HONDA INTEGRA 1998 4.G Workshop Manual

Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 371 of 1681

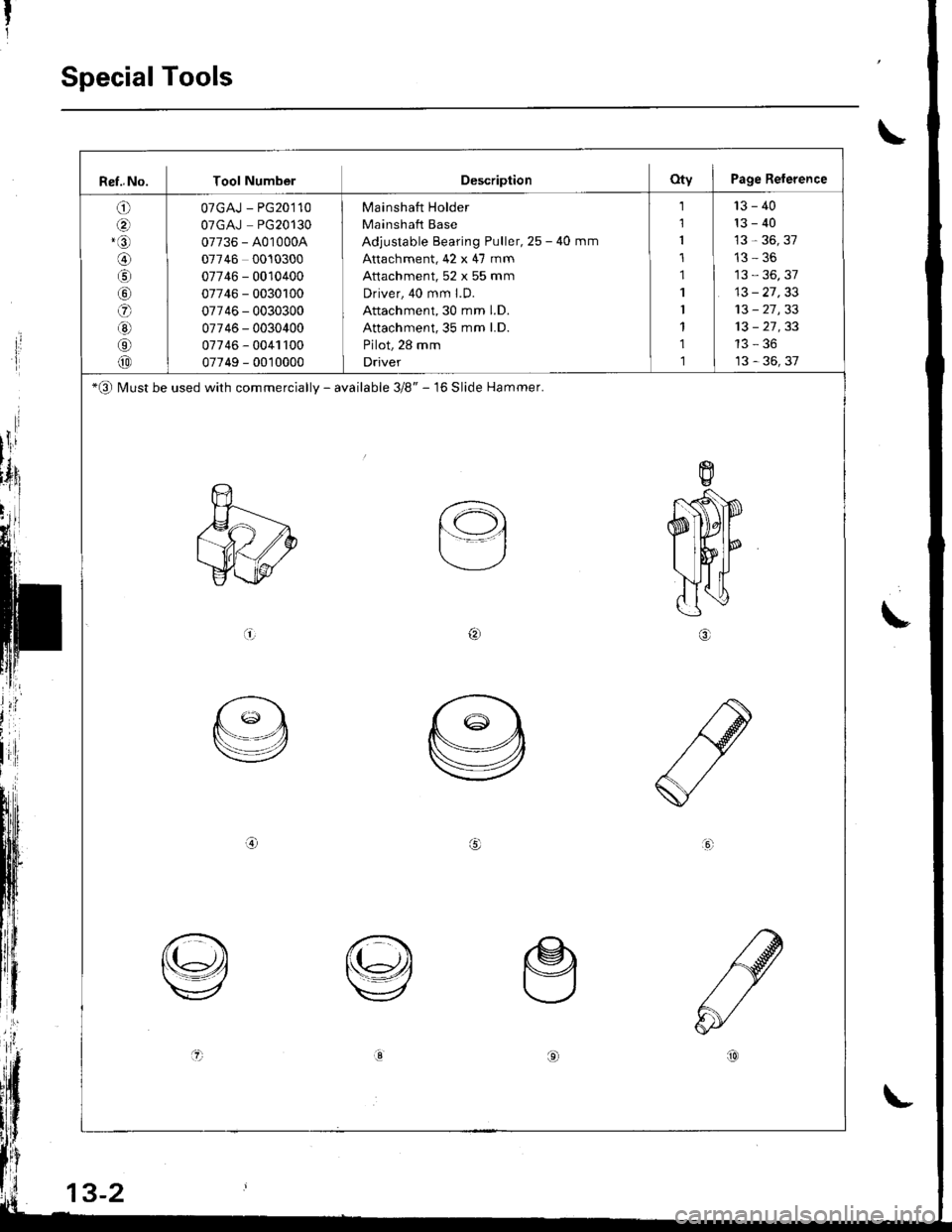

Ref..No. Tool NumberDescriptionOty I Page Reterence

o

@

@

G)

o

a0

o

@

07GAJ - PG20'110

OTGAJ PG20130

07736 - A010004

07746 0010300

07746 - 0010400

07746 - 0030100

07746 - 0030300

07746 - 0030400

07746 - 0041100

07749 - 0010000

Mainshatt Holder

Mainshaft Base

Adjustable Bearing Puller,25 - 40 mm

Attachment,42 x 47 mm

Attachment, 52 x 55 mm

Driver, 40 mm l.D.

Attachment, 30 mm l.D.

Attachment, 35 mm LD.

Pilot, 28 mm

Driver

1

l

1

1

1

1

I

1

1

1

13-40

13-40

13 - 36, 37

13 - 36, 37

13 - 27,33

13 - 27 ,33

13 - 36, 37

-O Must be used with commercially - available 3/8" - 16 Slide Hammer.

a

o

aJ,.3i0

jr

I

tll'

h,{ll

!,1' til

ffi1

Ir,

IlI

xr-

IJ|F-

ii'

l,l'

