HONDA INTEGRA 1998 4.G Workshop Manual

Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 391 of 1681

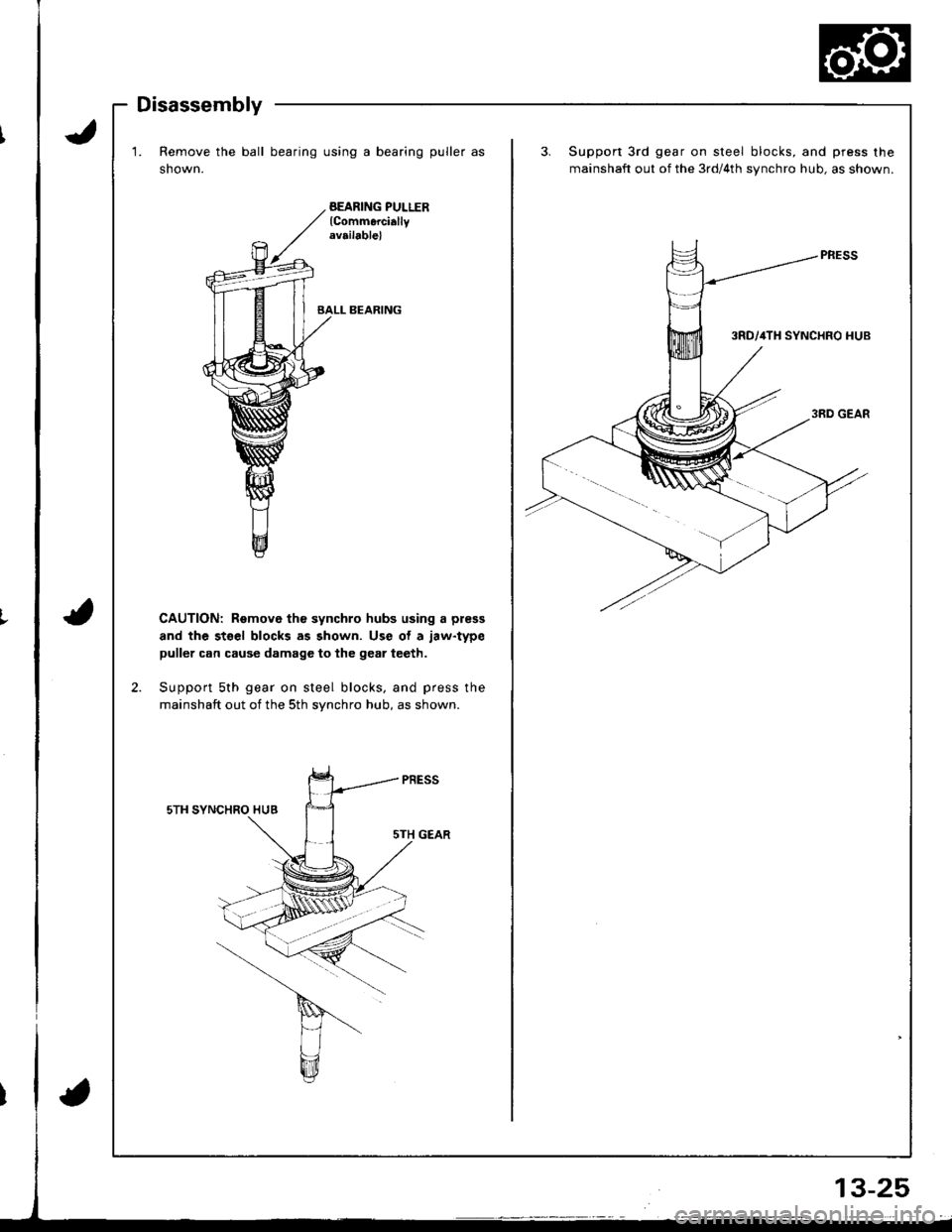

Disassembly

1. Remove the ball bearing using a bearing puller as

shown.

BEARING PULLERlCommerciallyrv.ilable)

BALL BEARING

CAUTION: Remove th€ synchro hubs using a press

and the stsel blocks as shown. Use ot a jaw.type

puller can cause damage to the gear teeth.

Support sth gear on steel blocks, and press the

mainshaft out of the sth synchro hub, as shown.

sTH SYNCHRO HUB

sTH GEAR

3.Support 3rd gear on steel blocks, and press the

mainshaft out of the 3rd/4th synchro hub, as shown.

