ISUZU KB P190 2007 Workshop Repair Manual

Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 2561 of 6020

Engine Mechanical – V6 Page 6A1–82

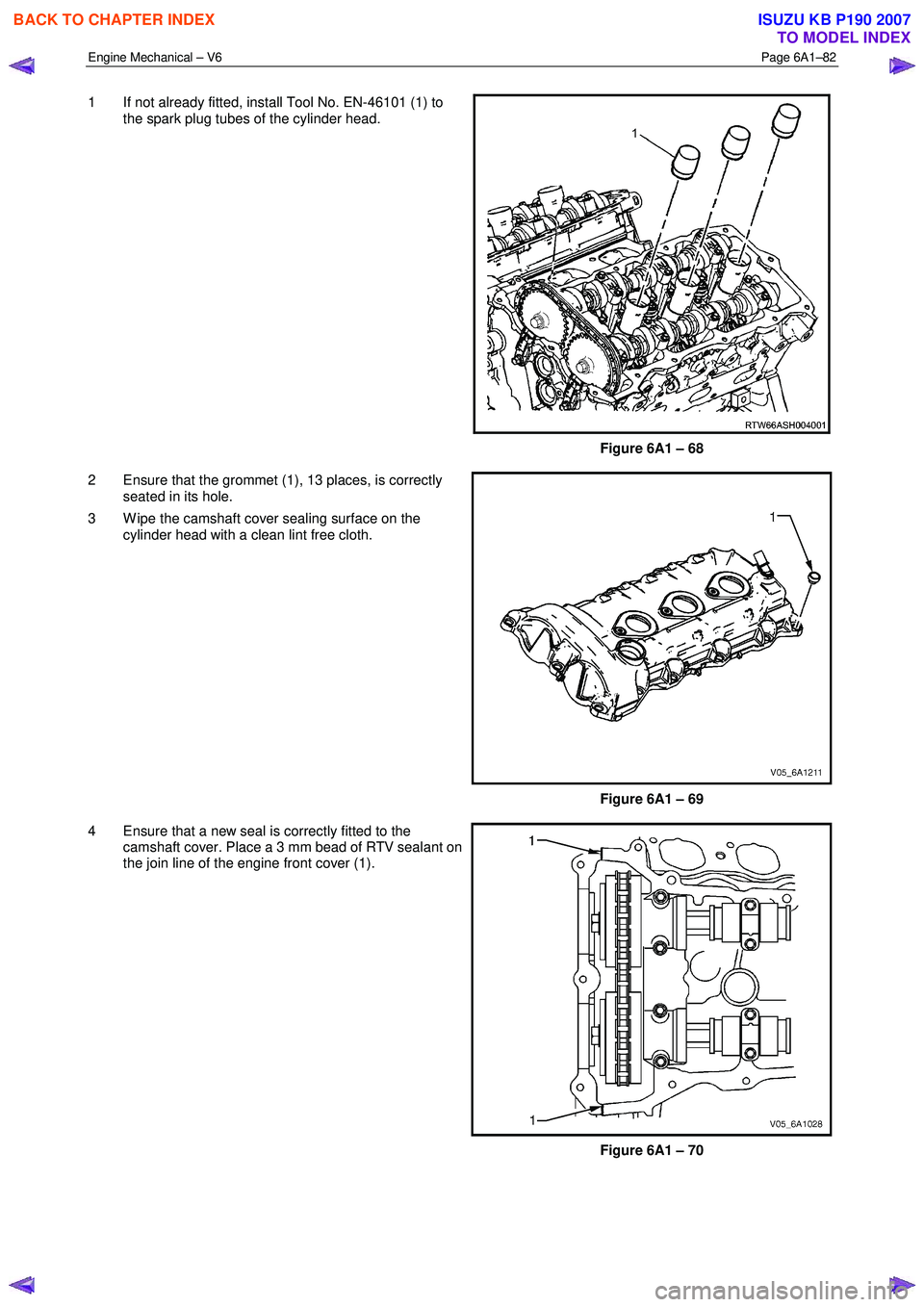

1 If not already fitted, install Tool No. EN-46101 (1) to

the spark plug tubes of the cylinder head.

