HONDA INTEGRA 1998 4.G Workshop Manual

Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 411 of 1681

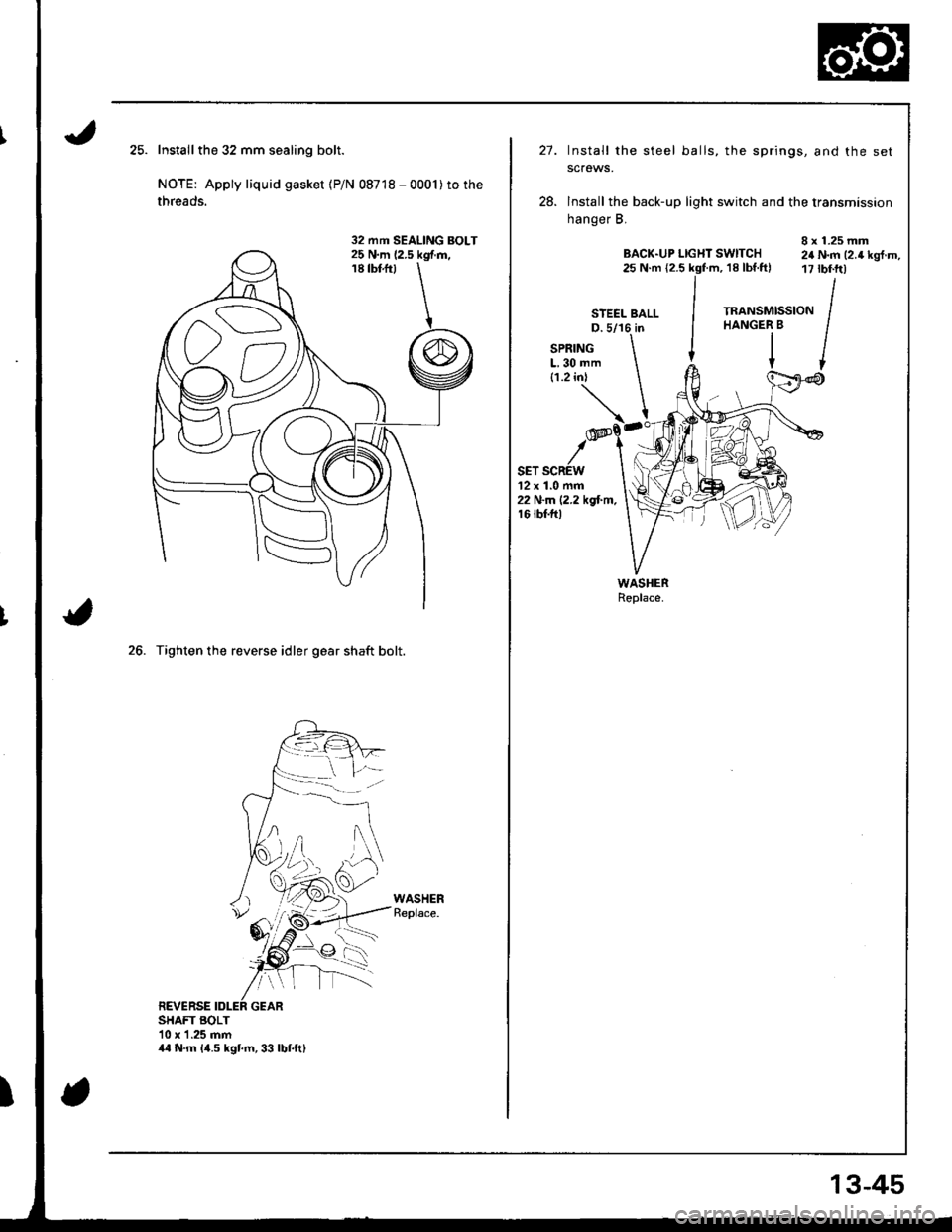

Installthe 32 mm sealing bolt.

NOTE: Apply liquid gasket (P/N 08718 - 0001)to the

threads.

26. Tighten the reverse idler gear shaft bolt.

REVERSEGEARSHAFT BOLT10 x 1.25 mm

32 mm SEALING BOLT

44 N.m 14.5 kgtm,33 lbf.ftl

13-45

STEEL BALI-

27.Install the steel balls, the springs, and the set

scfews.

lnstall the back-up light switch and the transmission

hanger B,

8 x 1.25 mmBACK-UP LlGl{T SWITCH 24 N.m t2.a kgt.rn,25 N.m {2.5 kgf.m, 18 lbf.ftl 17 tbf.ft)

12 x 1.0 mm22 N-ln 12.2 kgl.tn,16 rbf.ftl

Page 412 of 1681

I

Transmission Assembly

1.

2.

