HONDA INTEGRA 1998 4.G Workshop Manual

Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 351 of 1681

Il

1l

Iil

Emission Control SYstem

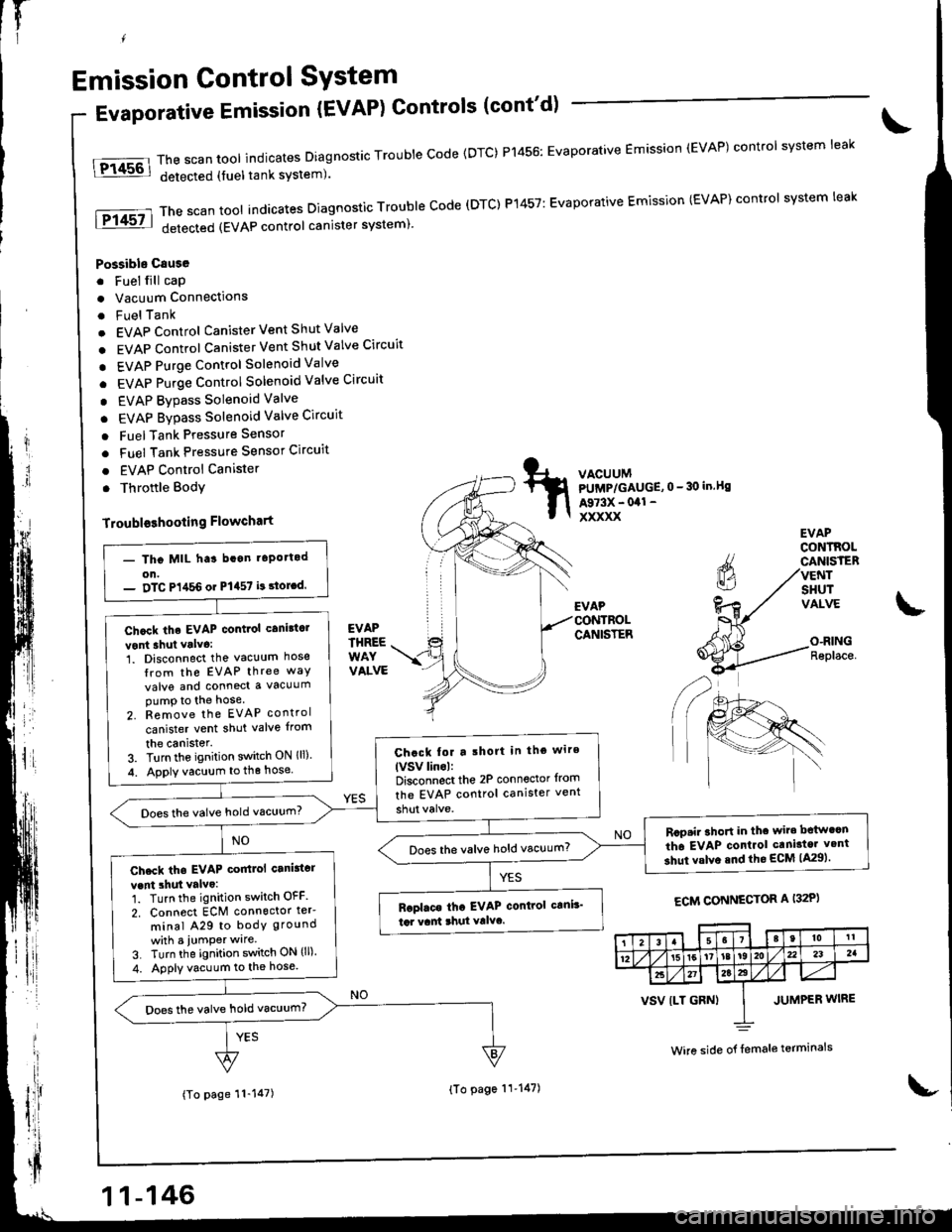

EVAPrHREEWAYVALVE

tFi4s6l

fPf 45? I

Evaporative Emission {EVAP) Controls (cont'd)

Possible Csuse

. Fuel fill cap

. Vacuum Connections

. FuelTank

. EVAP Control Canister Vent Shut Valve

. EVAP Control Canister Vent Shut Valve Circuit

. EVAP Purge control Solenoid Valve

. EVAP Purge Control Solenoid Valve Circuit

. EVAP Bypass Solenoid Valve

. EVAP Bypass Solenoid Valve Circuit

o FuelTank Pressure Sensor

. Fuel Tank Pressure Sensor Circuit

. EVAP Control Canister

. Throftle Body

Troubloshooling Flowchart

The scan tool indicates Diagnostic Trouble Code {DTC) P1456: Evaporative Emission (EVAP) control system leak

detected (fuel tank system).

ThescantoolindicatesDiagnosticTroubleCode(DTC)P't457:EvaporativeEmission(EVAP)controlsystemleak

detected (EVAP control canister system)'

VACUUMPUMP/GAUGE,0 - 30 in.Bs

A973X - 041 -

xxxxx

EVAP

CANISTER

EVAPCONTROLCANISTERVENTSHUTVALVE

O-RINGReplace.

ECM CONNECTOR A I32P)

(To page 11-147)

- Tho MIL ha3 bcan t6po.tod

on.- DTC P1,t56 or P1457 i! 3toLd.

Chcck the EVAP contiol canittc.

vont shut valva:1. Disconnect the vacuum hose

Irom the EVAP three way

valve and conned a vacuumpump to the hose

2. Remove the EVAP control

canister vent shut valve {rom

the canister.3. Turn the ignition switch ON lll)

4. Apply vacuum to the hose

Chack tor a lhort in tho wire

lVSv linol:Disconnect the 2P conn€ctor from

the EVAP control canister vent

Does the valve hold vacuum?