Figure 6A1 – 68

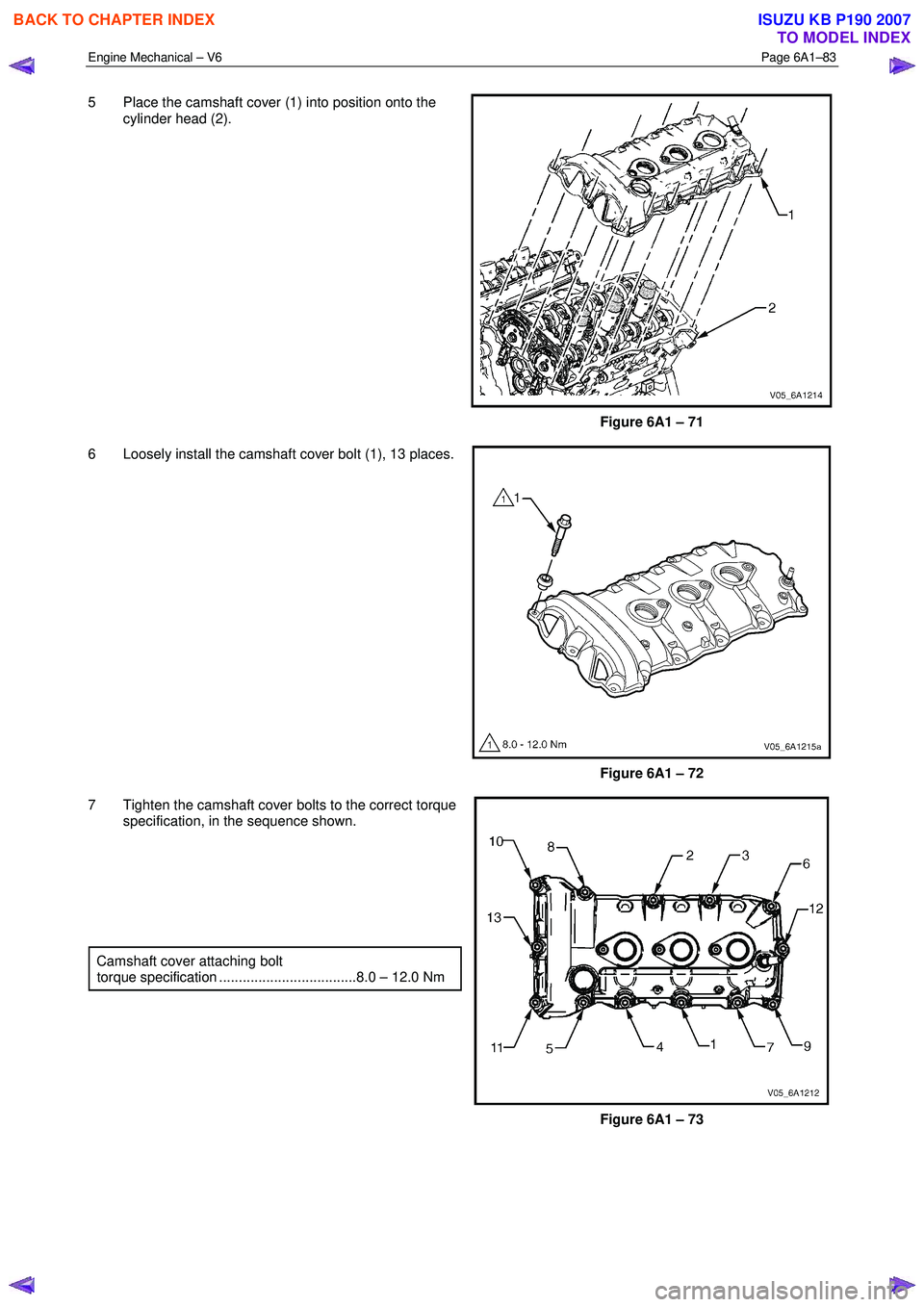

2 Ensure that the grommet (1), 13 places, is correctly seated in its hole.

3 W ipe the camshaft cover sealing surface on the cylinder head with a clean lint free cloth.

Figure 6A1 – 69

4 Ensure that a new seal is correctly fitted to the camshaft cover. Place a 3 mm bead of RTV sealant on

the join line of the engine front cover (1).

