HONDA INTEGRA 1998 4.G Workshop Manual

INTEGRA 1998 4.G

HONDA

HONDA

https://www.carmanualsonline.info/img/13/6069/w960_6069-0.png

HONDA INTEGRA 1998 4.G Workshop Manual

Trending: key, seat memory, ground clearance, immobilizer, headlight bulb, brake, steering wheel

Page 1221 of 1681

Lighting System

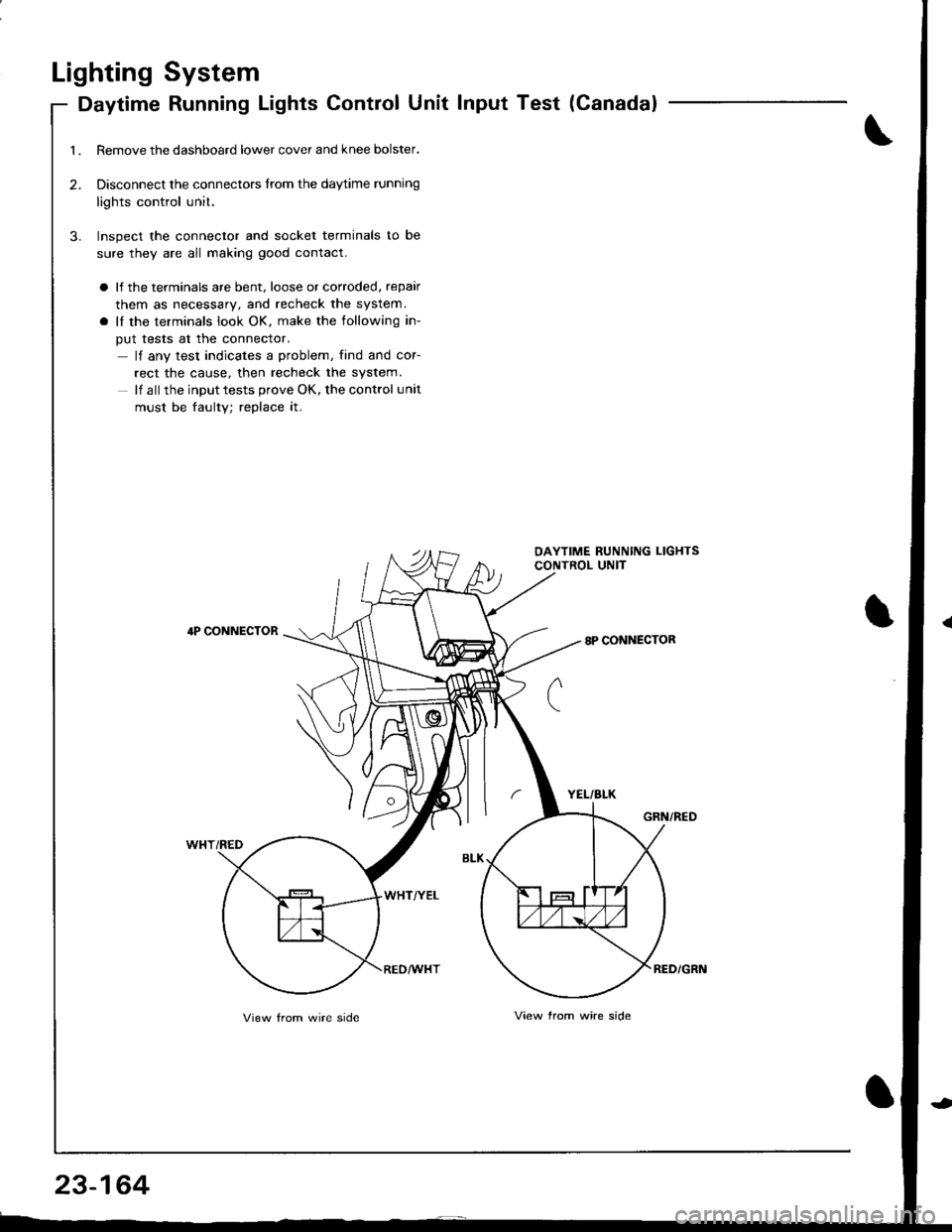

Daytime Running Lights Control Unit Input Test (Ganada)

Remove the dashboard lower cover and knee bolster.

Disconnect the connectors from the daytime running

lights control unit.

Inspect the connector and socket terminals to be

sure they are all making good contact.

a lf the terminals are bent, loose or corroded. repair

them as necessary, and recheck the system.

a ll the terminals look OK. make the lollowing in-

put tests at the connector.

lf any test indicates a problem, find and cor-

rect the cause, then recheck the system.

lf all the input tests prove OK, the control unit

must be faulty; replace it.