Page 392 of 1681

I

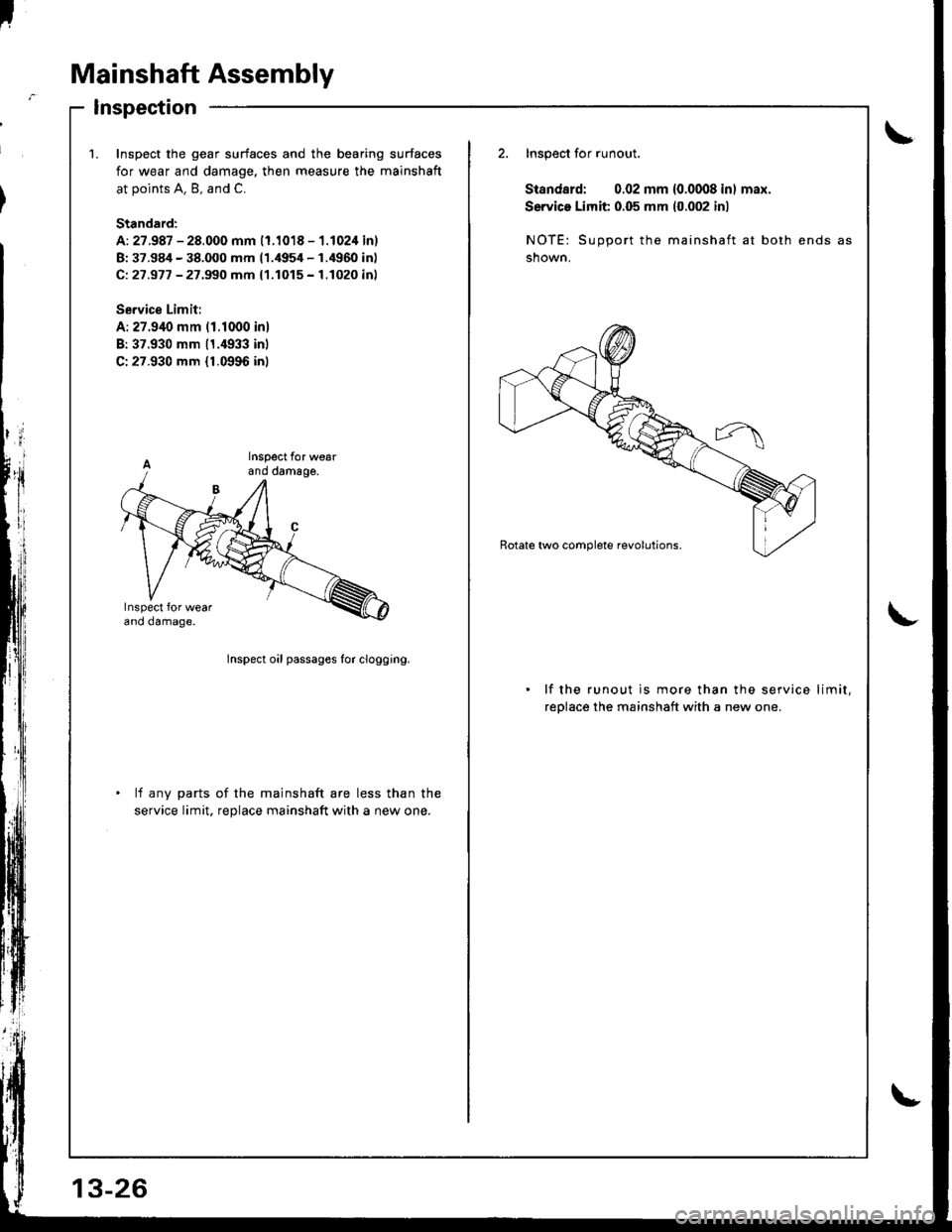

Mainshaft Assembly

Inspection

\1.Inspoct the gear surfaces and the bearing surfaces

for wear and damage, then measure the mainshaft

at points A. B, and C.

Standard:

A: 27.987 - 28.000 mm (1.1018 - 1.1024 inl

B: 37.984 - 38.000 mm 11.4954 - 1.4960 inl

Ci 27 .977 - 27 .99O mm { 1.1015 - 1.1020 inl

Se.vice Limit:

A: 27.940 mm 11.1000 inl

B:37.930 mm 11.4933 inl

C:27.930 mm {1.0996 inl

2. Inspect for runout.

Standard: 0.02 mm 10.0008 inl max.

Service Limit 0.05 mm (0.002 inl

NOTE: Support the mainshaft at both ends

shown.

lnspect oil passages for clogging.

lf the runout is more than the service limit,

reolace the mainshaft with a new one.

lf any parts of the mainshaft are less than the

service limit, reDlace mainshaft with a new one.

Page 393 of 1681

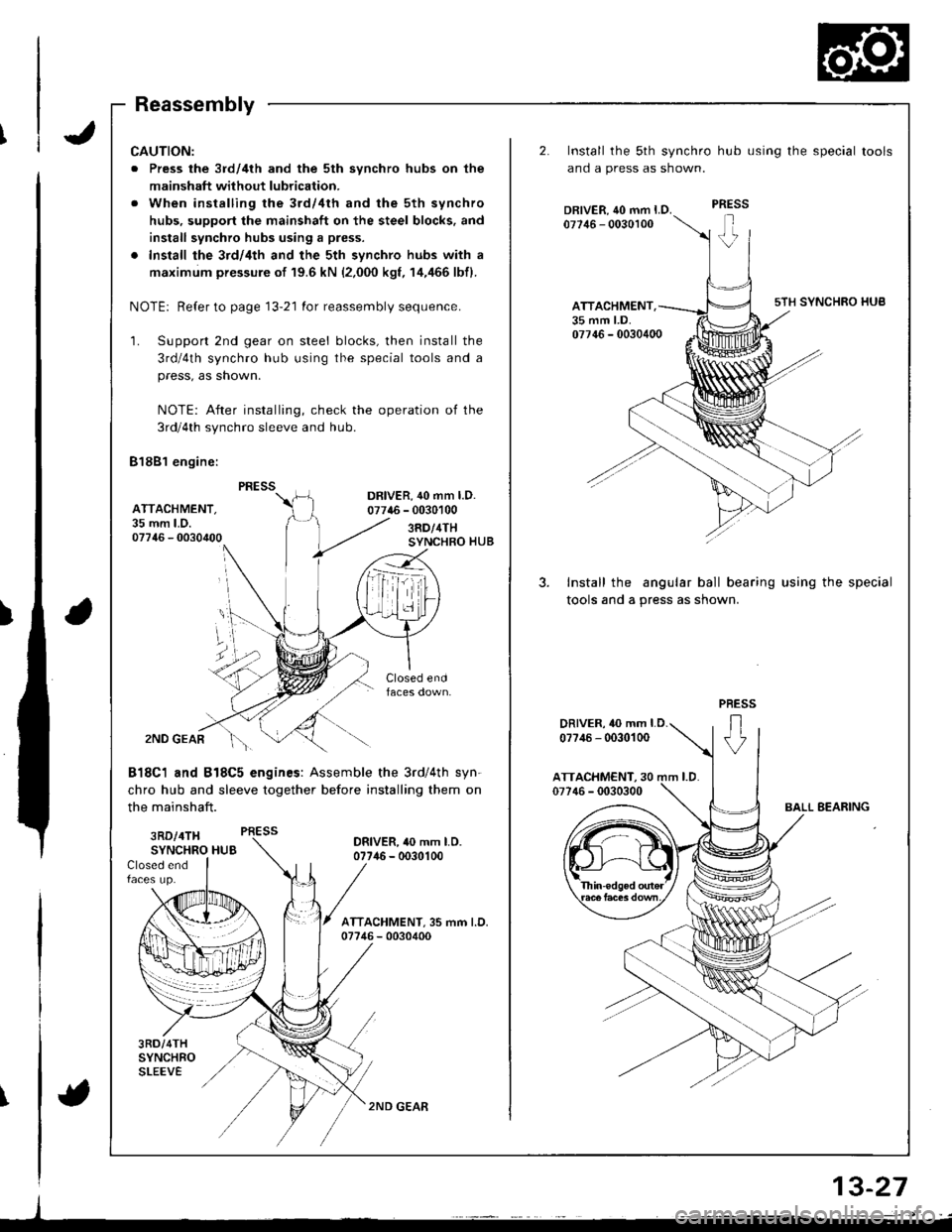

Reassembly

CAUTION:

. Press the 3rd/4th and the 5th synchro hubs on the

mainshaft without lubrication.