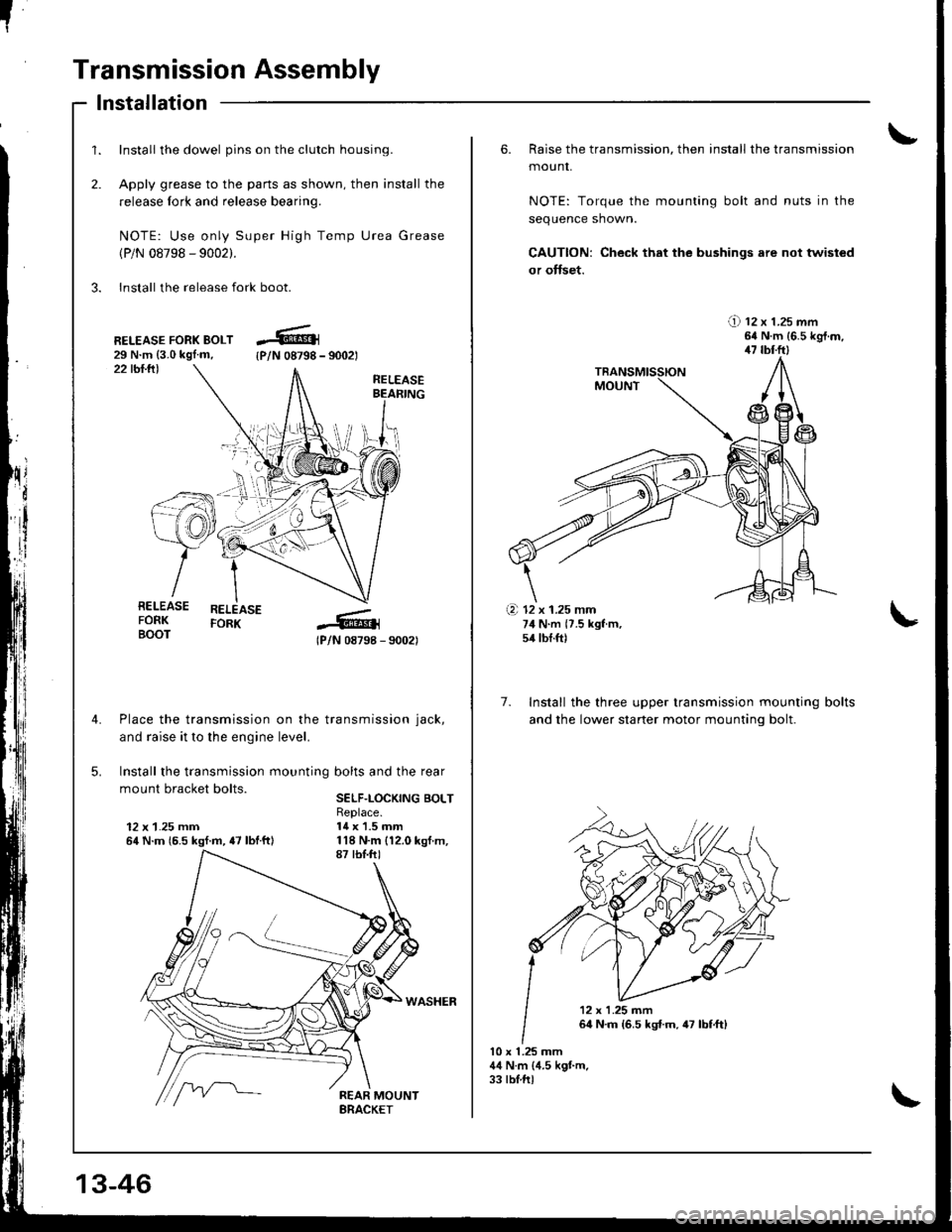

Install the dowel pins on the clutch housing.

Apply grease to the parts as shown, then install the

release fork and release bearing.

NOTE: Use only Super High Temp Urea Grease

(P/N 08798 - 9002).

3. Install the release fork boot.

lnstallation

22 tbl.lll

RELEASE FORK BOLT29 N.m {3.0 kgl.m,{P/N 08798 - 9002t

RELEASEBEAFING

RELEASEFORK

lPlN 08798 - 90021

Place the transmission on the transmission jack,

and raise it to the engine level.

Install the transmission mounting bolts and the rear

mount bracket bolts.SELF.LOCKING BOLT

12 x 1.25 mm64 N.m {6.5 kgf.m, {7 lbtftl

Replace.14 x 1.5 mm

RELEASEFORKBOOT

\i'l-r )i-

.+.i

13-46

6. Raise the transmission, then install the transmission

mounr,

NOTE: Torque the mounting bolt and nuts in the

sequence shown.

CAUTION: Check that the bushings are not twisted

or offset.

!) tz x t.zs mm64 N.m {6.5 kgt.m,47 tbl.ftl

7. Install the three upper transmission mounting

and the lower staner motor mountinq bolt.

bolts

10 x 1.25 mm44 N.m (4.5 kgt m.33 tblftl

(a 12 x 1.25 mm74 N.m {7.5 kgf m,54 tbf.ft)

'12x1.25m�n

64 N.m {6.5 kst.m,47 lbf,ft)

Page 413 of 1681

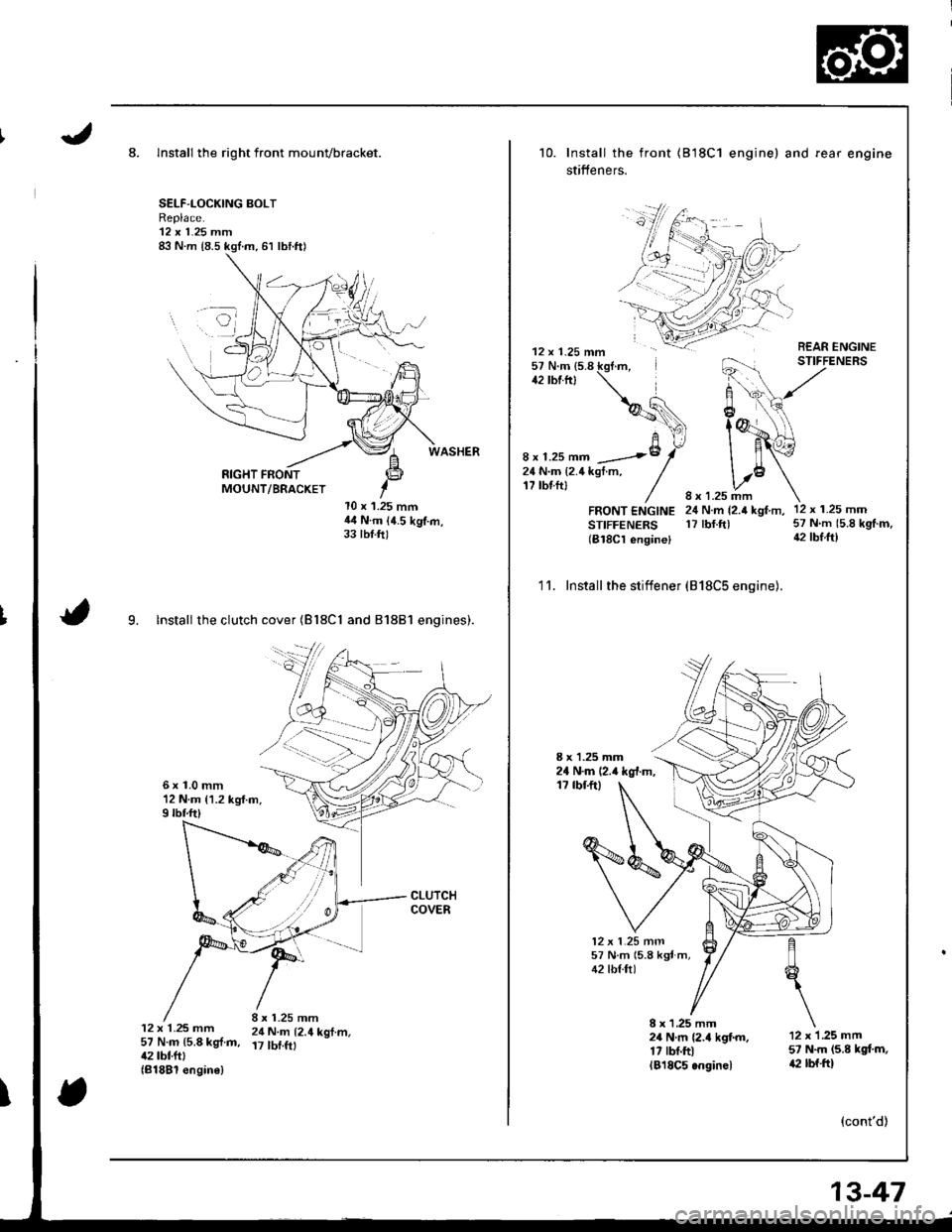

8. Install the right front mounvbracket.

SELF-LOCKING BOLTReplace.'12 x 1.25 mm

RIGHT FRONTMOUNT/BRACKET

l0 x 1.25 mmil4 N.m (4.5 kg'f.m,33 tbt.ft)

9. lnstall the clutch cover (Bl8Cl and 81881 engines).