Page 372 of 1681

aintenance

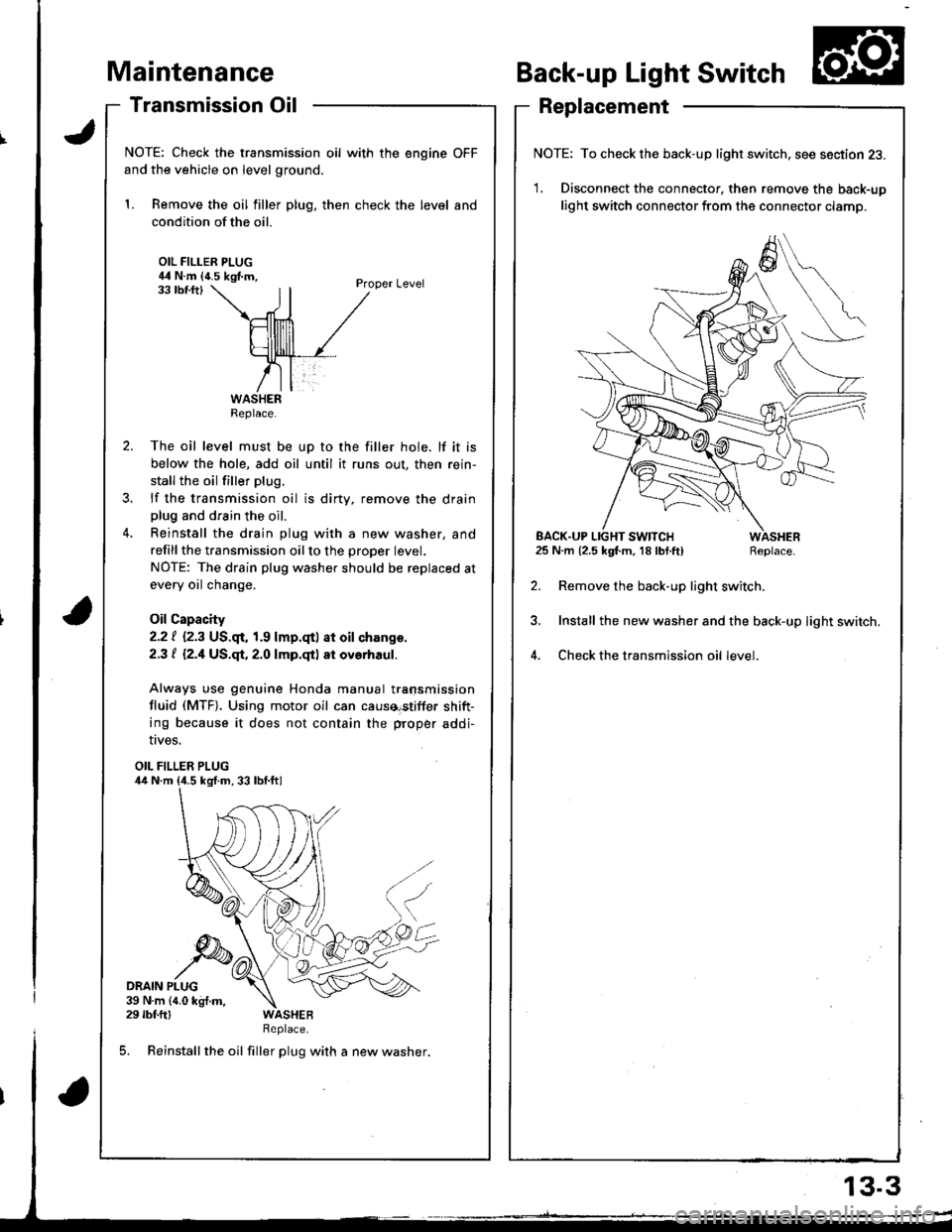

Transmission Oil

NOTE: Check the transmission oil with the engine OFF

and the vehicle on level ground.

1. Remove the oil filler plug, then check the level and

condition of the oil.

OIL FILLER PLUG44 N.m {4.5 kgf.m,Proper Level33 tbf.ftl

The oil level must be up to the filler hole. lf it is

below the hole, add oil until it runs out, then rein-

stall the oil filler plug.

lf the transmission oil is dirty, remove the drainplug and drain the oil.

Reinstall the drain plug with a new washer, and

refillthe transmission oilto the proper tevet.

NOTE: The drain plug washer should be replaced at

every oil change.

Oil Capacity

2.2 | i.2.3 US.qr,1.9 lmp.qtl at oil ch.nge.

2.3 t l2.1US.qt,2.O lmp.qtl at ovorhaul.

Always use genuine Honda manual transmission

fluid (MTF). Using motor oil can causa€tiffer shift-

ing because it does not contain the proper addi-

Back-up Light Switch

Replacement

NOTE: To check the back-up light switch. see section 23.

1. Disconnect the connector, then remove the back-up

light switch connector from the connector clamp.

l.m {2.5 kgf.m, 18lbf.ft) Replace.

Remove the back-up light switch.

Install the new washer and the back-up light switch.

Check the transmission oil level.

!ves.

OIL FILLER PLUG

DRAIN PLUG39 N.m {4.0 kg{.m,29 rbf.ftlReplace.

5. Reinstall the oil filler plug with a new washer,

Replace.

EACK.UP LIGHT SWITCH25 N.m {2.5 kgf.m, 18 lbf.ft)