. When installing rhe 3rd/4th and the 5th synchro

hubs, support the mainshaft on the steel blocks. and

install synchro hubs using a press.

. Install the 3rd/4th and the 5th synchro hubs with a

maximum pressure of 19.6 kN {2,000 kgf, 14,/166 lbfl.

NOTE: Refer to page 13-21 for reassembly sequence.

'1. Support 2nd gear on steel blocks, then install the

3rd/4th synchro hub using the special tools and a

press, as shown.

NOTE: After installing, check the operation of the

3rd/4th synchro sleeve and hub

81881 engine:

DR|VER,40 mm l.D.07746 - 0030100AITACHMENT.35 mm LD.07746 - 00304003RD/4THSYNCHRO HUB

f

2ND GEAR

818C1 and B18C5 engines: Assemble the 3rd/4th syn-

chro hub and sleeve together before installing them on

the mainshaft.

3RD/4TH PRESS

SYNCHRO HUBORIVER, 40 mm LO.07746 - 0030100Closed endfaces up.

3RD/4THSYNCHROSLEEVE

2ND GEAR

2.

3.

Install the sth synchro hub using the special tools

ano a press as snown.

Install the angular ball bearing using the special

tools and a press as shown.

ATTACHMENT.35 mm LD.

DRIVER, 10 mm LD.

07?,16 - 0030100

J

a

\

13-27

{

Page 394 of 1681

'f

I

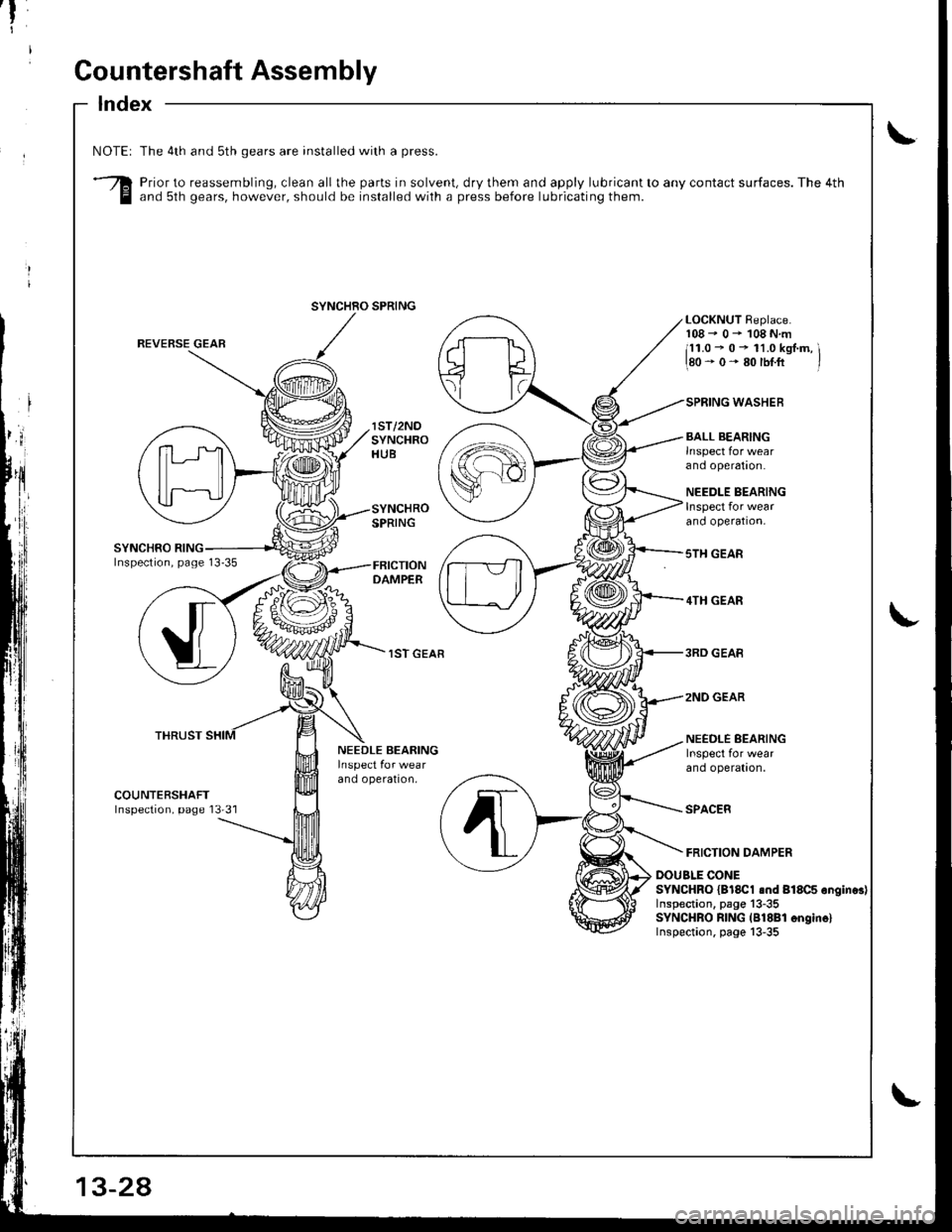

Gountershaft Assembly

Index

\NOTEI

3

The 4th and sth gears are installed with a press.