6x1.0mm12 N.m {1.2 kg{.m,9 rbf.ft)

12 x 1.25 mm 24 N.m t2.4 kof.m.57 N.m {5.8 kg{.m, 17 tbf.ftt42 tbt.ftl(81881 engin€)

10. Install the front

stifteners.

(818C1 engine) and fear engine

REAR ENGINESTIFFENERS

12 x 1.25 mm57 N'm 15.8 kg{.m.42 tbr.ltl

H!\,

f @^\

I B'�{o| \-

1.25 mmN.m {2.4 kgf m,rbf.ftl

12 x 1.25 mm57 N.m (5.8

{2 tbtft}

8 x 1.25 mm -8

24 N.m {2.4 kgt m,17 tbtftl

FRONT ENGINESTIFFENERS(B18Cl engine)

12 x 1.25 mn157 N m (5.8 kgt m,42 tbl.ftl

2111

'11. Install the stiffener (818C5 engine).

8 x 1.25 mm24 N.m (2.4 kg{.m,1? tbf.ftl

8 x 1 ,25 mm24Nm{2.4kgtm.17 rbr.ftllBl8C5.nginel

12 x 1 .25 mm57 N.m (5.8 kgl.m,a2 rbf.ftl

(cont'd)

13-47

Page 414 of 1681

[!

"

Transmission Assembly

Installation (cont'd)

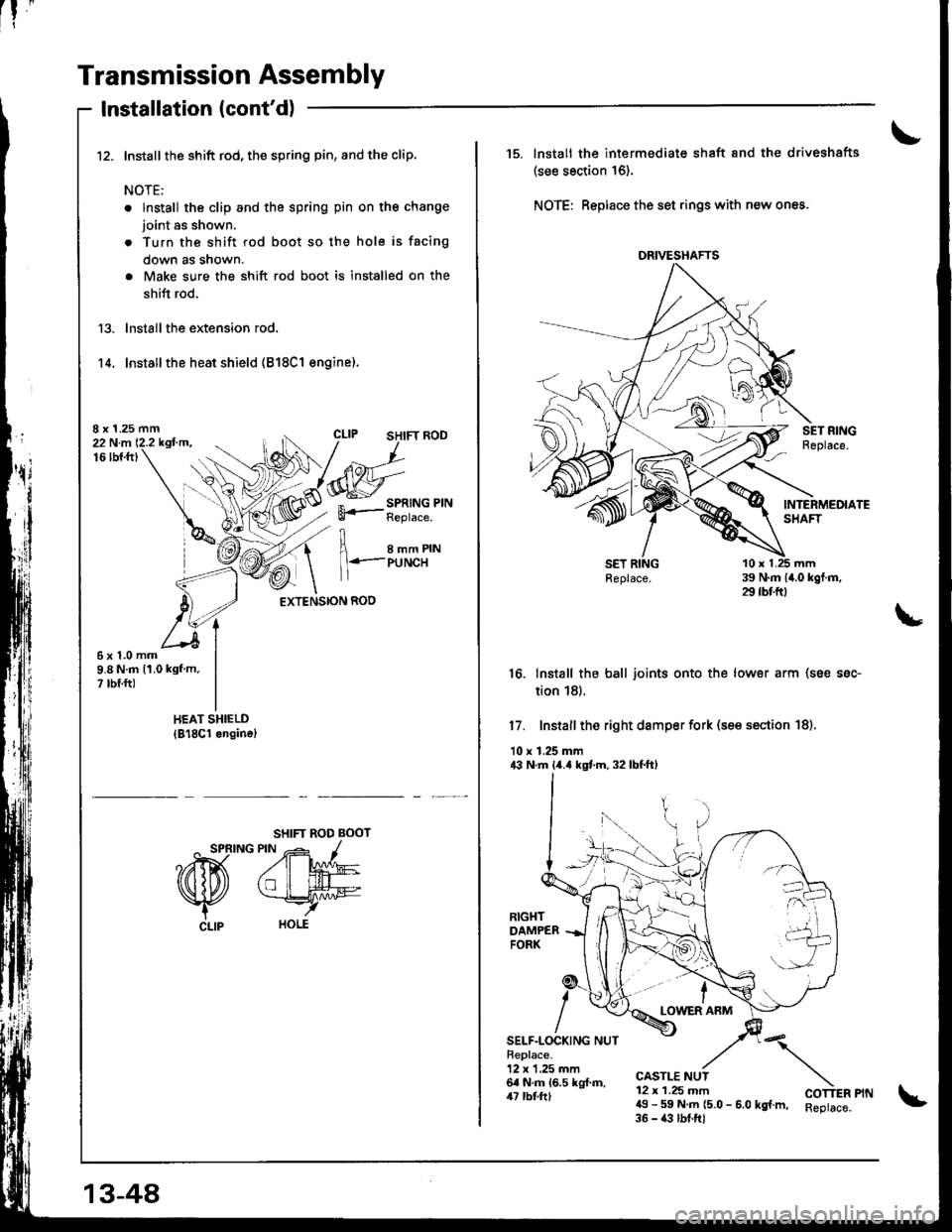

Install the shift rod, the spring pin, and the clip.

NOTE:

. lnstall the clip and the spring pin on the change

joint as shown.

. Turn the shift rod boot so the hole is facing

down as snown.

. Make sure the shift rod boot is installed on the

shift rod.

lnstall the extension rod.

Installthe heat shield (818C1 engine).'t 4.

8 x 1.25 mm22 N.m 12.2 kgfm.16lbt.ft)

I e--erru

1 l+.-PUNCH

EXTENSION ROD

6x1.0mm9.8 N.m 11.0 kgf m,? rbf.ft)

SHIFT ROD BOOT

^ SPRING PIN -- -1

?ffi A'W

Nfu *rry

CLlp HOLE

13-48

DRIVESHAFTS

15. lnstall the intermediate shaft 8nd the driveshafts

(see section 16).

NOTE: Beplace the set rings with new ones.

16. Install the ball joints onto the lower arm (soe ssc-

tion 18).