13.3

Page 373 of 1681

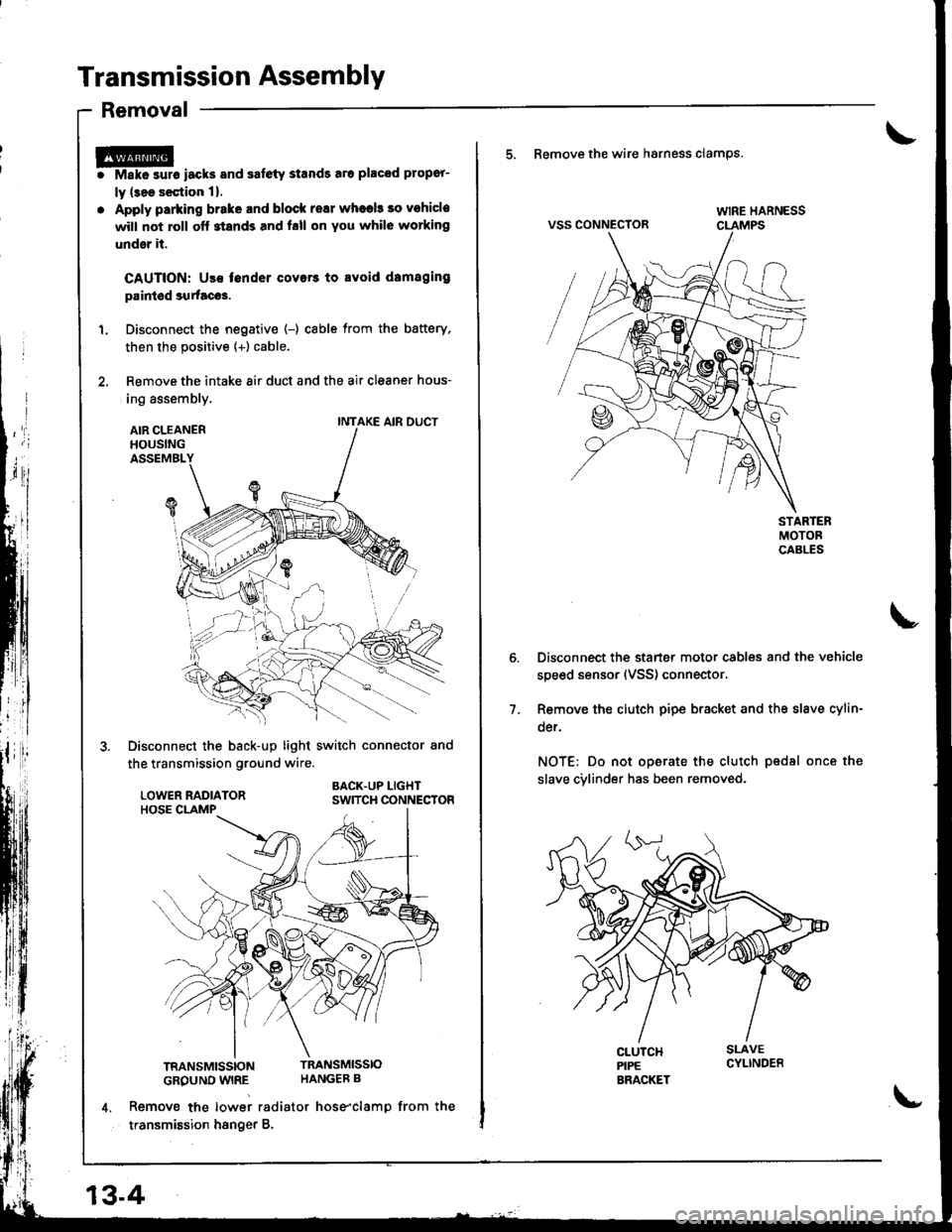

Transmission Assembly

Removal

r@i Make surs iacks and safety stands sro placod propor-

ly (3ee s€ction 1).

. Apply parking brake and block resr whaeb 30 vohicle

will not roll off stands and hll on You whil6 working

under it.

CAUTION: Use fender covers to svoid damaging

paintod surtacos.

1. Disconnect the negative (-) cable from the battery,

then the positive {+) cable.

2. Remove the intake 8ir duct and the air cleaner hous-

ing assembly,

AIR CLEANERHOUSINGASSEMBL

Disconnect the back-up light switch connector and

the transmission ground wire.

BACK.UP LIGHTSWITCH CONNECTOR

TRANSMISSIONTRANSMISSIO

GROUND WIRE HANGEB B

4. Remove tne lowei radiator hose"clamp from the

transmission hsnger B.

INTAKE AIR DUCT

13-4

\-

5. Remove the wire hsrness clamps.

VSS CONNECTOR

Disconnect the starter motor cables and the vehicle

speed sensor (VSS) connector.

Remove the clutch pipe bracket and the slave cylin-

der.

NOT€: Do not operate the clutch pedsl once the

slave cvlinder has been removed.

7.

Page 374 of 1681

I

T

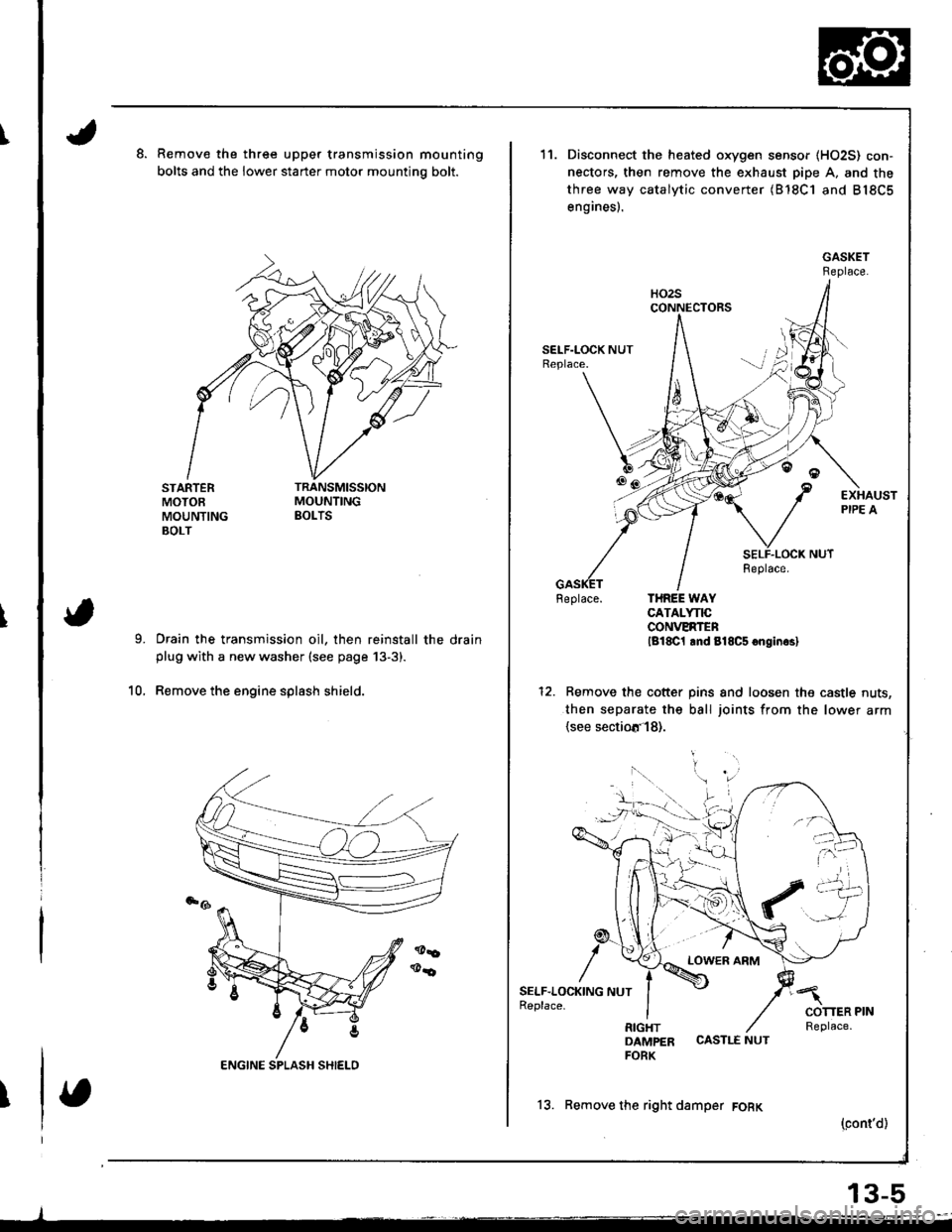

Remove the three upper transmission mounting

bolts and the lower starter motor mountino bolt.

