HONDA INTEGRA 1998 4.G Workshop Manual

INTEGRA 1998 4.G

HONDA

HONDA

https://www.carmanualsonline.info/img/13/6069/w960_6069-0.png

HONDA INTEGRA 1998 4.G Workshop Manual

Trending: compression ratio, Door lock repair, height, Cylinder, fuse box diagram, radiator cap, OBD port

Page 381 of 1681

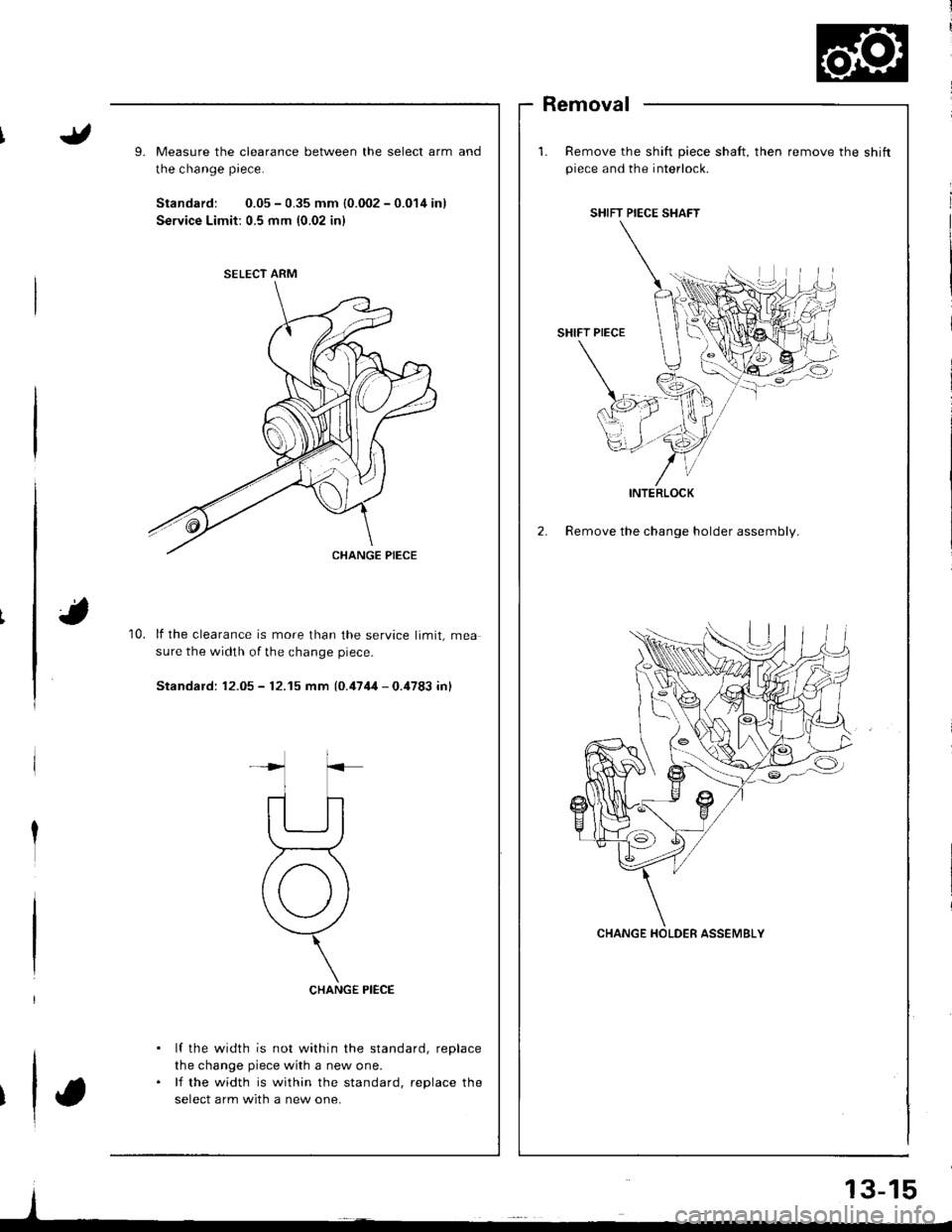

9.Measure the clearance between the select arm

the change piece.

Standard: 0.05 - 0.35 mm {0.002 - 0.014 in)

Service Limit: 0.5 mm {0.02 inl

Removal

Remove the shift piece shaft, then remove the shiftpiece and the interlock.

2. Remove the change holder assembly.

and

10.lf the clearance is more than the service limit, mea

sure the width of the change piece-

Standard: 12.05 - 12.15 mm {0.4744 - 0.4783 inl

CHANGE PIECE

lf the width is not within the standard, replace

the change piece with a new one.

lf the width is within the standard, replace the

select arm with a new one.