17. Install the right damper fork (see ssction 18).

10 r 1.25 mm43 N.m lir.a kgt m. 32 lbtftl

LOWER ARM

SELF.LOCKING NUTReplace.12 x 1,25 mm6a N.m 16.5 kg{.ft,/u rbl.tt)

CASTLE NUT12 x 1.25 mm49 - 59 N.m (5.0 - 6.0 kgf.m, Reptace.35 - 43 lbf.ftl

"\

COTTER PIN

Page 415 of 1681

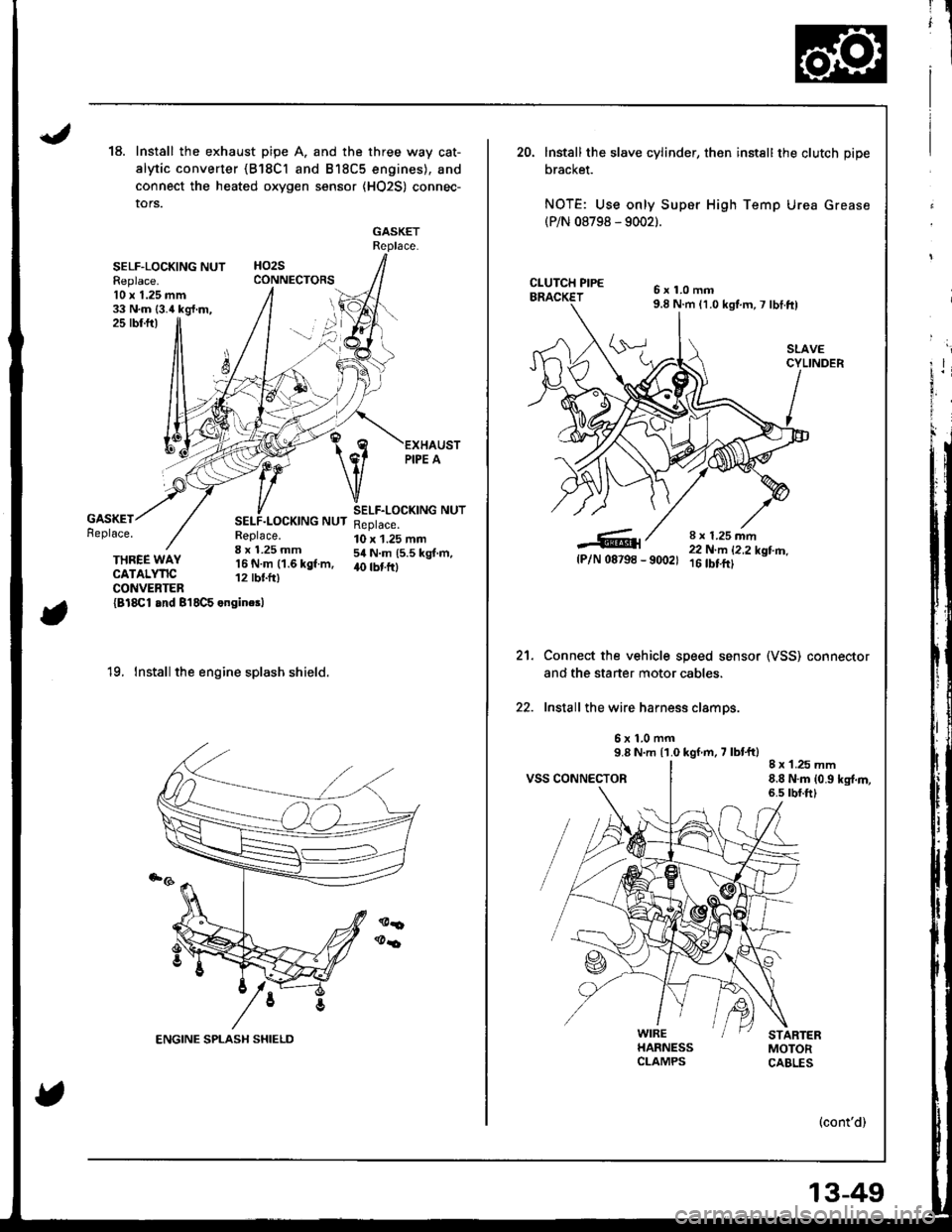

18.Install the exhaust pipe A. and the three way cat-

alytic converter {B18Cl and B18C5 engines), and

connect the heated oxygen sensor {HO2S) connec-

tors.

GASKETReplace.

HO2SCONNECTORSSELF-LOCKING NUTFeplace.10 x 1.25 mm33 N.m {3.4 kg{.m,jj25 rbr.ftl

GASKETReplace.SELF.LOCKING NUTReplace.8 x 1.25 mm'16 N.m (1.6 kgf.m,12 tbtfr)

SELF.LOCKING NUTReplace.10 x 1.25 mm54 N.m (5.5 kgt.m,40 tbt frlTHREE WAYCATALYTICCONVENTER{Bl8Cl and 8'18C5 engincsl

'19. Install the engine splash shield.

20. lnstall the slave cylinder, then instsll the clutch pipe

bracket.

NOTE: Use only Super High Temp Urea Grease(P/N 08798 - 9002).

6x1.0mm9.8 N.m 11.0 kgt m,7 lbI.ft)

SLAVECYLINDER

8 r 1.25 mm22 N.m 12,2 kotm_- 9(x)21 16 tbt.ftt

Connect the vehicle speed sensor (VSS) connestor

and the staner motor cables.

Install the wire harness clamps.

6x1.0mm9.8 N.m {1.0 kgf m, 7 lbt'ft)

VSS CONNECTOR8 x 1.25 mm8.8 N.m {0.9 kg{.m,6.s rbr.ft)

5{P/N 08798

21.

WIREHARNESSCLAMPS

(cont'd)

13-49

Page 416 of 1681

Transmission Assembly

Installation (cont'd)