Prior to reassembling, clean all the parts in solvent, dry them and apply lubricant to any contact surfaces. The 4thand sth gears, however, should be installed with a press before lubricating them.

REVERSE GEAR

THRUST

lST/2NOSYNCHROHUB

SYNCHROSPRING

DAMPER

lST GEAR

LOCKNUT Replace.r08- 0- 108N.m

il1.0 - 0 - 11.0 kgJ.m, \180-0-80rbt.fi /

SPRING WASHEB

BALL BEARING

ano operalron.

NEEDLE BEARINGInspect for wearano operaron,

sTH GEAR

4TH GEAR

3RD GEAB

2NO GEAR

NEEDLE SEARINGInspect for wea.ano opera[|on.

SPACER

FRICTION DAMPER

NEEDLE BEARING

ano operalton,

COUNTERSHAFTInspection, page 13'31

DOUBLE CONESYNCHRO {Bl8Cl snd 818C5 ongines)Inspection. page 13-35SYNCHRO RING (B18Bl 6ngin6lInspection. page 13-35

SYNCHRO SPRING

13-24

Page 395 of 1681

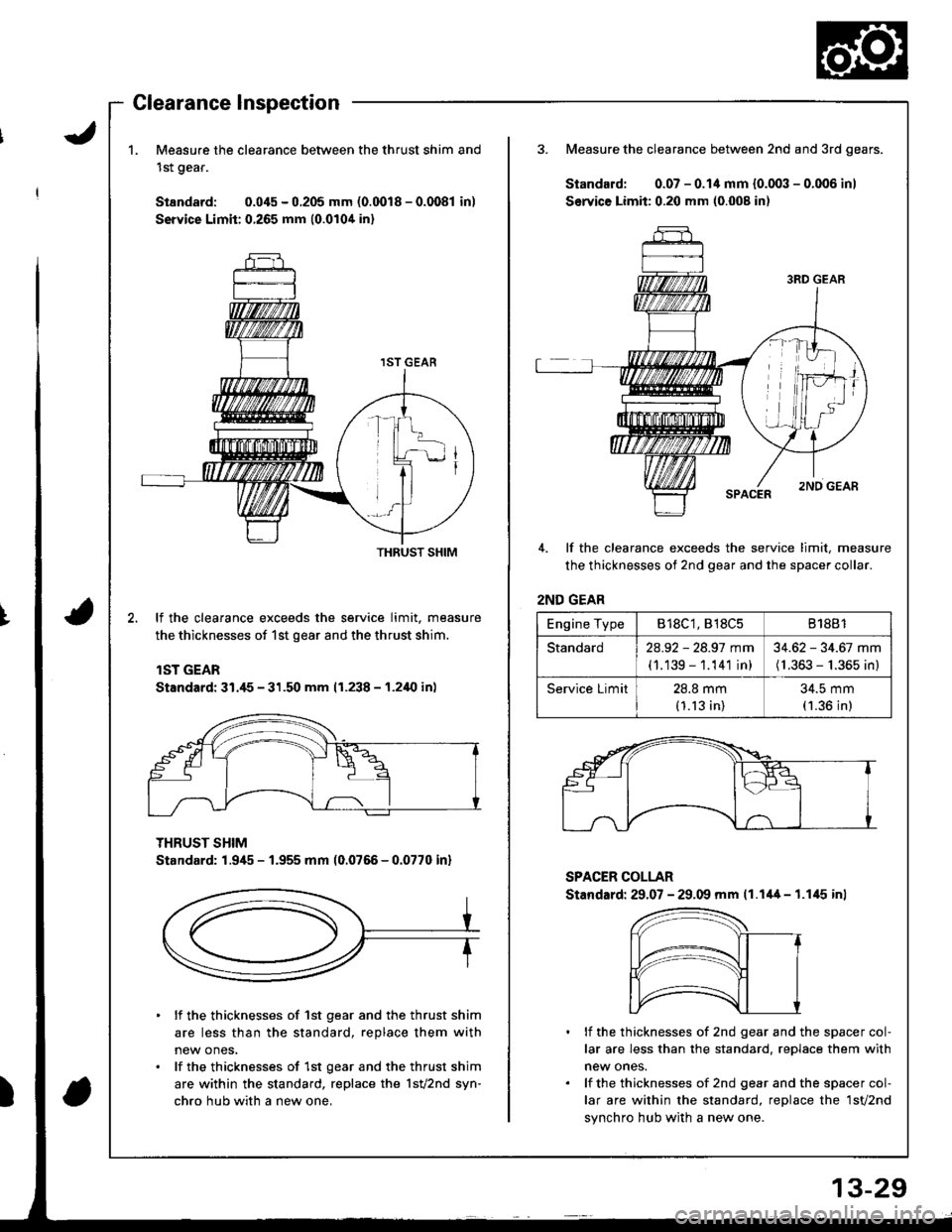

1.Measure the clearance between the thrust shim and

1st gear.

Standard: 0.045 - 0.205 mm (0.0018 - 0.0081 in)

Service Limit:0.265 mm {0.0104 in}

3. Measure the clearance between 2nd and 3rd gears.

Standard: 0.07 - 0.14 mm {0.003 - 0.006 inl

Service Limit: 0.20 mm (0.008 in)

4. lf the clearance exceeds the service limit, measure

the thicknesses of 2nd gear and the spacer collar.

2ND GEAR

lf the clearance exceeds the service limit, measure

the thicknesses of 1st gear and the thrust shim.

lST GEAR

Standard: 31./t5 - 31.50 mm (1.238 - 1.2i10 in)

THRUST SHIM

Standard: 1.945 - 1.955 mm (0.0766 - 0.0770 inl

SPACER COLLAR

Stand.rd: 29.07 - 29.09 mm 11.1'+4 - 1.1,15 inl

lf the thicknesses of 1st gear and the thrust shim

are less than the standard, replace them with

new ones,

lf the thicknesses of 1st gear and the thrust shim

are within the standard, replace the 1sv2nd syn-

chro hub with a new one,

lf the thicknesses of 2nd gear and the spacer col-

lar are less than the standard, reDlace them with

new ones.

lf the thicknesses of 2nd gear and the spacer col-

lar are within the standard, replace the 1sv2nd

synchro hub with a new one.