Rcp.i. ahoft in thc wir. bctw.cn

th6 EVAP conlrol caniator v.nt

3hut valve snd the ECM lA29).Does the valve hold vacuum?

Check tha EVAP coitlol canittcr

vent 3hut valvo:1. Turn the ignition switch OFF

2. Connect ECM connoctor ter'

minal A29 to bodY ground

whh a iumPer wlre

3. Turn the ignition switch ON (ll).

4. Apply vacuum to the hose.

Baplaca tha EVAP control c!ni!'

td vant 3hul Yalvc.

Does the valve hold vacuum?

38t0tl

1215[6'tat92Au232a

2t27a22

VSV {LT GRN) I JUMPER WIRE

Wire side o{ {emale terminals

11-146

{To page 11'147)

Page 352 of 1681

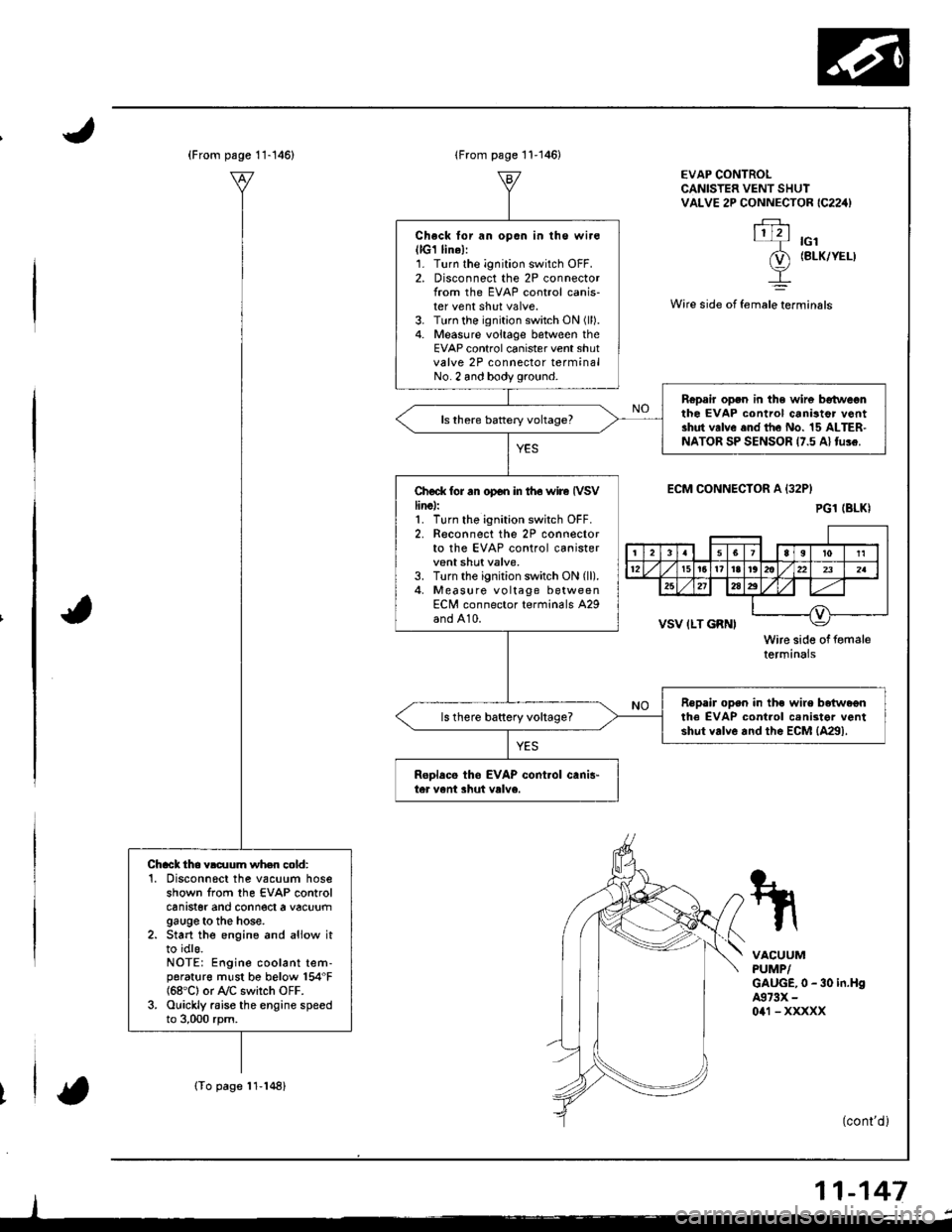

(From psge 11-146)

(To page 11-148)

Chack tho vldlum wh.n cold:'1. Disconnscl the vacuum hoseshown from the EVAP controlcanrster ano connect a vacuumgauge to the hose.2. Start the engine and aliow itto idls.NOTE: Engine coolant tem-porat{rre must be below 154"F{68'C} or A/C switch OFF.3. Ouickly raise the engine speedto 3,000 rpm.

lFrom page 11-146)

Check lor an opon in lhe wir€(lG1 lin6l:1. Turn the ignition switch OFF.2. Disconnect the 2P connectorlrom the EVAP control canis-ter vent shut valve.3. Turn the ignition switch ON (ll).

4. Measure voltage between theEVAP control canister vent shutvalve 2P connector terminalNo. 2 and body ground.

Ropair open in the wir6 betweonthe EVAP control canistor v6ntshut valve end the No. 15 ALTER-NATOR SP SENSOR 17.5 Al tu!e.

Ch€ck tor rn op€n in iho wire IVSVline):1. Turn tho ignition switch OFF.2. Reconnect the 2P connectorto the EVAP control canistervent shut valve,3. Turn the ignition switch ON (ll).

4, Measure vo ltage betweenECN/l connector terminals A29and A10.