4P CONNECTOR8P CONNECTOR

GNN/RED

WHTiRED

WHT/YEL

REO/WHTRED/GRN

YEL/BLK

23-164

View trom wire sideView from wire side

Page 1222 of 1681

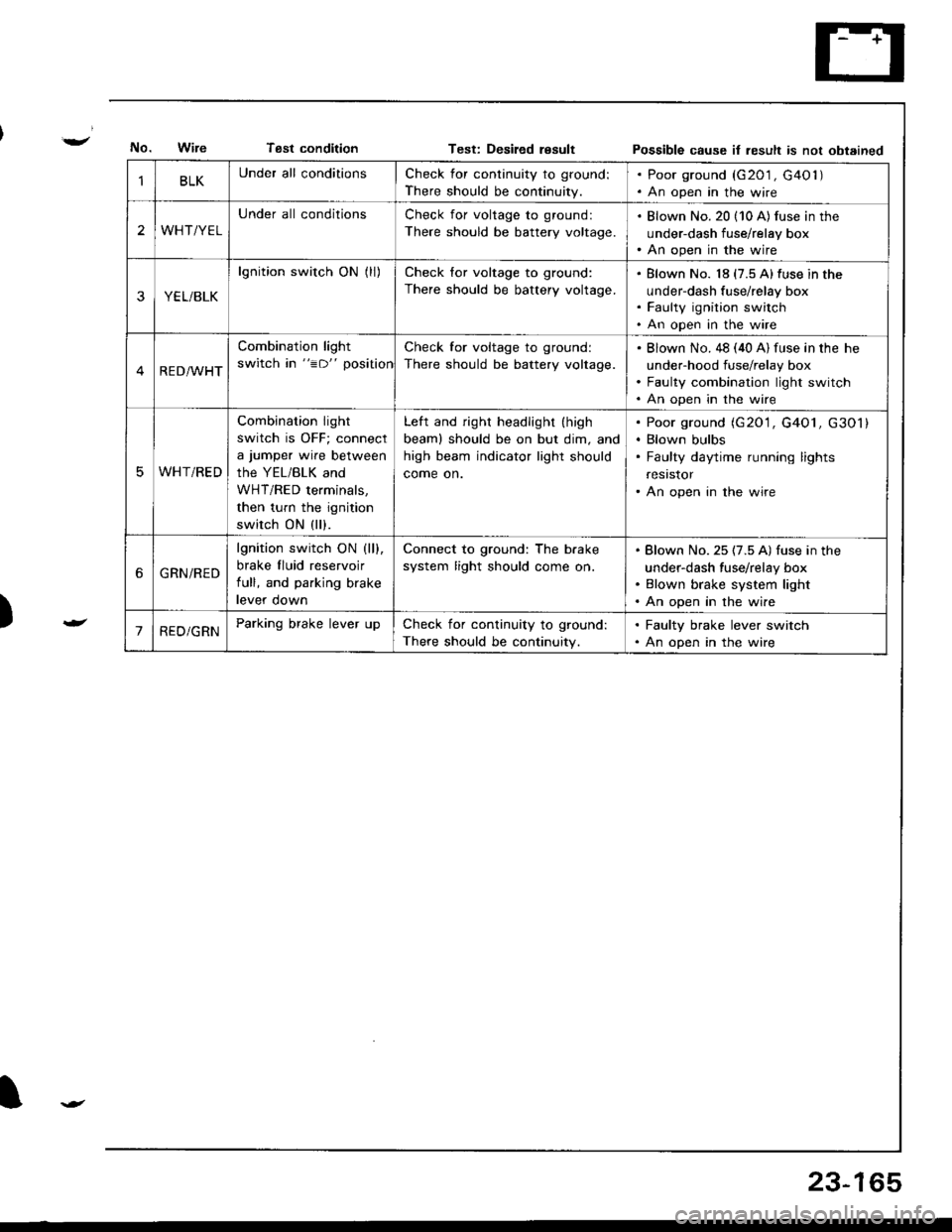

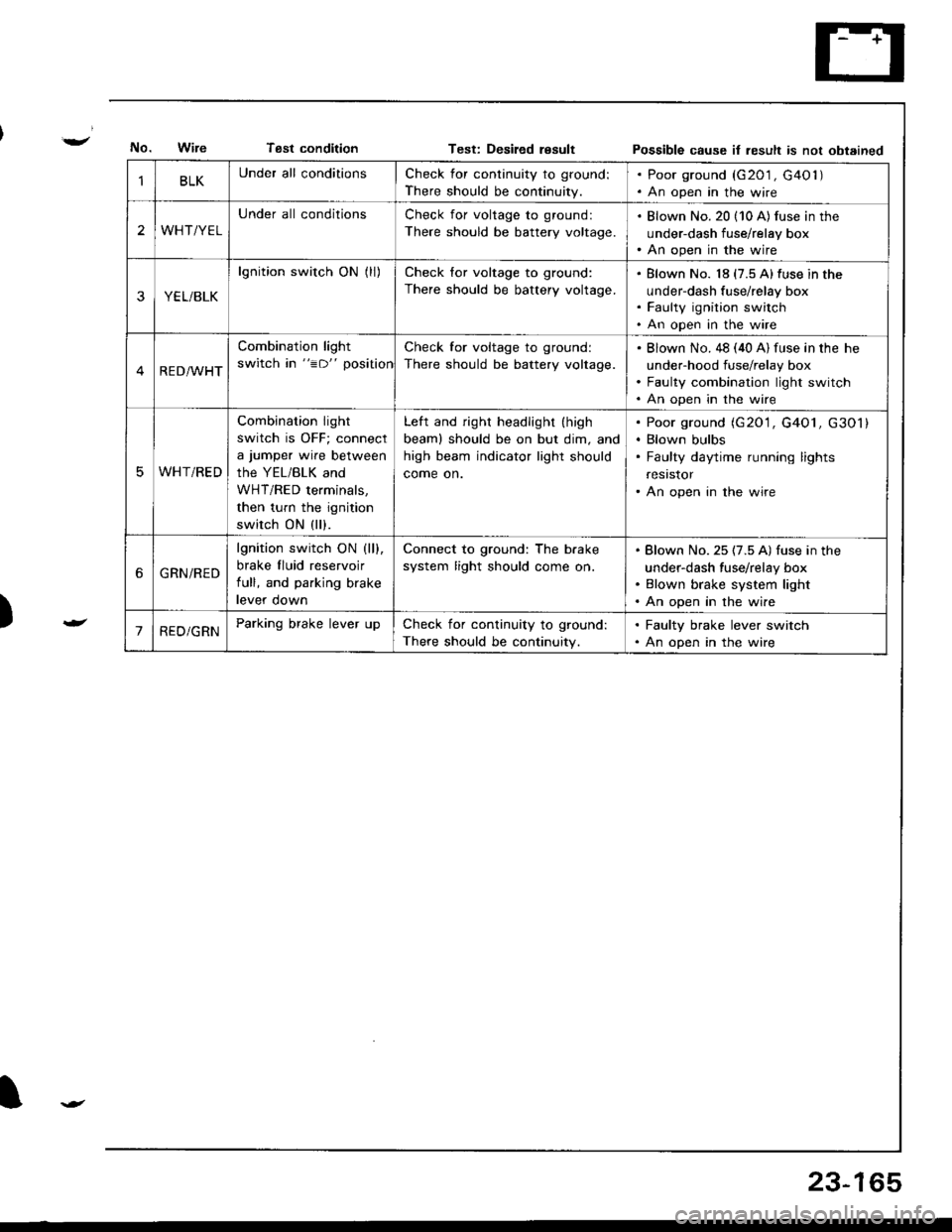

Tsst conditionTest: Desiled resultPossible cause it result is not obtained

)

BLKUnder all conditionsCheck for continuity to ground:

There should be continuity.

