ISUZU KB P190 2007 Workshop Repair Manual

Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 2701 of 6020

Engine Mechanical – V6 Page 6A1–222

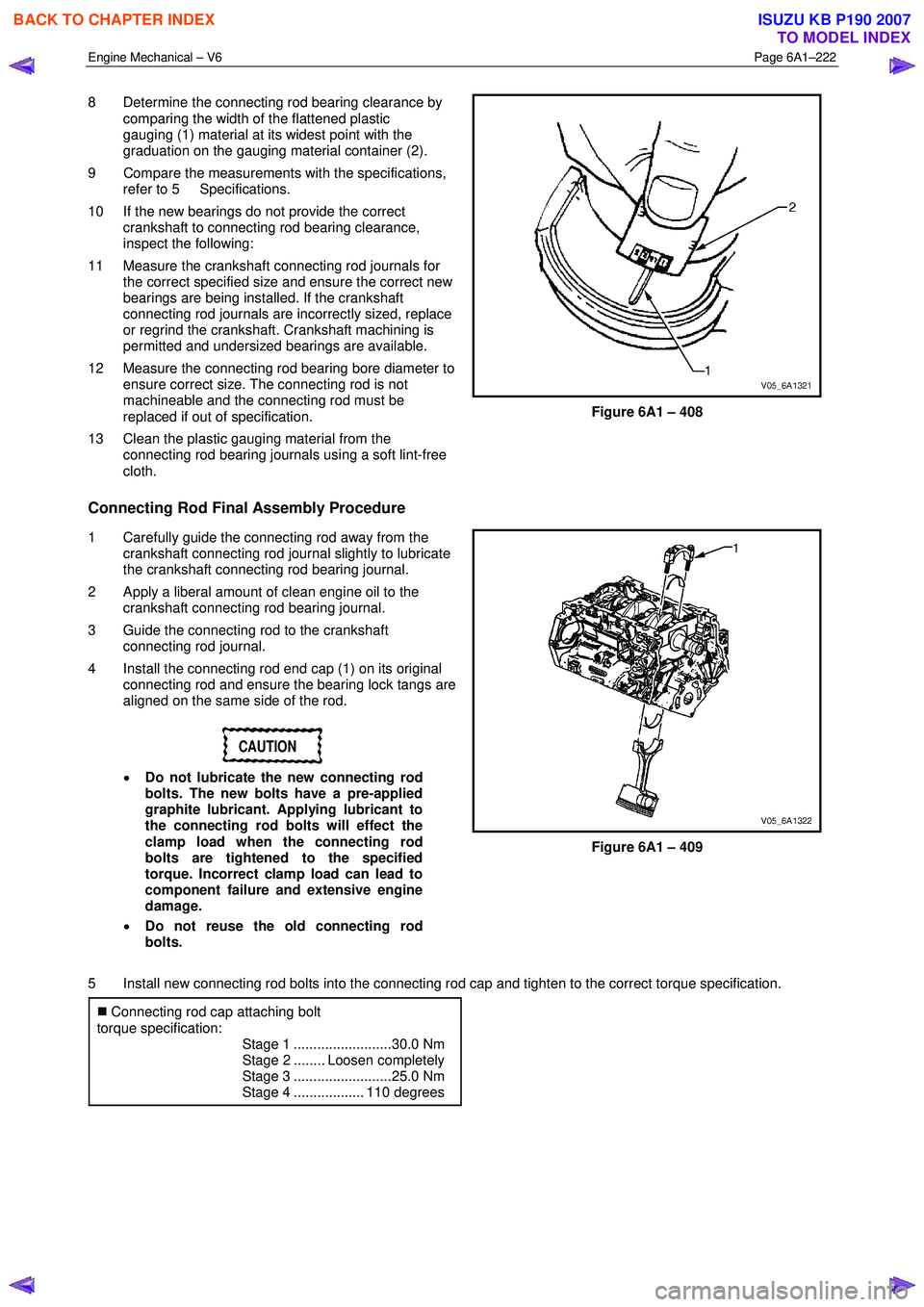

8 Determine the connecting rod bearing clearance by

comparing the width of the flattened plastic

gauging (1) material at its widest point with the

graduation on the gauging material container (2).

9 Compare the measurements with the specifications, refer to 5 Specifications.

10 If the new bearings do not provide the correct crankshaft to connecting rod bearing clearance,

inspect the following:

11 Measure the crankshaft connecting rod journals for the correct specified size and ensure the correct new

bearings are being installed. If the crankshaft

connecting rod journals are incorrectly sized, replace

or regrind the crankshaft. Crankshaft machining is

permitted and undersized bearings are available.

12 Measure the connecting rod bearing bore diameter to ensure correct size. The connecting rod is not

machineable and the connecting rod must be

replaced if out of specification.

13 Clean the plastic gauging material from the connecting rod bearing journals using a soft lint-free

cloth.