Figure 6A1 – 70

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2562 of 6020

Engine Mechanical – V6 Page 6A1–83

5 Place the camshaft cover (1) into position onto the

cylinder head (2).

Figure 6A1 – 71

6 Loosely install the camshaft cover bolt (1), 13 places.

Figure 6A1 – 72

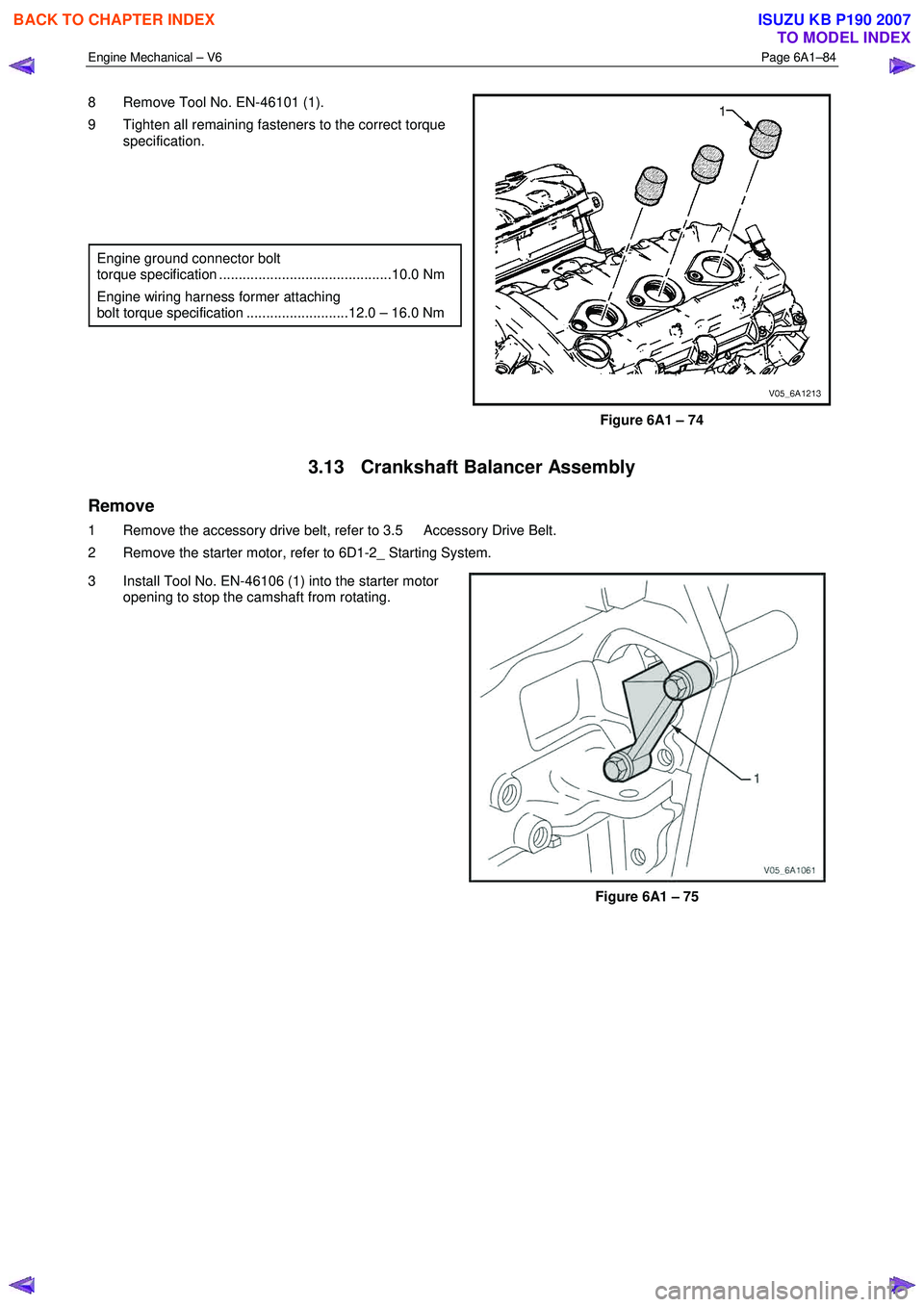

7 Tighten the camshaft cover bolts to the correct torque specification, in the sequence shown.

Camshaft cover attaching bolt

torque specification ...................................8.0 – 12.0 Nm

Figure 6A1 – 73

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2563 of 6020

Engine Mechanical – V6 Page 6A1–84

8 Remove Tool No. EN-46101 (1).

9 Tighten all remaining fasteners to the correct torque specification.

Engine ground connector bolt

torque specification ............................................10.0 Nm

Engine wiring harness former attaching

bolt torque specification ..........................12.0 – 16.0 Nm

Figure 6A1 – 74

3.13 Crankshaft Balancer Assembly

Remove

1 Remove the accessory drive belt, refer to 3.5 Accessory Drive Belt.

2 Remove the starter motor, refer to 6D1-2_ Starting System.

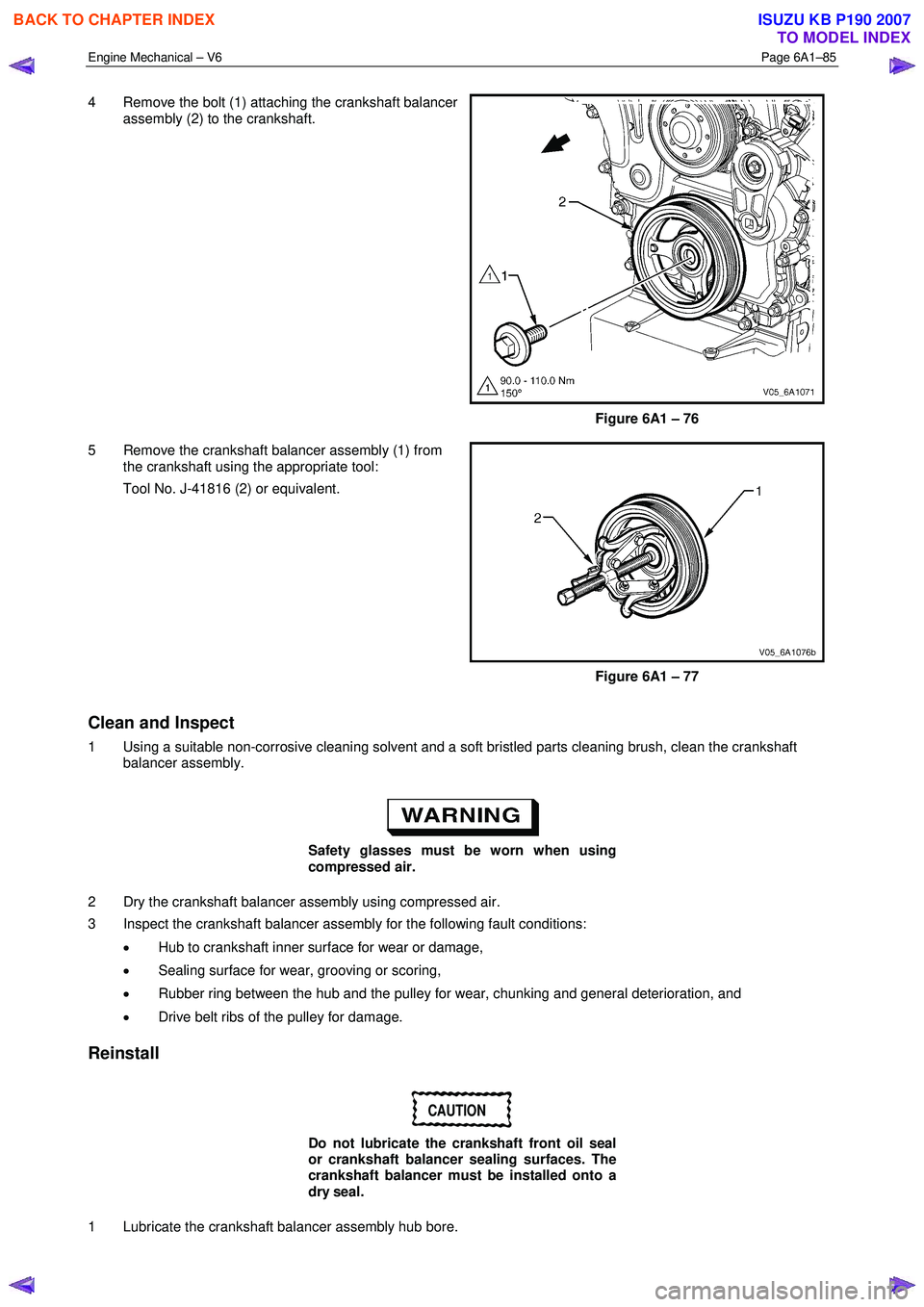

3 Install Tool No. EN-46106 (1) into the starter motor opening to stop the camshaft from rotating.

Figure 6A1 – 75

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2564 of 6020

Engine Mechanical – V6 Page 6A1–85

4 Remove the bolt (1) attaching the crankshaft balancer

assembly (2) to the crankshaft.

Figure 6A1 – 76

5 Remove the crankshaft balancer assembly (1) from the crankshaft using the appropriate tool:

Tool No. J-41816 (2) or equivalent.

Figure 6A1 – 77

Clean and Inspect

1 Using a suitable non-corrosive cleaning solvent and a soft bristled parts cleaning brush, clean the crankshaft balancer assembly.

Safety glasses must be worn when using

compressed air.

2 Dry the crankshaft balancer assembly using compressed air.

3 Inspect the crankshaft balancer assembly for the following fault conditions:

• Hub to crankshaft inner surface for wear or damage,

• Sealing surface for wear, grooving or scoring,

• Rubber ring between the hub and the pulley for wear, chunking and general deterioration, and

• Drive belt ribs of the pulley for damage.

Reinstall

CAUTION

Do not lubricate the crankshaft front oil seal

or crankshaft balancer sealing surfaces. The

crankshaft balancer must be installed onto a

dry seal.