STARTERMOTOEMOUNTINGBOLT

Drain the transmission oil, then reinstall the drainplug with a new washer (see page 13-3).

Remove the engine splash shield.10.

11.

6tr!

/

SELF.LOC1(ING NUTReplace.

Disconnect the heated oxygen sensor (HO2S) con-

nectors, then remove the exhaust pipe A. and the

three way catalytic converter (B'18C1 and B18C5

engines).

Feplace. THREE WAYCATALYNCCONVERTENlg18C1 lnd 818C5 onginrsl

Remove the cotter pins and loosen the castle nuts,

then separate the ball joints from the lower arm(see sectiotr'l8).

LOWER ARM

DAMPER CASTLE NUTFORK

13. Remove the right damper FORK

(cont'd)

13-5

Page 375 of 1681

Transmission Assembly

Removal (cont'dl

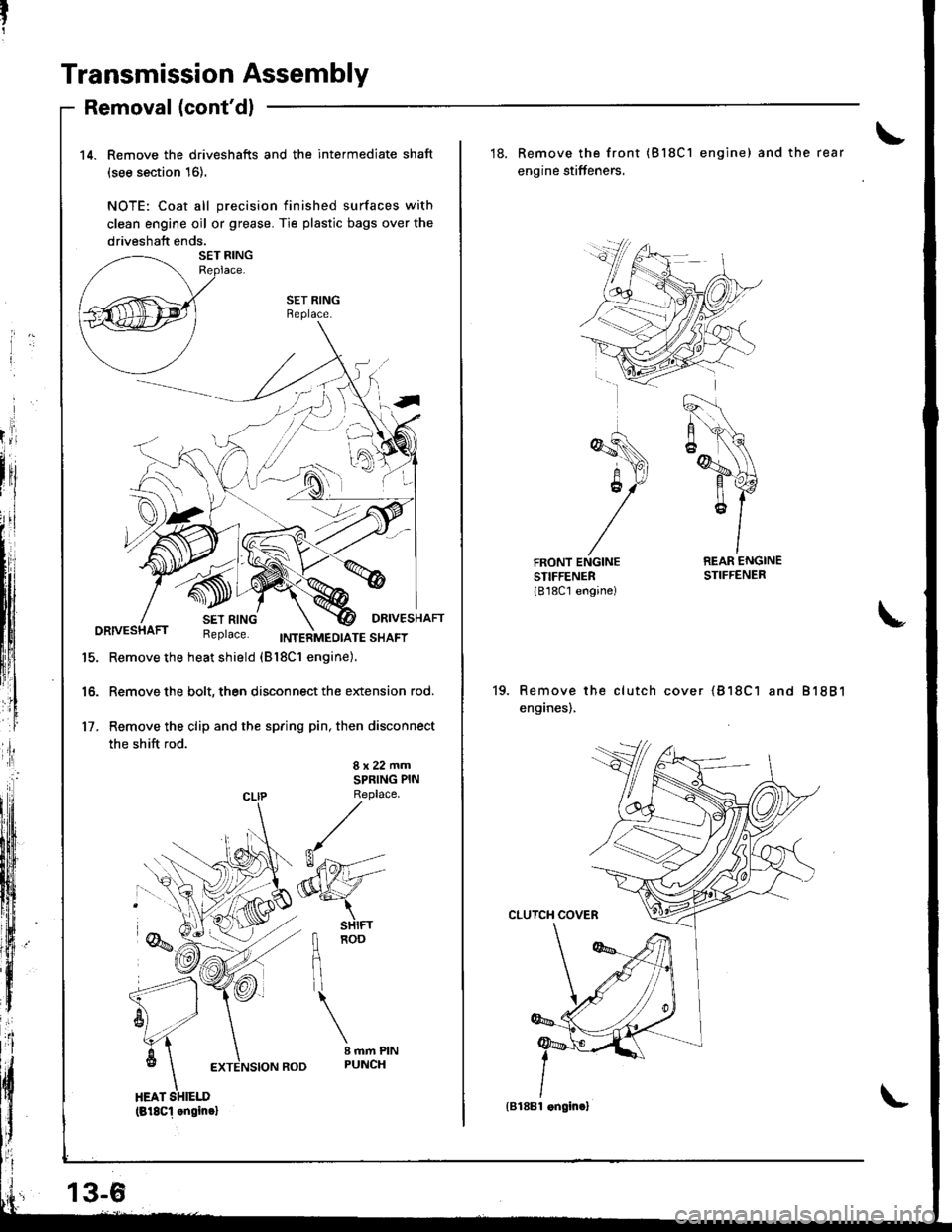

14. Remove the driveshafts and the intermediate shaft

(see section 16).

NOTE: Coat all precision finished surfaces with

clean engine oil or grease. Tie plastic bags over the

driveshaft ends.

SET RINGBeplace.

DRIVESHAFTDRIVESHAFT Replace. trweinnro,ora ""ot

15. Remove the heat shield (Bl8c1 engine).

16. Remove the bolt, then disconnect the extension rod.

17. Remove the clip and the spring pin, then disconnect

the shift rod.