SELECT ARM

SHIFT PIECE SHAFT

INTERLOCK

Page 382 of 1681

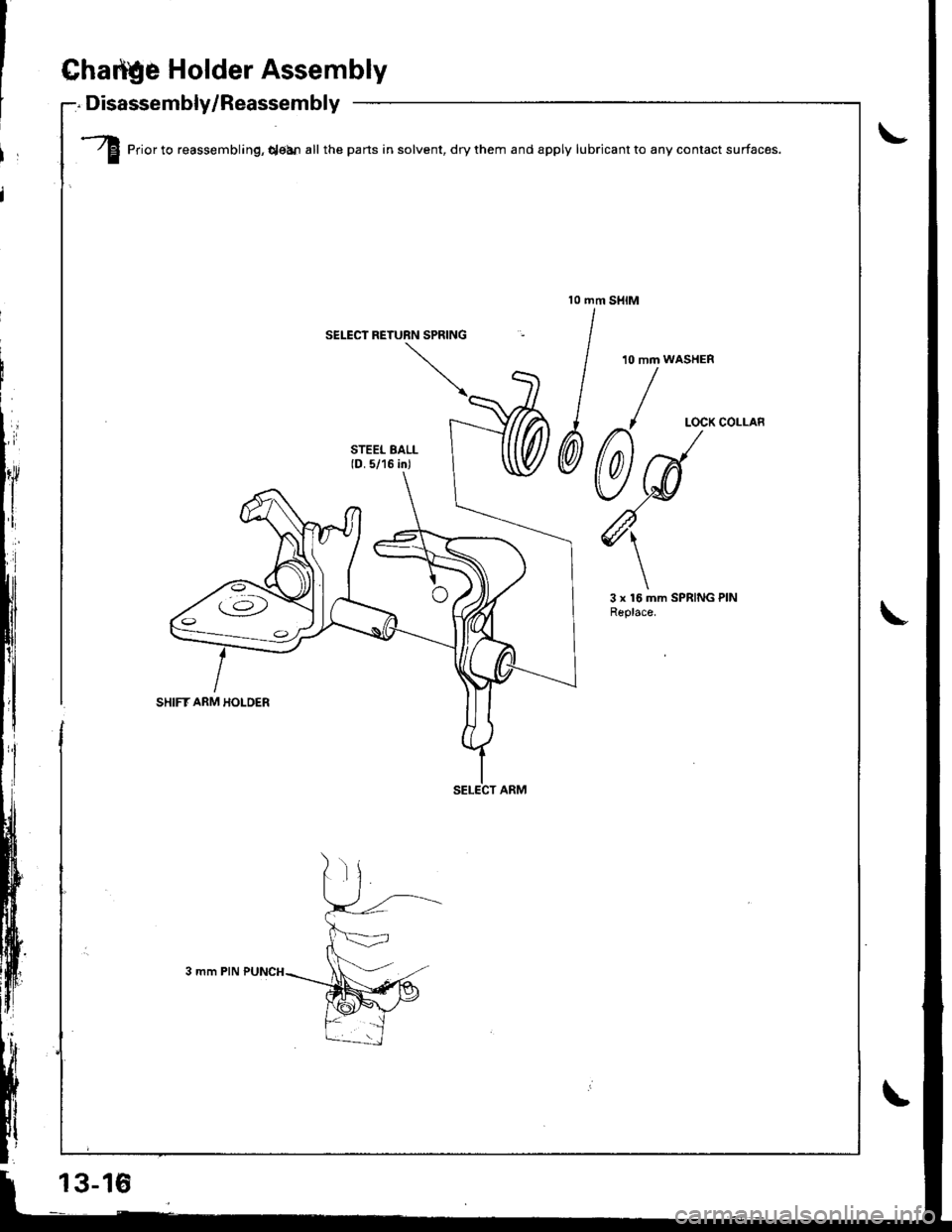

Ghattle Holder Assembly

Disassembly/Reassembly-:. Lrrl'al':'Err|rrry, nscs':'srrrrrry -

.---..rt/ El Prior to reassembling, qean all the parts in solvent, dry them and apply lubricant to any contact surfaces.f-

SELECT RETUBN SPRING

13-16

Page 383 of 1681

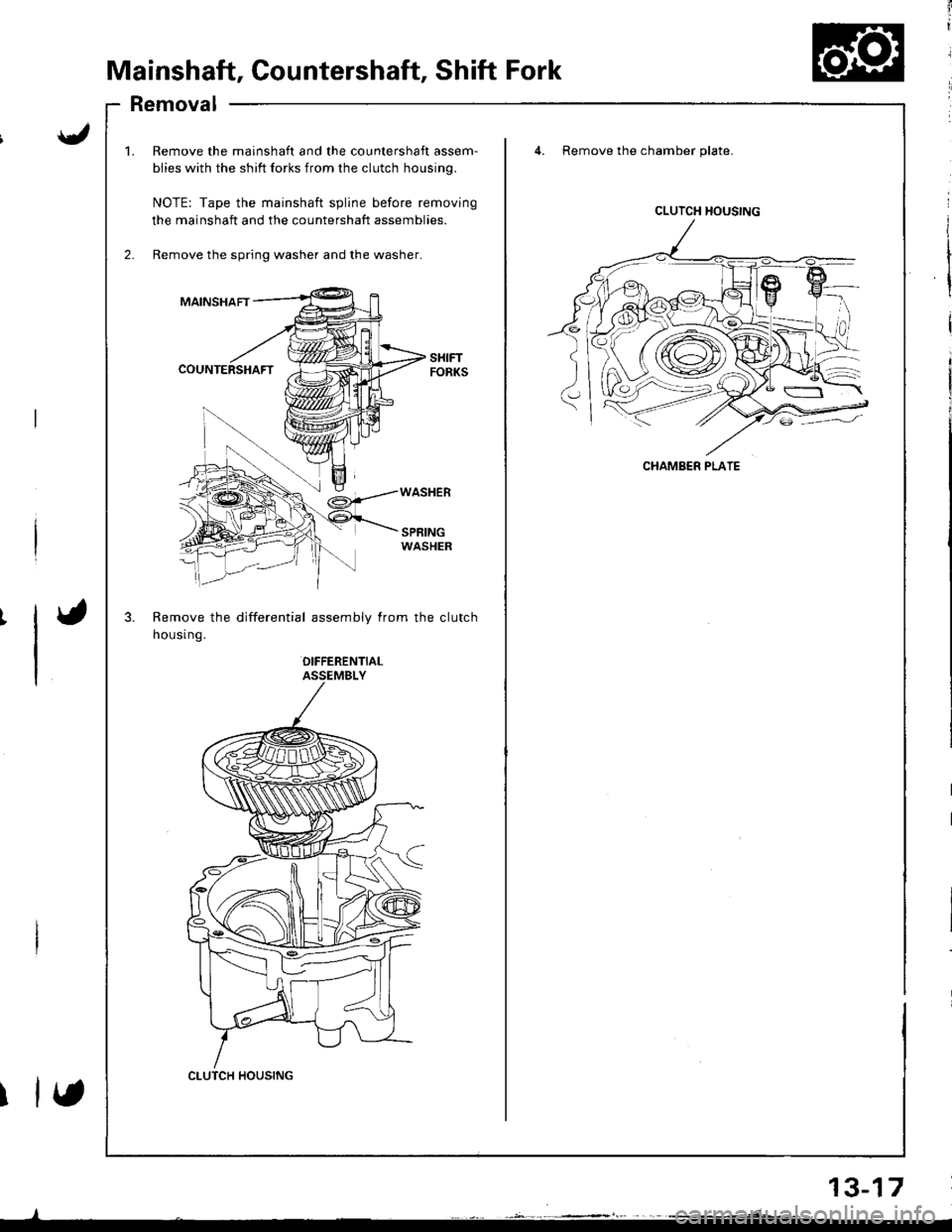

Mainshaft, Countershaft, Shift Fork

Removal

mainshaft and the countershaft assem-

? shift forks from the clutch housing.

the mainshaft spline before removing

ft and the countershaft assemblies.

spring washer and the washer.

differential assembly from the clutch

OIFFERENTIALASSEMBLY

4. Remove the chamber plate.

SPRINGWASHER

1.Remove the m€

biies with the sl

NOTE: Tape th

the mainshaft a

Remove the spr

MAINSHAFT

COUNTERSHAFT

Remove the

housr ng.