1 Lubricate the crankshaft balancer assembly hub bore.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2565 of 6020

Engine Mechanical – V6 Page 6A1–86

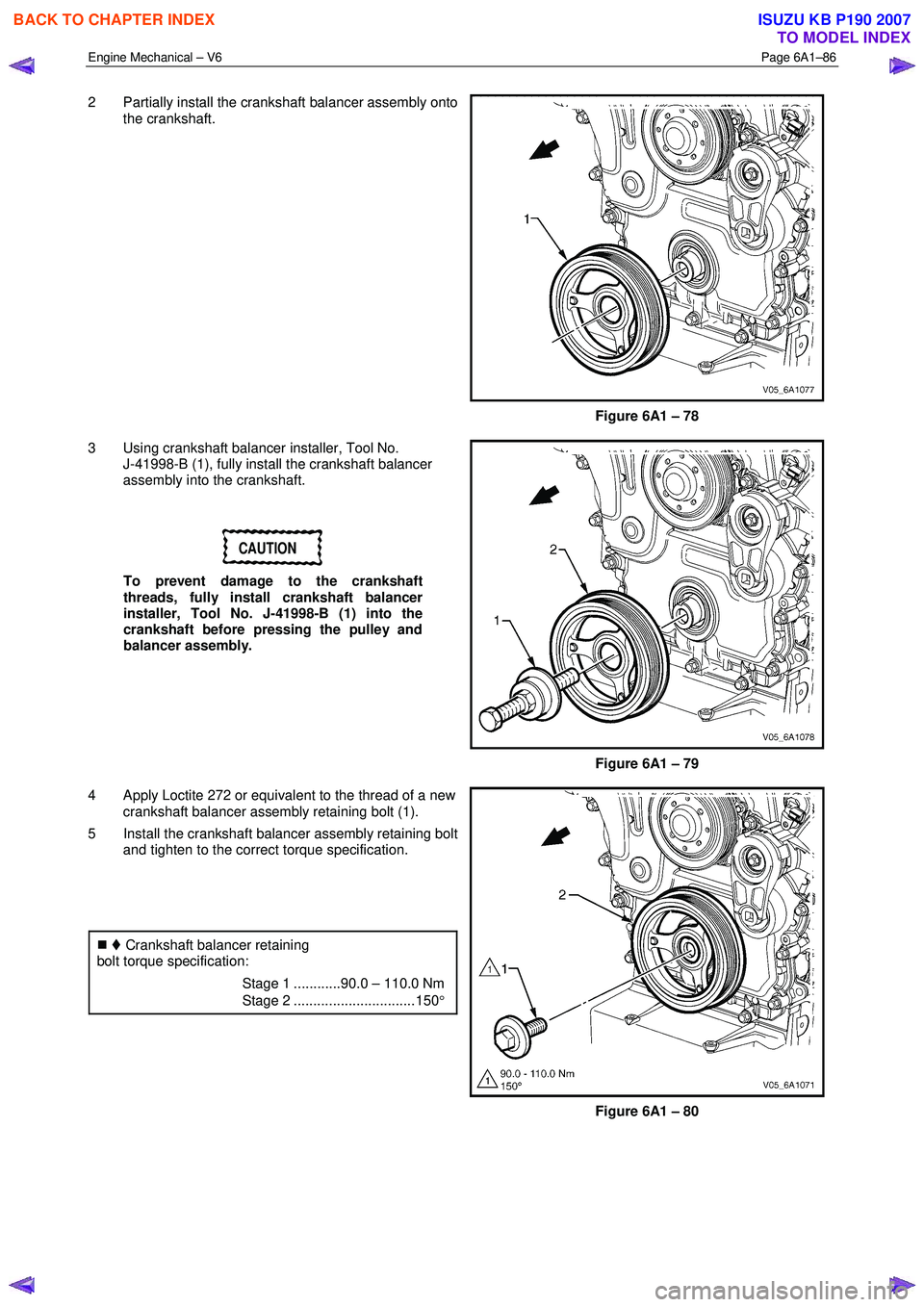

2 Partially install the crankshaft balancer assembly onto

the crankshaft.

Figure 6A1 – 78

3 Using crankshaft balancer installer, Tool No. J-41998-B (1), fully install the crankshaft balancer

assembly into the crankshaft.

CAUTION

To prevent damage to the crankshaft

threads, fully install crankshaft balancer

installer, Tool No. J-41998-B (1) into the

crankshaft before pressing the pulley and

balancer assembly.

Figure 6A1 – 79

4 Apply Loctite 272 or equivalent to the thread of a new crankshaft balancer assembly retaining bolt (1).

5 Install the crankshaft balancer assembly retaining bolt and tighten to the correct torque specification.

�„ Crankshaft balancer retaining

bolt torque specification:

Stage 1 ............90.0 – 110.0 Nm

Stage 2 ............................... 150°

Figure 6A1 – 80

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2566 of 6020

Engine Mechanical – V6 Page 6A1–87

3.14 Crankshaft Front Seal

Replace

1 Remove the crankshaft balancer assembly, refer to 3.13 Crankshaft Balancer Assembly.

2 Using a flat bladed tool (2) or seal remover, Tool No. E-308, carefully remove the crankshaft front seal (1)

from the front cover.

Figure 6A1 – 81

3 Using crankshaft front seal installer, Tool No. J-29184 (2) and a suitable hammer, install a new crankshaft

front seal (1) until fully seated against the front cover

housing.