8x22mmSPRING PIN

CLIP Replace

fl noo

flil

\

I mm PINPUNCH

(818c1 .ngin.l

13-6

'18. Remove the front (Bl8C1 engine) and the rear

engine stiffeners,

REAR ENGINESTIFFENER

Remove the clutch cover {818C1 and 81881

enganes),

{B188l .ngin.}

Page 376 of 1681

Transmission Housing

Removal

NOTE:

. lf tho transmission housing or clutch housing are

replaced, the bearing preload must be adjusted

(818C1 8nd 818C5 engines).

. Place the clutch housing on two pieces of wood thick

enough to keep the mainshaft from the hifting the

workbench.

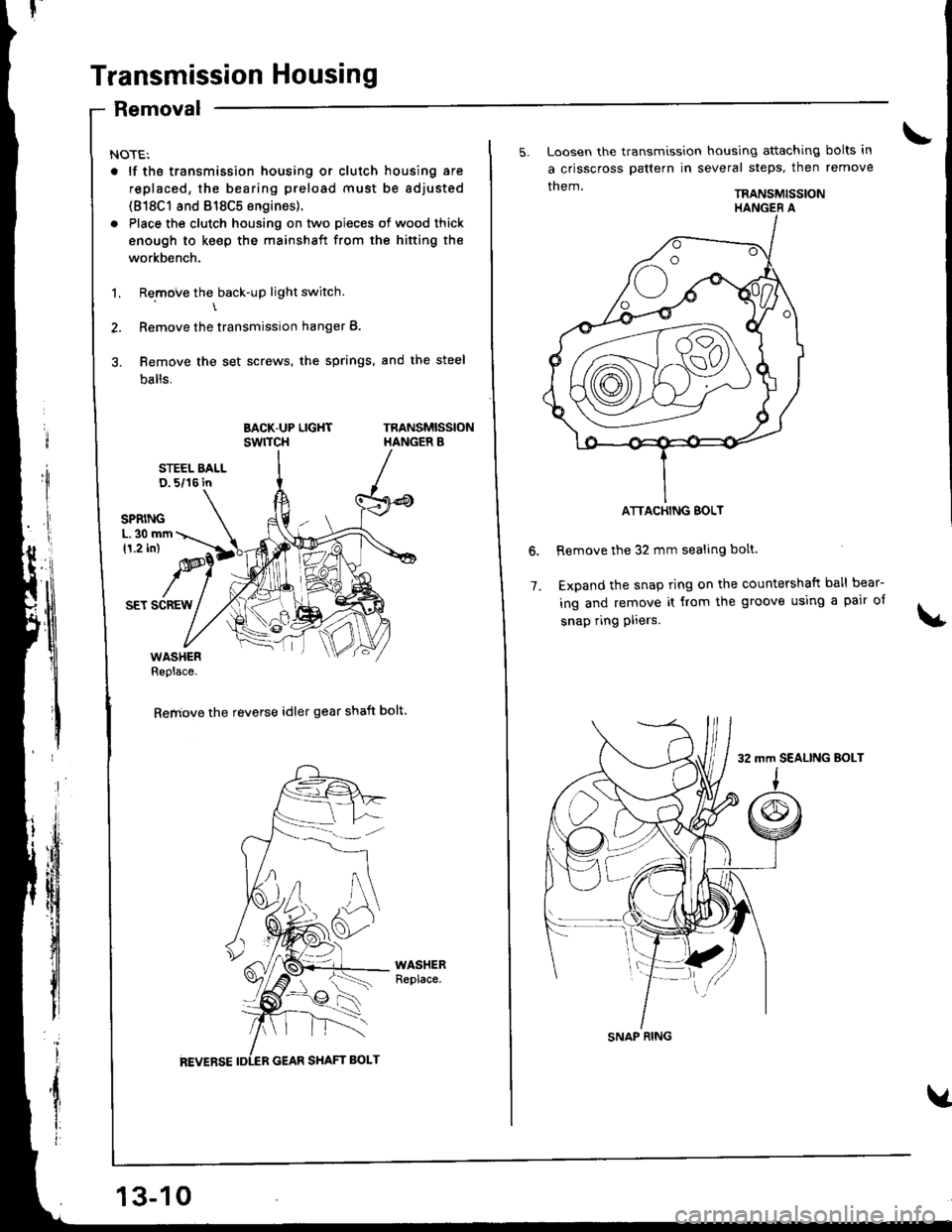

1. Remove the back-up light switch.\

2. Remove the transmission hanger B.

3. Remove the set screws, the springs, and the steel

balls.

BACK-UP LIGHTswrTcHTRANSMISSIONHANGER B

STEEL BALLD. 5/16 in

SET SCREW

WASHERReplace.

Remove the reverse idler gear shaft bolt.

13-10

5. Loosen the transmission housing attaching bolts in

a crisscross pattern in several steps, then remove

them.TRANSMISSION

Remove the 32 mm sealing bolt.

Expand the snap ring on the countershaft ball bear-

ing and remove it from the groove using a pair of

snap ring pliers.

6.

7.

ATTACHING BOLT

SNAP RING

32 mm SEALING BoLT

Page 377 of 1681

8.

9.