. Poor ground (G201 , G40l ). An open in the wire

2WHT/YEL

Under all conditionsCheck for voltage to ground:

There should be battery voltage.

. Blown No. 20 (10 A) fus€ in the

under-dash fuse/relay box. An open in the wire

YEL/BLK

lgnition switch ON (ll)Check for voltage to ground:

There should be battery voltage.

Blown No. 18 (7.5 A)fuse in the

under-dash fuse/relay box

Faulty ignition switch

An open in the wire

RED/WHT

Combination light

switch in "=D" position

Check for voltage to ground:

There should be battery voltage.

Blown No. 48 (40 A) fuse in the he

under-hood fuse/relay box

Faulty combination light switch

An open in the wire

WHT/RED

Combination light

switch is OFF; connect

a jumper wire between

the YEL/BLK and

WHT/RED terminals,

then turn the ignition

switch ON (ll).

Left and right headlight (high

beaml should be on but dim, and

high beam indicator light should

come on.

Poor ground (G20'1, G4O1, G301)

Blown bulbs

Faulty daytime running lights

resrstor

An open in the wire

6GRN/RED

lgnition switch ON (ll).

brake fluid reservoir

full, and parking brake

levef oown

Connect to ground: The b.ake

system light should come on.

Blown No. 25 (7.5 A) fuse in the

under-dash fuse/relay box

Blown brake system light

An open in the wire

'1RED/GRNParking brake lever upCheck for continuity to ground:

There should be continuity.

. Faulty brake lever switch. An open in the wire

23-165

Page 1223 of 1681

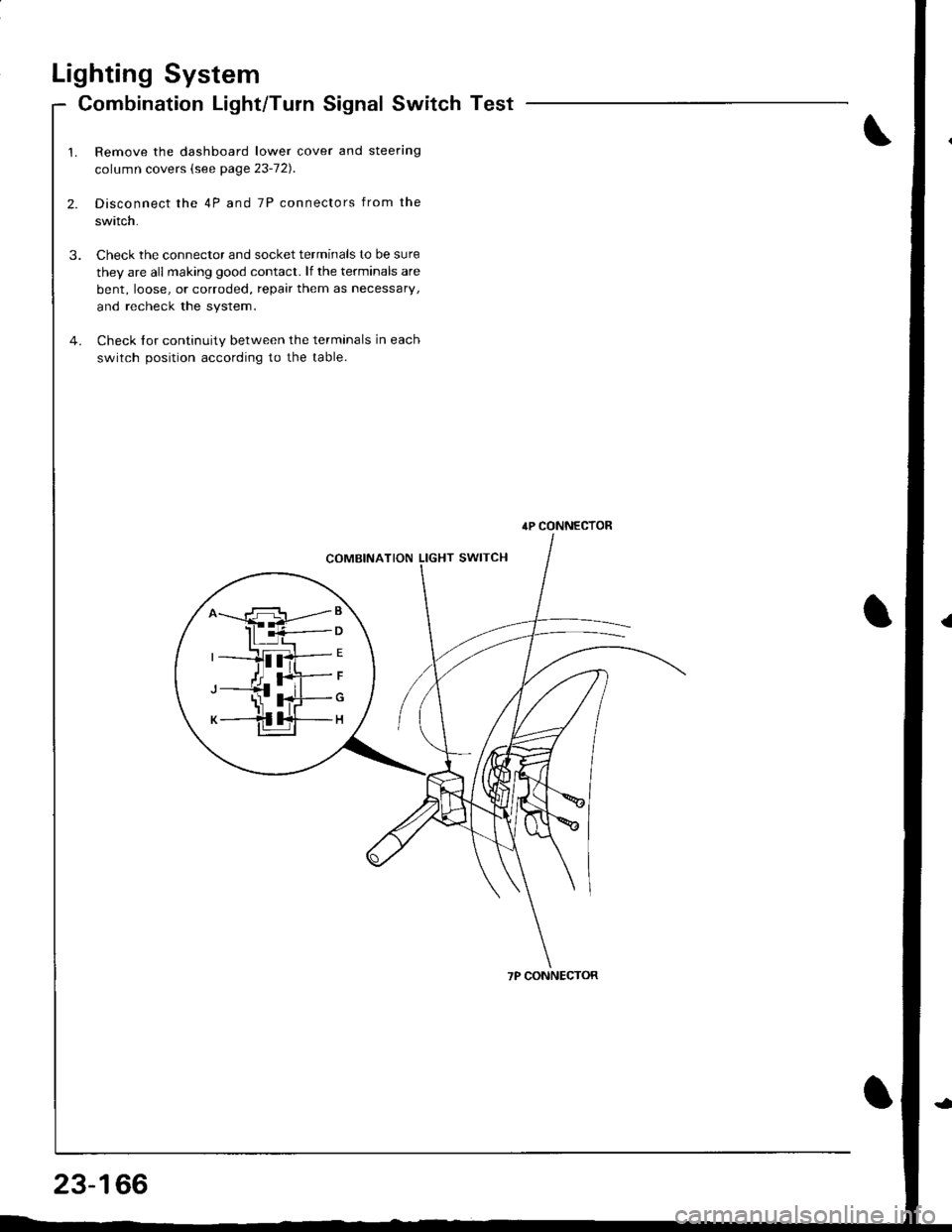

Lighting System

Combination Light/Turn Signal Switch Test

Remove the dashboard lower cover and steering

column covers {see page 23-721.

Disconnect the 4P and 7P connectors from the

switch.

Check the connector and socket terminals to be sure

they are all making good contact. lf the terminals are

bent, loose, or corroded, repair them as necessary,

and recheck the system.

Check lor continuity between the termanals in each

switch position according to the table.