4 Install the crankshaft balancer assembly, refer to 3.13 Crankshaft Balancer Assembly.

CAUTION

Do not lubricate the crankshaft front oil seal

or crankshaft balancer sealing surfaces. The

crankshaft balancer is installed into a dry

seal.

Figure 6A1 – 82

3.15 Front Cover Assembly

Remove

1 Drain the engine coolant, refer to 6B1_Engine Cooling.

2 Remove the water outlet pipe and coolant pump assembly, refer to 6B1_ Engine Cooling:

3 Remove the camshaft covers, refer to 3.12 Camshaft Cover.

4 Remove the crankshaft balancer assembly, refer to 3.13 Crankshaft Balancer Assembly.

5 Disconnect the purge vent hose from the water outlet pipe.

NOTE

Do not disconnect the power steering pipes or

drain the power steering fluid.

6 Remove the power steering pump reservoir mounting bracket, refer to 3.8 Power Steering Pump Bracket.

7 Remove the camshaft position sensor, refer to 6C1-3 Engine Management – V6 – Service Operations.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2567 of 6020

Engine Mechanical – V6 Page 6A1–88

NOTE

Do not disconnect the A/C compressor pipes.

8 Remove the bolt (2), 22 places, attaching the front cover assembly (1).

CAUTION

Only use the prise points and a bolt in the

jackscrew hole to remove the engine front

cover.