CLUTCH HOUSING

CLUTCH HOUSING

CHAMBER PLATE

etsY')

2r}5

(\cyl,//_\::iv/.

13-17

Page 384 of 1681

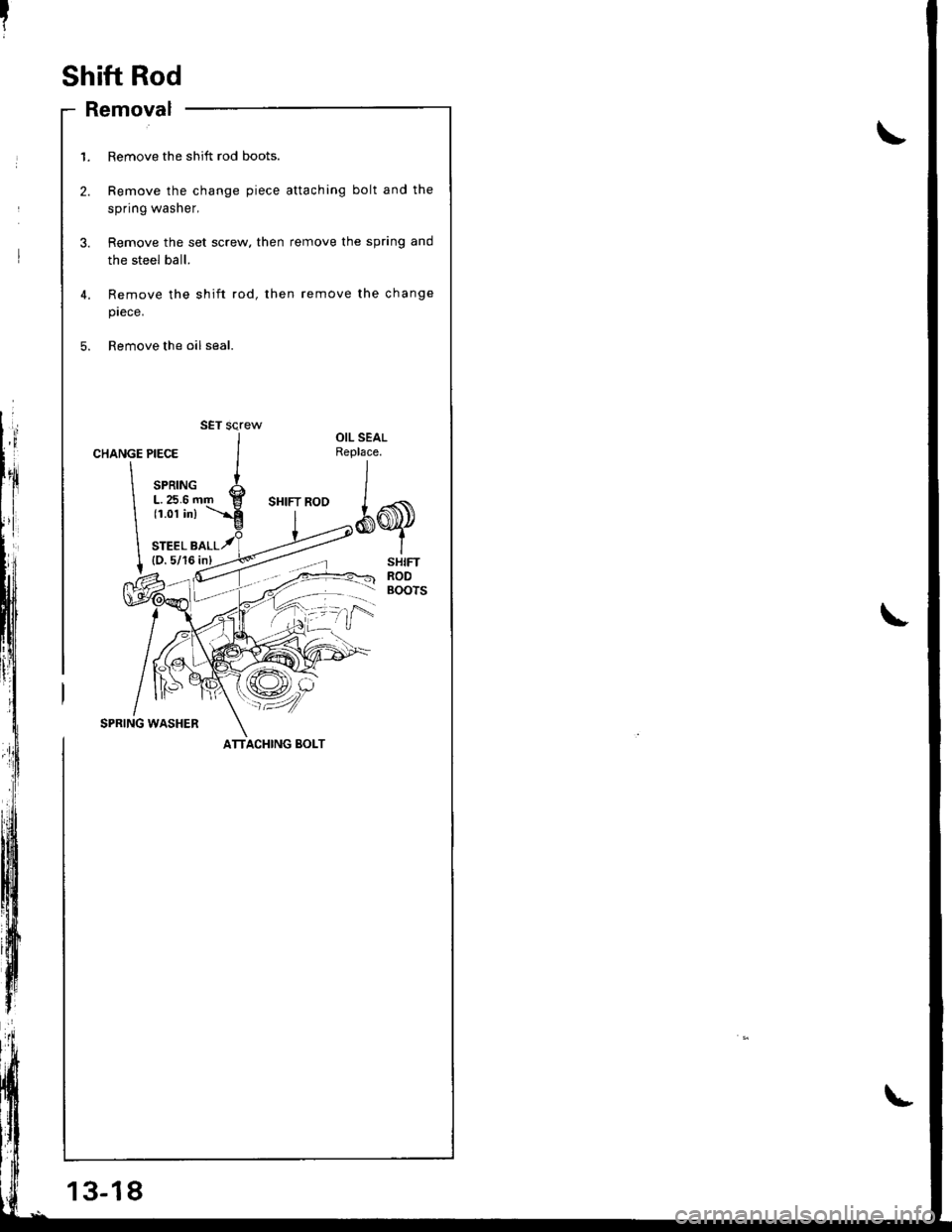

Shift Rod

- Removal

13-18

1. Remove the shift rod boots.

2. Remove the change piece attaching bolt and the

spring washer,

3. Remove the set screw. then remove the spring and

the steel ball.

4,

5.

Remove the shift rod, then remove the change

prece.

Remove the oil seal.

CHANGE

\

\

I

PIECE

SPRINGL.25.6 r(1.01 in)

STEEL B(D.5/16

OIL SEALReplace.