B

D

E

H

4P CONNECTOR

7P CONNECTOR

23-166

Page 1224 of 1681

Combination Light Switch :

OFFd

I

.,\

Lr"

G (Not us.d)

Tuln Signal Switch :

Terminal

PositionFJ

Headlight switchOFF

:m:oo

=DLOWo--ooo

HIGHoooo

Passing switchOFF

ONoo

LEFTRIGHT

I

Position

TerminalB

RIGHToo

NEUTRAL

LEFToo

23-167

Page 1225 of 1681

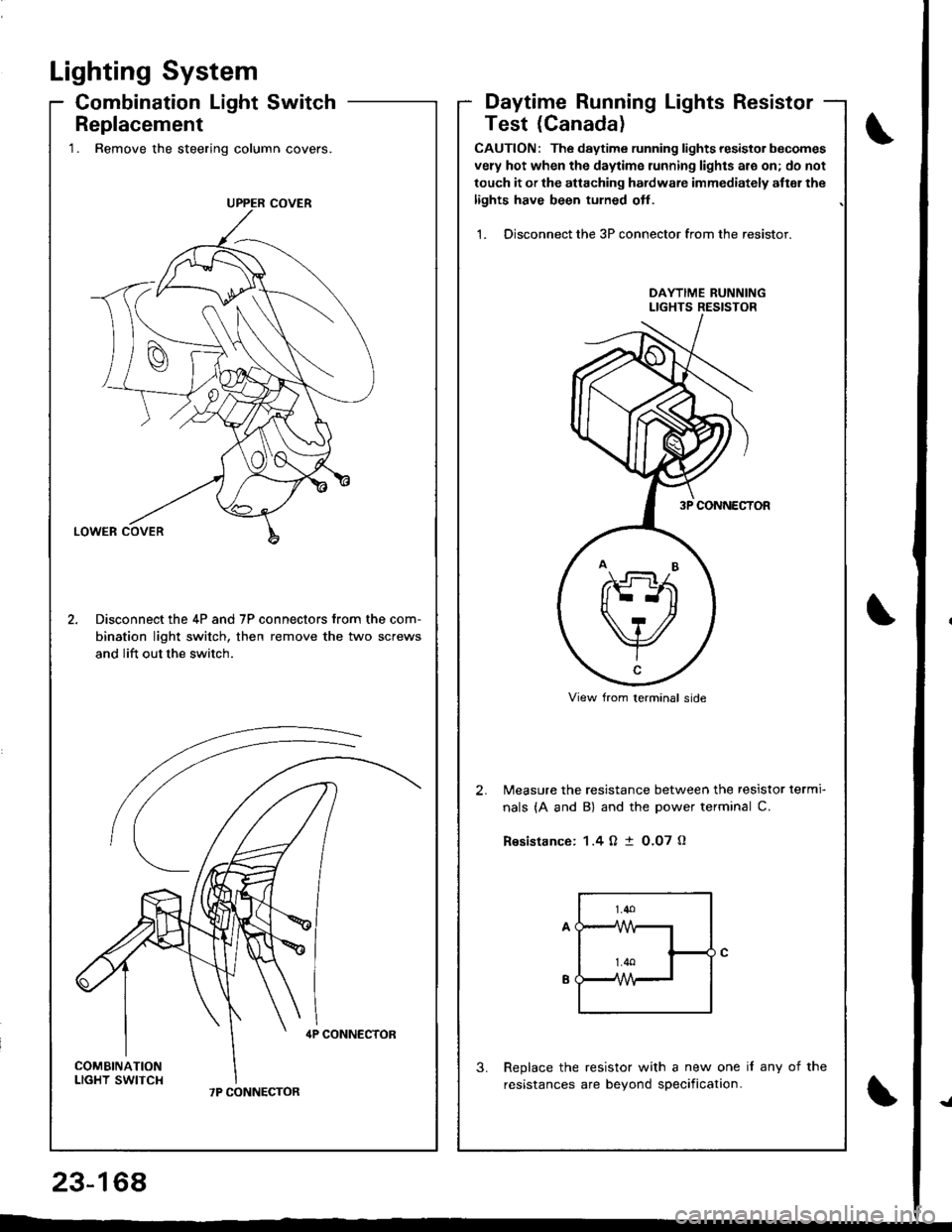

Replacement'1. Remove the steering column covers.

Disconnect the 4P and 7P connectors from the com-

bination light switch, then remove the two screws

and lift out the switch.

,P CONNECTOR

Lighting System

Combination Light SwitchDaytime Running Lights Resistor

Test (Canada)

CAUTION: The daytime running lights resistor becomes

vely hot when the daytime running lights arc on; do not

touch it or the attaching hardware immediately altel the

lights have been tulned otf.

1. Disconnect the 3P connector from the resistor.

DAYTIME RUNNINGLIGHTS RESISTOR

2.Measure the resistance between the resistor termi-

nals (A and B) and the power terminal C.

Resistance: 1.4 O 1 O.O7 o

Replace the resistor with a new one il any of the

resistances are beyond specification.

;w;

V

View from terminal side

23-168

Page 1226 of 1681

)