Figure 6A1 – 408

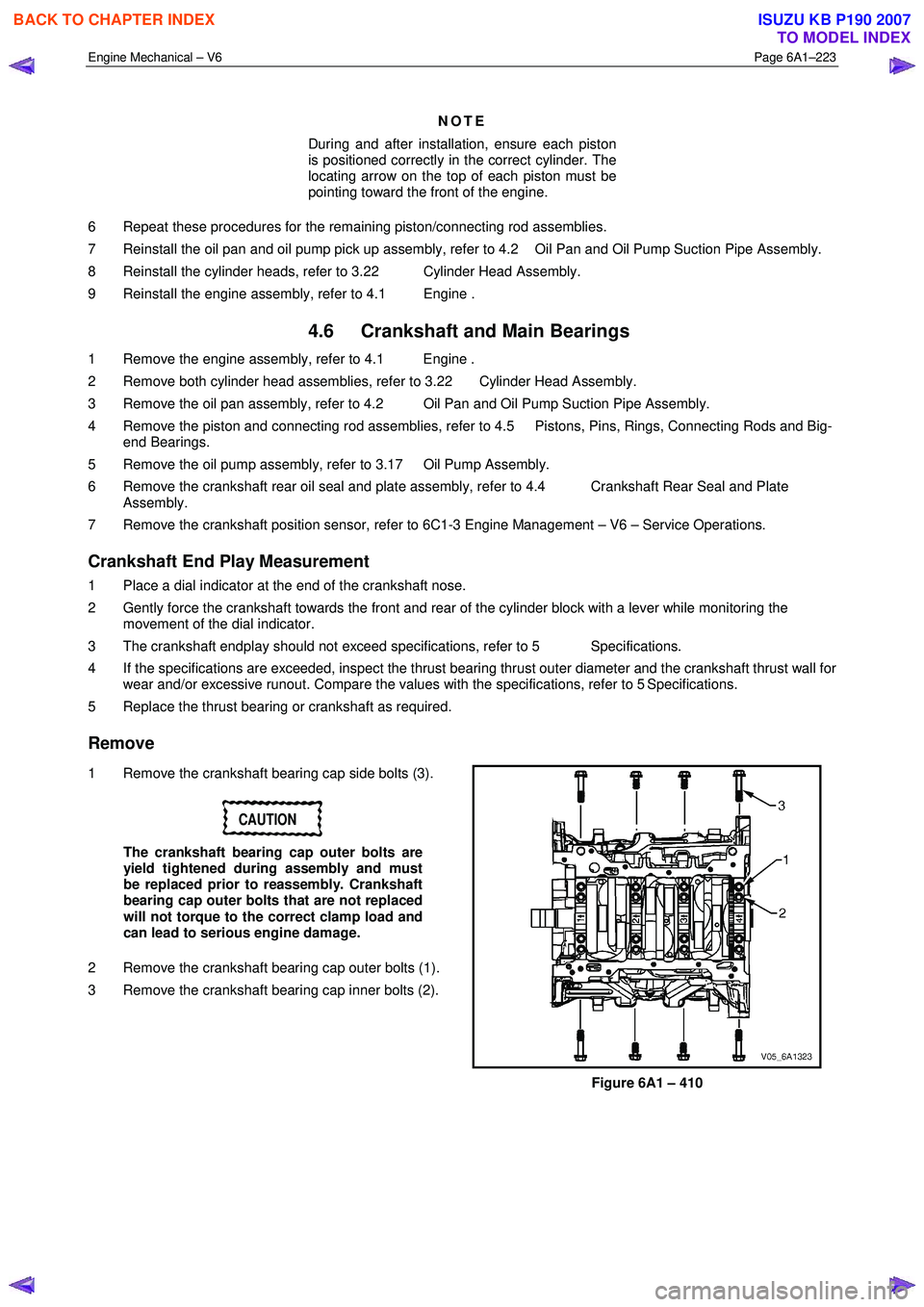

Connecting Rod Final Assembly Procedure

1 Carefully guide the connecting rod away from the crankshaft connecting rod journal slightly to lubricate

the crankshaft connecting rod bearing journal.

2 Apply a liberal amount of clean engine oil to the crankshaft connecting rod bearing journal.

3 Guide the connecting rod to the crankshaft connecting rod journal.

4 Install the connecting rod end cap (1) on its original connecting rod and ensure the bearing lock tangs are

aligned on the same side of the rod.

CAUTION

• Do not lubricate the new connecting rod

bolts. The new bolts have a pre-applied

graphite lubricant. Applying lubricant to

the connecting rod bolts will effect the

clamp load when the connecting rod

bolts are tightened to the specified

torque. Incorrect clamp load can lead to

component failure and extensive engine

damage.

• Do not reuse the old connecting rod

bolts.

Figure 6A1 – 409

5 Install new connecting rod bolts into the connecting rod cap and tighten to the correct torque specification. �„ Connecting rod cap attaching bolt

torque specification:

Stage 1 .........................30.0 Nm

Stage 2 ........ Loosen completely

Stage 3 .........................25.0 Nm

Stage 4 .................. 110 degrees

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2702 of 6020

Engine Mechanical – V6 Page 6A1–223

NOTE

During and after installation, ensure each piston

is positioned correctly in the correct cylinder. The

locating arrow on the top of each piston must be

pointing toward the front of the engine.

6 Repeat these procedures for the remaining piston/connecting rod assemblies.

7 Reinstall the oil pan and oil pump pick up assembly, refer to 4.2 Oil Pan and Oil Pump Suction Pipe Assembly.

8 Reinstall the cylinder heads, refer to 3.22 Cylinder Head Assembly.

9 Reinstall the engine assembly, refer to 4.1 Engine .

4.6 Crankshaft and Main Bearings

1 Remove the engine assembly, refer to 4.1 Engine .

2 Remove both cylinder head assemblies, refer to 3.22 Cylinder Head Assembly.

3 Remove the oil pan assembly, refer to 4.2 Oil Pan and Oil Pump Suction Pipe Assembly.

4 Remove the piston and connecting rod assemblies, refer to 4.5 Pistons, Pins, Rings, Connecting Rods and Big- end Bearings.

5 Remove the oil pump assembly, refer to 3.17 Oil Pump Assembly.

6 Remove the crankshaft rear oil seal and plate assembly, refer to 4.4 Crankshaft Rear Seal and Plate Assembly.

7 Remove the crankshaft position sensor, refer to 6C1-3 Engine Management – V6 – Service Operations.

Crankshaft End Play Measurement

1 Place a dial indicator at the end of the crankshaft nose.

2 Gently force the crankshaft towards the front and rear of the cylinder block with a lever while monitoring the movement of the dial indicator.

3 The crankshaft endplay should not exceed specifications, refer to 5 Specifications.

4 If the specifications are exceeded, inspect the thrust bearing thrust outer diameter and the crankshaft thrust wall for wear and/or excessive runout. Compare the values with the specifications, refer to 5 Specifications.