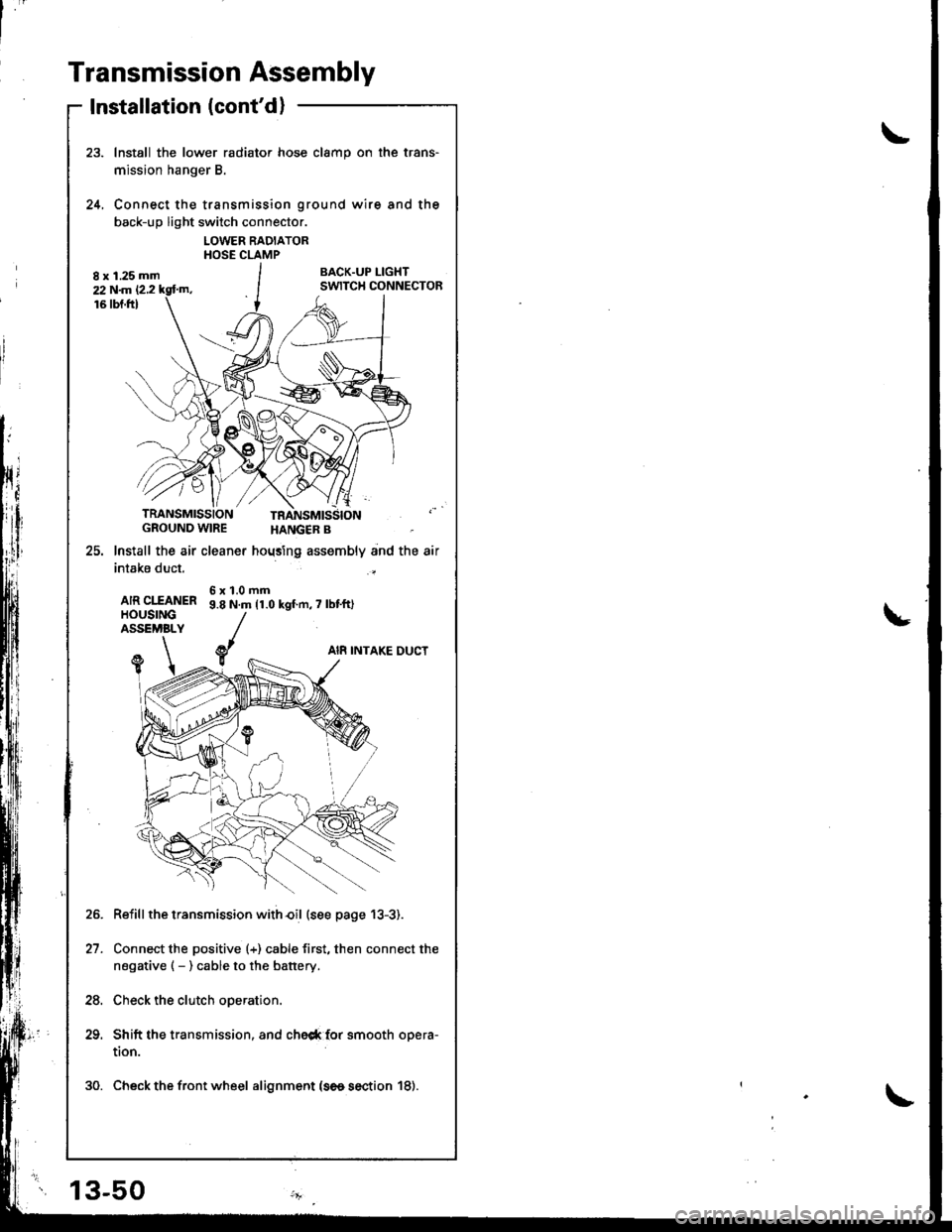

Install the lower radiator hose clamp on the trans-

mission hanger B.

Connect the transmission ground wire and the

back-up light switch connector.

LOWER RADIATORHOSE CLAMP

BACK.UP I-IGHTSWITCH CONNECTOR

24.

TRANSMISSIONGROUND WIRE

25. lnstall the air cleaner

intake duct.

AIR CIfANERHOUSINGASSEMBLY

HANGER B

hoqsing assembly and the air

6x1.0mm9.8 N.m 11.0 kgf.n,7 lbt'ft)

AI8 INTAKE DUCTY1

Reiill the transmission with€il (see page 13-3).

Connect the positive (+) cable first, then connect the

negative ( - ) cable to the battery.

Check the clutch operation.

Shift the transmission, and che6* {or smooth opera-

tion.

30. Check the front wheel alignment (se6 section 18).

21.

24.

13-50

Page 417 of 1681

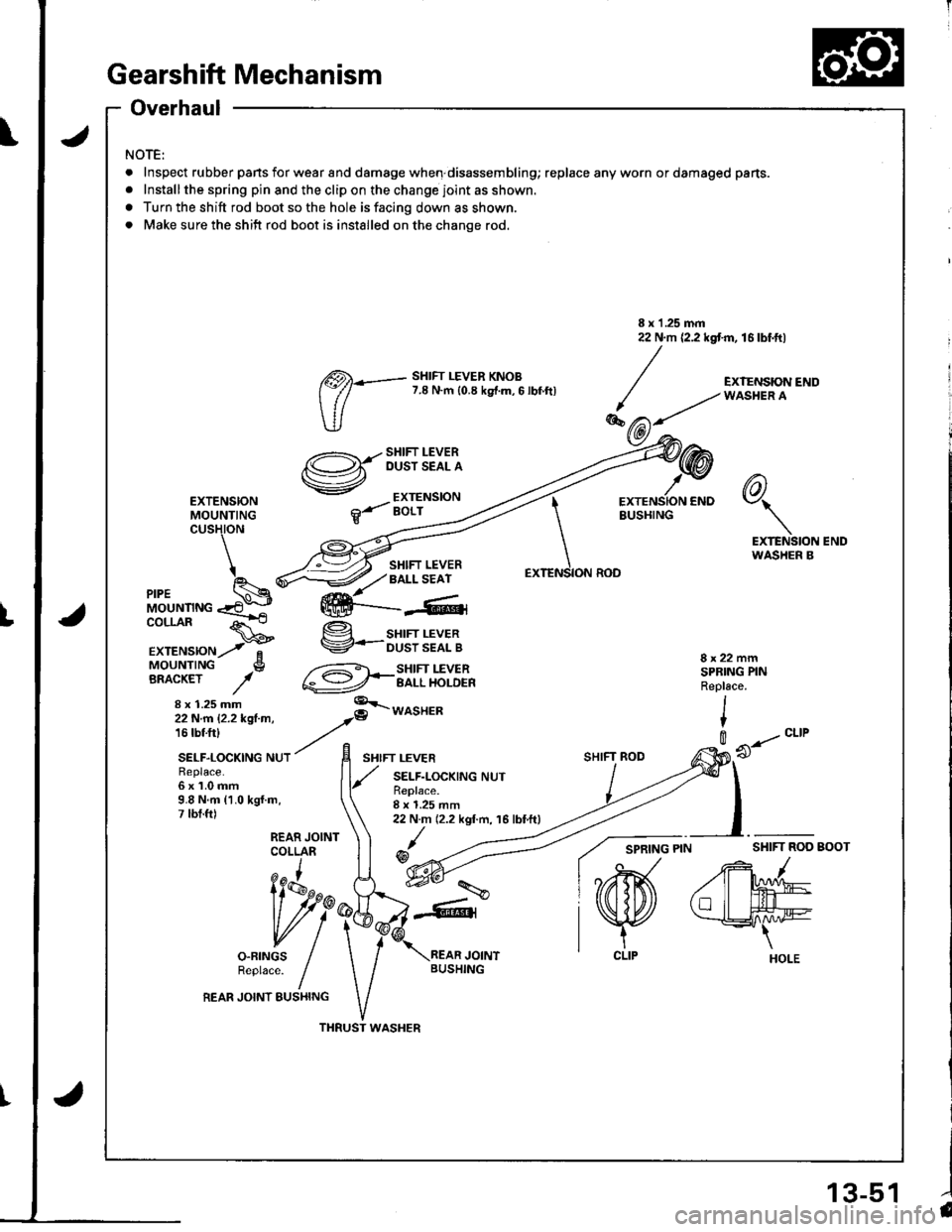

Gearshift Mechanism

Overhaul

NOTE:

.Inspe(

.lnstall

a Turn t

. Make

Inspect rubber pans for wear and damage when disassembling; replace any worn or damaged pans.