*q

SHIFTRODBOOTS

SPRING WASHER

SET screw

ATTACHING BOLT

Page 385 of 1681

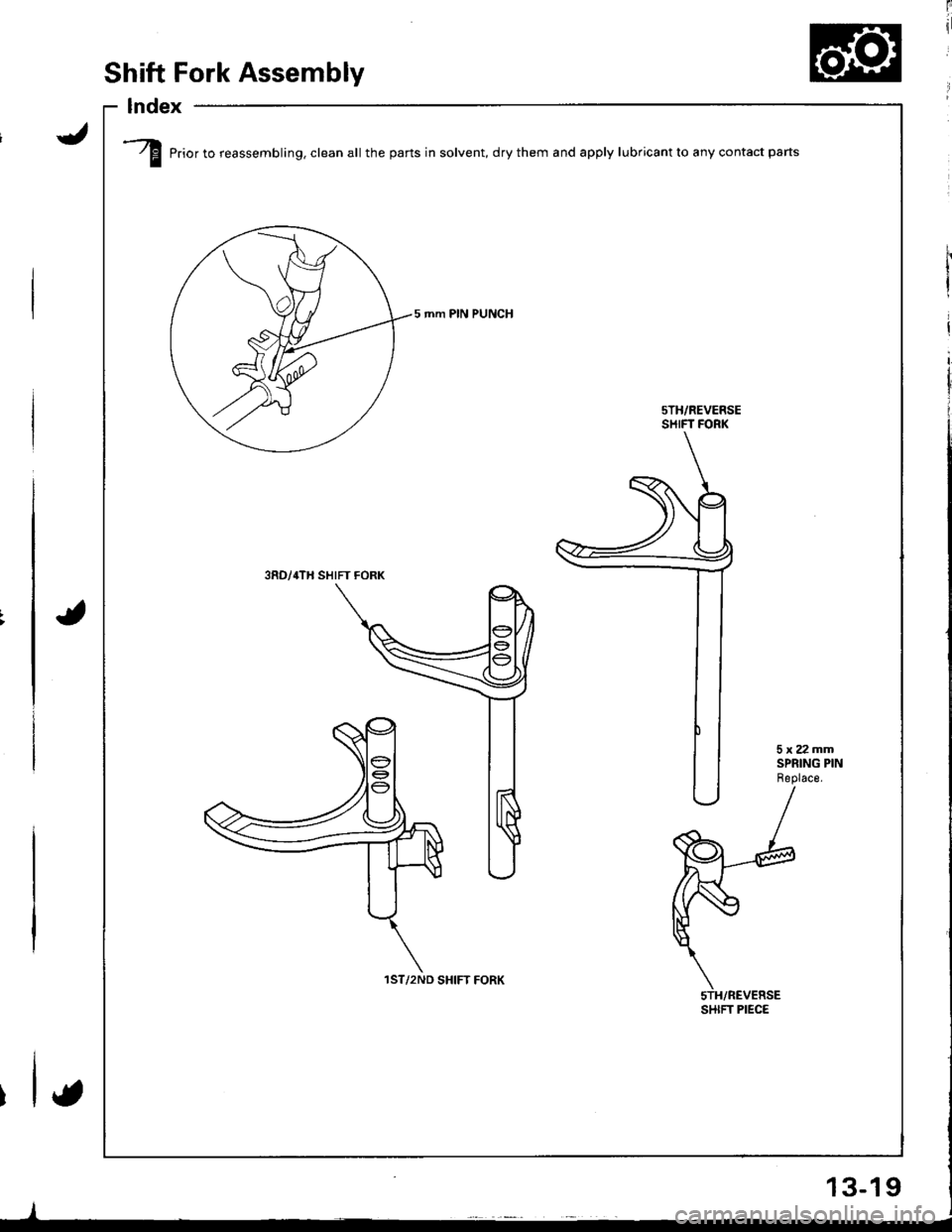

/f Prior to reassembling. clean all the parts in solvent, drythem and apply lubricantto any contact parts