Repair open in the wire beiwa€nthe EVAP cont.ol cenister ventshut valve and the EcM {4291.ls there baftery vohage?

ReDlacs tho EVAP cont.ol canis"ter vent shut valve.

EVAP CONTROLCANISTER VENT SHUIVALVE 2P CONNECTOR IC224)

.FJ.\1121-T rcl

(D (BLK/YEL)

I

Wire side ot female terminals

ECM CONNECIOR A {32P}

VSV ILT GRNI

Wire side of femaletermtnars

VACUUMPUMP/GAUGE,0 - 30 in.H94973X -

0a1 - xxxxx

(cont'd )

11-147

PG1 (BLKI

rl

4lq-r'rri l12t5t6t?l8r@llzzlzslul

25212a2

__l

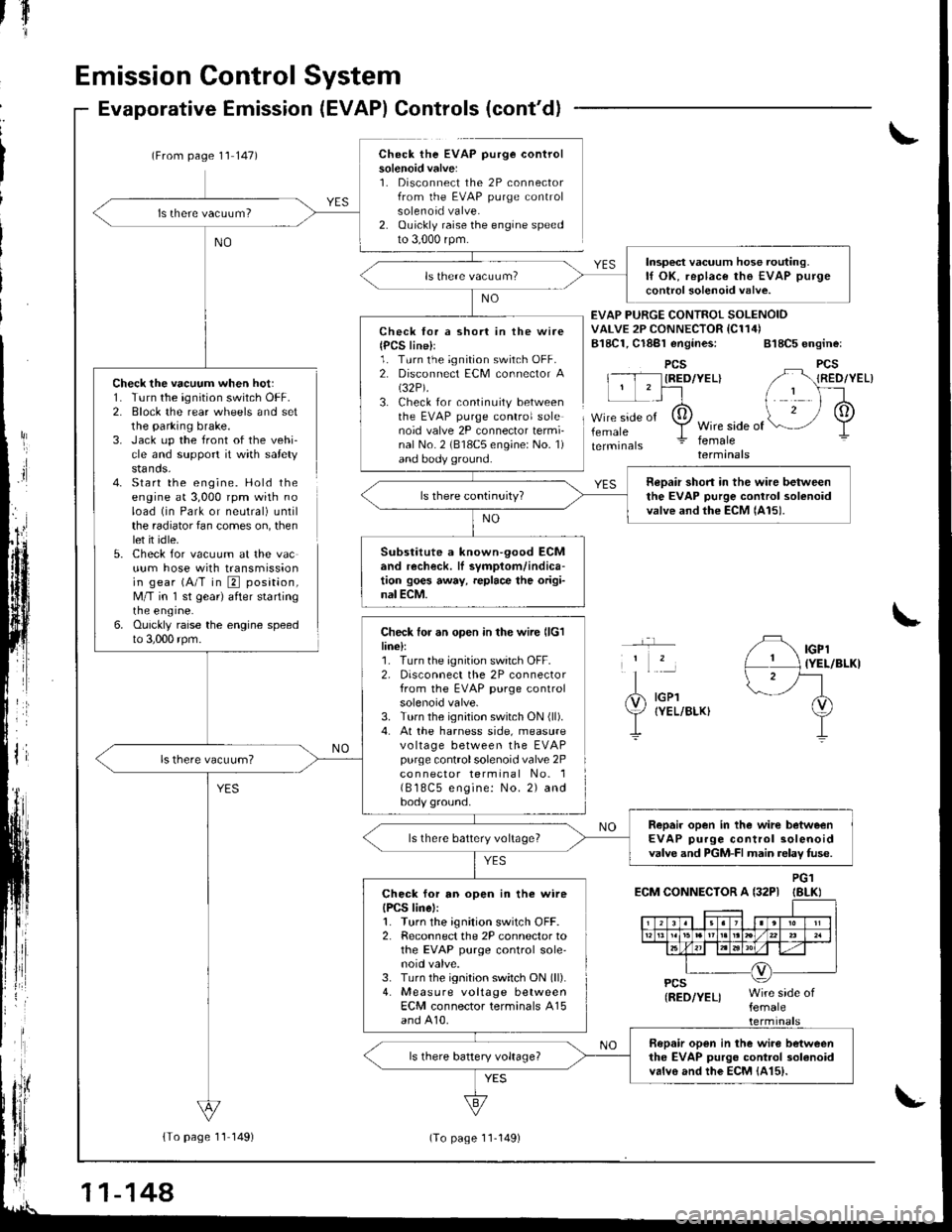

Page 353 of 1681

Emission Control System

Check the vacuum when hot:1. Turn the ignition switch OFF.2. Block the rear wheels and setthe parking brake.3. Jack up the front of the vehi-cle and support it with safetystands.4- Start the engine. Hold theengine at 3,000 rpm with noload (in Park or neutral) untilthe radiator fan comes on, thenlet it idle.5. Check for vacuum at the vacuum hose with transmissionin gear (A/T in E position,M/T in 'l st gear) after startingrne engrne.6. Ouickly raise the engine speedto 3,000 rpm.

Evaporative Emission (EVAP) Controls (cont'd)

(From page 1'l 147)Check the EVAP purge controlsolenoid valve:1. Disconnect the 2P connectorfrom the EVAP purge controlsolenoid valve.2. Ouickly raise the engine speedto 3,000 rpm.

{To page 11 149)

tfl'I

Check lor a short in the wire{PCS line}l1. Turn the ignition switch OFF.2. Disconnect ECM connector A(32P).

3. Check for continuity betweenthe EVAP purge control solenoid valve 2P connector termi-nal No. 2 (818C5 engine: No. 1)and body ground.