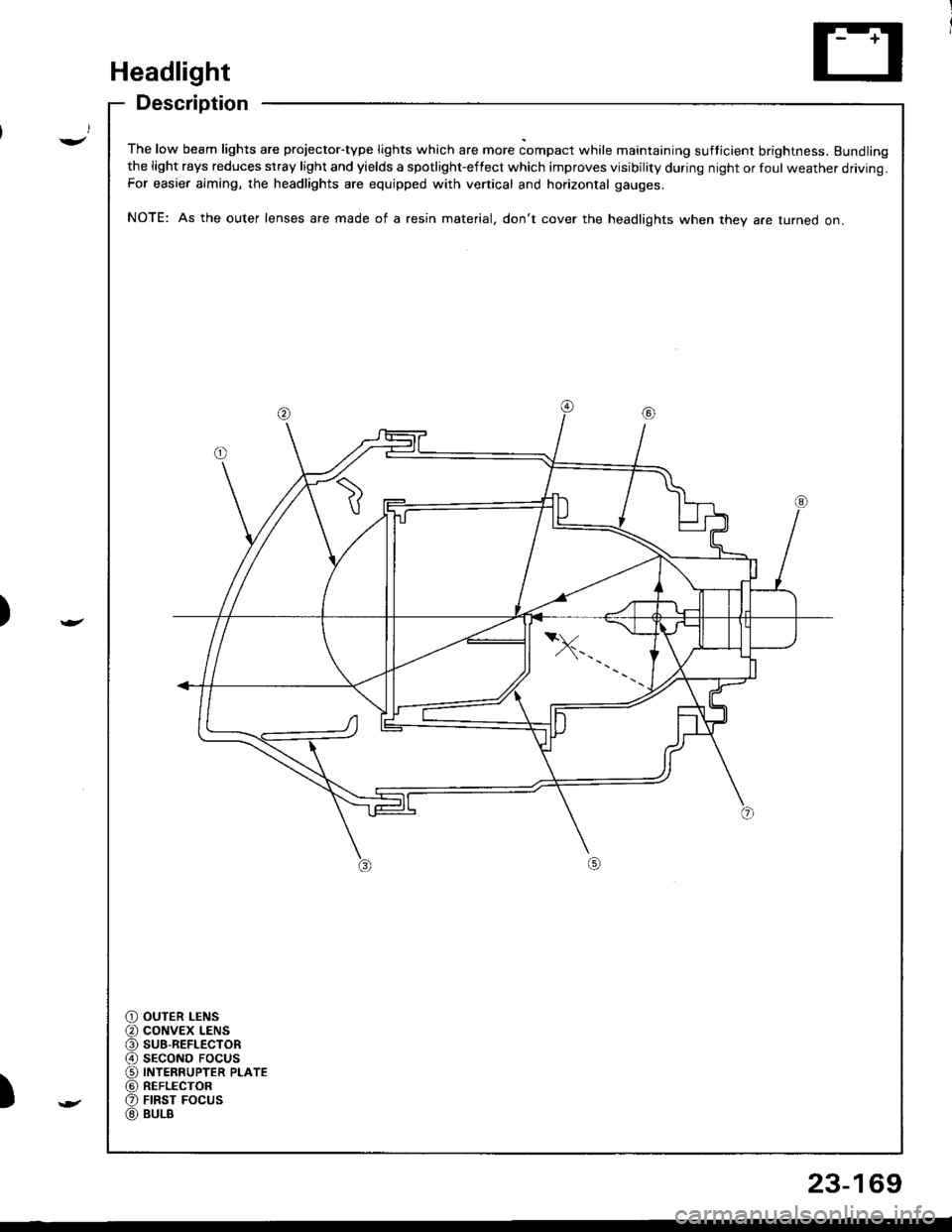

Headlight

Description

The low beam lights are projector-type lights which are more compact while maintaining sufticient brightness. Bundlingthe light rays reduces stray light and yields a spotlight-effect which improves visibility during night or foul weather driving.For easier aiming, the headlights are equipped with vertical and horizontal gauges.

NOTE: As the outer lenses are made of a resin material, don't cover the headlights when they a.e turned on.