5 mm PIN PUNCH

sTH/REVERSESHIFT FORK

3RD/,rTH SHIFT FORK

1ST/2ND SHIFT FORK

SHIFT PIEC€

Shift Fork Assembly

lndex

-/

lI

t

{

13-19

Page 386 of 1681

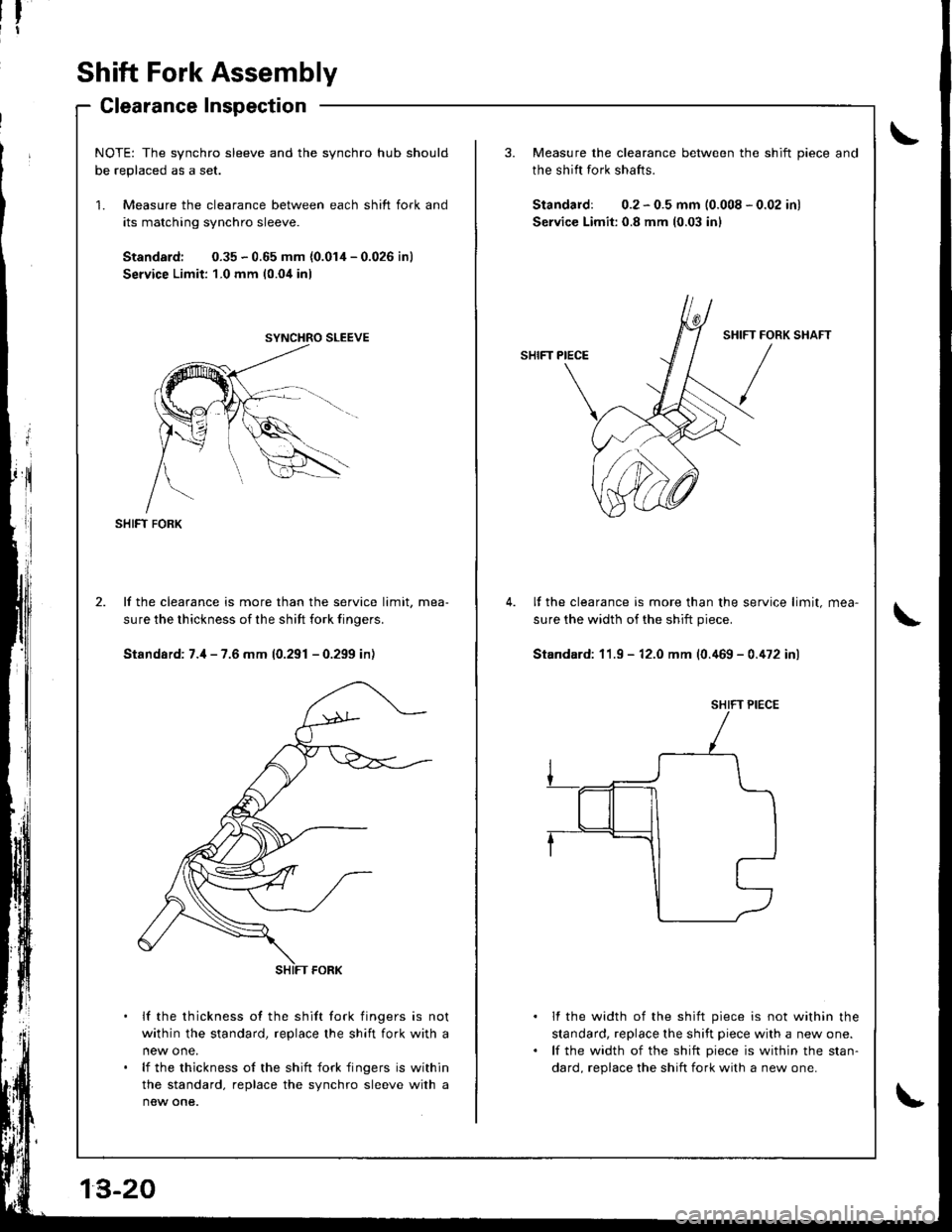

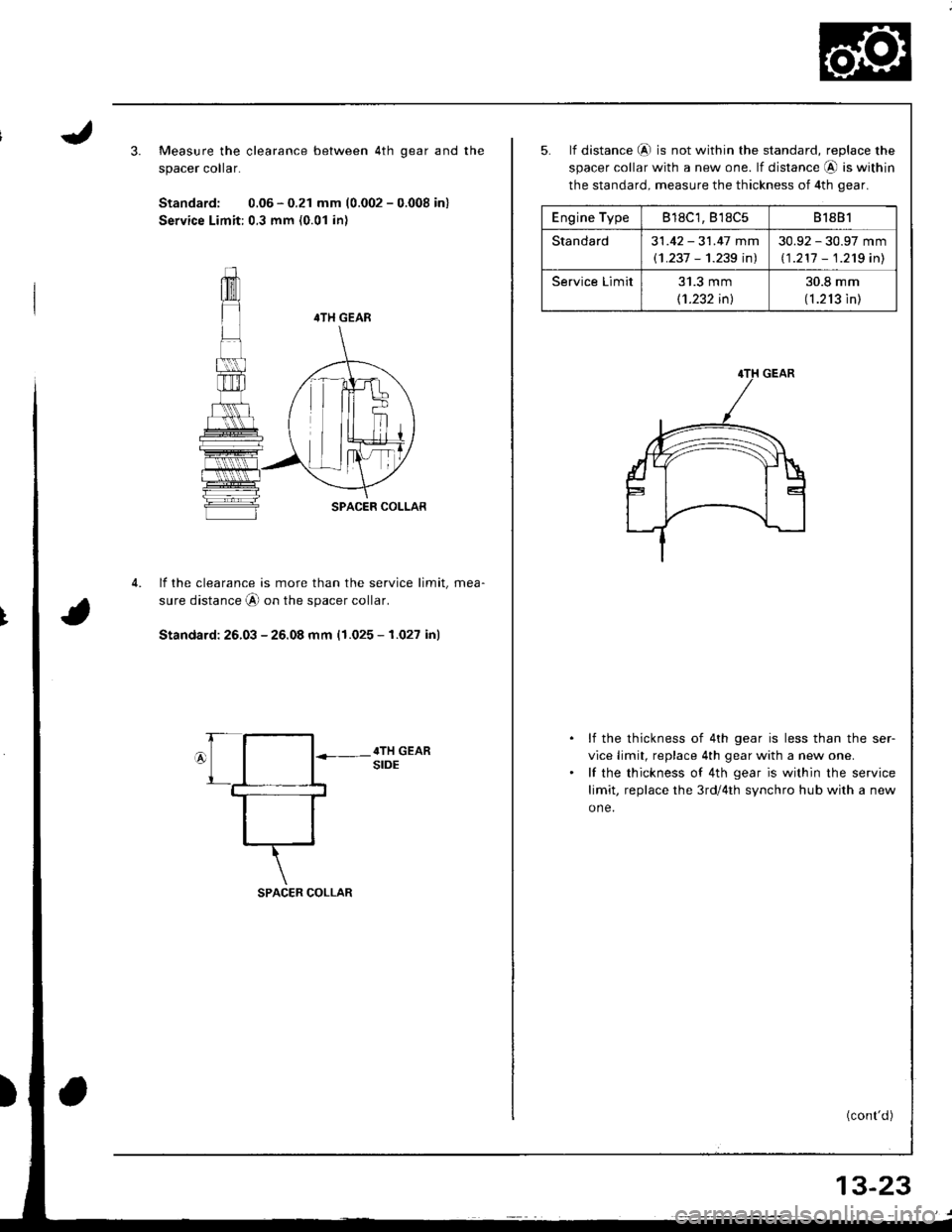

Shift Fork Assembly

Clearance Inspection

NOTE: The synchro sleeve and the synchro hub shouldh6 ronlr.o.l ,.. car

Measure the clearance between each shift fork and

its matching synchro sleeve.

Standard: 0.35 - 0.65 mm {0.014 - 0.026 inl

Service Limit: 1-0 mm 10.04 inl

SHIFT FORK

lf the clearance is more than the service limit, mea-

sure the thickness of the sh ift fork finoers.

Standard: 7.il - 7.6 mm (0.291 - 0.299 in)

lf the thickness of the shift fork fingers is not

within the standard, replace the shift fork with a

lf the thickness of the shift fork fingers is within

the standard, replace the synchro sleeve with a

new one.

3. Measure the clearance between the shift piece and

the shift fork shafts.

Standard: 0.2 - 0.5 mm (0.008 - 0.02 inl

Service Limit: 0.8 mm (0.03 inl

SHIFT PIECE

It the clearance is more than the service limit,

sure the width of the shift piece.

Standard: 11.9 - 12.0 mm (0.a69 - 0.a72 inl

lf the width of the shift piece is not within the

standard, replace lhe shift piece with a new one.

lf the width of the shift piece is within the stan-

dard. reolace the shift fork with a new one.