Check for an open in the wire llclline):1. Turn the ignition switch OFF.2, Disconnect the 2P connectorfrom the EVAP purge controlsolenoid valve.3. Turn the ignition switch ON (ll).

4. At the harness side, measurevo ltage between the EVAPpurge controlsolenoid valve 2Pco n nector terminal No. 1( B 18C5 engine: No. 2) andbody ground.

EVAP PURGE CONTROI SOLENOIDVALVE 2P CONNECTOR IC114)B18C1, Cl8Bl engines: 818C5 engine:

PCSIRED/YEL}

femaleWire side offemaleterminals

YES

IGPl{YEL/BLKI

IGPlIYEL/BLKI

ECM CONNECTOR A {32PIPG1IBLKI

Insp€ct vacuum hose routing.lf OK, replace the EVAP purge

control solenoid valve.

neDair short in the wire betweenthe EVAP purge control solenoidvalve and the ECM lAl5).

Substitute a known-90od ECMand recheck. lI symptom/indica-tion goes away, replace the origi-nal ECM.

Repair open in the wirc betweenEVAP purge control solenoidvalve and PGM-FI main relav fuse.ls there battery voltage?

Check for an open in the wireIPCS linel:1. Turn the ignition switch OFF.2. Reconnect the 2P connector tothe EVAP purge control sole'noid valve.3. Turn the ignition switch ON (ll).

4. Measure voltage betweenECM connector terminals A15and A10.

Bopair open in the wiro betweenthe EVAP purgo control 3olanoidvalvo and the EcM {415).

11-144

(To page 11-149)

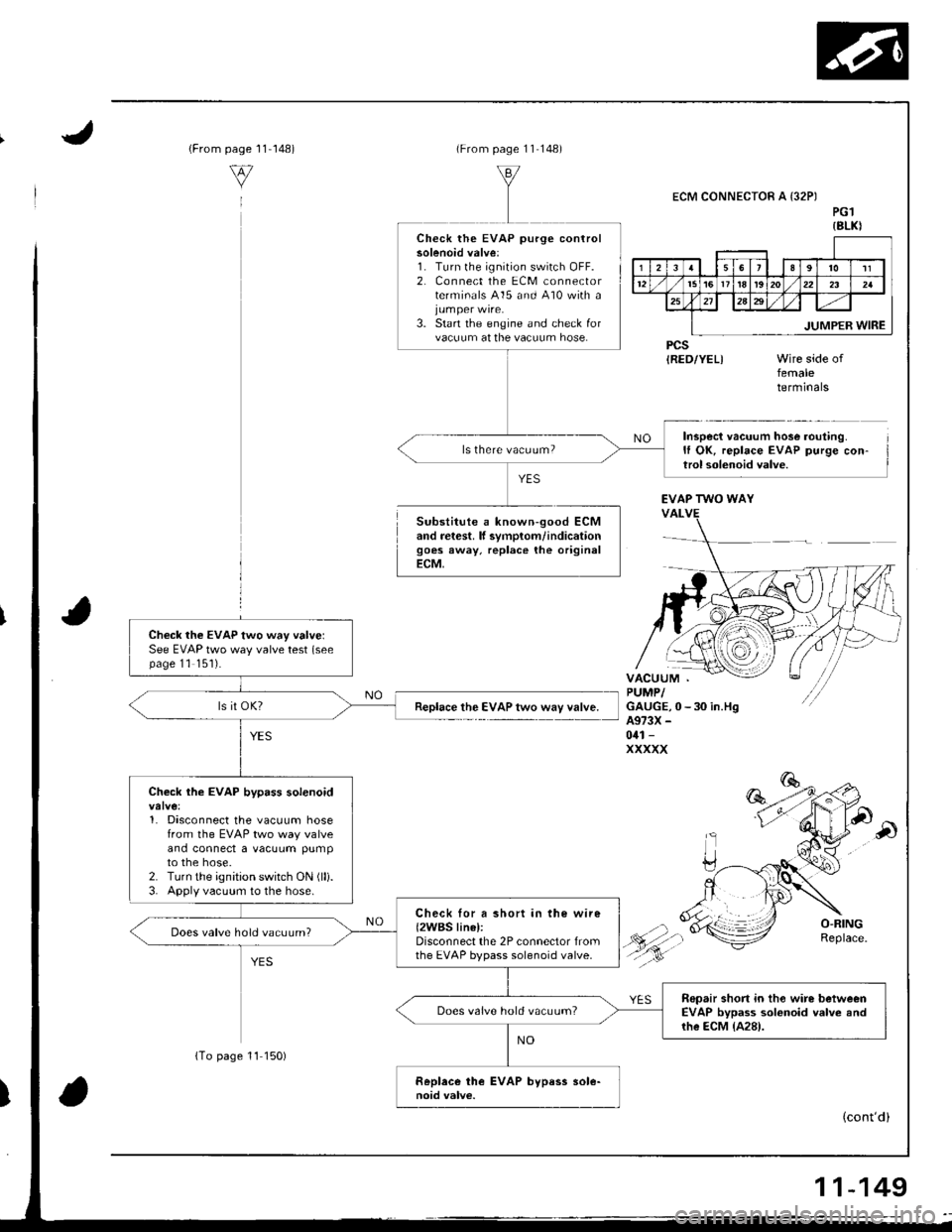

Page 354 of 1681

{From1 1-148)page

v

(From page 11 148)

Substitute a known-good ECMand retest. lf svmplom/indicationgoes away, replace the originalECM,

ECM CONNECTOR A {32PIPG1{8LKI

PCSIRED/YEL)femaletermrnars

Inspect vacuum hose routing.It OK, replace EVAP purge con-trol solenoid valve.

Check the EVAP purge controlsolenoid valve:1. Turn lhe ignition switch OFF.2, Connect the ECM connectorterminals 415 and 410 with a

3. Start the engine and check forvacuum at the vacuum hose.

ls there vacuum?