9 Loosely install a 10 x 1.5 mm bolt in the jackscrew hole (1).

10 Using the prise points (2) located at the edge of the front cover and the jackscrew, shear the RTV sealant.

Figure 6A1 – 83

Figure 6A1 – 84

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2568 of 6020

Engine Mechanical – V6 Page 6A1–89

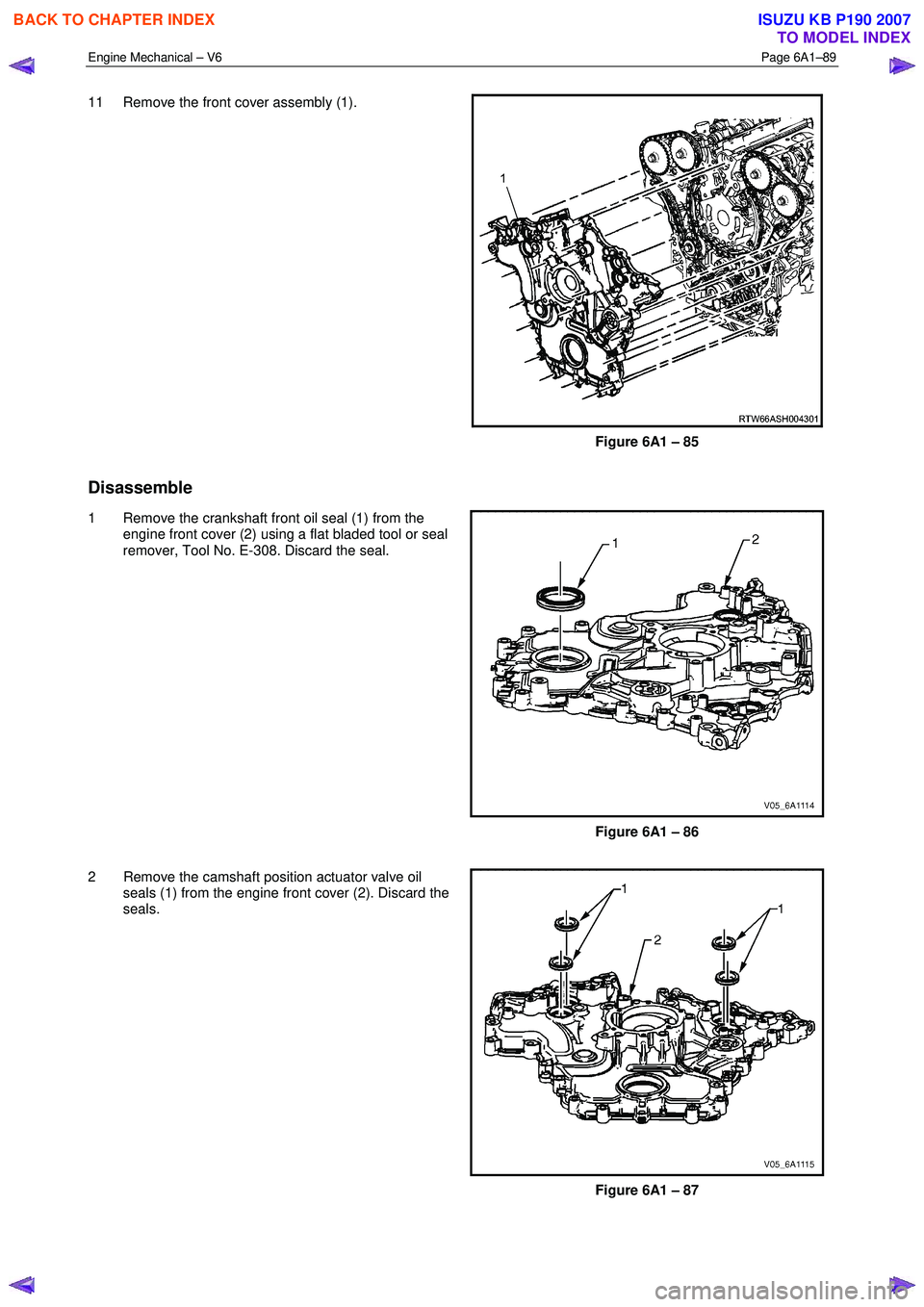

11 Remove the front cover assembly (1).

Figure 6A1 – 85

Disassemble

1 Remove the crankshaft front oil seal (1) from the

engine front cover (2) using a flat bladed tool or seal

remover, Tool No. E-308. Discard the seal.

Figure 6A1 – 86

2 Remove the camshaft position actuator valve oil seals (1) from the engine front cover (2). Discard the

seals.

Figure 6A1 – 87

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2569 of 6020

Engine Mechanical – V6 Page 6A1–90

3 Remove the coolant pump seal (1) from the engine

front cover (2). Discard the seal.

Figure 6A1 – 88

Clean

4 Remove any RTV sealant (1) from the engine front cover using a plastic or wood scraper.

CAUTION

• Insert a piece of cardboard between the

front of the oil pan and oil pump to

prevent any contaminants from falling

into the oil pan.

• Do not use a sharp or metal gasket

scraper to clean the sealing surfaces.

5 Clean out any debris from the bolt holes.

6 Clean the front cover with a suitable cleaning solvent.

7 Dry the front cover with compressed air.