OUTER LENSCONVEX LENSSU8-REFLECTORSECOND FOCUSINTERRUPTER PLATEREFLECTORFIRST FOCUSBULB

23-169

Page 1227 of 1681

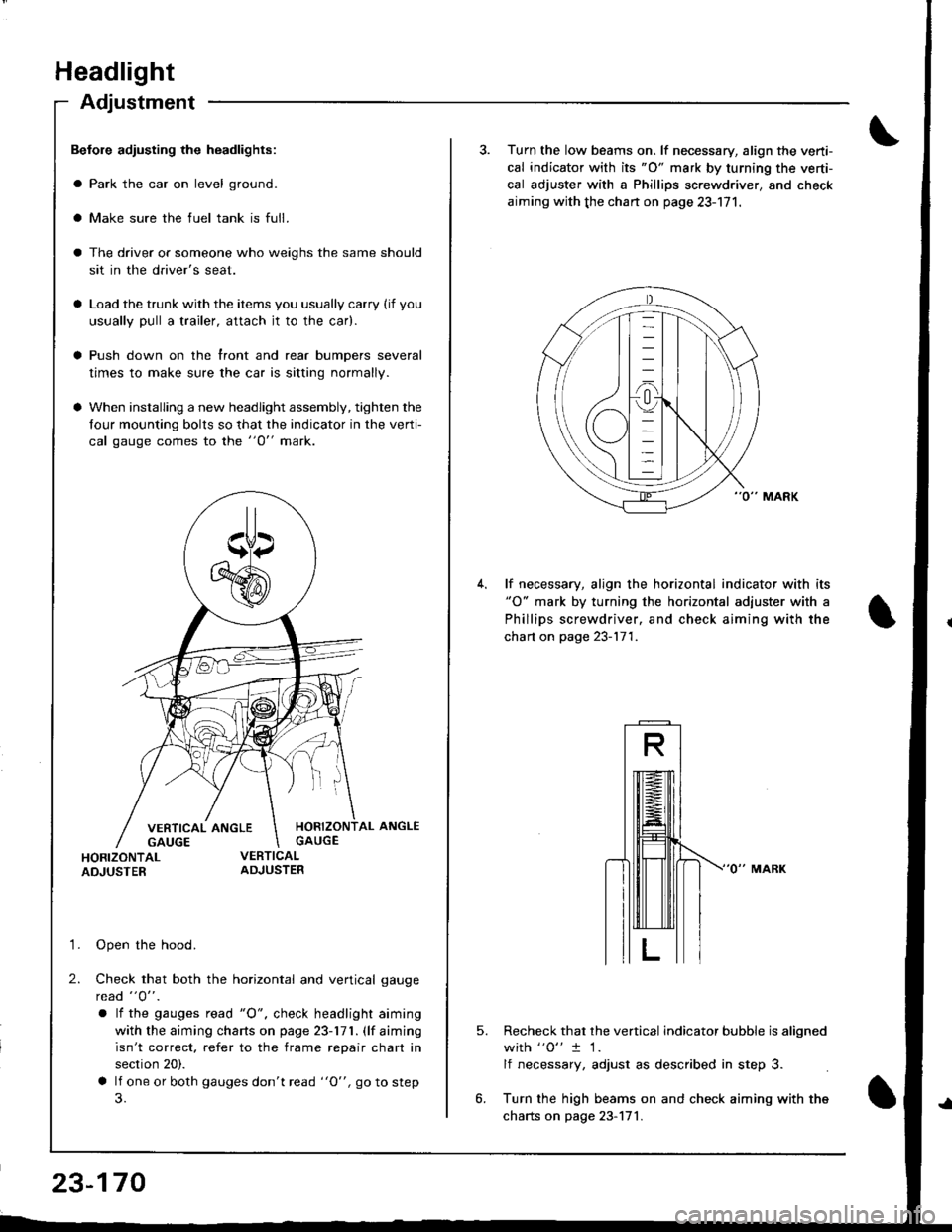

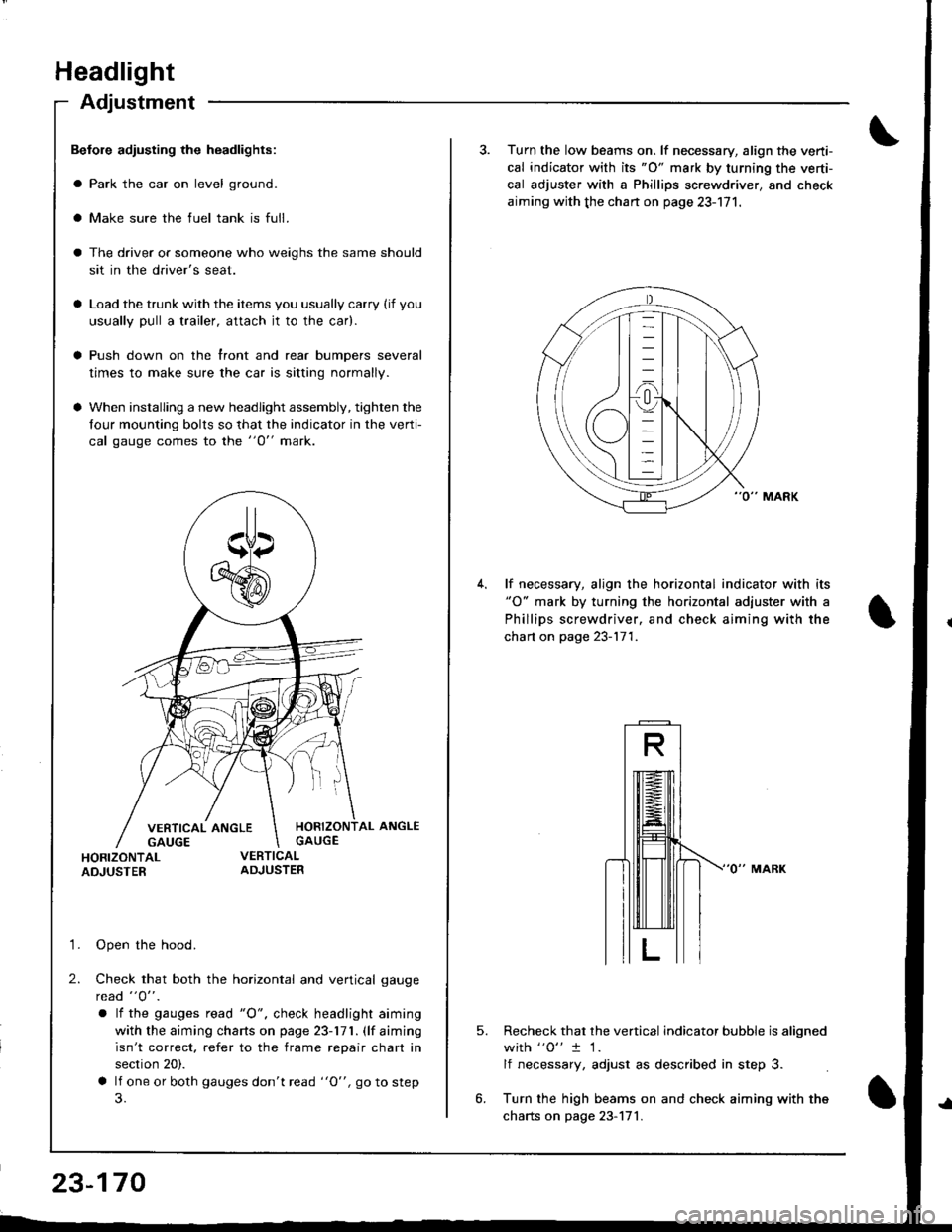

Headlight

Adjustment

Befole adiusting the headlights:

a Park the car on level ground.

a Make sure the fuel tank is full.

The driver or someone who weighs the same should

sit in the driver's seat.

Load the trunk with the items you usually carry (if you

usually pull a trailer, attach jt to the car).

Push down on the front and rear bumpers several

times to make sure the car is sitting normally.

When installing a new headlight assembly, tighten the

four mounting bolts so that the indicator in the verti-

cal gauge comes to the "O" mark.

HORIZONTAL ANGLEGAUGE

HORIZONTALADJUSTER

'1. Open the hood.

2. Check that both the horizontal and vertical gauge

rcad "O" .

a lf the gauges tead "O", check headlight aiming

with the aiming charts on page 23-171. (lf aiming

isn't correct. refer to the frame repair chart in

section 20).

a lf one or both gauges don't read "O", go to step

23-170

3. Turn the low beams on. lf necessary, align the verti-

cal indicator with its "O" mark by turning the verti-

cal adjuster with a Phillips screwdriver, and check

aiming with the chan on page 23-171.

lf necessary, align the horizontal indicator with its"O" mark by turning the horizontal adjuster with a

Phillips screwdriver, and check aiming with the

chart on page 23-171.

5.Recheck that the vertical indicator bubble is aligned

with "0" t 1.

lf necessary, adjust as described in step 3.

Turn the high beams on and check aiming with the

charts on page 23-171.