THRUST SHIM

Engine TypeB18C1, 818C581881

Standard2a.92 - 28.97 mm

(1.139 - 1.141 in)

34.62 - 34.67 mm(1.363 - 1.365 in)

Service Limit28.8 mm(1.13 in)

34.5 mm(1.36 in)

Page 396 of 1681

f-

Countershaft Assembly

BEARING PULLER

{Commerciallyavailable)

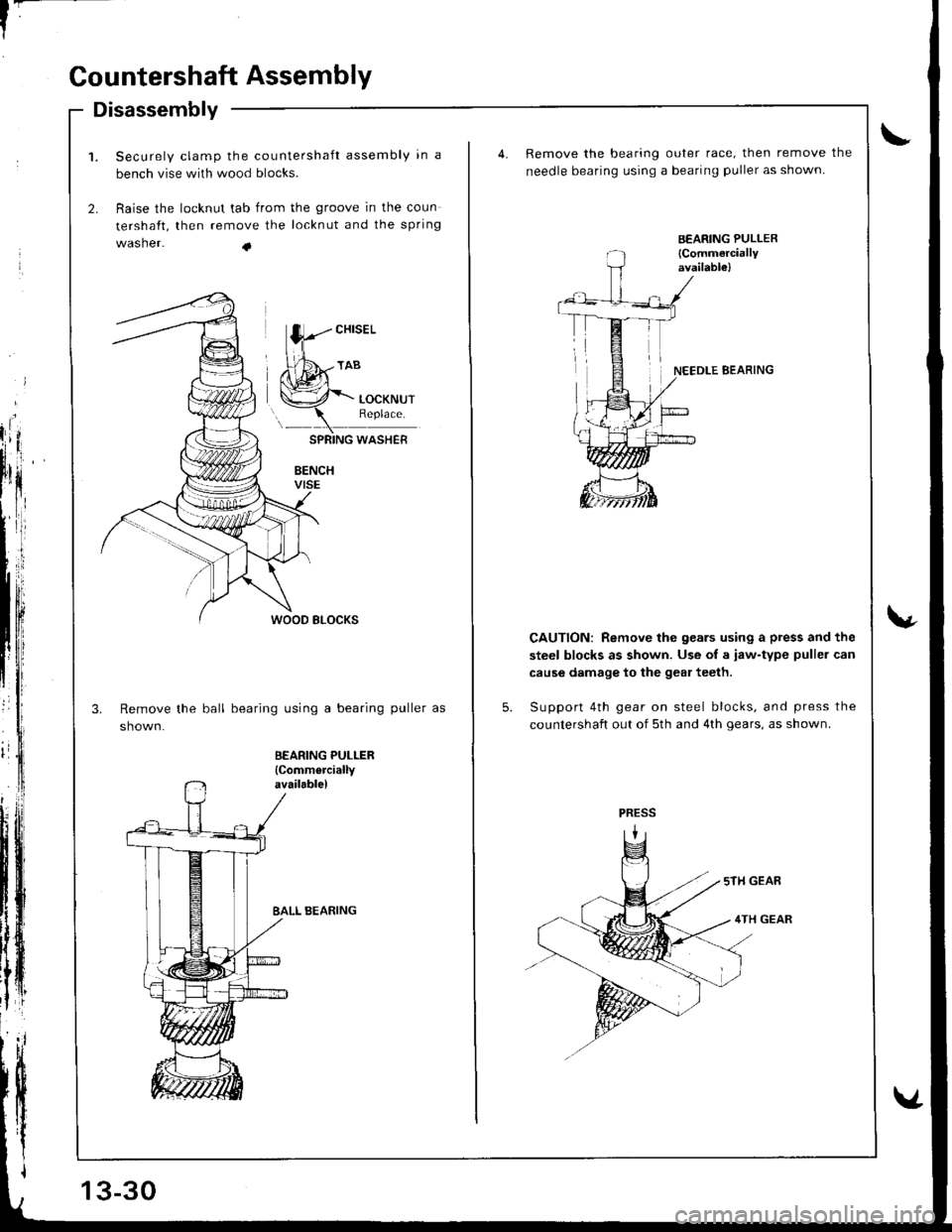

Disassembly

Securely clamp the countershaft assembly in a

bench vise with wood blocks.

Raise the locknut tab from the groove in the coun

tershaft, then remove the locknLlt and the spring

washer. +

WOOD BLOCKS

Remove the ball bearing using a bearing puller as

shown.

BALL BEARING

13-30

4.Remove the bearing outer race, then remove the

needle bearing using a bearing puller as shown.

,/NEEDLE BEARING

CAUTION: Remove the gears using a press and the

steel blocks as shown. Use oI a iaw-type puller can

cause damage to the geal teeth.

Support 4th gear on steel blocks. and press the

countershaft out of sth and 4th gears, as shown.