Safety glasses must be worn when using

compressed air. Figure 6A1 – 89

8 Use compressed air to remove any engine coolant from the engine cooling passages and from the top of the oil pan oil deflector.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2570 of 6020

Engine Mechanical – V6 Page 6A1–91

Inspect

1 Inspect both sides of the engine front cover for the

following conditions:

• damage to the camshaft position actuator valve

oil seal bores (1),

• damage to the bolt holes (2),

• damage and/or corrosion to the engine coolant

passage (3),

• dents or damage to the exterior (4),

• damage to the crankshaft front oil seal bore (5),

• gouges or damage to the coolant pump sealing

surfaces (6), and

• damage to the coolant pump bolt hole

threads (7).

2 Repair or replace the front cover as required.

Figure 6A1 – 90

Reassemble

1 Install a new crankshaft front oil seal (1) into the front cover (2) using crankshaft front seal installer, Tool

No. J-29184 (3) and a suitable hammer.

CAUTION

Do not lubricate the crankshaft front oil seal

or crankshaft balancer sealing surfaces. The

crankshaft balancer is installed into a dry

seal.

Figure 6A1 – 91

2 Install a new camshaft position actuator valve oil seal (1) into the front cover (2) using Tool No. EN-46103

(3) and a suitable hammer.

Figure 6A1 – 92

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007