5 Replace the thrust bearing or crankshaft as required.

Remove

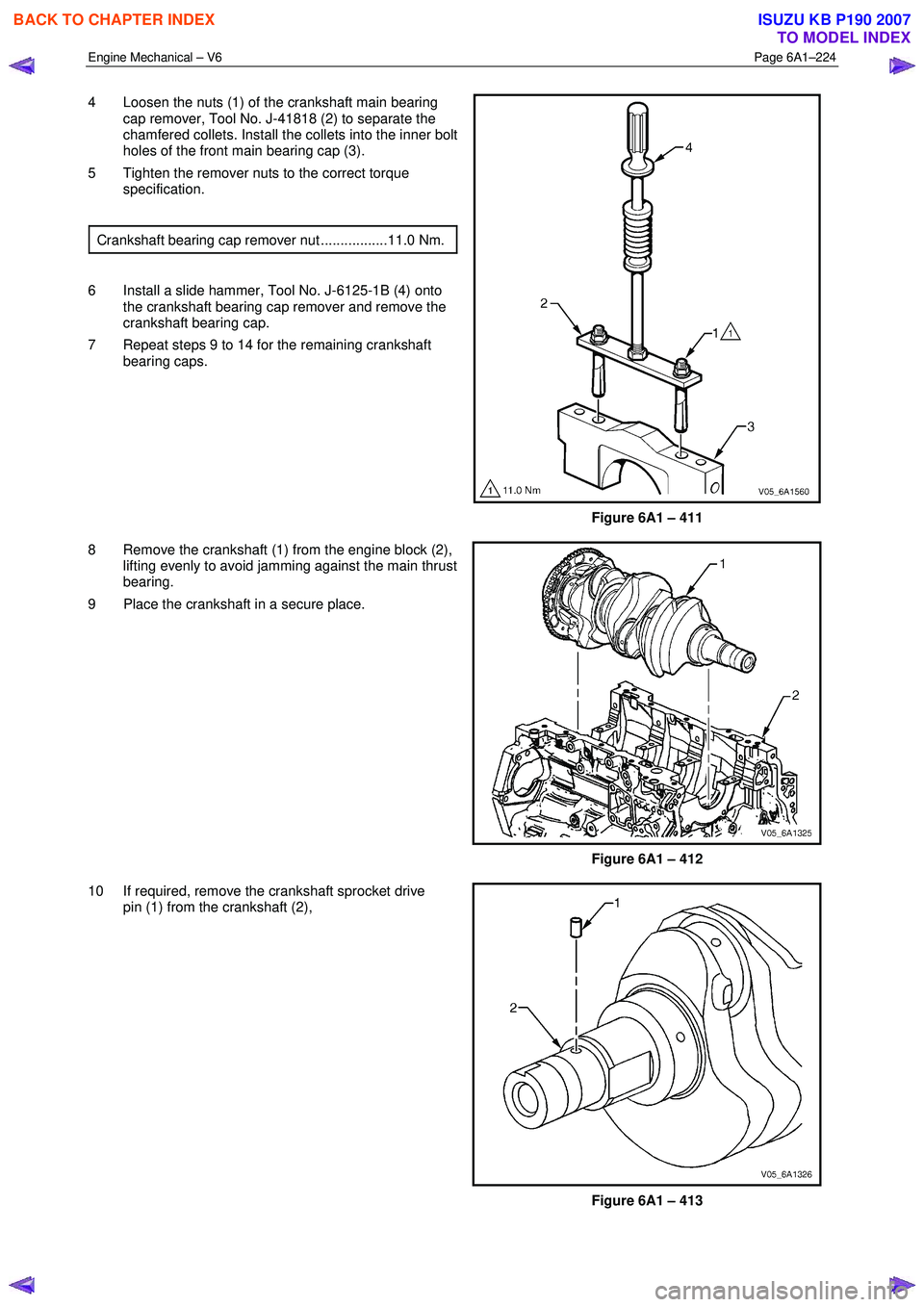

1 Remove the crankshaft bearing cap side bolts (3).

CAUTION

The crankshaft bearing cap outer bolts are

yield tightened during assembly and must

be replaced prior to reassembly. Crankshaft

bearing cap outer bolts that are not replaced

will not torque to the correct clamp load and

can lead to serious engine damage.

2 Remove the crankshaft bearing cap outer bolts (1).

3 Remove the crankshaft bearing cap inner bolts (2).

Figure 6A1 – 410

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2703 of 6020

Engine Mechanical – V6 Page 6A1–224

4 Loosen the nuts (1) of the crankshaft main bearing

cap remover, Tool No. J-41818 (2) to separate the

chamfered collets. Install the collets into the inner bolt

holes of the front main bearing cap (3).

5 Tighten the remover nuts to the correct torque specification.

Crankshaft bearing cap remover nut .................11.0 Nm.

6 Install a slide hammer, Tool No. J-6125-1B (4) onto the crankshaft bearing cap remover and remove the

crankshaft bearing cap.

7 Repeat steps 9 to 14 for the remaining crankshaft bearing caps.

Figure 6A1 – 411

8 Remove the crankshaft (1) from the engine block (2), lifting evenly to avoid jamming against the main thrust

bearing.