4TH GEAR

Page 397 of 1681

I

t

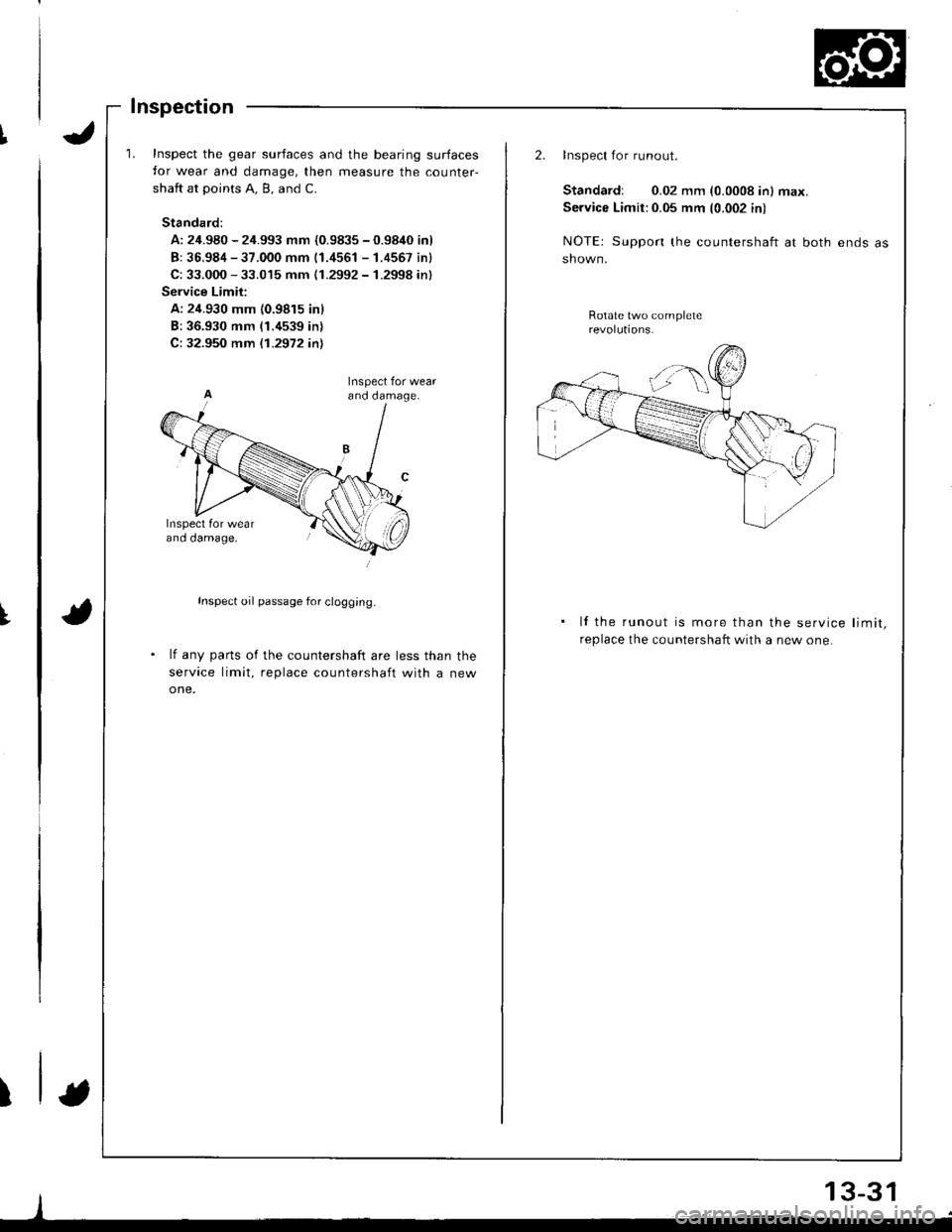

Inspect the gear surfaces and the bearing surfaces

for wear and damage, then measure the counter-

shaft at points A. B, and C.

Standard:

A: 24.980 - 24.993 mm {0.9835 - 0.9840 inl

B: 36.984 - 37.000 mm 11.4561 - 1.4557 inl

C: 33.000 - 33.015 mm (1.2992 - 1.2998 inl

Service Limit:

A: 24.930 mm {0.9815 inl

B:36.930 mm (1.4539 in)

C: 32.950 mm {.1.2972 inl

Inspect oil passage for clogg;ng.

lf any parts of the countershaft are less than the

service limit, replace countershaft with a new

one.

ano oamage,

I

2.Inspect for runout.

Standardr 0.02 mm (0.0008 in) max.

Service Limit:0.05 mm (0.002 in)

NOTE: Support the countershaft at both ends

shown.

Rotate two complete

lf the runout is more than the service limit,

replace the countershaft with a new one.