EVAP TWO WAY

Check the EVAP two way valvelSee EVAP two way valve test (seepage 11 '151).

Replace the EVAP two way valve.

Check the EVAP bypass solenoid

1. Disconnect the vacuum hosefrom the EVAP two way valveand connect a vacuum pumpto the hose.2. Turn the ignition switch ON (lli.

3. Apply vacuum to the hose.

Check lor a short in the wire{2WBS linel:Disconnect the 2P connector fromthe EVAP bypass solenoid valve.

Does valve hold vacuum?

Repair short in tho wire betweenEVAP bypass solonoid valve andrhe ECM {A28).

Does valve hold vacuum?

(cont'd)

{To page 11 150)

11-149

Page 355 of 1681

fIr

Emission Control System

Evaporative Emission Controls (cont'dl

t

ECM CONNECTOR A I32PI

JUMPERWIRE

EVAP BYPASS SOLENOIDVALVE 2P CONNECTOB (C793I

tGl(BLK/WHTIWire side of

femaleterminals

\

ECM CONNECTOR A (32PI

PGl (BLKI

Wire side of lem6l6termrnals

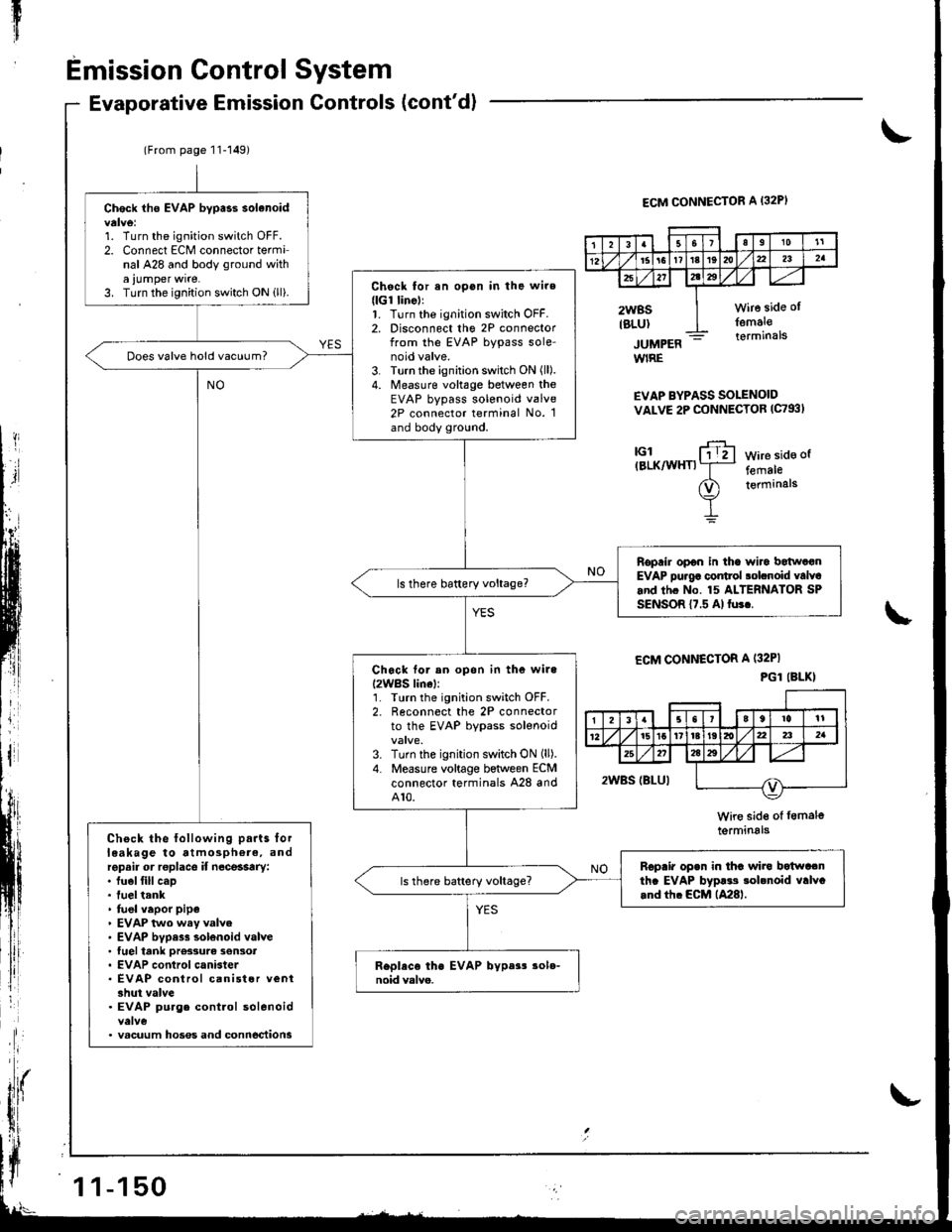

(From page 11-149)

Check iho EVAP bypass solanoid

1. Turn the ignitioo switch OFF.2. Connect ECM connector terminal A28 and body ground witha ,umper wrre.3. Turn the ignition switch ON ill).Chock for an opon in the wire(lGr linell1. Turn the ignition switch OFF.2. Disconnect tho 2P connectorfrom the EVAP bypass sole-noid valve.3. Turn the ignition switch ON (ll).

4. Measure voltage between theEVAP bypass solenoid valve2P connector terminal No. 1and body ground.

Does valve hold vacuum?

Roprir opon in tha wiro batwatanEVAP pu.g6 control solcnoid valvcand thc No. 15 ALTERNATOR SPSENSOR {7.5 Al fu3..