Installthe spring pin and the clip on the change joint as shown.

Turn the shift rod boot so the hole is facing down as shown.

Make sure the shift rod boot is installed on the change rod.

\

tu

<:;s\-

-,-"Ye/

R€place.6x1.0mm9.8 N.m {1.0 kgl.m,7 lbt.ft)

liAru^

vll

o-FTNGS /Reptace. fREAR JOINT EUSHING

I x 1 .25 mm22 N.m {2.2 kgt m, 16 lbf.ft)

EXTENSIONMOUNTINGcusHtoN

6)\7\

EXTENSION ENDWASHER B

MOUNTINGCOLLAR

EXTENSIONMOUNTINGBRACKET

x 1.25 mm

SHIFT LEVERBALL SEAT

g sHrFr LEVERV-ousrssflg

@*3li.T'lib'l'

8x22mmSPBING PINRepl6ce.

I

t

SHIFT ROD

0 --..- "ttt

REAR JOINTCOLLARSHIFI ROD BOOT/

/rM

tllL#e

THRUST WASHER

@)*- sHtFr LEVER KNoB

(:// 7.8 N.m {0.8 ks{.m,6 lbf.ftl

SHIFT LEVEROUST SEAL A

EXTENSIONBOLT

8 x 1.25 mm22 N.m (2.2 kgf.m, 16 lbtft)

/@

EXTENSION CNDBUSHING

ION ROD

-\

\

\EXTENS

ffi---4,

l'a13-51

Page 418 of 1681

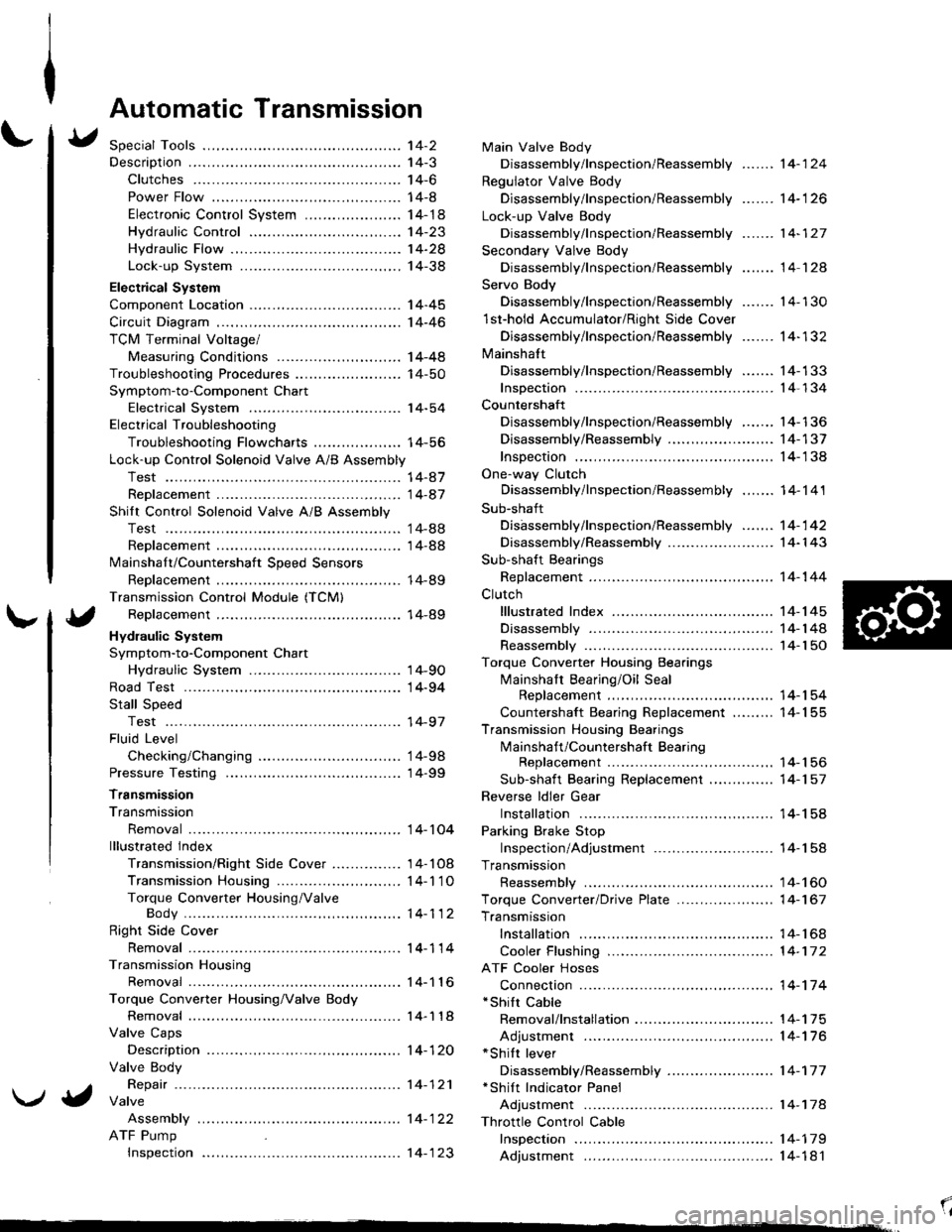

Automatic Transmission

Special Tools ................ '14-2

Descraption .................... 14-3

Clutches ............ ...... 14-6

Power Flow ..,........... 14-8

Electronic Control System ..................... 1 4-1 8

Hydraulic Control ...... 14-23

Hydraulic Flow .........- 14-28

Lock-up System ........ 14-38

Electrical System

Component Location -................................ 1 4-45

Circuit Diagram ............. 14-46

TCM Terminal Voltage/

Measuring Conditions ......,.................... 1 4-48

Troubleshooting Procedures .. . ... ........ ...... ... 14-50

Symptom-to-Component Chart

Electrical System ...... 14-54

Electrical Troubleshooting

Troubleshooting Flowcharts .......... ... ...,.. 14-56

Lock-up Control Solenoid Valve A/B Assembly

Test .................. ...... 14-A7

Replacement ............. 14-a7

Shilt Control Solenoid Valve A/B Assembly

Test .................. ...... '14-88

Replacement .,..,........ 14-88

lvlainshaf t/Countershaft Speed Sensors

Replacement ....-......,. 14-89

Transmission Control Module (TCM)