f;:Y:fffrf#:J'uer' Sl[

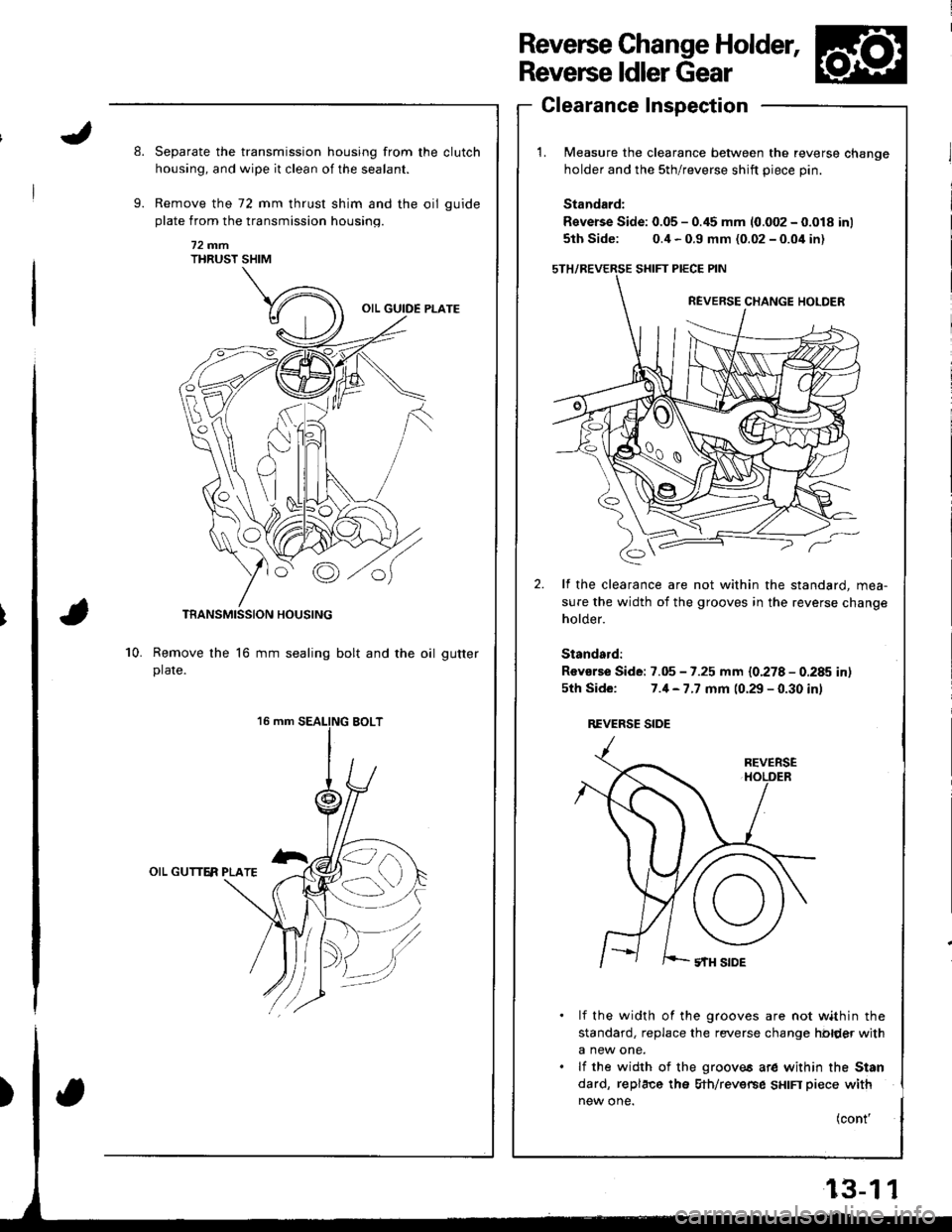

Measure the clearance between the reverse change

holder and the sth/reverse shift piece pin.

Standard:

Reverse Side: 0.05 - 0.45 mm (0.002 - 0.018 inl

5th Side: 0.4 - 0.9 mm (0.02 - 0.04 in)

Separate the transmission housing from the clutch

housing, and wipe it clean of the sealant.

Remove the 72 mm thrust shim and the oil guide

plate from the transmission housing

72 fifiTHRUST SHIM

10. Remove the l6 mm sealing bolt and the oil gutter

plate.

OIL GUTT6R PLATE

lf the clearance are not within the standard, mea-

sure the width of the grooves in the reverse change

holder.

Standard:

Revsrse Side: 7.05 - 7.25 mm {0.278 - 0.285 in)

5th Side: 7.4-7.7 mm (0.29 - 0.30 in)

REVERSE SIDE

lf the width of the grooves are not within the

standard, replace the rsverse change hbtder with

a new one.

lf the width of the grooves ar€ within the Stan

dard, replace the 9th/revense sHtFI piece wlth

new one.

(cont'