Page 1228 of 1681

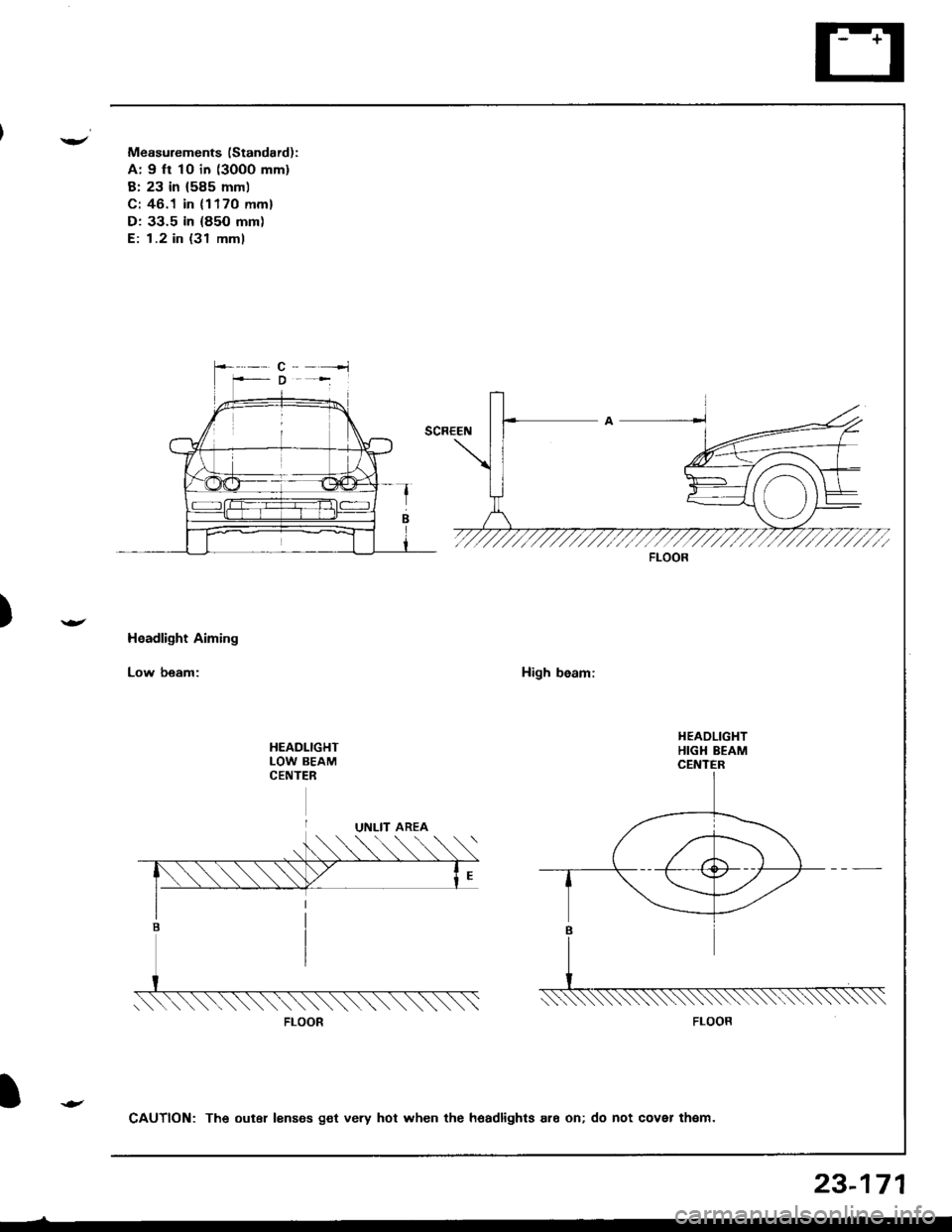

)

Measurements (Standard):

A: 9 ft 10 in (3000 mm)

B: 23 in (585 mml

C: 46.1 in (1170 mm)

D: 33.5 in (85O mm)

E: 1.2 in (31 mml

Headlight Aiming

Low beam:High beam:

HEADLIGHTLOW BEAMCENTER

FLOOR

FLOOR

CAUTION: The outer lenses get very hot when the hoadlights ar6 on; do not cover th€m.

