—Compressor Installed

STAR WASHERS

COMPRESSOR

F 1364-Aprocarmanuals.com

Page 108 of 413

03-03-03

Automatic Air Leveling System

03-03-03

COMPRESSOR LINE

AIR

CYLINDER LINE INTAKE PORT EXHAUSTPORT

ADJUSTMENT SCREW

MOUNTING BRACKET

HEIGHT CONTROL VALVE

REAR SUSPENSION UPPER

ARM

FIG. 3—Height Control Valve Installation

Al R CYLINDER

F 1365-A

FIG. 4—Air Cylinder Installation

3 MAJOR REPAIRS

AIR COMPRESSOR

Compressor repair should

be

limit-

ed

to the

cleaning

of the

micro-bon

filter.

REMOVAL

1.

Remove

the

three cover filter

at-

taching screws.

2.

Remove

the

filter

and

cover

gasket.

3.

Wash

the

filter

in

solvent, blow

it

dry

with compressed

air

working

from

the

inside outward.

INSTALLATION

1.

Position

a new

gasket

and the

cover

on the

compressor.

2.

Install

the

three attaching

screws.

HEIGHT CONTROL VALVE

Other than adjusting

the

trim

height,

no

repairs should

be

made

to

the height control valve.

1.

Thoroughly clean exterior

of the

height control valve.procarmanuals.com

Page 109 of 413

procarmanuals.com

Page 110 of 413

procarmanuals.com