Page 378 of 1681

Reverse Change Holder,

Clearance Inspection {cont'dl

Reverseldler Gear

Removal

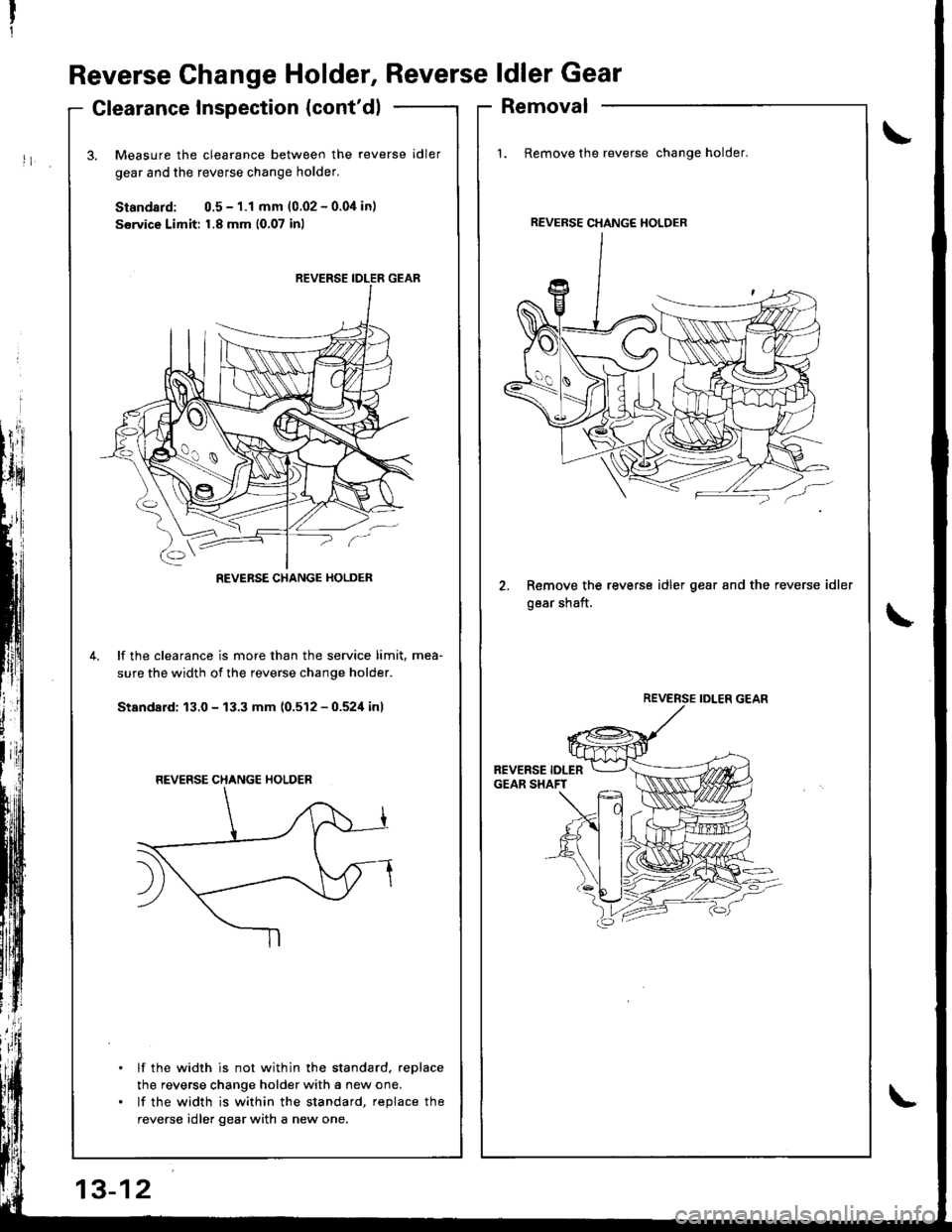

1. Remove the reverse change holder.

2. Remove the reverse idler gear and the reverse idler

oear shaft.

\

i1

\

Measure the clearance between the reverse idler

gear and the reverse change holder,

Standard: 0.5 - 1.1 mm (0.02 - 0.04 in)

Sorvice Limit: 1.8 mm (0,07 inl

4.lf the clearance is more than the service limit, mea-

sure the width of the reverse change holder.

Standa;d: 13.0 - 13.3 mm (0.512 - 0.524 inl

lf the width is not within the standard, reDlace

the reverse change holder with a new one.

lf the width is within the standard, reDlace the

reverse idler gear with a new one.

REVERSE IDLER GEAR

REVERSE CHANGE HOLDER

REVERSE CHANGE HOLDER

REVERSE CHANGE HOLDER

\

Page 379 of 1681

Change Holder Assembly

Clearance Inspection

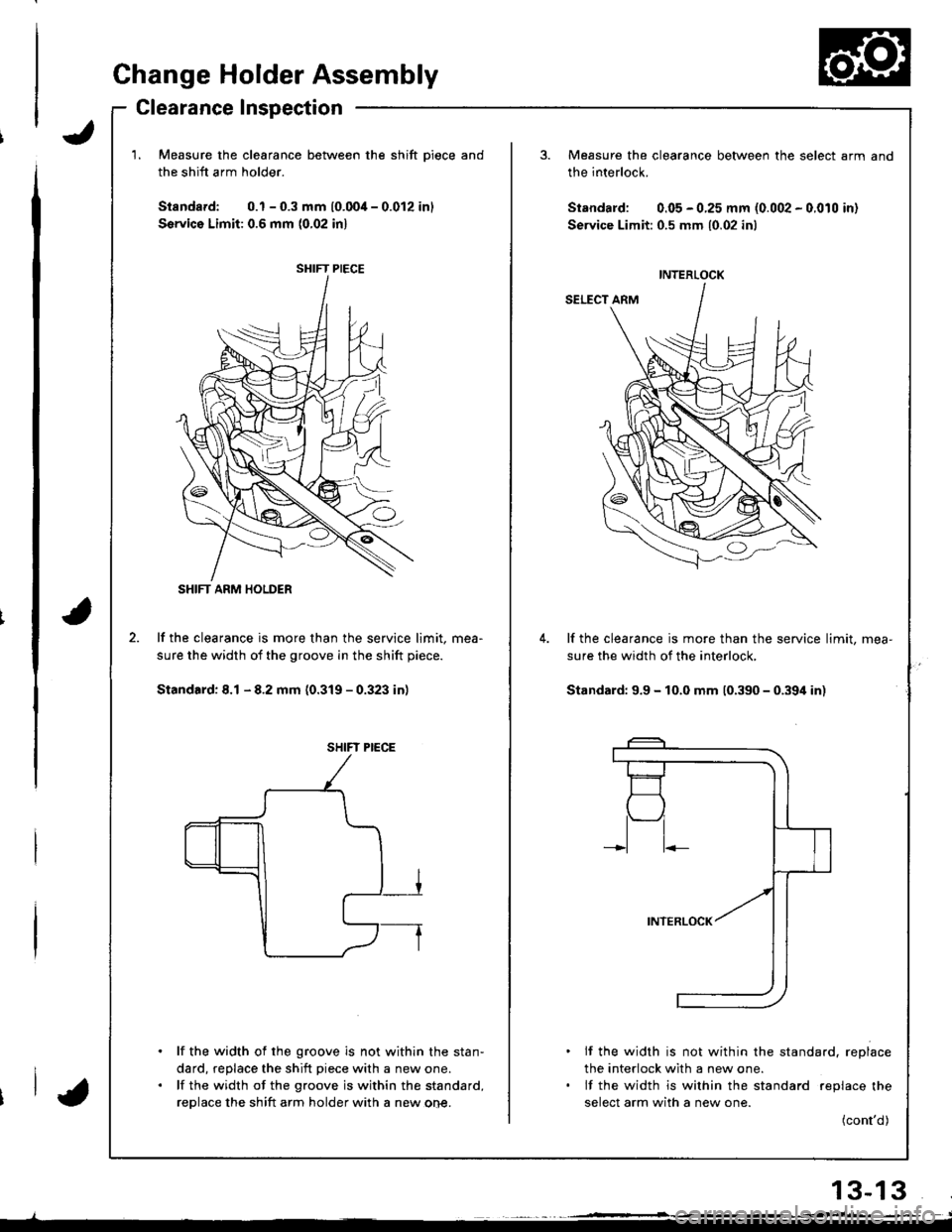

Measure the clearance betwe€n the shift Diece and

the shift arm holder.