9 Place the crankshaft in a secure place.

Figure 6A1 – 412

10 If required, remove the crankshaft sprocket drive pin (1) from the crankshaft (2),

Figure 6A1 – 413

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2704 of 6020

Engine Mechanical – V6 Page 6A1–225

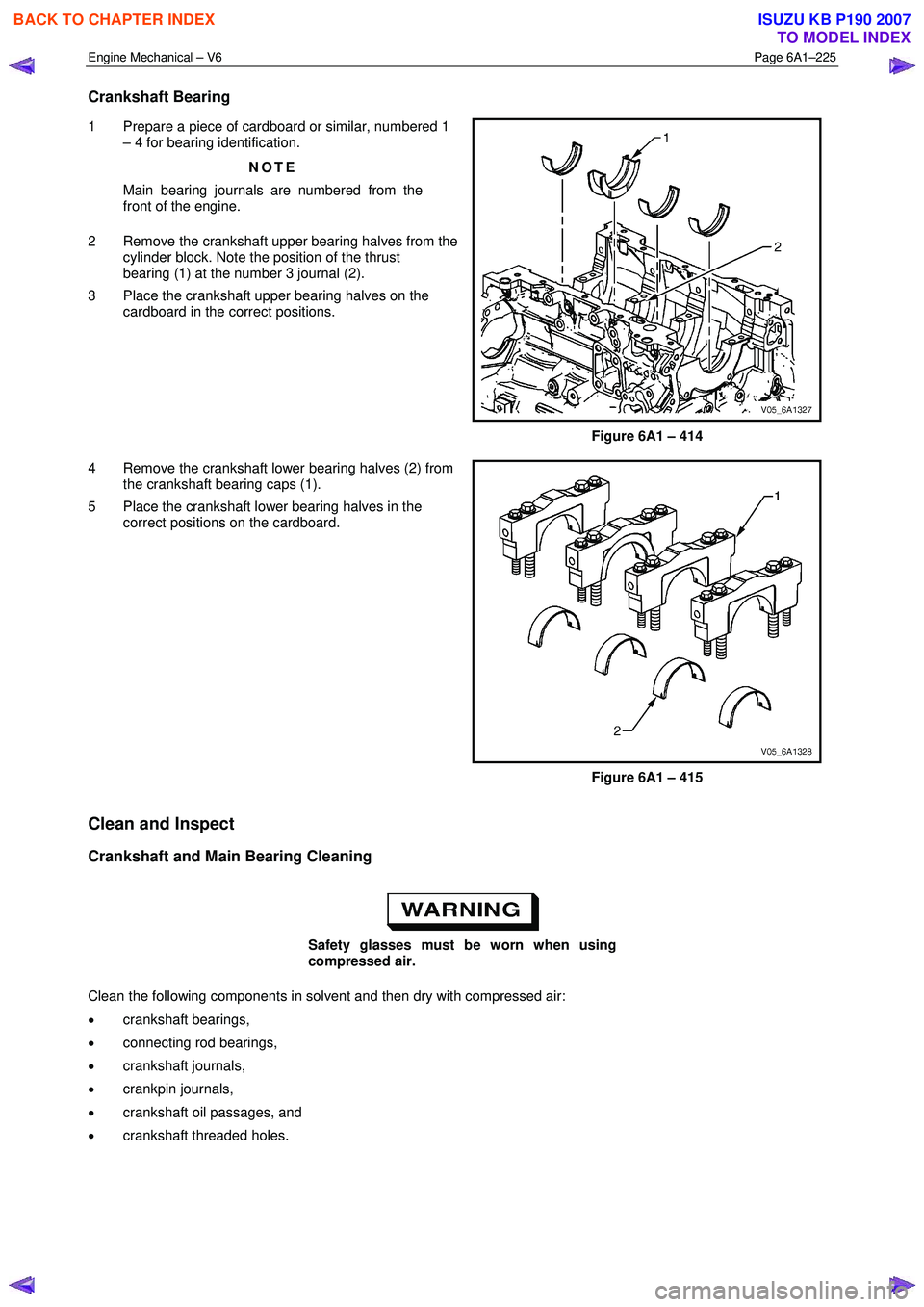

Crankshaft Bearing

1 Prepare a piece of cardboard or similar, numbered 1

– 4 for bearing identification.

NOTE

Main bearing journals are numbered from the

front of the engine.

2 Remove the crankshaft upper bearing halves from the cylinder block. Note the position of the thrust

bearing (1) at the number 3 journal (2).

3 Place the crankshaft upper bearing halves on the cardboard in the correct positions.

Figure 6A1 – 414

4 Remove the crankshaft lower bearing halves (2) from the crankshaft bearing caps (1).

5 Place the crankshaft lower bearing halves in the correct positions on the cardboard.

Figure 6A1 – 415

Clean and Inspect

Crankshaft and Main Bearing Cleaning

Safety glasses must be worn when using

compressed air.

Clean the following components in solvent and then dry with compressed air:

• crankshaft bearings,

• connecting rod bearings,

• crankshaft journals,

• crankpin journals,

• crankshaft oil passages, and

• crankshaft threaded holes.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2705 of 6020

Engine Mechanical – V6 Page 6A1–226

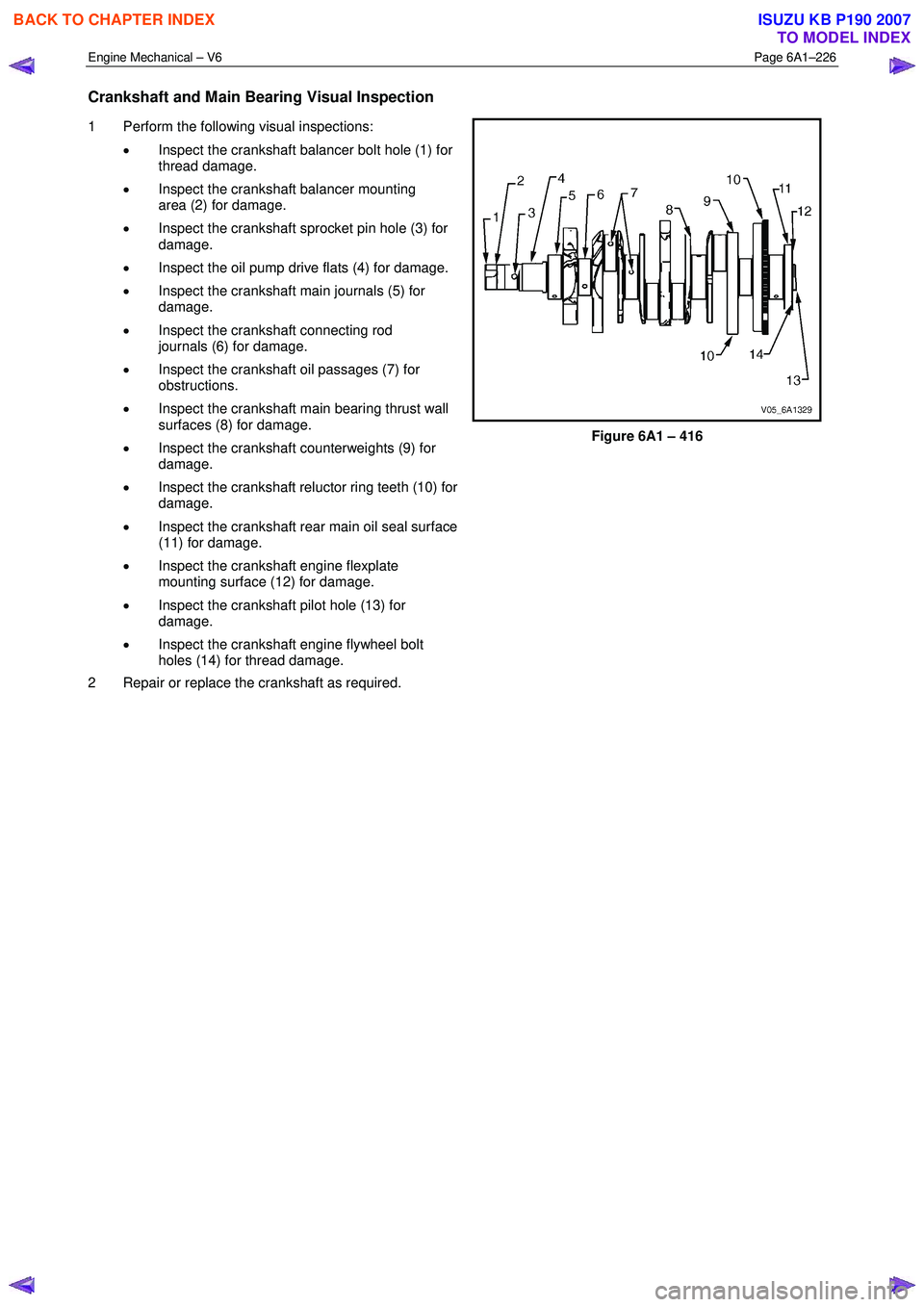

Crankshaft and Main Bearing Visual Inspection

1 Perform the following visual inspections:

• Inspect the crankshaft balancer bolt hole (1) for

thread damage.