IFT FORK

/

SHIFT PIECE

Page 387 of 1681

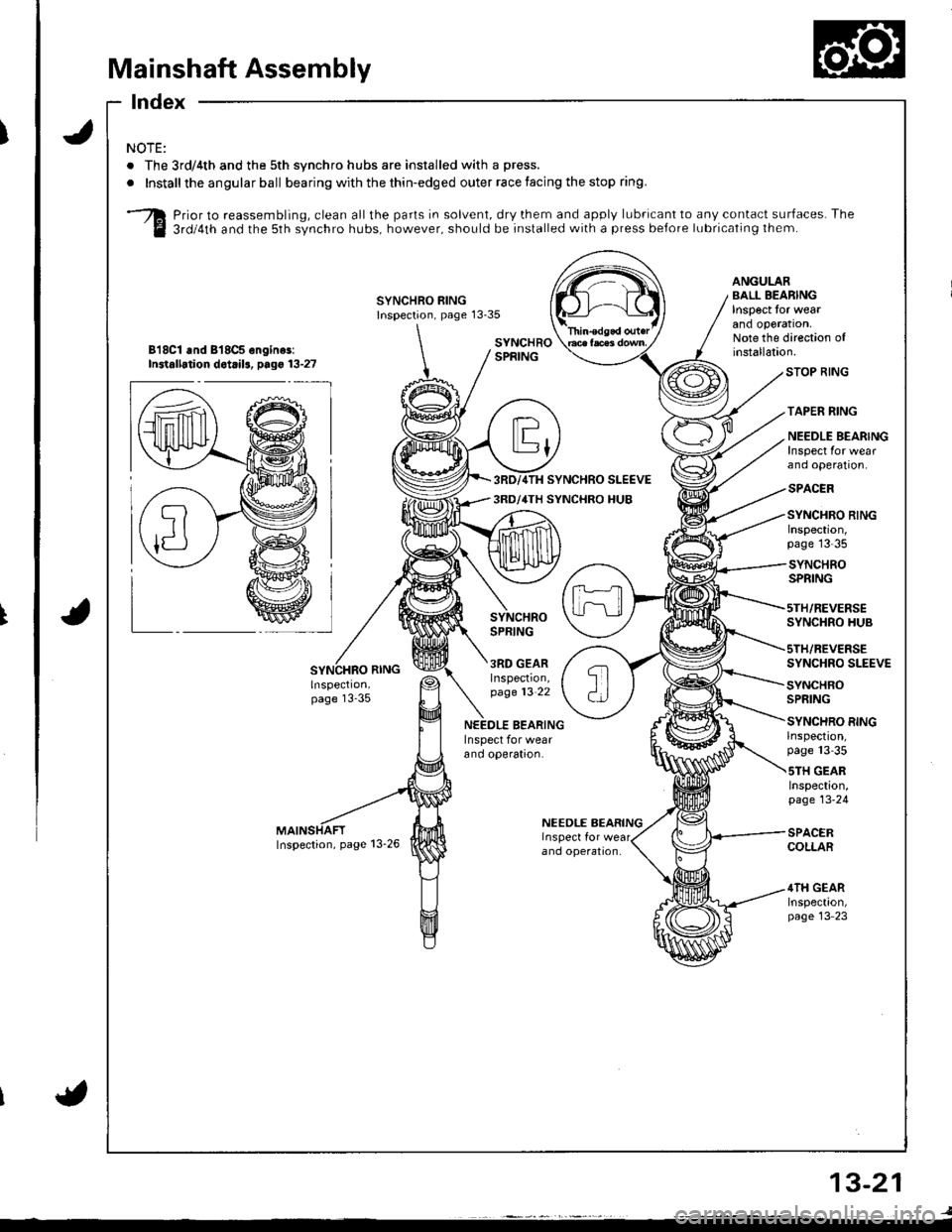

Mainshaft Assembly

lndex

J

t

NOTE:

. The 3rd/4th and the 5th synchro hubs are installed with a press.

.Installtheangularball bearing with the thin-edged outer race facing the stop ring.

Prior to reassembling, clean all the parts in solvent, dry them and apply lubricant to any contact surfaces. The

3rdl4th and the 5th synchro hubs, however, should be installed with a press before lubricating lhem.

SYNCHRO RINGInspection, page 13-35

ANGULARBALL BEARINGInspect tor weatano oporaron,Note the direction ofinstallation.818C1 .nd 818CS ongin$:In3tallation dot ils, p.go 13-27

I

LSYNCHROSPRING

3RD GEARInspection,page 13-22

STOP RING

TAPEN RING

NEEDLE BEARINGInspect for wearano operaton,

SPACER

SYNCHRO RINGInspecton,page'13-35

SYNCHROSPRING

5TH/REVERSESYNCHRO HUB

sTH/REVEBSESYNCHRO SLEEVE

SYNCHROSPRING

SYNCHRO RINGrnspect|on,page 13-35

sTH GEARInspection,page 13-24

SPACERCOLLAR

4TH GEARInspect|on,page 13-23

BEARINGInspect for wearano operaaron.

NEEOLE BEARING

ano operal|on.