Replacement ............. 14-89

Hydraulic System

Symptom-to-Component Chart

Hydraulic System ...... 14-90

Road Test ,................... 14-94

Stall Speed

Test .................. ...... 14-97

Fluid Level

Checking/Changing .... 14-98

Pressure Testing ........... 14-99

Transmission

Transmission

Removal ............. ...... 14-10�4

lllustrated lndex

Transmission/Right Side Cover ............... 1 4-1 08

Transmission Housin9 ................,..,....... 1 4-1'1 O

Torque Converter Housing/ValveBody .................. .. 14-112

Right Side Cover

Removal ............. ...... 14-114

Transmission Housing

Removal ............. ...... 14-1 l6

Torque Converter Housing/Valve Body

Removal ............. ...... l4-1 18

Valve Caps

Description ...........-... 14-120

Valve Body

Repair ................ ...... 14-12'l

Valve

Assembly

ATF Pump

Inspeclton

Main Valve Body

Disassembly/lnspection/Reassembly

Regulator Valve Body

Disassembly/lnspection/Reassembly

Lock-up Valve Body

Disassembly/lnspection/Reassembly

Secondary Valve Body

Disassembly/lnspection/Reassembly

Servo Body

....... 14-124

....... 14-126

....... 14-127

....... 14 124

Disassembly/lnspection/Reassembly .......

1st-hold Accumulator/Right Side Cover

Disassembly/lnspection/Reassembly .......