Ch6ck tor an opon in the wile

I2WBS lin6l:'L Tlrrn the ignition switch OFF.2. Reconnect the 2P connectorto the EVAP bypass solenoid

3. Turn the ignition switch ON (ll).

4. Measure voltage between ECMconnector terminals A28 andA10.

Check the following parts lorleakage to atmosphere, andrepsir or roplace if n6ce$try:. fuel fill cap. fuel tank' fuel vapor pipe. EVAP two wsy valve. EVAP bvpess solenoid valve. tuel tank ore33urc son3ot. EVAP control canister. EVAP control canist6r veni3hut valve. EVAP purg. control solenoid

. vacuum hoses and conn6ctions

Rcpair opan in thc wira botwa.nth. EVAP byp!.s sobnoid valvc.nd tfi. ECM lA28l.

3Ia10't1

12l61611t8t9dta22a2a

x272tz3

2WBSIBLUI

wire side ol

femal€terminals

1 1-150

Page 356 of 1681

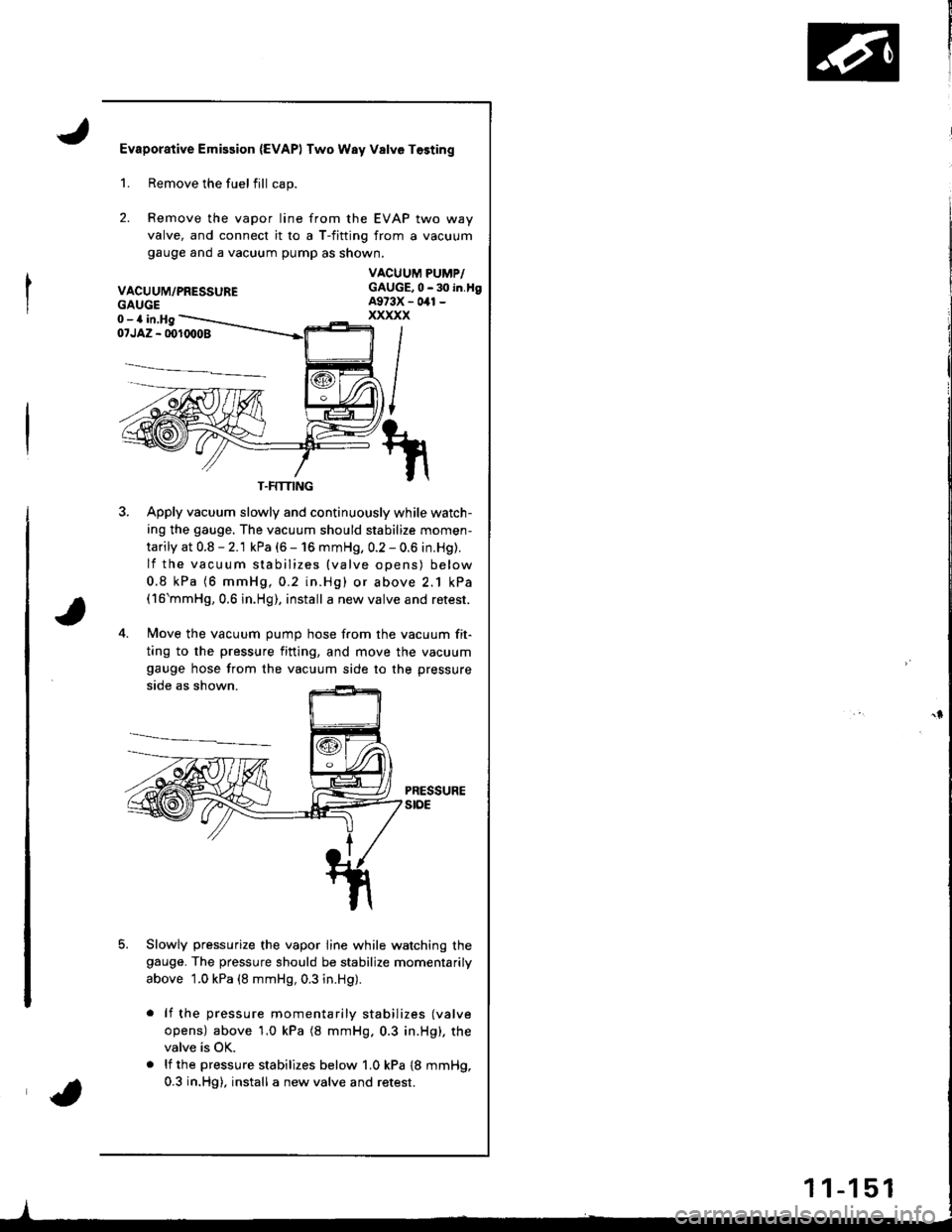

Evaporative Emission {EVAPI Two Way Valve Tosting

2.

Remove the fuelfill cap.

Remove the vapor line from the EVAP two way

valve, and connect it ro a T-fitting from a vacuum

gauge ano a vacuum pump as shown.

VACUUM/PRESSURE

1.

GAUGE0-a in,Hg

VACUUM PUMP/GAUGE,0 - 30 in.tlgA973X - 041 -

xxxxx

i/NI

t/

il\/

1il|

07JAZ - 001(X)08

3. Apply vacuum slowly and continuously while watch-

ing the gauge. The vacuum should stabilize momen-

tarily at 0.8 - 2.1 kPa (6 - 16 mmHg, 0.2 - 0.6 in.Hg).

lf the vacuum stabilizes {valve opens) below

0.8 kPa (6 mmHg,0.2 in.Hg) or above 2.1 kPa(16'mmHg,0.6 in.Hg), install a new valve and retest.

4. Move the vacuum oumo hose from the vacuum fit-

ting to the pressure fining, and move the vacuum

gauge hose from the vacuum side to the pressure

side as shown.