• Inspect the crankshaft balancer mounting

area (2) for damage.

• Inspect the crankshaft sprocket pin hole (3) for

damage.

• Inspect the oil pump drive flats (4) for damage.

• Inspect the crankshaft main journals (5) for

damage.

• Inspect the crankshaft connecting rod

journals (6) for damage.

• Inspect the crankshaft oil passages (7) for

obstructions.

• Inspect the crankshaft main bearing thrust wall

surfaces (8) for damage.

• Inspect the crankshaft counterweights (9) for

damage.

• Inspect the crankshaft reluctor ring teeth (10) for

damage.

• Inspect the crankshaft rear main oil seal surface

(11) for damage.

• Inspect the crankshaft engine flexplate

mounting surface (12) for damage.

• Inspect the crankshaft pilot hole (13) for

damage.

• Inspect the crankshaft engine flywheel bolt

holes (14) for thread damage.

2 Repair or replace the crankshaft as required.

Figure 6A1 – 416

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2706 of 6020

Engine Mechanical – V6 Page 6A1–227

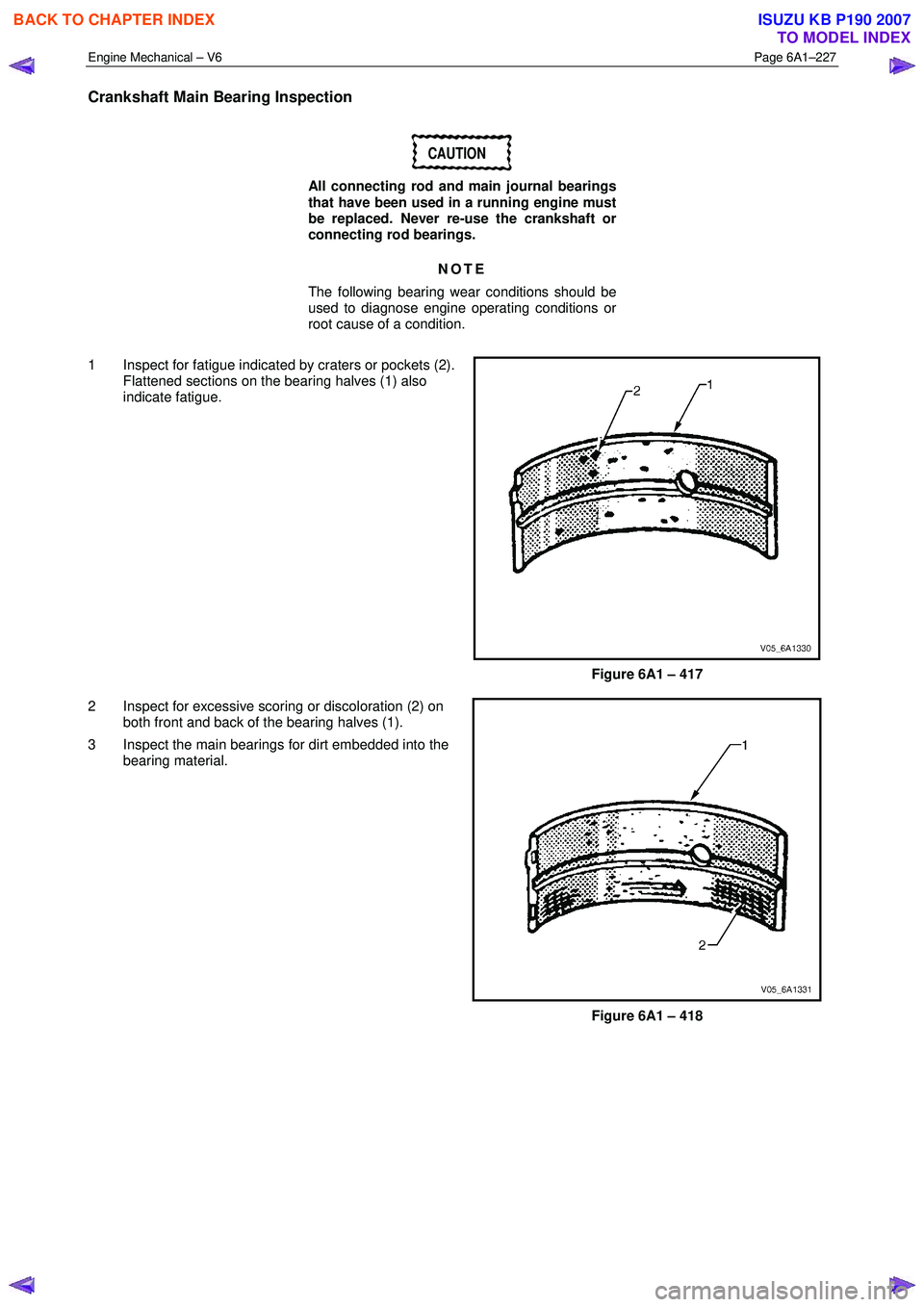

Crankshaft Main Bearing Inspection

CAUTION

All connecting rod and main journal bearings

that have been used in a running engine must

be replaced. Never re-use the crankshaft or

connecting rod bearings.

NOTE

The following bearing wear conditions should be

used to diagnose engine operating conditions or

root cause of a condition.

1 Inspect for fatigue indicated by craters or pockets (2). Flattened sections on the bearing halves (1) also

indicate fatigue.