Mainsha{t

14-130

14-132

Disassembly/lnspection/Reassembly ....... 14-133

Inspection ................. 14-134

Countershaft

Disassembly/lnspection/Reassembly,..,.., l4-136

Disassembly/Reassembly ..,...,..,.........,,.. 1 4-1 37

Inspection ......,...,..,... 14-138

One-way Clutch

Disassembly/lnspection/Reassembly ....,.. 14-141

Sub-shaft

Disassembly/lnspection/Reassembly ...,,..'14-142

Disassembly/Reassembly ....................... 1 4- l 43

Sub-shaft Bearings

Replacement ,..,,.,,..,.. 14-144

Clutch

lllustrated Index ................................... I 4-1 45

Disassembly ............. 14-144

Reassembly .............. 14-150

Torque Converter Housing Bearings

Mainshaft Bearing/Oil Seal

Replacement ......... 14-154

Countershaft Bearing Replacement ......... 1 4- 1 55

Transmission Housing Bearings

Mainshaft/Countershaft BearingReplacement ......,.. 14-'156

Sub-shaft Bearing Replacement .,............ 1 4-1 57

Reverse ldler Gear

Installation .........-..... 14-158

Parking Brake Stop

Inspection/Adjustment .......................... 1 4-1 58

Transmission

Reassembly .............. 14-160

Torque Converler/Drive Plate ..............,.,,.,, 1 4-1 67

Transmission

Installation ............... 14-168

Cooler Flushing ......... 14-172

ATF Cooler Hoses

Connection ,..,,,....,,.,, '14-'174

*shift cable

Removal/lnstallation . . .. .... ... .... ... .... .. . ... .. 14-'l75

Adjustment ,..,...,,,,.,, 14-'116*Shilt lever

Disassembly/Reassembly ....................... 1 4-'17 7'Shift Indicator Panel

Adjustment .............. 14-178

\l

)g

Page 419 of 1681

Special Tools

t

{

{

I

\-

\

14-2

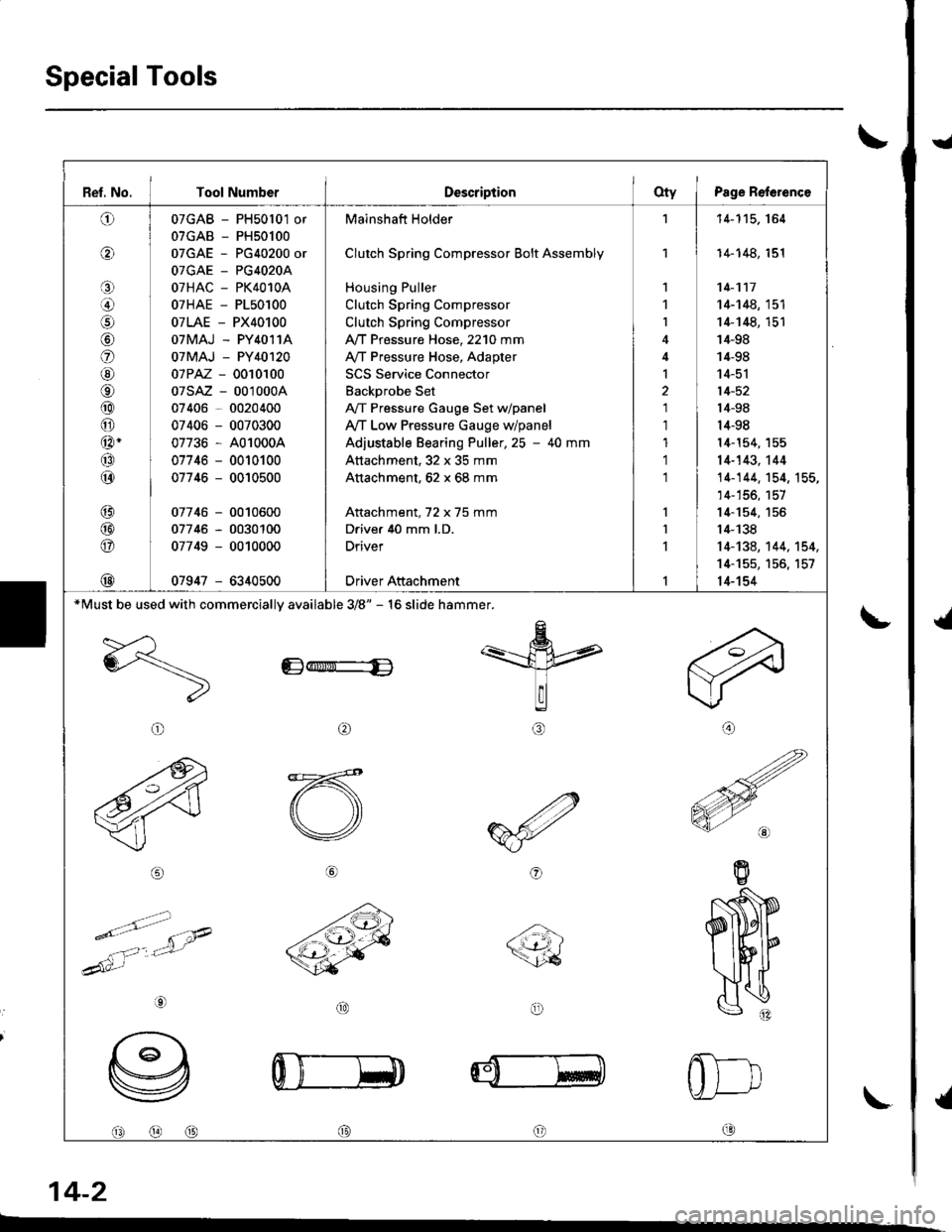

Ref. No. I Tool NumberDescriptionOty I Psge Reference

o

o

o

lol

o

@

o

@

@

@-

@

@

@

@

@

@

07GAB - PH50l01 or

07GAB - PH50100

07GAE - PG40200 or

OTGAE _ PG4O2OA

07HAC - PK4010A

07HAE - P150100

07LAE - PX40100

OTMAJ - PY4O11A

07MAJ - PY40120

07PAZ - 0010100

07sAz - 001000A

07406 - 0020400

07406 - 0070300

07736 - A01000A

07746 - 0010100

07746 - 0010500

07746 - 0010600

07746 - 0030100

07749 - 0010000

07947 - 6340500

Mainshaft Holder

Clutch Spring Compressor Bolt Assembly

Housing Puller

Clutch Spring Compressor

Clutch Spring Compressor

,VT Pressure Hose, 2210 mm

A/T Pressure Hose, Adapter

SCS Service Connector

Backprobe Set

A,/T Pressure Gauge Set dpanel

Ay'T Low Pressure Gauge w/panel

Adjustable Bearing Puller,25 - 40 mm

Attachment, 32 x 35 mm

Attachment, 62 x 68 mm

Attachment, 72 x 75 mm

Drive. 40 mm l.D.

Driver

Driver Attachment

1

1

I

I

1

1

1'l

'l

'11-115. 164

14-148, 151

14-117

14-148, 151

14-148, 151'14-98

14-98

14-51

14-52

l4-98

14-98

l4-154, 155

14-143,'t44

14-144. 154, 155,

14-156, 157

14-154, 155

14-138

14-134, 144, 't54,

14-155, 156, 157

14-154

*Must be used with commerciallv available 3/8" - 16 slide hammer.

Edr$ri"-E

arl

@o

@@@c0

Page 420 of 1681

Description

\J

t{

{

14-3

The automatic transmission is a combination of a 3-element torque converter and triple-shalt electronically controlled

automatic transmission which provides 4 speeds forward and 1 speed reverse. The entire unit is positioned in line with

the engrne.

Torque Converter, Gears, and Clutches

The torque converter consists of a pump, turbine, and stator, assembled in sigle unit. The torque converter is connected to

the engine crankshaft so they turn torether as a unit as the engine turns. Around the outside of the torque convener is a

ring gear which meshes with the starter pinion when the engine is being started. The entire torque converter assembly

serves as a flywheel while transmitting power to the transmission mainshaft.

The transmission has three parallel shafts; the mainshaft. the countershaft, and the sub shaft. The mainshaft is in-line with

the engine crankshaft.

The mainshaft includes the 1st, and 2ndl4th clutches,and gear for 3rd, 2nd, 4th, reverse, and 1st. (3rd gear is integral with

the mainshaft, while reverse gear is integral with the 4th gear.)

The countershaft includes the 3rd clutch and gears for 3rd,2nd, 4th, reverse, 1st, and parking. Reverse and 4th gears can

be loched to the countershaft at its center,providing 4th gear or reverse, depending on which way the selector is moved.

The sub-shaft includes the 1st-hold clutch and gears fo 1st and 4th.

The gears on the mainshaft are in constant mesh with those on the countersahft and sub-shaft.When certain combinations

of gears in the transmission are engaged by clutches. power in transmitted from the mainshaft to the countershaft via the

sub-shaft to orovude oil, lo'1. E, E. and E.

Electronic Control

The electronic control svstem consists of the Transmission Control Module (TCM), sensors, and four solenoid valves.

Shilting and lock-up are electronically controlled for comfortable driving under all conditions.

The TCM is located below the dashboard, behind the lelt side kick panel on the driver's side.

Hydraulic Control

The valve bodies include the main valve body, the secondary valve body, the regulator valve body, the serbvo body, and

the lock-up valve body, through the respective separator plates, They are bolted to the torque converter housing,

The main valve body contains the manual valve, the 1-2 shift valve, the 2-3 shitt valve, the Clutch Pressure Control

lCPC) valve, the 4th exhaust valve, the reliel valve, and the ATF pump gears.

The secondary valve body contains the 4-3 kick-down valve, the 3-2 kick-down valve, the 2-3 orifice control valve, the

3-4 shift valve, the orilice control valve, the modulator valve, and the servo control valve.

The regulator valve body contains the pressure regulator valve, the lock-up control valve, the torque converter check

valve, and the cooler check valve.

The servo body contains the servo valve, which is integrated with shift fork shaft, the throttle valve B, and the accumula-

tors.

The lock-up valve body contains the lock-up shift valve and the lock-up timing B valve, and is bolted to the regulator valve

ooqy.

Fluid from the regulator passes through the manual valve to the various control valves.

Shift Control Mechanism

Input to the TCM from various sensors located throughout the car determines which shift control solenoid valve should

be activated. Activating a shitt control solenoid valve changes modulator pressure, causing a shift valve to move. This

pressurizes a line to one ol the clutches, engaging that clutch and its corresponding gear.

Lock-uD Mechanism

In @ position, in 2nd, 3rd and 4th, and @ position in 3rd, pressurized fluid can be drained lrom the back oI the tor-

que converter through a fluid passage, causing the lock-up piston to be held against the torque converter cover. As this

takes place, the mainshaft rotates at the same speed as the engine crankshaft. Together with hydraulic control, the TCM

optimizes the timing of the lock-up mechanism.

The lock-up valves controlthe range of lock-up according to lock-up control solenoid valves A and B, and throttle valve B.

When lock-up control solenoid valves A and B activate, modulator pressure changes. Lock-up control solenoid valves

A and B are mounted on the torque converter housing, and are controlled by the TCM.

(cont'd)