13-31

-,i

Page 398 of 1681

Gountershaft Assembly

Reassembly

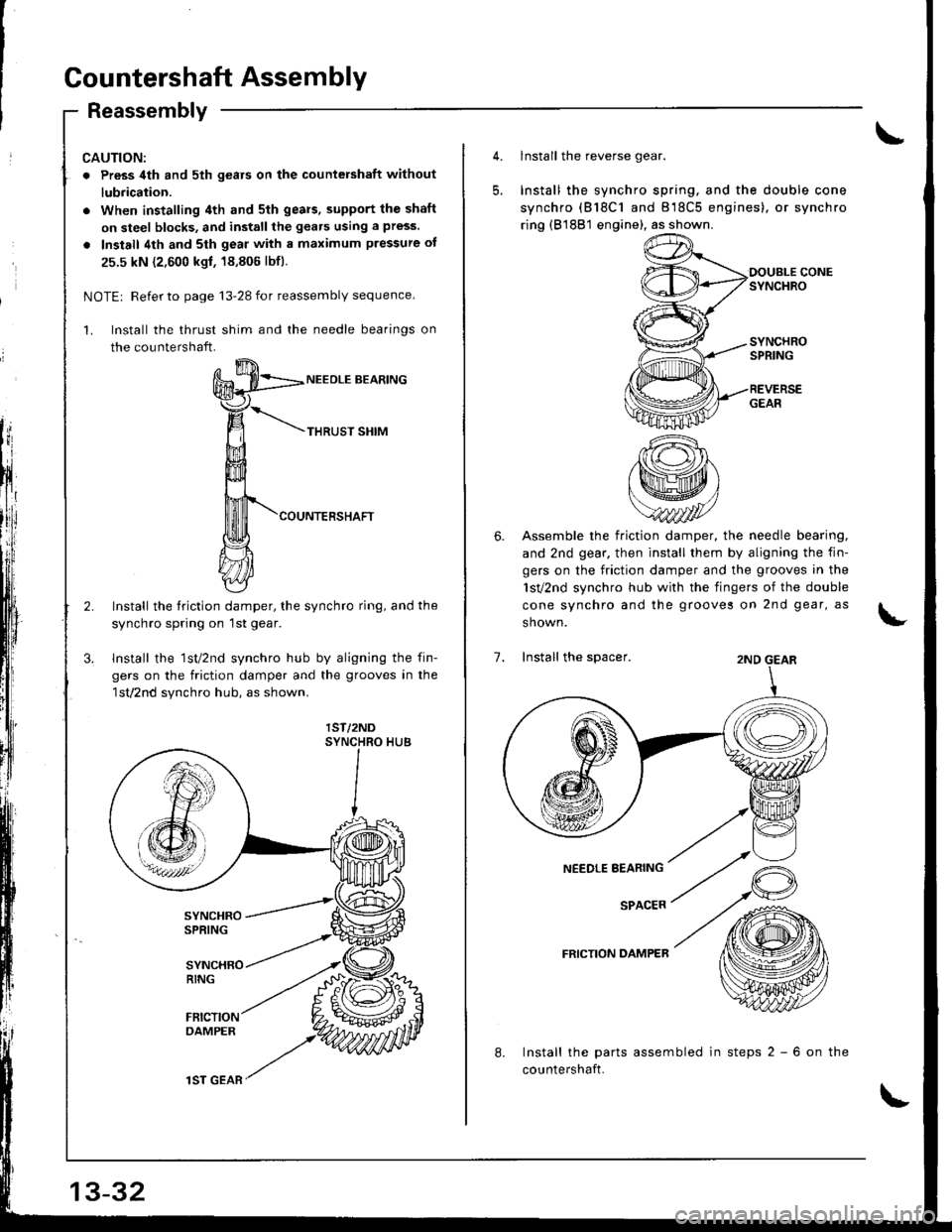

CAUTION:

. Press 4th and sth gears on the countershaft without

lubrication.

. When installing 4th and 5th gears, supPort the shaft

on steel blocks, and install the gears using a press.

. Install 4th and sth geal with a maximum pressure of

25.5 kN {2,600 kgf, 18,806 lbfl.

NOTEr Refer to page '13-28 for reassembly sequence

Install the thrust shim and the needle bearings on

the countershaft.

NEEOLE BEARING

THRUST SHIM

COUNTERSHAFT

Install the friction damper, the synchro ring, and the

synchro spring on lst gear.

Install the lst/2nd synchro hub by aligning the fin-

gers on the friction damper and the grooves in the

lst/2nd synchro hub, as shown.

lST/2ND

13-32

1ST GEAR

5.

lnstall the reverse gear.

Install the synchro spring. and the double cone

synchro (818C1 and 818C5 engines). or synchro

ring (81881 engine), as shown.

OOUELE CONESYNCHRO

SYNCHROSPRING

REVERSEGEAR

6. Assemble the friction damper, the needle bearing.

and 2nd gear. then install them by aligning the fin-

gers on the friction damper and the grooves in the

1sv2nd synchro hub with the fingers of the double

cone synchro and the grooves on 2nd gear, as

shown.

7. Install the spacer.2ND GEAR

SPACER

FRICTION DAMPER

8.Install the parts assembled in steps 2 - 6 on the

countershaft.

Page 399 of 1681

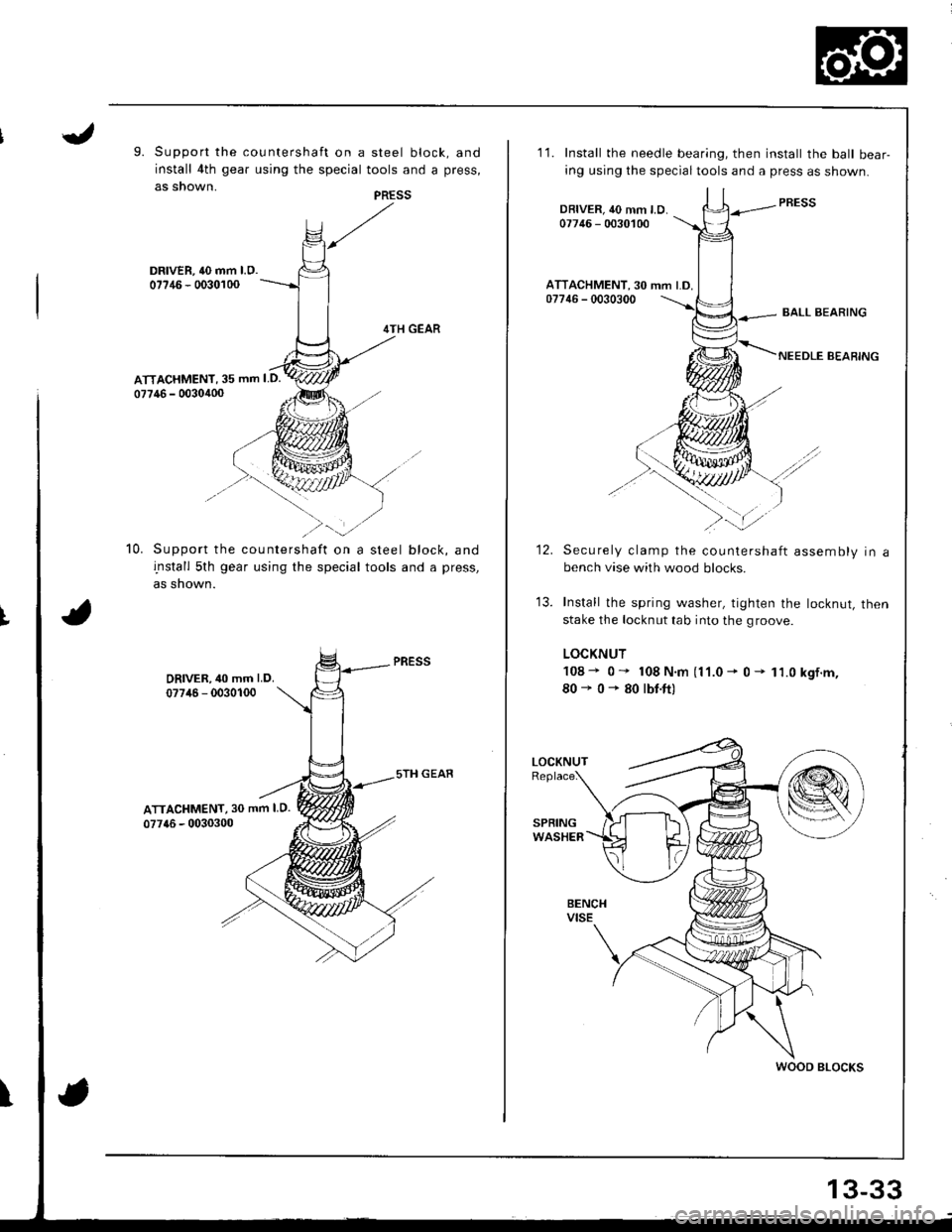

9. Support the countershaft on a steel block, and

install 4th gear using the special tools and a press,

as snown.