Figure 6A1 – 417

2 Inspect for excessive scoring or discoloration (2) on both front and back of the bearing halves (1).

3 Inspect the main bearings for dirt embedded into the bearing material.

Figure 6A1 – 418

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2707 of 6020

Engine Mechanical – V6 Page 6A1–228

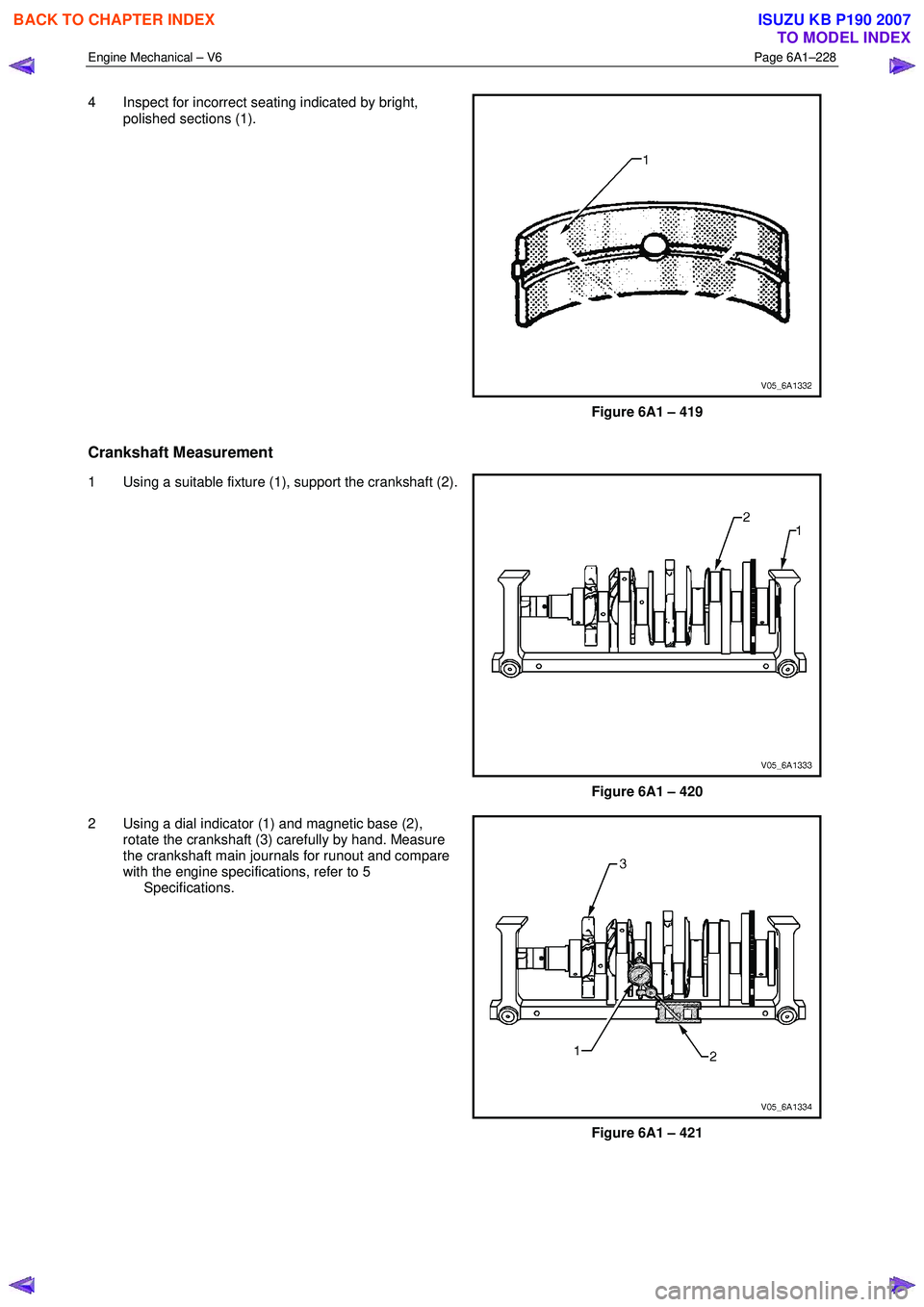

4 Inspect for incorrect seating indicated by bright,

polished sections (1).

Figure 6A1 – 419

Crankshaft Measurement

1 Using a suitable fixture (1), support the crankshaft (2).

Figure 6A1 – 420

2 Using a dial indicator (1) and magnetic base (2), rotate the crankshaft (3) carefully by hand. Measure

the crankshaft main journals for runout and compare

with the engine specifications, refer to 5

Specifications.