Standard: 0.1 - 0.3 mm (0.004 - 0.012 inl

Servico Limit: 0.6 mm (0,02 inl

lf the clearance is more than the service limit, mea-

sure the width of the groove in the shift piece.

Standard: 8.1 - 8.2 mm (0.319 - 0.323 in)

. lf the width of the groove is not within the stan-

dard, replace the shift piece with a new one.. lf the width of the groove is within the standard,

replace the shift arm holder with a new one.

SHIFT PIECE

t.-_

O

SHIFT ARM HOLDER

SHIFT PIECE

Measure the clearance between the select arm

the interlock.

Standard: 0.05 - 0.25 mm (0.002 - 0.010 in)

Service Limit:0.5 mm {0.02 inl

and

INTERLOCK

lf the clearance is more than the service limit, mea-

sure the width of the interlock,

Standard: 9.9 - 10.0 mm 10.390 - 0.394 in)

. lf the width is not within the standard. replace

the interlock with a new one.. lf the width is wilhin the standard replace the

select arm with a new one.

(cont'd)

13-13

Page 380 of 1681

Change Holder Assembly

Glearance Inspection (cont'd)

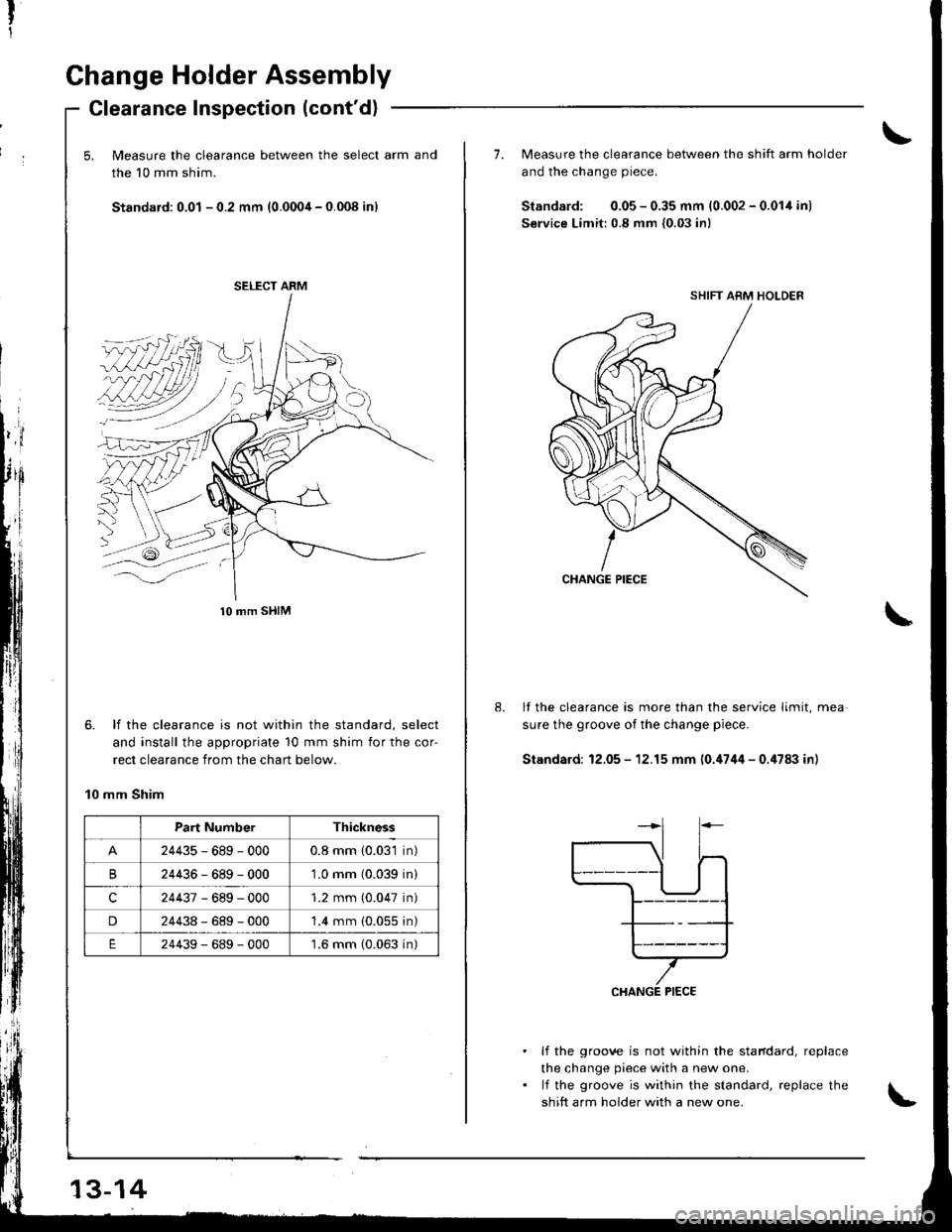

5. Measure the clearance between the select arm and

the 10 mm shim.

Standard: 0.01 - 0.2 mm (0.0004 - 0.008 inl

,id''l

I'l

6. lf the clearance is not within the standard, select

and install the appropriate 10 mm shim for the cor'

rect clearance from the chart below.

10 mm Shim

SELECT ARM

10 mm SHIM

Part Numb€rThickness

24435-689-0000.8 mm (0.031 in)

B24436-689-0001.0 mm (0.039 in)

24437-689-0001.2 mm (0.047 in)

D24438-689-000'1.4 mm (0.055 in)

24439-689-0001.6 mm (0.063 in)

73-14

7. Measure the clearance betlveen the shift arm holder

and the change piece.

Standard: 0.05 - 0.35 mm (0.002 - 0.014 in)

Service Limit:0.8 mm {0.03 in)

lf the clearance is more than the service limit, mea

sure the groove of the change piece.

Stsndard: 12.05 - 12.15 mm 10.'1744 - 0.'t78:l in)

. lf the groove is not within the stafdard, replace

the change piece with a new one.. lf the groove is within the standard, replace the

shift arm holder with a new one.

SHIFT ARM HOLDER