DRIVER, 40 mm l.O.07?46 - 0030100

4TH GEAR

ATTACHMENT, 35 mm I D.

07746 - 0030400

Support the countershaft on a steel block, and

install 5th gear using the special tools and a press,

as shown.

DRIVER,40 mm LD.

07746 - 0030100

ATTACHMENT, 30 mm I D.

077{6 - 0030300

10.

I

PRESS

11. Install the needle bearing, then install the balt bear-

ing using the specialtools and a press as shown.

DBIVER, 40 mm LD.07746 - 0030100

ATTACHMENT. 30 mm LD.07746 - 0030300

-..t

12.Securely clamp the countershaft assembly in abench vise with wood blocks.

Install the spring washer, tighten the locknut, then

stake the locknut tab into the groove.

LOCKNUT

108- 0" 108N.m (11.0- 0- 11.0kgf.m,

80'0+80rbr.ft)

WOOD BLOCKS

13-33

Page 400 of 1681

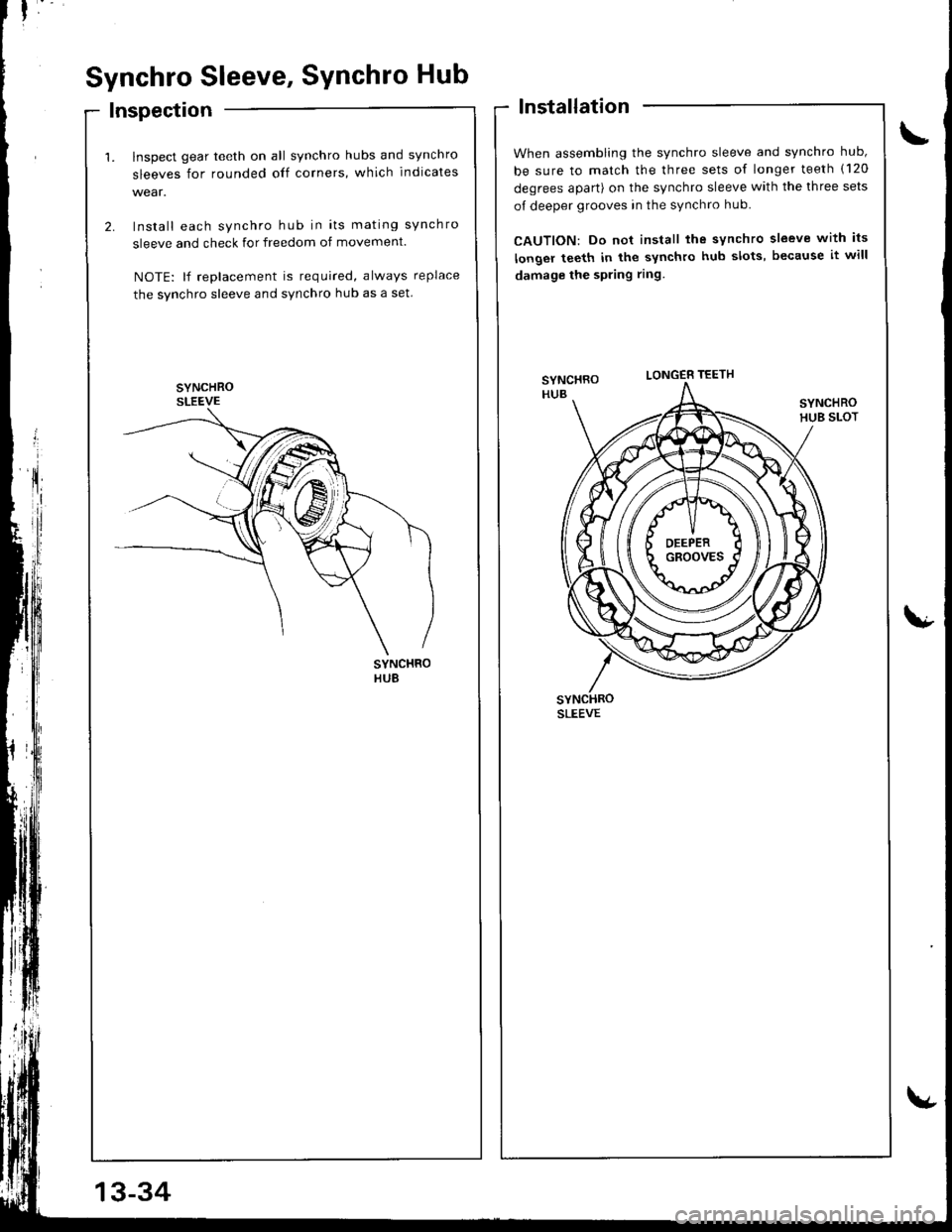

Synchro Sleeve, Synchro Hub

Inspection

1. lnspect gear teeth on all synchro hubs and synchro

sleeves for rounded off corners, which indicates

2. Install each synchro hub in its mating synchro

sleeve and check for freedom of movement.

NOTE: lf replacement is required, always replace

the synchro sleeve and synchro hub as a set.

lnstallation

When assembling the synchro sleeve and synchro hub,

be sure to match the three sets of longer teeth (120

degrees apart) on the synchro sleeve with the three sets

of deeper grooves in the synchro hub.

CAUTION: Do not install the synchro sleeve with its

longer teeth in the synchro hub slots, because it will

damage the spring ring

SYNCHROHUB SLOT

fll!)

LONGER TEETH

SLEEVE

SYNCHROHUB

13-34