Figure 6A1 – 421

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2708 of 6020

Engine Mechanical – V6 Page 6A1–229

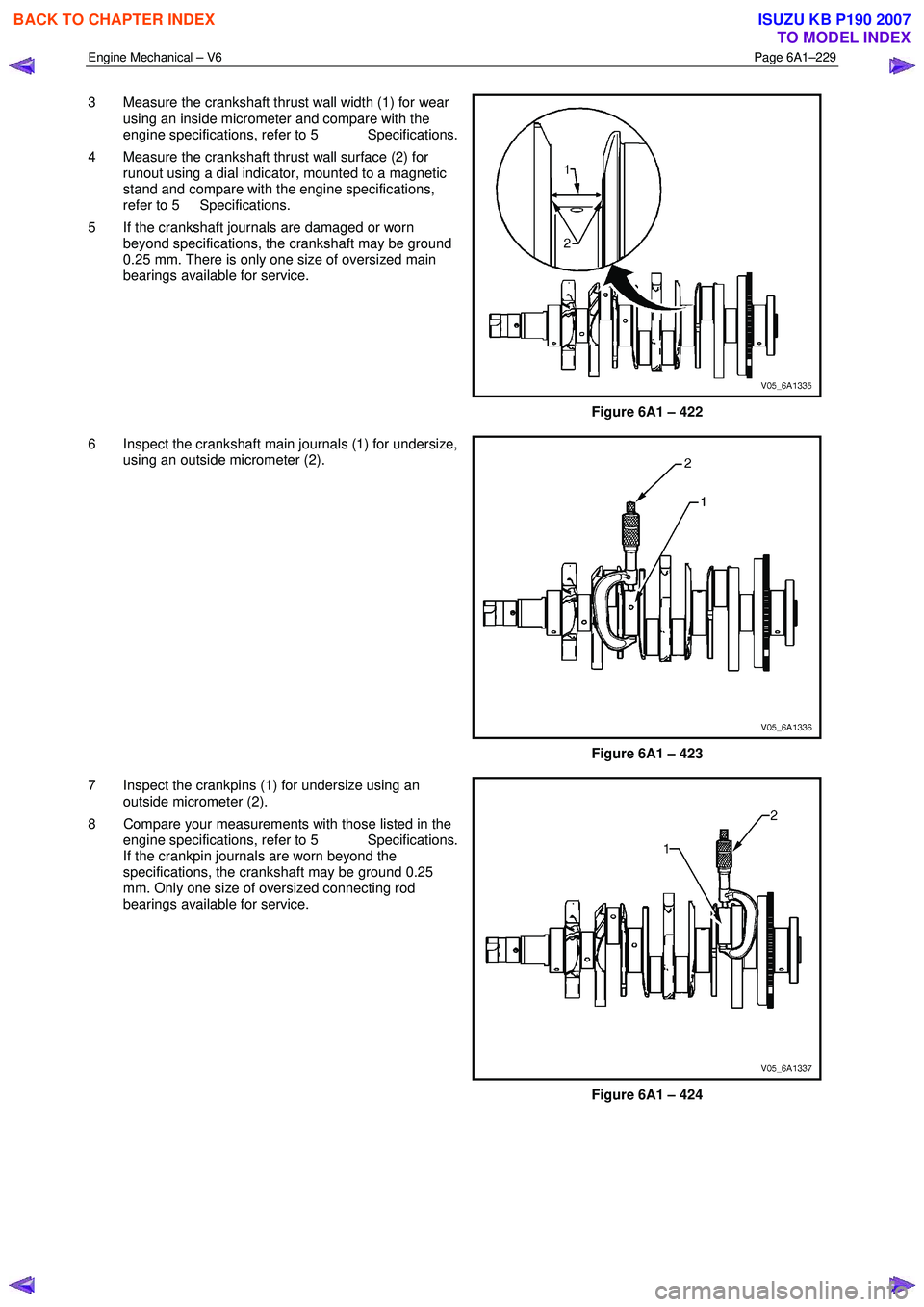

3 Measure the crankshaft thrust wall width (1) for wear

using an inside micrometer and compare with the

engine specifications, refer to 5 Specifications.

4 Measure the crankshaft thrust wall surface (2) for runout using a dial indicator, mounted to a magnetic

stand and compare with the engine specifications,

refer to 5 Specifications.

5 If the crankshaft journals are damaged or worn beyond specifications, the crankshaft may be ground

0.25 mm. There is only one size of oversized main

bearings available for service.

Figure 6A1 – 422

6 Inspect the crankshaft main journals (1) for undersize, using an outside micrometer (2).

Figure 6A1 – 423

7 Inspect the crankpins (1) for undersize using an outside micrometer (2).

8 Compare your measurements with those listed in the engine specifications, refer to 5 Specifications.

If the crankpin journals are worn beyond the

specifications, the crankshaft may be ground 0.25

mm. Only one size of oversized connecting rod

bearings available for service.

Figure 6A1 – 424

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2709 of 6020

Engine Mechanical – V6 Page 6A1–230

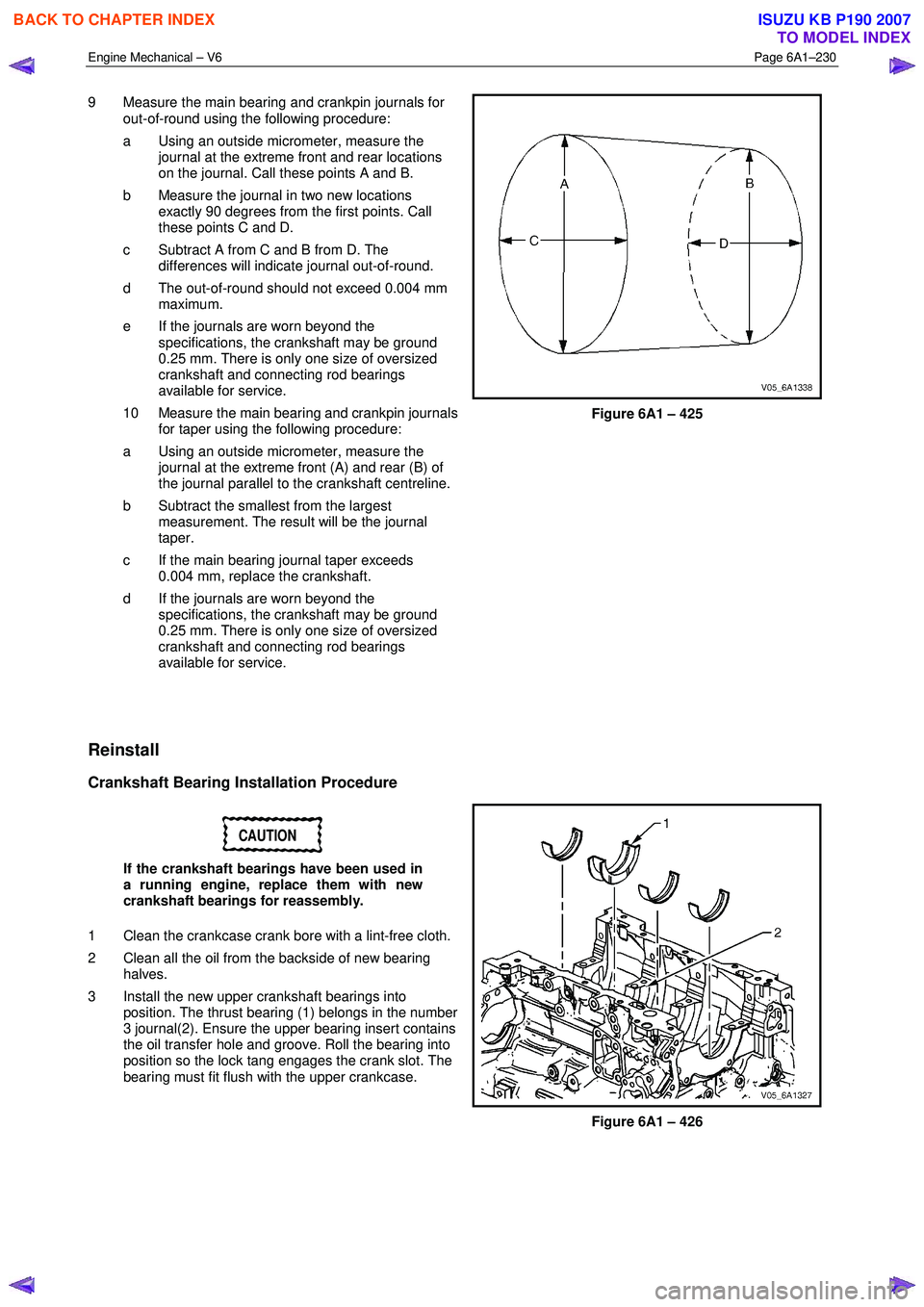

9 Measure the main bearing and crankpin journals for

out-of-round using the following procedure:

a Using an outside micrometer, measure the journal at the extreme front and rear locations

on the journal. Call these points A and B.

b Measure the journal in two new locations exactly 90 degrees from the first points. Call

these points C and D.

c Subtract A from C and B from D. The differences will indicate journal out-of-round.

d The out-of-round should not exceed 0.004 mm maximum.

e If the journals are worn beyond the specifications, the crankshaft may be ground

0.25 mm. There is only one size of oversized

crankshaft and connecting rod bearings

available for service.