{

13-21

Page 388 of 1681

|'I

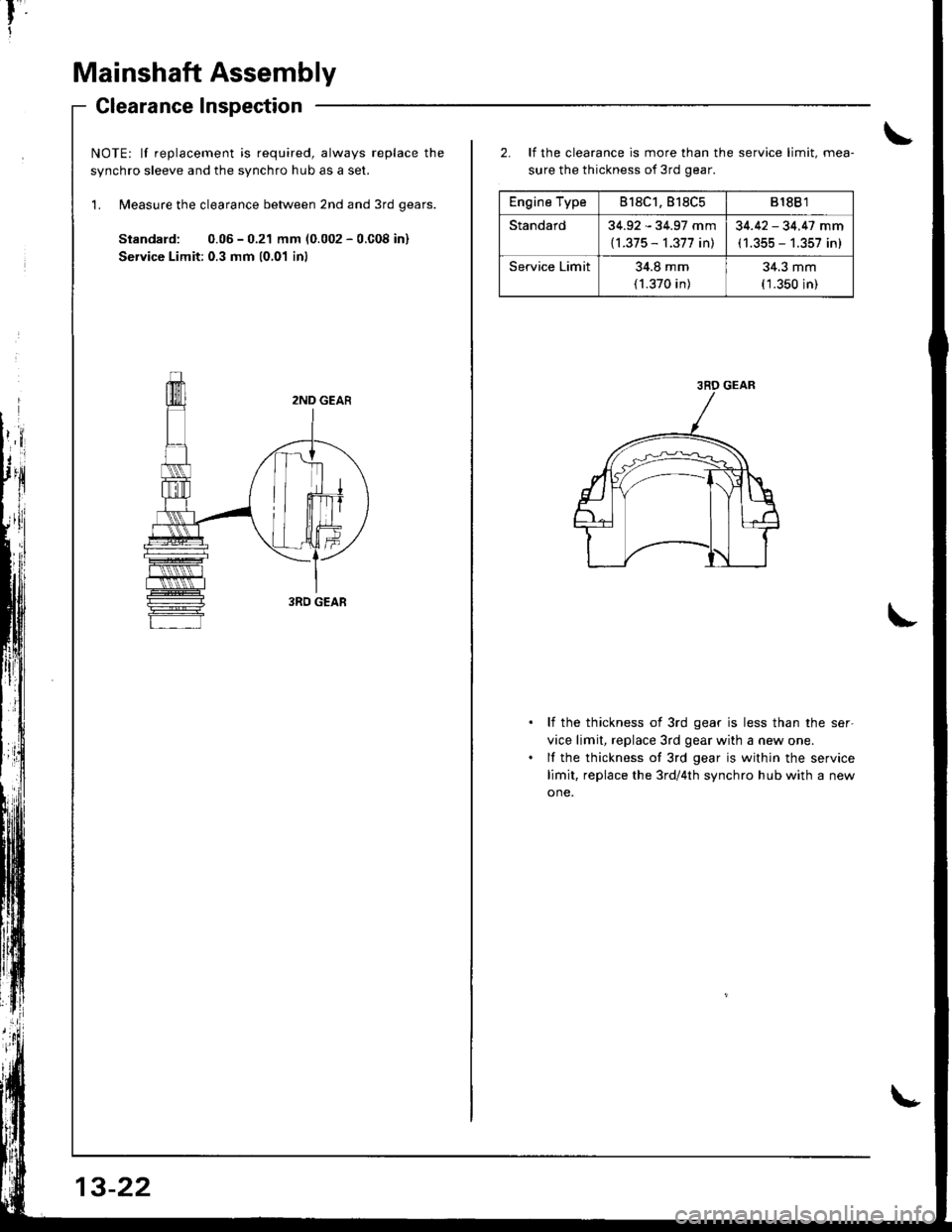

Mainshaft Assembly

Glearance Inspection

NOTE: lf replacement is required, always replace the

svnchro sleeve and the svnchro hub as a set.

'L Measure the clearance between 2nd and 3rd qears.

Standard: 0.05 - 0.21 mm (0.002 - 0.C08 in)

Service Limit: 0.3 mm 10,01 inl

13-22

Engine Type818C1.818C5818B 1

Standard34.92 - 34.97 mm

{l.375 - 1.377 in)

34.42 - 34.47 mm(1.355 - 1.357 in)

Service Limit34.8 mm

(1.370 in)

34.3 mm(1.350 in)

2. It the clearance is more than the service limit, mea-

sure the thickness of 3rd gear.

li the thickness of 3rd gear is less than the ser-

vice limit, replace 3rd gear with a new one.

lf the thickness of 3rd gear is within the service

limit, replace the 3rd/4th synchro hub with a new

one.

3RD GEAR

Page 389 of 1681

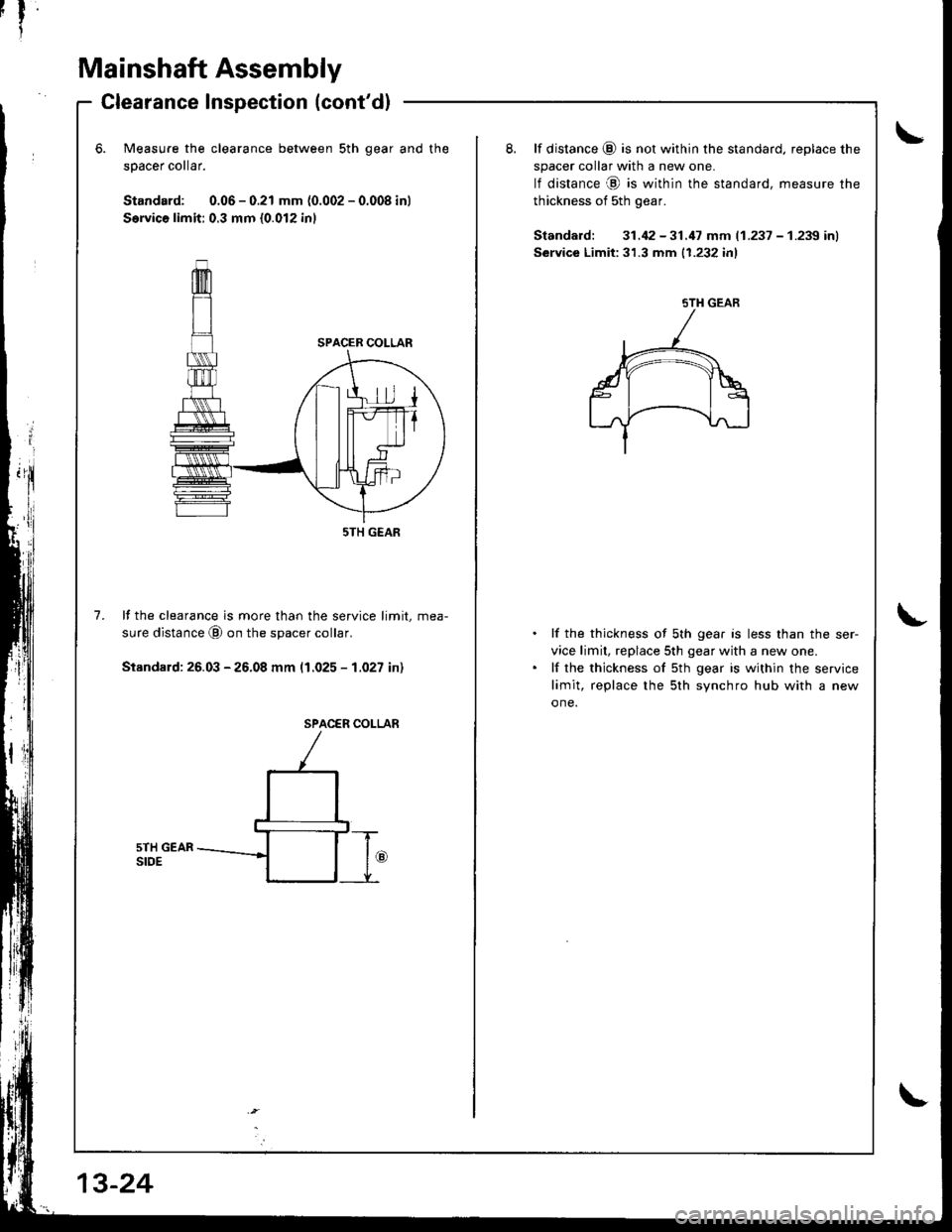

4.