23-171

Page 1229 of 1681

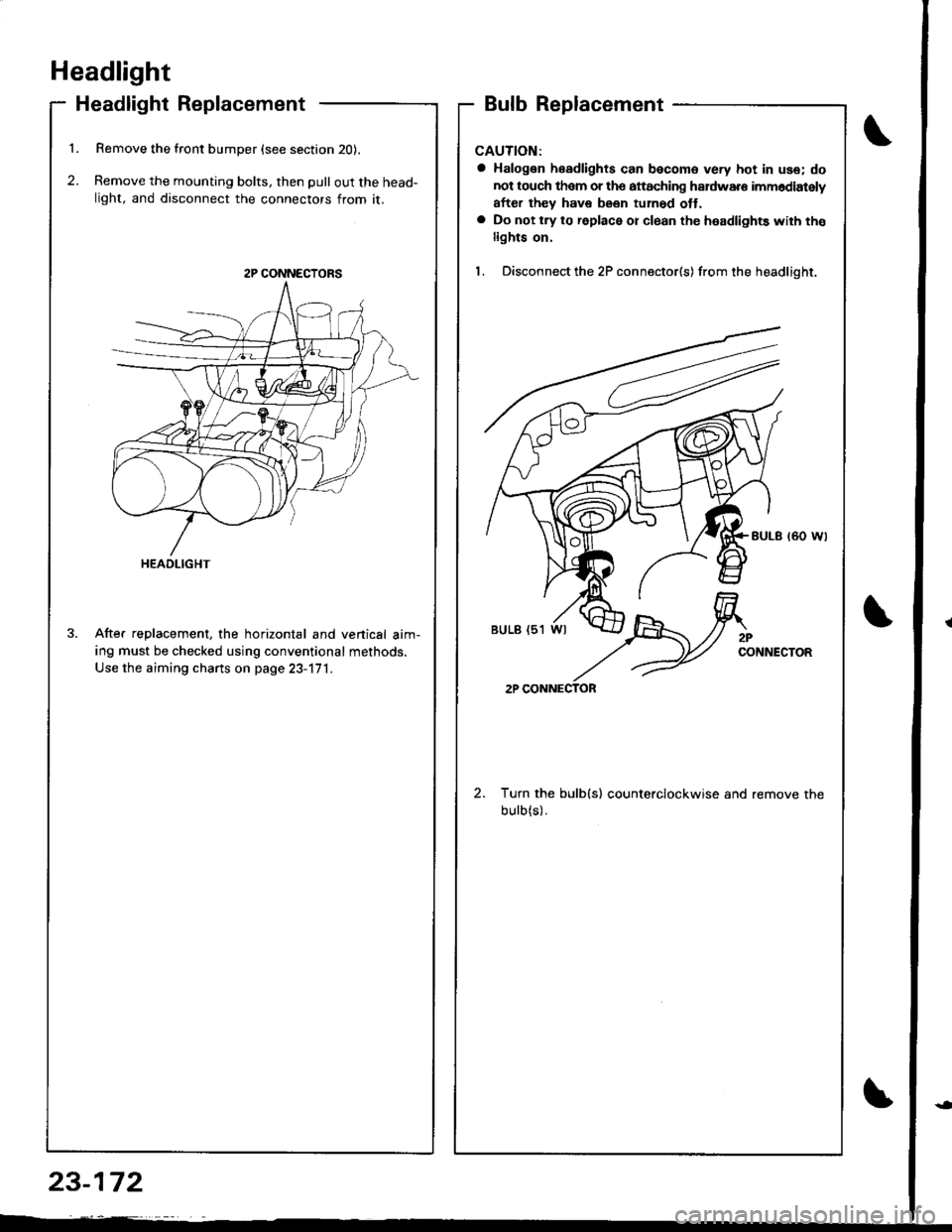

Headlight

Headlight Replacement

1. Remove the front bumper (see section 20).

2. Remove the mounting bolts, then pull out the head-

light, and disconnect the connectors from it.

After replacement, the horizontal and venical aim-

ing must be checked using conventional methods.

Use the aiming charts on page 23-171.

Bulb Replacement

CAUTION:

a Halogen headlights can becomo very hot in use; do

not touch them or the attaching haldware imm6diately

after they have been tuh6d ott.a Do not try to replace or cl6an the headlights with tho

lights on.

1. Disconnect the 2P connector(s) from the headlight.

Turn the bulb(s) counterclockwise and remove the

bulb(s).

2P CONNECTORS

HEADLIGHT

2PCONNECTOR

2P CONNECTOR

23-172

Page 1230 of 1681

)

I

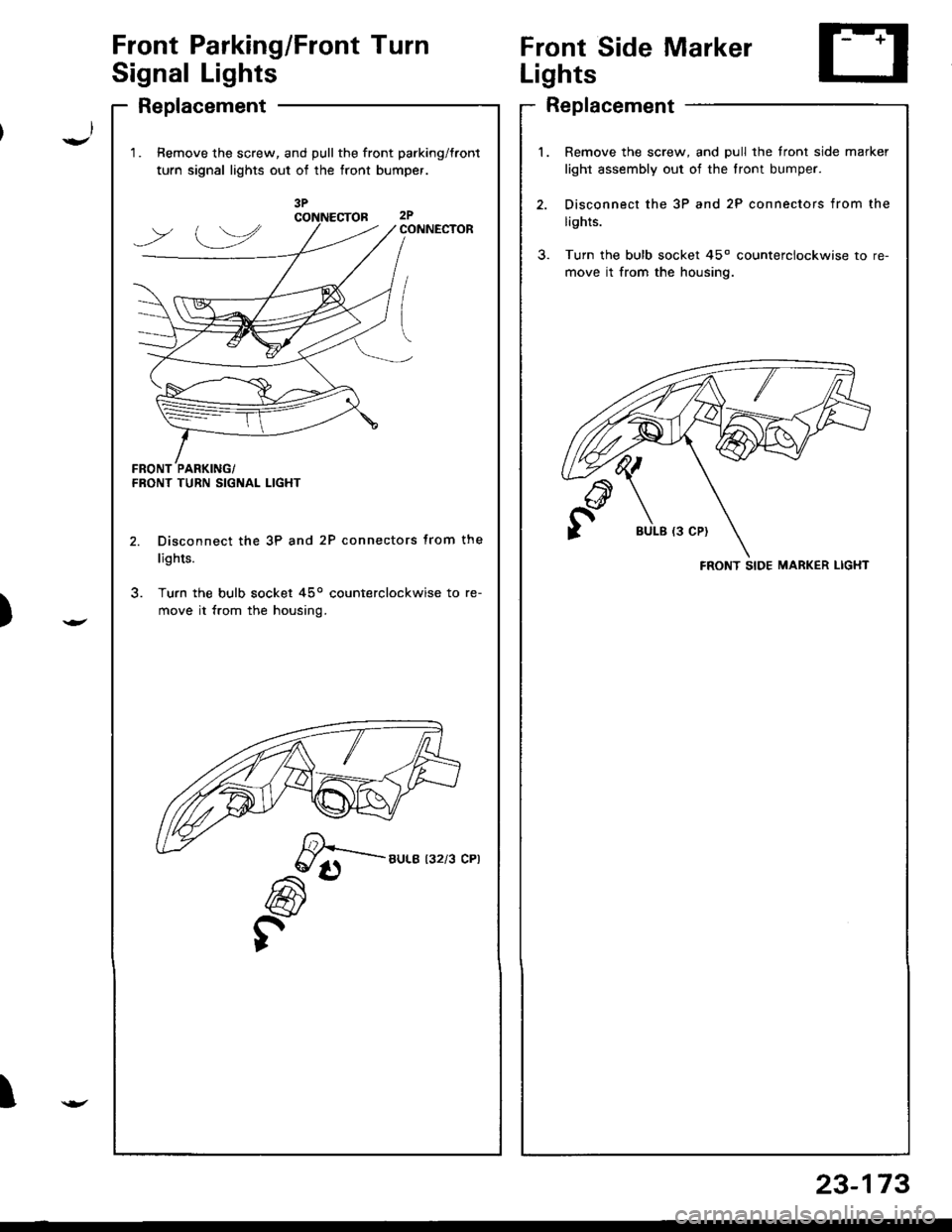

Front Parking/Front Turn

Signal Lights

Replacement

'1.Remove the screw, and pull the front parking/tront

turn signal lights out of the front bumper.

CONNECTOR

l.

FRONT TURN SIGNAL LIGHT

Disconnect the 3P and 2P connectors trom the

lights.

Turn the bulb socket 45o counterclockwise to re-

move it from the housing.

/e*----

Ar)

fl

Front Side Marker

Lights

1.Remove the screw, and pull the tront side marker

light assembly out of the tront bumper.

Disconnect the 3P and 2P connectors from the

lights.

Turn the bulb socket 45o countefclockwise to re-

move it from the housing.

FRONT SIDE MARKER LIGHT

Replacement

23-173

Trending: check engine, load capacity, heating, Obd, automatic transmission, fuel pressure, brake rotor