10 Measure the main bearing and crankpin journals for taper using the following procedure:

a Using an outside micrometer, measure the journal at the extreme front (A) and rear (B) of

the journal parallel to the crankshaft centreline.

b Subtract the smallest from the largest measurement. The result will be the journal

taper.

c If the main bearing journal taper exceeds 0.004 mm, replace the crankshaft.

d If the journals are worn beyond the specifications, the crankshaft may be ground

0.25 mm. There is only one size of oversized

crankshaft and connecting rod bearings

available for service.

Figure 6A1 – 425

Reinstall

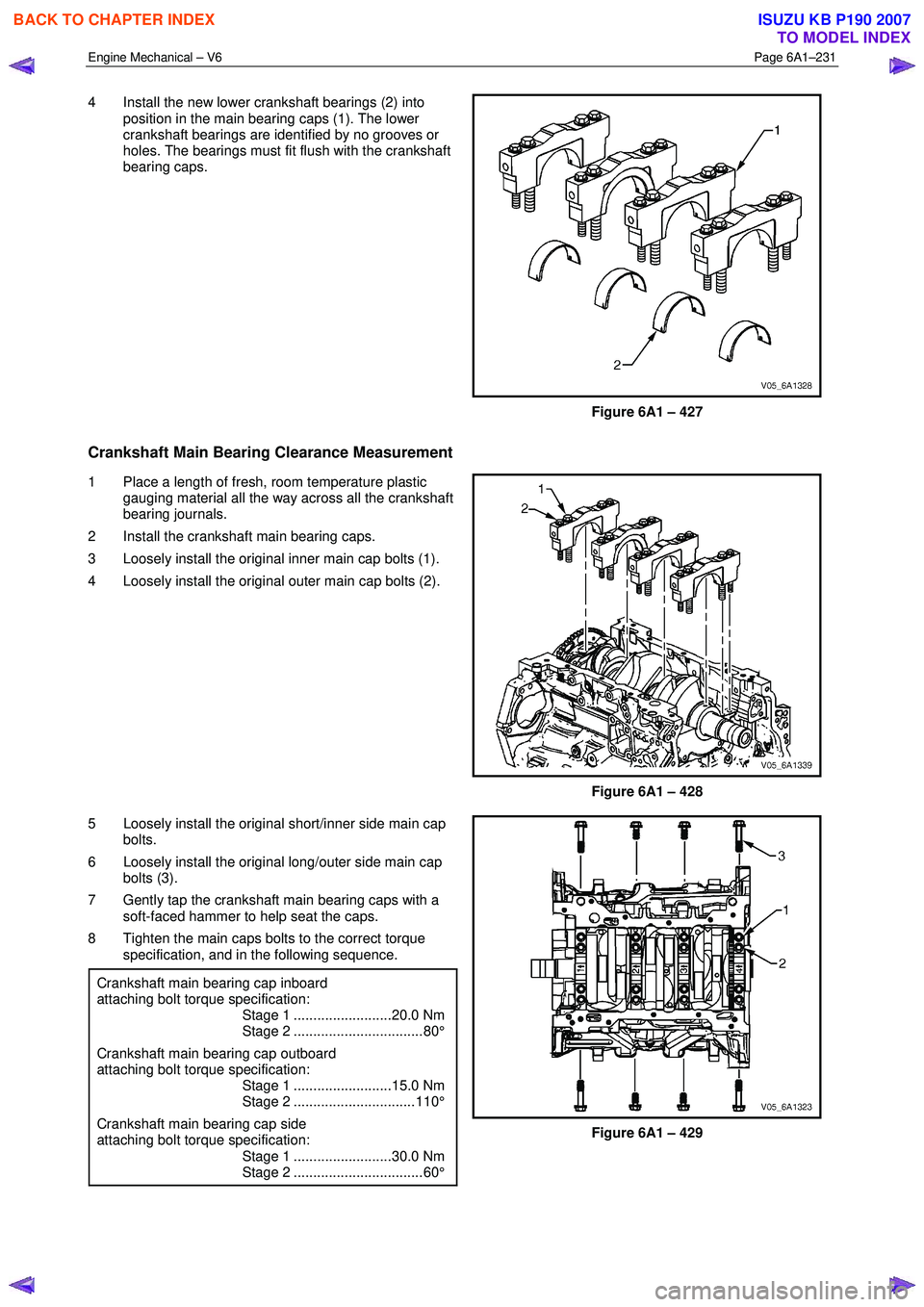

Crankshaft Bearing Installation Procedure

CAUTION

If the crankshaft bearings have been used in

a running engine, replace them with new

crankshaft bearings for reassembly.

1 Clean the crankcase crank bore with a lint-free cloth.

2 Clean all the oil from the backside of new bearing halves.

3 Install the new upper crankshaft bearings into position. The thrust bearing (1) belongs in the number

3 journal(2). Ensure the upper bearing insert contains

the oil transfer hole and groove. Roll the bearing into

position so the lock tang engages the crank slot. The

bearing must fit flush with the upper crankcase.

Figure 6A1 – 426

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2710 of 6020

Engine Mechanical – V6 Page 6A1–231

4 Install the new lower crankshaft bearings (2) into

position in the main bearing caps (1). The lower

crankshaft bearings are identified by no grooves or

holes. The bearings must fit flush with the crankshaft

bearing caps.

Figure 6A1 – 427

Crankshaft Main Bearing Clearance Measurement

1 Place a length of fresh, room temperature plastic gauging material all the way across all the crankshaft

bearing journals.

2 Install the crankshaft main bearing caps.

3 Loosely install the original inner main cap bolts (1).

4 Loosely install the original outer main cap bolts (2).

Figure 6A1 – 428

5 Loosely install the original short/inner side main cap bolts.

6 Loosely install the original long/outer side main cap bolts (3).

7 Gently tap the crankshaft main bearing caps with a soft-faced hammer to help seat the caps.

8 Tighten the main caps bolts to the correct torque specification, and in the following sequence.

Crankshaft main bearing cap inboard

attaching bolt torque specification:

Stage 1 .........................20.0 Nm

Stage 2 ................................. 80°

Crankshaft main bearing cap outboard

attaching bolt torque specification:

Stage 1 .........................15.0 Nm

Stage 2 ............................... 110°

Crankshaft main bearing cap side

attaching bolt torque specification:

Stage 1 .........................30.0 Nm

Stage 2 ................................. 60°

Figure 6A1 – 429

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007