Measure the clearance between 4th qear and the

spacer colar.

Standard: 0.06 - 0.21 mm (0.002 - 0.008 in)

Service Limit:0.3 mm (0.01 in)

4TH GEAR

SPACER COLLAR

lf the clearance is more than the service limit, mea-

sure distance A on the spacer collar.

Standard: 26.03 - 25.08 mm (1.025 - 1.027 in)

SPACER COLLAR

Engine Type818C1, B'�l8C581881

Standard31 .42 - 31.47 mm

(1 .237 - 1.239 inl

30.92 - 30.97 mm

11 .211 - 1.2'tg inl

Service Limit31.3 mm

11.232 inl

30.8 mm

(1.213 in)

5. lf distance @ is not within the standard, replace the

spacer collar with a new one. lf distance @ is within

the standard, measure the thickness of 4th gear.

lf the thickness of 4th gear is less than the ser-

vice limit, replace 4th gear with a new one.

lf the thickness of 4th gear is within the service

limit, replace the 3rd/4th synchro hub with a new

one.

(cont'd)

13-23

Page 390 of 1681

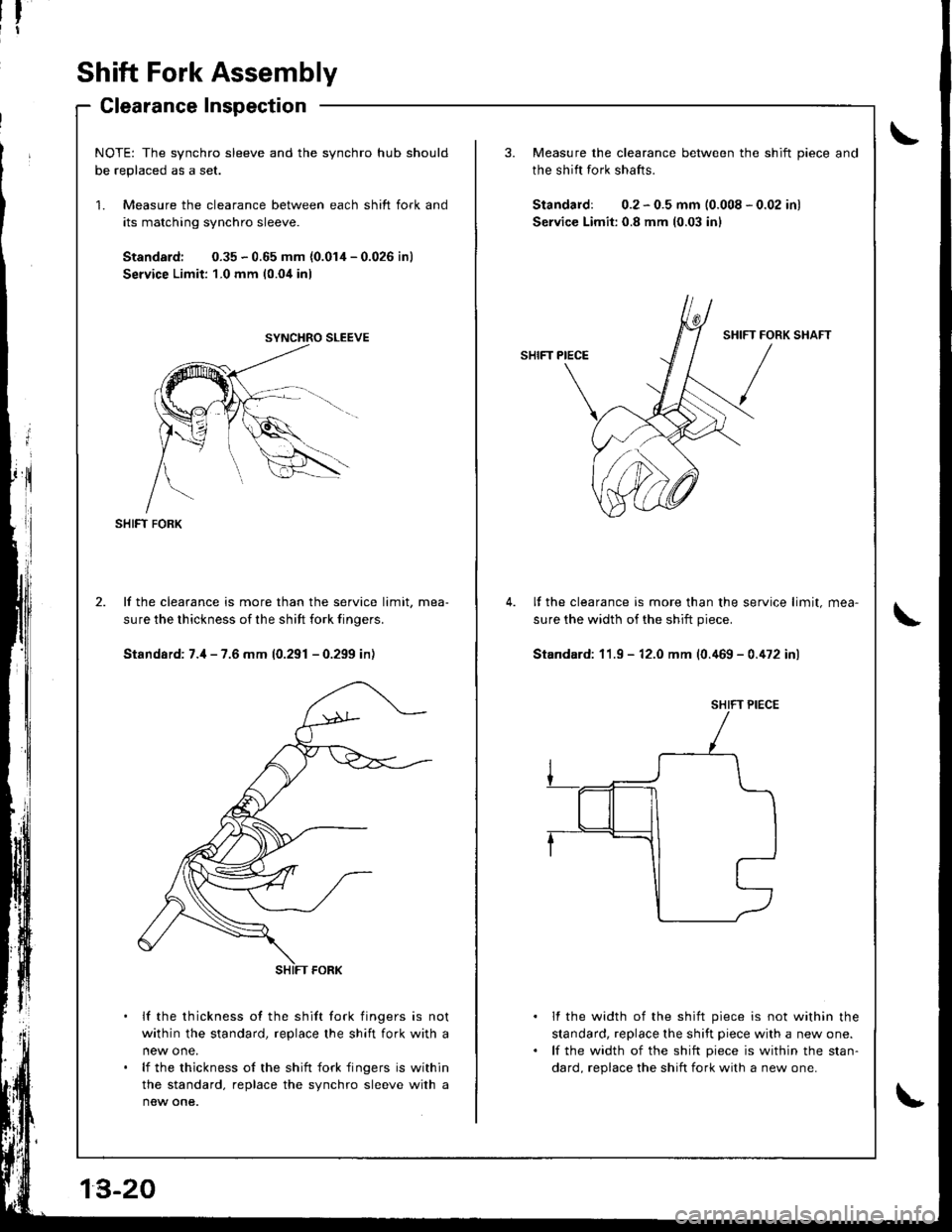

Mainshaft Assembly

Clearance Inspection (cont'dl

Measure the clearance between sth qear and

50acer collar.

Standard: 0.06 - 0.21 mm (0.002 - 0.008 in)

S€rvica limit: 0.3 mm {0.012 inl

the8. lf distance (9 is not within the standard, replace the

spacer collar with a new one.

lf distance @ is within the standard, measure the

thickness of sth gear.

Standard: 31.42 -31.17 mm (1.237 - 1.239 inl

Service Limit:31.3 mm {1.232 inl

7.lf the clearance is more than the service limit, mea-

sure distance @ on the spacer collar.

Stsndard: 26.03 - 26.08 mm (1.025 - 1.027 in)

lf the thickness of sth gear is less than the ser-

vice limit, replace 5th gear with a new one.

lf the thickness of sth gear is within the service

limit, replace the 5th svnchro hub with a new

one.

SPACER COI-LAR

sTH GEAR

5TH GEAR

Trending: audio, 18-8, radio, bulb, automatic transmission fluid, headlight bulb, check oil