PRESSUREstoE

Slowly pressurize the vapor line while watching thegauge. The pressure should be stabilize momentarily

above 1.0 kPa (8 mmHg, 0.3 in.Hg).

lf the pressure momentarily stabilizes (valve

opens) above'1.0 kPa (8 mmHg.0.3 in.Hg), the

valve is OK.

lf the pressure stabilizes below 1.0 kPa {8 mmHg,

0.3 in.Hg), install a new valve and retest.

T.FMING

1 1-1 51

Page 357 of 1681

Transaxle

Clutch ...........12-1

Manual Transmission ............................ 13-1

Automatic Transmission ....................... 1 4-1

Differential

Manual Transmission

B1881 engine ................................... 15-1

818C1 engine ................................... 15-9

B18C5 engine .............. 15-19

Automatic Transmission ................. .. 15-27

Driveshafts ... 16-1

Page 358 of 1681

Clutch

Speciaf Tools ........ .'--"" 12-2

lflustrated Index ........ ".' 12-3

Clutch Pedal

Adjustment "..".""'...' 12-4

Clutch Master Cylinder

Removal/lnstallation -'.' 12-5

Slave Cylinder

Removal/lnstallation '..' 12-6

Pressure Plate

Removal/lnspection .'-.' 12-7

Clutch Disc

Removal/lnspection '...' 12-a

Flywheel, Flywheel Bearing

fnspection ' 12-9

Replacement .................'............. 1 2-9

Clutch Disc, Pressure Plate

lnstallation ................. 12-10

Release Bearing

Removal/lnspection "'.' 12-11

fnstaffation ".""".-'."'. 12-12

Page 359 of 1681

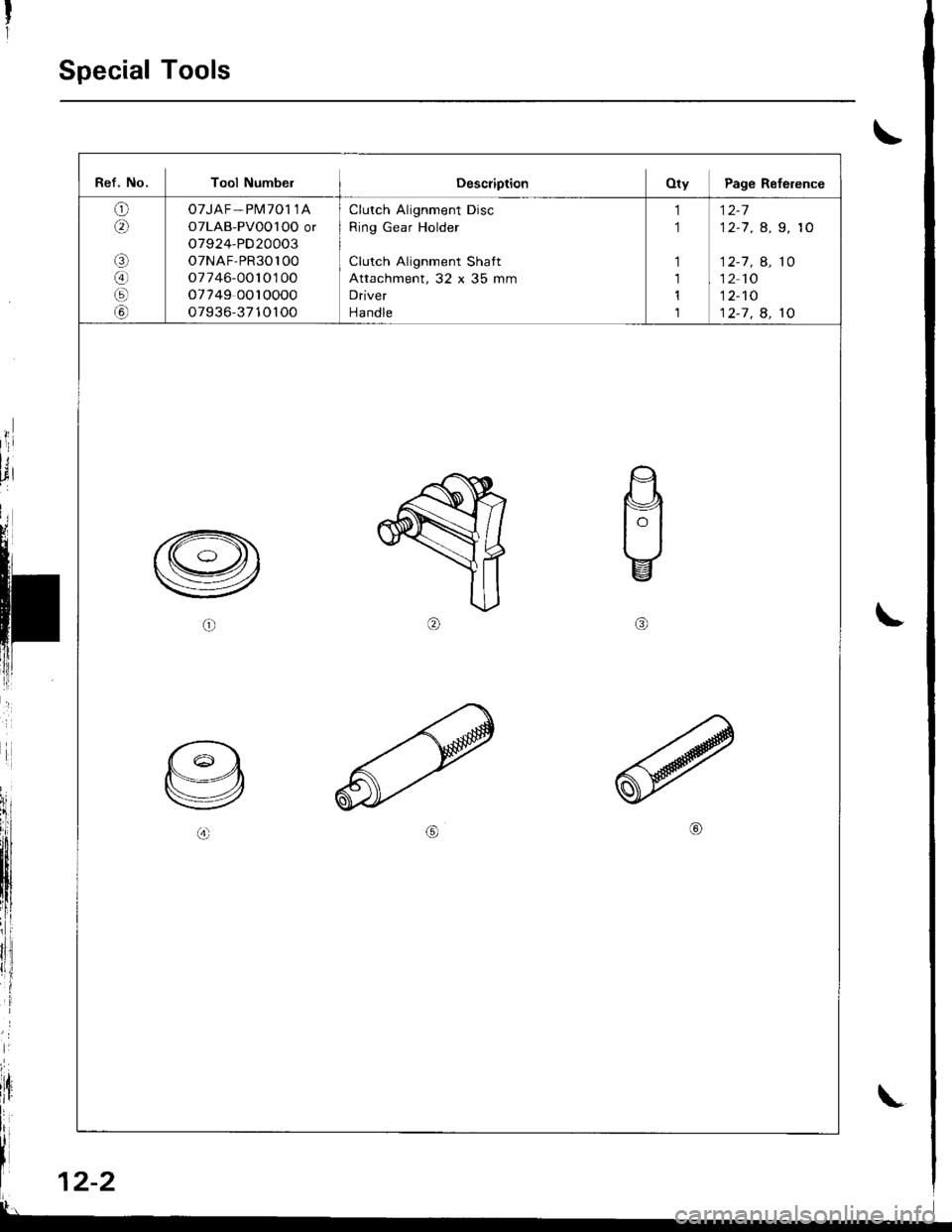

Special Tools

\

t

rl

;

lt, 12-2

Ref. No. Tool NumbelDescriptionOty Page Reference

o6\

aa

G)

07JAF - Pl\il701 1A

OTLAB-PVoO l OO or

o7924-PD20003

o7NAF,PR30100

o7746-0010100

o7749 0010000

o7936-3710100

Clutch Alignment Disc

Ring Gear Holder

Clutch Alignment Shatt

Attachment, 32 x 35 mm

Driver

Handle

1

1

1

1,l

1

12-7

12-7 , a, 9, 10

12-1 , A, 10

12 10

12-'tO

12-7 . 8. 10

\

Page 360 of 1681

lllustrated Index

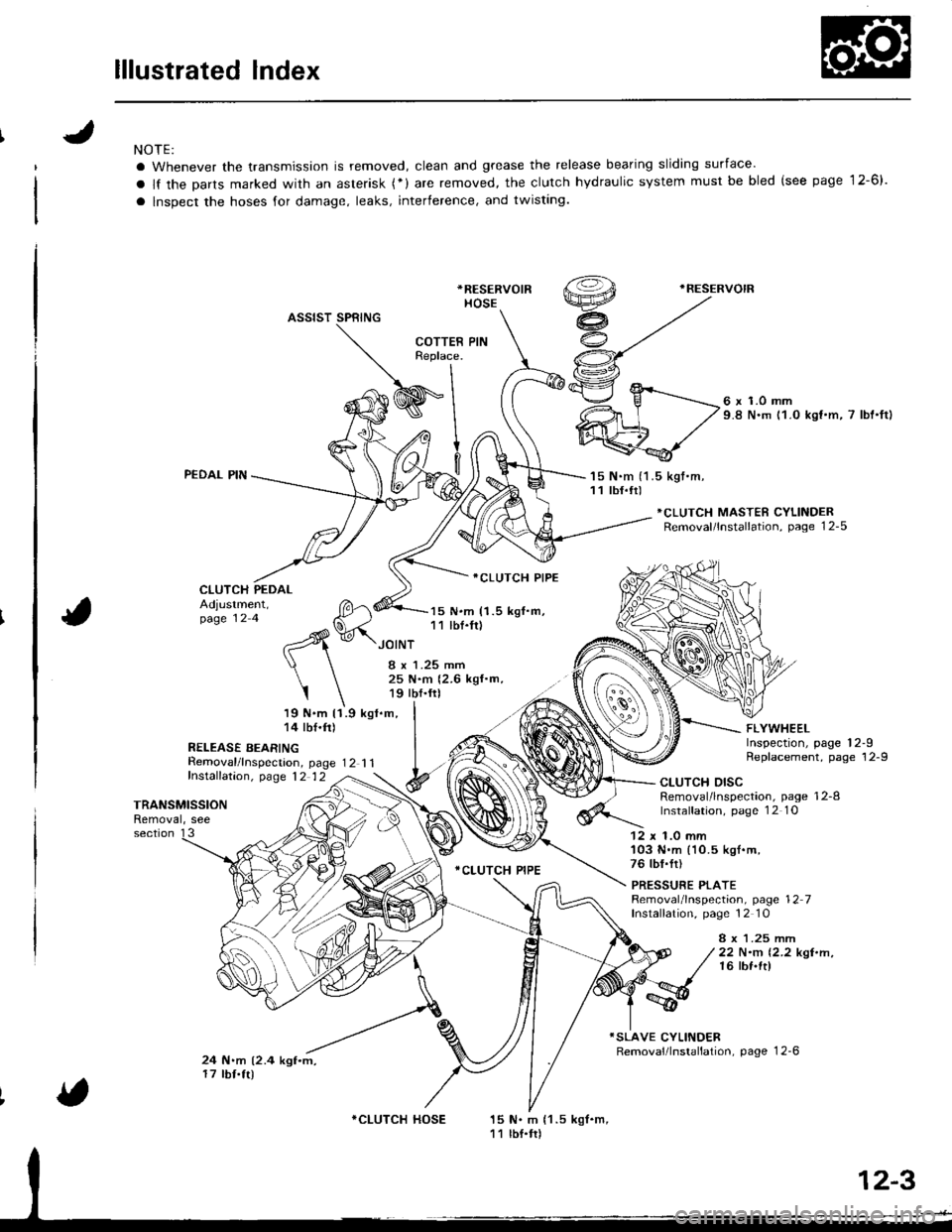

NOTE:

a Whenever the transmission is removed, clean and grease the release bearing sliding surface'

a lf the Darts marked with an asterisk (*) are removed, the clutch hydraulic system must be bled (see page 12-6).

a lnspect the hoses for damage, leaks, interference, and twisting.

*RESERVOIR

HOSE

.RESERVOIR

ASSIST SPRING

PEDAL PIN

CLUTCH PEDAL

Removal/lnspecrion, page 12 1 1fnstalfation, p,age 12 12

6 x 1.0 mm9.8 N.m 11.0 kst.m, 7 lbt'ftl

'15 N.m (1 .5 kgt.m,11 tbf.tr)

*CLUTCH MASTER CYLINDERRemoval/lnstallation, page 12-5

Adjustment,page 12 4

19 N.m 11.9 kgl.m,14 tbf.ft)

R€LEASE BEARING

15 N.m (1.5 kgf.m,11 lbf.fr)

ICLUTCH PIPE

.CLUTCH PIPE

FLYWHEELInspection, page 12-9Replacement, page 12-9

JOINT

I x 1.25 mm25 N.m {2.6 kgf.m,19 tbf.frl

I

TRANSMISSIONRemoval, see

CLUTCH DISCRemoval/lnspection, page 12-8lnstalfation, page 1 2 1O

section 1312 x 1.0 mm'103 N.m (10.5 kgl.m,76 tbf.fr)

PRESSURE PLATERemoval/lnspection, page 12 7Installation, page 12 10

8 x 1.25 mrr|22 N.m 12.2 kgt.n,16 lbf.ft)

24 N.m (2.4 kgf.m,17 tbf.tr)

15 N. m {1 .5 kgf.m,11 lbf.tr)

COTTERReplace.

I

WInl

9l

v.^- fl

*CLUTCH HOSE